Page 1

**Installat ion recommendation:

INSTALLATION INSTRUCTIONS

JB A recommends in mos t cases that the vehicle be taken to a reputable exhaust shop.

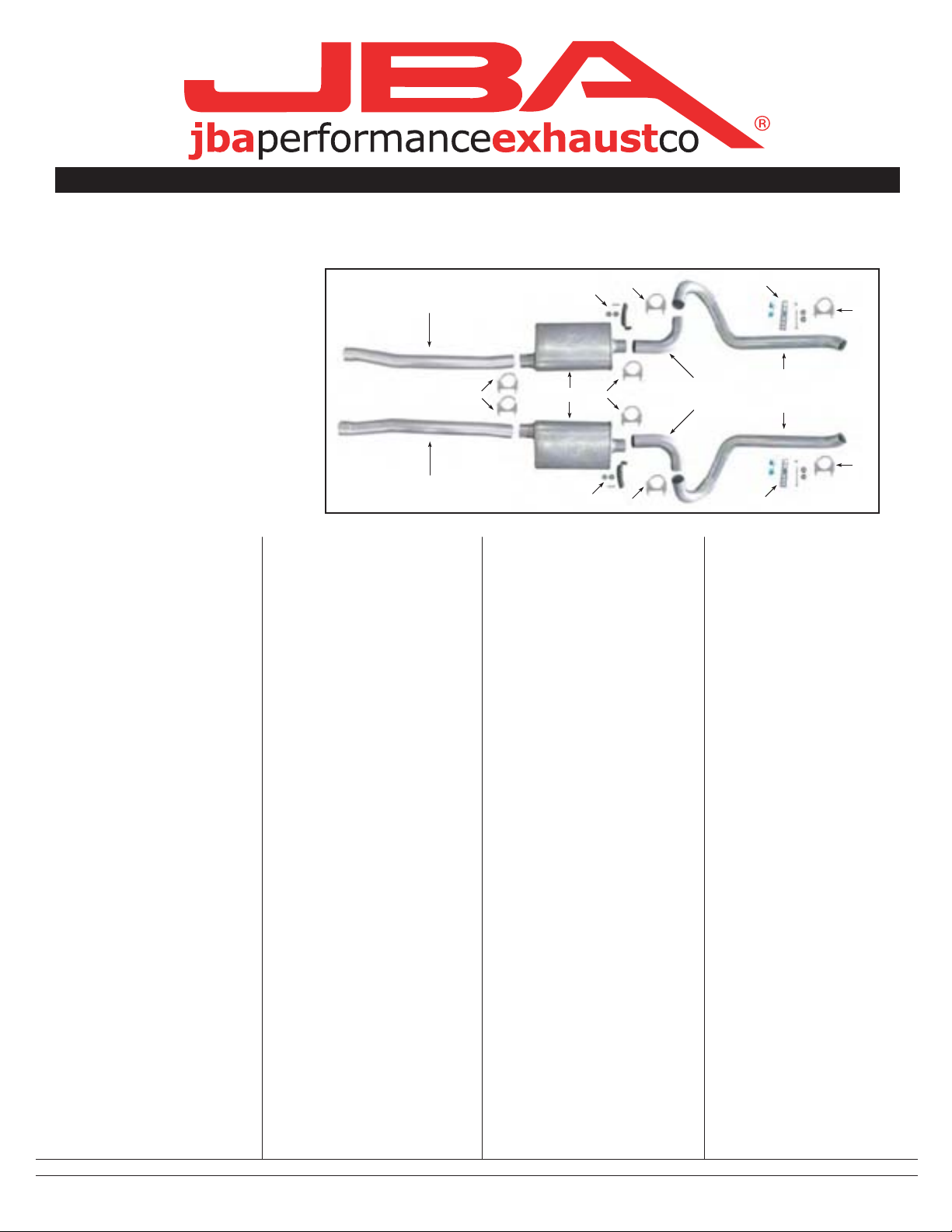

40-2650x

40-2650

(customer supplied mufflers use offset inlet/center outlet 14" body) Not shown

(shown)

‘65-‘70 Mustang V8 with

JBA H-pipe

Parts List:

A. P/S intermediate pipe 1

B. D/S intermediate pipe 1

C. JBA muffler 2

D. 90º bend 2

E. P/S tail pipe 1

F. D/S tail pipe 1

G. 2-1/2" Clamp 8

H. Universal Muffler hanger 2

I. Tailpipe hanger 1

Start:

Note-this system will not fit a

convertible. Tail pipe installation

should be performed with rear

axle at ride height. (Suspension

loaded)

Typically the stock exhaust

system on early cars is long

gone. These instructions

contemplate the installation of a

new JBA Exhaust System after

the original exhaust system has

been removed. This system is

designed to work with a JBA HPipe built for your application.

1. Remove and inventory the

JBA Exhaust System.

2. Disconnect the negative

battery cable and allow the

exhaust system to completely

cool.

3. With the H-Pipe installed, and

all exhaust removed from the

car, slip the intermediate pipes

onto the H-pipe. Orient them so

the small single bend is flat, and

pointing to the outside of the

car. The int. pipe should be just

below the seat belt bolt. If you

have replaced your factory bolts,

it may be necessary to shorten

an aftermarket bolt. Allow at

least a quarter inch clearance on

the bolt.

A

B

4. Slip a muffler clamp on each

exhaust pipe. Slip the mufflers on

to the Int. pipe. Align mufflers to

be flat with the floor, maintain

alignment with flat bend of the

intermediate pipe. The muffler

should have a minimum 1/2”

clearance to the front floor hump,

and a minimum 11/4” clearance

on top.

5. Support the muffler

temporarily. Universal hangers

are supplied with the kit, or you

can adapt your factory dual

hangers. If using the universal

hangers, self-tapping screws and

fender washers are supplied.

Position the hanger on the outlet

tube of the muffler. Mark the

floorboard at the sher onto the

S/T screw, slip the screw through

the hanger at whichever hole you

marked, slip another fender

washer on the screw, and attach

the hanger to the floor pan.

Fasten the hanger to the muffler

using a supplied clamp. Do both

sides; be sure to match muffler

heights.

6. The rear tail pipe hangers bolt

through the rear frame where the

shipping tie-down brackets bolt

on. If your car has these

brackets, they must be removed.

Assemble the grommet onto the

strap hanger. Slip a fender

washer onto the 3 1/2” bolt. Slip

the bolt through the frame at the

forward hole. Slip the

hanger/grommet assy. onto the

bolt. Add another fender washer

and a lock nut and tighten until

grommet just starts to compress.

H

G

7. Slip the tailpipes over the

axle. Install the small 90º bends,

long side into the muffler. Drop

the tail pipe onto the 90* bend.

Align the tailpipe so that it fits

into the notch in the floor pan,

just inside of the shock. Allow at

least 1/2” clearance on the floor.

8. On 2650 systems, position

the end of the tailpipe

approximately 3/4” below the

valance panel and

approximately 1/2” forward from

the edge. (Adjust front to rear

position at back of muffler.) Atta

justed” to clear the 2 1/2” pipe

and clamp. Usually a good

smack with your hand against

the tailpipe into the gas tank will

gain the necessary clearance.

9. On 2653 systems, follow

above instructions except

position tailpipe tips through

holes in rear valance. Align and

adjust for depth. Secure with

clamp to hanger.

10. Very Important- Once the

tailpipes are secured with the

rear clamp, the tails of the clamp

bolts must be trimmed off so

they don’t hang up on the leaf

spring.

11. Check the clearance of

exhaust to floor and rear axle

along the complete system.

Securely tighten all clamps.

Tack weld all slip joints.

C

G

H

G

G

I

G

E

D

F

G

I

We recommend taking the vehicle to a muffler shop and having all slip connections tack welded.

7/28/04

Loading...

Loading...