Jaypro Sports PB-95 User Manual

Jaypro Sports

976 Hartford Turnpike

Waterford, CT 06385 USA

(800)243-0533

www.jaypro.com

(800)988-3363 Fax

MODEL NO.:

PRODUCT NAME:

EFFECTIVE DATE:

DRAWN BY: MT

1/24/2011

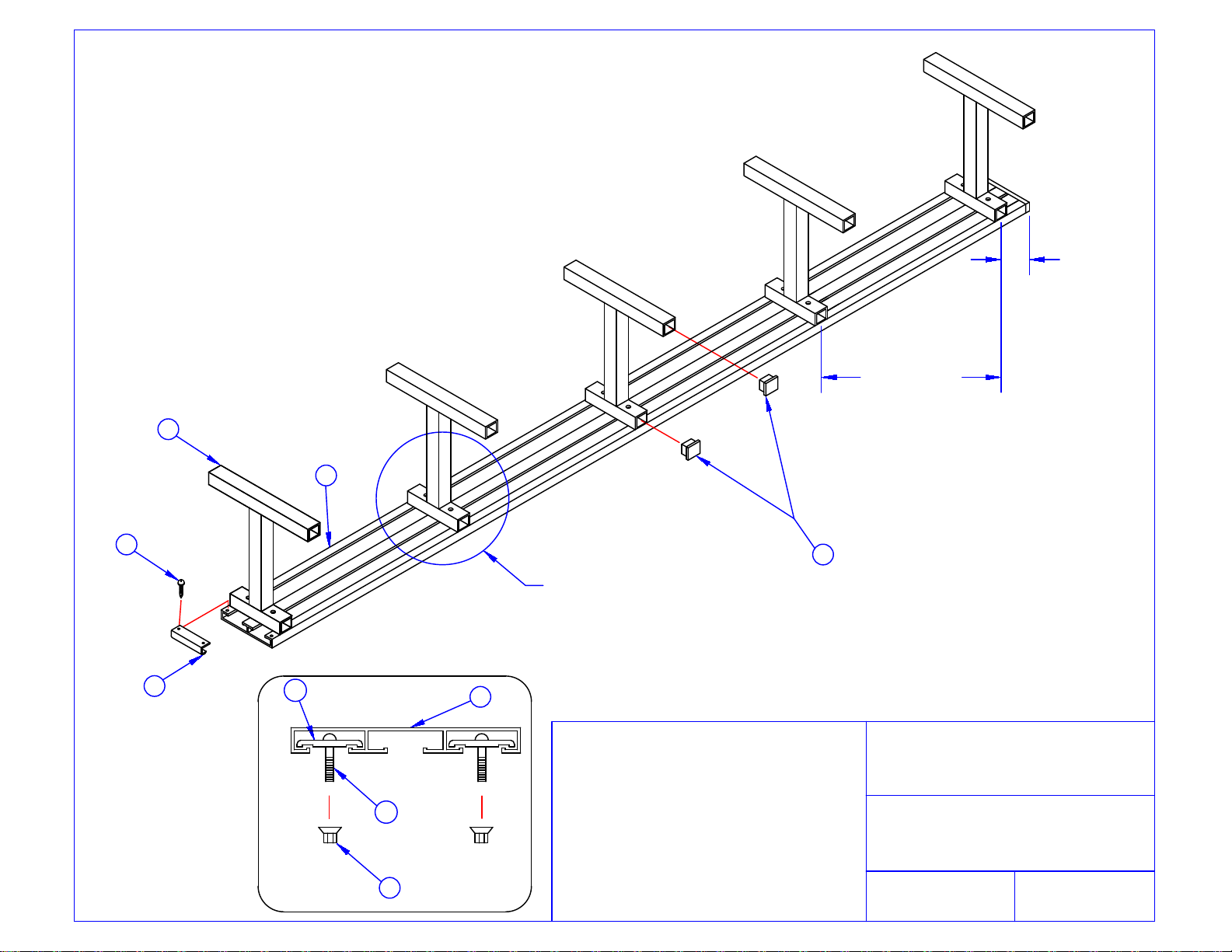

76 1/2"TYP

CTR TO CTR

SEE VIEW

A-A

4

8

1

2

7

VIEW A-A

7

6

5

3

REPLACEMENT, PLEASE CALL YOUR DEALER

MENT MAY BE HAZARDOUS. FOR REPAIR OR

3) ALTERATION OR MODIFICATION OF EQUIP-

INTENDED, MAY BE HAZARDOUS.

2) USE OF THIS EQUIPMENT OTHER THAN

PERFORMED BEFORE EACH USE

INSPECTION AND MAINTENANCE MUST BE

HIGH PERFORMANCE FROM THIS EQUIPMENT,

1) FOR SAFE OPERATION AND CONTINUED

PLEASE NOTE:

PB-95

27' PLAYERS BENCH

9"TYP

EACH END

JAYPRO SPORTS

27’ PLAYER’S BENCH, PB-95

LIST OF MATERIALS

PIECE # PART # DESCRIPTION QTY.

1 AR5111 SEAT PLANK 27’ 1

2 PB751 BENCH LEG 5

3 HN5046 5/16” FLANGE NUT 10

4 EP0018 2” x 2” END CAP 20

5 HB5030 5/16”-18 x 3” CARRIAGE BOLT 10

6 AR5044 HOLD DOWN CLIP 10

7 AR5045A END CAP 2

8 HS5035 #8 PAN HEAD SCREW x ½” 4

ASSEMBLY INSTRUCTIONS

TOOLS REQUIRED: PHILLIPS SCREWDRIVER BIT W/ ELECTRIC DRILL (1),

½” SOCKET WRENCH OR ADJUSTABLE WRENCH (1)

1) Slip the end caps (7) snugly onto each end of the plank (1). Using the electric

drill, assemble a self-drilling screw (8) through the cap and into the flange of

the plank. Two screws are required per end cap.

2) For easiest assembly, position seat plank (1) on a level raised surface such

as a desk top, bleacher seat or work bench. Place the carriage bolt (5) and

bolt clips (6) approximately into place within the slots of the plank. Note that

the legs should be no more than 8” from the plank edge or 9” from edge to

center leg.

3) Position the legs as shown and loosely assemble the hardware illustrated in

detail ‘a-a’. Do not fully tighten the hardware at this time. Level the bench

and make sure the legs are adequately spaced apart. Tighten all fasteners

fully.

REV- 5/9/2011

Loading...

Loading...