Jasic TIG 200 AC/DC Digital Series, TIG 315 AC/DC Digital Series, JT-200D, JT-315D Operator's Manual

wilkinsonstar.com

TIG 200 / 315 AC/DC

Digital Series

AC/DC MMA / TIG Welding machine

Order code ! JT-200D, JT-315D

OPERATOR MANUAL

Your new product

Thank you for selecting this Jasic Technology, Wilkinson Star product.

This product manual has been designed to ensure that you get the most from your new product. Please ensure that you are fully

conversant with the information provided paying particular attention to the safety precautions. The information will help protect

yourself and others against the potential hazards that you may come across.

Please ensure that you carry out daily and periodic maintenance checks to ensure years of reliable and trouble free operation.

Wilkinson Star Limited are a leading supplier of equipment in the UK and our products are supported by our extensive service

network. Call your distributor in the unlikely event of a problem occurring. Please record below the details from your product as

these will be required for warranty purposes and to ensure you get the correct information should you require assistance or

spare parts.

Date purchased! _____________________________________________________

From where ! ! _____________________________________________________

Serial Number! _____________________________________________________

(The serial number will normally be located on the equipment data plate on the underside of the machine or on the rear panel)

Please note products are subject to continual development and may be subject to change without notice

i

Safety Precautions

1

These general safety norms cover both arc welding

machines and plasma cutting machines unless

otherwise noted.

The equipment must only be used for the purpose it was

designed for. Using it in any other way could result in

damage or injury and in breach of the safety rules.

Only suitably trained and competent persons should use the

equipment. Operators should respect the safety of other

persons.

Prevention against electric shock

The equipment should be installed by a qualified person and

in accordance with current standards in operation.It is the

users responsibility to ensure that the equipment is

connected to a suitable power supply. Consult with your

utility supplier if required

If earth grounding of the work piece is required, ground it

directly with a separate cable.

Do not use the equipment with the covers removed.

Do not touch live electrical parts or parts which are

electrically charged.

Turn off all equipment when not in use.

Cables (both primary supply and welding) should be

regularly checked for damage and overheating. Do not use

worn, damaged, under sized, or poorly jointed cables.

Ensure that you wear the correct protective clothing, gloves,

head and eye protection.

Insulate yourself from work and ground using dry insulating

mats or covers big enough to prevent any physical contact

with the work ground.

Never touch the electrode if you are in contact with the work

ground, or another electrode from a different machine.

Do not wrap cables over your body.

Ensure that you take additional safety precautions when you

are welding in electrically hazardous conditions such as

damp environments, wearing wet clothing, and metal

structures. Try to avoid welding in cramped or restricted

positions.

Ensure that the equipment is well maintained. Repair or

replace damaged or defective parts immediately. Carry out

any r e g u l ar ma i n t e n an c e in accordanc e with the

manufacturers instructions.

Safety against fumes and welding gases

Locate the equipment in a well-ventilated position.

Keep your head out of the fumes. Do not breathe the fumes.

Ensure the welding zone is in a well-ventilated area. If this is

not possible provision should be made for suitable fume

extraction.

If ventilation is poor, wear an approved respirator.

Read and understand the Material Safety Data Sheets

(MSDS’s) and the manufacturer’s instructions for metals,

consumable, coatings, cleaners, and de-greasers.

Do not weld in locations near any de-greasing, cleaning, or

spraying operations. Be aware that heat and rays of the arc

can react with vapours to form highly toxic and irritating

gases.

2

Do not weld on coated metals, unless the coating is

removed from the weld area, the area is well ventilated, and

while wearing an air-supplied respirator. The coatings on

many metals can give off toxic fumes if welded.

Prevention against burns and radiation

Arc rays from the welding process produce intense, visible

and invisible (ultraviolet and infrared) rays that can burn eyes

and skin.

Wear an approved welding helmet fitted with a proper shade

of filter lens to protect your face and eyes when welding or

watching

Wear approved safety glasses with side shields under your

helmet.

Never use broken or faulty welding helmets.

Always ensure there are adequate protective screens or

barriers to protect others from flash, glare and sparks from

the welding area. Ensure that there are adequate warnings

that welding or cutting is taking place.

Wear suitable protective flame resistant clothing.

The sparks and spatter from welding, hot work pieces, and

hot equipment can cause fires and burns

Welding on closed containers, such as tanks, drums, or

pipes, can cause them to explode.

Accidental contact of electrode to metal objects can cause

arcs, explosion, overheating, or fire.

Check and be sure the area is safe and clear of inflammable

material before carrying out any welding.

Protection against noise

Some welding and cutting operations may produce noise.

Wear safety ear protection to protect your hearing.

Protection from moving parts

When the machine is in operation keep away from moving

parts such as motors and fans. Moving parts, such as the

fan, may cut fingers and hands and snag garments.

Protections and coverings may be removed for maintenance

and controls only by qualified personnel, after first

disconnecting the power supply cable.

Replace the coverings and protections and close all doors

when the intervention is finished, and before starting the

equipment.

Take care to avoid getting fingers trapped when loading and

feeding wire during set up and operation.

When feeding wire be careful to avoid pointing it at other

people or toward your body.

Always ensure machine covers and protective devices are in

operation.

Precautions against fire and explosion

Avoid causing fires due to sparks and hot waste or molten

metal

Ensure that appropriate fire safety devices are available near

the cutting / welding area.

Remove all flammable and combustible materials from the

cutting / welding zone and surrounding areas

Do not cut/weld fuel and lubricant containers, even if empty.

These must be carefully cleaned before they can be cut/

welded.

Always allow the cut/welded material to cool before touching

it or placing it in contact with combustible or flammable

material.

Do not work in atmospheres with high concentrations of

combustible fumes, flammable gases and dust.

Always check the work area half an hour after cutting to

make sure that no fires have begun.

Risks due to magnetic fields

The magnetic fields created by high currents may

affect the operation of pacemakers or electronically

controlled medical equipment.

Wearers of vital electronic equipment should consult their

physician before beginning any arc welding, cutting, gouging

or spot welding operations.

Do not go near welding equipment with any sensitive

electronic equipment as the magnetic fields may cause

damage.

3

RF Declaration

Equipment that complies with directive 2004/108/EC

concerning electromagnetic compatibility (EMC) and the

technical requirements of EN60974-10 is designed for use in

industrial buildings and not those for domestic use where

electricity is provided via the low voltage public distribution

sy stem. Difficultie s ma y ari se in ass uring clas s A

electromagnetic compatibility for systems installed in

domestic locations due to conducted and radiated

emissions.

In the case of electromagnetic problems, it is the

responsibility of the user to resolve the situation. It may be

necessary to shield the equipment and fit suitable filters on

the mains supply.

LF Declaration

Consult the data plate on the equipment for the power

supply requirements.

Due to the elevated absorbance of the primary current from

the power supply network, high power systems affect the

quality of power provided by the network. Consequently,

co n ne ct i on re s tr i ct io n s o r m ax i m u m i mp e da n ce

requirements permitted by the network at the public network

connection point must be applied to these systems.

In this case the installer or the user is responsible for

ensuring the equipment can be connected, consulting the

electricity provider if necessary.

Materials and their disposal

The equipment is manufactured with materials, which do not

contain any toxic or poisonous materials dangerous to the

operator.

When the equipment is scrapped, it should be dismantled

separating components according to the type of materials.

Do not dispose of the equipment with normal waste. The

European Directive 2002/96/EC on Waste Electrical and

Electronic Equipment states the electrical equipment that

has reached its end of life must be collected separately and

returned to an environmentally compatible recycling facility.

Handling of Compressed gas cylinders and

regulators

All cylinders and pressure regulators used in welding

operations should be handled with care.

Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

Always secure the cylinder safely

Never deface or alter any cylinder

4

Product Overview

2

The JT-200D and 315D are a series of digital controlled AC/

DC pulsed TIG/MMA inverter welding machines with

excellent performance and utilising advanced technology

system. They It have various AC/DC modes such as AC

square-wave TIG, AC pulsed TIG, DC TIG, DC pulsed TIG,

AC MMA (SMAW), DC MMA (SMA, TIG spot welding (DC,

pulsed or AC), and composite waveform TIG, etc., and can

be widely used in high quality welding of a wide range of

materials.

The design uses both advanced and mature technologies to

ensure reliability and extended machine life.

Key features

Advanced digital control

The machines adopt advanced MUC intelligent digital

control technology, and all the major functions are

performed through the software. It is this digital control that

provides a much improved performance when compared

with the traditional welding machines.

Advanced inverter technology

The primary inverter frequency is 100 KHz, which greatly

reduces the volume and weight of the welder. The great

reduction in magnetic and resistance loss obviously

enhances the transformer efficiency and energy saving

effect. The working frequency is beyond audio range, which

almost eliminates the noise pollution.

Automatic protection functions

When the mains voltage fluctuates sharply, the welding

machine will automatically stop working with the fault

information displayed, and it will automatically recover after

the mains voltage turns stable. In the case of over current or

overheating, the machine will stop working automatically

with the fault information displayed. Such protection

functions greatly increase the lifespan of the machine.

Excellent consistency and stable performance

The machines adopt intelligent digital control, so it is not

sensitive to the change of parameters of components. That

is,the performance of welding machine will not be affected

by the change of the parameters of certain components. It

can also compensate for any change of the working

environment such as temperature and humidity, etc.

Therefore, the consistency and stability of the digital control

welder is better than that of traditional welder.

Parameters are easy to adjust and software easy to update

The control of parameters for a welding machine with

intelligent digital control is much easier and more accurate,

because its main functions are achieved through software.

To change the a function or some of the parameters, you do

not need to change the circuit, and the only thing you have

to do is to download the updated software.

User-friendly interface

This machine adopts international standard graphic

language interface, which is simple, clear, intelligible, and

convenient for users’ operation.

Practical welding process management function

The machine allows users to divide the welding parameters

into five groups, according to different techniques during

operation, each of which can complete a particular welding

task. It undoubtedly facilitates the technical standardisation

management in welding production.

High-quality MMA welding

MMA welding performance is significantly improved with an

excellent control algorithm: easier to ignite arc, stable

welding current, little spatter, no electrode sticking, good

shaping, and adaptable to the change of length or section

of welding cable.

High-quality TIG welding

Improved digital technology for constant current ensures

the low noise and a high stability of arc quality as well. The

mature control algorithm provides users with a convenient

and practical approach to control the current. Totally 20 TIG

operation modes, including the typical 2T/4T, and 4 of them

5

are programmable, which offers a facility for a user‘s special

application.

Remote control available

The machine offers an analog remote control mode (foot

control), which can realise real-time adjustment of TIG

welding current over 10m away.

Robot system for automatic welding available

The machine is provided with RS-485 communication

interface, and it is easy for users to use with an automatic

welding system or with other equipment with the embedded

standard ModBus communication protocol. Available as a

special order.

Perfect automatic recording function

All data such as cumulative start up times, cumulative

running time, cumulative welding time, cumulative TIG

welding time, accumulative MMA welding time, cumulative

times of alarm, cumulative times of over current, cumulative

times of overheating, cumulative times of under voltage and

cumulative times of water-cooling alarm can be calculated

and stored in FLASH memory.

Control interface for automatic welding equipment available

This machine provides torch trigger signal, current signal and

fault alarm signal for connection with automatic welding

equipment.

Wide input voltage range tolerance

6

Technical data

3

7

Product design may vary due to continual improvements or customer requirements.

Parameter

JT-200D AC/DC

JT-315D AC/DC

Input voltage Range

Single-phase 190~250V AC, 50/60Hz

3-phase 280~420V AC, 50/60Hz

Rated input capacity (KVA)

4.6

9

Rated input power (KW)

4.2

8.4

Recommended fuse capacity (A)

40

40

Rated duty cycle @ 400C

TIG: 200@35%- MMA: 160@40%

TIG: 315@20% - MMA: 250@40%

No-load voltage (V)6050

Insulation class

B

Cooling mode

Forced air cooling

Protection class

IP21S

Overall size (mm)

570×350×420

590×375×380

Weight (kg)

27

33

Welding current range MMA(A)

DC: 10~160; AC: 20~160

DC: 10~250; AC: 20~250

Arc ignition current range MMA(A)

DC: 10~200; AC: 20~200

DC: 10~300; AC: 20~300

Arc force current range MMA(A)

0~100

0~100

Initial current range (A)

DC: 10~200; AC: 20~200

DC: 10~320; AC: 20~250

Peak current range (A)

DC: 10~205; AC: 30~205

DC: 10~320; AC: 30~320

Base current range (A)

DC: 10~205; AC: 30~205

DC: 10~320; AC: 30~320

Crater current range (A)

DC: 10~200; AC: 20~200

DC: 10~320; AC: 20~250

DC pulse frequency range (Hz)

0.5~200

DC pulse duration ratio range (%)

10~90

AC frequency range (Hz)

20~70

Positive and negative half-wave

time ratio (%)

10~60

AC pulse frequency range (Hz)

0.5~5.0

AC pulse duration ratio range (%)

10~90

Upslope time (s)

0~60

Downslope time (s)

0~60

Pre-flow time (s)

0~15.0

Post-flow time (s)

0~20.0

Spot welding time (s)

0.0~8.9

Arc ignition mode

Contact arc ignition, HF arc ignition

Controls

4

Front view JT-200D

1. Control panel

2. Negative output socket

3. Torch gas connector

4. Torch switch connector

5. Remote control connector

6. Positive power connector

7. Mains switch

8. Adjustment control

Front view JT-315D

1.! Control panel

2.! Negative output socket

3.! Torch gas connector

4.! Torch switch connector

5.! Remote control connector

6.! Water connection

7.! Positive power connector

8.! Adjustment control

8

Rear View JT-200D!

9! Data plate

10! Power cable input

11. Shield gas input connector

12. Serial number

Rear View JT-315D

9.! Data plate

10.! Power cable input

11.! Water input connector

12. Shield gas input connector

13. Serial number

14. Mains switch

9

Control Panel

1—Welding mode selecting zone

It is used to select the welding mode. Press the key in this zone to shift the welding mode among “” (AC square-wave

TIG), “” (AC pulsed TIG), “” (DC TIG), “” (DC pulsed TIG), “” (AC SMAW) and “” (DC SMAW) with the corresponding

LED lit. However, if the LED flashes, it indicates that welding is being carried out in the corresponding welding mode

and that re selection cannot be performed.

2—Parameter and alarm display zone

The digital meter is used for displaying the parameters and error codes, and it also displays the software version when

starting the machine. The details are as below.

A." Generally, the digital meter displays the pre-set current, time, pulse duration ratio and frequency with the

corresponding LED “A S % Hz” lit. Parameters can be adjusted by turning the knob. The digital meter displays the

welding current during welding, and parameters can be adjusted at this time as well. It displays the parameter being

adjusted, and turns to display the welding current 3s after the adjustment.

B." Press the key “↓” in this zone to shift the display of the digital meter among “A S % Hz”, “V”, “” and “MEMORY”

with the corresponding LED lit. “V” indicates the output voltage; “” is used for selecting the operation mode of TIG

welding

“MEMORY” can store 5 groups of parameters, and users may perform welding conveniently with these parameters.

C." The digital meter displays the software version after the machine is started, and displays the pre-set current 2

seconds later.

D. In normal condition, all alarm LEDs are off. In case of any error, the corresponding LED will illuminate, and the

digital meter will display the corresponding error code.

When the “OC” LED illuminates and the digital meter displays “E-0” or “E-1”, it indicates that over current occurs.

Restart the machine, and welding can be continued.

When the “LV/OV” LED illuminates and the digital meter displays “E-2”, it indicates that the mains voltage is overly low

or that the secondary inverter drive power source fails. In the former condition, welding can be recovered when the

mains voltage goes into normal. In the latter condition, please consult the service department.

When the “OH” LED illuminates and the digital meter displays “E-3” or “E-4”, it indicates that welding is forced to stop

because the main circuit of the machine is overheated. In this condition, it is unnecessary to turn off the machine, but

just wait a few minutes, and then welding can be continued.

3—Parameter adjustment knob

It is used to adjust all adjustable parameters.

4—Mains switch

1. Welding mode selector

2. Parameter and alarm

displays

3. Parameter adjustment

knob

4. Mains on off switch

5. TIG parameter

selection area

6. MMA parameter

selection area

7. Remote control

selection

JT-200D panel shown

11

5—TIG parameter selecting zone

Hz

%

% Hz

2

1

3

4

5

6

7

8

9101112

!

6-MMA Parameter selection area

$

7—Foot control selecting zone

Select the foot control to control the welding current by pressing the foot control key until the LED is on. The welding current

should be 30A at least (to avoid arc breaking due to overly low current) and should not be higher than the pre-set current. The

foot control is effective only in TIG mode.

1-Pre-flow time

7-Pilot arc current

2-Initial current

8-Post-flow time

3-Upslope time

9-Pulse frequency

4-Base current

10-Pulse duration ratio

5-Peak current

11-AC frequency

6-Downslope-time

12-Cathode current

1-Arc ignition current

2-Arc ignition time

3-Welding current

4-Arc force current

5-MMA parameter selecting key

12

Parameter setting

Operation hints

Selection and adjustment of parameters

● Press “↓” in parameter display selecting zone to select the parameter to be displayed.

● Press “↓” in welding mode selecting zone to select welding mode (totally 6 welding modes).

● Press “←”or “→” in TIG parameter selecting zone to select parameter in TIG. (only parameters associated with TIG mode can

be adjusted)

● Press “→”in MMA parameter selecting zone to select parameter in MMA. (only parameters associated with MMA mode can be

adjusted)

● Turn the adjustment knob to set or amend the parameter currently selected.

Operation hints

Parameter storage

The parameters having been adjusted will be auto saved in the parameter group currently used (no auto saving will be done if no

welding is done after parameters are adjusted or the machine was turned off within 3s’ time). When the machine is turned on

next time, the parameters in this parameter group will be the parameters used last time. No special save key and manual saving

operation is available for this machine.

Concept hints

Parameter group

5 parameter groups (1-5) are available for users to save the welding parameters based on a welding application, and all

parameters in all the six welding modes can be saved in each parameter group. Every time when the machine is turned on, the

parameter group of last time when the machine is turned off will be used. If users do not reselect a different parameter group,

the machine will continue its working under this parameter group. Users can set different parameters in different parameter

groups and select the corresponding one to weld. (Note: Parameters in all the five parameter groups are the same and are all

default when using the machine for the first time.)

Parameter group selecting

In standby mode, press “↓” in parameter and alarm display zone to light the “MEMORY” LED, and at this time, what the digital

meter displays is the number of the parameter group being used. Turn the adjustment knob, the parameter group number will be

changed, and you can select the desired parameter group. After selecting the parameter group, you can repress “↓” to exit, or

you can wait for about 10s when the machine return to parameter display status automatically.

Program key setting

MMA (DC)

Note: ! t0—Standby: No welding current; output voltage is the no-load !

! voltage.

! t1—Arc ignition: Welding current is arc ignition current (I1).

! t3—Arc burning: Welding current is the pre-set current (I2).

! t4—Short-circuit transfer: Welding current is the short-circuit !

! transfer current (I3).

In MMA mode, 4 parameters that can be adjusted directly

and 1 parameter that can only be adjusted through

programming are available for this machine. These are

shown below.

Current (I2): This is the welding current when arc is burning,

and users can set it according to their own technical

requirements.

Arc force: It refers to the ascending slope of the current in

short circuit, and it is set as the amperage increased per

millisecond in this machine. The current will rise from the

pre-set value by this slope after short circuit occurs. (E.g.

When the pre-set current is 100A and the arc force is 20, the

current will be 200A 5ms after short circuit occurs.) If it is still

under short circuit when the current increases to the

allowable maximum value 250A, the current will not rise any

more. If the short circuit status lasts for 0.8s or more, the

machine will enter into electrode sticking process: to wait the

disconnection of the electrode under low current. Arc force

should be set according to the electrode diameter, pre-set

current and the technical requirement. If the arc force is high,

the molten drop can be transferred quickly, and electrode

sticking seldom occurs. However, too high arc force may

lead to excessive spatter. If the arc force is low, there will be

little spatter, and the weld bead will be shaped well.

However, too small arc force may lead to soft arc and

electrode sticking. Therefore, the arc force should be

increased when welding with thick electrode under low

current. In general welding, the arc force may be set at 5~50.

Arc ignition current (I1) and arc ignition time (T1): Arc

ignition current is the output current of the machine when the

arc is ignited. Arc ignition time is the time the arc ignition

current lasts. When in high current ignition mode, the arc

ignition current is generally 1.5~3 times the welding current,

and the arc ignition time is 0.02~0.05s. When in low current

ignition mode, the arc ignition current is generally 0.2~0.5

times the welding current, and the arc ignition time is

0.02~0.1s.

Operation hints

Arc ignition modes in MMA

Low current arc ignition: This can be also called lift/soft arc

ignition. Set the arc ignition current (I1) to be a value lower

than I2 and the machine will enter into low current arc

ignition mode. Touch the work piece with the electrode, and

lift the electrode to the normal position to weld after arc is

ignited.

High current arc ignition: This can be also called contact/

thermal arc ignition. Set the arc ignition current (I1) to be a

value not lower than I2 and the machine will enter into high

current arc ignition mode. Touch the work piece with the

electrode, and normal welding can be carried out without

lifting the electrode.

Arc breaking voltage (U1): This parameter is used for

setting the arc breaking voltage during welding. It is specially

designed to meet the requirement in HF intermittent welding,

and its resolution is 0.1V. The arc breaking voltage indicates

the maximum allowable arc voltage during welding, that is to

say, welding can be continued when the arc voltage is lower

than U1, or else welding will stop immediately. This

parameter cannot be simply adjusted like other parameters,

and should be adjusted by the following method.

Operation hints

Arc breaking voltage programming

Enter into the amendment state: Press the MMA parameter

selecting key and turn on the machine, and the parameter

display meter will flash “P-1”, which will disappear 5s later.

At this time, the voltage LED will turn on, and the machine

will enter into arc breaking voltage amendment state.

Amend the arc breaking voltage: After entering into arc

breaking voltage amendment state, what the parameter

display meter shows is the effective arc breaking voltage

before amendment. You can amend it to your desired value

by turning the knob.

Exit the amendment state: Exit by pressing the MMA

parameter-selecting key after amendment. At this time, the

new arc breaking voltage comes into being and it can be

automatically saved.

Note: In general welding, the arc breaking voltage should be

above 45V. If it is too low, arc breaking will occur during

welding.

13

MMA (AC)

T0-Arc ignition time (0.01~1s)

T1-AC period (20ms)&

(i.e. frequency=50Hz)

I0-Arc ignition current (20~300A)

I1-Welding current (20~250A)

In MMA AC mode, the adjustment of all parameters is the

same with that in MMA DC mode except that the arc force is

0 fixed.

TIG DC welding

In the DC TIG mode, 8 adjustable parameters are available

for this machine. These are described below.

Current (I3): This parameter can be set according to users’

own technical requirements.

Initial current (I1): It is the current when arc is ignited by

pushing the torch trigger, and it should be set according to

users’ own technical requirements. If the initial current is

high enough, arc is easier to ignite. However, it should not be

too high when welding thin plate, so as to avoid burn

through the work piece during arc ignition. In some operation

modes, the current can stay at the initial current value to

preheat the work piece or illuminate the weld area.

Pilot arc current (I5): In some operation modes, the arc does

not stop after current downslope but stays in the pilot arc

state. The working current in this state is called pilot arc

current, and it should be set according to users’ technical

requirements.

Pre-flow time: It indicates the time from the torch trigger is

operated to the arc being ignited in non-contact mode.

Commonly it should be longer than 0.5s to make sure that

the gas has been delivered to the welding torch in normal

flow before arc ignition. The pre-flow time should be

increased if the gas hose is long.

Post-flow time: It indicates the time from the welding current

being cut off to the gas valve inside the machine being

closed. If it is too long, it will lead to a waste of shield gas; if

it is too short, it will result in the oxidation of weld bead and

electrode. When in AC TIG or for special materials, the time

should be longer.

Upslope time (tr): It indicates the time taken for the current to

rise from 0 to the pre-set value, and it should be set

according to users’ technical requirements.

Downslope time (td): It indicates the time taken for the

current to fall from the pre-set value to 0, and it should be

set according to users’ technical requirements.

Pulsed TIG DC welding

Current change in pulsed TIG welding

In pulsed TIG mode, all DC TIG parameters except current

(I3) and another 4 adjustable parameters are available for

this machine. Describe them as below.

Peak current (Ip): It should be adjusted according to users’

technical requirements.

Base current (Ib): It should be adjusted according to users’

technical requirements.

Pulsed frequency (1/T): T=Tp+Tb. It should be adjusted

according to users’ technical requirements.

Pulse duration ratio (100%*Tp/T): The percentage peak

current time holding in pulse period. It should be adjusted

according to users’ technical requirements.

AC square wave TIG welding

tc

tp

I0

I2

I1

tu

td

!

I0-Initial current, I1-Welding current, I2-Pilot arc current,

tu-Upslope time, td-Downslope time

tp-AC period, tc-Cathode current time

Current change in AC square wave TIG welding

In AC square wave TIG welding, the pre-flow time and postflow time are the same as in DC TIG welding. Others

parameters are described as below.

Initial current (I0), welding current (I1) & pilot arc current (I2):

The pre-set value of the three parameters is approximately

the absolute average of the practical welding current, and

can be adjusted according to users’ technical requirements.

Pulse frequency (1/tp): It can be adjusted according to users’

technical requirements.

14

I

t

0

T0

I1

T1

I0

!

Cleaning strength (100%*Tc/Tp): Generally, in AC welding,

when taking the electrode as the anode, the current is called

the cathode current. Its main function is to break up the

oxidized layer of the work piece, and the cleaning strength is

the percentage cathode current holding in the AC period.

This parameter is 10~40% commonly. When the value is

smaller, arc is concentrated, the molten pool is narrow and

deep, and when it is larger, the arc is spread, the molten pool

is wide and shallow.

AC pulsed TIG welding

tc-Cathode current time, tp-AC period

Tp-Pulsed peak current time, T-Pulse period

Current change in AC pulsed TIG welding

AC pulsed TIG welding is almost the same as AC square

wave TIG welding, and what makes them different is that in

AC pulsed TIG welding, the welding current varies with the

pulse peak current and base current. For the AC square

wave parameter selecting and setting, please refer to the

corresponding contents in AC square wave TIG welding. For

the pulse frequency and pulse duration ratio, users may refer

to the corresponding contents in DC pulsed TIG welding.

The pulse frequency (1/T) can be adjusted between 0.5Hz

and 5Hz. The pulse duration ratio (Tp/T) can be adjusted

between 10% and 90%.

TIG spot welding

Select TIG operation mode 1 and TIG spot welding function

can be achieved. Spot welding is available in all the four TIG

welding modes. Please note that the spot welding time is

1/10 of the upslope time, and that the upslope time is still

the pre-set value. For current change in DC TIG spot

welding, pulsed TIG spot welding, AC TIG spot welding and

AC pulsed TIG spot welding; please refer to the figures

below. In AC mode, the pre-set value of spot welding current

is approximately the absolute average of welding current.

C u r r e n t

change in

D C T I G

s p o t

welding

C u r r e n t

change in

p u l s e d

TIG s p ot

welding

C u r r e n t

change in AC

T I G s p o t

welding

Current change

in AC pulsed TIG

spot welding

Complex waveform TIG welding

Ib

Ip

Id

T2

T2

!

Current change in complex waveform DC pulsed welding

This machine can provide complex waveform TIG welding

through programming. Special pulsed welding can be

obtained in DC TIG mode, dual-pulse welding can be

obtained in pulsed TIG mode, and variable polarity pulsed

welding can be obtained in AC TIG mode. To obtain complex

waveform TIG welding, it is necessary to select the

appropriate TIG operation mode or reprogram the TIG

operation mode according to the appendix Programming

Guide for Users (TIG mode). Take complex waveform DC

pulsed welding for example. By adding a pulsed current with

15

!

!

higher frequency to the peak pulsed current with lower

frequency, some special welding requirements can be met.

Complicated complex waveform DC pulsed welding can be

obtained by selecting the operation mode 18/19 or selfprogramming in pulsed welding mode. A typical waveform of

complex waveform DC pulsed welding (operation mode 18)

is showed in the above figure, in which, Ib and Ip stand for

the base current and peak current in pulsed welding mode

respectively. Id ‘s value is equal to that of the pilot arc

current, but it has no sense of pilot arc current, and it can be

considered as secondary base current. T2 stands for the

period of the secondary pulse (LF), and here in this example

T2 is 200ms. In operation mode 19, the period of the

secondary pulse (LF) can be changed at any moment by

adjusting the upslope time.

TIG operation mode

20 TIG operation modes are available for this machine, in

which 0-15 cannot be amended by users, and 16-19 can be

amended. If you want to amend the TIG operation modes,

please refer to the appendix Programming Guide for Users

(TIG mode).

TIG operation mode should be selected according to users’

technical requirements. All the 20 TIG operation modes for

this machine are listed in the table TIG operation modes

below.

TIG operation modes

Mode no.

Operation

Torch trigger

operation and

current curve

0

Follow mode:

① Push the torch trigger:

arc is ignited and current

rises to the pre-set value.

② Release it: arc stops.

1

1T/Spot welding mode:

① Push the torch trigger:

arc is ignited and current

rises to the p re -s et

value.

② When the spot welding

time is up, current drops

gradually, and arc stops.

Note: Spot welding time is

1/10 of the upslope time.

2

Standard 2T mode:

① Push the torch trigger:

arc is ignited and current

rises gradually.

② Release the torch

tr i gg e r: cu rre nt dr o ps

gradually, and arc stops.

③ If the torch trigger is re

operated again before arc

stops, the current will

gradually rise again, to

status ②.

3

Double operation 2T

mode:

① Push the torch trigger:

a r c i s i g ni t e d a n d

current rises gradually.

The torch trigger can be

released at any time.

② Push it again: current

drops gradually, and arc

stops. The torch trigger

can be released at any

time.

③ If the torch trigger is re

operated again before

arc stops, the current

will gradually rise again,

to status ②.

16

!

!

!

!

Torch trigger operation notes

Torch trigger operation notes

Push the torch

trigger.

Release the torch

trigger.

Push the torch

trigger and then

release it at any

time.

Release the torch

trigger and then

push it at any time.

Push and release

the torch trigger

within 0.5s, or

release and push

the torch trigger

within 0.5s.

Push the torch

trigger twice within

0.5s, or release the

torch trigger twice

within 0.5s.

17

!

1s

1s

4

Standard 4T mode:

① Push the torch trigger: arc is ignited and current

reaches the initial value.

② Release it: current rises gradually.

③ Push it again: current drops to pilot arc current

value.

④ Release it: arc stops.

5

Double operation 4T mode:

① Push the torch trigger: arc is ignited and current

reaches the initial value. The torch trigger can be

released at any time.

② Release it: current rises gradually. The torch trigger

can be released at any time.

③ Push it again: current drops to pilot arc current

value. The torch trigger can be released at any time.

④ Release it: arc stops.

6

Cycle single operation mode without initial current:

①" Push the torch trigger: arc is ignited and current

rises gradually.

②" Release it: current drops to pilot arc current value.

③" Push it again: current rises gradually again, and

then turn to ②.

④" If push the torch trigger and release it at once, arc

will stop.

7

Cycle single operation mode with initial current:

①" Push the torch trigger: arc is ignited and current

reaches the initial value.

②" Release it: current rises gradually.

③" Push it again: current drops to pilot arc current

value, and turn to ②.

④" If release the torch trigger and push it at once, arc

will stop.

8

Inner timing operation mode:

① Push the torch trigger: arc is ignited and current

rises gradually.

② If release it within 1s, arc will stop; if release it after

1s, it will turn to ③.

③ Push it again: current drops gradually, and arc

stops. The torch trigger can be released at any

time.

④ If push the torch trigger again before arc stops, the

current will gradually rise again, and then turn to ③.

9

Outer timing operation mode:

①" Push the torch trigger: arc is ignited and current

rises gradually.

②" If release it within 1s, it will turn to ③; if release it

after 1s, arc will stop.

③" Push it again: current drops gradually, and arc

stops.

18

1s

10

Cycle double operation mode without initial

current:

①" Push the torch trigger: arc is ignited and current

rises gradually. The torch trigger can be released at

any time.

②" Push the torch trigger and release it at once:

current drops to pilot arc current value.

③" Push the torch trigger and release it at once:

current gradually rises again, and then turn to ②.

④" If push the torch trigger twice within 0.5s, the

current will drop gradually, and arc will stop.

11

Cycle double operation mode with initial current:

①" Push the torch trigger: arc is ignited and current

reaches the initial value. The torch trigger can be

released at any time.

②" Push the torch trigger and release it at once:

current gradually rises.

③" Push the torch trigger and release it at once:

current drops to pilot arc current value, and then

turn to ②.

④" If push the torch trigger twice within 0.5s, the

current will drop gradually, and arc will stop.

12

Single operation 3T mode:

①" Push the torch trigger: arc is ignited and current

rises gradually.

②" Release it: current drops to pilot arc current value.

③" Push it again: arc stops.

13

Double operation 3T mode:

①" Push the torch trigger: arc is ignited and current

rises gradually. The torch trigger can be released at

any time.

②" Push the torch trigger and release it at once:

current drops to pilot arc current value.

③" Push it again: arc stops.

14

Real time waveform control operation mode with

initial current (intermittent up-down):

①" Push the torch trigger: arc is ignited and current

reaches the initial value.

②" Release it: current gradually rises.

③" Push it again: current stops rising.

④" Release it: current drops gradually.

⑤" Push it again: current stops dropping, and then turn

to ②.

⑥" If the torch trigger is not pushed after the current

begins to drop, the current will drop gradually till arc

stops.

15

Real time waveform control operation mode

without initial current (intermittent up-down):

①" Push the torch trigger: arc is ignited and current

rises gradually.

②" Release it: current stops rising.

③" Push it again: current drops gradually.

④" Release it: current stops dropping.

⑤" Push it again: current rises gradually, and then turn

to ②.

⑥" If the torch trigger is not pushed after the current

begins to drop, the current will drop gradually till arc

stops.

When reading the above table, please note:

•

Whether the arc is ignited by HF or by striking the

electrode, and no matter what kind of operation mode is

selected, after arc is ignited successfully, it enters into

initial current, and later into operational mode control.

•

Some operation modes adopt the exit mode by pushing

the torch trigger. The operator should release it after

exiting welding. In this way, another welding operation can

be entered by pushing the torch trigger.

•

Current curves in all operation modes are drawn on the

assumption that the machine works in DC TIG mode. If the

machine works in pulsed TIG mode, the current curve

appears a pulse shape; if the machine works in AC TIG

mode, the current curve appears a variable polarity pulse

shape.

•

Normally, the TIG operation modes most widely used are

2T and 4T, which exactly correspond to operation mode 2

and 4 for this machine respectively.

•

Use the operation mode programming function carefully,

since it can be complicated.

19

!

!

16

Manual pulsed single operation mode:

①" Push the torch trigger: arc is ignited and current

reaches the preset value.

②" Release it: current drops to pilot arc current value.

③" Push it again: current rises to the preset value, and

then turn to ②.

④" If push the torch trigger and release it at once, or

release the torch trigger and push it at once, arc will

stop.

Note: Preset value is the peak value; pilot arc value is

the base value. It is programmable.

17

Manual pulsed double operation mode:

①" Push the torch trigger: arc is ignited and current

reaches the preset value. The torch trigger can be

released at any time.

②" Push the torch trigger and release it at once:

current drops to pilot arc current value.

③" Push the torch trigger and release it at once:

current rises to the preset value, and then turn to

②.

④" If push the torch trigger twice within 0.5s, the

current will drop gradually, and arc will stop.

Note: Preset value is the peak value; pilot arc value is

the base value. It is programmable.

18

Pulsed welding with fixed frequency (5Hz) and

fixed duty cycle (50%):

①" Push the torch trigger: arc is ignited and

current reaches the initial value.

②" Release it: current gradually rises.

③" Push it again: current drops to pilot arc

current value, and the timing function is

started.

④" If time is out, do peak-base switch.

⑤" Release the torch trigger: arc stops.

Note: Preset value is the peak value; pilot arc

value is the base value. It is programmable.

19

Pulsed welding with unfixed frequency (the cycle

is 1/5 of the upslope time) and fixed duty cycle

(50%):

The same with that of mode 18.

Installation

5

Unpacking

Check the packaging for any signs of damage.

Carefully remove the machine and retain the packaging until

the installation is complete.

Location

The machine should be located in a suitable position and

environment. Care should be taken to avoid moisture, dust,

steam, oil or corrosive gases

Place on a secure level surface and ensure that there is

adequate clearance around the machine to ensure natural

airflow.

Input connection

Before connecting the machine you should ensure that the

correct supply is available. Details of the machine

requirements can be found on the data plate of the machine

or in the technical parameters shown in the manual.

The equipment should be connected by a suitably qualified

competent person. Always ensure the equipment has a

proper grounding.

Never connect the machine to the mains supply with the

panels removed.

Output connections

Electrode polarity

In general when using manual arc welding electrodes the

electrode holder is connected the the positive terminal and

the work return to the negative terminal. Always consult the

electrode manufacturer’s data sheet if you have any doubts.

When using the machine for TIG welding the TIG torch

should be connected to the negative terminal and the work

return to the positive terminal

MMA welding DC

Insert the cable plug with electrode holder into the “+”

socket on the front panel of the welding machine, and

tighten it clockwise.

Insert the cable plug of the work return lead into the “-”

socket on the front panel of the welding machine, and

tighten it clockwise

If the welding mode is not pointing to “DC MMA”, press the

key in the welding mode selecting zone on the front panel of

the machine to select “ ” DC MMA mode. After

adjusting all parameters according to relevant content in this

manual, SMAW can be carried out. When welding, the digital

meter displays the welding current, and it can also display

the arc voltage if you press the key in the parameter and

alarm display selecting zone.

MMA welding AC

The only difference from that of SMAW (DC) is that the

welding mode points to “ ”.

TIG Welding

Insert the cable plug with the work clamp into the “+” socket

on the front panel of the welding machine, and tighten it

clockwise.

Insert the cable plug of the TIG torch into the “-” socket on

the front panel of the machine and tighten clockwise.

Connect the TIG torch control switch into the socket on the

machine front panel.

Connect the remote control if fitted into the socket on the

machine front panel.

Connect the gas hose to the regulator / flowmeter located on

the shield gas cylinder and connect the other end to the

machine.

20

Operation

Before starting any welding activity ensure that you have

suitable eye protection and protective clothing. Also take

the necessary steps to protect any persons within the

area.

MMA (DC)

After connecting the cables as above, make sure that all are

correctly installed. Switch on the mains supply to start the

machine. Select the welding mode “ ” DC MMA by

pressing the key in the welding mode selecting zone on the

front panel of the machine. After adjusting all parameters

according to relevant content in this manual, MMA welding

can be carried out. When welding, the digital meter displays

the welding current, and it can also display the arc voltage if

you press the selection key in the parameter and alarm

display selecting zone.

For DC welding, the connection as mentioned above is

DCEP polarity. The operator may choose DCEP/DCEN

acco rding to work piece and electrode application

requirement. Generally, DCEP polarity is recommended for

basic electrodes, while there is no special polarity

requirement for acid electrodes.

MMA (AC)

The only difference from that of MMA (DC) is that the

welding mode points to “ ”.

Set the amperage on the machine suitable for the electrode

being used. Please see below a guide to amperages

required. Ensure you check that you have the electrode

polarity correct.

Set the arc force current percentage as required. This can be

adjusted during welding.

TIG Welding

After making sure that all leads and cables are correctly

installed, close the power supply switch to start the

machine. Select AC square wave TIG, AC pulsed TIG, DC

TIG or DC pulsed TIG by pressing the welding mode

selecting key on the front panel of the machine, or select

welding mode such as TIG spot welding or composite

waveform TIG welding by selecting operation mode. Open

the gas valve of the cylinder, adjust the gas flow to the

proper value, select the correct cooling mode, adjust all

parameters to the proper value according to the relevant

content in this manual, and TIG welding can be carried out.

The arc ignition mode of this machine is non contact arc

ignition. During welding, the parameter display meter

displays the welding current, and it can display the arc

voltage by pressing the key in the parameter display

selecting zone.

Foot control

Foot control function is generally used in TIG mode:

Connect the foot control to the corresponding terminal on

the front panel of machine with a special cable.

Press the foot control selecting key on the front panel of the

machine to lighten the foot control LED.

Adjust the welding parameters to the proper value, and then

welding can be carried out.

When welding under foot control, TIG operation mode 0 is

used, and it has nothing to do with the current operation

mode setting.

Step on the foot control to ignite arc in non-contact arc

ignition mode. After arc is ignited successfully, the welding

current will be controlled by the foot control. The minimum

current value is 30A, while the maximum current is the preset

value.

Note: Foot control is optional. Give your requirement when

placing your order if necessary.

Application of automatic welding

Connect the computer with the communication interface

RS-485 (It is optional, and give your requirement when

placing your order if necessary.) of the machine; equip

proper software; and computer-controlled automatic welding

can be carried out. The communication protocol of

automatic control is available against payment with this

machine, while the computer software for automatic welding

should be provided by users themselves.

Press the foot control selection key on the front panel of the

machine to light the foot control LED.

Adjust the welding parameters to the proper value, and then

welding can be carried out.

When welding under foot control, TIG operation mode 0 is

used, and it has nothing to do with the current operation

mode setting.

For welder training please visit our Academy website at

www.wilkinson-welding-academy.com

21

Electrode Diameter (mm)

Recommended Welding Current (A)

1.6

44~84

2.0

60~100

2.5

80~120

3.2

108~148

4.0

140~180

Maintenance and troubleshooting

6

The following operation requires sufficient professional

knowledge on electric aspects and comprehensive

safety knowledge. Make sure the input cable of the

machine is disconnected from the electricity supply and

wait for 5 minutes before removing the machine covers.

In order to guarantee that the arc welding machine works

efficiently and in safety, it must be maintained regularly.

Operators should understand the maintenance methods and

means of arc welding machine operation. This guide should

enable customers to carry on simple examination and

safeguarding by oneself, try to reduce the fault rate and

repair times of the arc welding machine, so as to lengthen

service life of arc welding machine

Troubleshooting

Before arc welding machines are dispatched from the

factory, they have already been checked thoroughly. The

machine should not be tampered with or altered.

Maintenance must be carried out carefully. If any wire

becomes loose or is misplaced, it maybe potential danger to

user!

Only professional maintenance personnel should repair the

machine!

Ensure the power is disconnected before working on the

machine. Always wait 5 minutes after power switch off

before opening the case.

NOTE

•

When the inverter welder is powered on, defective

components may explode or lead to explosion of other

components.

•

Wear face guard and long-sleeved clothing when

maintaining the inverter welder.

•

Wear a grounded antistatic wristband when carrying PCBs

and components.

•

Store, carry and transport PCBs with appropriate antistatic

bags or boxes.

•

Cut off the power supply of the welder before testing.

•

Test with appropriate instruments and leads

•

Read the instructions of the testing equipment carefully.

22

Period

Maintenance item

Daily

examination

Carry out a full visual inspection. Check

for any damage to the machine, leads,

cables and connections. Replace where

necessary.

Switch on the machine and check for any

warning Led’s and general operation

Monthly

examination

Using the dry compressed air to clean the

inside of arc welding machine. Especially

check for build up of dust / debris on

intake grills, main voltage transformer,

inductance, IGBT module, the fast recover

diode and PCB, etc. Take care when

blowing electronic components and do not

dislodge any wiring connections

Check the security of output connections

and plugs. Replace if signs of overheating.

Yearly

examination

Carry out an annual service. Check earth

continuity and insulation resistance of the

machine at the relevant points.

PLEASE NOTE THIS WORK SHOULD

BE CARRIED OUT BY A TRAINED

COMPETENT PERSON.

23

Phenomena

Cause

Solution

The power cord is not well connected.

Reconnect the power cord.

The fan does not work or it works

Input failure

Solve the input failure problem.

The fan does not work or it works

abnormally.

The mains voltage is overly low.

Welding can be carried out after the mains

voltage recovers.

The power cord is not well connected.

Reconnect the power cord.

The fan does not work or it

Input failure

Solve the input failure problem.

The fan does not work or it

works abnormally.

The mains voltage is overly low.

Welding can be carried out after the mains voltage

recovers.

Hard to ignite arc

The arc ignition current is too low or the arc

ignition time is too short.

Increase the arc ignition current or prolong the arc

starting time.

Excessive spatter or the

molten pool is too big.

The arc ignition current is too high or the arc

ignition time is too long.

Reduce the arc ignition current or shorten the arc

ignition time.

MMA

Normal arc cannot be

started.

Input failure of the mains power supply or the

power cord is not well connected.

Solve the input failure problem or reconnect the

power cord.

MMA

Electrode sticking

The arc force current is too low.

Increase the arc force current.

MMA

The electrode holder

becomes very hot.

The rated current of the electrode holder is

lower than its actual working current.

Replace it with a higher rated current holder.

MMA

Arc is easy to break.

Arc breaking voltage is too low.

Increase the arc breaking voltage.

There is no current

Welding can be exited when the torch trigger is

pushed in some TIG operation modes.

Release the torch trigger and try again.

There is no current

output when pushing

the torch trigger.

The welding circuit is not in good connection.

Check the welding circuit, and reconnect it if

necessary.

There is no discharge

and arc cannot be

The torch trigger is not connected.

Connect the torch trigger.

There is no discharge

and arc cannot be

ignited when pushing

the torch trigger in HF

arc ignition mode.

The spark gap on the discharge board is too

big.

Adjust the spark gap on the discharge board to

about 1.0mm.

The electrode burns

The output polarity connection is incorrect.

Exchange the polarity.

The electrode burns

quickly in TIG welding.

The cleaning strength is too big in AC mode.

Reduce the cleaning strength.

TIG

The weld bead is not well protected and is

oxidized.

Make sure the gas valve of the cylinder is open and

the pressure inside the cylinder is high enough.

Generally, it is necessary to refill the cylinder when

the pressure is lower than 0.5MPa.

TIG

Black weld bead

The weld bead is not well protected and is

Check if the gas flow is normal. You may select

different gas flow according different welding

current. However low the current is, the gas flow is

recommended to be not less than 5L/min.

Otherwise, the weld bead may not be fully covered

for lack of shielded gas.

TIG

Black weld bead

The weld bead is not well protected and is

oxidized.

Check if the gas path is air proof and if the gas is

pure enough.

TIG

Black weld bead

The weld bead is not well protected and is

oxidized.

Check if the environment is with strong wind.

Alarms

24

Phenomena

Cause

Solution

Replace it with electrode of better quality.

The electrode you use is

Remove the oxidized layer of the electrode.

Arc is hard to start

but easy to break.

The electrode you use is

of poor quality or is badly

oxidized.

Prolong the post-flow time to avoid oxidization of the electrode.

Arc is hard to start

but easy to break.

The electrode you use is

of poor quality or is badly

oxidized.

Adjust the spark gap on the discharge board to about 1.0mm.

TIG

Unstable current

Mains voltage fluctuates

badly, or the input cable

is loosely connected with

the mains power supply.

Check the mains power supply for normal state, and reconnect the power cord.

TIG

Unstable current

during welding

There is serious

interference from other

electric appliances

Do not connect the machine to the power cord, which is connected to other electric

appliances of serious interference.

Other malfunction

Contact the service centre

Typ e

Alarm

Automatic response

Cause

Solution

Over current

Over current LED

flashes and there

are alarm beeps.

Cut off the main circuit

permanently.

Load current is too high, or over

current protection of main

power unit occurs.

Restart the machine. If the problem remains, shut down

the machine and contact the service department.

Under voltage

Over voltage/

under voltage LED

flashes and there

are alarm beeps.

Cut off the main circuit

temporarily.

The mains voltage is low

Problem will be automatically eliminated when the mains

power supply recovers, and welding can be continued. If

under-voltage sustains, ask an electrician to check the

input power. Welding cannot be carried out until the mains

power supply recovers. If the mains voltage is normal, but

alarm beeps still exist, contact the service department

Overheating

Overheating LED

flashes and there

are alarm beeps.

Cut off the main circuit

temporarily.

Excessive work of the main

circuit

It is unnecessary to shut down the machine, but just wait

for the overheating LED to go off, and then welding can be

continued.

Electrical schematic

7

25

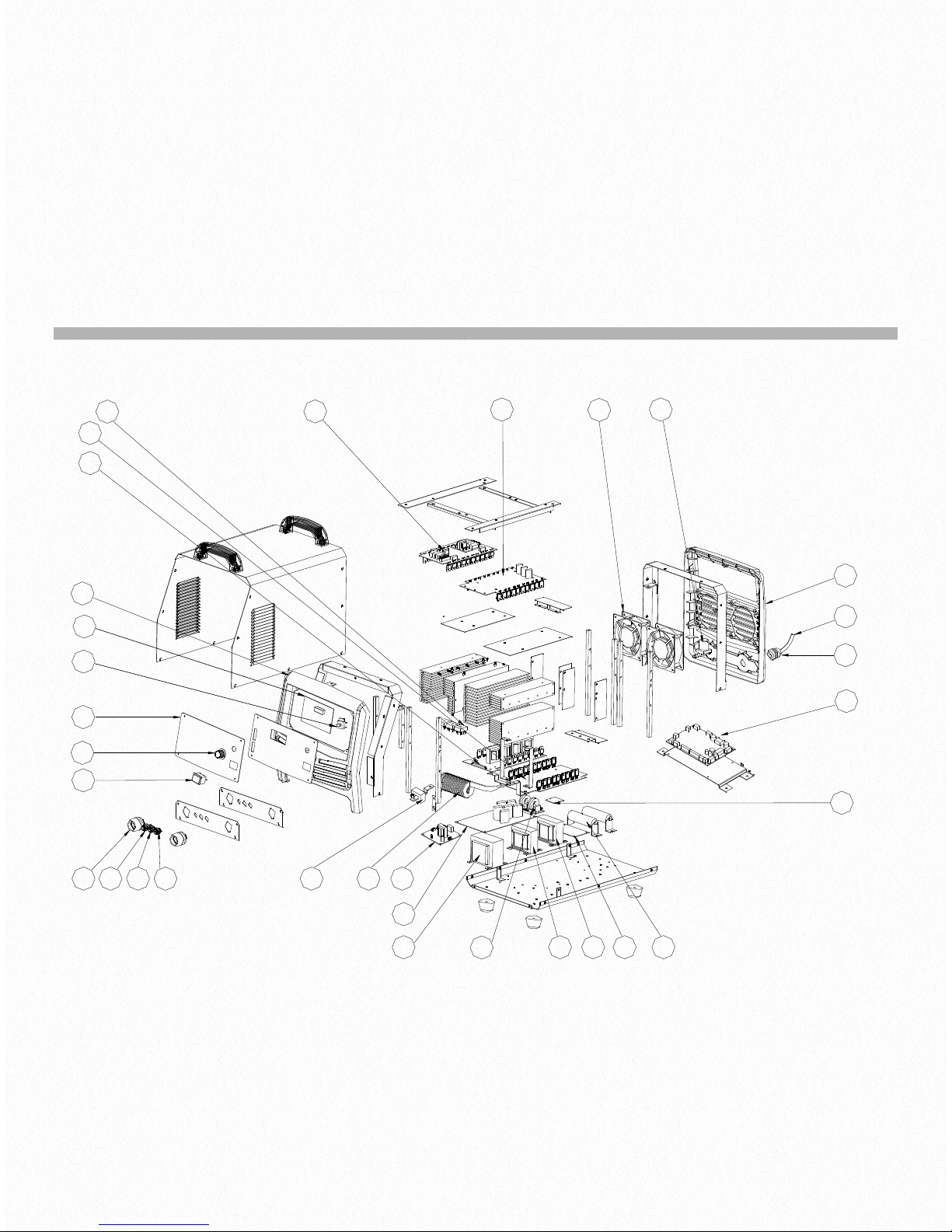

Parts list

8

JT-200D

26

!

JT-200D

JT-315D

No.

Part no

Description

No.

Part no

Description

1

10040581

Summary board

18

10022040

Solenoid value

2

10006625

Silicon bridge

19

10006520

Encoder

3

10020434

Bottom panel

20

10040130

Control board

4

10020604

Arc start board

21

10044448

Front panel

5

10006560

Reactor

22

10044430

Panel overlay (with electro circuit)

6

10020646

Hand switch board

23

10004919

Knob710005295

Glaze resistor

24

10045761

Underneath stick for the front panel

8

10040654

Power transformer

25

10004684

Two pin socket

9

10037776

Secondary driver board

26

10004685

Five pin socket

10

10020665

Secondary power transformer

27

10016390

Water connection

11

10020608

Power transform board

28

10021856

Quick socket

12

10037448

Back Panel

29

10020975

Secondary inverter board A

13

10004935

Power switch

30

10020977

Secondary inverter board B

14

10037303

EMC3110040578

Top board

15

10022057

Fan3210038699

Central board

16

10016389

Connector for water

33

10020826

Power line

17

10021912

Line button

27

No.

Part no

Description

No.

Part no

Description

1

10014869

Front Panel

17

10020665

Secondary power transformer

2

10038551

Panel overlay

18

10037776

Secondary inverter driver board

3

10040580

Summary board

19

10005305

Glaze resistor

4

10006803

Electric current trans

20

10020809

Power line

5

10004946

Power switch

21

10013302

Back panel

6

10004919

Knob2210022039

Solenoid value

7

10021855

Quick Socket

23

10022060

Fan810016390

Water fast socket

24

10020998

Secondary inverter board A

9

10004684

Two pin socket

25

10040579

Top board

10

10001685

Five pin socket

26

10042330

Control board

11

10021002

Arc coil

27

10006520

Encoder

12

10020441

Bottom panel

28

10021912

Line button

13

10006562

Reactor

29

10006625

Silicon bridge

14

10021614

EMC3010020997

Secondary inverter board B

15

10020608

Power transform board

31

10039434

Central board

16

10040655

Power transformer

32

10020646

Hand switch board

JT-315D

28

!

JT-200D / JT-315D DIGITAL AC/DC PULSE TIG/MMA WELDING

MACHINE

Order code ! JT-200D, JT-315D

© Wilkinson Star Limited

Issue 1 January 2014

Product is subject to change without notice

xxix

Appendix

PROGRAMMING GUIDE FOR USERS (TIG MODE)

Skip this chapter over if user-programming function (TIG mode) is not to be used.

4 programmable TIG operation modes (No.16-19) are available for this welding machine, and all the 4 modes are clearly defined

when leaving the factory. Users can freely modify them to meet their special requirements according to the methods provided in

this chapter. Read this chapter carefully and fully understand all contents before the re-programming or modifications of the

operation modes.

1. Operation of the torch trigger

It is the operation mode’s connotation that different operation of the torch trigger during welding lead to different current

waveform. The operation of torch trigger typically includes the following forms:

⊙ Push the torch trigger (↓)

⊙ Release the torch trigger (↑)

⊙ Push the torch trigger and release it at once (↓↑)

⊙ Release the torch trigger and push it at once (↑↓)

⊙ Push the torch trigger twice within 0.5s (↓↑↓or↑↓↑↓)

⊙ Release the torch trigger twice within 0.5s (↑↓↑or↓↑↓↑)

These are the general descriptions of the operation of the torch trigger. In addition, descriptions based on operation times are

used in this chapter.

•

Single operation: Push or release the torch trigger.

•

Double operation: Push and release the torch trigger within 0.5s, or release and push the torch trigger within 0.5s.

•

Triple operation: Push, release and push the torch trigger within 0.5s, or release, push and release the torch trigger within

0.5s.

•

Quartic operation: Push, release, push and release the torch trigger within 0.5s, or release, push, release and push the torch

trigger within 0.5s.

•

2. Coding of operation mode

•

For digital welding machine, the function of TIG operation mode is realized by running an orderly code group. This orderly

code group is called operation mode code sequence, and codes that composing of this sequence code are named operation

30

mode codes. To plan and design a new TIG operation mode is actually to design a code sequence group and to program it

into the welding machine. The code sequence of operation mode is composed of the following.

•

Operation mode code sequence: C0, C1, C2, C3, C4, C5, C6, C7, C8, C9

•

In this sequence, Ci (i stands for code no. 0~9) is a code in the code sequence. The code sequence of an operation mode is

composed of 10 codes, and each code can be a number among 0~99. The meaning of all codes in the code sequence are

detailed as below.

•

C0 is the no. 0 code in the sequence, and it defines the operation time of the operation mode:

•

C0=0~89 stands for that the operation time is 0.0~8.9s.

•

C0=9X stands for that the operation time is (X+1)/10 of the upslope time.

•

C1~C9 respectively stands for no.1~9 code in the sequence and also the operation stipulation of step 1~9. Different values of

these codes stand for different operation stipulations. 100 codes are classified and explained in Attached Table 2 based on

their functions and characteristics, and users should fully understand all those. For welding machine, operation mode is

realized by implementing the code sequences one by one. Here Attached Figure 1 and Attached Figure 2 show the general

steps to implement the code sequences.

Attached Figure 1 Flow chart of operation sequences without code transfer

Attached Figure 2 Flow chart of operation sequences with code transfer

General steps for operation mode code sequence design:

①! Function setting: set operation function according to the welding technical requirements.

②! Function decomposing: decompose function referring to Attached Table 2 to bring out several sub-functions.

③! Code selecting: select appropriate codes referring to Attached Table 2 to realize each sub-function.

④! Sequence composing: arrange the order of codes appropriately to compose applicable code sequences.

Tips in operation mode code sequence design:

31

C

4

C

5

C

6

C7 C2 C3 C8 C9 C

1

Start

Stop

!

C4 C5 C7 C2 C3 C8 C9 C

1

Start

Stop

C

6

!

①! During welding, users always enter into operation mode control after the torch trigger is pushed and arc is successfully

ignited, so users do not need to care about the arc ignition requirements of welding in the code design.

②! Operation mode control will be exited once arc stops. If users want to enter into it again, arc should be ignited for another

time.

③! Operation codes "1X" and "2X" are with a rapid response, while "3X", "4X" and "5X" are with a slow response, because it

takes about 0.5s for the latter to collect the effective changes of torch trigger.

④! Except C0, select “0” in any other codes means no operation and not turning to the next step (i.e. waiting).

⑤! Since as many as 100 kinds of operation codes are available for this machine, there is more than one code sequence to

achieve the specific operation function, and users only need to choose one of them.

⑥! It should be stressed that not all the programming codes can be combined arbitrarily. Some code combinations do not

make sense, and some can achieve some specific functions but against users’ habit. Therefore, users should pay attention

when obtaining code combinations.

20 kinds of TIG operation modes are available for this machine, in which 0-15 are non-programmable, and 16-19 are

programmable. Whether non-programmable ones or programmable ones, they are achieved by their own operation mode code

sequences, which are obtained based on “Operation mode encoding rules” (see Attached Table 1). Please refer to the

description of the operation modes in the text when reading this table.

32

Attached Table 1 TIG operation mode code sequences list

33

Mode

Code sequences

Code sequences

Code sequences

Code sequences

Description

(SEE TEXT FOR DETAILS)

0

Follow mode

1

1T/spot welding mode

2

Standard 2T mode

3

Double operation 2T mode

4

Standard 4T mode

5

Double operation 4T mode

6

Cycle single operation mode

without initial current

7

Cycle single operation mode

with initial current

8

Inner timing operation mode

9

Outer timing operation mode

10

Cycle double operation mode

without initial current

11

Cycle double operation mode

with initial current

12

Single operation 3T mode

13

Double operation 3T mode

14

Real time waveform control

operation mode with initial

current (intermittent up-

down)

15

Real time waveform control

operation mode without initial

current (intermittent up-

down)

16

Manual pulsed single

operation mode

17

Manual pulsed double

operation mode

18

Pulsed welding with fixed

frequency (5Hz) and fixed

duty cycle (50%)

19

Pulsed welding with unfixed

frequency (the cycle is 1/5 of

the upslope time) and fixed

duty cycle (50%)

Attached Table 2 TIG operation mode code function

34

Code

Operation stipulation

Code

Operation stipulation

0X

Immediate executive code:

Execute order X immediately.

5X

Transfer code in torch trigger operation

condition:

Wait for the torch trigger operation. Stop arc if

triple or quartic operation, turn to next step if

single operation, and if double operation:

X=0: Turn to next step

X≠0: Turn to Step X (X=0~9)

1X

Executive code in torch trigger

operation condition:

Wait for the torch trigger operation,

and execute order X when pushing

the torch trigger.

6X

Timing executive code:

Wait for the operation time, and during this

period, no influence if single or double

operation, stop arc if triple or quartic operation.

If no operation of the torch trigger and time is

up, execute order X.

2X

Executive code in torch trigger

operation condition:

Wait for the torch trigger operation,

an d e xe cu t e or de r X w he n

releasing the torch trigger.

7X

Timing transfer code:

Wait for the operation time, and during this

period, turn to next step if single or double

operation, stop arc if triple or quartic operation.

If no operation of the torch trigger:

X=0: Turn to next step

X≠0: Turn to Step X (X=0~9)

3X

Executive code in torch trigger

operation condition:

Wait for the torch trigger operation.

If single operation, execute order