Jay R. Smith 8750, 8760 Installation Manual

INTERCEPTORS

TECHNICAL DATA

SCIENTIFICALLY ENGINEERED

D

N

A

D

R

G

N

I

B

M

U

L

P

B

M

E

M

I

N

S

T

I

has conducted hundreds of tests both in the laboratory and in

A

I

N

A

G

E

the field, in order to offer efficient grease interceptors which

R

E

have improved operational characteristics suitable for most

®

E

T

U

T

applications.

When designing our line of interceptors, we kept in mind the fact that these units

must be for practical applications. As a result, the units embody practical features that make installation easier and also simplify cleaning and servicing.

PLUMBING AND DRAINAGE INSTITUTE CERTIFICATION SEAL

Interceptors bear the certification seal of the Plumbing and Drainage Institute.

Ratings shown in the catalog conform with the rigid standards established by the

Institute. This seal on Smith Grease Interceptors is your guarantee that the designs

and ratings have met or surpassed all standards established by the Institute.

PRACTICAL FEATURES The one piece cover used on SMITH Interceptors is

equipped with a single lock and lift ring (two on large sizes). No bolts or nuts to

get lost or wrenches to look for . . . the locking device is a practical feature of the

cover assembly.

A soft, flat neoprene gasket is firmly attached to the body of all interceptors.

This eliminates the gasket tearing loose every time the cover is removed.

Interceptors have an air relief to eliminate the possibility of siphonage, and are

furnished with a separate flow control device to insure the interceptor will function within its rated capacity.

For over fifty years, JAY R. SMITH MFG. CO.

Many Smith

SMITH

CUSTOMER

DRIVEN

®

APPLICATION A Grease Interceptor is necessary where grease, fats, oils or

other similar line clogging contaminants are present in waste water that must be

disposed of through the sanitary system.

Preventing grease from entering drainage lines should always be considered when designing the plumbing drainage system in any restaurant, cafeteria, hotel, school, hospital, institutional or commercial building having facilities for the preparation and serving of food in quantity. In these installations, as well as in commercial food processing plants, dairies, and other

industries where greases and fats are a by-product, an efficient SMITH

interceptor should be installed to prevent this material from entering the

drainage lines.

HOW THE INTERCEPTOR OPERATES

Water draining to the interceptor passes through a flow control fitting which

regulates the velocity of the water to the capacity of the interceptor. As the

water enters the interceptor at this controlled rate of flow it is free of turbulence. It then passes over a series of separator baffles which are strategically

located to insure that greases, fats and oils are efficiently separated from the

waste water. Once separated, these contaminants rise to the surface of the

water in the interceptor by natural flotation and are accumulated until

removed. The waste water now relieved of over 90% of the contaminant oils

and greases, continues to flow through the interceptor into the sanitary system.

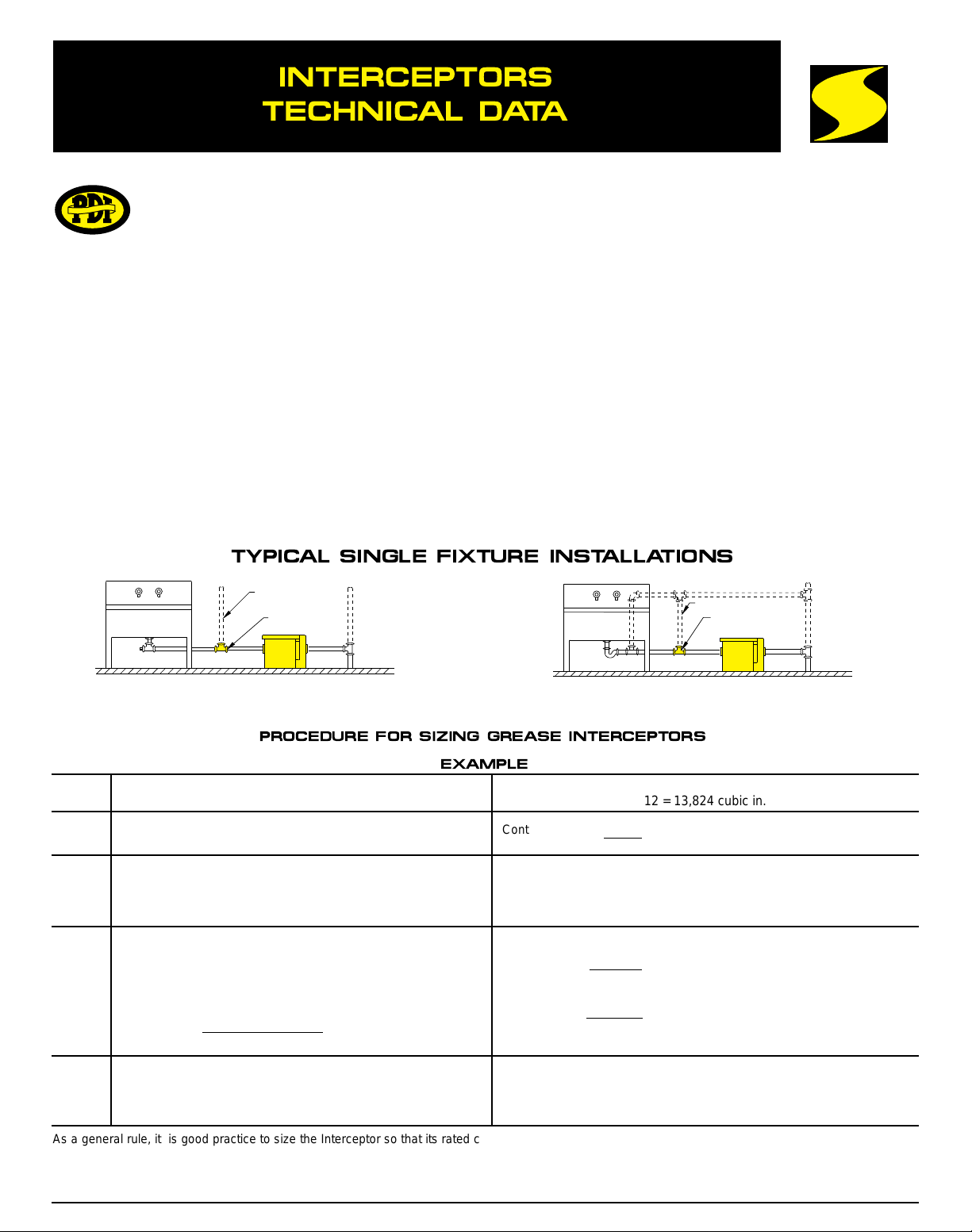

TYPICAL SINGLE FIXTURE INSTALLATIONS

▲Air Intake

Flow Control

FIXTURE NOT TRAPPED

▲See Footnote Pg. 8-02.

FIXTURE TRAPPED AND VENTED SEPARATELY

PROCEDURE FOR SIZING GREASE INTERCEPTORS

EXAMPLE

STEP 1 Determine the cubic content of the fixture by multiplying length x

width x depth.

STEP 2 Determine the capacity in gallons.

1 gal. = 231 cubic inches.

STEP 3 Determine actual drainage load.

The fixture is usually filled to about 75% of capacity with waste

water. The items being washed displace about 25% of the fixture

content. Actual drainage load = 75% of fixture capacity.

STEP 4 Determine the flow rate and the drainage period. In general,

good practices dictate a one minute drainage period, however

where conditions permit, a 2 minute period is acceptable.

Drainage period is the actual time required to completely empty

the fixture.

Flow Rate =

Actual Drainage Load

Drainage Period

STEP 5 Select the Interceptor which corresponds to the flow rate calcu-

lated. Note – Select larger size when flow rate falls between two

sizes listed. If flow rate is above 50 GPM, select a larger

Interceptor from page 8-07, Fig. 8400 Series.

As a general rule, it is good practice to size the Interceptor so that its rated capacity is never less than 40% of the fixture capacity in gallons. In the example

above, the actual fixture capacity is 59.8 gals., and 40% of this would be 23.9 gals. or a Fig. 8025. It is readily seen that a drainage period other than one or

two minutes can be used. If conditions justify, any period between one and two minutes is satisfactory, however, we do not recommend a period longer than

2 minutes. Using the 40% rule of thumb gives a drainage period of 1 7/8 minutes.

A sink 48" long by 24" wide by 12" deep

Cubic content 48 x 24 x 12 = 13,824 cubic in.

Contents in gals. 13,824

231

= 59.8 gals.

Actual Drainage Load .75 x 59.8 gals. = 44.9 gals.

Calculate flow rate for 1 minute period.

Flow Rate 44.9 gals.

1 Min.

For 2 minute period

Flow Rate 44.9 gals.

2 Min.

For 1 minute period

44.9 GPM requires a Fig. 8050

For 2 minute period

22.5 GPM requires a Fig. 8025

▲Air Intake

Flow Control

= 44.9 GPM

= 22.5 GPM

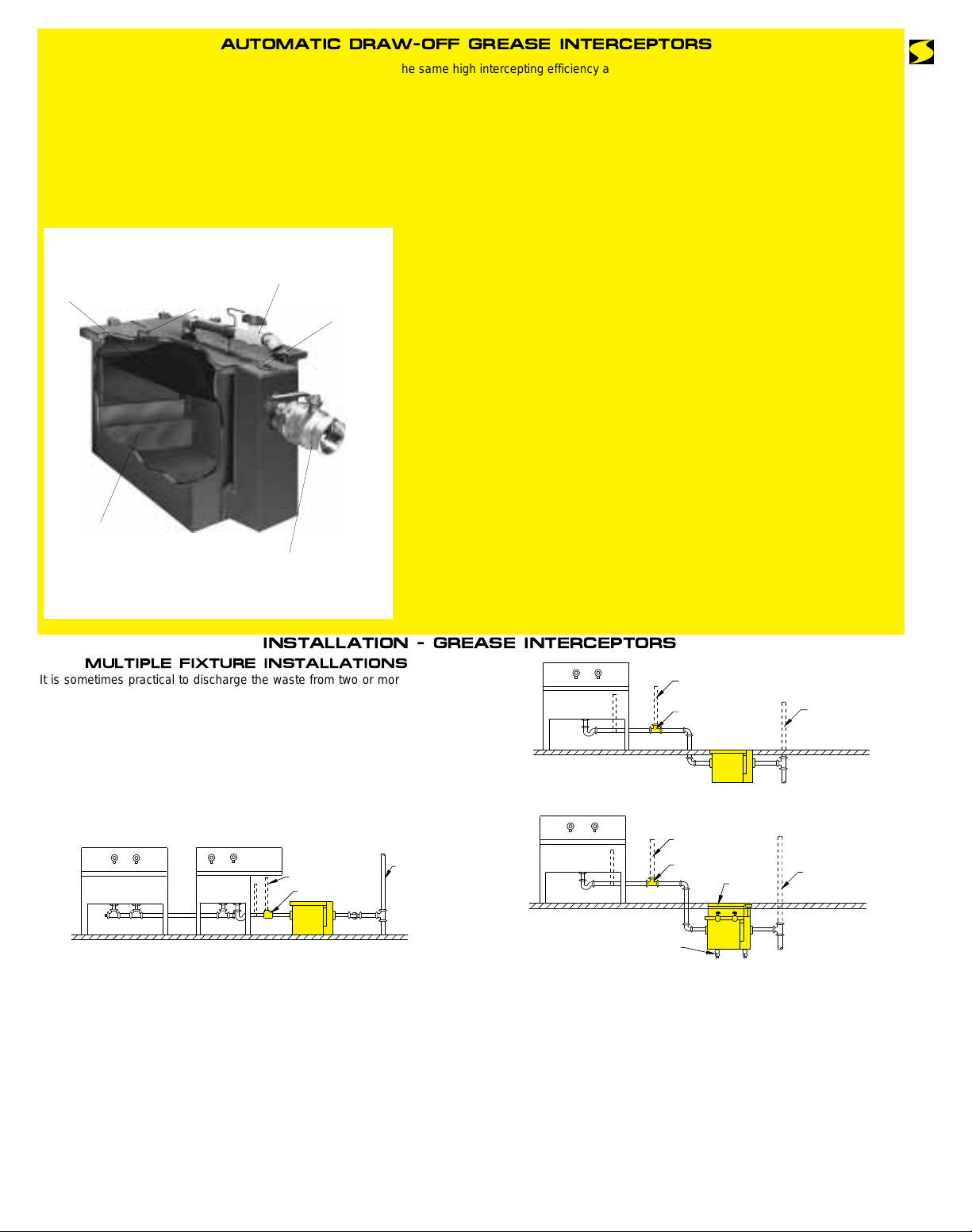

AUTOMATIC DRAW-OFF GREASE INTERCEPTORS

Smith "GT" Series Automatic Draw-off Grease Interceptors offer the same high intercepting efficiency as the conventional manual cleaned models, but

completely eliminate the unsanitary and undesirable job of removing the accumulated grease manually.

The automatic draw-off interceptor eliminates . . . • time consuming cover removal

manually removing accumulated grease

•

offensive odors

•

Since cleaning a "GT" interceptor is simple, fast and efficient, maintenance personnel will more likely follow the regular cleaning schedule. This is a distinct

advantage over the conventional units which are frequently left unattended.

When to Clean - The ideal time to clean is immediately after the interceptor has been heavily used.

Cleaning Frequency - The frequency of the draw-off cycle is determined by the use

load factor of the interceptor. An ideal cleaning cycle can be set after the unit is in operation for several weeks. By observing the amount of grease used and the frequency of

use, the operator can determine a logical cleaning cycle.

Cleaning Operation 8000 GT Series

1. Unit in normal use has the line control valve open and automatic draw-off valve

closed. When cleaning is required, run a full stream of hot water through interceptor. It is preferable to have this water at 140° or higher, running for a period of at

least two minutes.

2. Turn off hot water running into the interceptor and wait for a period of three to five

minutes for grease in the interceptor to liquefy.

3. Automatic draw-off cycle can now be started. Close the line control valve.

4. Open automatic draw-off valve at top of the interceptor and place a container

underneath this valve. Run hot water through interceptor at a rate of between 1 1/2

and 2 1/2 G.P.M.

5. After water has run into interceptor at this rate for a short period, the unit will fill.

Accumulated liquefied grease will be raised into cone and draw-off piping.

6. Allow accumulated liquefied grease to flow out of draw-off valve until clear water

appears.

7. When clear water appears, shut off flow of hot water into interceptor, turn line control valve to open position. Close automatic draw-off valve at top of interceptor.

8. Interceptor at this stage is ready again for normal use.

Grease Accumulating

Cone (Inside)

Removable

Baffles (Inside)

Lift Handle

Fig. 8000GT

Automatic

Draw-Off Valve

Cleanout

Line Control Valve

SMITH

CUSTOMER

DRIVEN

®

INSTALLATION - GREASE INTERCEPTORS

MULTIPLE FIXTURE INSTALLATIONS

It is sometimes practical to discharge the waste from two or more sinks into a

single Interceptor. This practice is only recommended when all fixtures are

close together, avoiding installation of long piping runs to the Interceptor. For

multiple installations, size as follows:

1. Determine total capacity of all sinks.

2. Establish the maximum simultaneous discharge of the sinks and fixtures.

3. Using the maximum simultaneous load capacity, determine the

SINGLE INSTALLATION - FULLY RECESSED

Interceptor required using the sizing method shown on page 8-01.

Vented

▲Air Intake

Flow Control

Fig.

8000

ON FLOOR INSTALLATION

▲Terminate Air Intake outside above the rim of sink with return bend or con-

nect to vent or vent stack as required by local code.

Waste

Interceptor Independently

Supported On Hangers

RECESSED WITH EXTENSION TO FLOOR LEVEL

Interceptor cover may be brought to floor level by using an extension when

Interceptor installation is below the floor.

GREASE INTERCEPTORS WITH EXTENSION

INSTALLATION NOTE

The Extension of 8200 Series Interceptors is designed to increase the roughing dimension from the Inlet-Outlet center line to the finished floor. The Extension

should not be used to support the entire unit. When installed in ground floor locations, the Interceptor body must rest on solid ground or on a suitable concrete pad. If

the 8200 Series unit is installed in an upper floor (suspended in the ceiling below), a suitable method of supporting the entire unit must be provided. The installation

sketch shows a typical Interceptor with Extension and a recommended method of supporting the entire weight.

SUSPENDED INTERCEPTOR INSTALLATION CONSIDERATIONS

Whenever an interceptor is to be installed suspended with receiving cradle (8300 series) or independently (all other series interceptors), proper support is essential for safety and functional integrity of the installation.

Trapeze type hangers such as those employed for support of multiple runs of horizontal piping are recommended for support of independent interceptors. Such

supports should also be considered for 8300 series receiving cradles to supplement the integral concrete anchor flange.

Supports must be of sufficient strength for the purpose intended and meet with the approval of the architect or engineer.

▲Air Intake

Flow Control

Air Intake

▲

Flow Control

Fig.

8000

Fig.

8200

Steel

Extension

Vented

Waste

Vented Waste

Loading...

Loading...