Jay R. Smith 5810, 5811 User Manual

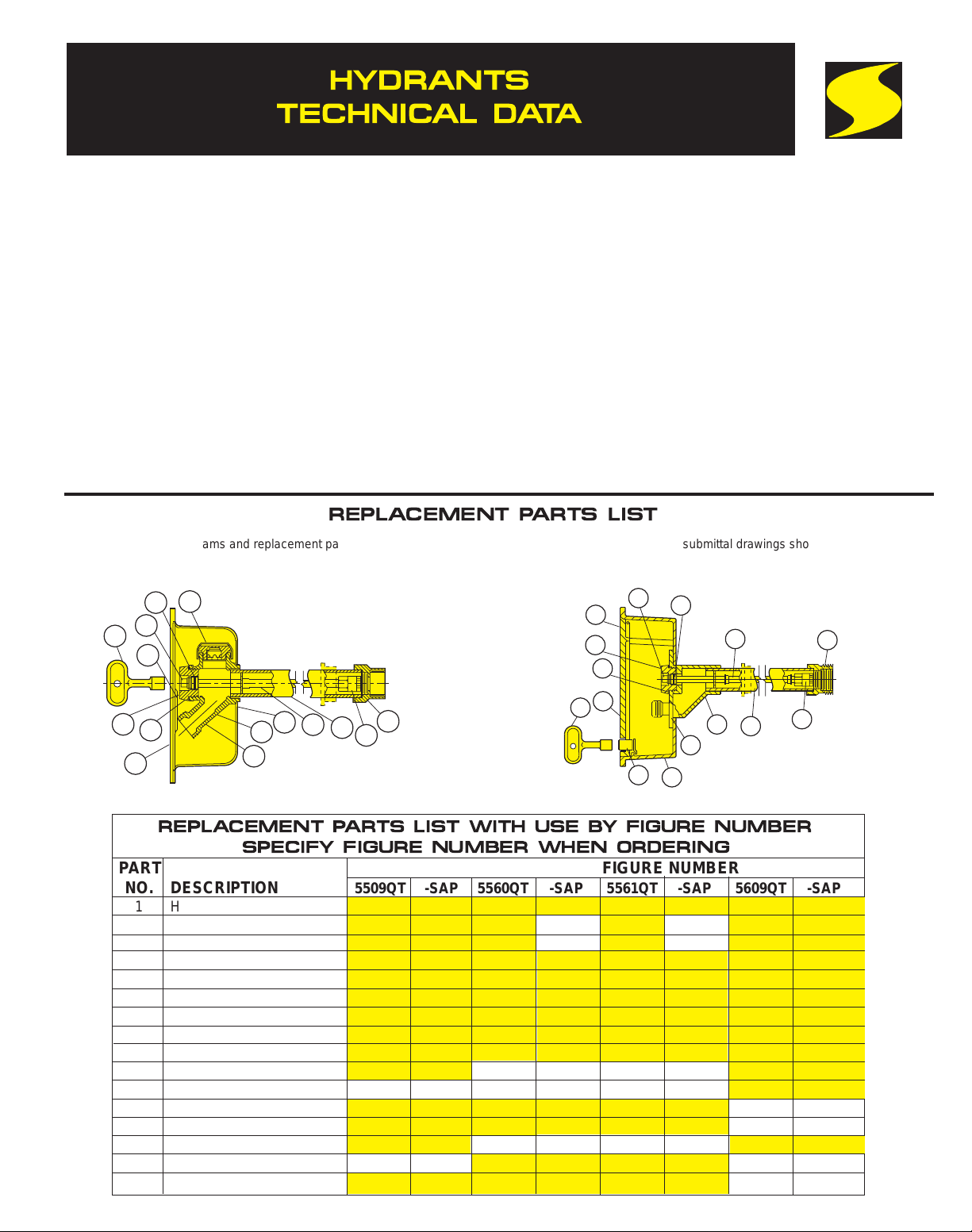

REPLACEMENT PARTS LIST WITH USE BY FIGURE NUMBER

SPECIFY FIGURE NUMBER WHEN ORDERING

PART FIGURE NUMBER

NO. DESCRIPTION

5509QT -SAP 5560QT -SAP 5561QT -SAP 5609QT -SAP

1 HEAD/CASING ASSY.

1a HEAD

1b CASING

1c VALVE HOUSING

2 FACE NUT

3 KEY

4 ACTUATOR SHAFT

5 ACTUATOR “O” RING

6 OPERATING ROD

7 FACE NUT WASHER

8

BACKER PLATE

10 BOX

11 COVER

12

VACUUM BREAKER ASSY

.

13 HINGE PINS (2)

14 LOCKING DEVICE

QUARTERHORSE 1/4 TURN NON-FREEZE WALL HYDRANTS

Box-type 1/4 turn non-freeze wall hydrants are recommended for all finished

exterior walls. Smith regularly furnishes this type wall hydrant with a stainless

steel box. Figures 5560QT Series has a bronze box with a high polished

chrome plated face. Stainless Steel and chrome plate finish will not "oxide

stain" finished exterior walls. All Smith boxes are face-of-wall design. The box

flange covers the rough opening and fits flush against exterior wall surface.

The hinged locking cover conceals the hose nozzle and all operating parts.

Advantages of flush recessed box type non-freeze hydrants are:

• No protruding hose connection, operating mechanism or key.

• Cannot be used by unauthorized persons.

• Protected against vandalism and tampering.

• Flush design offers the ultimate in appearance in any finished exterior wall.

Projecting hose connection type 1/4 turn non-freeze hydrants (5600 Series)

are recommended in finished exterior walls where protruding parts will not present a problem and where vandalism or tampering protection is not a necessity. This type is recommended with a nickel plated face to prevent staining of

finished walls. Usually, the exposed type hydrant is installed where shrubs or

other plantings conceal the hydrant and where property is protected by fencing

or other security measures.

HOSE CONNECTIONS Smith 1/4 Turn Non-Freeze Wall Hydrants are

regularly furnished with a 3/4" - 11 1/2 NH garden hose connection. This connection is regularly furnished for both 3/4" and 1" inlet sizes. A 1" 11 1/2 NPSH

water hose connection can be furnished (-HC1) when specified.

1/4 TURN NON-FREEZE SERIES With exception of short as possible

(-SAP) types, series 5500 and 5600 should always be used where outside

temperatures drop below freezing. In mild climates or at indoor locations where

freezing temperatures are not encountered, the 5509QT-SAP type mild climate

box hydrants are recommended. These series are regularly furnished with a

stainless steel box to protect the finished wall from staining.

The 5509QT and 5609QT series non-freeze wall hydrants are regularly furnished with an integral atmospheric vacuum breaker. The 5560QT and

5561QT series are regularly furnished without a vacuum breaker. These are

available with an add-on type vacuum breaker as variation (-H) when specified.

Back siphonage is prevented when a negative pressure or vacuum occurs in

the hydrant by automatically closing the vacuum breaker and opening air

ports, thus breaking the vacuum within the hydrant.

HYDRANTS

TECHNICAL DATA

CUSTOMER

DRIVEN

SMITH

®

3

1

1a

10

6

1b

9

1c

4

5

12

14

2

7

11

3

11

7

2

13

4

5

6

9

1b

1a

1

10

14

1c

REPLACEMENT PARTS LIST

The following diagrams and replacement parts list can be used in figure numbers below. All Smith hydrant submittal drawings show a complete parts

list on reverse side of drawing.

Fig. 5509QT

Fig. 5609QT

Fig. 5560QT

Fig. 5561QT

SMITH

®

HYDRANTS TECHNICAL DATA AND

OPTIONAL INLET CONNECTIONS

CUSTOMER

DRIVEN

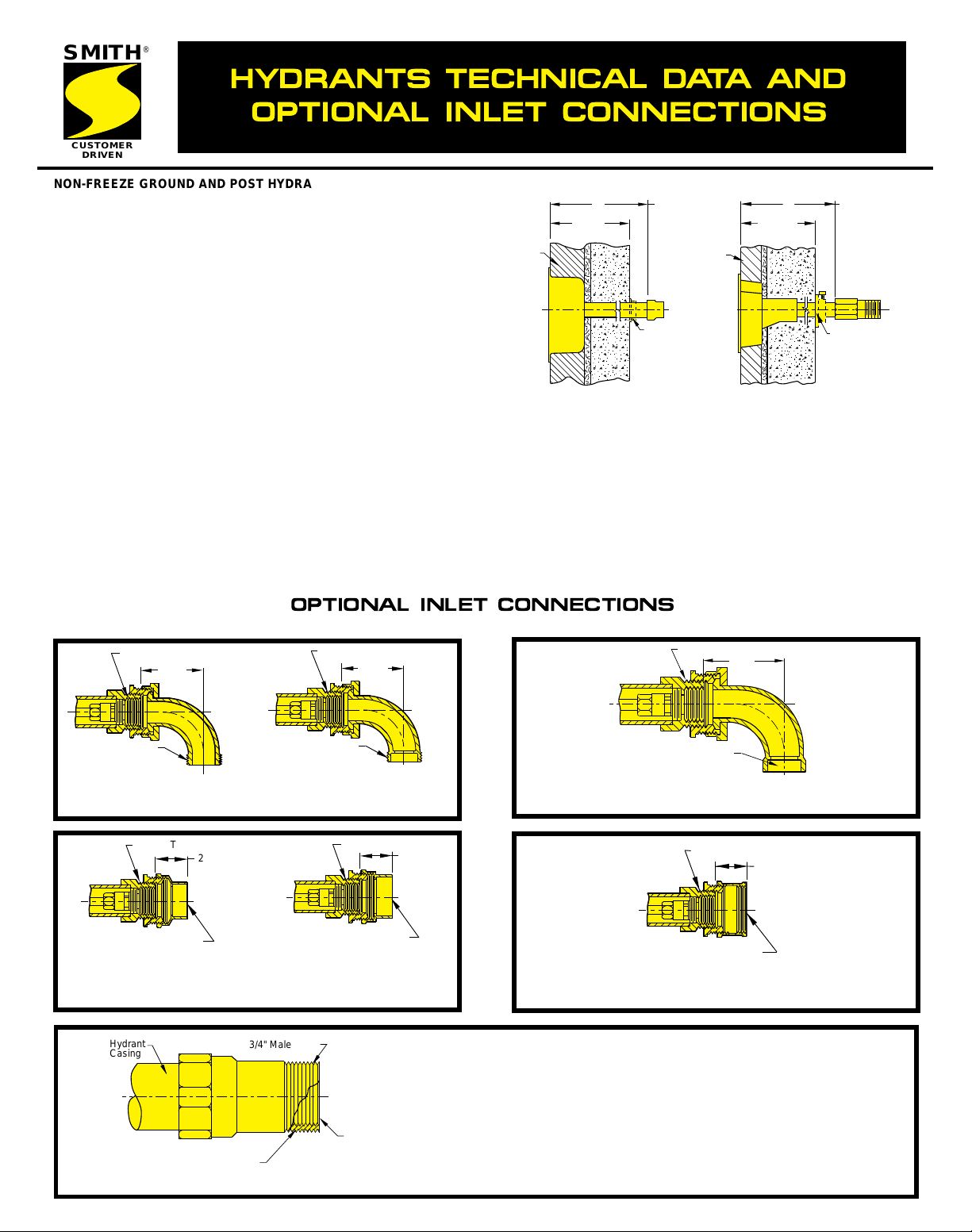

NON-FREEZE GROUND AND POST HYDRANTS are supplied with a spe-

cial valve housing which prevents freezing of hydrant during non-use periods.

The valve housing must be installed below the frost line (minimum depth of

bury) which prevails for the area of installation. The valve housing has a

drain hole which drains the casing of hydrant when hydrant is shut off. In

effect, there is no water in the casing during non-use periods. Normally,

water from the drain hole is allowed to drain into the ground. The valve housing should be set in a bed of gravel so that water drained from casing can

leach into ground.

Some locations which require Non-Freeze Ground Hydrants cannot tolerate

water draining from the drain hole. Examples are parking garages, plazas,

and roof decks used for recreational purposes. Often in this type of application the valve housing will protrude into a finished area which is not subject to

freezing temperatures. To eliminate the problem of water drainage in this

type of installation, Smith can supply a tapped drain hole in the hydrant box

and a tapped drain hole in the valve housing. By using the tapped drain hole,

water accumulation in the box, and the normal drain down water from the

valve housing drain hole can be piped to a suitable drain.

SPECIFYING WALL SIZE Primary function of both 5500 and 5600 Series

1/4 Turn Non-Freeze Wall Hydrants is to supply water to the building exterior

without danger of freezing, regardless of how low the outside temperature

falls. For this reason, the hydrant must be specified with a casing long

enough to locate the valve seat inside the heated building. (Fig. 1) shows

how to determine proper size required.

NOTE: All wall hydrant series are available in short as possible types for mild climate

installation. Specify series number -SAP.

A

Wall

Thickness

Finished

Exterior

Wall

NOTE: When ordering, specify Figure Number and "A" dimension. "A" should always be

greater than wall thickness for non-freeze installations. When a wall clamp is specified, add 1

1/4" to the wall thickness to arrive at a minimum required "A." The "A" specified should be the

next larger, even number; such as 6", 8", 10", etc. Wall hydrants are furnished in lengths of 2"

increments.

This is the

dimension

to the valve

housing.

Finished

Exterior

Wall

Adjustable Wall Clamp

(When Specified)

Fig. 1

A

Wall

Thickness

This is the

dimension

to the valve

housing.

Adjustable Wall Clamp

(When Specified)

Often, non-freeze wall hydrants must be concealed entirely within the wall.

When so required, an overall dimension can be specified. This dimension is

measured from face of hydrant box to extreme end of inlet connection. When

the valve seat must be concealed within the wall, extra precautions must be taken to properly insulate the valve seat housing to protect against freezing.

3/4" NPT

2 3/8

3/4" NPT Male

SUFFIX -E

UNION ELBOW - 3/4" NPT

3/4" NPT

For 3/4" Copper Tubing

Female Sweat Connection

SUFFIX -SS

STRAIGHT SWEAT - 3/4"

Hydrant

Casing

OPTIONAL INLET CONNECTIONS

3/4" NPT

2 3/8

1" NPT Male

SUFFIX -E1

UNION ELBOW - 1" NPT

2

STRAIGHT SWEAT - 1"

3/4" Male NPT

3/4" NPT

For 1" Copper Tubing

Female Sweat Connection

SUFFIX -SS-1

2

UNIVERSAL INLET CONNECTION

For 3/4" Copper Tubing

Female Sweat Connection

UNION ELBOW -SWEAT -3/4”

3/4" NPT

SUFFIX -SE

SUFFIX -MF1

STRAIGHT FEMALE - 1"

2 3/8

3/4" NPT

2

1" NPT Female

1/2" Female NPT

Union Ground

Joint

Hydrants are regularly furnished with a unique inlet connection, 3/4"

NPT Male thread, 1/2" NPT Female thread, and union ground joint carefully engineered to accommodate inlet connections shown above.

Loading...

Loading...