Page 1

En

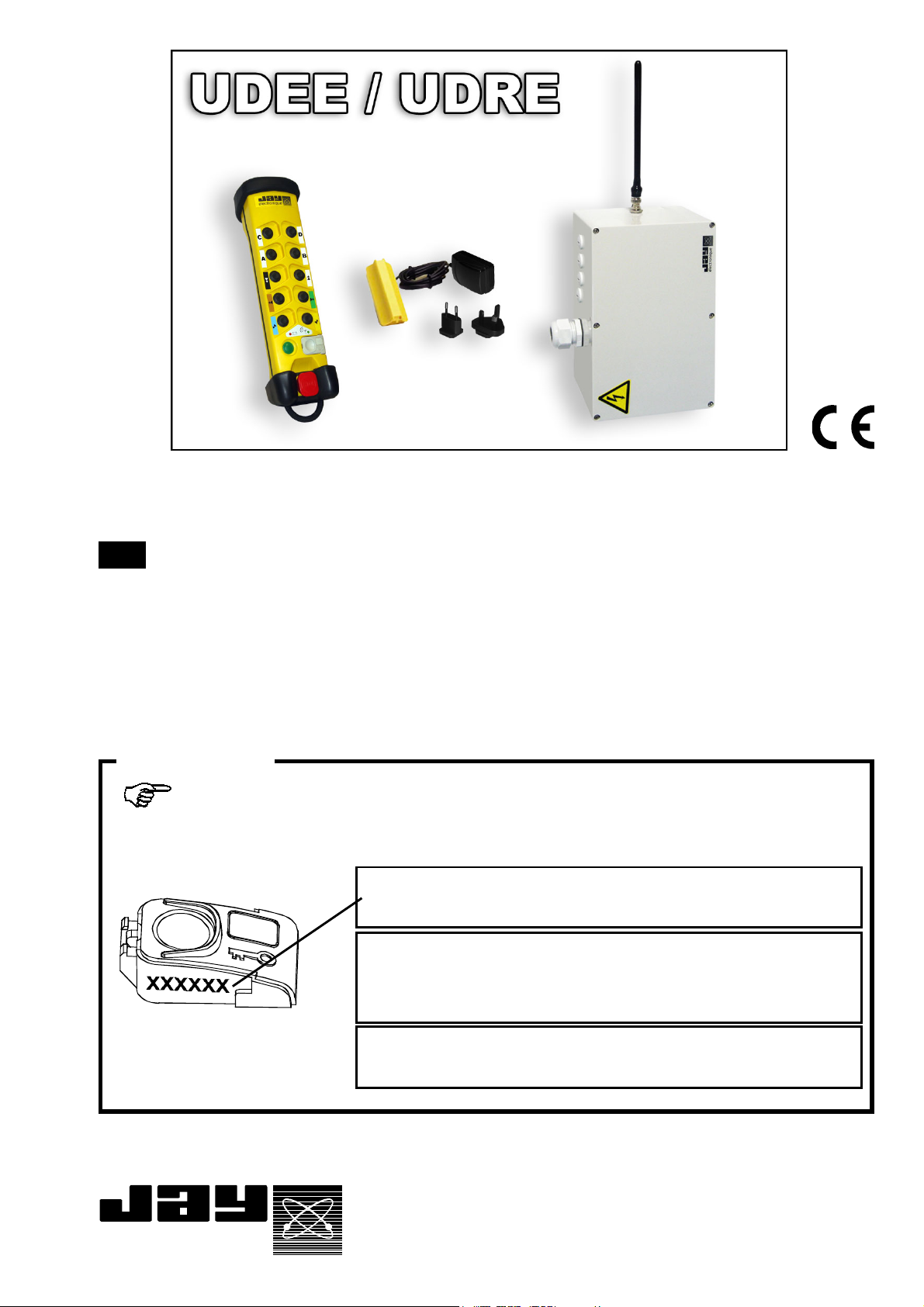

Industrial enhanced-safety radio remote

controls

Installation and user technical manual ....................................................... Page 2

Appendix ............................................................................................................. Page 42

IMPORTANT

An identification number is engraved on the side of the electronic key.

Take a moment now to write down this number :

N° :

•Identity code number of associated receiver :

(electronic key of the transmitter UDEE)

électronique

•Equipment controlled :

PRELIMINARY

Document

Ref. doc :

332170A

revision02

Page 2

- TABLE OF CONTENTS -

General safety rules .......................................................................................... p. 4

1 Description of UDEE/UDREE radio remote control .......................................... p. 5

2 Installation ......................................................................................................... p. 6

2.1 Composition of the UDEE/UDRE Series and description of elements ............ p. 6

2.2 Unpacking the products ..................................................................................... p. 7

2.3 Product identification.......................................................................................... p. 8

2.3.1 UDEE transmitter ............................................................................................... p. 8

2.3.2 UDRE receiver ................................................................................................... p. 8

2.3.3 Accessories ....................................................................................................... p. 9

2.4 Delivery configuration ....................................................................................... p. 10

2.5 Installation recommendations ......................................................................... p. 11

2.5.1 Implementation of elements ............................................................................ p. 11

2.5.2 Marking of the controlled equipment ............................................................... p. 12

2.5.3 Wiring ............................................................................................................... p. 12

2.5.4 Interference suppression ................................................................................ p. 14

2.5.5 Electrical power supply protection ................................................................... p. 14

2.5.6 Minimum and maximum current of relay outputs ............................................ p. 14

2.5.7 Auxiliary control ................................................................................................. p. 14

2.5.8 Choice of operating radio frequency ................................................................ p. 14

2.6 UDEE transmitter function button labels ......................................................... p. 15

3 Commissioning .............................................................................................. p. 16

3.1 Precautions when commissioning ................................................................. p. 16

3.2 Periodic checks and checks performed following maintenance operations . p. 16

3.3 First startup of the radio remote control .......................................................... p. 17

3.4 Functioning block diagram .............................................................................. p. 18

3.5 Configuring the UDEE/UDRE radio remote control ........................................ p. 19

3.5.1 Procedure : «locking-unlocking» the electronic key (access to UDEE transmitter

programming) .................................................................................................. p. 20

3.5.2 Procedure : working frequency programming ................................................. p. 21

3.5.3 Procedure : «Dead man» function time programming ................................... p. 22

3.5.4 Procedure : «Copying electronic key identity code in the UDEE transmitter» p. 23

3.6 Configuring the receiver UDRE ....................................................................... p. 24

4 Use and operation ............................................................................................ p.25

4.1 Reminder of the general safety rules .............................................................. p. 25

4.2 Starting up the remote control .......................................................................... p. 26

4.3 Indicator light functions .................................................................................... p. 27

4.3.1 UDEE transmitter indicator lights .................................................................... p. 27

4.3.2 UDRE receiver indicator lights ......................................................................... p. 28

- 2 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 3

5 Technical characteristics............................................................................... p. 29

5.1 Function button interlocking ............................................................................. p. 29

5.2 Correspondence between function buttons and relays .................................. p. 29

5.3 UDEE transmitter technical characteristics .................................................... p. 30

5.3.1 Identity code ..................................................................................................... p. 30

5.3.2 Electronic key ................................................................................................... p. 31

5.3.3 «Dead man» function ...................................................................................... p. 32

5.4 UDRE receiver technical characteristics ......................................................... p. 33

5.4.1 Connection to relays ........................................................................................ p. 34

5.4.2 Relay characteristics ........................................................................................ p. 34

5.4.3 Protection of receiver board and relays ........................................................... p. 36

5.5 UDB2 plug-in battery technical characteristics ............................................... p. 37

5.5.1 Battery pack storage precaution ...................................................................... p. 37

5.5.2 Precaution when inserting battery pack in transmitter unit ............................. p. 37

5.5.3 Display of battery pack charge state ................................................................ p. 38

6 Servicing .......................................................................................................... p. 39

7 Special functions ............................................................................................ p. 40

8 Warranty and FFC compliance ....................................................................... p. 40

Appendix :

A Receiver UDRE detailed internal view .......................................................... p. 42

B Transmitter UDEE detailed view ................................................................... p. 43

C Dimensions of elements ................................................................................. p. 44

D Wiring example (En. version) ......................................................................... p. 45

E Table of programmable radio frequencies .................................................... p. 46

F CE Declaration of conformity ......................................................................... p. 47

UDEE / UDRE - 332170A revision02 - 3 -FrEnDePRELIMINARY

Page 4

General safety rules

A radio remote control is considered as a machine control device and as a safety

component used to stop a machine as specified by the EEC Machinery Directive.

All applicable rules must therefore be observed to ensure safe, correct operation

of such devices.

- For maximum safety when using the radio remote control, we recommend that

the operator carefully follow the instructions provided in this manual.

- The operator must be appropriately trained and certified to operate machines

by radio remote control.

- The operator must have uninterrupted visibility of the manoeuvre which he

is performing. When the operator's direct field of view is inadequate, the lifting

machinery must be equipped with auxiliary devices to improve visibility.

When several machines are being moved simultaneously, the equipment must be

fitted out to limit to consequences of a possible collision.

- To avoid any risks of electrocution, don't open the receiver case when

powered.

- Never leave the transmitter lying around anywhere, in particular when it is

powered up.

- Never leave the radio control transmitter on the ground or on a metal surface. If

doing so becomes indispensable, press the stop palmswitch on the radio control.

- If several radio controls are used at the same site, different radio frequencies

should be used, spaced by at least two channels (for example, channels 5, 7, 9,

etc.). The more space there is between the chosen radio channels, the less the

risks of disturbance are.

- For safety reasons, remove the electronic key when not in use. Store it in a safe

and tracked down place.

- Do not forget to recharge the battery pack when discharged.

- In the event of a malfunction, immediately shut down the installation by pressing

the stop palmswitch on the transmitter and remove the electronic key.

- Service your equipment and perform all the periodic checks as may be required

by the intensity with which your equipment is used. Follow necessarily the

instructions of cleaning described in the chapter "Servicing".

- 4 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 5

1- Description of UDEE/UDRE radio remote control

Thank you for choosing our UDEE/UDRE SeriesThank you for choosing our UDEE/UDRE Series

Thank you for choosing our UDEE/UDRE Series

Thank you for choosing our UDEE/UDRE SeriesThank you for choosing our UDEE/UDRE Series

industrial enhanced-safety radio remote control.industrial enhanced-safety radio remote control.

industrial enhanced-safety radio remote control.

industrial enhanced-safety radio remote control.industrial enhanced-safety radio remote control.

The UDEE/UDRE radio remote control is designed for remote control applications on

handling machines and for industrial equipment applications.

The radio remote control enables the operator to better focus on his work as it allows

him to choose his observation position which is only limited by safety considerations

(example: no one should be standing under a load).

The radio remote control completes and enhances the classic safety circuits (emergency

stop circuits).

Special attention has been given to ensure operator comfort through the following features :

z Ergonomic transmitters enabling one-hand control

z Control button accessibility

z Button touch sensitivity

z Identification of functions controlled

z Light-weight, compact transmitter

z Transmitter endurance, and fast charging battery pack

z Adaptability to all radio configurations of the environment by possibility for changing

frequency by a trained operator

z Mechanical protection of function buttons to avoid any unintentional action

z Transmitter carrying strap which hooks onto belt when unit is idle, or removable shoulder

strap (optional accessories)

To further enhance safety when using this equipment, technical solutions and innovative options are

also proposed :

z Radio remote control shutdown category 3 per EN954-1 and Hamming distance superior

or equal to 4 for each transmitted message

z Access is enabled by electronic key to an authorised operator only

z Memorisation of use of remote control by recording number of operations and durations

for each movement (option)

Easy maintenance :

z Customization entirely stored in electronic key

z Diagnostic aid indicator lights

z Parameter definition software (accessory)

Finally, the UDEE/UDRE radio remote controls fully satisfy the safety requirements of the current

applicable and draft standards and comply with the following European directives:

z Machinery Directive, shutdown category 3 per EN954-1

z RTTE : microwave equipment and telecommunication terminals (low voltage,

electromagnetic compatibility, radio-electric spectrum) ART conformity certificate

z American regulation FCC part 15

For any recommendations or questions concerning installation of the UDEE/UDRE remote control system,

))

)

))

contact us at our customer service department :

Tel : +33.(0)4.76.41.44.00

Fax: +33.(0)4.76.41.44.44

Email : support.technique.client@jay-electronique.fr

UDEE / UDRE - 332170A revision02 - 5 -FrEnDePRELIMINARY

Page 6

2- Installation

2.1- Composition of the UDEE/UDRE Series and description of

elements

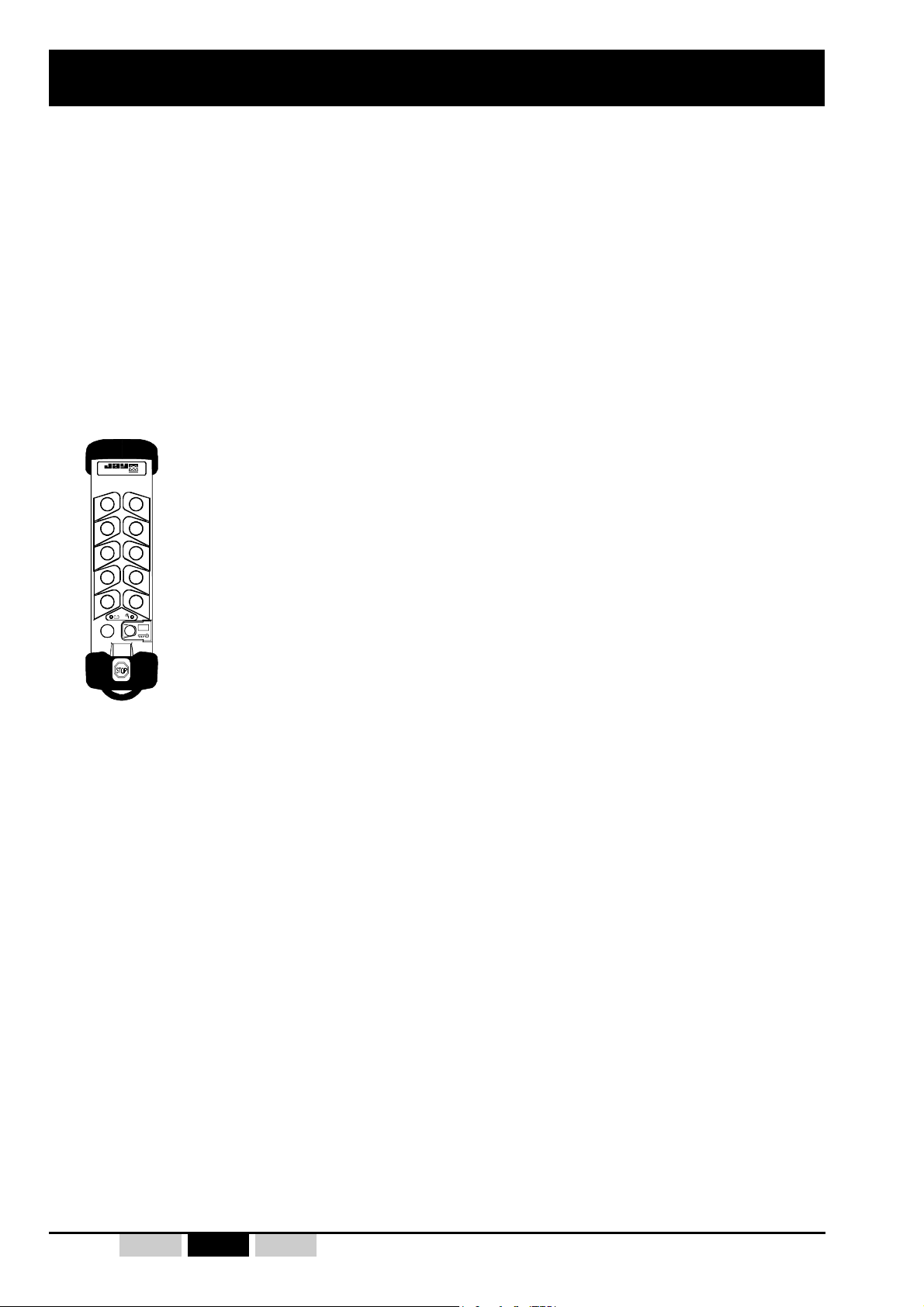

The UDEE/UDRE Series comprises :

A transmitter : «UDEE» with radio communication :

élect roniq ue

10+2 button version

(10 function buttons + 1 «On/Horn» button + 1 «stop palmswitch button»)

A receiver «UDRE» which decodes the information generated by the remote control and

controls movements of the machines.

A battery pack «UDB2» (transmitter battery).

A battery pack charger «UBCU».

Accessories (strap, label kits, common wiring accessory etc...).

- 6 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 7

2.2- Unpacking the elements

IMPORTANT

When unpacking the products, be sure to :

- Write down the electronic key number on the cover page of this manual.

This number will allow you to order a new, identical electronic key defined with

your parameters.

- Put the battery pack on load for 14 hours minimum before a first use.

1st package

Transmitter

UDEE

électronique

electronic key

D

U

O

P

W

N

N

S

O

O

U

R

T

T

H

H

N

S

O

U

R

D

D

(1) = mounted on transmitter

(1)

R

F

R

S

E

O

L

I

H

V

R

E

E

W

G

U

F

R

A

H

N

S

R

T

E

D

T

T

W

E

+

-

E

A

R

R

S

S

P

P

T

T

M

M

O

1•12

U

E

•

12

E

S

S

T

T

1

•2•3•

2

1+2

•

Descriptive label

électronique

Ref :

UDE . . . . .

Freq : .... .. ....MHz

Serie : .../... .

Date : .. / ..

ON

•

OFF

1 2 3

GATE

7 8 9

123

34

12

3+4

1+2

34

43

3+4

4

3

IP65

4

5 6

label

kits

Battery pack

UDB2

2nd package

Battery pack charger

(for charging the UDB2 battery pack)

UBCU

(1)

110-230VAC/12VDC

with european and

english plugs

3rd package

Descriptive label

Receiver

UDRE

Ref :

UDR . . . . . - . . .

Freq : .... .. ....MHz

Serie : .../... . Alim : .....V..

électronique

Date : .. / ..

IP65

4 colored directional

arrows

Antenna

UDEE / UDRE - 332170A revision02 - 7 -FrEnDePRELIMINARY

F 38330 Montbonnot

Code : . . . .

common wiring

accessory

Technical manual

Technical manual

only for additional

options

Page 8

2.3- Product identification

(according to sales reference)

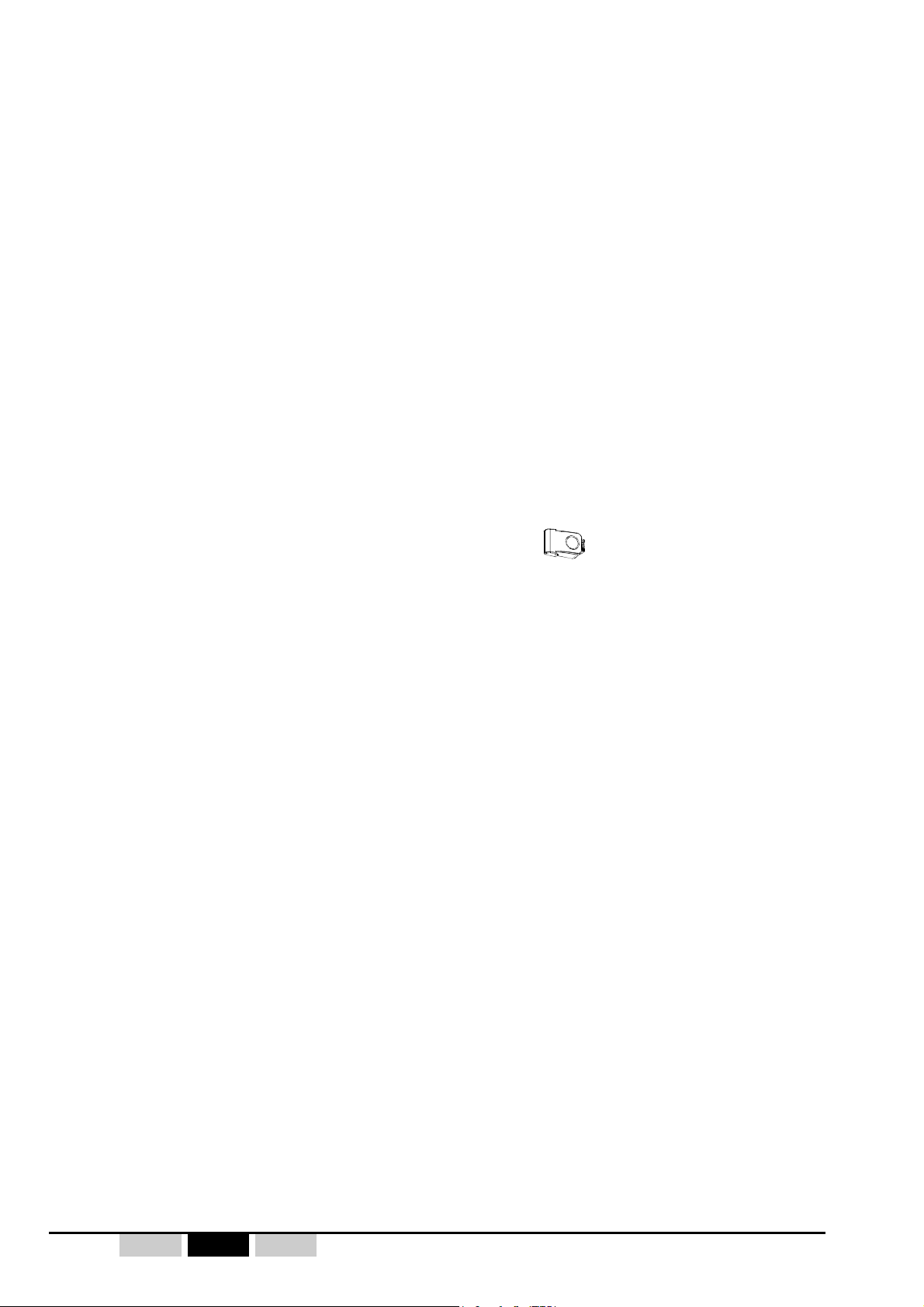

2.3.1- Transmitter UDEE

UDEE22222

2.3.2- Receiver UDRE

Programming of button - relay correspondence :

Number of relays controlled by BPDV (double speed

pushbutton)

= 3 relays

1

= 4 relays

2

= special (equipment definition covered by a customization

x

data sheet)

UDR

ECB

Programming of transmitter button interlocking :

= no interlocking

0

= interlocking button n°1-n°2, n°-n°4, n°5-n°6

1

with output relays set to OFF

= interlocking button n°1-n°2, n°-n°4, n°5-n°6

2

with priority on left button

= interlocking button n°1-n°2, n°-n°4, n°5-n°6

3

with priority on right button

= special (equipment definition covered by a

x

customization data sheet)

0

-

01

- 8 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 9

Reference Description

UBCU

Charger for battery pack, 110-230VAC/12VDC with european and english plugs

UDB2

(1)

Transmi tter plug-in ba tter y pack

UDC1

Wall br acket f or stowing and batt e ry pack chargi ng when id le

UDWE2 2 X

(1)

Programmed electronic key (electronic key number to be supplied)

UDP1

Bel t fastenin g cli p

UWE 102

Removable shoulder strap

UWE 303

Protective case for transmitter 10+2 button version

UWE 202

(2)

Kit of 6 colored labels "movements" for double speed pushbuttons (2 steps)

UWE 205

Kit of 48 white blank labels for cutomized marking

UWE 207

(2)

Kit of 90 white/black labels "movements, special functions and customizati on" for

switches and pushbuttons

Reference Description

VUB984

BNC straight antenna, 1/2 wave in 911-918MHz

VUB105

2m extension for antenna + non insulated bracket BNC

VUB125

5m extension for antenna + non insulated bracket BNC

VUB131

10m extension for antenna + non insul at e d bracket BNC

UWE 001

2 ways dire cti onal colored ar rows for trav el ling crane

UWE 002

(1)

4 ways dire cti onal colored ar rows for trav el ling crane

UDWR38

Fastening Kit for receivers by magnetic contacts

UDWR12

(1)

Common wiring accessory

UDWR13

24-pin plug-in connector + 2m cable

UDWR14

16-pin plug-in connector + 2m cable

UDWR23

UDWR13 cabling realization in UDRE receiver

UDWR24

UDWR14 cabling realization in UDRE receiver

UDWR32

Serial li nk boa rd (kit UDW R36 sof twar e + cabl e to be ordered separately)

UDWR36

PC "DialogUD" Software (CD-ROM+ computer PC/ receiver UDRE cable)

2.3.3- Accessories

For UDEE transmitter

For UDRE receiver

(1)= 1 accessory supplied with product

(2)= Label kits supplied systematically with transmitter

UDEE / UDRE - 332170A revision02 - 9 -FrEnDePRELIMINARY

Page 10

2.4- Delivery configuration

• Radio channel number :

- Programmed with radio channel number 01 (911,800MHz)

• Duration of the temporization for the "Dead Man" function (automatic shutdown of

remote control in case of prolonged non-use) :

- Programmed for 4 mn

• Button / relay configuration and button interlocking:

- According to product definition with order (receiver reference) or special (equipment

definition covered by a customization data sheet).

• Locking of the UDEE transmitter electronic key :

(access to UDEE transmitter programming)

- The transmitter is supplied with an "unlocked" electronic key, programmings : Radio channel

and "Dead man" function duration can be directly modified by a trained operator (see

programming procedures on chapter «transmitter configuration»).

- 10 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 11

2.5- Installation recommendations

Experience shows that the functional efficiency of the system basically depends on the quality of

the installation :

- Implementation of elements,

- Marking of the controlled equipment,

- Wiring quality of UDRE receiver,

- Interference suppression,

- Electrical power supply protection,

- Minimum and maximum current of relay outputs,

- Choice of operating frequency.

2.5.1- Implementation of elements

))

)

))

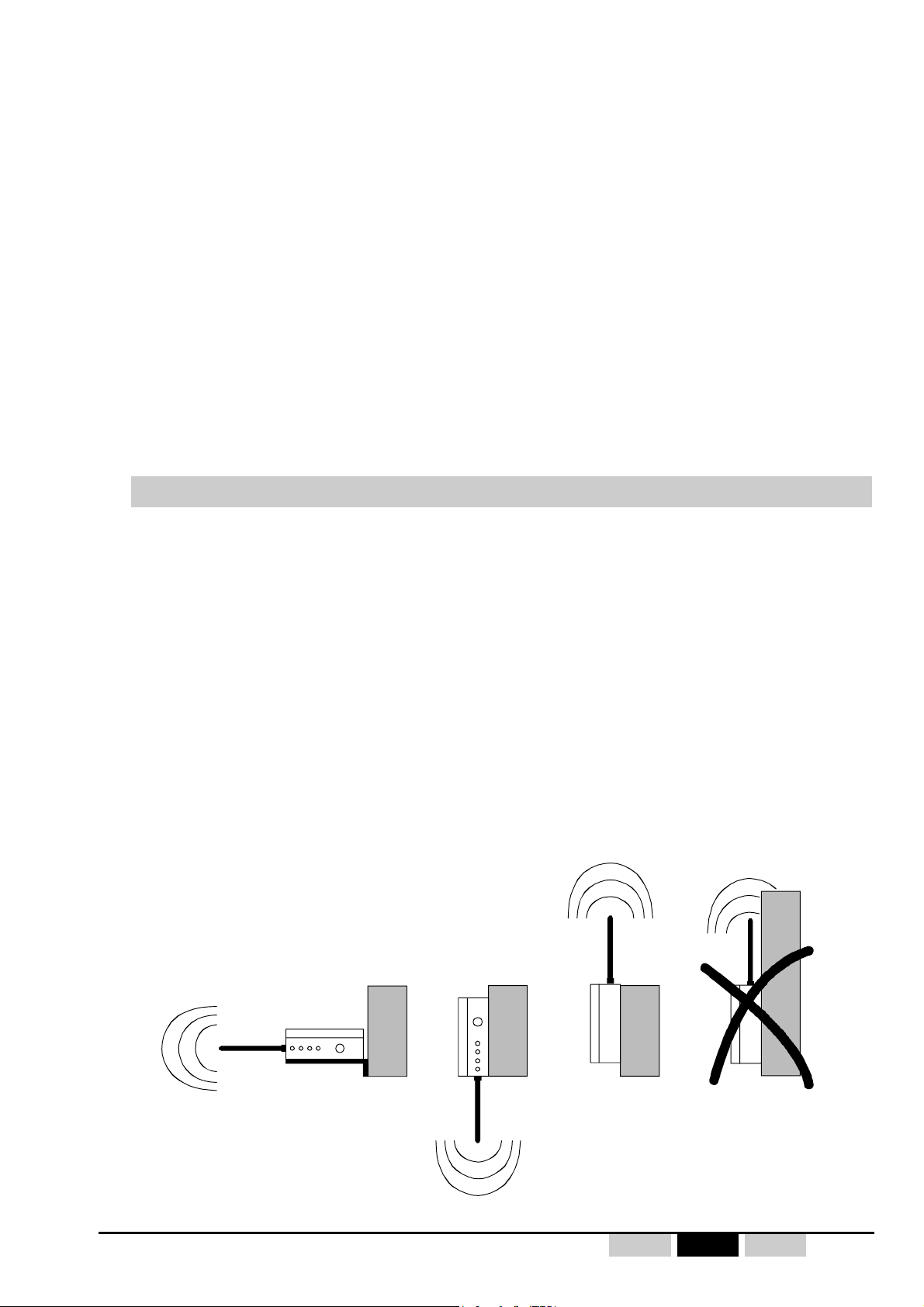

Receiver position

The remote control receiver UDRE should be mounted as close as possible to the control

cabinet, vertical with respect to the machine structure. The receiver should be sheltered from

shocks and weather.

The antenna should be as far as possible from the class 3 cables and power components

(power supply, motor, variable speed drive, etc.) while remaining within an area favorable to

radio reception :

z The antenna should be located at a height, above the operator using the transmitter UDEE.

z The antenna must be directed toward the transmitter working areas (downward with a hoist).

z The antenna orientation is indicated in the figure below :

Element dimensions are available for consultation in Appendix C

No metal object which could create a screen should be located between the operator and

the antenna.

Good

UDRE

Metal

UDEE / UDRE - 332170A revision02 - 11 -FrEnDePRELIMINARY

Good

Metal

Good

Metal

Metal

Wrong

Page 12

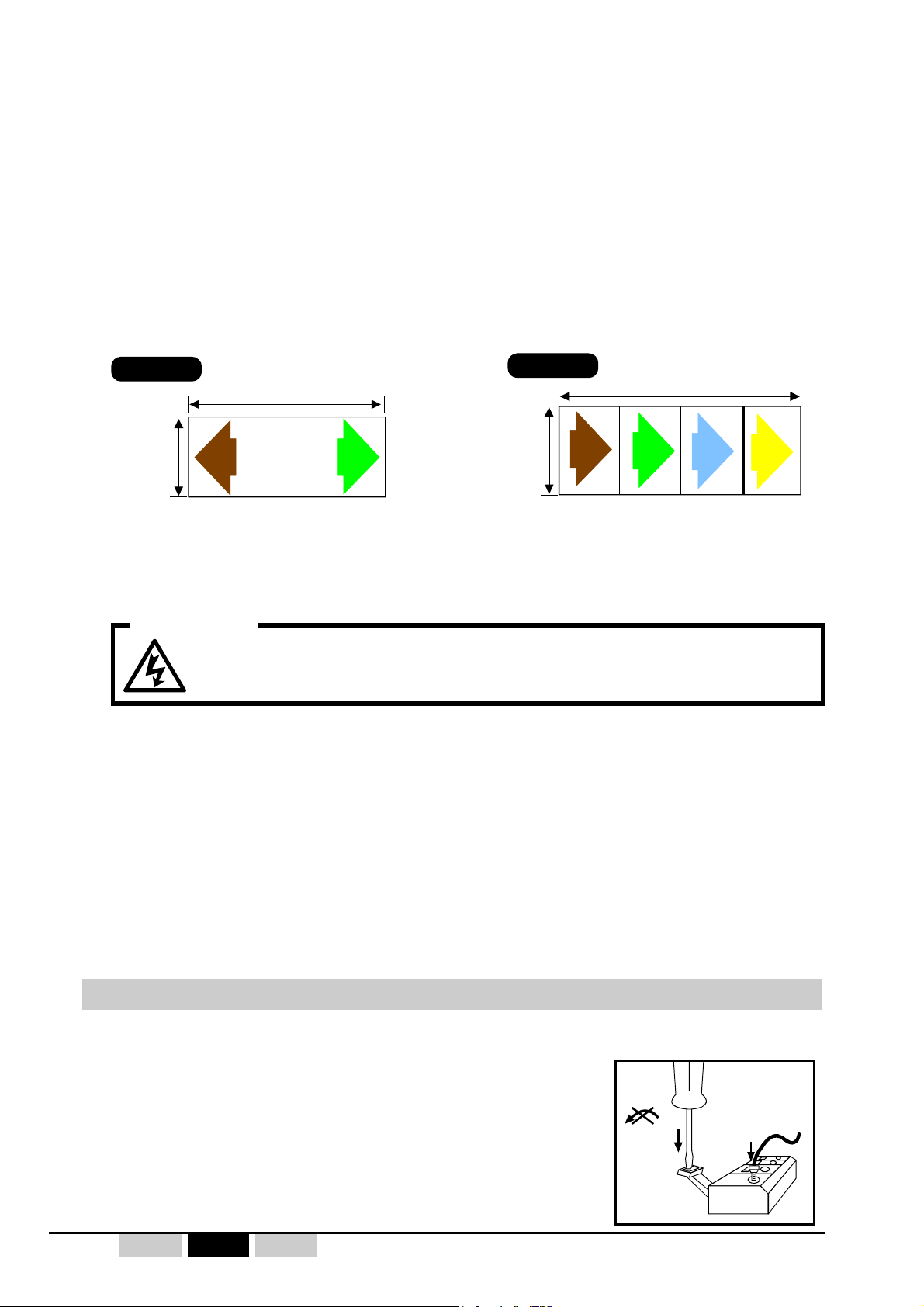

2.5.2- Marking of the controlled equipment,

490 mm

180

mm

If there are several equipment fitted with similar radio remote control systems working in the

same neighbourhood (e.g. in a plant), each transmitter shall carry a clear indication which

tells the equipment driver which equipment is controlled by the transmitter in question.

In this respect, signalling arrows are available as an accessory.

Place the different arrows on the equipment to be controlled so that each arrow colour

corresponds to that on the associated transmitter control button.

The direction of movement of control buttons shall whenever possible be consistent with

equipment motion. Symbols shall be fixed in such positions that there is a clear and unambiguous

relationship between the action on buttons in the control station and the corresponding direction

of motion.

The arrows are available in the following versions:

Reference :

UWE001

160

mm

Reference :

2 ways directional self-adhesive

color arrows

400 mm

brown green brown green blue yellow

UWE002

4 ways directional self-adhesive

color arrows

(independent arrows)

2.5.3- Wiring

WARNING

To avoid any risks of electrocution, do not open the receiver case

when powered.

Important :

Do not place cables of different classes side by side.

A minimum space (20 cm) should be observed between the different classes :

- Class 1 : Radio, antenna cable (case of an antenna extension).

- Class 2 : Mains for power supply of various units.

- Class 3 : Power control for motors, variable speed drive, etc...

Ideally, each cable class should be run through a cable path specific to the class. If only one

cable path is available, cables of different classes should be separated as much as possible.

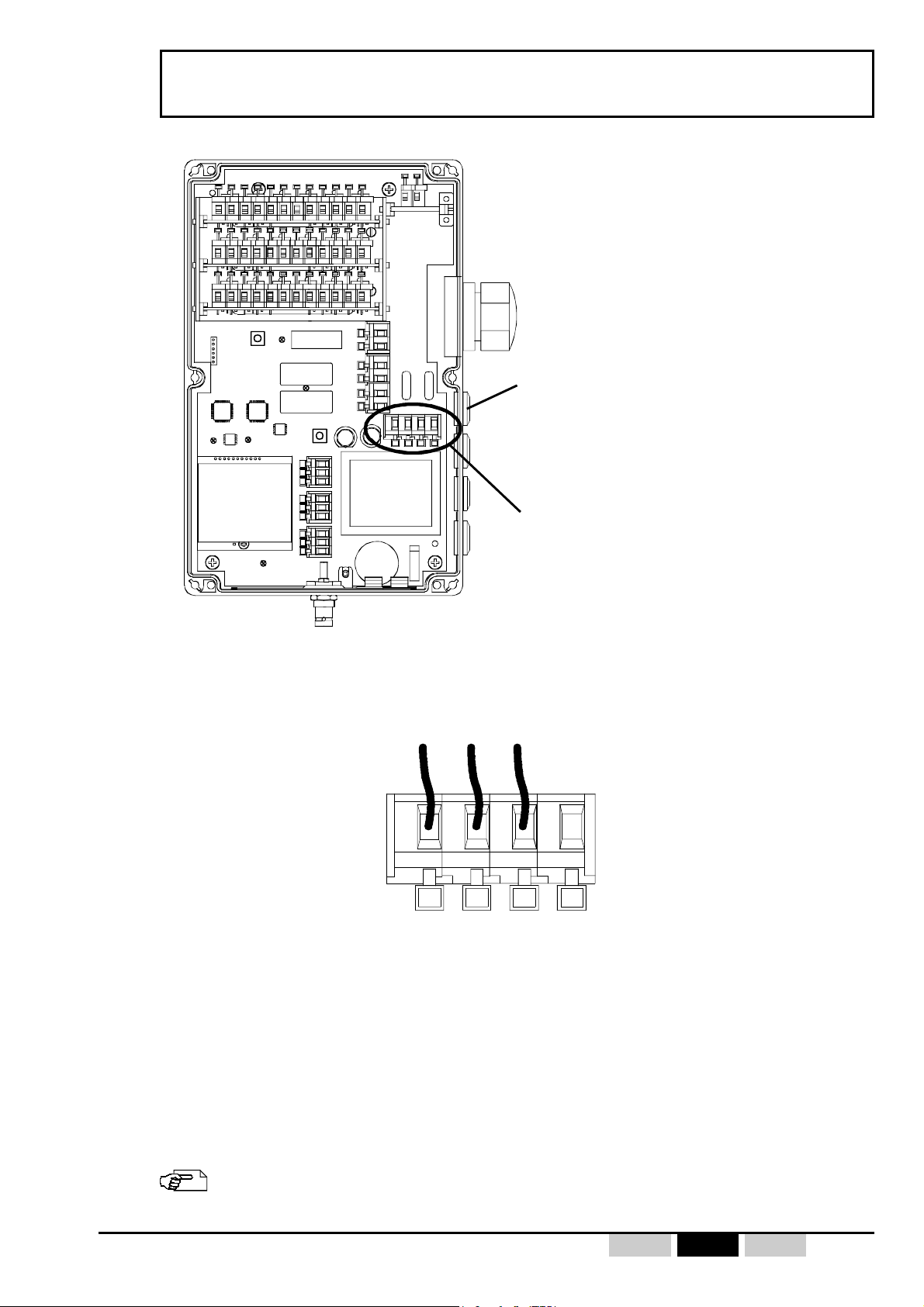

Wiring the receiver UDRE

If flexible stranded wire is used, crimped terminations should be used to avoid false contacts

and short circuits.

To open the connection terminal strips:

- Vertically push the screwdriver (flat tip screwdriver of 1.5 to

3 mm width) on the lever,

- Exercise a moderated pressure up to opening the terminal

- Insert the wire,

- Remove the screwdriver.

- 12 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 13

2223 21 20

UDRECB00 - **1

115/230 VAC

115VAC

230VAC

N

Caution: The electrical connections should be made such that when the main switch

is off, the UDEE/UDRE remote control receiver is also deactivated.

A

B

C

RK

RS1

RS2

F1

Advised way for power supply cable

F2

Power supply terminals strips

UDR receiver reference :

For the wiring and to determine the correspondence between the action on a function button

and the relay controlled, refer to the configuration table supplied with the receiver (label on

housing cover) and appendix A.

UDEE / UDRE - 332170A revision02 - 13 -FrEnDePRELIMINARY

See wiring example in appendix D

Page 14

2.5.4- Interference suppression

In the event of inductive loads on the relay outputs (contactor coils, solenoid valves or electrobrakes), interference suppression devices such as capacitors, RC circuits, diodes, etc. must

be placed directly at the terminals of the controlled components using the shortest possible

connections.

2.5.5- Electrical power supply protection

Protection against overcurrents (EN60204-1 § 7.2) resulting from overvoltages.

A fuse or other protection device should be provided in the power supply circuit of the receiver

(see wiring diagram for standard assemblies, item F in appendix D). The assigned current is

defined in the table in § «UDRE receiver technical characteristics».

2.5.6- Minimum and maximum current of relay outputs

Be sure not to exceed the minimum and maximum characteristics specified in § «UDRE

receiver technical characteristics» by installing, if necessary, an additional load or intermediate

relays (auxiliary contacts in electrical cabinet for power control, for example).

2.5.7- Auxiliary control

Measures should be taken to ensure, that when the radio control is not in service, another

control system can be used to ensure the safety of the operator and the manipulated load.

2.5.8- Choice of operating radio frequency

The 64 radio channels in 911-918MHz of the UDEE/UDRE provide a broad range of choices

among the available frequencies. To ensure good operating quality, it is important that the

radio channel used be free (as well as the preceding and the following one) throughout the

area in which the machine will be controlled.

If several radio remote controls are operating on the same site, frequencies spaced by at least

two channels (for example: 5, 7, 9 …) should be used and, if necessary, a frequency plan

should be drawn up, specifying the various machines controlled and their working frequency.

- 14 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 15

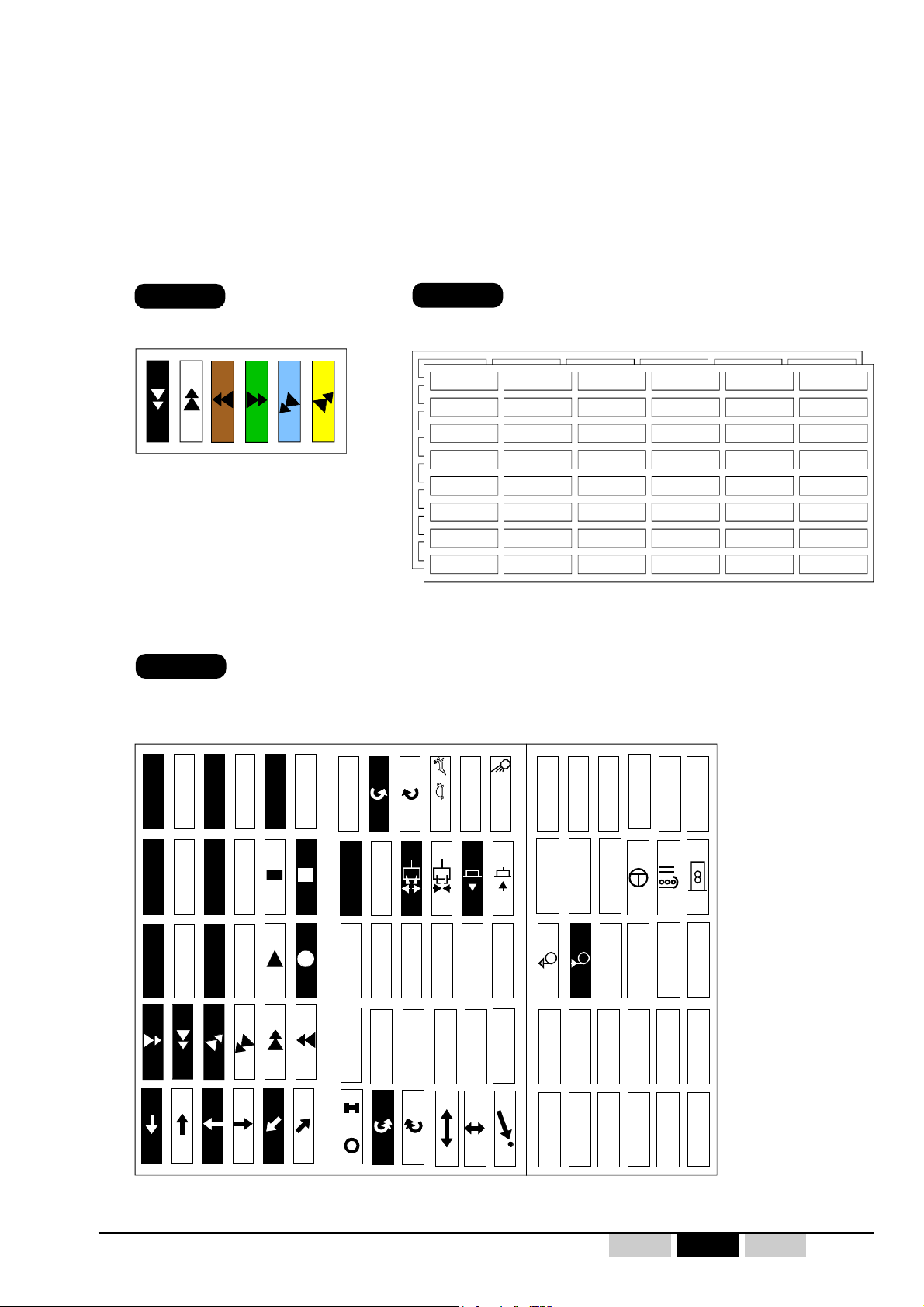

2.6- UDEE transmitter function button labels

The various button functions are identified by means of adhesive labels placed in the recesses

provided in the transmitter unit envelope at each button location.

The labels are supplied in the form of sheets with the various labels you will need for your application.

Simply choose the labels corresponding to your configuration.

2 label kits are systematically supplied with UDEE transmitter: UWE202 and UWE207.

Reference :

UWE202

Kit of 6 colored labels, «movements»,

for double speed pushbuttons (2 steps)

brownwhiteblack green blue yellow

Reference :

Reference :

UWE205

Kit of 48 white blank labels, «customization» + 48 transparent protecting labels.

UWE207

Kit of 90 white/black labels, «movements, special functions and customization» for switches and

pushbuttons (with 16 labels for personalized marking with indelible felt-tip)

D

O

W

N

S

O

U

T

H

S

U

D

N

O

H

N

O

U

P

R

T

R

D

W

E

S

T

O

U

E

S

T

F

R

E

O

V

R

E

W

R

A

R

S

D

E

E

A

S

T

E

S

R

G

H

T

S

I

H

U

N

T

+

-

R

R

P

P

M

M

L

E

F

T

1•12

•

12

ON

OFF

•

1 2 3

GATE

4

5 6

7 8 9

34

123

12

1+2

3+4

T

1

2

1+2

•

•2•3•

34

43

3+4

4

3

UDEE / UDRE - 332170A revision02 - 15 -FrEnDePRELIMINARY

Page 16

3- Commissioning

3.1- Precautions when commissioning

• The installer must :

- ensure that the transmitter and receiver identity code and radio channel match correctly,

- ensure that the radio channel chosen corresponds to the frequency plan set up for the site,

- perform a final check to verify that the desired Button-Relay correspondence is in place.

• During the previous check, the installer must check that when the "On/Horn" button is pressed

on startup, only the function relays assigned to the rotary button selections are in the "ON"

state.

• Verify the priority general shutdown mode (remote control in operation and radio link

established)::

Active stop : When the stop palmswitch button on the transmitter is pressed, the receiver

safety relays (RS1 and RS2) should instantaneously change state.

Passive stop : When the electronic key is removed from the transmitter in operation, the

receiver safety relays (RS1 and RS2) should change state within two seconds

max.

• "Dead man" function duration :

Check the effective duration of the "Dead man" function (automatic shutdown of transmitter) :

Start up the remote control and leave it without activating any control. Record the time after

which the receiver safety relays (RS1 and RS2) are deenergized and check that this duration

corresponds to the standard duration supplied (4min.) or the duration specified on order

(special programming, see customisation sheet), or to the new duration defined by a trained

and authorized operator in accordance with the procedure described in chapter «transmitter

configuration».

• Radio range limits :

Evaluate the range limit of the transmitter/receiver assembly (by moving up to the range limit).

• Special function: masking of certain function buttons :

If button masks are included in the electronic key, check that they properly correspond to the

application for which they have been provided.

3.2- Periodic checks and checks performed following

maintenance operations

In addition to the commissioning checks which should be performed, also check :

- That the ergonomic features of the transmitter unit have been preserved, such as: pressure on

function buttons, correct rotation of rotary switches, correct functionning of emergency stop

button, etc.

- Response time of commands between transmission of a command and resulting movement.

- 16 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 17

3.3- First radio remote control startup

1- Switch ON the UDRE receiver.

2- Plug the UDB2 battery pack into UDEE transmitter housing.

(Take care that UDB2 battery pack is loaded and is well

connected to UDEE transmitter back.)

3- Install the electronic key on the transmitter or take care of

its presence on UDE transmitter.

4- Copy electronic key identity code to UDEE transmitter

memory, see procedure on § 3.5.4.

5- Unlock the transmitter stop palmswitch button.

UDEE

transmitter

UDB2

battery pack

électronique

electronic

key

6- Press the green «On/Horn» button until the receiver is

started up (safety relays are activated).

7- Use the radio remote control to control the equipment.

To stop the radio remote control :

press the UDEE transmitter stop palmswitch button.

NB : if this procedure is not observed the transmitter indicates an error with the red and green

indicator light :

- «3 flashes error type» (The green and red leds flash 3 times, mark a break, then flash 3

times etc.) : resume identity code copy procedure described in § 3.5.3.

- «5 flashes error type» (The green and red leds flash 5 times, mark a break, then flash 5

times etc.) : Stop or startup error (make sure that the pack battery is correctly inserted in the

transmitter housing and resume the radio remote control startup procedure).

See startup block diagram on next page

UDEE / UDRE - 332170A revision02 - 17 -FrEnDePRELIMINARY

Page 18

3.4- Functioning block diagram

Or

Passive stop if "Dead Man"

duration is exceeded (1)

or

Battery pack is

disconnected/discharged (2)

or

Electronic key removed from

Active stop by pressing

stop palmswitch button

UDE transmitter in operation

(1) "Dead Man" duration

T

(2)

Last action on

function pushbutton

UTILISATION

Green "On/Horn"

button pressed

90% > Charge > 10 % Charge < 10 %

Battery pack charge > 90 %

Charge < 10 %

90% > Battery pack charge > 10%

Passive stop : battery pack is discharged

Battery pack charge < 10%

Active

Red stop palmswitch

unlocked,

UDEE transmitter

powered up

- 18 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Standby

3 states

OFF

of UDEE

UDRE receiver RS1 and

RS2 safety relays

UDEE transmitter

green indicator light

3 states of red

indicator light of UDEE

(battery pack charge

state)

Page 19

n°1 n°2

n°5

n°6

n°3 n°4

3.5- UDEE/UDRE system configuration and parameter setting

The following parameters are configurable from the UDEE transmitter unit :

• Transmit frequency (radio channel number selection).

• The "Dead man" function duration (01 to 98 minutes and infinite).

• Copy of electronic key identity code to transmitter memory.

These configuration operations use procedures implementing buttons n°1, n°2, n°3, stop plamswitch

and "On/Horn" without having to open the transmitter or the receiver.

By a specific operating mode, the person in charge of the equipment can lock or unlock the

access to the programming of Transmit frequency and "Dead man" function duration by locking or

unlockin the electronic key (see §3.5.1).

Programming

n°3

button

Programming

button

n°1

"On/Horn" button

Programming

n°2

button

stop plamswitch button

UDEE / UDRE - 332170A revision02 - 19 -FrEnDePRELIMINARY

Page 20

3.5.1 Procedure: "Locking-unlocking" the electronic key

(access to programming of transmitter UDEE)

The transmit radio frequency and the "Dead man" function duration are saved into the electronic

key. Procedure below enables authorization (electronic key unlocked) or prohibition (electronic

key locked) of any modification of these 2 parameters.

1- Switch off the UDRE receiver.

2- Insert the electronic key in the UDEE transmitter unit.

3- Holding buttons n°1, n°2 and n°3 pressed, unlock the stop palmswitch button (fig.1).

4- Release the buttons.

Indicator lights statuses:

- electronic key locked : red indicator light on, green indicator light off.

- electronic key unlocked : red and green indicator lights on.

5- Select «locked» or «unlocked» by pressing button n°2; the selected mode is shown by the

indicator lights (fig.2&3).

6- Validate the selected mode by pressing the "On/Horn" button (fig.4).

7- The UDEE transmitter saves the new mode in the electronic key and switches off the indicator

lights.

8- Exit the "locking - unlocking" configuration mode by pressing the stop palmswitch button (fig.6).

Remark: If an operator attempts to program the frequency or the "dead man" function duration

with the electronic key locked, the UDEE transmitter will indicate an error by its

indicator lights (red and green) which will flash in alternation.

Unlocking

the

electronic

key

Fig.1

Fig.2

Locking

the

electronic

key

Fig.3

DATA

Fig.4

Fig.5 Fig.6

- 20 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 21

3.5.2 Procedure : working radio frequency channel programming

+1

+10

DATA

1- Switch on the UDRE receiver.

2- Insert the electronic key in the UDEE transmitter unit.

3- Holding buttons n°1 and n°2 pressed, unlock the stop palmswitch on the transmitter (fig.1).

The radio channel already selected is indicated by two flashing indicator lights on the transmitter

which represent the tens (red) and units (green).

If transmitter red and green indictor lights flash in alternation :

The electronic key is locked. Press the stop palmswitch button and follow procedure described

on chapter §3.5.1. Start again this procedure at point Nb.3.

4- Select the new channel using buttons n°1 and n°2 (fig.2&3).

Press button n°1 to increment the tens and button n°2 to increment the units.

During these operations, the newly selected channel is displayed by the 2 indicator lights on the

transmitter which flash accordingly.

5- Once the desired channel is selected (between 01 and 64 for 911-918MHZ bands), press the "On/

Horn" button to validate your selection (fig.4).

Briefly pressing "On/Horn" button : the transmitter sends the selected radio channel number to

the receiver and saves its new working radio channel (fig. 5).

By pressing and holding the "On/Horn" button (3 seconds) : the transmitter sends the selected

channel number to the receiver (on each of the radio link channels between 01 to 64 for 911918MHZ bands) and saves its new working channel. Wait until the transmitter indicator lights

no longer flash (around 30 seconds) (fig. 5)

(this longer procedure is preferable and should be performed when you are not familiar with the initial

working channel of the receiver).

6- Exit the "frequency" programming mode by pressing the stop palmswitch button (fig.6).

7- Check that the UDRE receiver has changed channel by performing the startup procedure.

Fig.1 Fig.2

électronique

Fig.4

UDEE / UDRE - 332170A revision02 - 21 -FrEnDePRELIMINARY

Fig.3

Fig.5 Fig.6

Page 22

3.5.3 Procedure : "Dead man" function time programming

(Automatic shutdown of transmitter UDEE)

1- Switch off the UDRE receiver.

2- Insert the electronic key in the UDEE transmitter unit.

3- Holding buttons n°1 and n°3 pressed, unlock the stop palmswitch button on the transmitter

(fig.1).

The "dead man" time is displayed by two flashing indicator lights on the transmitter representing

the tens (red) and the units (green) of the number of minutes.

If transmitter red and green indictor lights flash in alternation :

The electronic key is locked. Press the stop palmswitch button and follow procedure described

on chapter §3.5.1. Start again this procedure at point Nb.3.

4- Select the new time using buttons n°1 and n°2 (fig.2&3).

Press button n°1 to increment the tens and button n°2 to increment the units.

During these operations, the new time selected is displayed by the two indicator lights on the

transmitter.

5- Once you have selected the desired "dead man" time (between 01 and 99), press the «On/

Horn» button to validate your selection (fig.4).

Caution: No. 99 corresponds to an infinite "dead man" time

> This function is then deactivated and forgetting to switch off the transmitter (by

pressing the stop palmswitch button) will result in complete discharge of the

battery pack.

6- Exit the "dead man" time programming mode by pressing the stop palmswitch button (fig.6).

+10

Fig.1

mn

Fig.2 Fig.3

+1

mn

DATA

Fig.4

Fig.5

- 22 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Fig.6

Page 23

DATA

3.5.4 Procedure: "Copying electronic key identity code to UDEE transmitter

memory"

Apply this procedure when :

- starting the radio remote control for the first time

- using a maintenance transmitter

- changing the electronic key

Reminder :

To use the UDEE/UDRE radio remote control system, the identity code contained in the transmitter

memory must match the identity code in the electronic key which is itself identical to that of the

receiver.

If a maintenance transmitter is used or if you change electronic key, the information contained in the

electronic key must be copied in the UDEE transmitter memory.

Conditions for using this procedure :

The configuration of the backup transmitter buttons must be identical to that described in the

electronic key (or the original transmitter).

1- Switch off the UDRE receiver

2- Insert the electronic key in the UDEE transmitter unit.

3- While holding buttons n°2 and n°3 pressed, unlock the transmitter emergency stop button (fig.

1): the 2 indicator lights on the transmitter will flash rapidly.

4- Press the "On/Horn" button to perform automatic programming of the identity code: the two

indicator lights on the transmitter go off (fig. 2).

5- The "identity code" information is copied from the electronic key to the transmitter memory (fig.

3).

6- Exit the programming mode by pressing the stop palmswitch button (fig.4).

Fig.1

electronic key

memory

Fig.2 Fig.4

Fig.3

UDE

transmitter

memory

UDEE / UDRE - 332170A revision02 - 23 -FrEnDePRELIMINARY

Page 24

3.6- UDRE receiver configuration

The following parameters can be configured on the receiver :

• Transmitter button interlockings :

Factory configured or using a PC via serial link option (ref.:UDWR32) with PC

software DialogUD (ref.:UDWR36).

• Transmitter buttons / receiver function relays correspondence :

Factory configured or using a PC via serial link option (ref.:UDWR32) with PC

software DialogUD (ref.:UDWR36).

• Transmit radio frequency :

The radio reception frequency (channel No.) can be programmed in two ways:

• By the transmitter matched to the receiver implementing the transmitter

frequency programming procedure, see §3.5.2.

• By using a PC via serial link option (ref.:UDWR32) with PC software DialogUD

(ref.:UDWR36).

The receiver reception frequency (channel No.) can be read :

• By using a PC via serial link option (ref.:UDWR32) with PC software DialogUD

(ref.:UDWR36).

- 24 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 25

4- Use and operation

4.1- Reminder : General safety rules

A radio remote control is considered as a machine control device and as a safety

component used to stop a machine as specified by the EEC Machinery Directive.

All applicable rules must therefore be observed to ensure safe, correct operation

of such devices.

- For maximum safety when using the radio remote control, we recommend that the

operator carefully follow the instructions provided in this manual.

- The operator must be appropriately trained and certified to operate machines by

radio remote control.

- The operator must have uninterrupted visibility of the manoeuvre which he is

performing. When the operator's direct field of view is inadequate, the lifting machinery

must be equipped with auxiliary devices to improve visibility.

When several machines are being moved simultaneously, the equipment must be

fitted out to limit to consequences of a possible collision.

- To avoid any risks of electrocution, don't open the receiver case when powered.

- Never leave the transmitter lying around anywhere, in particular when it is powered

up.

- Never leave the radio control transmitter on the ground or on a metal surface. If doing

so becomes indispensable, press the stop palmswitch on the radio control.

- If several radio controls are used at the same site, different radio frequencies should

be used, spaced by at least two channels (for example, channels 5, 7, 9, etc.). The

more space there is between the chosen radio channels, the less the risks of

disturbance are.

- For safety reasons, remove the electronic key when not in use. Store it in a safe and

tracked down place.

- Do not forget to recharge the battery pack when discharged.

- In the event of a malfunction, immediately shut down the installation by pressing the

stop palmswitch on the transmitter and remove the electronic key.

- Service your equipment and perform all the periodic checks as may be required by

the intensity with which your equipment is used. Follow necessarily the instructions of

cleaning described in the chapter "Servicing".

UDEE / UDRE - 332170A revision02 - 25 -FrEnDePRELIMINARY

Page 26

4.2- Radio remote control start up

1- Switch ON the UDRE receiver.

2- Plug the UDB2 battery pack into UDEE transmitter housing.

(Take care that UDB2 battery pack is loaded and is well

connected to UDEE transmitter back.)

UDEE

transmitter

UDB2

battery pack

électronique

3- Install the electronic key on the transmitter or take care of

its presence on UDE transmitter.

4- Unlock the transmitter stop palmswitch button.

5- Press the green «On/Horn» button until the receiver is

started up.

electronic

key

6- Use the radio remote control to control the equipment.

To stop the radio remote control :

press the UDEE transmitter stop palmswitch button.

NB : If during this procedure, both UDEE transmitter indicator light begin flashing,

please contact the technical person in charge of the installation.

- 26 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 27

Transmitter state

(The trans mitter stop

pa lms witc h is unlocke d)

Red

indi cator l ight

Green

indi cator light

Possib le causes of failure Possib le re medies

Before or after

"O n/ ho rn" bu tto n is

pressed

- Battery pack is discharged or disconnected

- Internal electronic failure

- Check battery pack load

or

- Contact the technical person in charge of

the installation

Before or after

"O n/ ho rn" bu tto n is

pressed

- Electronic key is not connected to

trans mitter

- Bad connection of the electronic key

- Electr on ic k ey failu re

- Internal electronic failure

- Install electronic key on tranmitter before

powering up the transmitter

or

- Contact the technical person in charge of

the installation

Before or after

"O n/ ho rn" bu tto n is

pressed

- Access to the transmitter programming is

prohibited (the electronic key is locked)

- If the transmit frequency or "Dead man"

function duration must be changed, the

electronic key must be unlocked. Follow

procedure described in §3.5.1.

or

- Contact the technical person in charge of

the installation

Before "On/horn"

button is pressed

- The transmitter identity code is different

from that contained in the electronic key

- Internal electronic failure

- Reprogramming is required, see

procedure in §3.5.4.

or

- Contact the technical person in charge of

the installation

Before or after

"O n/ ho rn" bu tto n is

pressed

- The button configuration is different from

that contained in the electronic and the

physical configuration on the transmitter

- One or several function buttons are

defective

- Internal electronic failure

- Contact the technical person in charge of

the installation

Before "On/horn"

button is pressed

- Micro power cuts due to a bad battery pack

connection

- Internal electronic failure

- Check that battery pa ck is correctly

inserted in transmitter housing

or

- Contact the technical person in charge of

the installation

Before "On/horn"

button is pressed

- Internal electronic failure

- Contact the technical person in charge of

the installation

Before "On/horn"

button is pressed

- Internal electronic failure

- Contact the technical person in charge of

the installation

Before "On/horn"

button is pressed

- Internal electronic failure

- Contact the technical person in charge of

the installation

Transmitter state

(stop pal mswitch button

unlock ed)

Red

indi cator l ight

Green

indi cator light

Before "On/horn"

button is pressed

OFF ON

Before "On/horn"

button is pressed

Flashes SLOW ON

Before "On/horn"

button is pressed

Flashes FAST ON

After "O n/horn" button

is pressed

OFF Flashe s

After "O n/horn" button

is pressed

Flashes FAST Flashes

8 flashes

Error messages

continuously OFF

continuously ON

3 flashes

4 flashes

flash in a alternative way

5 flashes

6 flashes

7 flashes

Battery pack charge level

Funct ion or corres ponding message

Radio transmission

Battery pack charge < or = LOW BATT level

Battery pack charge > 90%

90% > Battery pack charge > LOW BATT level

Battery pack charge < or = LOW BATT level

Radio transmission

Battery pack charge > LOW BATT level

4.3- Product indicator lights function

4.3.1 UDEE transmitter indicator lights

RED

indicator

light

GREEN

indicator

light

«LOW BATT level» = low battery (battery pack charge level lower than 10%), the battery pack must be reloaded.

UDEE / UDRE - 332170A revision02 - 27 -FrEnDePRELIMINARY

Page 28

RK

RS1

RS2

F1

F2

A

B

C

g

4.3.2 UDRE indicator lights

Function relay indicator lights (red)

«Horn» relay indicator light (red)

«RS1 and RS2» safety relays indicator lights (red)

Microprocessor n°1 indicator light (red)

Microprocessor n°2 indicator light (green)

Power supply indicator light (red)

Name and col or o f

indicator li

Mi cropro cessor n°1

indicator light

(RED)

Mi cropro cessor n°2

indicator light

(GREEN)

"Horn" relay ind.light

(RED)

Power supply ind.l ight

(RED)

Safety relays ind.light

(RED)

Function relays ind.light

(RED)

ht

Mode Indication Message Status

No message reception OFF

Normal

Serial

link

Normal

Serial

link

All Ind ic ates "Horn " r elay s tate

All

All I ndicates saf ety r elays stat e

All

Indicates validity

of identity code

"R S2 32 Mode" The rec eiver pr ogramming is in pr og ress ON

Indicates radio

reception quality

"RS232 Mode" OFF

Indicates receiver power

supply state

Indicates each function relays

state

Message reception with correct identity code OFF

Mess age r ecept ion with wrong i denti ty code Regu lar flashes

No radio message reception OFF

Poor radio reception Flashing

Good radio reception ON

Not activated (OFF) OFF

activated (ON) ON

Receiver switched OFF OFF

Receiver switched ON ON

Not activated (OFF) OFF

activated (ON) ON

Not activated (OFF) OFF

activated (ON) ON

Error messages

Micro n° 1

indicator light

- RED -

OFF

(Mainboard power supplied but power

supply red indicator light remains OFF)

2 flashes

3 flashes

4 flashes

5 flashes

6 flashes

7 flashes

Micro n° 2

indicator light

- GREEN -

Possible causes of failure Possible remedies

- Melted fuses

- Wrong power supply wiring

- Internal electronic failure

- Internal electronic failure

- 28 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

- Check fuse state and calibre

- Check power supply wiring diagram according to

receiver model

or

- Contact the technical person in charge of the

installation

- Contact the technical person in charge of the

installation

Page 29

1st button of

interlocked pair

1nd button of

interlocked pair

Acronym

Button n°1 Button n°2 B1-B2

Button n°1 Button n°3 B1-B3

Button n°1 Button n°4 B1-B4

Button n°2 Button n°3 B2-B3

Button n°2 Button n°4 B2-B4

Button n°3 Button n°4 B3-B4

Button n°3 Button n°5 B3-B5

Button n°4 Button n°6 B4-B6

Button n°5 Button n°6 B5-B6

Button n°7 Button n°8 B7-B8

Button n°7 Button n°10 B7-B10

Button n°8 Button n°9 B8-B9

Button n°9 Button n°10 B9-B10

5- Technical data

5.1- Function button interlockings

The following function button interlocking configurations are possible:

n°9

n°10

*

n°7

n°5

n°8

*

n°6

*

*

n°3

n°4

*

*

n°1 n°2

(UDEE transmitter front panel view)

For each of the desired interlocking configurations, simultaneous action on the two buttons will result

in three operating modes which depend on the programs defined :

- program «

1» : By pressing the 2 button pair, the two commands are deactivated (corresponding

relays set to OFF).

*= Standard interlocking configurations defined in sales reference

for UDRE receiver (see §2.3.2 «product identification»).

- program «

- program «3» : The 2nd button of the interlocked pair has priority.

- program «X» : special (according to a customization data sheet).

2» : The first button of the interlocked pair has priority.

(ex.: button n°1 and button n°2 interlocked: when these two buttons are pressed

simultaneously, only button n°1 is acknowledged).

(ex.: button n°2 and button n°4 interlocked: when these two buttons are pressed

simultaneously, only button n°4 is acknowledged).

5.2- Correspondence between «transmitter function buttons

and receiver relays»

))

)

))

Each "BPDV" button type pair is assigned either 3 relays (2 movement relays and a third relay

for high speed), or 4 relays. This information is contained in the UDRE receiver product

reference data (see § «product identification»).

))

)

))

UDEE / UDRE - 332170A revision02 - 29 -FrEnDePRELIMINARY

In its standard configuration, the "buttons-relays" are assigned naturally by the increasing

order of the button numbers and relay numbers :

For non-standard "button-relay" configurations, be sure to properly fill in the configuration

sheet located in the UDRE cover.

Page 30

5.3-

UDEEUDEE

UDEE transmitter technical characteristics

UDEEUDEE

Mechanical and environment withstand characteristics

Housing

Weight

(with battery pack)

Dim ens ions

Operating temperature range

Storage temperature range

without battery pack

with battery pack

Attachment when idle

ABS Choc, yellow - IP65 - Mechanical button protection

"10+2 button version" : 490 g

"10+2 button version" : 70x53x276 mm

- 20°C to + 50°C

- 30°C to +70°C

- 30°C to +35°C

Wall or belt by fastening strap

Electric al and radio ch aracteristics

Power supply

Endurance (25°C) with buttons typical

average use

Transmit radio frequency

(see list in appendix)

Transmit power

(built-in antenna)

Modulation

Average range (1)

Plug-in NiMH battery

In 911-918MHz bands : 20hours / 50% transmit time

64 programmable frequencies in 911-918 MHz bands

<94 dBµV/m in 911-918MHz

FM

100m in typical industri al environment

300m in unobstructed area

Functionnal characteristics

Function button type

"Dead man" funct ion

(Automatic shutdown of UDE transmitter)

Indicator lights

- 10 function buttons :

- double speed pushbutton (2 steps)

- 1 pushbutton "On/Horn"

- 1 active priority emergency stop palmswitch

Time is user-programmable

1 red "battery level" and "diagnostic" indicator light

1 green "On" and "diagnostic" indicator light

"BPDV"

(1) = Range will vary according to environment conditions of transmitter and reception antenna

(metal frameworks, walls … ).

5.3.1- Identity code

UDEE transmitter and UDRE receiver are linked by an identity code.

A receiver can only recognise and execute commands generated by the associated transmitter

(with electronic key containing the receiver identity code).

- The receiver identity code is a unique, fixed code (it can't be reprogrammed).

This identity code is contained in the electronic key and can be copied to a transmitter by a

trained and authorized user (see procedure in § 3.5.4)

Identity codes have 65536 different combinations.

- 30 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 31

5.3.2- Electronic key

The electronic key used on the UDEE/UDRE radio remote control system has a dual function :

- It enables start-up of the transmitter by limiting access to the remote control to trained and

authorized persons only.

- It contains all the information required for operation of the product, including :

- the system identity code

- the last frequency programmed *

- the "dead man" function duration *

- the transmitter button configuration

- the button mask (special function)

- and the option register (micro-speed etc...)

* = reprogrammable by a trained operator, see §3.5

When the key is removed, it prevents unauthorized use of the transmitter. For this reason, it

should be removed (like the battery pack) when the remote control is put away.

Preferably, the electronic key should be removed after pressing the stop palmswitch button.

Removal of the key before the stop palmswitch button button is pressed will result in a fault

indication (2 flashes) and passive shutdown of the receiver.

If necessary, it can be used to stop the system.

The transmitter cannot be started up without its electronic key.

))

)

))

The transmitter UDEE also has an internal memory containing an identity code.

- If identity code of the electronic key matches the identity code stored in the UDEE, the

transmitter can be started up.

- If the identity code of the electronic key and that of the UDEE do not match, the transmitter

indicates the problem by its two indicator lights (3 flashes). In this case, perform the

programming procedure described in §3.5.4.

électronique

UDEE can be started up provided :

Transmitter identity code

=

Electronic key identity code

In the event of a transmitter failure :

You can recover the electronic key and connect it on a maintenance transmitter (button

configuration should be the same as that of the failed transmitter, otherwise, buttons that

are different will be ineffective).

To perform this operation, you must reprogram the key identity code in the new transmitter

UDEE as described in the procedure in §3.5.4.

Identity code contained

in transmitter UDEE

Identity code contained

in electronic key

if your electronic key is lost :

You can order another electronic key (reference UDWE22X) making sure to specify the

following information on the order :

- The unique 6-digit number of the old key (written on the cover page of this manual

when you unpacked your product).

or, if you do not have key number :

- the associated receiver identity code (on receiver descriptive label) and transmitter

button configuration

This information will allow you to receive an electronic key identical to the old one containing

all the parameters indicated above for your radio remote control.

UDEE / UDRE - 332170A revision02 - 31 -FrEnDePRELIMINARY

Page 32

5.3.3- "Dead man" function

The "Dead man" safety function deactivates the UDEE transmitter (radio transmission cut off)

when the pushbuttons (function buttons BPDV or "On/Horn") have not been actuated for

a duration of N minutes or seconds.

The N parameter is user-configurable and can take the values 01 to 98 minutes

On delivery, the duration is defined for 4 minutes.

- If the N value configured is 99 minutes, the transmitter considers that the dead man duration

is infinite (until the battery pack is entirely discharged).

Restarting the transmitter after the "Dead man" function has been activated:

- Press the stop palmswitch button on the transmitter.

- Follow startup procedure in §4.2

Changing the dead man duration :

The dead man duration or unit N can be modified by a trained operator by performing the

procedure described in § 3.5.3.

- 32 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 33

Housing

ABS, Grey - IP65

Weight

2 kg (approx.)

Dimensi ons

160x250x120 mm (without antenna and cable gland)

Operating temperature range

- 20°C to + 50°C

Storage temperature range

- 30°C to + 70°C

Cable lead-outs

Power supply : 1 M16 caps (Ø 5 to 7 mm cables)

Control outputs : 1 M32 plastic cable gland (Ø 20 to 26 mm cables )

Connection

Spring-type terminal strips for 0.08² to 2.5² section wires

64 programmable UHF channels in 911-918 MHz bands

ref:

VUB984

, 1/2 wave in 911-918MHz

Sensitivity

< -100dBm

AC version

115VAC, -15% to +10%, 180mA

230VAC, -15% to +10%, 85mA

Control

1 "Horn" relay and 18 function relays

Safety

2 safety relays with linked and guided contacts

Response time

On start-up : 0,5s max.

On control : 55 ms max.

Active shutdown time

145 ms max.

Passive shutdown time

1,1 s max.

Indicator lights

1 red indicator light "power on"

1 red + 1 green indicator lights for diagnostic

1 red indicator light for relay status

Protections

Power supply :

Against overcurrents by fuse

Reception frequency

(see list in appendix)

Mechanical and environment withstand characteristics

Ra dio char ac teristic s

Electrical characteristics

Characteristics complying with FCC part 15

Antenna

(BNC plug-in type)

Power supply and consumption

(1)

(with 2 safety relays and 8 control

relays pulled in)

5.4-

UDRE UDRE

UDRE receiver technical characteristics

UDRE UDRE

(1) = The number of function relays controlled simultaneously is limited to 10 relays connected to

UDRE receiver..

A large label in the housing cover gives the following information to facilitate configuration and

maintenance of the UDEE/UDRE system :

- connection point numbers

- wiring indication

- fuse characteristics

- indicator light functions

- table showing the "Buttons/Relays/Functions" configurations for the application and the

UDEE / UDRE - 332170A revision02 - 33 -FrEnDePRELIMINARY

interlocking configuration.

Page 34

5.4.1- Connection to relays

Connections are made on spring terminals with connection points identified by numbers.

The flexible wire section is between 0.08 mm square and 2.5 mm square.

No common line is provided on the printed circuits (all contacts are potential-free).

An accessory, referenced : UDWR12 with 16 connection points for easy connection of the

common lines (supplied as a standard feature with the receiver).

5.4.2- Relay characteristics

Summary table

Relay function Number of relays

Safety relays 2 2 (1 T contact )

"On / Horn" 1 2 (1 T contact)

6, 12 or 18

Control / Movement

according to number of

relay boards inserted in

receiver

Number of connection

points per relay

2 (1 T contact)

Safety relays

The two safety relays are activated when UDEE transmitter «On/Horn» button is pressed.

These relays are auto-maintained until passive stop (electronic key removed when transmitter

is in functioning, or battery pack discharged/disconnected from transmitter, or radio

interferences) or active stop (when transmitter stop palmswitch is pressed).

• Contacts : AgNi10+Au5µm

• Maximum power at cosphi=1 : 2000 VA

• Maximum current switching : 8 A

• Maximum voltage switching : 250 VAC

• Minimum current / voltage advised switching : 50 mA / 12 VDC

• 100 000 switching cycles at 250 VAC, 8 A, cosphi=1

• 100 000 switching cycles at 24 VDC, 6 A

• Tests per EN 60947-5-1 :

DC13 at 2 A / 24 VDC

AC15 at 3 A / 250VAC

- 34 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 35

Safety

relays

"Horn" and

"control" relay

Switching under 230VAC (70VA,cosphi=0,75)

4,5 x 10

6

2 x 10

6

Switching under 110VAC, (70VA,cosphi=0,75)

4,5 x 10

6

1 x 10

6

Switching under 48VAC (70VA,cosphi=0,75)

4,5 x 10

6

0,5 x 10

6

Number of switching cycles

Contactor

type

Physical unit switched by relay

CA2DN

LC1D09

LC1D18

LC2D09

«Horn» and control relays

The «Horn» relay is activated when UDEE transmitter «On/Horn» button is pressed.

This relay isn’t auto-maintained.

«Control» relays are active when transmitter function buttons are pressed and once UDEE/

UDRE system started up.

• Contacts : AgNi 0,15

• Maximum power at cosphi=1 : 2000 VA

• Maximum current switching : 8 A

• Maximum voltage switching : 400 VAC

• Minimum current / voltage advised switching : 50 mA / 12 VDC

• 100 000 switching cycles at 250 VAC, 8 A, cosphi=1

• 50 000 switching cycles at 24 VDC, 8 A

• Tests per EN 60947-5-1 :

DC13 at 0,5 A / 24 VDC

AC15 at 3 A / 250VAC

Number of switching cycles on various contactors

UDEE / UDRE - 332170A revision02 - 35 -FrEnDePRELIMINARY

Page 36

5.4.3- Protection of receiver board and relays

Protection of power supplies

- AC versions :

• Against overcurrents : 1 fuse on phase.

• Non-reversible thermal protection of transformer (in the event of overloads at

secondary).

Fuse characteristics

RS1

RS2

RK

F1

B

C

F2

Element Fuse characteristics (5x20)

Receiver supplied with 115 VAC 315 mA / 250 VAC / T

Receiver supplied with 230 VAC 160 mA / 250 VAC / T

Safety relays No protection

A

Loaction of fuse to

be used

F2

F1

/

"Horn" relay No protection

"Control" relays No protection

- 36 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

/

/

Page 37

Housing ABS Choc, yellow, plug-in

IP40

Dimensions

40x96x23 mm

Storage temperature range -30°C to +35°C

Charging temperature range 0°C to +45°C

Complete slow charging time 14 hours

Indicator lights Charging : 1 red light indicator on battery pack

Charge status : 1 red light indicator on transmitter

Charging voltage

10 to 30 VDC

Mechanical, functional and environmental characteristics

5.5-

UDB2 UDB2

UDB2 Battery pack technical characteristics

UDB2 UDB2

5.5.1- Battery pack storage precaution

UDB2 battery pack must be stored charged in a proper and dry area with specified temperature

range on above table.

5.5.2- Precaution when inserting battery pack in transmitter unit

Whenever changing the battery pack, check that it is

properly secured in its housing in the back of the

transmitter.

If not, a type 5 fault caused by power supply microcutouts can occur (following fault list generated by

the transmitter)

UDEE / UDRE - 332170A revision02 - 37 -FrEnDePRELIMINARY

Insertion of battery

pack in the back of

transmitter

Page 38

5.5.3- Display of battery pack charge state

Charging the UDB2 battery pack

The red battery pack indicator light shows that battery pack is well supplied from the charger.

This indicator light does not swho the load level

Charger UBCU

110-230VAC/12VDC

Battery pack red indicator light

(power supplied, the battery

pack is in charge)

battery pack UDB2

Only UBCU charger or UBC1 connector, from Jay Electronique are perfectly suited to

charge the UDB2 battery pack.

UDEE transmitter red indicator light

électr oniqu e

RED indicator light

Two battery charge status display functions are provided on the transmitter :

• When the remote control is powered up (stop palmswitch button out), the

red indicator light on the transmitter shows the battery pack charge level :

Red indicator light off : ..................... Battery pack charge > à 90%

Red indicator light flashes slowly : .. Battery pack charge is between 90% and 10 %

Red indicator light flashes quickly : .. The battery pack must absolutely be charged

(battery pack charge < 10%)

• During operation of the remote control (radio transmission), a LOW BATT (battery low

level, charge < 10%) indication is given by the red indicator light which flashes quickly.

This indication is used to inform the operator that the remote control will soon be unavailable

(within around 15 minutes).

- 38 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 39

6- Servicing

BEFORE STARTING ANY SERVICING OPERATION, SWITCH OFF THE MAIN POWER SUPPLY

FOR THE SYSTEM CONTROLLED.

Servicing the UDEE transmitter :

- Housing of the UDEE transmitter must not be opened. The UDEE transmitter can be

dismanteld only be a trained staff, in a "controlled" environment, spare parts can be changed

only by identical and original parts.

- If one of the membranes of the function buttons or the seal of the transmitter

is damaged, the UDEE must not be any more used until replacement of these

tightness spare parts.

In opposite case, any liquid, any dust or any foreign body can damage the transmitter.

- The attention of the user is attracted to the risks of the use of the remote control in an

environment containing solvents of polymers or glues which can degrade the good

functioning of transmiiter mechanical organs.

- Verify regularly the good state of the transmitter, paying a special attention to the function

button membranes, to the electronic key connector and to the battery pack connector.

- Clean the transmitter by eliminating any foreign body.

Only use non aggressive cleaning product on base of soapy solution.

Servicing the UDRE receiver :

Check the following points:

- Wiring of receiver to electrical unit on machine.

- Control relay contacts.

- Correct operation of stop circuits, active and passive.

- Condition of cover seal, tightening of screws and cable glands and tightness of antenna,

check the antenna connection and check that it is clean and free of any oxidation.

- Clean the receiver by eliminating any foreign body.

Only use non aggressive cleaning product on base of soapy solution.

- To check operation of the active stop function (UDEE/UDRE system started up) :

simply press the UDEE transmitter stop palmswitch button. Receiver safety relays should

immediately de-energise.

- To check operation of the passive stop function (UDEE/UDRE system started up) :

simply remove the electronic key or battery pack from the transmitter or wait until "Dead

man" function duration is exceeded ; receiver safety relays should de-energise within 2

seconds.

UDEE / UDRE - 332170A revision02 - 39 -FrEnDePRELIMINARY

Page 40

7- Special functions

By its high degree of adaptability, the UDEE/UDRE series remote control is able to satisfy all the needs

for non-standard functions.

Following consultation and validation of a customer request, our customer service will print out a

customisation sheet for the remote control.

The "non-standard" functions which can be covered by a customisation sheet are :

- Masking of certain function buttons by electronic key.

- Duration of "Man-dead man" function temporization different than 4mn programmed on delivery.

- Other function button interlocking

- Other button/relay match-ups.

If your remote control is covered by a customisation sheet, we strongly recommend that you set it

aside in a safe location for information which may be needed for subsequent commissioning and

maintenance operations.

8- Warranty and FFC compliance

All our devices are guarantied 2 years as of the date of manufacture indicated on the

product, wear parts not included. Repair, modification or replacement of a unit during the warranty

period will not give rise to extension of the period.

8.1- Limits of warranty

The warranty does not cover defects resulting from :

• transport

• false manoeuver or non-observance of connection diagrams when setting the equipment

into service

• insufficient supervision or servicing, utilization not complying with the specifications

detailed in the technical manual and, as a general rule, storage, operation or environment

conditions (atmospheric, chemical, electrical or other conditions).

• Conditions not specified on order of the equipment

The warranty shall not apply subsequent to any modifications or additions to the equipment

performed by the customer without written approval by JAY Electronique.

The JAY Electronique responsability during the warranty period is limited to material and

construction defects. This warranty comprises repair in the JAY workshops or replacement,

free of charge, of parts recognized to be defective following expert inspection by the Jay

Technical Department.

The warranty shall not give rise to any compensation for damage claims.

Any disputes relative to a supply or settlement thereof shall be ruled by the COURT OF

COMMERCE OF GRENOBLE FRANCE, solely competent, even in the event of an Appeal or a

plurality of defendants.

- 40 - UDEE / UDRE - 332170A revision02Fr En De PRELIMINARY

Page 41

8.2- Limits of FCC compliance

UDEE/UDRE complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

The user that changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.