Jay electronique RS Series, RSEP4A Series, RSEP4B Series, RSEP40 Series, RSCP Series Installation And User Manual

...Page 1

Doc ref. : 332190D – EN

28.04.2014

Page 1 / 49

RS Series

Wireless enabling handle

Installation and User Manual

- TRANSLATED IN ENGLISH FROM ORIGINAL FRENCH VERSION -

RSRB

RSCP

RSEP

Page 2

Doc ref. : 332190D – EN

28.04.2014

Page 2 / 49

TABLE OF CONTENTS

1 Safety rules and general safety guidelines ...................................... 5

2 Product identification data ................................................................ 5

3 Theory of operation ............................................................................ 6

4 Check of functions, initial start-up ................................................... 7

4.1 « Ex-FACTORY » parameters ...................................................................................................... 7

4.2 Setting the wireless enabling handle into service ..................................................................... 7

4.3 Setting the charger into service .................................................................................................. 8

4.4 Warning regarding the battery of the enabling handle .............................................................. 9

4.5 Setting up the product ............................................................................................................... 10

4.6 Testing the unit........................................................................................................................... 11

5 Setting the product into service ..................................................... 12

5.1 Electrical power supply, installation and wiring ...................................................................... 12

5.1.1 Receiver .................................................................................................................................................................. 12

5.1.2 Charger.................................................................................................................................................................... 12

5.2 Receiver antenna ........................................................................................................................ 12

5.3 Intervention mode and operation of enabling handle .............................................................. 13

5.3.1 Conditions for intervention in «monitoring - diagnostic» mode ................................................................................ 13

5.3.2 Conditions for intervention in « manual control » mode ........................................................................................... 14

5.3.3 Summary of conditions for intervention on machine. ............................................................................................... 14

5.3.4 Configuration of enabling handle operating mode ................................................................................................... 15

5.3.5 Receiver : selecting the program ............................................................................................................................. 15

5.3.6 Adjusting the machine area access time. ................................................................................................................ 16

5.4 Receiver : operation and wiring ................................................................................................ 17

5.4.1 Operation and wiring of function outputs ................................................................................................................. 17

5.4.2 Operation and wiring of safety relays K1-K2. ........................................................................................................... 18

5.4.3 Monitoring of main contactor : operation and wiring ................................................................................................ 19

5.4.4 Reset button : wiring and management ................................................................................................................... 19

5.4.5 Wiring of a wired safety shutdown device. ............................................................................................................... 20

5.4.6 Wiring of a machine area access authorisation request function. ............................................................................ 20

5.4.7 Wiring of an equipment with area access protection ............................................................................................... 21

5.4.8 Wiring of an equipment without area access protection .......................................................................................... 22

5.4.9 Wiring of “handle on charger” detection function ..................................................................................................... 22

5.4.10 Wiring of indicator light column on receiver ............................................................................................................. 23

5.4.11 Wiring of receiver power supplies ............................................................................................................................ 24

5.5 Charger : wiring and management. ........................................................................................... 25

5.5.1 Association of charger and wireless enabling handle .............................................................................................. 25

5.5.2 Wiring of charger power supply ............................................................................................................................... 25

5.5.3 Taking the wireless enabling handle off its charger ................................................................................................. 25

5.5.4 Setting the wireless enabling handle on its charger ................................................................................................. 25

5.6 Language selection .................................................................................................................... 26

5.7 Radio working frequency ........................................................................................................... 27

5.7.1 Selection of radio working frequency. ...................................................................................................................... 27

5.7.2 List of channels and radio frequencies (in accordance with enabling handle model) .............................................. 27

5.7.3 Reading the working frequency. .............................................................................................................................. 28

5.7.4 Changing the working frequency ............................................................................................................................. 28

5.8 Radio transmit power ................................................................................................................. 29

5.8.1 Transmit power selection ......................................................................................................................................... 29

(1) = The average range will depend on the product environment (presence of metal obstacles, …) ...................................... 29

5.8.2 Reading/changing the transmit power ..................................................................................................................... 29

5.9 Identity code ............................................................................................................................... 30

5.9.1 Identity code selection ............................................................................................................................................. 30

5.9.2 Reading the identity code, software version and SIM card serial number ............................................................... 30

5.9.3 Changing the identity code ...................................................................................................................................... 30

Page 3

Doc ref. : 332190D – EN

28.04.2014

Page 3 / 49

5.10 Handle locking function ......................................................................................................... 31

5.10.1 Locking the handle .................................................................................................................................................. 31

5.10.2 Activating/deactivating the locking function ............................................................................................................. 31

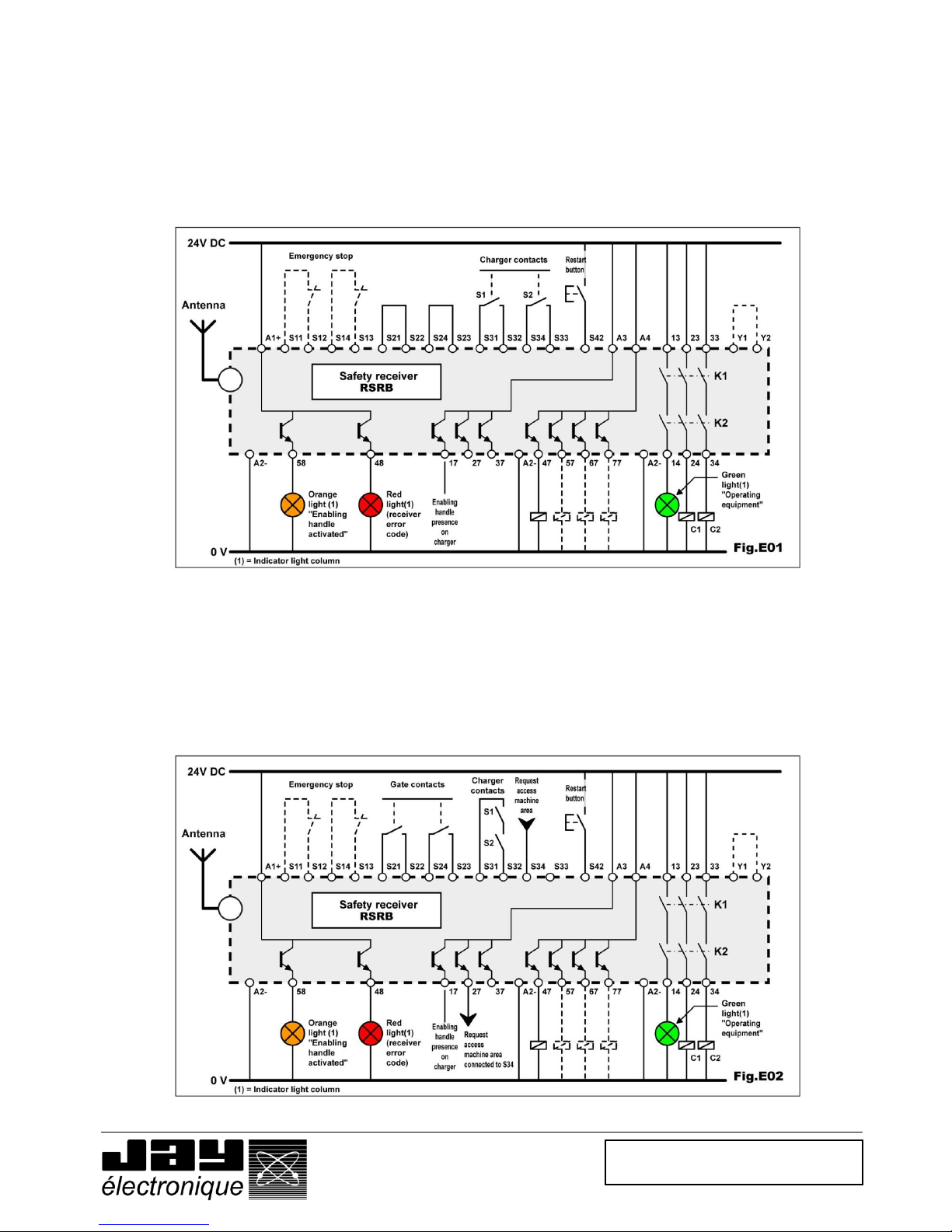

5.11 Receiver wiring examples ...................................................................................................... 32

5.11.1 Wiring diagram for configuration without access control .......................................................................................... 32

5.11.2 Wiring diagram for configuration with access control by gate .................................................................................. 32

5.11.3 Wiring diagram for configuration with access control by safety light barrier............................................................. 33

6 Diagnostic ......................................................................................... 34

6.1 Faults communicated by wireless enabling handle ................................................................. 34

6.2 Faults communicated by receiver ............................................................................................. 35

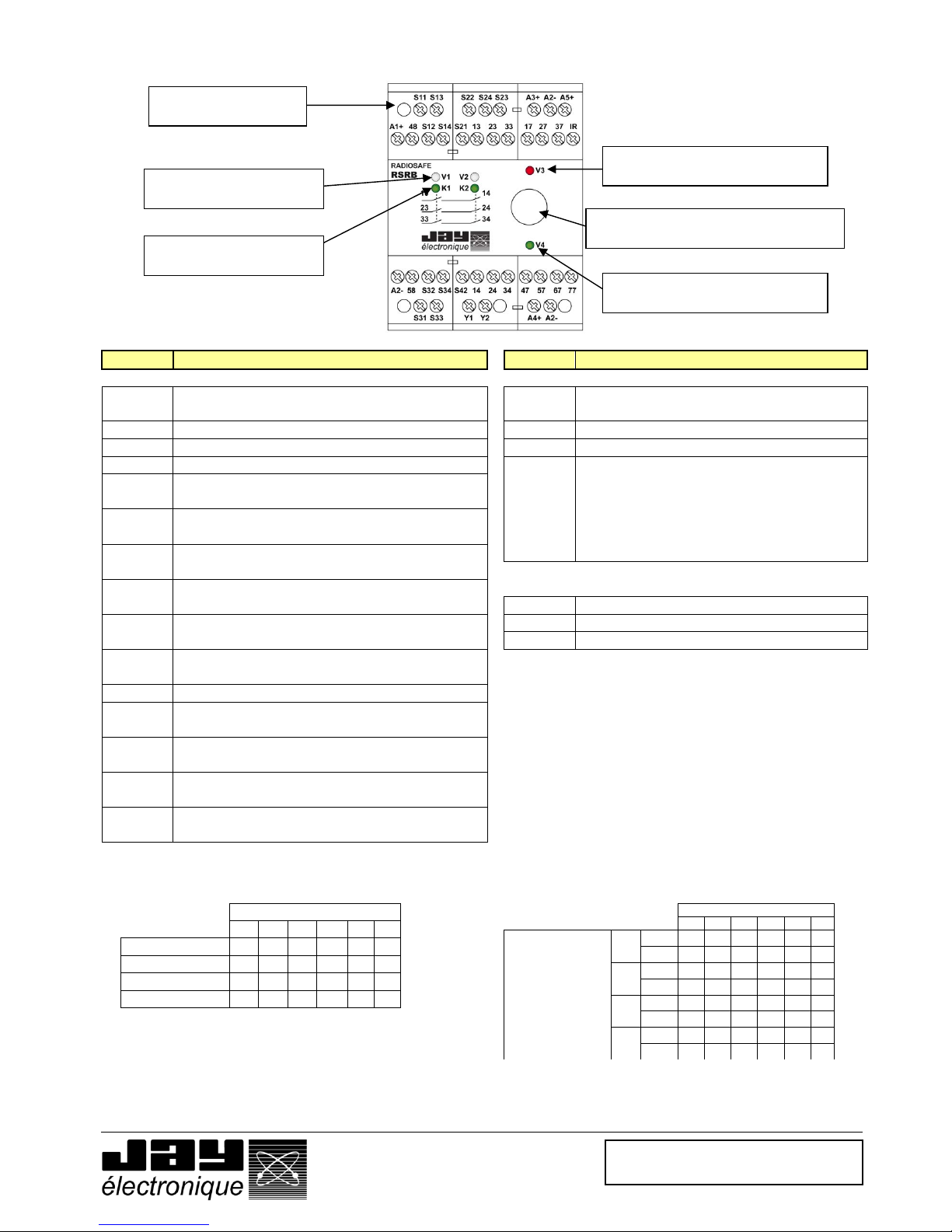

6.2.1 V3 and V4 LED status ............................................................................................................................................. 36

7 Servicing ........................................................................................... 37

7.1 Servicing the wireless enabling handle .................................................................................... 37

7.2 Servicing the charger ................................................................................................................. 37

8 Maintenance ...................................................................................... 37

8.1 Setting a backup handle into service ........................................................................................ 37

8.2 Replacing a receiver. ................................................................................................................. 37

8.3 Replacing a charger. .................................................................................................................. 37

9 Warranty ............................................................................................ 38

10 Appendices .................................................................................... 39

10.1 Dimensions of components (mm) ......................................................................................... 39

10.2 Technical characteristics ....................................................................................................... 40

10.2.1 Wireless enabling handle RSEP .............................................................................................................................. 40

10.2.2 Charger RSCP ......................................................................................................................................................... 40

10.2.3 Receiver RSRB ....................................................................................................................................................... 41

10.3 Indicator lights and assignment of receiver outputs ........................................................... 42

10.4 «IR start-up» option ................................................................................................................ 43

10.4.1 Positioning the IR module UDF ............................................................................................................................... 43

10.4.2 Connecting the UDF module to the receiver ............................................................................................................ 43

11 Procedures ..................................................................................... 44

11.1 Accessing a machine area in « monitoring - diagnostic » mode ......................................... 44

11.2 Accessing a machine area in « manual » mode ................................................................... 45

12 Environmental data ....................................................................... 46

13 Residual risks ................................................................................ 46

14 Foreseeable misuse ...................................................................... 46

15 Contraindications .......................................................................... 46

16 Waste recycling and management ............................................... 46

17 Manufacturer information ............................................................. 46

18 CE Declarations of conformity ..................................................... 47

18.1 RSEP40-x / RSCP-x / RSRBx4xx-x and RSEP41-x / RSCP-x / RSRBx4xx-x ........................ 47

18.2 RSEP4A-x / RSCP-x / RSRBx4xx-x and RSEP4B-x / RSCP-x / RSRBx4xx-x ....................... 48

Page 4

Doc ref. : 332190D – EN

28.04.2014

Page 4 / 49

Reference serial model submitted to approval: April 2014

Page 5

Doc ref. : 332190D – EN

28.04.2014

Page 5 / 49

1 Safety rules and general safety guidelines

Under the terms of the European Machinery Directives, the wireless enabling handle is understood as a control

unit and as a safety component used to stop a system. All applicable safety rules must be observed when

installing and using the wireless enabling handle.

The instructions given in this manual must be observed to ensure safe use of the wireless enabling handle.

The unit must only be used by appropriately trained operators qualified to use the product.

The operator must have uninterrupted visibility of the manoeuvre which he is controlling with the enabling handle.

The wireless enabling handle should never be left unattended in any random location.

The location of the charger RSCP must be clear of any obstructions that prevent the reload of the wireless

enabling handle. The load will be carried out inside, in a dry place (protection against moisture IP 20).

If several wireless enabling handles are used on the same site, they should be configured with different radio

frequencies spaced by at least two channels (for example, channels 5, 7, 9 ...) or by five channels when several

systems are being used within a radius of 10 meters.

In the event of a malfunction, immediately stop the installation by fully pressing and releasing the trigger on the

enabling handle.

The enabling handle is designed to meet the requirements of Machinery Directive 2006-42 on the basis of the

following standards:

• EN ISO 13849-1 (2008) for the performance level e (Category 4)

• EN 61508-1-7 (2001) for SIL 3

The enabling handle is equipped with a system detecting it on its charger which inhibits operation of the equipment

if the handle is not placed on its charger after it has been used.

2 Product identification data

The "RADIOSAFE wireless enabling handle" comprises :

The wireless enabling handle : RSEP4B-* (trigger with 2

positions) or ref RSEP41-* (trigger with 3 positions) supplied

with :

o A battery

o A handle configuration software

o The installation and user manual (CD)

A charger, ref. : RSCP-*

A radio receiver, ref. : RSRB*400-* supplied with :

o A SIM card

o A ¼ wave antenna, ref. : VUB084

o A BNC elbow connector, ref. : VUB060

o A 50 cm antenna extender, ref. : VUB170

Page 6

Doc ref. : 332190D – EN

28.04.2014

Page 6 / 49

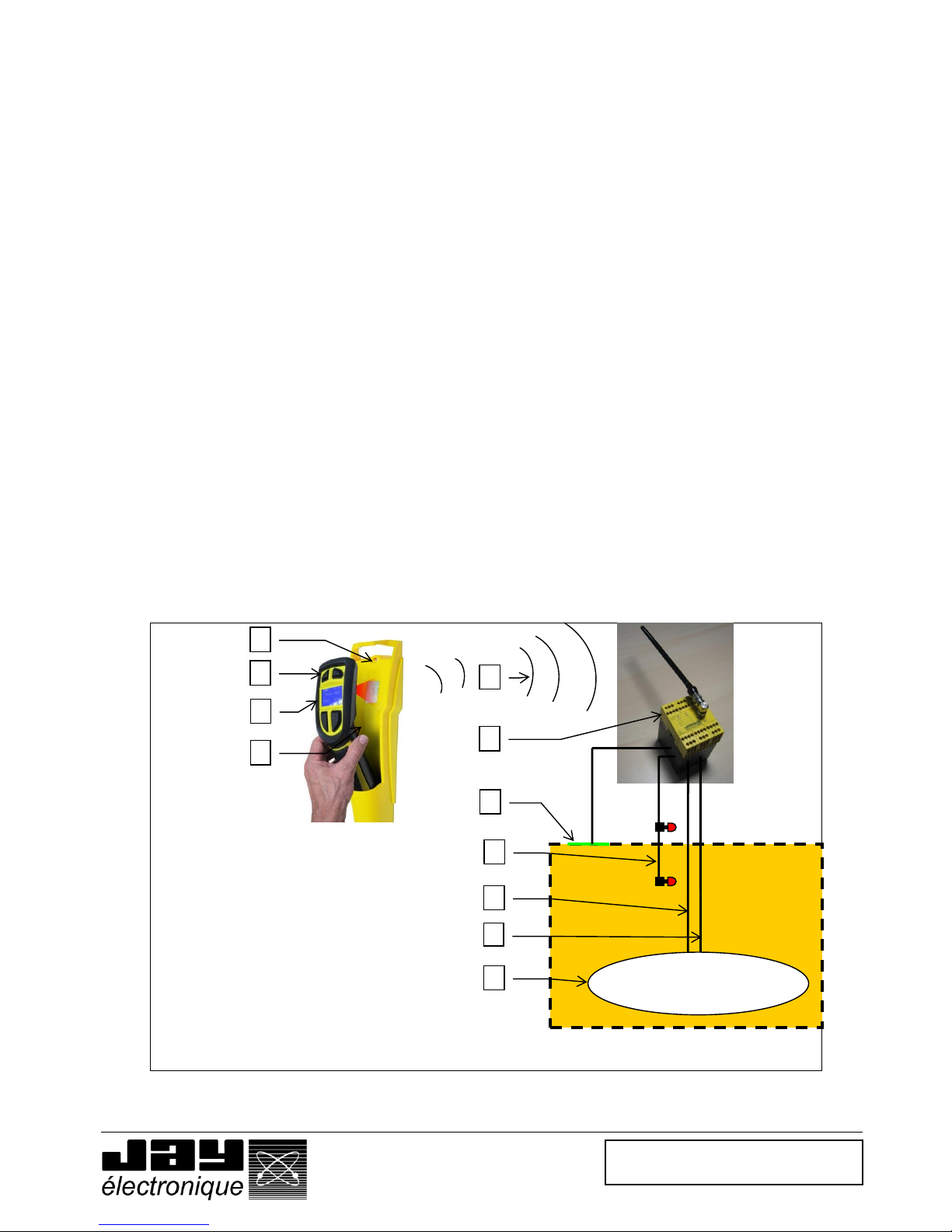

3 Theory of operation

The receiver (R) is integrated in the machine control unit.

The wireless enabling handle (P) transmits, by radiowave, the trigger operating request (G) and possible commands

generated using the buttons (B).

The receiver (R) enables (or not) operation (F) of the machine (M) and transfers the commands (O) assigned to the

buttons.

The receiver (R) stops operation of the machine in the following cases :

Case 1 - Trigger (G) released or clenched (in the case of the 3-position trigger) on wireless enabling handle (P) during

use ;

During use, the wireless enabling handle transmits a stop command as soon as the user releases or

clenches the trigger.

Safety shutdown following stop request or operator incident.

Case 2 - Radio link (L) interrupted during use ;

During use, the wireless enabling handle operates with a continuous radio link with the receiver. If the link is

interrupted more than 300ms, the receiver automatically stops the system.

Safety shutdown prior to loss of control of the stop function.

Case 3 - Procedure for picking up or setting down wireless enabling handle on charger not observed (C) ;

The wireless enabling handle has been removed from its charger and the trigger has not been activated within

the required period of time.

Safety shutdown subsequent to incorrect use of wireless enabling handle.

Case 4 - A secure access area (Z) has been opened without a prior access request;

The access to the area has been opened without prior request by the user, or following a defined time delay for

opening of the secure area access.

Safety shutdown following detection of intrusion into a secure area.

Case 5 - A wired emergency stop system (A), if used, has been opened ;

The wired emergency stop system(s), connected to the receiver, has been opened.

Safety shutdown of machine subsequent to activation of wired emergency stop system(s).

Case 6 - Detection of a fault (see section : « Faults communicated by receiver »)

> See « Procedures » in section 11.

L

P

C

G

Machine

Z

A

M

R

A : Wired emergency stop

system

B : Control button

C : Charger

F : Operation enabled

G : Trigger

L : Radio link

M : Machine controlled

O : Command

P : Wireless enabling handle

R : Receiver

Z : Protected access area

F

O

B

Page 7

Doc ref. : 332190D – EN

28.04.2014

Page 7 / 49

4 Check of functions, initial start-up

This section is aimed at familiarising you with the product.

Detailed procedures are given to allow you to simulate operation of the equipment in its « ex-factory »

configuration.

4.1 « Ex-FACTORY » parameters

Operating mode .................................... : 4 control buttons

Radio channel number ......................... : 64 (434,675MHz)

Transmit power level ............................. : Set to maximum for all handle models

Handle configuration lock ................... : « deactivated »

Time delay (1) ........................................ : “A” selectors set to « 5 » (10 seconds)

Receiver application program ............. : “B” selector set to « 0 » (no area access management)

(1) Time delay for « secure area access inhibit » and « trigger activation » on enabling handle pick-up

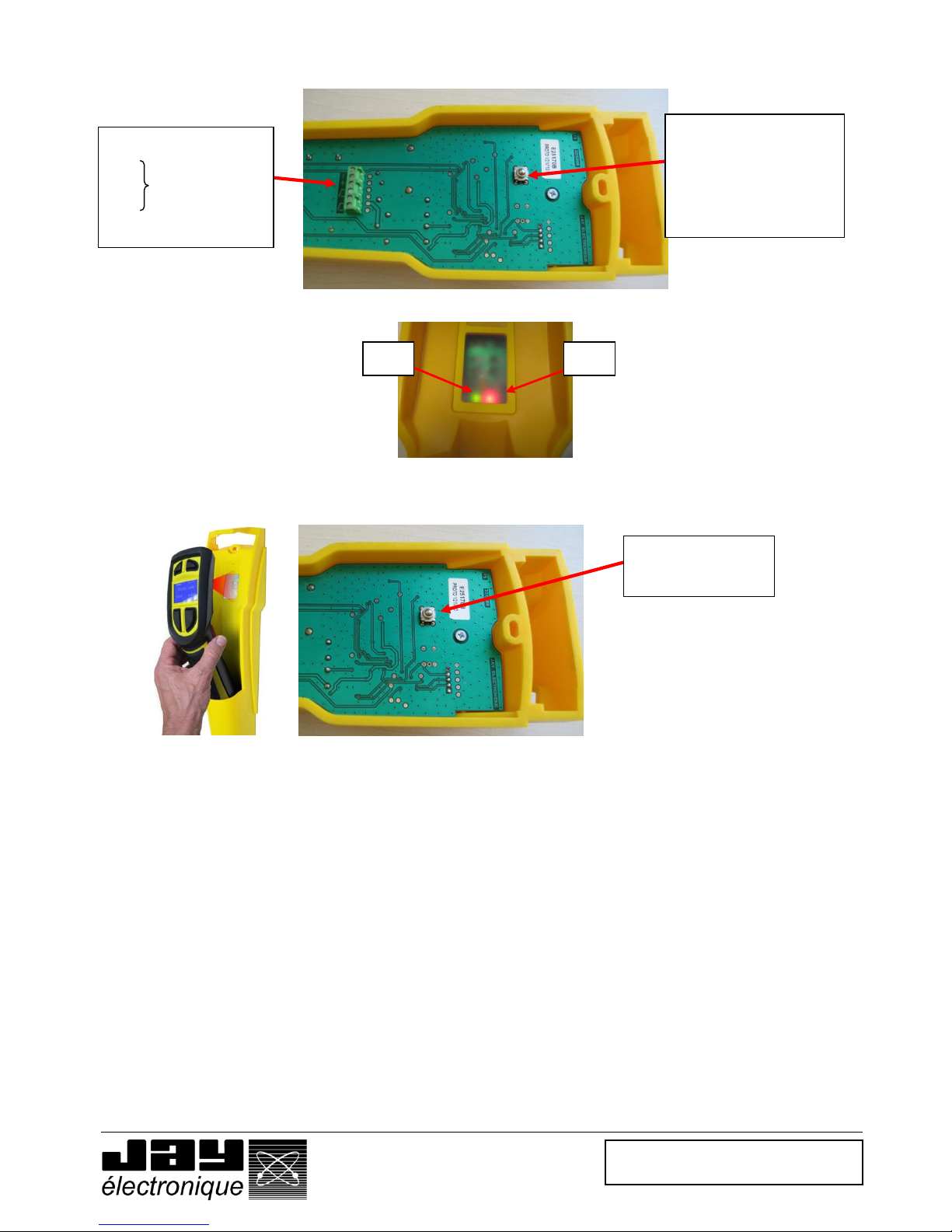

4.2 Setting the wireless enabling handle into service

• Step 1 Open the enabling handle

• Step 2 Insert the SIM card supplied with the receiver or separately (pay attention to insertion direction)

• Step 3 Connect the battery

• Step 4 Close the handle using a Pozidriv No.1 screwdriver (2), by screwing in, without blocking, the central

screw, followed by the two top screws and the bottom screw. Finish up by blocking the 4 screws.

(2) Do not use an electric screwdriver without torque control.

• Notes

The SIM card contains the complete configuration for the handle.

The basic functions of the wireless enabling handle can be configured directly using the buttons on the front panel. The basic functions

are :

- Read information on handle (identity code, SIM card serial number, software version, number of current configuration file)

- Change screen display language

- Change frequency channel

- Change power level

- Lock handle configuration

To modify the basic parameters, refer to section 5.

Protective

foam

Page 8

Doc ref. : 332190D – EN

28.04.2014

Page 8 / 49

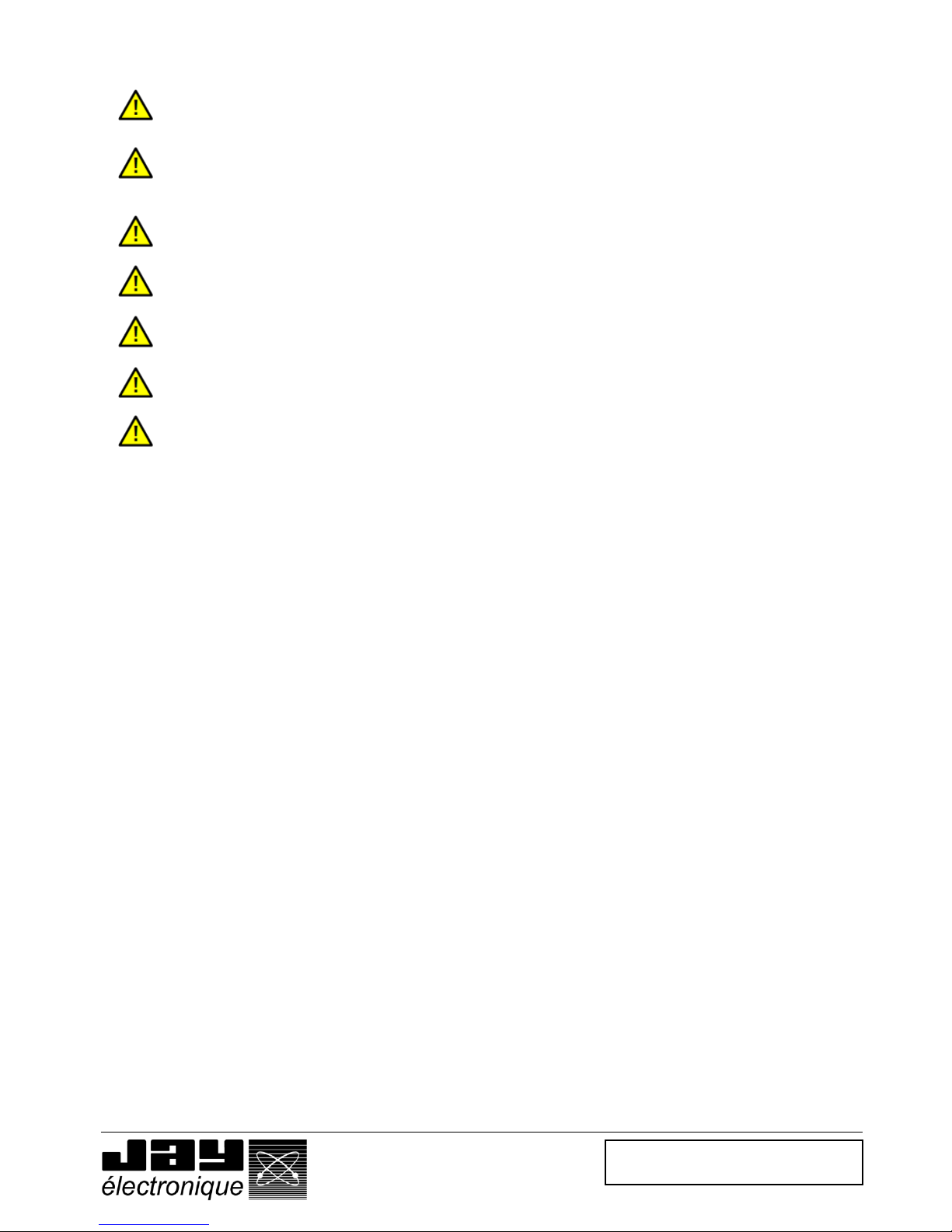

4.3 Setting the charger into service

• Step 1 Connect a 24VDC (+/- 5 %) stabilised power supply to the – (ground) and + (+24Vdc) terminals.

• Step 2 Supply the charger

The red indicator light V2 should come on.

• Step 3 Pair the handle with its charger by placing it in front of its charger and pressing the association button

at the rear of the charger.

The green indicator light V1 (handle present) on the charger should come on.

• Step 4 Release the pairing button

The green indicator light V1 should stay on. The handle is now paired with the charger.

• Notes

When the handle is located at a distance greater than 30cm from the charger, the green indicator light

V1 goes off. It comes back on when the handle is brought nearer to the charger.

The 2 outputs, S1 and S2, are active when the handle is present on the charger.

The handle is charged contact-free (inductive charge). The charger is equipped with a « handle

presence » detection function. This detection function inhibits the enabling handle and keeps the

receiver safety relays active.

The "handle on charger" condition is monitored by an infrared link.

24 VDC power supply

S1

S2

Pairing button:

This button ensures

pairing of the handle with

the charger. The charger

will learn the Identity code

of the handle.

V2

V1

Button used to pair

handle with charger.

« Handle on

charger »

outputs

Page 9

Doc ref. : 332190D – EN

28.04.2014

Page 9 / 49

4.4 Warning regarding the battery of the enabling handle

There is a risk of explosion if battery is replaced by a battery of an incorrect type. Only the battery intended

for the enabling handle and supplied by JAY Electronique is suitable

Only the charger ref. :RSCP from JAY Electronique is suitable for recharging the battery of the enabling

handle.

Do not expose the battery to temperature above 50°C (122°F).

Do not open or attempt to modify the battery.

Failure to follow instructions may cause fi re or explosion.

Please respect the dispose of used batteries as directed.

The load must be performed in a dry (protection against moisture IP 20), sheltered and protected place.

Page 10

Doc ref. : 332190D – EN

28.04.2014

Page 10 / 49

4.5 Setting up the product

Test wiring: does not take account of your application :

• Step 1 Prepare a 24VDC (+/- 5 %) stabilised power supply, 500 mA min.

Prepare a pushbutton, for the reset function.

• Step 2 Wire the receiver as follows :

- Shunt the terminal pairs [S11-S12], [S13-S14], [S21-S22], [S24-S23] and [Y1-Y2]

- Connect the terminals S31, S32, S33 and S34 to the charger

- Install a reset button between terminal S42 and the +24Vdc of the power supply

- Connect the +24VDC of the stabilised power supply to terminals A1+, A3 and A4

- Connect the power supply ground to the two A2- terminals

• Step 3 Supply the receiver

Indicator light V1 of the receiver comes on steady and indicator light V2 of the receiver flashes

regularly.

Page 11

Doc ref. : 332190D – EN

28.04.2014

Page 11 / 49

4.6 Testing the unit

• Step 1 Place the handle on the charger.

The green indicator light on the charger comes on. If not, check that the handle is paired with the

charger. Refer to the section « Setting the charger into service ».

• Step 2 Press the reset button to engage the output relays of the receiver, K1-K2

The 2 indicator lights K1 and K2 should come on and indicator light V2 of the receiver should go

off.

• Step 3 Pick up the enabling handle and place the trigger in the « active » position within 10 seconds.

The antenna symbol should appear on the display screen.

Notes : 1 - Safety relays K1 and K2 deenergise when the trigger is released or clenched (in the case of 3-

position trigger).

2 - Safety relays K1 and K2 energise again when the trigger is reactivated after it has gone through

the « released » position (1)

3 – The safety relays remain active when the trigger is released within 30 cm of the charger.

(1) Wait 3 or 4 seconds before you reactivate the trigger to allow the receiver to correctly reinitialise.

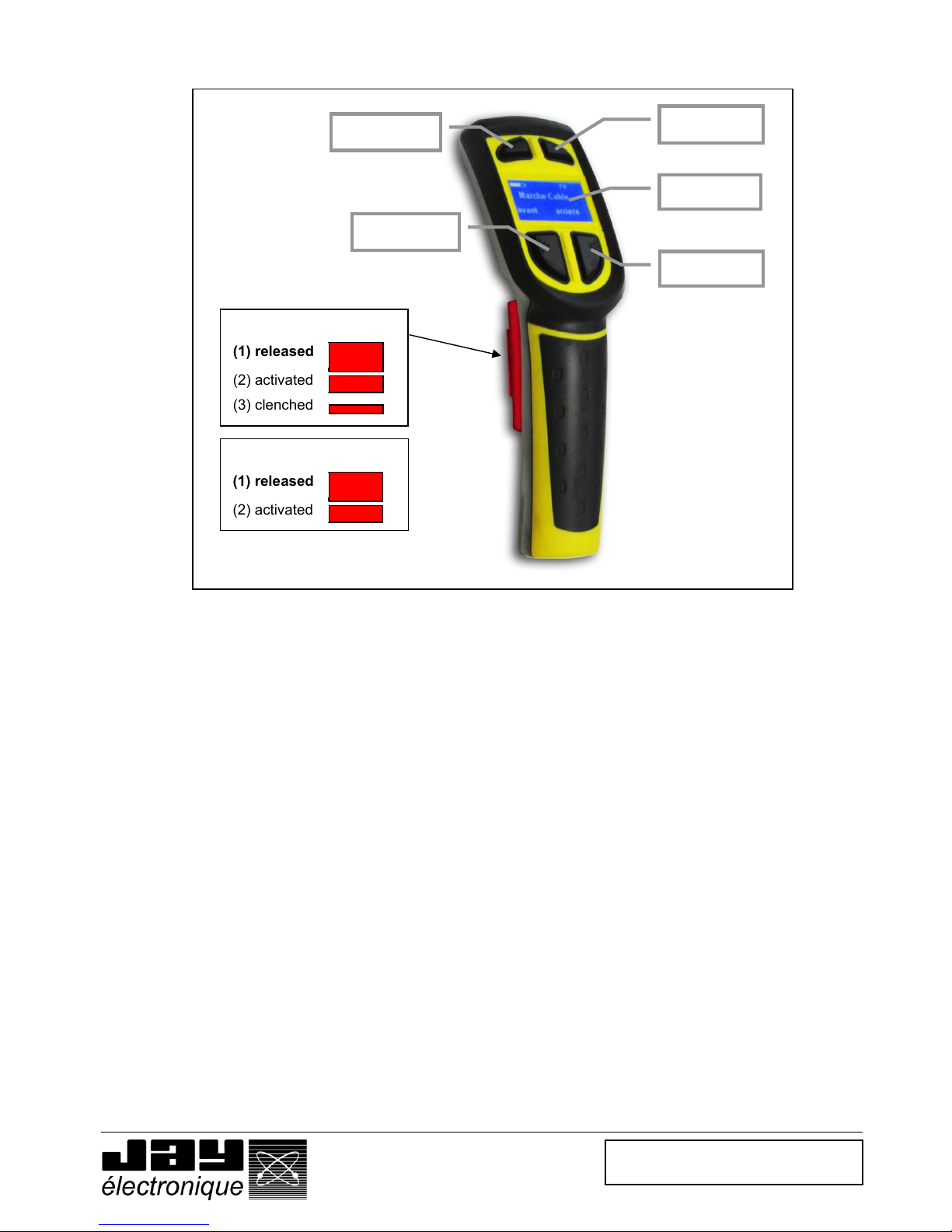

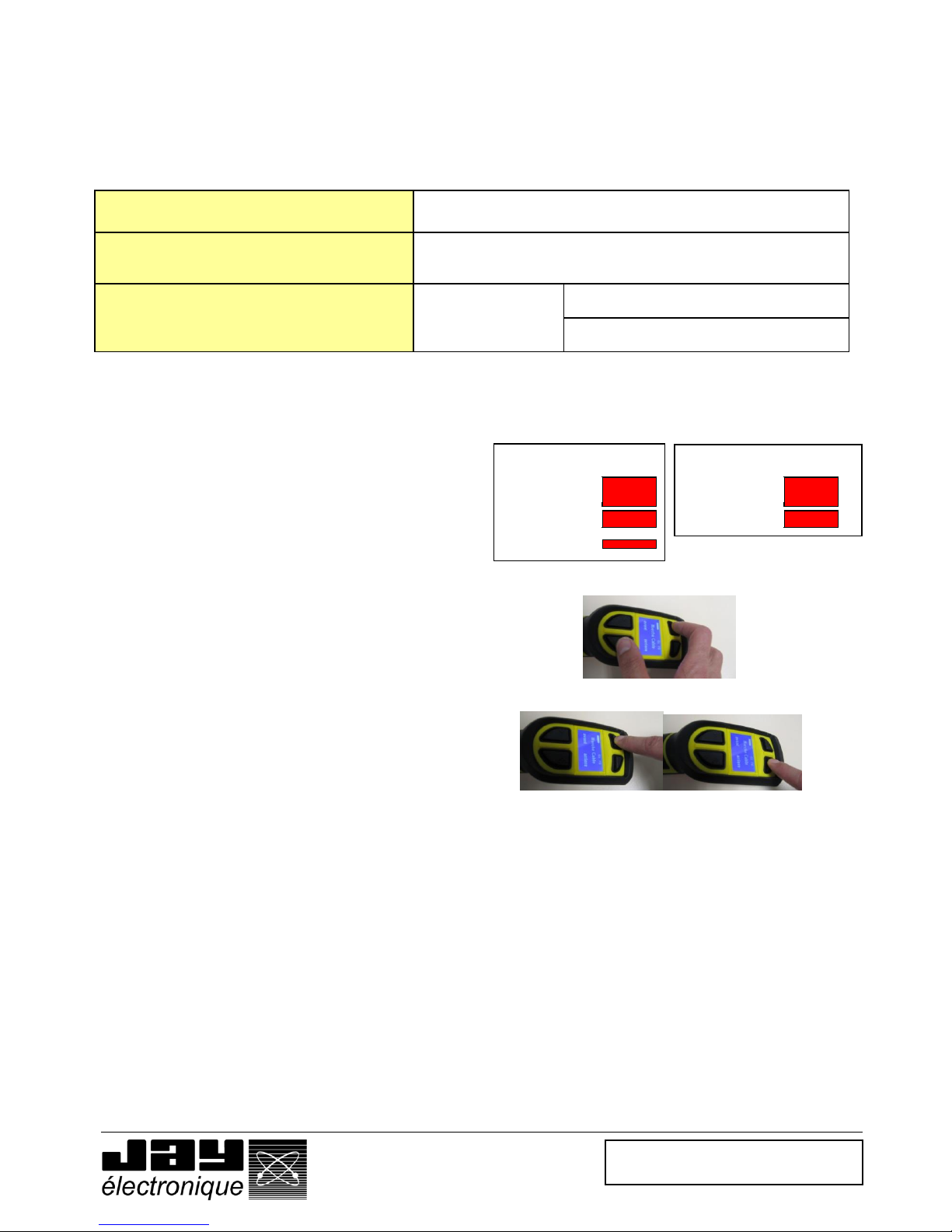

Button B4

Button B2

Button B3

Button B1

Display

(1) released

(2) activated

(3) clenched

3-position trigger

(1) released

(2) activated

2-position trigger

Page 12

Doc ref. : 332190D – EN

28.04.2014

Page 12 / 49

5 Setting the product into service

Experience has shown that functional reliability basically depends on :

- the quality of the electrical power supply and the associated protection circuits ;

- the characteristics of the components connected to the receiver.

- the position of the reception antenna.

- the configuration and wiring of the various components

5.1 Electrical power supply, installation and wiring

Final wiring in the receiver cabinet and of the charger must only be performed with the power shut down.

5.1.1 Receiver

Recommendations :

- The product should be installed near the intervention area.

- The receiver should be installed in a housing.

- A wire-type emergency stop should be wired on the front panel of the housing ; this emergency stop can be

used when the handle is set on its charger.

- Provide a position for a reset button, required to reset the receiver module when setting into service, following

a fault, or following a safety shutdown.

- On the top of the housing, secure a 3-color (green, orange, red) indicator light column to indicate the operating

status of the wireless enabling handle.

- Near the indicator light column, fasten an information sign indicating the meaning of the various states of the

indicator lights (example given on last page of this manual).

- The receiver must be supplied with 24 VDC +/- 15% across terminals [A1+ and A2-].

- Provide a protection system implementing a 1 amp delayed fuse in series on input A1 (24V DC) of the

receiver.

- Familiarise yourself with the other characteristics in the section entitled « Technical characteristics »

5.1.2 Charger

- The charger must be supplied with 24VDC +/- 5%. (Jay charger, ref. : RSCU)

- Electrical protection : 0.5 A delayed fuse.

5.2 Receiver antenna

The receiver is supplied with an antenna, a 50 cm antenna extension and a BNC-BNC elbow connector.

If a metal housing is used, the receiver antenna should be mounted on the top of the housing.

If a plastic housing is used, the antenna can be connected directly on the receiver using the BNC elbow

connector supplied with the receiver.

If poor radiowave propagation is observed, for example, intervention in a closed enclosure, the receiver

antenna should be mounted inside the enclosure.

NOK

NOK

OK

OK

OK

Page 13

Doc ref. : 332190D – EN

28.04.2014

Page 13 / 49

5.3 Intervention mode and operation of enabling handle

The intervention mode and operation of the product depend on the needs of the application.

Intervention mode

- The wireless enabling handle can be used on machines in the following modes :

o « Monitoring - Diagnostic»

o « Manual control ».

The detailed intervention conditions are given in the next section.

The wireless enabling handle can be configured to manage access to a machine area. For this purpose, the

« 4 control buttons » mode is used.

The principle of the machine area access function is detailed below :

- Application programs 8 and 9 of the receiver are dedicated to this purpose (chosen using the 2 “B”

selectors)

- The access gate or safety light barrier is controlled by the receiver using 2 inputs.

- The user makes a request for authorisation to access the machine area using one of the two buttons (B1

or B2) on the wireless enabling handle.

- This request initiates a time delay (1) inhibiting the two gate contacts or the safety output of a safety light

barrier.

- While the gate is opened or while crossing the safety light barrier, the receiver safety relays remain

active.

- Once the gate has been closed or the safety light barrier has been crossed, the inhibit condition is

stopped to prevent entry of any other person.

(1) configurable by 2 « A » selectors on receiver.

Handle operating mode

- The wireless enabling handle can be used in the following 2 operating modes :

o « 4 control buttons »

o « function selection ».

This will depend on the number of commands to be generated. For an application requiring more than 4

commands to be generated, the handle will need to be configured in « function selection » mode using the

« Dialog RSP » PC software supplied with the handle.

5.3.1 Conditions for intervention in «monitoring - diagnostic» mode

Safety condition in this intervention mode :

This intervention mode must satisfy the requirements of standard NF EN12100-2 §5.5 «Additional preventive

measures».

In this intervention mode, the product provides a wireless individual protection system for qualified personnel

intervening for equipment monitoring or diagnostic purposes, whether in downgraded operation or not.

The regulations prohibit direct intervention on the equipment.

The « monitoring - diagnostic» intervention mode is only possible provided the enabling handle is configured for

« 4 control buttons » operation (ex-factory configuration)

The « monitoring - diagnostic» intervention mode is only acceptable provided:

o The risk assessment shows that injury to the intervening technician can be avoided in the event

of an immediate danger.

o The risk assessment shows that the time required to stop the equipment by releasing or

clenching the trigger is sufficiently short to prevent placing the intervening technician in danger.

o An emergency shutdown of the equipment by clenching or release of the enabling handle trigger

does not produce any additional dangerous condition.

o The operator can keep the enabling handle in his hand without releasing the trigger throughout

the time of the intervention.

In the « monitoring - diagnostic » mode, the receiver can manage (or not) access to the machine area.

Page 14

Doc ref. : 332190D – EN

28.04.2014

Page 14 / 49

5.3.2 Conditions for intervention in « manual control » mode

Safety condition in this intervention mode

This mode satisfies the requirements of standard NF EN12100-2 §4.11.8 « Guidelines relative to manual control ».

This mode is possible insofar as control of the movement using the control buttons associated to action on the handle

trigger is sufficient to stop the equipment if necessary.

The « manual » intervention mode is only acceptable provided:

- The risk assessment shows that injury to the intervening technician can be avoided in the event of an

immediate danger.

- The risk assessment shows that the time required to stop the equipment by releasing or clenching the trigger

is sufficiently short to prevent placing the intervening technician in danger.

- An emergency shutdown of the equipment by clenching or release of the enabling handle trigger does not

produce any additional dangerous condition.

Conditions for use of product in « manual control » intervention mode

- The equipment must be stopped from the supervision station or by opening an access gate.

- The enabling handle must be removed from its charger. The « handle withdrawn » information is accessible

on output 17 of the receiver (active at the high state).

- To ensure the « manual controls » on the equipment, the operator must actuate the trigger to the active

position, and use the four control buttons to generate a command.

- So long as the handle is not set down on it charger (operator has not withdrawn from intervention area), the

equipment will not be able to operate again in automatic mode.

- The « manual control » intervention mode is possible in « 4 control buttons » mode and in « function

selection » mode.

- The « manual control » intervention mode does not allow the receiver to manage access to a machine area.

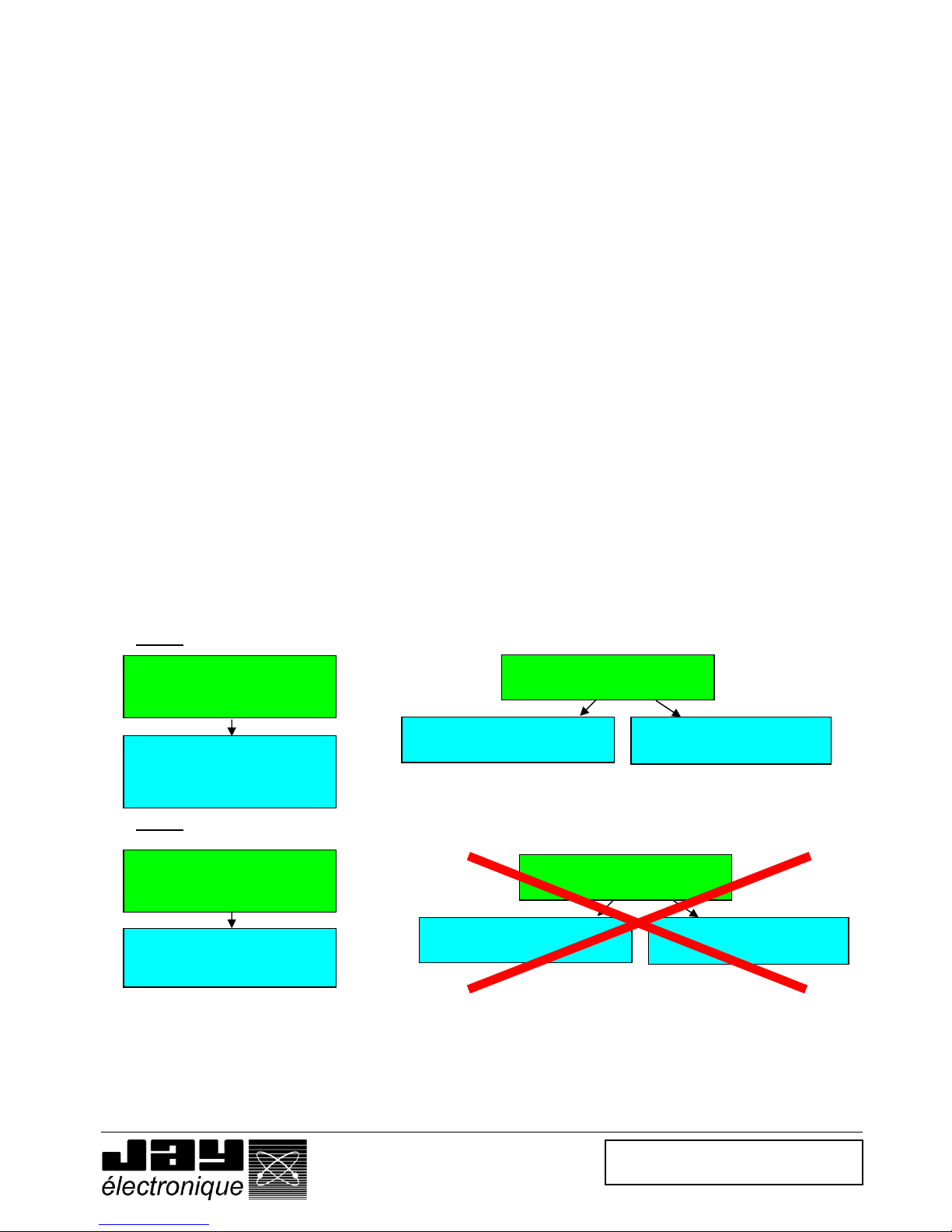

5.3.3 Summary of conditions for intervention on machine.

The conditions for intervention on a machine using the enabling handle can be summarised as follows :

Case 1 : Application without management of machine area access by receiver

Case 2 : Application with management of machine area access by receiver

(1) With a machine in operation, the regulations prohibit acting on the machine in the « monitoring - diagnostic » mode.

« manual control »

intervention mode

« 4 control buttons »

operating mode

« Function selection »

operating mode

« Diagnostic- monitoring »

intervention mode

(1)

« 4 control buttons »

operating mode

(control buttons not used – only

trigger is used)

« Diagnostic- monitoring »

intervention mode

(1)

« 4 control buttons »

operating mode

(Button(s) used .)

« manual control »

intervention mode

« 4 control buttons »

operating mode

« Function selection »

operating mode

Page 15

Doc ref. : 332190D – EN

28.04.2014

Page 15 / 49

5.3.4 Configuration of enabling handle operating mode

The wireless enabling handle operating mode can be configured using the Dialog RSP PC software supplied with the

handle.

This software is used to :

- Configure the handle in « 4 control buttons » or « function selection » operating mode.

- Modify the content of the screen display on the handle by loading or creating new pictograms.

- Save or re-load a new handle configuration in the SIM card of the handle.

- Re-load an old configuration.

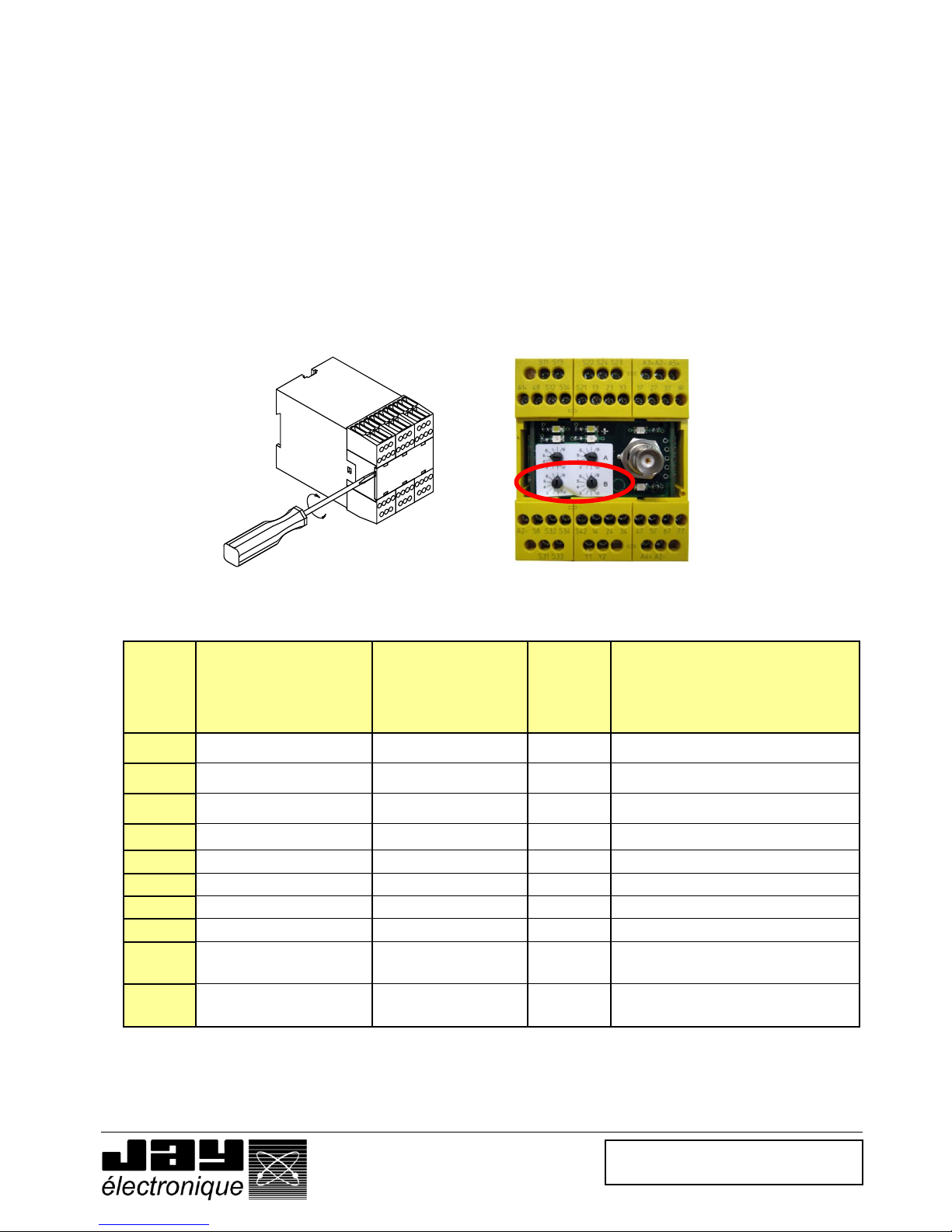

5.3.5 Receiver : selecting the program

The receiver has 10 programs which can be selected using the two « B » selectors.

Access to the configuration selectors is obtained by removing the front panel of the receiver.

Important : the 2 « B » selectors must be set to the same position to validate the selected program.

Position of

« B »

selectors

Reset mode, following a wired

emergency shutdown or

opening of a gate

Reset mode, following

release or clenching of the

handle trigger

Dangerous

area access

control

Remarks

0

Control console

Trigger

NO

1

Control console

Control console

NO

2

Automatic

Trigger

NO

3

Automatic

Control console

NO

4

Not used

5

Not used

6

Not used

7

Not used

8

Control console

Trigger

YES

The receiver module controls access to the

dangerous area using the handle.

9

Control console

Control console

YES

The receiver module controls access to the

dangerous area using the handle.

Note : The « manual control » intervention mode cannot be used for programs 8 and 9.

Page 16

Doc ref. : 332190D – EN

28.04.2014

Page 16 / 49

5.3.6 Adjusting the machine area access time.

The machine area access time and the time during which the gate or safety light barrier is inhibited to allow

intervention in a machine area are configurable using the 2 « A » selectors on the receiver.

Important : The 2 « A » selectors must be set to the same position to validate the selected time delay.

Position of «A»

selectors

0 1 2 3 4 5 6 7 8

9

Machine area

access time

5 s.

6 s.

7 s.

8 s.

9 s.

10 s.

15 s.

20 s.

25 s.

30 s.

Inhibit time (1)

(Muting)

5 s.

10 s.

20 s.

40 s.

1 min.

2 min.

3 min.

4 min.

5 min.

10 min.

Caution : The machine area access time is the same as the enabling handle pickup time after it has been withdrawn

from its charger.

(1) This time corresponds to the muting time of a gate or safety light barrier. Once the gate has been closed or the

barrier has been crossed, the muting function is stopped to prevent any unauthorised person from entering into the

area.

Page 17

Doc ref. : 332190D – EN

28.04.2014

Page 17 / 49

5.4 Receiver : operation and wiring

5.4.1 Operation and wiring of function outputs

The receiver is equipped with 6 solid state outputs (100 mA max). Assignment of the enabling handle buttons (B1 to

B4) with respect to the outputs depends on the operating mode selected using the RSP configuration software.

Assignment of receiver outputs in « 4 control buttons » mode.

In the « 4 control buttons » mode, buttons B1,

B2, B3 and B4 of the enabling handle respectively

control outputs 27, 37, 47 and 57.

Output 67 is activated as soon as one of the four

buttons is pressed (common output)

Reminder : If the receiver is managing machine area access, B1 and/or B2 and the associated outputs 27 and/or 37

are used to process the muting enable request for the gate or safety light barrier.

Assignment of receiver outputs in « function selection » mode.

This operating mode is configurable using the dialog RSP PC software.

In « function selection »mode, buttons B3 and

B4 are used to select the machine component to

be controlled (F1 to F4) and buttons B1 and B2

are used to select the direction of movement.

Reminder : Machine area access cannot be managed in the « function selection » operating mode.

Caution, the loads connected to the outputs must not deliver more than 100 mA with 24VDC.

Receiver RSRB outputs

27

37

47

57

67

77

Selection of

function by B3

and B4

F1

B1

X X

B2

X X

F2

B1

X X

B2

X X

F3

B1

X

X

B2

X

X

F4

B1

X

X

B2

X

X

Receiver RSRB outputs

27

37

47

57

67

77

B1

X X

B2

X X

B3

X X

B4

X X

Page 18

Doc ref. : 332190D – EN

28.04.2014

Page 18 / 49

5.4.2 Operation and wiring of safety relays K1-K2.

The safety stop chain is cut out by safety relays K1 and K2 (internal to receiver) which control the contacts

accessible by terminals 22-23 and 32-33.

The state of relays K1 and K2 depends : on the position of the trigger (table 1), possible faults detected, and

possible radio link losses.

Other external safety stop devices can be added including an emergency stop palmswitch and a gate control

device, wired to the inputs provided for this purpose on the receiver. The state of the inputs will act directly on

relays K1 and K2 through the receiver.

The state of safety relays K1 and K2 is available between terminals 13 and 14.

State of safety outputs as a function of enabling handle trigger position :

Trigger

position

State of

safety relays

K1 and K2

S14

State of contact chains accessible by terminals

S13-S14 / S23-S24 / S33-S34

Released

Inactive

0

Open

Active

Active

+24 Vdc

Closed

Clenched

Inactive

+24 Vdc

Open

Page 19

Doc ref. : 332190D – EN

28.04.2014

Page 19 / 49

5.4.3 Monitoring of main contactor : operation and wiring

Input « Y1-Y2 » is used to monitor the state of the contactor(s) connected to the K1-K2 safety outputs.

The state of the contactor contact(s) wired to input Y1-Y2 must be closed in order to reset the receiver.

Note : If this input is not used, wire a jumper across inputs Y1 and Y2.

5.4.4 Reset button : wiring and management

Following a safety shutdown, safety relays K1 and K2 deernergise and open the contacts accessible by terminals 22-23

and 32-33.

In accordance with the application program selected using the two « B » selectors on the receiver, the safety relays are

automatically reset, or reset is requested using a pushbutton wired on input S42.

This being said, the reset button is always necessary except with application program « 2 ».

Note : For information on the reset modes selected using the 2 « B » selectors, refer to the section entitled “ Receiver,

selecting a program “.

Page 20

Doc ref. : 332190D – EN

28.04.2014

Page 20 / 49

5.4.5 Wiring of a wired safety shutdown device.

The external safety shutdown devices (wired safety shutdown palmswitches ...) must be wired to the « Emergency

stop » inputs. To do so, you must use external safety shutdown devices comprising two redundant contacts. One of

the contacts must be connected across terminals S11-S12, and the other across S13-S14 (fig 2).

Note : If this wired emergency stop function is not used, you must wire two jumpers across S11-S12 and S13S14.

5.4.6 Wiring of a machine area access authorisation request function.

- The enabling handle must be configured in the « 4 control buttons » operating mode.

- Output 27 (associated to button B1) or output 37 (associated to button B2) must be connected to input S34 to

ensure the machine area access authorisation request.

- Using the Dialog RSP PC software, you can load a pictogram suited to this application on the enabling handle

screen. See pictograms available in Dialog RSP PC software library.

Note : The wiring diagram shown below is designed for an area access request using button B1 (output 27)

Note : The wiring is the same for an access by gate or an access protected by a safety light barrier .

Page 21

Doc ref. : 332190D – EN

28.04.2014

Page 21 / 49

5.4.7 Wiring of an equipment with area access protection

The enabling handle can be used with machinery located in an area with protected accesses, or with machinery for which

access is not protected.

On equipment with protected access, the wireless enabling handle can be used to generate access requests and can control

the access to a protected area :

- The accesses must be equipped with a system used to detect passage of a person.

- For an access by which a gate is opened and closed, 2 contacts must be wired across terminals S21-S22 and S23-S24 of

the receiver.

- For an access by which a safety light barrier must be crossed, the barrier outputs must be wired to inputs S22- and S24

of the receiver.

- The receiver monitors the coherency and the state of the 2 contacts of the gate or of the two outputs of the safety light

barrier.

- On user request (handle button B1 or B2 pressed and released), the receiver temporarily inhibits (adjustable time delay) the

two contacts of the gate or the two outputs of the safety light barrier.

- The orange indicator light on the indicator light column wired on output 58 flashes.

- The user can enter or exit the secured area without tripping the two safety outputs K1 and K2 of the equipment.

- Once the gate is closed or the safety light barrier is crossed, the orange indicator light on the indicator light column stops

flashing and is steadily lit

Diagram 1 : Access protected by access gate.

Diagram 2 : Access protected by safety light barrier.

Page 22

Doc ref. : 332190D – EN

28.04.2014

Page 22 / 49

5.4.8 Wiring of an equipment without area access protection

If the equipment does not have a peripheral protection system with a machine area access feature, you must connect

jumpers across the machine area access monitoring inputs, S21-S22 and S23-S24.

5.4.9 Wiring of “handle on charger” detection function

This function must be wired to inhibit the enabling handle when it is not used. Once an intervention on a machine is

completed, the operator must place the enabling handle on its charger in order to allow the equipment to operate

again in automatic mode.

The two outputs, S1 and S2, must be connected to the receiver.

- These should be connected to inputs S31-S32 and S33-S34 when the receiver is not used to manage

machine area access (see diagram 1)

- These must be connected in series to inputs S31-S32 when the receiver is used to manage machine area

access. The passage request must be connected on input S33 (see diagram 2)

- Output 17 gives the “handle on charger” status (output active = handle present).

Diagram 1 : Wiring for configuration without machine area access

Page 23

Doc ref. : 332190D – EN

28.04.2014

Page 23 / 49

Diagram 2 : Wiring for configuration with machine area access (example with gate)

5.4.10 Wiring of indicator light column on receiver

We strongly recommend that you wire an indicator light column on the receiver. The column will indicate the status of the

equipment and of the wireless enabling handle. The indicator light column status information panel should be fastened near to the

indicator light column (an example is given in the last page of this manual).

The consumption of the indicator lights of the column must not exceed 100 mA with 24VDC. If this is not the case, the indicator

lights should be relayed.

Status of lights on indicator light column

Indicator

light

On steady

Flashing

Off

Remarks

Green

Equipment in service

Equipment stopped

Red

Equipment stopped

Receiver on standby for

reset

Equipment in service

Red and orange indicator lights

will flash a specific number of

times in the event of a receiver

malfunction

Orange

Handle removed from

charger

Handle removed from

charger or area access

request

Handle on charger

Page 24

Doc ref. : 332190D – EN

28.04.2014

Page 24 / 49

5.4.11 Wiring of receiver power supplies

This operation should be performed at the end of the wiring procedure.

Page 25

Doc ref. : 332190D – EN

28.04.2014

Page 25 / 49

5.5 Charger : wiring and management.

5.5.1 Association of charger and wireless enabling handle

If the charger has not been associated to its handle, refer to the section entitled « Setting the charger into service ».

5.5.2 Wiring of charger power supply

To supply the charger, refer to the section entitled « Setting the charger into service »

5.5.3 Taking the wireless enabling handle off its charger

When the wireless enabling handle is withdrawn from its charger, you have a limited time delay to activate the trigger.

After this time delay, safety relays K1 and K2 de-energise to stop the equipment.

This time delay is configurable between 5 and 30 seconds by 2 «A» selectors on the receiver.

The 2 selectors must always be set to the same position.

Position «A»

selectors

0 1 2 3 4 5 6 7 8

9

Handle pickup time

delay

5 s.

6 s.

7 s.

8 s.

9 s.

10 s.

15 s.

20 s.

25 s.

30 s.

Note : The two « A » selectors are also used to define the machine area access time described in the previous section. If this area

access function is also used, the position of the two « A » selectors must be chosen to best satisfy the two functions

5.5.4 Setting the wireless enabling handle on its charger

When you go to set the wireless enabling handle on its charger, you must keep the trigger activated until the green

indicator light on the charger comes on (when you are within 30 cm of the charger). You can then release the trigger

without de-energising the safety relays, then set the wireless enabling handle on its charger.

The enabling handle recharges once it is engaged on its charger.

Page 26

Doc ref. : 332190D – EN

28.04.2014

Page 26 / 49

5.6 Language selection

Several dialog languages are available with the enabling handle display.

The language is chosen by simultaneously pressing buttons B3 and B4.

• Pick up the handle, leaving the trigger in the

released position (1).

• *Simultaneously press buttons B3 and B4

The language currently used is displayed.

• Press the – (B3) or + (B4) button to change

language.

Note : If the handle is locked against installation

configuration changes, see §3.3.

• Validate the new working language by pressing

OK* (B1).

• or, cancel the change by pressing EXIT (B2).

Page 27

Doc ref. : 332190D – EN

28.04.2014

Page 27 / 49

5.7 Radio working frequency

5.7.1 Selection of radio working frequency.

To limit unintentional cut-outs linked to radio interference, it is important to choose a radio channel (frequency) which is available.

Use the following guidelines in making your choice :

- Consider the point of installation of the receiver as the centre of the radio link ;

- Estimate the maximum distance « D » which may occur between the operator and the receiver ;

- Identify the frequencies used by all the radio transmitters located within a radius of 2xD.

- Choose a frequency which is as far as possible from those used by the nearest transmitters, and which is not being used by

the transmitters identified.

5.7.2 List of channels and radio frequencies (in accordance with enabling handle model)

433-434 MHz bands, intervals between adjacent channels: 0.025 MHz

Channel

No.

Frequency

MHz

Channel

No.

Frequency

MHz

Channel

No.

Frequency

MHz

01

433,100

23

433,650

45

434,200

02

433,125

24

433,675

46

434,225

03

433,150

25

433,700

47

434,250

04

433,175

26

433,725

48

434,275

05

433,200

27

433,750

49

434,300

06

433,225

28

433,775

50

434,325

07

433,250

29

433,800

51

434,350

08

433,275

30

433,825

52

434,375

09

433,300

31

433,850

53

434,400

10

433,325

32

433,875

54

434,425

11

433,350

33

433,900

55

434,450

12

433,375

34

433,925

56

434,475

13

433,400

35

433,950

57

434,500

14

433,425

36

433,975

58

434,525

15

433,450

37

434,000

59

434,550

16

433,475

38

434,025

60

434,575

17

433,500

39

434,050

61

434,600

18

433,525

40

434,075

62

434,625

19

433,550

41

434,100

63

434,650

20

433,575

42

434,125

64

434,675

21

433,600

43

434,150

22

433,625

44

434,175

Note : In the extended range version RSEP41, only channels 40 to 64 are accessible.

Page 28

Doc ref. : 332190D – EN

28.04.2014

Page 28 / 49

5.7.3 Reading the working frequency.

• Pick up the handle, leaving the trigger in the released

position.

• Simultaneously press buttons B1 and B2

The radio channel programmed is displayed

• Press EXIT (B2) to exit.

Note : The receiver working frequency is not accessible.

5.7.4 Changing the working frequency

• Switch on the receiver RSRB

• Pick up the handle, leaving the trigger in the

released position (1).

• Simultaneously press buttons B1 and B2

The programmed radio channel is displayed

• Press the – (B3) or + (B4) button to go to the

desired radio channel.

Note : If the handle is locked against installation

configuration changes, see §3.3.

• Validate the new working frequency by pressing

OK* (B1).

- Either for 1 second = fast mode

(to be used only if the receiver and enabling

handle were set on the same frequency)

- Or, for 3 seconds = long scan mode.

(to be used if receiver and handle can be set

on different frequencies)

The word SCAN is displayed on the

screen

• Release the OK button (B1)

• Hold the trigger in the activated position until you

get the indication to release it.

(In long scan mode, the channel Nos., C01 to

C64 scroll on the display for around 30

seconds).

*Note : Only the channels authorised in accordance with the handle model can be used.

(1) released

(2) activated

(3) clenched

3-position trigger

(1) released

(2) activated

(3) clenched

3-position trigger

(1) released

(2) activated

2-position trigger

(1) released

(2) activated

2-position trigger

Page 29

Doc ref. : 332190D – EN

28.04.2014

Page 29 / 49

5.8 Radio transmit power

5.8.1 Transmit power selection

We recommend that you increase the power when the desired radio ranges are great or when radio interferences

produce accidental cut-outs.

It is preferable to decrease the power when working at limited ranges and where several systems are working together

within a radius of less than 10m.

Power

Min. --------------------------------- Max.

Radio power level scale

1 -------------------------------------- 10

Average range (1)

30 m -------------

150 m (handle with standard range)

250 m (handle with extended range)

(1) = The average range will depend on the product environment (presence of metal obstacles, …)

5.8.2 Reading/changing the transmit power

• Pick up the handle, leaving the trigger in the

released position.

• Simultaneously press buttons B2 and B3

The transmit power used is displayed

• Press the – (B3) or + (B4) button to change the

transmit power.

Note : If the handle is locked against installation

configuration changes, see §3.3.

• Validate the selection by pressing OK (B1).

• Press EXIT (B2) to exit

(1) released

(2) activated

(3) clenched

3-position trigger

(1) released

(2) activated

2-position trigger

Page 30

Doc ref. : 332190D – EN

28.04.2014

Page 30 / 49

5.9 Identity code

5.9.1 Identity code selection

The identity code is used to pair the handle and its receiver.

To communicate with a receiver RSRB, the handle must be programmed with the same identity code.

5.9.2 Reading the identity code, software version and SIM card serial number

• Pick up the handle, leaving the trigger in the

released position.

• Simultaneously press buttons B2 and B4

The identity code used, the software version

and the SIM card serial number are displayed on

the screen.

• Press EXIT (B2) to exit.

The receiver identity code is given on the external label.

5.9.3 Changing the identity code

The identity code programmed in the handle is stored in the SIM card.

You can change the identity code using the Dialog RSP software (see Dialog RSP manual) or by replacing the SIM

card by a card corresponding to the receiver (see § « Setting backup handle into service », or contact your installer).

Note : The identity code programmed in the receiver cannot be changed.

(1) released

(2) activated

(3) clenched

3-position trigger

(1) released

(2) activated

2-position trigger

Page 31

Doc ref. : 332190D – EN

28.04.2014

Page 31 / 49

5.10 Handle locking function

5.10.1 Locking the handle

You can protect your installation parameters (frequency, transmit power) against handling mistakes by locking the

handle.

We recommend that you activate this protection function on completion of your installation procedure.

Locking the handle will protect you against accidental changes, but will not prevent you from reading the identity code

and the frequency channel, or from running a scan to realign a receiver on the same frequency channel used in the

enabling handle.

5.10.2 Activating/deactivating the locking function

• Pick up the handle, leaving the trigger in the

released position.

• Simultaneously press buttons B1 and B4

The locked status is displayed

• Press the NO button (B3) or the YES button

(B4) to respectively deactivate or activate the

locking function.

• Validate the selection by pressing OK (B1).

• Press EXIT (B2) to exit.

(1) released

(2) activated

(3) clenched

3-position trigger

(1) released

(2) activated

2-position trigger

Page 32

Doc ref. : 332190D – EN

28.04.2014

Page 32 / 49

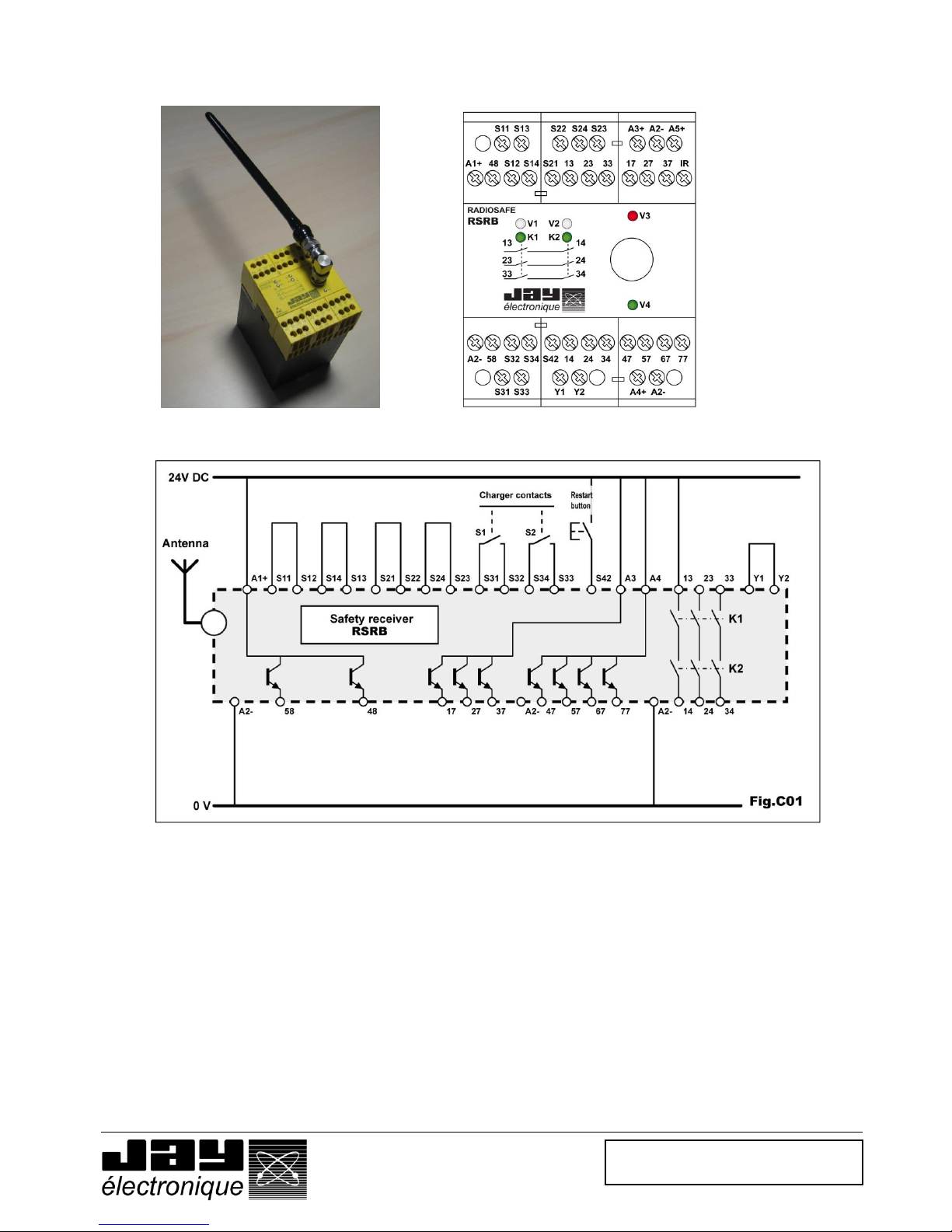

5.11 Receiver wiring examples

5.11.1 Wiring diagram for configuration without access control

The receiver does not manage machine area access.

In addition to the radio input associated to the enabling handle, an emergency stop can be wired to the receiver. Otherwise,

you must wire 2 jumpers across S11-S12 and S13-S14.

To select the correct application program, refer to the « receiver configuration » section.

5.11.2 Wiring diagram for configuration with access control by gate

Reminder : The handle can only be configured in « 4 control buttons » mode.

To monitor access to the machine area, it is necessary to wire two NO contacts on the gate on inputs S21-S22 and S23-S24.

These contacts will be inhibited to allow the operator to access the machine area without deactivating the machine

emergency stop system.

In the diagram below, output 27, associated to button B1 of the handle, is wired to output S34.

For a machine access request using your right hand (pressing B2 instead of B1), be sure to connect output 37 (instead of

27) to input S34.

Page 33

Doc ref. : 332190D – EN

28.04.2014

Page 33 / 49

5.11.3 Wiring diagram for configuration with access control by safety light barrier

Reminder : The handle can only be configured in « 4 control buttons » mode.

To monitor access to the machine area, it is necessary to wire the outputs of the safety light barrier on inputs S21-S22

and S23-S24.

These outputs will be inhibited to allow the operator to access the machine area without deactivating the machine

emergency stop system.

In the diagram below, output 27, associated to button B1 of the handle, is wired to output S34.

For a machine access request using your right hand (pressing B2 instead of B1), be sure to connect output 37 (instead

of 27) to input S34.

Page 34

Doc ref. : 332190D – EN

28.04.2014

Page 34 / 49

6 Diagnostic

In the event of a problem, the handle and the receiver will indicate a fault detected by an error message.

On the wireless enabling handle, the error messages are shown on the display screen.

On the receiver, the error messages are indicated by indicator lights V1 to V4.

6.1 Faults communicated by wireless enabling handle

Message shown on

display, in French and

English

Possible causes of faults

Action

Battery pictogram empty and

flashing

Battery discharged

Recharge handle on its charger

« no SIM card »

SIM card not connected when battery is

connected

Insert SIM card

« SIM connection fault »

SIM card disconnected

Reinstall SIM card

No message (display off)

Battery not charged

Place handle on its charger

Internal electric fault

Return to factory

Button fault

Function button has been activated

before any action on trigger

Repeat handle start-up procedure

Button stuck

Contact your technical manager

Incorrect trigger handling

Trigger activated too quickly

Reactivate trigger

Trigger malfunction

Contact your technical manager

SIM fault

SIM memory fault

Contact your technical manager

Page 35

Doc ref. : 332190D – EN

28.04.2014

Page 35 / 49

6.2 Faults communicated by receiver

To indicate faults, the receiver uses 4 indicator lights, V1 to V4.

The 2 white indicator lights, « V1 and V2 », indicate the status of the receiver safety functions.

The red and green indicator lights, « V3 and V4 », indicate the status and processing of radio signal reception.

V1 status

V2 status

Error detected

Cause(s)

Action(s)

On steady

Off

None

Handle on charger

None

On steady

On steady

None

Handle active

None

On steady

1 flash

Reset fault

Reset not done

Place handle on charger and

activate reset button on control panel

“Handle on charger” contact open or

wiring of contacts has been reversed

Check wiring of 2 handle presence

contacts

Radio link between handle and receiver

not established (V4 off)

Perform a scan to check that handle

and receiver are on same frequency

channel. See section “Frequency

channel selection”

In "area access" mode, gate passage

button on handle has not been

released following gate passage

request.

Place handle on its charger and

activate reset button on the control

panel to cancel error

Off

Off

Communication

problem

Problem internal to product

Return to factory

On steady

2 flashes

Protection inactive

Emergency stop button(s) locked or

gate contacts open

Check condition of buttons and

contacts, and wiring

On steady

3 flashes

Time delay error

Contacts of a safety component

(emergency stop or gate) have not

been activated in required time frame

- Close its contacts simultaneously.

- Place handle on its charger.

- Press reset button.

Once removed from its charger, handle

has not been started up within a

sufficiently short time (T0 > T defined

by 2 “A” selectors)

Repeat handle start-up procedure or

increase handle pickup time delay

On steady

4 flashes

Reset button fault

Contact on reset button has remained

closed

Check condition and type of reset

button contact (pulse type

pushbutton)

Off or 5 flashes

Off or 5 flashes

Adjustment error

« A » or « B » selectors not aligned on

same position.

« Off » status or « 5 flashes » status

depends on whether selectors have

been set with power on or with power

off

Switch off receiver power supply and

check position of A and B selectors

On steady

6 flashes

Charger contact

error

At least one of the charger contacts

has remained closed at moment the

was started up

Check condition of charger contacts

(NO contacts, handle off charger)

6 flashes

Off

Under-voltage

6 flashes on V1: Receiver power

supply voltage is less than 0.85Un

Check receiver power supply

Off

6 flashes

Over-voltage

6 flashes on V2: Receiver power

supply voltage is greater than 1.15Un

Page 36

Doc ref. : 332190D – EN

28.04.2014

Page 36 / 49

Off

7 flashes

Error on input(s)

One of the emergency stop inputs is

incorrectly wired

Check wiring of emergency stop or

gate inputs

8 flashes

8 flashes

Safety relay error

One of safety relays K1 or K2, or

associated control circuit, is faulty

Return to factory

Off

8 flashes

Safety relay error

Return loop to terminals Y1-Y2 not

closed when safety outputs are inactive

Check loop Y1 and Y2 and contacts

of external relays K3, K4.

Off

9 flashes

Relay K1-K2 error

Control circuit of one of the safety

relays is faulty

Return to factory

Off

10 flashes

11 flashes

Program error

An error has occurred during execution

of program

Return to factory

Off

12 flashes

Version error

Software versions of the 2

microprocessors are different

Return to factory

Off

13 flashes

14 flashes

Memory error

Memory is faulty

Return to factory

6.2.1 V3 and V4 LED status

The V3 (red) and V4 (green) led states describe a malfunction in the radio part of the safety receiver.

Name of Led

and colour

Mode

Indication

Message

State

V3

indicator light

(RED)

Normal

Indicates validity of

identity code

Message not received

OFF

Message received with

correct identity code

OFF

Message received with

incorrect identity code

Flashing

regularly

Serial link

ON

In case of

fault

Indicates a fault

Power supply error

2 flashes

Safety relay

3 flashes

EEPROM

4 flashes

RAM

5 flashes

ROM

6 flashes

Micro type

7 flashes

V4

Indicator light

(GREEN)

Normal

Indicates radio

reception quality

No radio reception

OFF

Bad radio reception

Flashing

Good radio reception

ON

Serial link

OFF

In case of

fault

Indicates a fault

Power supply error

2 flashes

Safety relay

3 flashes

EEPROM

4 flashes

RAM

5 flashes

ROM

6 flashes

Micro type

7 flashes

Page 37

Doc ref. : 332190D – EN

28.04.2014

Page 37 / 49

7 Servicing

BEFORE PERFORMING ANY MAINTENANCE OPERATION, MAKE SURE THE RECEIVER AND CHARGER

POWER SUPPLIES ARE CUT OFF.

7.1 Servicing the wireless enabling handle

The handle can only be disassembled by properly trained personnel working in a “controlled” environment; parts must only

be replaced by genuine, identical spare parts.

The user’s attention is drawn to the risks involved in using the handle in an environment containing polymer solvents or

glues which could impact correct operation of the mechanical components of the handle.

Clean the enabling handle by eliminating any foreign matter which may be sticking to the handle.

Do no use any aggressive cleaning agents. Use only a soap solution when cleaning the handle.

7.2 Servicing the charger

Check that the handle charging receptacle is clean and dry.

Do no use any aggressive cleaning agents. Use only a soap solution when cleaning the handle.

8 Maintenance

The level of accessibility to the spare parts will depend on the level of training of the end user:

Level 1 : Spare parts not requiring any tools or special know-how. Example : Battery, handle front panel, SIM card,…

Level 2 : Level 2 spare parts are only accessible to customers who have completed a level 2 training course, and to the

JAY Electronique service stations.

8.1 Setting a backup handle into service

Step 1 : Open the broken or faulty handle.

If the handle has been lost or is not available, reprogram a SIM card using the dialog RSP software (see installer if

necessary).

Step 2 : Remove the SIM card and install it in the backup handle.

Step 3 : Close the backup handle.

Step 4 : Have the faulty handle repaired.

8.2 Replacing a receiver.

Step 1 : Cut off the power supply

Step 2 : Disconnect the removable terminals on the receiver

Step 3 : Program the new receiver identically to the faulty receiver (see position of A and B selectors accessible under the

window on the front panel of the receiver.

Step 4 : Connect and supply the new receiver.

8.3 Replacing a charger.

Cut off the power supply and disconnect outputs S1 and S2

Associate the new charger to the handle. See section « Setting the charger into service »

Page 38

Doc ref. : 332190D – EN

28.04.2014

Page 38 / 49

9 Warranty

All our devices are guarantied 2 years as of the date of manufacture indicated on the product (except for the

enabling handle battery which has 1 year warranty). No repair, modification or replacement of a product during the

warranty period can be understood as an extension of the warranty period.

Limits of warranty:

The warranty does not cover defects resulting from:

• Transport,

• False manoeuver or non-observance of connection diagrams when setting the equipment into service,

• Insufficient supervision or servicing, utilization not complying with the specifications detailed in the technical manual

and, as a general rule, storage, operation or environment conditions (atmospheric, chemical, electrical or other

conditions).

• Conditions not specified on order of the equipment.

The warranty shall not apply subsequent to any modifications or additions to the equipment performed by the

customer without written approval by JAYElectronique.

The JAY Electronique responsibility during the warranty period is limited to material and construction defects. This

warranty comprises repair in the JAY Electronique workshops or replacement, free of charge, of parts recognized to

be defective following expert inspection by the JAY Electronique Technical Department.

The warranty shall not give rise to any compensation for damage claims.

Any disputes relative to a supply or settlement thereof shall be ruled by the COURT OF COMMERCE OF

GRENOBLE, solely competent, even in the event of an Appeal or a plurality of defendants.

Page 39

Doc ref. : 332190D – EN

28.04.2014

Page 39 / 49

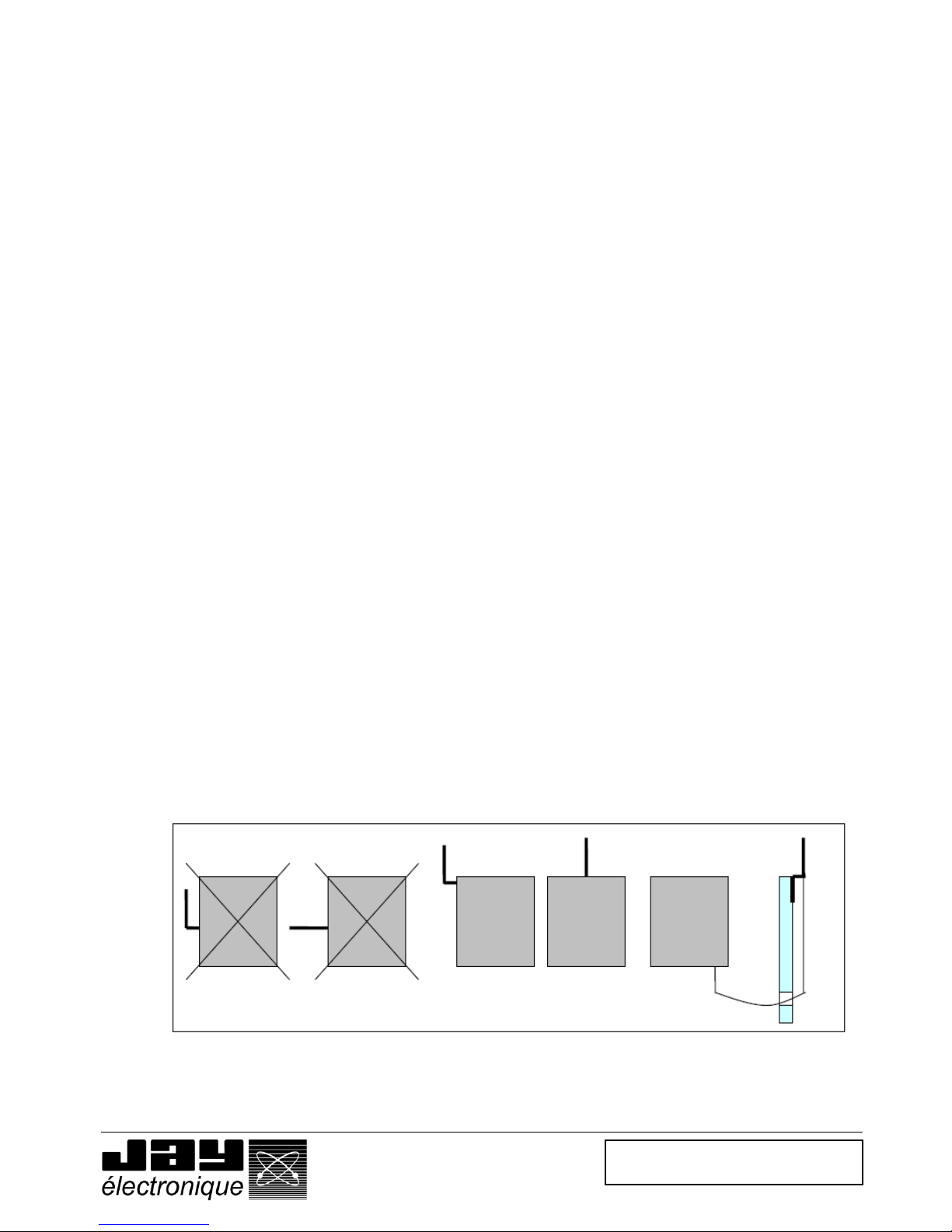

10 Appendices

10.1 Dimensions of components (mm)

Wireless enabling handle RSEP Charger RSCP

Receiver RSRB Infrared module UDF

(for "IR start-up" option)

Plug-in BNC antennas Voltage adapter RSCU 230VAC/24VDC

Page 40

Doc ref. : 332190D – EN

28.04.2014

Page 40 / 49

10.2 Technical characteristics

10.2.1 Wireless enabling handle RSEP

Mechanical and environment withstand characteristics

Housing material : Two-material plastic

Protection index : IP 54

Weight (with battery) : 340 g

Operating temperature range : -20 °C to + 50 °C

Storage temperature range : -20 °C to + 45 °C

Charging temperature range : 0 °C to + 35 °C

Electrical and radio characteristics

Power supply : Li-Ion battery

Endurance (at 25°C) :

Trigger activated : 8 hours

Trigger not activated : 40 hours

Complete charge duration : 6 hours

Radio transmit frequencies :

(Interval between adjacent channels : 0.025 MHz)

RSEP40 : 64 frequencies, from 433.100 MHz to 434.675 MHz

RSEP41 : 25 frequencies, from 434.075 MHz to 434.675 MHz

Transmit power : <10 mW

Average range in typical industrial environment (1) :

RSEP40 : 150 m

RSEP41 : 250 m

Functional characteristics

Display : Backlighted LCD

Function button type :

4 single-acting pushbuttons

Trigger : 3 or 2 positions

Range limitation : configurable

Indications :

Radio channel, battery level, diagnostic, displayable on enabling handle screen

Configuration of functions and display :

Configurable by PC software

(1)= Range will vary according to environment conditions of enabling handle and receiver reception antenna (frameworks, metal partitions, … ).

10.2.2 Charger RSCP

Mechanical characteristics

Housing material : Plastic

Protection index : IP 40

Electrical characteristics

Power supply voltage : 24 V DC +/- 5%

Consumption when charging : 300 mA

Contact (handle detection) : 2 NO / 8 A

Handle detection : by infrared (contactless)

Type of charge : by induction (contactless)

Page 41

Doc ref. : 332190D – EN

28.04.2014

Page 41 / 49

10.2.3 Receiver RSRB

Mechanical and environment withstand characteristics

Housing material : Plastic

Protection index : IP 40

Weight : 500 g

Operating temperature range : 0 °C to + 50 °C

Storage temperature range : - 30 °C to + 70 °C

Connection : Screw terminals for wires 0.08² to 2.5²

Antenna : 1/4 wave, as accessory, plug-in on BNC connector

Electrical characteristics

Power supply voltage : 24 V DC +/- 15%

Max. consumption : 120 mA (solid state outputs not loaded)

Safety relay outputs :

Contacts : 3 NO with guided contacts

Triggering time (reaction) :

• Active stop time following clenching or release of trigger : 50 ms

• Passive stop time : 300 ms

Max. switching voltage : 250 V AC

Switching power :

• Per AC 15 : AC 3 A / 230 V for NO contacts EN60947-5-1

• Per DC 13 : DC 8 A / 24 V at 0.1 Hz EN60947-5-1

Electrical service life :

• Per AC15 at 2A, AC230V : 100 000 cycles EN60947-5-1

Solid state outputs :

Number and type of outputs : 6 PNP outputs

Output voltage : 24 V DC, 100 mA max.

Indication : 6 indicator lights

Page 42

Doc ref. : 332190D – EN

28.04.2014

Page 42 / 49

10.3 Indicator lights and assignment of receiver outputs

Terminal

Function

Terminal

Function

Safety inputs and outputs

Solid state outputs assigned to enabling handle

A1+

24VDC power supply for receiver safety

module RSRB

A3+

24VDC power supply for solid state outputs

assigned to enabling handle

A2 -

Common ground

A2-

Common ground

48

24V solid state output : safety module status

17

enabling handle on charger indication

58

Enabling handle utilisation status

27

37

47

57

67

77

Function outputs (see detail below)

S11

S12

Input 1 for first emergency stop or first safety

light barrier

S13

S14

Input 2 for first emergency stop or first safety

light barrier

S21

S22

Input 1 for second emergency stop or second

safety light barrier

S23

S24

Input 2 for second emergency stop or second

safety light barrier

Connection for infrared module (UDF)

A5+

12VDC output

S31

S32

Input for monitoring of 1st charger

IR

Receiver signal

A2-

Common ground

S33

S34

Input for monitoring of 2nd charger

S42

Input for wired START pushbutton

Y1

Y2

Input for auxiliary relay return loop

13

14

1st safety output (NO contact)

23

24

2nd safety output (NO contact)

33

34

3rd safety output (NO contact)

«4 control buttons» mode (on delivery) «Function selection» mode

In this mode, the outputs are activated as follows : In this mode, the outputs are activated as follows

Removable connection

block, screw terminals

White ind. lights V1 and V2

"Safety module status"

Green ind. lights K1 and K2

"Safety relay status"

Red ind. light V3

"Wrong identity code or diagnostic"

BNC connector