Translation of the original operating instructions

JAUDT

Dosiertechnik

Maschinenfabrik

GmbH

Metering, feeding,

removal, shutting off,

regulating and controlling

Raiffeisenstraße 3-5

D-86167 Augsburg

Tel. +49 821 796 05-0

Fax +49 821 796 05-67

+49 821 796 05-69

verkauf@jaudt.de

www.jaudt.de

JAUDT – VARIO-SLIDE VALVE

FSV 6110…

Contents

1 DESCRIPTION .................................................................................................................. 2

1.1 Validity of these operating instructions................................................................. 2

1.2 Identification ......................................................................................................... 2

1.3 Reference documentation .................................................................................... 2

1.4 Technical prerequisites for operation of power-operated slide valves ................ 3

2 NOTES ON SAFETY ........................................................................................................ 3

2.1 Scope of application ............................................................................................. 4

2.2 Noise emission ..................................................................................................... 5

3 TRANSPORT AND STORAGE......................................................................................... 5

3.1 Transport .............................................................................................................. 5

3.2 General storing instructions ................................................................................. 5

4 INSTALLATION, START-UP, OPERATION ..................................................................... 6

4.1 Installation ............................................................................................................ 6

4.2 Start-up ................................................................................................................. 7

4.3 Operation .............................................................................................................. 7

5 MAINTENANCE ................................................................................................................ 8

6 INSPECTION AND SERVICING ....................................................................................... 8

6.1 How to adjust and replace the stuffing box gland ................................................ 9

6.2 Airmatik seal ....................................................................................................... 10

6.3 Electric motor drive ............................................................................................. 11

6.4 Electropneumatic drive ....................................................................................... 11

7 DRIVES ........................................................................................................................... 12

8 SPARE PARTS STANDARD VERSION ......................................................................... 13

9 ORDERING SPARE PARTS .......................................................................................... 15

10 TROUBLESHOOTING .................................................................................................... 15

11 CLEANING ..................................................................................................................... 16

12 DISPOSAL ...................................................................................................................... 16

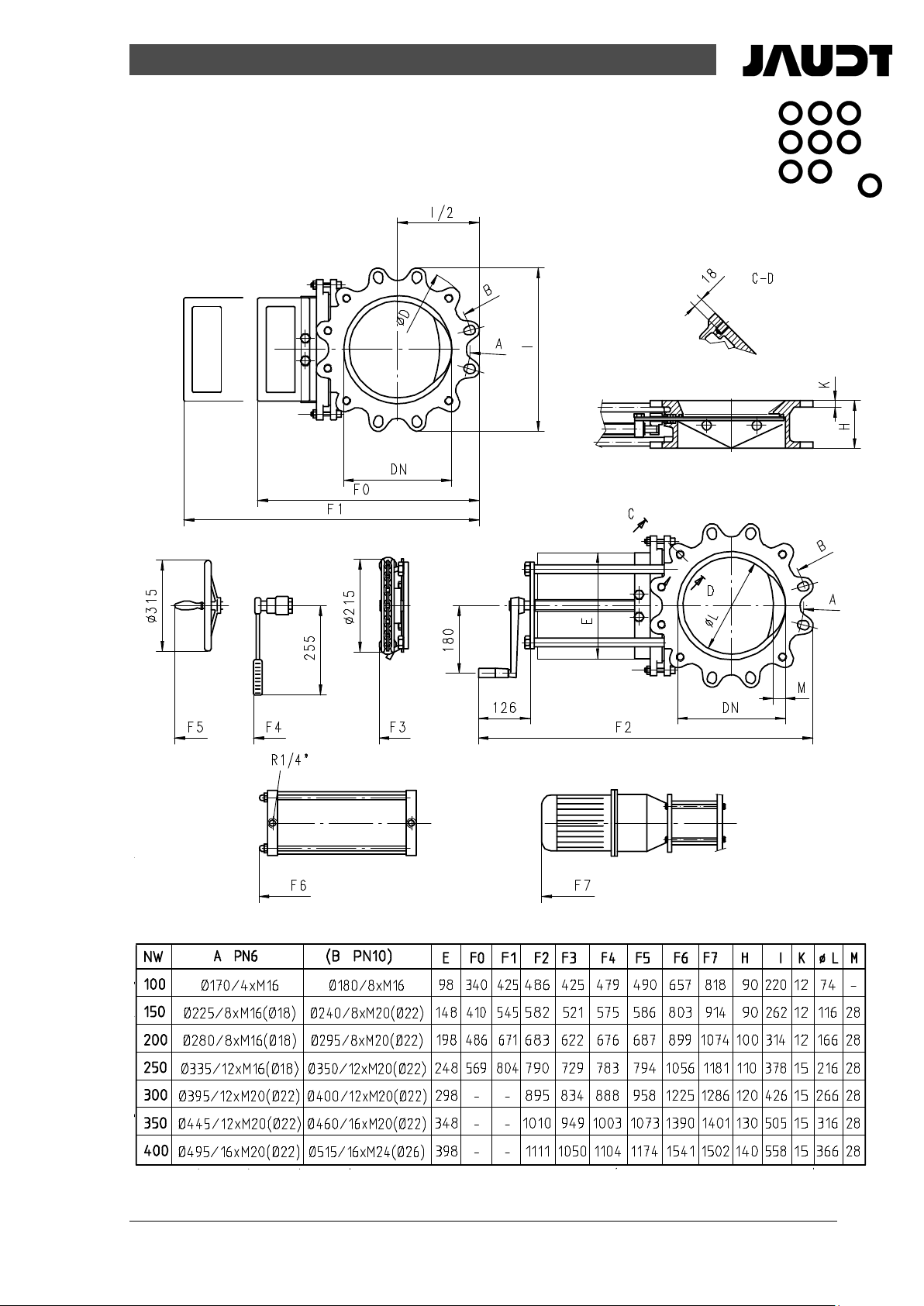

13 DIMENSION SHEET FOR STANDARD VERSION ........................................................ 17

14 DECLARATION OF INCORPORATION ......................................................................... 18

15 APPENDIX ...................................................................................................................... 19

© BA6110.0002_EN_Rev11.docx

Operating Instructions FSV 6110…

1 Description

JAUDT vario-slide valves serve the purpose of shutting off and metering liquid media and

free-flowing powdery to fine-grained bulk materials. JAUDT vario-slide valves are robust, tight-closing and

require little maintenance.

1.1 Validity of these operating instructions

These operating instructions are applicable to JAUDT vario-slide valves with nominal diameter 100, 150,

200, 250, 300, 350, 400, 500 and 600 mm with following operating equipment:

Manual operation with handle, hand crank, hand wheel, ratchet or chain

Electric motor drive

Electropneumatic drive

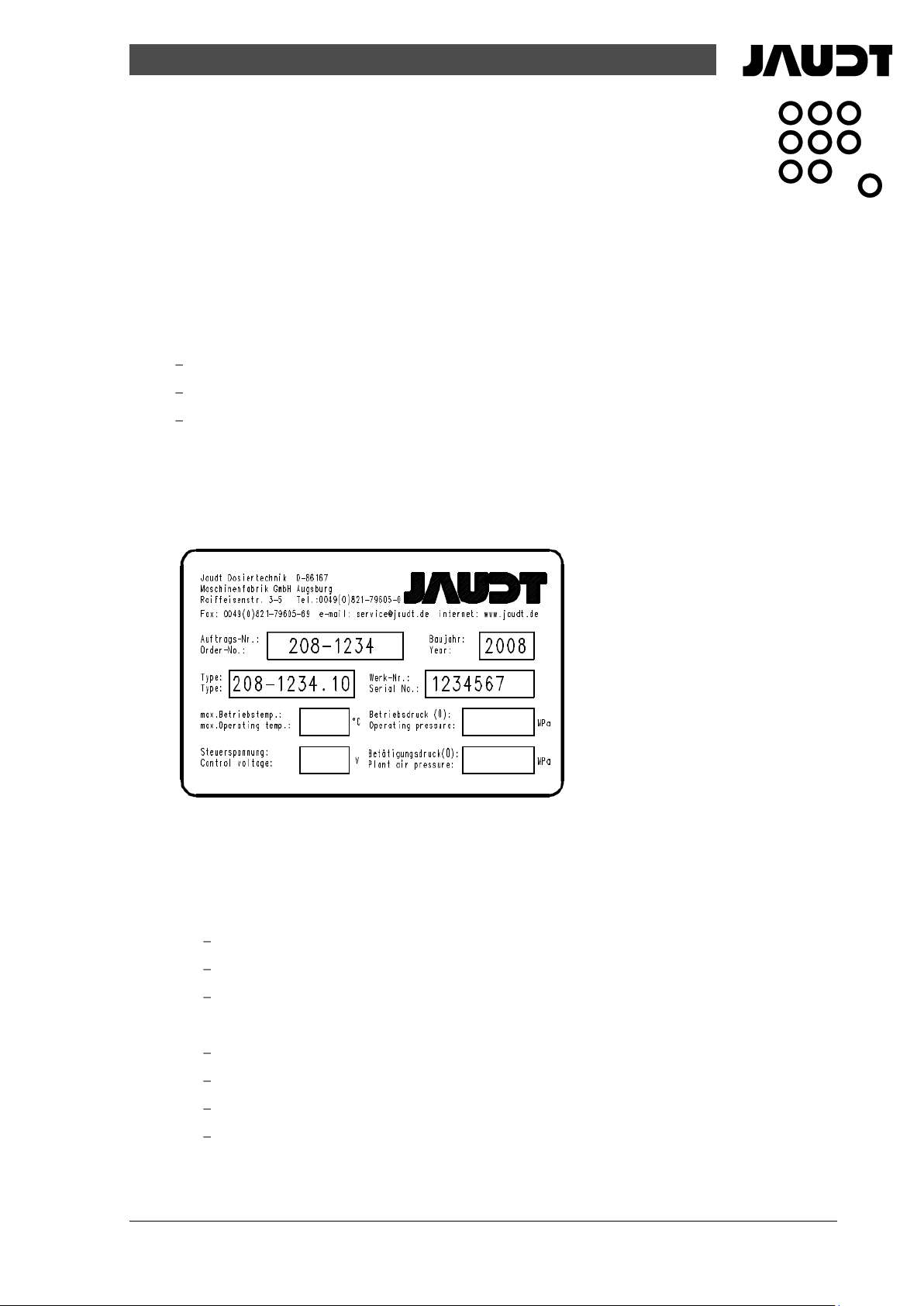

1.2 Identification

A type plate is affixed to each JAUDT vario-slide valve and identifies the vario-slide valve.

The paint and the accessories are not defined in the type number.

Please always indicate the type and order number when ordering spare parts or asking ques-

tions.

1.3 Reference documentation

The order confirmation is a constituent part of this instruction manual and lists the following information:

Model, identical with the model on the nameplate

Designated application; the design of the slide valve will be customised to this application

Technical data relating to slide valve and, where applicable, technical data relating to drive

The following additional documents are appended to every instruction manual:

Dimension sheet

Manual incl. lubrication chart for motor (if supplied with motor)

Data sheet for limit switch or solenoid valve (if supplied with limit switch or solenoid valve)

ATEX insert if required to conform to RL94/9/EC or used in areas at risk of explosion

These enclosures and appendices form a constituent part of this instruction manual!

© BA6110.0002_EN_Rev11.docx Page 2 of 19

Operating Instructions FSV 6110…

Be careful! Danger of death!

This sign draws your attention to a danger to people because of electrical connections.

Be careful! Danger of injury!

This sign draws your attention to a danger that represents a threat to people.

Be careful! Damage to material!

This sign draws attention to an act that might cause damage to the JAUDT slide valve.

•

This dot prompts you to take action. Extreme care must be taken to carry out the

necessary steps in the right order.

1.4 Technical prerequisites for operation of power-operated

slide valves

The valve must be securely enclosed in order to protect against injury. If this enclosure was not ordered or

the operator converts the valve, the regulations of the Machine Directive must be observed. JAUDT supplies enclosures which can be adapted to the different requirements.

Supply voltages:

Refer to voltage specifications in the reference documentation (Section 1.3).

Compressed air:

Electropneumatic drive: 0.5...1.0 MPa (5...10 bar absolute), filtered, free of water and oiled.

2 Notes on safety

Take particular care to ensure that local accident prevention regulations are observed.

Before starting to do any work on the JAUDT vario slide valve, take the necessary steps to make sure that

the drive unit is switched off/disconnected and that the appropriate control staff have been informed. If aggressive or hot substances are being stopped by the JAUDT vario slide valve, suitable safety precautions

must be made before work on the slide valve begins. They include protective clothing, breathing apparatus, positioning of collection containers.

If there is a safety officer and/or an environmental protection officer, he/she/they must be informed before

work begins.

JAUDT vario slide valves are based on a state-of-the-art design. Nevertheless, personal injury and damage to property can occur due to carelessness. We provide appropriate warnings in the form of corresponding information. This information is emphasised by special symbols.

© BA6110.0002_EN_Rev11.docx Page 3 of 19

Operating Instructions FSV 6110…

FSV Ø150

FSV Ø200

FSV Ø250

FSV Ø300

FSV Ø350

FSV Ø400

FSV Ø500

6 bar

5 bar

4.5 bar

4 bar

3 bar

3 bar

1,5 bar

Material

Component

Max. operating temperature

Aluminium

Housing, thrust piece

150 °C

GG 25

Housing

420 °C

1.4581

Housing

500 °C

1.4301

Slide plate

500 °C

Aramide

Gland

280 °C

NBR

O-ring

120 °C

Silicone

Airmatik seal

200 °C

2.1 Scope of application

2.1.1 Seal variants

- JAUDT vario-slide valves without an O-ring seal or Airmatic seal

are suitable only for free-flowing materials with a particle size of 0.05 ... 6 mm,

e.g. ash, filter dust, plaster, lime, flour, dry salt, sand, cement, sugar

- JAUDT vario-slide valves with an O-ring seal in the intake collar

are dust-tight and are suitable for free-flowing materials with a particle size of less than 0.05 mm and for

non-aggressive liquids (after consultation with JAUDT), e.g. filter dust, flue dust, mash, water

- JAUDT vario-slide valves with an O-ring seal in the gland (goggle seal)

are dust-tight to the outside; gas-tight to the outside in accordance with DIN 3230 Part 3 leakage rate 3

(blowing) to 0.5 bar and approx. 1000 strokes – thereafter adjustment or seal change is required.

- JAUDT vario-slide valves with an Airmatic seal

This is a pneumatically charged hollow-profile seal that permits greater tightness in the opening of the

JAUDT valve.

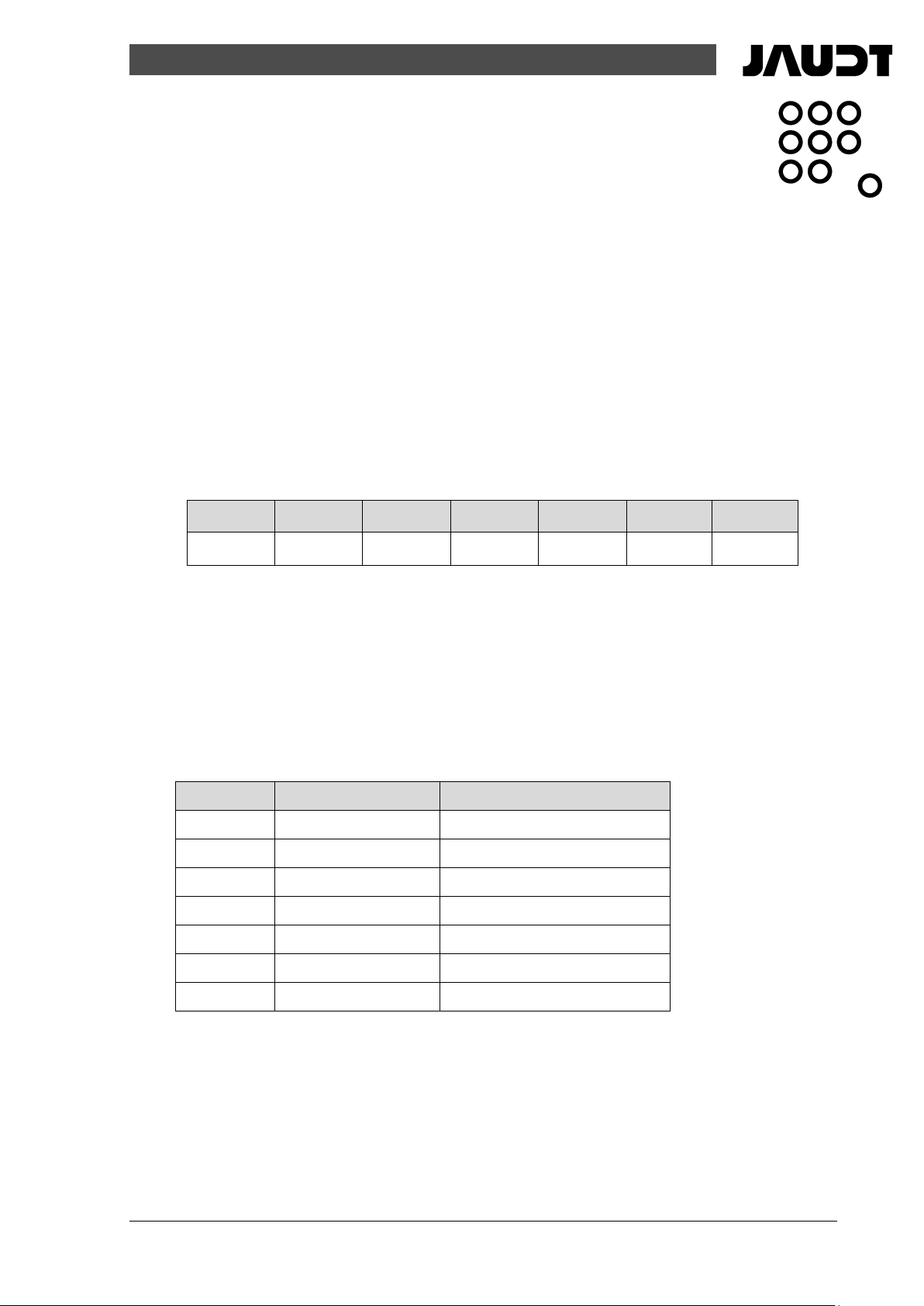

The pressure-tightness given above depends on the nominal diameter. These figures can be taken from

the following table (max. tightness):

In principle, a 2 bar higher seal pressure is required or tightness in the opening = operating pressure – 2

bar!

In the event of an application deviating from the above contact JAUDT GmbH for expert advice.

2.1.2 Temperature limits

The operating temperature must not exceed the value defined in the order. The table below shows a selection of the maximum operating temperatures depending on the component material:

© BA6110.0002_EN_Rev11.docx Page 4 of 19

Operating Instructions FSV 6110…

2.1.3 Misuse

JAUDT vario-slide valves must not be used to meter or shut off aggressive liquids (acids,

alkaline solutions) and liquid foods.

The conditions of use must not exceed the load limits of the materials used (e.g. corrosion, temperature).

JAUDT vario-slide valves which are intended for manual operation must not be connected to an external

drive.

For instance, the chain drive must not be connected to a motor drive.

2.2 Noise emission

The noise emission is 85 dB (A) in the productless operation. With higher noise emission in the plant group

and in the regular operation suitable measures are to be met by the plant engineer.

3 Transport and storage

3.1 Transport

To ensure the O-ring seal (optional) is not damaged, JAUDT vario-slide valves should only be trans-

ported and stored in the "Slide valve closed“ -position.

Transport the slide valve lying on its discharge flange.

Secure the slide valve properly to prevent it suffering shocks and blows and prevent damaging the

paintwork by placing suitable elements between the securing tape and the slide valve.

Secure the slide valve to prevent it slipping and protect the particularly exposed parts such as the

drive unit and accessories.

3.2 General storing instructions

Store the slide valve lying on its discharge flange.

Cables, hose lines, the drive unit and mounted accessories must be protected properly from damage.

Recommended storage temperature -10°C…+40°C.

Max. relative humidity 65%.

Store the device in a dry, dust-free place and pay attention to the storage temperatures, especially in

extreme climes like the tropes, the desert, or very cold regions.

Do not store device in aggressive atmosphere or together with aggressive media like acid, oil, dissol-

ver or salt.

Precautions for a long-term storage (more than three months):

Protect unfinished device parts with an anti-corrosion coating, e.g. with a film of oil.

Seal the device against the ingress of dust and moisture.

Operate the device once a year.

Do not store the device more than four years.

© BA6110.0002_EN_Rev11.docx Page 5 of 19

Operating Instructions FSV 6110…

NW [mm]

Ø 100

Ø 150

Ø 200

Ø 250

Ø 300

Ø 350

Ø 400

Ø 500

Load [kg]

200

300

400

500

740

870

990

1000

Storing packing, plastic parts, glands and sealings

(conditions according to DIN 7716)

Recommended storage temperature -10°C …+40°C.

Max. relative humidity 65 %.

Store the slide valve in a dry, dust-free place.

Do not store the glands in an oily or aggressive atmosphere.

Protect against sunlight.

Store glands and sealings flat lying and in the original packing.

4 Installation, start-up, operation

4.1 Installation

This installation work should only be carried out by a specially trained installation technician.

Work on the electrical system must only be carried out by a qualified electrician.

JAUDT vario-slide valves are supplied assembled ready for operation.

Before installation, check that the vario-slide valve is adjusted correctly. Adjust the slide valve if neces-

sary:

Check that the thrust piece is at the correct distance from the housing (avoid canting).

Check that the slide valve closes tightly. Readjust the eccentric screws if necessary.

Inductive limit switch (optional): Check the "Slide valve OPEN“ - "Slide valve CLOSED“ settings.

Check that the O-ring seal (optional) is suitable for the particular application (see Section 2.1.2 e.g. ma-

terial, operating temperature).

4.1.1 Determine installation position

Installation position horizontal inclined by up to max. 30°.

Do not install slide valve upside down, refer to cover sheet for installation position.

4.1.2 Permissible suspension loads

© BA6110.0002_EN_Rev11.docx Page 6 of 19

Operating Instructions FSV 6110…

M8

M10

M12

M16

M20

M24

M27

M30

10 Nm

20 Nm

35 Nm

90 Nm

150 Nm

200 Nm

250 Nm

300 Nm

4.1.3 Notes on installation

Clean flange surfaces.

Align the JAUDT vario-slide valves such that the opening forms a funnel for the flow-

ing bulk material.

Fit a seal at the pipe flanges (not supplied).

Caution Material Damage!

Install the JAUDT vario-slide valve free of tension - otherwise risk of material damage.

Carefully observe the following installation instructions.

Align the JAUDT vario-slide valve with respect to the piping system.

Check parallel alignment of the counterflanges.

Tighten the connection elements crosswise.

Max. tightening torques:

4.2 Start-up

Start-up work should only be carried out by specially trained personnel.

Work on the electrical system must only be carried out by a qualified electrician.

Caution Danger of Injury!

Make sure that the system is switched off and secured

to prevent it being switched on again. Inform the control room.

Check the JAUDT vario-slide valve when installed

for low-noise and smooth operation of the slide valve

for leaks

that the securing elements are firmly tightened

Additional checks for power-operated versions:

Check the electropneumatic system with regard to function and leaks.

Check that the electric motor is connected correctly.

Inductive limit switch: Check the switch positions "Slide valve OPEN“ and "Slide valve CLOSED“.

4.3 Operation

Observe the notes on safety.

Operation of JAUDT vario-slide valves is simple in all drive variants.

Caution Danger of Injury! – Manually operated vario-slide valves:

Always wear protective gloves when metering hot materials

– Danger of burns.

Depending on the type, open and close the JAUDT vario-slide valves with the handle, hand crank, hand

wheel, ratchet, sprocket, electric motor or electropneumatic drive.

© BA6110.0002_EN_Rev11.docx Page 7 of 19

Operating Instructions FSV 6110…

Inspection

every 3 months

Servicing

every 3 months

Under constant working cycles or critical operating conditions

every 6 months

For other applications as stop slide valve

Comply with the inspection and servicing intervals for vendor parts – see "Reference Documentation“ (Section 1.3).

Be careful! Danger of injury!

Make sure that the equipment has been switched off before work starts and that

precautions have been taken so that it cannot start up again unintentionally. Inform

the appropriate control staff.

Be careful! Danger of injury! – When substances that are hot or irritate the skin are

being metered.

Protect yourself by wearing protective clothing, safety goggles, breathing apparatus.

Inform the safety and environmental protection officer(s).

Keep a suitable collection container close at hand.

Be careful! Danger of death!

Made sure that the drive unit has been switched off or disconnected. Make sure that

the equipment has been switched off before work starts and that precautions have

been taken so that it cannot start up again unintentionally. Inform the appropriate

control staff.

5 Maintenance

Maintenance includes servicing, inspection and repairs.

Maintenance should only be carried out by JAUDT GmbH.

Servicing and inspection should only be carried out by specially trained qualified personnel.

Work on the electrical system must only be carried out by qualified electricians.

Special tools for maintenance:

You do not need any special tool beside the current tools like spanner, Allen key, screwdriver,

feeler gauge and calliper rule to maintain your JAUDT-device.

But we suggest to use a capable lifting system for heavy device parts and, if necessary, protecting

clothing.

To identify needed special tools for mounted accessories from other manufacturer please consider

their operating manual.

6 Inspection and servicing

Inspection must also be carried out as part of the servicing work.

Indicates inspection- or servicing work

© BA6110.0002_EN_Rev11.docx Page 8 of 19

Operating Instructions FSV 6110…

Refer to "Spare parts“ (Section 8) for illustrated assembly instructions.

Check that the screws and securing elements are firmly in place. Remove any dirt

and rust.

Lubricate the spindles with suitable grease.

Carry out a visual inspection. If necessary, replace any damaged components.

Check that the vario-slide valve does not leak. Tighten the packing goggle if necessary.

If necessary, replace worn seals and adjust the eccentric screws.

Check the vario-slide valve for smooth movement and noise emission.

If necessary, disassemble and clean the JAUDT vario-slide valve.

Always replace the self-locking screws.

Disassemble and clean the vario-slide valve. Always replace the self-locking screws.

Replace the seals and adjust the eccentric screws such that there is a gap of 0.5 mm between the

slide plate and the housing collar. In the case of slide valves with the seal in the opening (O-ring) the

seal should abut the slide plate and completely surround the opening .

Adjust and replace the stuffing box gland (see Section 6.1).

6.1 How to adjust and replace the stuffing box gland

6.1.1 To adjust the stuffing box gland

If leaks occur on the stuffing box gland (material falling out) it must be adjusted. This is done using the nuts

on the thrust piece. Tighten all the nuts (up to a nominal size of Ø250 there are two, over a nominal size of

Ø300 there are five) evenly in sequence by half a turn at a time. The tightening torque should not exceed

approx. 20 Nm. The gland has been tightened correctly if the slide can be moved easily and no material is

drawn out with it.

6.1.2 To replace the stuffing box gland

If adjusting the gland does not produce the required result after it has been in use for some time, it should

be replaced. To do this, proceed as follows (see illustration in Section 8):

If necessary, remove the safety cover (S)

Undo the connection screws between the slide plate (5) and the spindle nut (7)

If necessary, remove the angle piece (switch lug) on the slide plate

Undo the M16 nuts on the rods (6)

Remove the drive

Undo the nuts on the thrust piece (4) and remove the thrust piece

Pull out the gland using a sharp object (marking scribe) and replace it with a new gland.

Please note: Offset the butt joints of the various gland cords

Assemble the unit again following the above instructions in reverse.

Replace the self-locking M16 nuts with new ones.

© BA6110.0002_EN_Rev11.docx Page 9 of 19

Operating Instructions FSV 6110…

6.2 Airmatik seal

6.2.1 General:

The Airmatik seal (21) is positively located in a profile groove below the intake collar of

the housing (1). Pressure is applied by means of the pneumatic connection on the housing. It must not be

applied before the slide plate (5) is fully closed. This is achieved by means of the mechanical valve (23)

being actuated into the "Closed" position.

6.2.2 Seal changes:

Use a screwdriver to raise the Airmatik seal (21) at a particular place and then remove it from the profile

groove along with the seal join (22). Examine the profile groove and remove any dirt and furrows.

Lightly grease the O-ring of the valve connection of the new seal and carefully insert the new Airmatik seal

completely into the place of the valve connection. Introduce the Airmatik seal into the groove evenly on

both sides, starting from the valve connection.

The profile of the seal must engage completely in the profile groove. If this does not happen completely,

there is a risk that the seal will be forced out of the groove under pressure and will be damaged. Suitable

tools can be ordered from Jaudt.

Do not use any tools with sharp edges, e.g. small screwdrivers, when installing the new Air-

Attention: Damage to materials!

matik seal!

Make sure the valve connection is properly located!

© BA6110.0002_EN_Rev11.docx Page 10 of 19

Operating Instructions FSV 6110…

ØD

A

Order-number

of the repair kit:

80

M16x1,5

601372

100

M16x1,5

318610.0001

125

M20x1,5

601108

160

M30x1,5

601109

200

M30x1,5

416610.0107

6.3 Electric motor drive

Work on the electrical system must only be carried out by qualified electricians.

Adhere to the "Reference Documentation“ (Section 1.3) as well.

Check the electric motor drive. If noise emission develops, replace the ball bearing between the gear

unit and spindle.

Ensure that the electrical connection is not oxidised, damaged or leaking.

Check the limit switches with regard to their function and technical condition.

Replace the lubricant sensor.

Ensure the accident prevention guard is firmly fitted.

Adjust and replace the stuffing box gland (see Section 6.1).

6.4 Electropneumatic drive

Work on the electrical system must only be carried out by qualified electricians.

Check the pneumatic supply (pressure) and drain off if necessary.

Ensure that all solenoid valves are operating correctly.

Check the pneumatic system for leaks.

Check the limit switches (optional) with regard to their function and technical condition.

Ensure that the electrical connection is not oxidised, damaged or leaking.

Ensure that the accident prevention guard is firmly fitted.

See Section 6.1 for details of how to adjust and replace the stuffing box gland

The cylinder pipe of the electropneumatic drive is dependently of the nominal size of the vario slide valve

equipped with different diameters ØD.

Overview of the repair kit of the electrpneumatic drive make JAUDT:

© BA6110.0002_EN_Rev11.docx Page 11 of 19

Operating Instructions FSV 6110…

Drive with hand wheel or

ratchet

Same as drive with hand crank

Drive with sprocket

Same as drive with hand crank. The chain must be routed through

both hooks.

Version with handle

The handle is secured directly to the slide valve.

7 Drives

The JAUDT vario-slide valve with hand crank, electric motor and electropneumatic drive is illustrated under

Section 8 (Spare Parts).

The other drive variants are assembled in the same way as the drive with hand crank:

© BA6110.0002_EN_Rev11.docx Page 12 of 19

Operating Instructions FSV 6110…

1

Housing

11

Lock pin

2

Eccentric screw

13

Limit switch

3

Seal

14

Ball bearing

4

Thrust piece

15

Gear motor

5

Slide plate

16

Lubricant sensor

6

Rod

17

Pneumatic cylinder

7

Spindle nut

18

5/2-way valve

8

Spindle

19

O-ring

9

Washer

A

Type plate

10

Hand crank with handle

S

Protective cover

8 Spare Parts Standard Version

(see also spare parts list and drawing in appendix / size DN500, DN600 different

construction)

Illustrations not to scale

© BA6110.0002_EN_Rev11.docx Page 13 of 19

Operating Instructions FSV 6110…

1

Housing

9

Washer

18

5/2-way valve

2

Eccentric screw

10

Hand crank with handle

19

O-ring in intake collar

3

Seal

11

Lock pin

20

O-ring gland

4

Thrust piece

13

Limit switch

21

Airmatik seal

5

Slide plate

14

Ball bearing

22

Seal join

6

Rod

15

Gear motor

23

Mechanical 3/2-way valve

7

Spindle nut

16

Lubricant sensor

A

Type plate

8

Spindle

17

Pneumatic cylinder

S

Protective cover

Detail of seal variants

Standard gland: Goggle seal and O-ring in intake collar:

Airmatik version:

© BA6110.0002_EN_Rev11.docx Page 14 of 19

Operating Instructions FSV 6110…

Error

Cause

Remedy

Leak to the outside on slider

plate

Glands worn

Glands not sealed

Slider plates worn or with product

accumulation

Non-specified use

Replace glands

Tighten glands

Clean or replace slider plate

Check conditions of use (for

example pressure and

temperature)

Leak in passage through the

slider plate

Product accumulation on the

slider plate or casing

Seal in passage (if there is one)

worn

Non-specified use

Clean

Replace seal

Check conditions of use (for

example pressure and

temperature)

Slider plate jerks or does not

move

Product accumulation on slider

plate including guides or in casing

Glands worn or excessively

stressed

Drive or power supply and

controller defective

Clean

Replace or adjust glands

Check and repair

Pulse generator does not

generate any signals

Pulse generator defective

Actuation element loose or pulse

generator maladjusted

Limit settings are not reached

Replace

Check and repair

Remove accumulations or

foreign bodies; Check drive unit

and power supply

9 Ordering spare parts

Send your spare parts order by mail to verkauf@jaudt.de or by fax to ++ 49 (0)821 7960567.

If you have a JAUDT customer number you can also order spare parts at www.jaudt.de.

Please give us the following information when ordering spare parts:

Name and item from the spare parts list (appendix)

Order no. and type of the JAUDT slide valve according to the type plate

Example:

Suppose you require a new slide plate. We need the following details:

Slide plate, item 5, No. 120610.0107

Order no. according to type plate, e.g. AB03-0211

Type according to type plate, e.g. AB03-0211.10 or 600808.4002

10 Troubleshooting

© BA6110.0002_EN_Rev11.docx Page 15 of 19

Operating Instructions FSV 6110…

11 Cleaning

Cleaning agents containing acid and alkaline solutions must not be used.

Foodstuffs:

If food is to be metered, clean the JAUDT vario-slide valve under running drinking water and with a soft

brush.

If heavily soiled, use commercially available detergents. Make sure that these detergents are not toxic and

do not form toxic compounds. You must also make sure that they contain no acids and alkaline solutions.

Rinse with plenty of drinking water.

12 Disposal

Used oil and lubricants are special waste. Please dispose of them in an environmentally acceptable manner.

© BA6110.0002_EN_Rev11.docx Page 16 of 19

Operating Instructions FSV 6110…

13 Dimension Sheet for Standard Version

(see also dimension sheet in the appendix)

© BA6110.0002_EN_Rev11.docx Page 17 of 19

Operating Instructions FSV 6110…

14 DECLARATION OF INCORPORATION

within the meaning of EU Directive 2006/42/EC, Annex II Part 1.B

Manufacturer, address JAUDT Dosiertechnik

Maschinenfabrik GmbH

Raiffeisenstr. 3 - 5

86167 Augsburg

Tel. ++49 (0)821 79605-0

Documentation officer Wolfgang Morell, JAUDT Dosiertechnik GmbH

Product denomination / Device Type Vario-slide valve / 6110…

The above partly completed machinery is governed by the requirements of Directive

2006/42/EC Annex I, its general principles and its Part 1 and where appropriate Point 2.1. If

used in areas at risk of explosion Directive 94/9/EC (ATEX) also applies.

The fundamental requirements 1.3.3 and 1.3.4 can be ensured. The above requirements can

only be ensured through proper installation.

In addition, the above product conforms in the supplied version to the provisions of Directive

2006/95/EC “Low Voltage Directive” and 2004/108/EC “Electromagnetic Compatibility”.

For the purposes of assessment of conformity the manufacturer produced the special technical documentation pursuant to Directive 2006/42/EC Annex VII Part B. This documentation will

be sent to the authorities of the individual member states in file form on justified request.

The above partly completed machinery is intended solely for incorporation in another machine.

Commissioning is prohibited until it has been ascertained that the machine / system into which

the partly completed machinery is to be incorporated meets the requirements of all the above

directives.

JAUDT Dosiertechnik GmbH

Raiffeisenstraße 3-5 Robert Roßkopf

D-86167 Augsburg Managing Director

Augsburg, 01.10.2012

© BA6110.0002_EN_Rev11.docx Page 18 of 19

Operating Instructions FSV 6110…

15 Appendix

On the following pages the technical data sheets or the documentation of the accessories

are specified

© BA6110.0002_EN_Rev11.docx Page 19 of 19

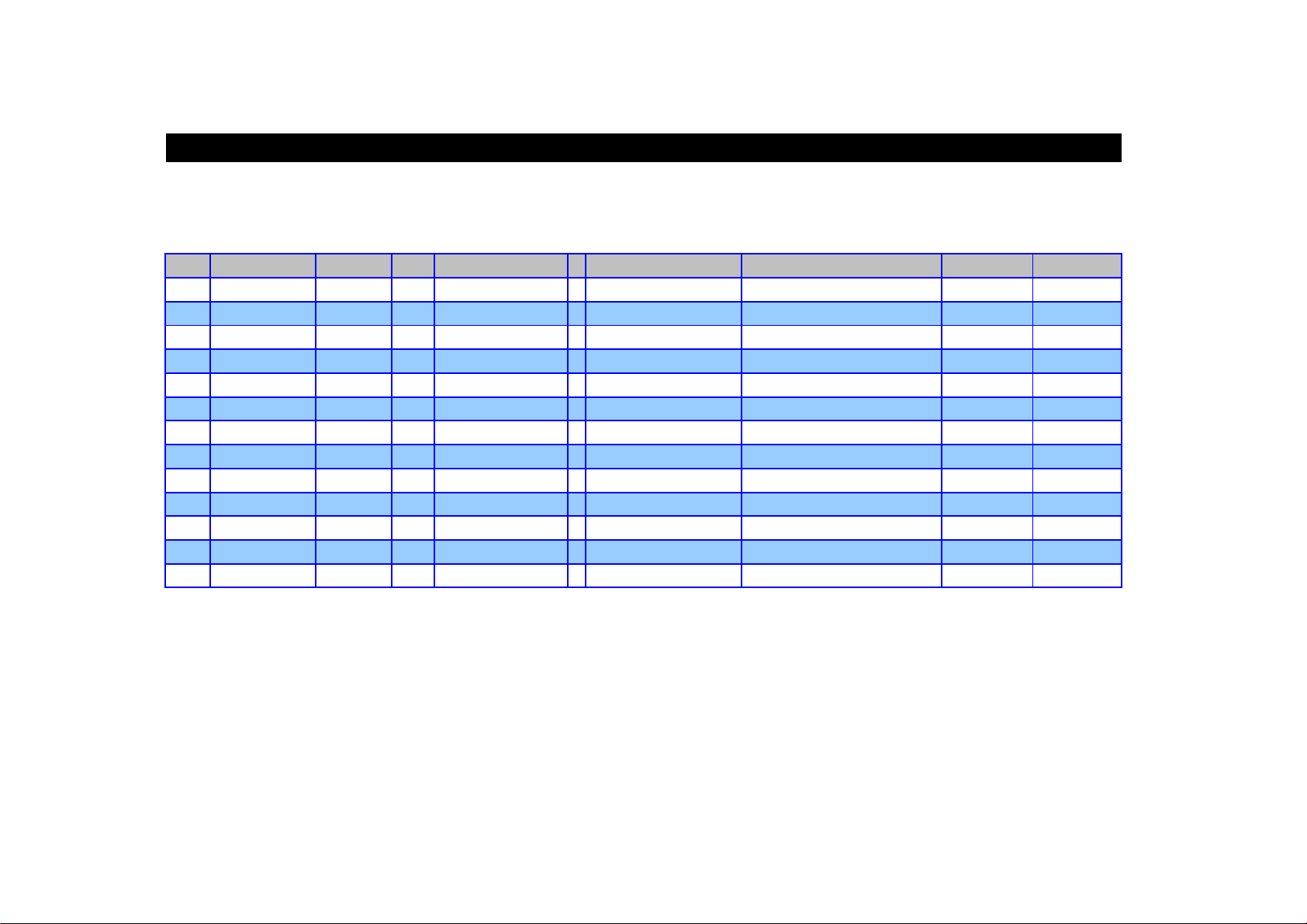

JAUDT - Spare parts list - english

25.11.2014

Rappenglitz

611009.7002

FSV 300 K

Alu

214-1117 / 20

Item Part number Quantity Unit Description E Material Remark L

20 120610.0111 1 STK slide plate 2 1.4301 Bl 8x298x407 x

30 121610.0031 3 STK packing 1 Aramid 6x6

35 015610.0222 1 STK o-ring 1 Silikon transparent 192x6 x

40 104610.0121 1 STK sealing element 3 GK-AlSi10Mg(Cu) x

50 105610.0041 4 STK eccentric bolt 2 8.8 vz M16x30

60 121610.0037 4 STK rod 3 1.0037 Rd 20x414 x

70 119610.0104 1 STK spindle nut 2 EN-GJL-250 Tr 26x5 li x

80 119610.0038 1 STK spindle 2 1.0531 Tr 26x5 li x 397 x

210 120610.0120 1 STK washer 3 Ms 58 Rd 35 x

300 111610.0015 1 STK chain wheel 3 GG verz. ø20 m. Bohrungen x

310 600055 4 M crane chain 3 Stahl galv. verzinkt 5 x 18,5 mm lehrenhaltig x

320 111610.0014 1 STK chain guide 3 1.4301 Bl 4 x

E=spare part; 1 wearing part, 2 spare part for two-year working,

3 spare part; STK=part; M=meter; L = part is in stock

Seite 1 von 1

JAUDT Dosiertechnik

Maschinenfabrik GmbH

86167 Augsburg

Loading...

Loading...