Page 1

INSTALLATION INSTRUCTIONSINSTALLATION INSTRUCTIONSINSTALLATION INSTRUCTIONSINSTALLATION INSTRUCTIONS

**Inst**Inst**Inst**Inst allation recommendation:allation recommendation:allation recommendation:allation recommendation:

JBA recommends in most cases that the vehicle be taken to a reputable exhaust shop.JBA recommends in most cases that the vehicle be taken to a reputable exhaust shop.JBA recommends in most cases that the vehicle be taken to a reputable exhaust shop.JBA recommends in most cases that the vehicle be taken to a reputable exhaust shop.

1988-94 Ford F-250, F-3501988-94 Ford F-250, F-3501988-94 Ford F-250, F-3501988-94 Ford F-250, F-350

V8-5.8L, 7.5LV8-5.8L, 7.5LV8-5.8L, 7.5LV8-5.8L, 7.5L Ext. cab/Long bedExt. cab/Long bedExt. cab/Long bedExt. cab/Long bed

TTTTOOLS RECOMMENDED:OOLS RECOMMENDED:OOLS RECOMMENDED:OOLS RECOMMENDED:

ratchetratchetratchetratchet

9/16 deep socket9/16 deep socket9/16 deep socket9/16 deep socket

15mm deep socket15mm deep socket15mm deep socket15mm deep socket

9/16" box wrench9/16" box wrench9/16" box wrench9/16" box wrench

reciprocating saw or hack sawreciprocating saw or hack sawreciprocating saw or hack sawreciprocating saw or hack saw

ppppair of channel lock pliers, 12"air of channel lock pliers, 12"air of channel lock pliers, 12"air of channel lock pliers, 12"

spray lubricant or penetrating oilspray lubricant or penetrating oilspray lubricant or penetrating oilspray lubricant or penetrating oil

anti-seizeanti-seizeanti-seizeanti-seize

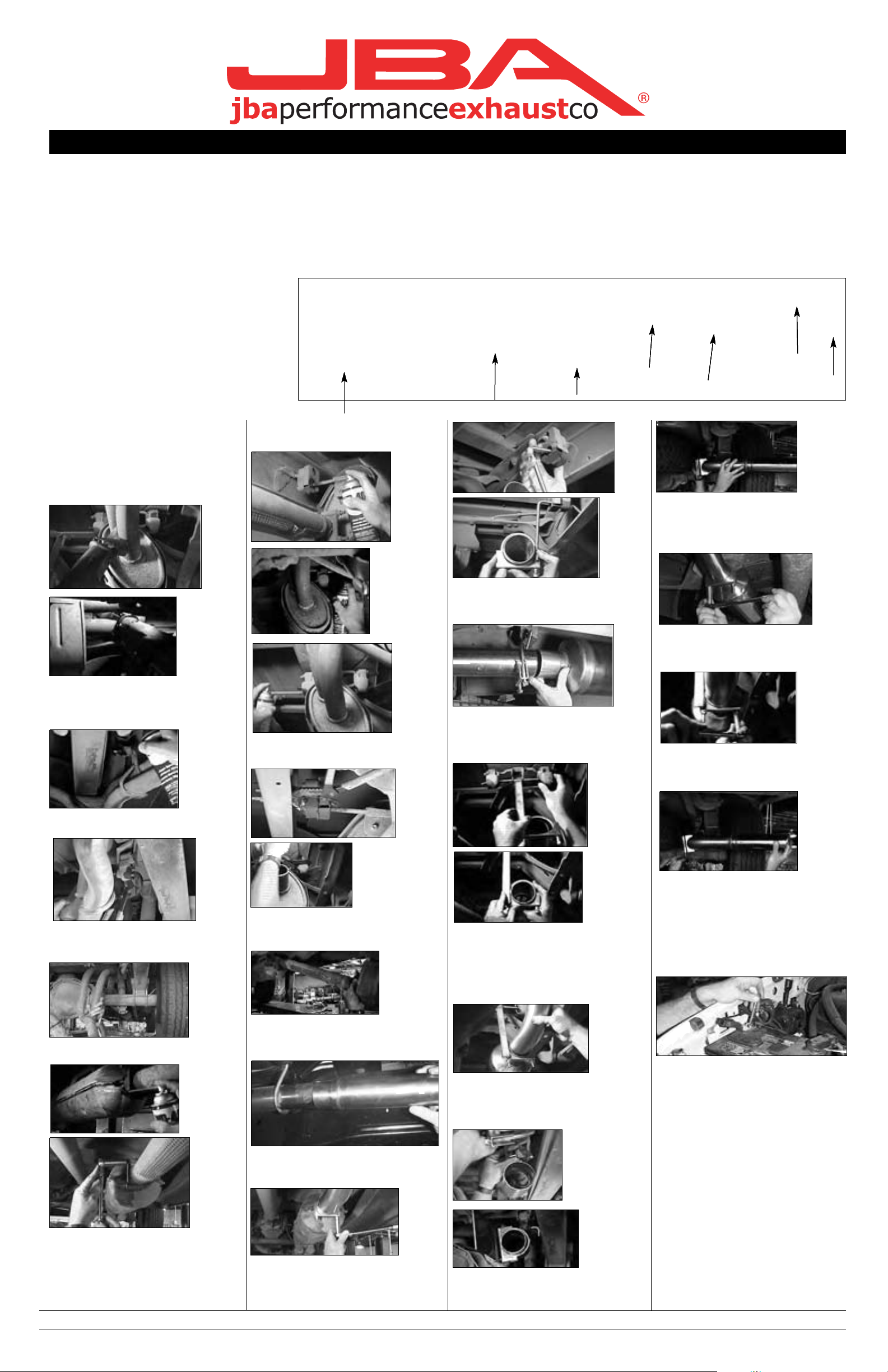

PartPartPartPart s Lists Lists Lists List

A.A.A.A. Head pipeHead pipeHead pipeHead pipe 1111 E.E.E.E. 2-1/2" H.P2-1/2" H.P2-1/2" H.P2-1/2" H.P. clamp. clamp. clamp. clamp 1111

B.B.B.B. MufMufMufMufflerflerflerfler, 24", 24", 24", 24" 1111 FFFF.... Front mufFront mufFront mufFront muffler 3" clamp/hangerfler 3" clamp/hangerfler 3" clamp/hangerfler 3" clamp/hanger 1111

C.C.C.C. TTTTail pipeail pipeail pipeail pipe 1111 GGGG.... Rear mufRear mufRear mufRear muffler 3"fler 3"fler 3"fler 3" clamp/hangerclamp/hangerclamp/hangerclamp/hanger 1111

D.D.D.D. TTTTurn outurn outurn outurn out 1111 H.H.H.H. TTTTurn out 3" clamp/hanger w/shieldurn out 3" clamp/hanger w/shieldurn out 3" clamp/hanger w/shieldurn out 3" clamp/hanger w/shield 1111

D

B

G

F

A

E

C

D

B

G

F

A

E

C

D

B

G

F

A

E

C

D

B

G

F

A

E

C

HHHH

TTTT OOOO STSTSTST ARTARTARTART ::::

2. Disconnect negative battery cable and2. Disconnect negative battery cable and2. Disconnect negative battery cable and2. Disconnect negative battery cable and

allow vehicle exhaust to cool.allow vehicle exhaust to cool.allow vehicle exhaust to cool.allow vehicle exhaust to cool.

1. Remove and inventory new JBA1. Remove and inventory new JBA1. Remove and inventory new JBA1. Remove and inventory new JBA

exhaust.exhaust.exhaust.exhaust.

18. Inst18. Inst18. Inst18. Install turn out (D) over end of tall turn out (D) over end of tall turn out (D) over end of tall turn out (D) over end of tail pipeail pipeail pipeail pipe

(C) and tighten clamp/hanger (H) lightly with(C) and tighten clamp/hanger (H) lightly with(C) and tighten clamp/hanger (H) lightly with(C) and tighten clamp/hanger (H) lightly wi

9/16" wrench.9/16" wrench.9/16" wrench.9/16" wrench. NOTE:NOTE:NOTE:NOTE: Put anti-seize onPut anti-seize onPut anti-seize onPut anti-seize on

threads.threads.threads.threads.

th

3. With vehicle raised and properly sup-3. With vehicle raised and properly sup-3. With vehicle raised and properly sup-3. With vehicle raised and properly supported, using a reciprocating saw or hackported, using a reciprocating saw or hackported, using a reciprocating saw or hackported, using a reciprocating saw or hack

sawsawsawsaw, cut t, cut t, cut t, cut tail pipes approximately 3"ail pipes approximately 3"ail pipes approximately 3"ail pipes approximately 3"

behind rear of mufbehind rear of mufbehind rear of mufbehind rear of mufflerflerflerfler....

4. S4. S4. S4. Spray lubricant on rear tpray lubricant on rear tpray lubricant on rear tpray lubricant on rear tail pipe hangerail pipe hangerail pipe hangerail pipe hanger

rubber grommet.rubber grommet.rubber grommet.rubber grommet.

8. S8. S8. S8. Spray lubricant on front and rear mufpray lubricant on front and rear mufpray lubricant on front and rear mufpray lubricant on front and rear mufflerflerflerfler

hanger rod grommethanger rod grommethanger rod grommethanger rod grommets.s.s.s.

13. Inst13. Inst13. Inst13. Install 3" clamp/hanger (F) into frontall 3" clamp/hanger (F) into frontall 3" clamp/hanger (F) into frontall 3" clamp/hanger (F) into front

mufmufmufmuffler hanger rubber grommet and positionfler hanger rubber grommet and positionfler hanger rubber grommet and positionfler hanger rubber grommet and position

clamp over end of end of head pipe (A).clamp over end of end of head pipe (A).clamp over end of end of head pipe (A).clamp over end of end of head pipe (A).

14. Inst14. Inst14. Inst14. Install mufall mufall mufall muffler (B) over head pipe (A)fler (B) over head pipe (A)fler (B) over head pipe (A)fler (B) over head pipe (A)

with JBA logo towards rear of vehiclewith JBA logo towards rear of vehiclewith JBA logo towards rear of vehiclewith JBA logo towards rear of vehicle

making sure mufmaking sure mufmaking sure mufmaking sure muffler bottoms out on slipfler bottoms out on slipfler bottoms out on slipfler bottoms out on slip

joint.joint.joint.joint.

19. Position 3" clamp/hanger (F), level and19. Position 3" clamp/hanger (F), level and19. Position 3" clamp/hanger (F), level and19. Position 3" clamp/hanger (F), level an

tighten completely using 9/16" seep socket.tighten completely using 9/16" seep socket.tighten completely using 9/16" seep socket.tighten completely using 9/16" seep socke

NOTE:NOTE:NOTE:NOTE: Use anti-seize on threads.Use anti-seize on threads.Use anti-seize on threads.Use anti-seize on threads.

20. Position t20. Position t20. Position t20. Position tail pipe (C) to desired positionail pipe (C) to desired positionail pipe (C) to desired positionail pipe (C) to desired positio

and tighten 3" clamp/hanger (G) completelyand tighten 3" clamp/hanger (G) completelyand tighten 3" clamp/hanger (G) completelyand tighten 3" clamp/hanger (G) complete

using 9/16" deep socket.using 9/16" deep socket.using 9/16" deep socket.using 9/16" deep socket.

d

t.

n

ly

5. Using a p5. Using a p5. Using a p5. Using a pair of channel lock pliers,air of channel lock pliers,air of channel lock pliers,air of channel lock pliers,

remove tremove tremove tremove tail pipe hanger rod from rubberail pipe hanger rod from rubberail pipe hanger rod from rubberail pipe hanger rod from rubber

grommet.grommet.grommet.grommet.

9. With muf9. With muf9. With muf9. With muffler supported, using channelfler supported, using channelfler supported, using channelfler supported, using channel

lock pliers, remove front and rear muflock pliers, remove front and rear muflock pliers, remove front and rear muflock pliers, remove front and rear mufflerflerflerfler

hanger rods from rubber grommethanger rods from rubber grommethanger rods from rubber grommethanger rods from rubber grommets.s.s.s.

15. Inst15. Inst15. Inst15. Install 3" clamp/hanger (G) into rearall 3" clamp/hanger (G) into rearall 3" clamp/hanger (G) into rearall 3" clamp/hanger (G) into rear

mufmufmufmuffler rubber grommetfler rubber grommetfler rubber grommetfler rubber grommets with flat bars with flat bars with flat bars with flat bar

towards driver side. Slip clamp/hanger (G)towards driver side. Slip clamp/hanger (G)towards driver side. Slip clamp/hanger (G)towards driver side. Slip clamp/hanger (G)

over end of slip joint of mufover end of slip joint of mufover end of slip joint of mufover end of slip joint of muffler (B). Handfler (B). Handfler (B). Handfler (B). Hand

22.22.22.22. AfAfAfAfter instter instter instter installation, it is recommended thatallation, it is recommended thatallation, it is recommended thatallation, it is recommended th

all clampall clampall clampall clamps be retightened and joints be retightened and joints be retightened and joints be retightened and joints ts ts ts tackackackack

welded in 3 spotwelded in 3 spotwelded in 3 spotwelded in 3 spots.s.s.s.

21. Rot21. Rot21. Rot21. Rotate turn out (D) to desired positionate turn out (D) to desired positionate turn out (D) to desired positionate turn out (D) to desired position

and tighten 3î clamp/hanger (H) completelyand tighten 3î clamp/hanger (H) completelyand tighten 3î clamp/hanger (H) completelyand tighten 3î clamp/hanger (H) completel

23. Using a sof23. Using a sof23. Using a sof23. Using a soft cloth, remove all printt cloth, remove all printt cloth, remove all printt cloth, remove all prints froms froms froms fro

turn out tip.turn out tip.turn out tip.turn out tip.

at

m

y....

6. Remove t6. Remove t6. Remove t6. Remove tail pipe assembly from rear ofail pipe assembly from rear ofail pipe assembly from rear ofail pipe assembly from rear of

vehicle.vehicle.vehicle.vehicle.

10. Using some form of heat and force,10. Using some form of heat and force,10. Using some form of heat and force,10. Using some form of heat and force,

disengage and remove mufdisengage and remove mufdisengage and remove mufdisengage and remove muffler assemblyfler assemblyfler assemblyfler assembly

without damaging converter pipe.without damaging converter pipe.without damaging converter pipe.without damaging converter pipe.

tighten clamp at this time.tighten clamp at this time.tighten clamp at this time.tighten clamp at this time.

NOTE:NOTE:NOTE:NOTE: Use anti-seize on threads.Use anti-seize on threads.Use anti-seize on threads.Use anti-seize on threads.

16. Inst16. Inst16. Inst16. Install tall tall tall tail pipe (C) into mufail pipe (C) into mufail pipe (C) into mufail pipe (C) into muffler (B)fler (B)fler (B)fler (B)

from rear of vehicle. Longest end towardsfrom rear of vehicle. Longest end towardsfrom rear of vehicle. Longest end towardsfrom rear of vehicle. Longest end towards

mufmufmufmuffler making sure tfler making sure tfler making sure tfler making sure tail pipe bottoms outail pipe bottoms outail pipe bottoms outail pipe bottoms out

in slip joint.in slip joint.in slip joint.in slip joint.

24. Lower vehicle and reatt24. Lower vehicle and reatt24. Lower vehicle and reatt24. Lower vehicle and reattach the negativeach the negativeach the negativeach the negativ

battery cable.battery cable.battery cable.battery cable.

NOTES:NOTES:NOTES:NOTES:

1) It may be necessary to loosen and realign1) It may be necessary to loosen and realign1) It may be necessary to loosen and realign1) It may be necessary to loosen and reali

the spthe spthe spthe spare tire for proper clearance.are tire for proper clearance.are tire for proper clearance.are tire for proper clearance.

gn

e

11111. Inst1. Inst1. Inst1. Install head pipe (A) aligning notchall head pipe (A) aligning notchall head pipe (A) aligning notchall head pipe (A) aligning notch

with locating pin.with locating pin.with locating pin.with locating pin. NOTE:NOTE:NOTE:NOTE: Make sure pin isMake sure pin isMake sure pin isMake sure pin is

bottomed out in notch.bottomed out in notch.bottomed out in notch.bottomed out in notch.

2)2)2)2) All exhaust systems will expAll exhaust systems will expAll exhaust systems will expAll exhaust systems will expand about 1"and about 1"and about 1"and about 1

rearward when exhaust temperature strearward when exhaust temperature strearward when exhaust temperature strearward when exhaust temperature start toart toart toart

rise.rise.rise.rise.

3) Use3) Use3) Use3) Use Anti-seize on threads of clampAnti-seize on threads of clampAnti-seize on threads of clampAnti-seize on threads of clamps.s.s.s.

to

"

7. S7. S7. S7. Spray penetrating lubricant on frontpray penetrating lubricant on frontpray penetrating lubricant on frontpray penetrating lubricant on front

head pipe clamp threads at rear of con-head pipe clamp threads at rear of con-head pipe clamp threads at rear of con-head pipe clamp threads at rear of converter and remove using a 15mm deepverter and remove using a 15mm deepverter and remove using a 15mm deepverter and remove using a 15mm deep

socket..socket..socket..socket..

12. Inst12. Inst12. Inst12. Install 2-1/2" clamp (E) on front por-all 2-1/2" clamp (E) on front por-all 2-1/2" clamp (E) on front por-all 2-1/2" clamp (E) on front portion of head pipe (A).tion of head pipe (A).tion of head pipe (A).tion of head pipe (A). TTTTighten completelyighten completelyighten completelyighten completely

with 9/16" deep socket.with 9/16" deep socket.with 9/16" deep socket.with 9/16" deep socket. NOTE:NOTE:NOTE:NOTE: Use anti-Use anti-Use anti-Use anti-

seize on threads.seize on threads.seize on threads.seize on threads.

17. Inst17. Inst17. Inst17. Install 3" clamp/hanger with heatall 3" clamp/hanger with heatall 3" clamp/hanger with heatall 3" clamp/hanger with heat

shield (H) into rear tshield (H) into rear tshield (H) into rear tshield (H) into rear tail pipe rubber grom-ail pipe rubber grom-ail pipe rubber grom-ail pipe rubber grommet. Slip clamp over end of tmet. Slip clamp over end of tmet. Slip clamp over end of tmet. Slip clamp over end of tail pipe (C).ail pipe (C).ail pipe (C).ail pipe (C).

17041170411704117041

WWWWeeee recommend taking the truck to a muffler shop and having all slip connections tack welded.recommend taking the truck to a muffler shop and having all slip connections tack welded.recommend taking the truck to a muffler shop and having all slip connections tack welded.recommend taking the truck to a muffler shop and having all slip connections tack welded.

6-20-026-20-026-20-026-20-02

40-2509

Loading...

Loading...