JAVAC CC-31, CC-141, CC Series, CC-231, JAV-1065 Safety Instructions & Operation Manual

...

CC-31 (UK)

JAV-1069 (EU)

CC-141 (UK)

CC-231 (UK)

JAV-1065 (EU)

JAV-1067 (EU)

CC SERIES VACCUM PUMP

EN

Safety Instructions & Operation Manual

FR

Instructions de sécurité et notice d’utilisation

DE

Sicherheitsanweisungen und Bedienungsanleitung

ES

Instrucciones de seguridad y manual de funcionamiento

IT

Istruzioni di sicurezza e manuale d’uso

EN

CC SERIES VACCUM PUMP

Thank you for purchasing a JAVAC product.

Please read this operation manual carefully before use.

Only suitably qualied personnel should operate this equipment.

CONTENTS

1.0 APPLICATION

2.0 PUMP COMPONENTS

3.0 BEFORE STARTING

4.0 TROUBLE SHOOTING

5.0 GUARANTEE

1.0 APPLICATION

CC - Series two-stage oil sealed rotary vane vacuum pumps are basic equipment to evacuate

domestic, automotive and light commercial refrigeration and AC equipment. They are suitable for use

with R134A, R22 and compatible refrigerants.

2

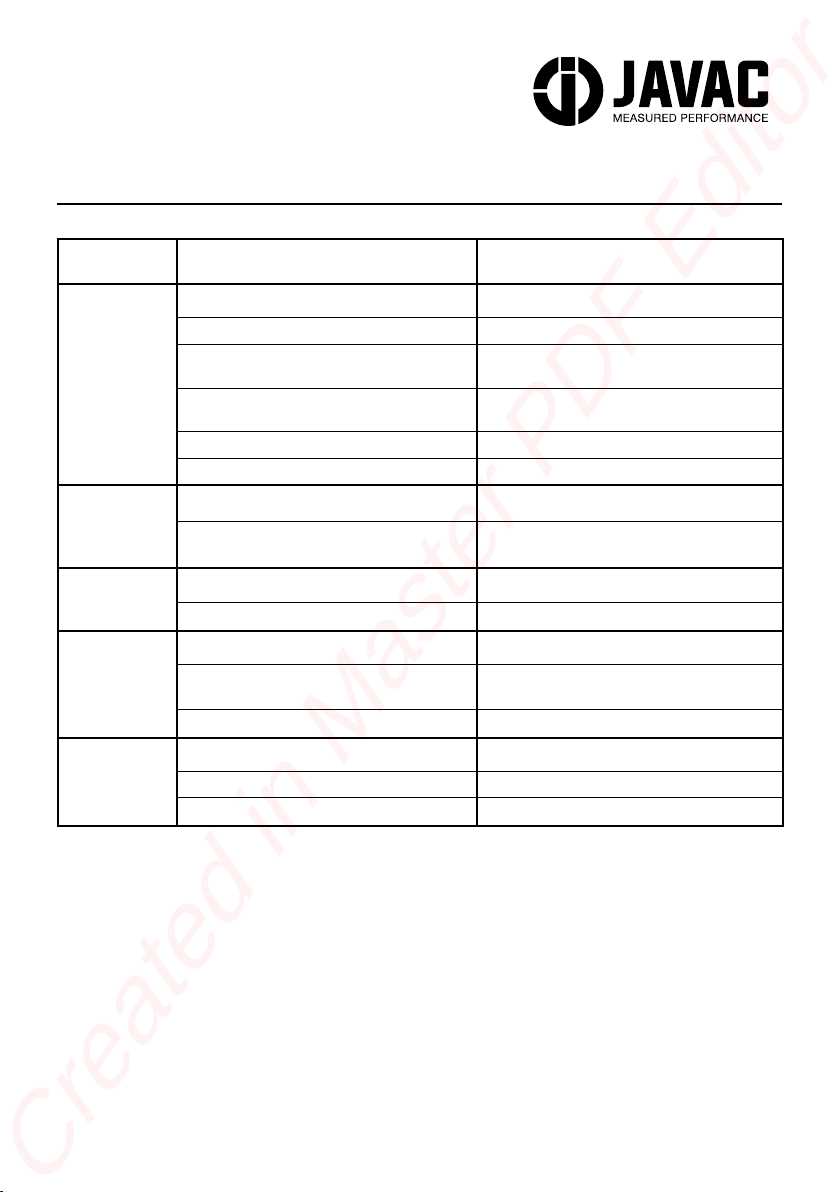

2.0 PUMP COMPONENTS

Exhaust

tting

Board

MODEL CC-31 CC-141 CC-231

VOLTAGE

FREE AIR DISPLACEMENT

(CFM / L/M)

Plate

Intake

tting

Gas

Ballast

Power

Switch

Fan CoverMotorBase

110 V / 240 V 50 Hz

1.4 / 40 5.3 / 140 9, 225

Sight Glass

Oil Tank

Oil Drain

ULTIMATE VACUUM

MOTOR

MOTOR SPEED

OIL CAPACITY

DIMENSIONS

NET WEIGHT

15 Microns 15 Microns 12 Microns

1/4 HP 1/3 HP 2/3 HP

1440 r/m 2880 r/m 2880 r/m

380 ml 450 ml 500 ml

330 x 135 x 255

mm (130” x 53”

x 100”)

9.8 Kg (21.6 lbs) 12 Kg (21.6 lbs) 15.5 Kg (34 lbs)

350 x 135 x 255

mm (138” x 53” x

100”)

380 x 160 x 285

mm (150” x 63” x

112”)

3

EN

3.0 BEFORE STARTING

Add vacuum pump oil and always check the oil level before use. Low oil level or poor quality oil will

result in premature wear and poor performance.

Install on a at surface with adequate ventilation; allow 5cm on all sides of the pump.

Remove the intake and exhaust tting cap and connect via a suitable hose to a manifold or suitable

circuit.

Connect to a suitable safe power source using earth leakage devices when using extension cords.

CAUTION:

• Do not use with combustible, explosive, poisonous or reactive/corrosive gases.

• Do not allow dust particles to enter the pump.

• Do not allow the pump to run to open air / atmosphere for more than 3 minutes.

• Do allow the inlet temperature of gases to exceed 80’C. Do not use in environments over 50°C.

• Not suitable for use as a compressor, transfer pump or recovery pump.

• Do not operate without oil.

• Pump surface may be hot.

• Do not block air outlet when pump is in use.

• Suitable for indoors use only.

4

4

4.0 TROUBLE SHOOTING

PROBLEM CAUSE ACTION

POOR

VACUUM

OIL

LEAKAGE

OIL

DISCHARGE

OVERHEATING

DIFFICULT

STARTING

4.1 Oil insucient

4.2 Pump oil emulsied, not clean

4.3 Oil inlet blocked or oil feeding

inadequate

4.4 Pump hose or vessel leak

4.5 Improper pump chosen

4.6 Worn oomponents

4.7 Oil seal damaged

4.8 Oil casing gasket loose or

damaged

4.9 Too much oil

4.10 Inlet pressure too high

4.11 Temperature below +5C

4.12 Motor overloaded

4.13 Foreign matter falling in the pump

4.14 Low voltage

4.15 Overheated

4.16 Safety if in any doubt

Add oil to centre line of oil scale

Replace with new oil

Clean oil inlet and ltering

screen

Check hose and vessel for leakage and

repair

Pump too small - use larger pump

Repair or replace with a new pump

Replace with a new oil seal

Tighten screws or replace O-type ring

Drain oil to oil base line on sight glass

Use recovery pump to remove pressure

Allow temperature to rise

Wait 5 minutes, re start, or press motor

reset if installed

Check and eliminate the foreign matter

Avoid long extension leads

Check fan, ventilation and repair

Consult JAVAC

5

Loading...

Loading...