Page 1

Model V-630/650/660/670

Spectrophotometer

Hardware/Function Manual

P/N: 0302-1935D February 2010

Page 2

Safety Considerations

To ensure operation safety, this instrument must be operated correctly and maintained according

to a regular schedule. Carefully read to fully understand all safety precautions in this manual

before operating the instrument. Please take a moment to understand what the signal words

!

WARNING

(1) Safety symbols

WARNING

CAUTION A CAUTION indicates a potentially hazardous situation which, if not

Note A Note provides additional information to help the operator achieve

, CAUTION, and Note mean in this manual.

Instruction manual symbol. If the product is marked with this symbol,

refer to the instrument manuals to protect the instrument against

damage.

!

A WARNING

!

indicates a potentially hazardous situation which, if

not avoided, could result in serious injury or even death.

avoided, may result in minor or moderate injury. It may also be

used to alert against damaging the equipment.

!

Do not proceed beyond a WARNING

or CAUTION notice until you

understand the hazardous conditions and have taken the

appropriate steps.

optimal instrument performance.

i

Page 3

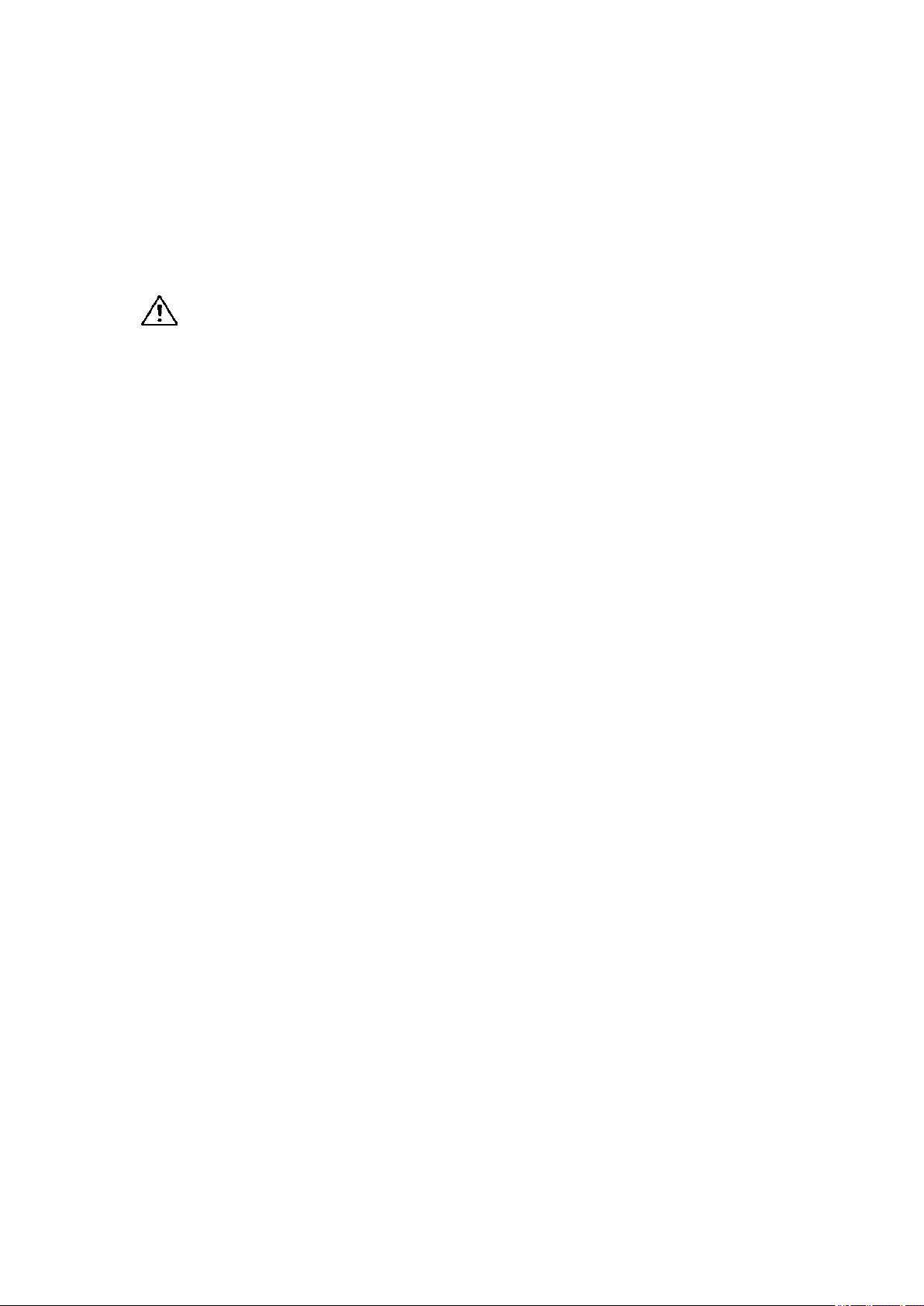

(2) Warning indication

Warnings are indicated at several locations on this instrument. Do not deface or damage the

warning indication.

Figure.1 Warning indication

1) Warning for FUSE (Fig. 2 or Fig. 3)

Only use fuses of the designated rating to protect both operator and instrument from fire and

other hazards. Whenever replacing the lamp, be sure to turn the “Power” switch OFF and

unplug the power cable from the power outlet to avoid the risk of electric shock and other

hazards.

2) Warning for GROUND (Fig. 2 or Fig. 3)

You may receive an electric shock if the instrument is not properly grounded. Correctly ground

the instrument using the grounding terminal on the power board. Do not use water supply

pipes for grounding because they are often made of nonmetals. For the same reason, do not

use gas piping for grounding either.

Warning indication

Figure 2 V-630 Rear Panel

ii

Page 4

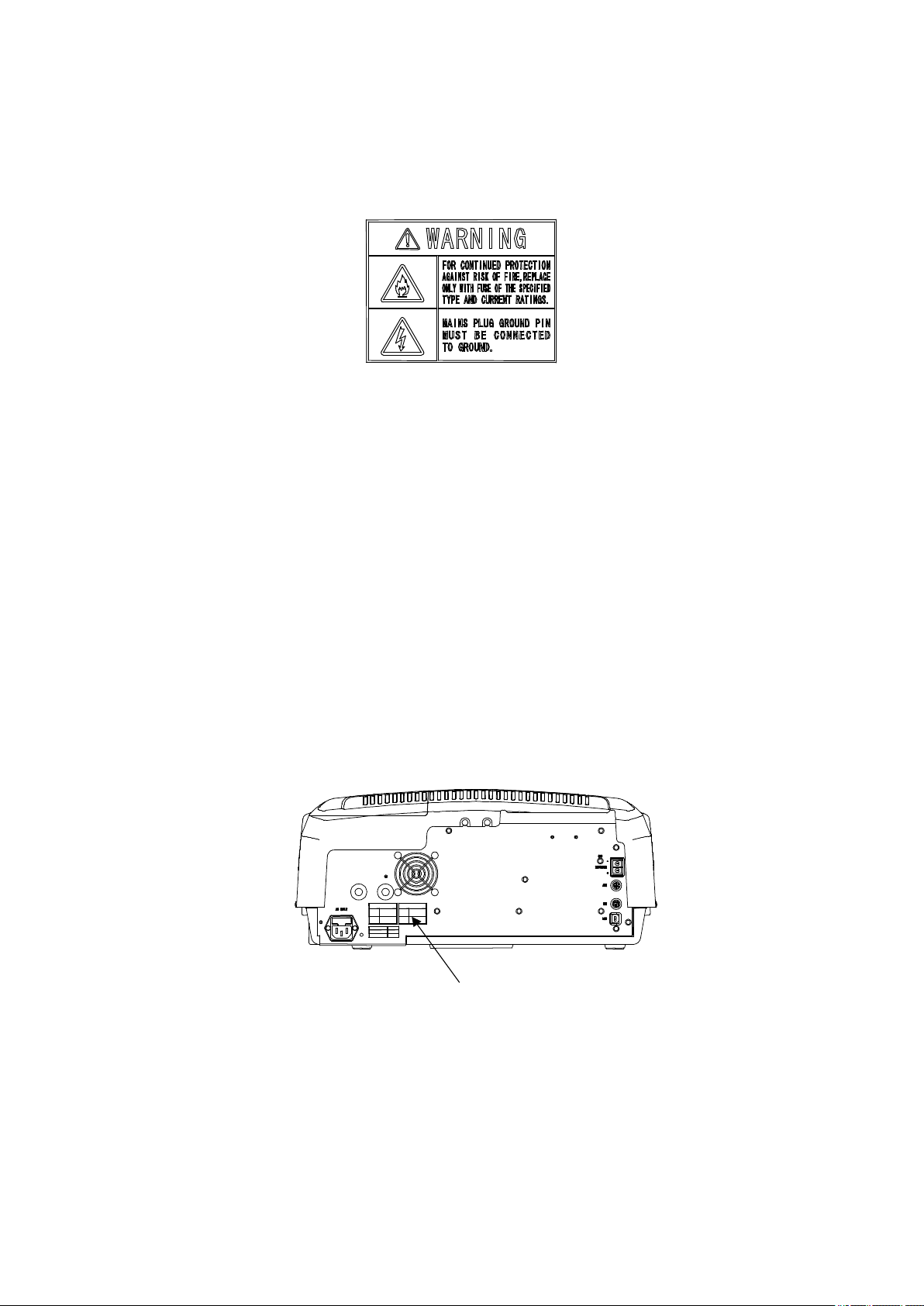

Warning indication

Figure 3 V-650/660/670 Rear Panel

(3) Warning for carrying

These instruments weigh as follows:

V-630: 15.0 kg V-650: 27.0 kg

V-660: 29.0 kg V-570: 28.0 kg

When carrying the instrument, hold the carrying handle at the bottom of the instrument

firmly (See Fig. 4 or Fig. 5).

Carrying handle (both sides)

Figure 4 V-630 side view

iii

Page 5

Carrying handle (both sides)

Figure 5 V-650/660/670 side view

iv

Page 6

Connecting the Power Cable

Line

WARNING!: The green/yellow ground core of the mains lead must be connected

to a ground that complies with the local electricity supply authority (or

equivalent body). The instrument is dangerous if not correctly

grounded.

240 Volt (nominal) Supply

Wire Color

Ground

Line

Neutral

115 Volt (nominal) Supply

Wire Color

Ground

Neutral

View of pin side of plug

Green/Yellow

Black

White

Green/Yellow

Brown

Blue

Note: Instruments intended for operation at 115 V, 60 Hz are supplied with a mains

cable with a molded plug and socket.

v

Page 7

Regulatory Statement

CE Notice

The symbol indicates compliance of this JASCO system to the EMC (Electromagnetic

Compatibility) and Low Voltage Directives of the European Community. This symbol indicates

that this JASCO system meets the relevant basic safety and health requirements of the EC

Directive based on the following technical standards:

· EN61326-1: "Electrical equipment for measurement, control and laboratory use – EMC

requirements – Part 1: General requirements"

WARNING!: This is a Class A product. In a domestic environment this product

may cause radio interference, in which case the user may be

required to take corrective measures.

· IEC61000-3-2: "Electromagnetic compatibility (EMC) Part 3-2: Limits – Limits for harmonic

current emissions (equipment input current up to and including 16A per phase) "

· IEC61010-1: "Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements"

· A "Declaration of Conformity" in accordance with the above standards has been made and is

on file at JASCO CORPORATION, 2967-5 Ishikawa-machi, Hachioji-shi, Tokyo 192-8537,

JAPAN.

FCC Statement (for USA only)

Federal Communications Commission Radio Frequency Interference Statement

WARNING!: This equipment generates, uses, and can radiate radio frequency

energy. If it is not installed and used in accordance with the

instruction manual, it may cause interference to radio

communications. It has been tested and found to comply with the

limits for a Class A computing device pursuant to Part 15 of FCC

Rules, which are designed to provide reasonable protection against

such interference when operated in a commercial environment.

Operation of this equipment in a residential area is likely to cause

interference, in which case the users at their own expense will be

required to take whatever measures may be required to correct the

interference.

vi

Page 8

Preface

This instruction manual is your guide for using this instrument. It instructs first-time users on how

to use the instrument, and serves as a reference for experienced users.

Before using the instrument, please read this instruction manual carefully, and make sure that the

contents are fully understood. This manual should be easily accessible to the operator at all times

during instrument operation. When not using the instrument, keep this manual in a safe place. If this

instruction manual becomes lost, order a replacement from your local JASCO distributor.

Note: The operating procedure varies with the type of instrument. Operation is

described by type. Read the portion relevant to your instrument.

vii

Page 9

Installation Requirements

To ensure operation safety, observe the following conditions:

(1) Do not operate the instrument under voltage fluctuations exceeding 10% of the

recommended line voltage. Otherwise, the instrument may not function properly.

(2) Frequency or spike noise in the power supply should be minimal.

(3) Ensure that the instrument is grounded.

(4) Operate the instrument in a temperature range of 15 to 30 °C.

(5) Operate the instrument in humidity below 85% (RH). JASCO recommends operating the

instrument in humidity below 60% to avoid the deterioration of the optical components due

to the condensation caused by high humidity.

(6) Operate the instrument in an atmospheric pressure range of 750 to 1060 hPa.

(7) Avoid strong magnetic fields and sources of high frequency. The instrument may not

function properly when near a strong magnetic field or high frequency source.

(8) Avoid vibration from vacuum pumps, electric motors, processing equipment and machine

tools.

(9) Avoid dust and corrosive gas. Do not install the instrument where it may be exposed to dust,

especially in locations exposed to outside air or ventilation outlets that discharge dust

particles.

(10) Do not install the instrument in a location where it may be exposed to direct sunlight.

(11) Install the instrument in a horizontal and stable position. (This includes a table or desk upon

which the instrument is installed.)

(12) Ensure that no air conditioner blows air directly onto the instrument. This may prevent

stable measurement.

(13) Install the instrument in a location that allows easy access for maintenance.

Note: The above conditions do not guarantee optimal performance of this

instrument.

viii

Page 10

Servicing

Contact your local JASCO distributor for instrument servicing. In addition, contact your JASCO

distributor before moving the instrument to another location. Consumable parts should be ordered

according to part number from your local JASCO distributor. If a part number is unknown, give

your JASCO distributor the model name and serial number of your instrument.

Do not return contaminated products or parts that may constitute a health hazard to

JASCO employees.

Notices

(1) JASCO shall not be held liable, either directly or indirectly, for any consequential damage

incurred as a result of product use.

(2) Prohibitions on the use of JASCO software

Copying software for purposes other than backup

Transfer or licensing of the right to use software to a third party

Disclosure of confidential information regarding software

Modification of software

Use of software on multiple workstations, network terminals, or by other methods (not

applicable under a network licensing agreement concluded with JASCO)

(3) The contents of this manual are subject to change without notice for product improvement.

(4) This manual is considered complete and accurate at publication.

(5) This manual does not guarantee the validity of any patent rights or other rights.

(6) If a JASCO software program has failed causing an error or improper operation, this may

be caused by a conflict from another program operating on the PC. In this case, take

corrective action by uninstalling the conflicting product(s).

(7) Windows is a registered trademark of Microsoft Corporation in the United States and other

countries. In general, company names and product names are trademarks or registered

trademarks of the respective companies. However, the TM and ® marks are not used in all

cases in this manual.

(8) JASCO and the JASCO logo are registered trademarks of JASCO Corporation in Japan

and other countries.

(C) JASCO Corporation, 2010. All rights reserved. Printed in JAPAN.

ix

Page 11

Limited Warranty

Products sold by JASCO, unless otherwise specified, are warranted for a period of one year from

the date of shipment to be free of defects in materials and workmanship. If any defects in the

product are found during this warranty period, JASCO will repair or replace the defective part(s)

or product free of charge.

THIS WARRANTY DOES NOT APPLY TO DEFECTS RESULTING FROM THE FOLLOWING:

(1) IMPROPER OR INADEQUATE INSTALLATION

(2) IMPROPER OR INADEQUATE OPERATION, MAINTENANCE, ADJUSTMENT OR

CALIBRATION

(3) UNAUTHORIZED MODIFICATION OR MISUSE

(4) USE OF CONSUMABLE PARTS NOT SUPPLIED BY AN AUTHORIZED JASCO

DISTRIBUTOR

(5) CORROSION DUE TO THE USE OF IMPROPER SOLVENTS, SAMPLES, OR DUE TO

SURROUNDING GASES

(6) ACCIDENTS BEYOND JASCO'S CONTROL, INCLUDING NATURAL DISASTERS

This warranty does not cover the consumable parts listed below:

(1) Tungsten lamp, and other light sources

(2) Mirrors in the light source section, and cell windows

(3) Fuses, batteries, glassware, chart paper and ink

THE WARRANTY FOR ALL PARTS SUPPLIED AND REPAIRS PROVIDED UNDER THIS

WARRANTY EXPIRES ON THE WARRANTY EXPIRATION DATE OF THE ORIGINAL

PRODUCT. FOR INQUIRIES CONCERNING REPAIR SERVICE, CONTACT YOUR JASCO

DISTRIBUTOR AFTER CONFIRMING THE MODEL NAME AND SERIAL NUMBER OF YOUR

INSTRUMENT.

JASCO Corporation

2967-5, Ishikawa-machi, Hachioji-shi

Tokyo 192-8537

JAPAN

x

Page 12

Contents

Safety Considerations............................................................................................... i

Connecting the Power Cable ................................................................................... v

Regulatory Statement ............................................................................................. vi

Preface .................................................................................................................... vii

Installation Requirements..................................................................................... viii

Servicing .................................................................................................................. ix

Notices...................................................................................................................... ix

Limited Warranty ...................................................................................................... x

Contents................................................................................................................... xi

1 Unpacking and Installation ............................................................................... 1

1.1 Unpacking ...............................................................................................................1

1.2 Installation and Connecting Cables......................................................................4

1.2.1 Preparation ...........................................................................................................4

1.2.2 Connecting the Cable of iRM Type.......................................................................4

1.2.3 Connecting the Cable of PC Type ........................................................................4

2 Specifications ....................................................................................................... 6

2.1 V-630 UV/VIS Spectrophotometer Specifications................................................6

2.2 V-650 UV/VIS Spectrophotometer Specifications................................................7

2.3 V-660 UV/VIS Spectrophotometer Specifications................................................8

2.4 V-670 UV/VIS/NIR Spectrophotometer Specifications.........................................9

3 General Description of Instrument.................................................................... 11

3.1 V-630 Spectrophotometer Optical System .........................................................11

3.2 V-650/660/670 Spectrophotometers Optical System .........................................13

3.3 iRM System ...........................................................................................................16

4 Names and Functions of Components ............................................................. 17

4.1 V-630 Spectrophotometer ....................................................................................17

4.1.1 Overview.............................................................................................................17

4.1.2 Rear Panel..........................................................................................................18

4.2 V-650/660/670 Spectrophotometers: Overview..................................................19

4.2.1 Overview.............................................................................................................19

4.2.2 Rear Panel..........................................................................................................20

4.3 Standard Cell Holder (Model USE-753 Rectangular Cell Holder) .....................21

4.4 Intelligent Remote Module (iRM) .........................................................................22

5 Maintenance........................................................................................................ 23

5.1 Cautions for Routine Operation ..........................................................................23

5.2 Cleaning the Sample Compartment ....................................................................23

5.3 Replacement of Consumables ............................................................................24

5.3.1 Replacement of Fuse..........................................................................................24

xi

Page 13

5.3.2 Lamp Replacement and Adjustment of the Light Source Mirror .........................26

5.3.2.1 Lamp replacement ...................................................................................... 26

5.3.2.2 Adjustment of iRM type light source mirror .................................................27

5.3.2.3 Adjustment of PC type light source mirror ..................................................29

5.3.3 Consumable Parts .............................................................................................30

6 Troubleshooting ................................................................................................. 31

xii

Page 14

1 Unpacking and Installation

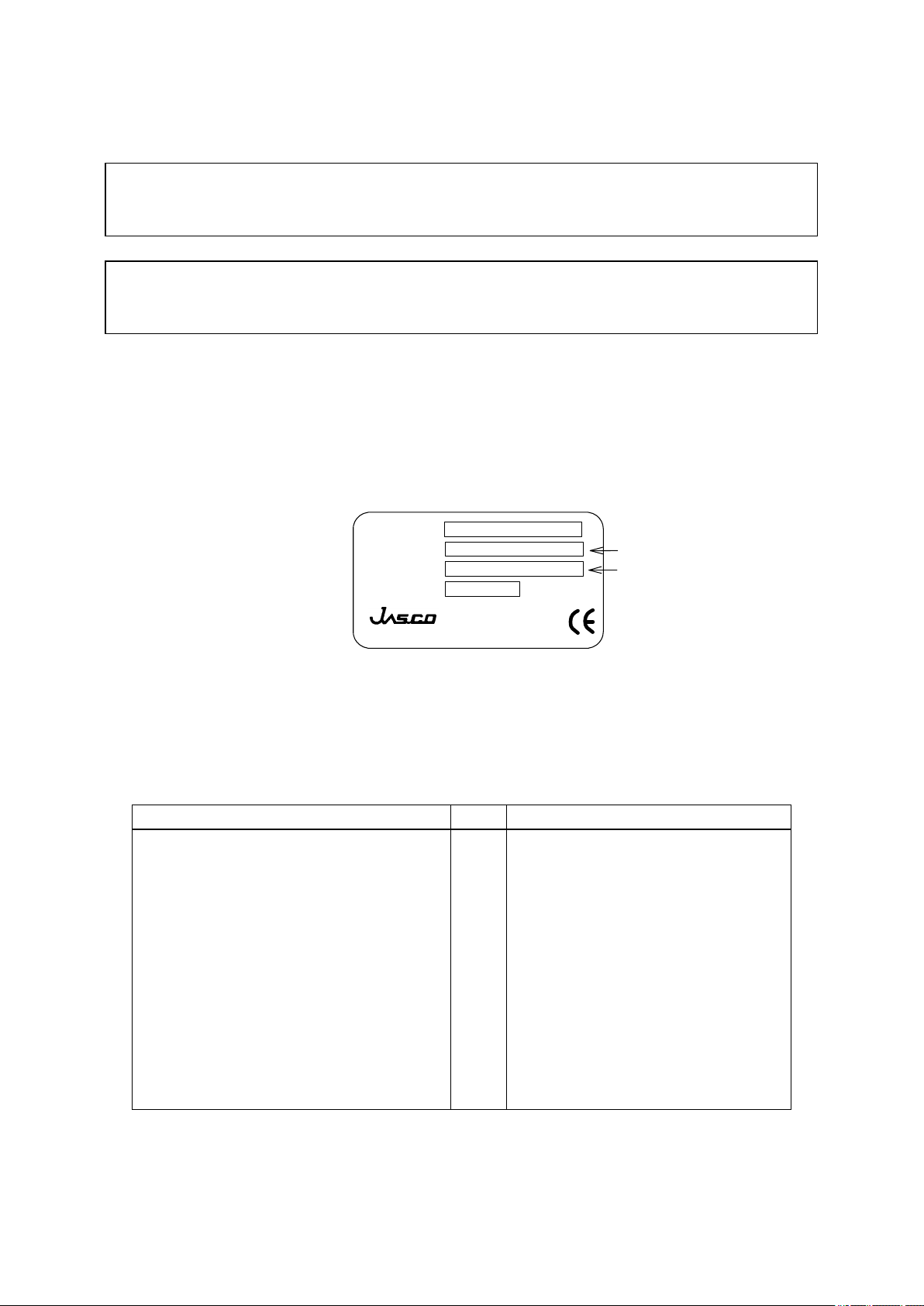

MODEL

SERIAL No.

POWER

CLASS I

日本分光株式会社

_

AC

WARNING!: This section is intended for trained JASCO servicemen. If the user

attempts unpacking and installation, injury may result. Please leave

unpacking and installation to your JASCO serviceman.

CAUTION: Use this manual when you are unpacking/installing the instrument in

conjunction with a JASCO serviceman’s instructions in the case of a

problem.

1.1 Unpacking

(1) Unpacking the main unit

Take out the main unit from the carton and make sure that the serial No. displayed on the serial

No. label located on the left side of the unit and the serial No. on the inspection certificate agree.

Also ensure that the line voltage is consistent with the power requirement of the instrument.

PROTECT

JASCO Corpration

V 50/60Hz VA

MADE IN JAPAN

192-8537 東京都八王子市石川町 2967-5

Serial Number

Line voltage, frequency

Figure 1.1 Serial No. label

(2) Unpacking the standard accessories

Remove the standard accessories from the carton and check them against the packing list. If you

find any parts missing or damaged items, contact your local JASCO distributor.

Table 1.1 List of Standard Accessories for V-630 iRM Type

Description Qty.

Intelligent remote module(iRM)

iRM touch pen

Compact flash

Card adapter

Holmium glass

Time-lag fuse

AC power cable

Allen wrench

Certificate of inspection

Instruction manual

1

1

1

1

1

2

1

1

1

1 set

Bifunctional holmium glass

holder/shielding plate

For adjustment of the light source

mirror

Comments

1

Page 15

Note 1: Use of the holmium glass does not guarantee wavelength accuracy.

Note 2: Holmium glass holder can also be used as a shielding plate by rotating it

through 90 degree from its usual position.

Table 1.2 List of Standard Accessories for V-650/660/670 iRM Type

Description Qty.

Intelligent remote module(iRM)

iRM touch pen

Compact flash

Card adapter

Holmium glass

Time-lag fuse

AC power cable

Phillips screw driver

Certificate of inspection

Instruction manual

1

1

1

1

1

2

1

1

1

1 set

Bifunctional holmium glass

holder/shielding plate

For adjustment of the light source

mirror

Comments

Note 1: Use of the holmium glass does not guarantee wavelength accuracy.

Note 2: Holmium glass holder can also be used as a shielding plate by rotating it

through 90 degree from its usual position.

Table 1.3 List of Standard Accessories for V-630 PC Type

Description Qty. Comments

Holmium glass

Time-lag fuse

USB cable

AC power cable

Allen wrench

Software setup CD

Certificate of inspection

Instruction manual

1

2

1

1

1

1

1

1 set

Bifunctional holmium glass

holder/shielding plate

For adjustment of the light source

mirror

Note 1: Use of the holmium glass does not guarantee wavelength accuracy.

Note 2: Holmium glass holder can also be used as a shielding plate by rotating it

through 90 degree from its usual position.

2

Page 16

Table 1.4 List of Standard Accessories for V-650/660/670 PC Type

Description Qty.

Holmium glass

Time-lag fuse

USB cable

AC power cable

Phillips screw driver

Software setup CD

Certificate of inspection

Instruction manual

1

2

1

1

1

1

1

1 set

Bifunctional holmium glass

holder/shielding plate

For adjustment of the light source

mirror

Comments

Note 1: Use of the holmium glass does not guarantee wavelength accuracy.

Note 2: Holmium glass holder can also be used as a shielding plate by rotating it

through 90 degree from its usual position.

3

Page 17

1.2 Installation and Connecting Cables

Note:

Be certain to comply with the instrument installation requirements

described in this manual (see page ⅷ). Failure to comply with these

requirements can cause faults with the instrument.

1.2.1 Preparation

Prepare a table which can bear a weight of about 50 kg (differs according to instrument) and has

an area of 700 mm (length) × 600 mm (width) when using the iRM type.

If using a PC as well, prepare a table, which can hold a weight of about 70 kg (differs according to

instrument) and has an area of 700 mm (length) × 1500 mm (width), allowing space for a printer.

Confirm that the power switch of the main unit is off and that the power switch of the PC is off

when using a PC.

1.2.2 Connecting the Cable of iRM Type

WARNING!: You may receive an electric shock if the instrument is not properly

grounded. Correctly ground the instrument using the grounding

terminal on the power board.

CAUTION: For grounding, do not use water pipes, which are often made of

nonmetals. For safety reasons, do not use gas tubing for grounding

either.

Note: Use of a 3-pin power plug with a grounding terminal is recommended.

(1) Connect the cable from the iRM to the “iRM” connector on the rear of V-600.

(2) Connect the AC power cable to the “AC INPUT” connector on the rear of V-600.

Connect the other end of the AC power cable to an electrical outlet.

1.2.3 Connecting the Cable of PC Type

WARNING!: You may receive an electric shock if the instrument is not properly

grounded. Correctly ground the instrument using the grounding

terminal on the power board.

CAUTION: For grounding, do not use water pipes, which are often made of

nonmetals. For safety reasons, do not use gas tubing for grounding

either.

Note: Use of a 3-pin power plug with a grounding terminal is recommended.

(1) Connect the “USB” port located on the rear of V-600 and the USB port on the PC using the

USB cable.

4

Page 18

(2) Connect the PC and the monitor.

(3) Connect the AC power cable to the “AC INPUT” connector on the rear of V-600. Connect

the other end of the AC power cable to an electrical outlet.

(4) Connect the AC power cables to the AC input connector of PC and monitor. Connect the

other ends of the AC power cables to an electrical outlet.

5

Page 19

2 Specifications

The specifications of each model covered in this manual are given below.

2.1 V-630 UV/VIS Spectrophotometer Specifications

Optical system Single monochromator

UV/VIS region: 1200 lines/mm concave grating

Rowland off-circle arrangement

Double beam type

Light source Deuterium lamp: 190 to 350 nm

Halogen lamp: 330 to 1100 nm

Light source exchange

wavelength

Detector Silicon photodiode (S1337)

Wavelength range 190 to 1100 nm

Wavelength accuracy ±0.2 nm (at 656.1 nm, when the room temperature is

Wavelength repeatability ±0.1 nm

Slew speed 12000 nm/min

Spectral bandwidth 1.5 nm fixed

Photometric range 0 to 10000 %T

Photometric accuracy

Photometric repeatability

Stray light 1 % (198 nm KCL 12 g/L aqueous solution)

Baseline stability 0.0004 Abs/hour

Baseline flatness

RMS noise 0.00006 Abs (0 Abs, wavelength: 500 nm, measurement

Power requirements

Dimensions and weight

Note: Values given for wavelength accuracy, wavelength repeatability, photometric

accuracy, photometric repeatability, baseline flatness, and RMS noise are

those obtained more than one hour after the light source was turned on.

Any wavelength between 330 and 350 nm can be

selected.

stabilized.)

-2 to 3 Abs

±0.002 Abs (0 to 0.5 Abs)

±0.003 Abs (0.5 to 1 Abs)

±0.3 %T

(Tested with NIST SRM 930D)

±0.001 Abs (0 to 0.5 Abs)

±0.001 Abs (0.5 to 1 Abs)

0.04 % (220 nm NaI 10 g/L aqueous solution)

0.02 % (340 nm NaNO2 50 g/L aqueous solution)

0.02 % (370 nm NaNO2 50 g/L aqueous solution)

(10 mm cell used)

(Value obtained more than two hours after turning on the

light source, when the room temperature is stabilized,

wavelength: 250 nm, and response: slow.)

±0.0006 Abs

(Value obtained after baseline correction with a

temperature variation of less than 5°C, wavelength: 200

to 1000 nm, response: medium, with smoothing

processing and wavelength scanning speed: 400 nm

/min.)

time: 60 sec, response: medium)

100, 115, 200, 220, 230, 240 V ±10 %, 105 VA

216(H) ´ 486(W) ´ 441(D)mm (excluding protrusions)

15 kg

6

Page 20

2.2 V-650 UV/VIS Spectrophotometer Specifications

Optical system Single monochromator

UV/VIS region: 1200 lines/mm plane grating

Czerny-Turner mount

Double beam type

Light source Deuterium lamp: 190 to 350 nm

Halogen lamp: 330 to 900 nm

Light source exchange

wavelength

Detector Photomultiplier tube

Wavelength range 190 to 900 nm

Wavelength accuracy

Wavelength repeatability

Slew speed 12000 nm/min

Spectral bandwidth 0.1, 0.2, 0.5, 1, 2, 5, 10 nm

Photometric range 0 to 10000 %T

Photometric accuracy

Photometric repeatability

Stray light 1 % (198 nm KCL 12g/L aqueous solution)

Baseline stability 0.0003 Abs/hour

Baseline flatness

RMS noise 0.00003 Abs (0 Abs, wavelength: 500 nm, measurement

Power requirements

Dimensions and weight

Note: Values given for wavelength accuracy, wavelength repeatability, photometric

accuracy, photometric repeatability, baseline flatness, and RMS noise are

those obtained more than one hour after the light source was turned on.

Any wavelength between 330 and 350 nm can be

selected.

±0.2 nm (at a spectral bandwidth of 0.5 nm, wavelength:

656.1 nm, when the room temperature is stabilized.)

±0.05 nm

L2, L5, L10 nm (low stray-light mode)

M1, M2 nm (micro-cell mode)

-2 to 4 Abs

±0.002 Abs (0 to 0.5 Abs)

±0.003 Abs (0.5 to 1 Abs)

±0.3 %T

(Tested with NIST SRM 930D)

±0.001 Abs(0 to 0.5 Abs)

±0.001 Abs(0.5 to 1 Abs)

0.005 %(220 nm NaI 10g/L aqueous solution)

0.005 %(340 nm NaNO2 50g/L aqueous solution)

0.005 %(370 nm NaNO2 50g/L aqueous solution)

(spectral bandwidth: L2 nm, 10 mm cell used)

(value obtained more than two hours after turning on the

light source, when the room temperature is stabilized,

wavelength: 250 nm, response: slow, and spectral

bandwidth: 2nm.)

±0.0003 Abs

(value obtained after baseline correction with a

temperature variation of less than 5°C, wavelength: 200

to 850 nm, response: medium, spectral bandwidth: 2 nm,

and wavelength scanning speed: 400 nm/min with

smoothing processing)

time: 60 sec, response: medium, spectral bandwidth: 2

nm)

100, 115, 200, 220, 230, 240 V ±10 %, 145 VA

270(H) ´ 460(W) ´ 602(D) mm (excluding protrusions)

27 kg

7

Page 21

2.3 V-660 UV/VIS Spectrophotometer Specifications

Optical system Double monochromator

UV/VIS region: 600 lines/mm plane grating

Czerny-Turner mount

Double beam type

Light source Deuterium lamp: 187 to 350 nm

Halogen lamp: 330 to 900 nm

Light source exchange

wavelength

Detector Photomultiplier tube

Wavelength range 187 to 900 nm

Wavelength accuracy

Wavelength repeatability

Slew speed 12000 nm/min

Spectral bandwidth 0.1, 0.2, 0.5, 1, 2, 5, 10 nm

Photometric range 0 to 10000 %T

Photometric accuracy

Photometric repeatability

Stray light 1 % (198 nm KCL 12 g/L aqueous solution)

Baseline stability 0.0003 Abs/hour

Baseline flatness

RMS noise 0.00005 Abs (0 Abs, wavelength: 500 nm, measurement

Power requirements

Dimensions and weight

Any wavelength between 330 and 350 nm can be

selected.

±0.1 nm (at a spectral bandwidth of 0.5 nm, wavelength:

656.1nm, when the room temperature is stabilized.)

±0.05 nm

L2, L5, L10 nm (low stray-light mode)

M1, M2 nm (micro-cell mode)

-2 to 6 Abs

±0.002 Abs (0 to 0.5 Abs)

±0.003 Abs (0.5 to 1 Abs)

±0.3 %T

(Tested with NIST SRM 930D)

±0.001 Abs (0 to 0.5 Abs)

±0.001 Abs (0.5 to 1 Abs)

0.00008 % (220 nm NaI 10 g/L aqueous solution)

0.00008 % (340 nm NaNO2 50 g/L aqueous

solution)

0.00008 % (370 nm NaNO2 50g/L aqueous

solution)

(spectral band width: L2 nm, 10 mm cell used)

(Value obtained more than two hours after turning on the

light source, when the room temperature is stabilized,

wavelength: 250 nm, response: slow, and spectral

bandwidth: 2nm)

±0.0005Abs

(Value obtained after baseline correction with a

temperature variation of less than 5°C, wavelength: 200 to

800 nm, response: medium, spectral bandwidth: 2 nm,

smoothing processing and wavelength scanning speed:

400 nm/min)

time: 60 sec, response: Medium, spectral bandwidth: 2

nm)

100, 115, 200, 220, 230, 240 V ±10 %, 145 VA

270(H) ´ 460(W) ´ 602(D) mm (excluding protrusions)

29 kg

8

Page 22

Note: Values given for wavelength accuracy, wavelength repeatability, photometric

accuracy, photometric repeatability, baseline flatness, and RMS noise are

those obtained more than one hour after the light source was turned on.

2.4 V-670 UV/VIS/NIR Spectrophotometer Specifications

Optical system Single monochromator

UV/VIS region: 1200 lines/mm plane grating

NIR region: 300 lines/mm plane grating

Czerny-Turner mount

Double beam type

Light source Deuterium lamp: 190 to 350 nm

Halogen lamp: 330 to 2700 nm

Light source exchange

wavelength

Detector Photomultiplier tube

Detector exchange

wavelength

Wavelength range 190 to 2700 nm

Wavelength accuracy

Wavelength repeatability

Slew speed 12000 nm/min (UV/VIS region)

Spectral bandwidth 0.1, 0.2, 0.5, 1, 2, 5, 10 nm (UV/VIS region)

Photometric range 0 to 10000 %T

Photometric accuracy

Photometric repeatability

Stray light 1 % (198 nm KCL 12g/L aqueous solution)

Any wavelength between 330 and 350 nm can be selected.

PbS photoconductive cell

Any wavelength between 750 and 900 nm can be selected.

The diffraction grating is set to the same wavelength as the

detector exchange wavelength.

Using the optional wavelength extension accessory,

wavelength of up to 3200 nm can be measured.

±0.3 nm (at a spectral bandwidth of 0.5 nm, UV/VIS region,

when the room temperature is stabilized.)

±1.5 nm (at a spectral bandwidth of 2.0 nm, NIR region,

when the room temperature is stabilized.)

±0.05 nm (at a spectral bandwidth of 0.5 nm, UV/VIS

region)

±0.2 nm (at a spectral bandwidth of 2.0 nm, NIR region)

48000 nm/min (NIR region)

L2, L5, L10 nm (low stray-light mode, UV/VIS region)

M1, M2 nm (micro-cell mode)

0.4, 0.8, 1, 2, 4, 8, 20, 40 nm (NIR region)

L8, L20, L40 nm (low stray-light mode, NIR region)

M4, M8 nm (micro-cell mode, NIR region)

-2 to 4 Abs (UV/VIS region)

-2 to 3 Abs (NIR region)

±0.002 Abs (0 to 0.5 Abs)

±0.003 Abs (0.5 to 1 Abs)

±0.3 %T

(Tested with NIST SRM 930D)

±0.001 Abs (0 to 0.5 Abs)

±0.001 Abs (0.5 to 1 Abs)

0.005 % (220 nm NaI 10g/L aqueous solution)

0.005 % (340 nm NaNO2 50g/L aqueous solution)

0.005 % (370 nm NaNO2 50g/L aqueous solution)

(spectral band width: L2 nm, 10 mm cell used)

0.04% (1690 nm H2O 10 mm cell used)

9

Page 23

0.1% (1690 nm CH2Br2 50 mm cell used)

(spectral bandwidth: L8 nm)

Baseline stability 0.0003 Abs/hour

(Value obtained more than two hours after turning on the

light source, when the room temperature is stabilized,

wavelength: 250 nm, response: slow, and spectral

bandwidth: 2nm)

Baseline flatness

RMS noise 0.00003 Abs (0 Abs, wavelength: 500 nm, measurement

Power requirements

Dimensions and weight

±0.0005 Abs

(Value obtained after baseline correction with a temperature

variation of less than 5°C, wavelength: 200 to 850 nm,

response : medium, spectral bandwidth: 2 nm, smoothing

processing and wavelength scanning speed: 400 nm/min,

spectral bandwidth: 8 nm in wavelength 850 to 2500 nm)

time 60 sec, response: medium, spectral bandwidth: 2 nm)

100, 115, 200, 220, 230, 240 V ±10 %, 145 VA

270(H) ´ 460(W) ´ 602(D) mm (excluding protrusions)

28 kg

Note: Values given for wavelength accuracy, wavelength repeatability, photometric

accuracy, photometric repeatability, baseline flatness, and RMS noise are

those obtained more than one hour after the light source was turned on.

10

Page 24

3 General Description of Instrument

D D

Sam

F G

WI

5

M

2

S

2

4

WI D

2

S

F

G

BS

D

Sam

Ref

Deuterium lamp

H

alogen lamp

Slit

Grating

Bea

m

spl

itter

Detector

Sample beam

Reference beam

3.1 V-630 Spectrophotometer Optical System

(1) Optical System

The V-630 is designed to measure the absorption spectrum of a sample over a wavelength range

of 190 to 1100 nm. The light sources used are a deuterium (D2) lamp (190 to 350 nm) for the UV

region, and a halogen (WI) lamp (330 to 1100 nm) for the VIS/NIR region. The light from the light

source is focused and enters the monochromator. The light is dispersed by the grating in the

monochromator and focused onto the exit slit. The light that passes through the exit slit is

monochromated. This light is split into two beams, one going to the sample to be measured and

the other to the reference sample such as a solvent. The light that has passed through the

sample and the reference sample is incident upon the silicon photodiode.

M

1

D

Ref

M

M

2

Filter

S

3

(BS)

M

Figure 3.1 V-630 Optical system

(2) Electrical System

A schematic diagram of the electrical system used in the V-630 is shown in Fig. 3.2. The light

detected by the silicon photodiode is converted into an electrical signal and, after being subjected

to synchronous rectification, is converted into a digital signal and is sent to the computer. The

signal processed by the computer is displayed on the monitor as digital data or a spectrum.

Actions such as light source exchange, wavelength drive, filter drive, etc. are controlled by the

computer.

11

Page 25

Figure 3.2 V-630 electrical system diagram

12

Page 26

3.2 V-650/660/670 Spectrophotometers Optical System

(1) Optical System

The optical system varies between the models of the instrument. Figures 3.3 through 3.5 show

the optical systems. The V-650 measures the absorption spectrum of a sample over a

wavelength range of 190 to 900 nm, the V-660 measures the absorption spectrum of a sample

over a wavelength range of 187 to 900 nm and the V-670 measures the absorption spectrum of a

sample over a wavelength range of 190 to 2700 nm (can be extended to 3200 nm using the

optional wavelength extension accessory). The light sources used are a deuterium (D2) lamp (187

to 350 nm) for use in the UV region and a halogen (WI) lamp (330 to 2700 nm) for use in the

VIS/NIR region. The light from the light source is focused and enters the monochromator. It is

dispersed by the grating in the monochromator and focused on to the exit slit. The light that

passes through the exit slit is monochromated. This light is split into two beams by a sector mirror,

one going to the sample to be measured and the other to the reference sample such as a solvent.

The beams that have passed through the sample and reference sample are alternately incident

upon the detector (that is a photomultiplier tube or a PbS photoconductive cell).

WI, D2 : Light source

M : Mirror

S : Slit

F : Filter

G : Grating

M8 : Sector mirror

PM : Detector

Sam : Sample beam

Ref : Reference beam

W : Window

Figure 3.3 V-650 Optical system

13

Page 27

WI, D2 : Light source

M : Mirror

S : Slit

F : Filter

G : Grating

M8 : Sector mirror

PM : Detector

Sam : Sample beam

Ref : Reference beam

W : Window

Figure 3.4 V-660 Optical system

WI, D2 : Light source

M : Mirror

S : Slit

F : Filter

G : Grating

M8 : Sector mirror

PM : UV/VIS Detector

PbS : NIR detector

Sam : Sample beam

Ref : Reference beam

W : Window

Figure 3.5 V-670 Optical system

14

Page 28

(2) Electrical System

Figure 3.6 shows a schematic diagram of the electrical system used in the V-650, V-660 and V670 spectrophotometers. The light incident upon the photomultiplier tube or PbS photoconductive

cell is converted into an electrical signal and, after being subjected synchronous rectification, it is

converted into a digital signal. The signal processed by the computer is displayed on the monitor

as digital data or a spectrum.

Actions such as light source exchange, wavelength drive, slit drive, filter drive, etc. are controlled

by the computer.

Figure 3.6 V-650/660/670 electrical system diagram

15

Page 29

3.3 iRM System

Figure 3.7 shows the schematic diagram of the iRM system.

The iRM can be connected to the V-630/650/660/670 spectrophotometers, and can be used to

control measurement, printing, and saving. Various menus can be selected using the touch panel

key on the color LCD.

Figure 3.7 iRM system diagram

16

Page 30

4 Names and Functions of Components

4.1 V-630 Spectrophotometer

4.1.1 Overview

Sample compartment

Light source lid

“START” switch

“Power" switch

Fixing screws

Figure 4.1 V-630 appearance

Name Function

Sample compartment Slide the lid to the back to open it. The single position cell holder

(the standard cell holder) is installed. The cell holder located

toward the front is the sample cell holder, and the one located

toward the rear is the reference cell holder.

Fixing screws Fixes the standard cell holder in position. Loosen the two fixing

screws, pull the standard cell holder toward you a little and lift to

remove it.

“Power” switch When the switch is pressed on, the power supply is turned on.

“START” switch Switch to start measurement. The lamp flashes during

measurement.

Light source lid The light source is housed here.

17

Page 31

4.1.2 Rear Panel

"

AUX

"

"

GND

"

" iRM "

Fuse

" RECORDER "

" USB "

"AC INPUT"

Warning indications

Figure 4.2 V-630 rear panel

Name Function

AC INPUT The power supply input connector. Connect with the power cable.

Fuse Fuses for the main unit

Warning

indications

GND Grounding terminal

RECORDER Terminal for analog output.

AUX Auxiliary connector for connecting an accessory.

iRM Connector for connecting the cable of iRM.

USB Connector for connecting the cable with PC.

Warning indications for fuse and ground.

The value specified by setting the scale of [Abs/%T meter] program is

recorded in the range 0 to 1 V.

18

Page 32

4.2 V-650/660/670 Spectrophotometers: Overview

Light source lid

"

START

" switch

4.2.1 Overview

Sample compartment

Fixing screws

"Power" switch

Figure 4.3 V-650/660/670 appearance

Name Function

Sample compartment Slide the lid back to open it. The single position cell holder (the

standard cell holder) is installed. The cell holder located toward

the front is the sample cell holder, and the one located toward the

rear is the reference cell holder.

Fixing screws Fixes the standard cell holder in position. Loosen the two fixing

screws, pull the standard cell holder toward you a little and lift to

remove it.

“Power” switch When the switch is pressed on, the power supply is turned on.

“START” switch Switch to start measurement. The lamp flashes during

measurement.

Light source lid The light source is housed here.

19

Page 33

4.2.2 Rear Panel

"AC I

NPUT

"

Fuse

"

AUX

"

"

GND

"

"

USB

"

" RECORDER "

" iRM "

Warning indications

Figure 4.4 V-650/660/670 rear panel

Name Function

AC INPUT The power supply input connector. Connect with the power cable.

Fuse Fuses for the main unit.

Warning

indications

GND Grounding terminal.

RECORDER Terminal for analog output.

AUX Auxiliary connector for connecting an accessory.

iRM Port for connecting the cable of iRM.

USB Port for connecting the cable with PC.

Warning indications for fuse and ground.

The value specified by setting the scale of [Abs/%T meter] program is

recorded in the range 0 to 1 V.

20

Page 34

4.3 Standard Cell Holder (Model USE-753 Rectangular Cell Holder)

Accessory information

Accessory information

Reference cell holder

Sample cell holder

contact

Fixing screw holes

chip

Figure 4.5 Standard cell holder (Model USE-753 Rectangular cell holder)

Name Function

Sample cell holder Mount the cell containing the sample here.

Reference cell holder Mount the cell containing the reference solvent here.

Fixing screw holes Screw holes for attaching the standard cell holder.

Accessory information

Memory chip for accessory information.

chip

Accessory information

Contact pin for reading accessory information.

contact

21

Page 35

4.4 Intelligent Remote Module (iRM)

Display panel

Cable

(Appearance)

Connector for printer

(USB interface)

Connector for printer

(Parallel I/0 interface)

Card slot

Connector for accessory

(Rear panel)

Figure 4.6 Intelligent remote module

Name Function

Display panel 320x240 pixel color LCD. Displays wavelength, absorbance,

measurement parameters, etc. Also used for selecting menus and

editing measurement parameters via the touch key pad.

Cable Connects to the main unit.

Card slot

Connector for printer

Connector for

accessory

Accepts a compact flash card or a flash ATA card. Card adapter is

necessary for the compact flash card.

Connector for the printer (USB interface and parallel I/O interface).

Connects to an accessory.

22

Page 36

5 Maintenance

Pay attention to the instrument operating environment and always keep it clean so that the

instrument can be used in a stabilized condition over a long period.

This section contains instructions on how to clean the sample compartment when a sample is

spilt, and on replacing consumables.

It is recommended that the validation program be used for checking the performance of the

instrument.

5.1 Cautions for Routine Operation

(1) Before operating the instrument, allow the instrument to warm-up for at least 15 minutes after

turning the power on.

(2) Do not place anything on the instrument.

(3) After completing measurements, remove the sample from the sample compartment.

5.2 Cleaning the Sample Compartment

If a sample is spilt in the sample compartment, quickly wipe up the spillage using gauze or a

similar material, remove the cell holder, and clean it using the following procedure.

CAUTION: Use ethanol to clean the sample compartment. Do not use other types

of organic solvent as this may remove the instrument paint.

(1) Removing the standard cell holder

a) Open the sample compartment lid and loosen the two fixing screws located on the front

underside of the sample compartment by hand (see Fig. 4.1 or Fig. 4.3).

b) Pull the standard cell holder toward you a little and lift to remove it.

(2) Cleaning the standard cell holder

<<When the sample is soluble in water>>

Wipe up the spilt sample using gauze or a similar material. Remove any trace of the spillage

with gauze soaked in water. Finally, remove any moisture with gauze and then allow drying.

<<When the sample is insoluble in water>>

Wipe up the spilt sample using gauze or a similar material. Remove any trace of the spillage

with gauze soaked in ethanol. Finally, remove any moisture with gauze and then allow drying.

(3) Remounting the standard cell holder

a) Locate the standard cell holder over the two positioning pins on the main unit certainly

and move it toward to the back.

b) Ensure that light is incident upon the center of the cell holder. To check it visually, set the

wavelength to 500 nm and place a piece of white paper in front of the cell holder.

c) Firmly tighten the two fixing screws of the bottom of the standard cell holder.

23

Page 37

5.3 Replacement of Consumables

5.3.1 Replacement of Fuse

WARNING!: Only use fuses of the rated capacity to prevent injury to personnel

and overheating of the instrument.

WARNING!: To avoid electric shock, always turn off the power switch and unplug

the AC power cable from the outlet before replacing a fuse.

V-630 uses 2A time-lag fuses (P/N: 5840-H102A 5pcs/set) when using a 100 V voltage supply

and 1.6 A time-lag fuses (P/N: 5840-H106A 5pcs/set) when using a 200 V voltage supply. V650/660/670 use 2.5 A time-lag fuses (P/N: 5840-H103A 5pcs/set) when using a 100 V voltage

supply and 1.6 A time-lag fuses (P/N: 5840-H106A 5pcs/set) when using a 200 V voltage supply.

(V-630)

100 V to 120 V: 2.0 A time-lag fuse

200 V to 240 V: 1.6 A time-lag fuse

(V-650/660/670)

100 V to 120 V: 2.5 A time-lag fuse

200 V to 240 V: 1.6 A time-lag fuse

Fuse

Figure 5.1 V-630 rear panel

Fuse

Figure 5.2 V650/660/670 rear panel

24

Page 38

Fuse

s

Note: Replace both fuses, even if only one is burned out.

(1) Turn off the power and disconnect the AC power cable from the “AC INPUT”.

(2) Insert a flat-head screwdriver under the fuse holder, then pull forward to remove the fuses

with the holder (Fig. 5.3).

(3) Take the old fuses out of the holder, and replace with new ones. Insert the fuse holder in its

original position.

(4) Plug the power cable into the “AC INPUT” and turn the power switch on, then check that the

instrument can be operated.

Note: If the fuses burn out again soon after replacement, contact your nearest local

JASCO distributor.

Fuse holder

Figure 5.3 Replacement of fuse

25

Page 39

5.3.2 Lamp Replacement and Adjustment of the Light Source Mirror

The lifetime of both the deuterium (D2) lamp and the halogen (WI) lamp is approx. 1000 hours.

After prolonged use, the noise level in the measured data will increase because of the low light

intensity.

5.3.2.1 Lamp replacement

WARNINGS!:

(1) The lamp is hot when lit. Therefore, before replacing the lamp,

switch off the light source and wait for at least 15 minutes.

(2) To avoid electric shock, turn off the power and remove the power

cable from the outlet.

Notes:

(1) Never loosen any screws other than those required for lamp

replacement.

(2) When handling the lamp, wear clean cloth gloves. Never handle the

lamp with bare hands.

(3) Never touch the mirror or any other optical elements by hands.

(4) If the lamp surface is contaminated, clean it with gauze soaked in

ethanol and wipe it with dry clean gauze.

<<Replacement of halogen (WI) lamp>>

(1) Slide the outer lid of the light source unit to remove it and then remove the inner lid (Fig. 5.4).

The way to remove the lamp is the same for V-630, even though V-650/660/670 is shown in

figure 5.4.

Light source lid (inner side)

Light source lid (outside)

Figure 5.4 Removal of light source lid (V-650/660/670)

(2) Remove the halogen lamp from the socket.

(3) Insert a new halogen lamp into the socket (Fig. 5.5 or 5.6).

(4) Adjust the light source mirror as described in Section 5.3.2.2 or 5.3.2.3.

26

Page 40

<<Replacement of deuterium lamp>>

2

WI lamp stopper

2

A

djustment screw

WI

lamp

D2 lamp stopper

Adjuatment screw

(1) Slide the outer lid of the light source unit to remove it.

(2) Remove the deuterium lamp from the socket.

(3) Insert a new deuterium lamp into the socket (Fig. 5.5 or 5.6).

(4) Adjust the light source mirror as described in Section 5.3.2.2 or 5.3.2.3.

lamp stopper

D

Adjustment screw

lamp

D

WI lamp

Figure 5.5 Light source unit (V-630)

WI lamp stopper

Adjustment screw

D

lamp

2

Figure 5.6 Light source unit (V-650/660/670)

5.3.2.2 Adjustment of iRM type light source mirror

When the light source is replaced, if the beam from the lamp is not incident upon the entrance slit

correctly, problems will occur, such as insufficient light intensity, a non-linear baseline, and

incorrect values for measurements. Whenever the lamp is replaced, be sure to adjust the light

source mirror.

WARNINGS!:

(1) The lamp is hot when lit. Do not touch with bare hands.

(2) Wear glasses (ordinary glasses or sunglasses) during adjustment to

(3) Do not touch the wiring either with your hand or with a screwdriver.

Note: Never loosen any screws other than those required for lamp replacement.

protect your eyes from ultraviolet rays.

Contact with the wiring may cause electric shock.

27

Page 41

<<Adjustment of light source mirror for halogen lamp>>

(1) Turn on the instrument and the halogen lamp.

(2) Select [Environment] from the main menu to display the [Environment] menu.

(3) Select [Single Beam Measurement] from the [Environment] menu to display the single beam

measurement window.

(4) Set parameters as follows.

V-630 measurement parameters V-650/660/670 measurement parameters

Photometric mode Sam Photometric mode Sam

Response Fast Response Fast

Band Width 2.0 nm

PMT Voltage 200 V

(5) Set the wavelength to 500 nm.

(6) Slide the lid of the light source unit to remove it (see Fig. 5.4).

Note: Do not mistakenly loosen other screws instead of the adjustment screw.

(7) Turn the halogen lamp stopper adjustment screw (Fig. 5.5 or 5.6) and search for a position

where the value displayed on the monitor is a maximum.

(8) Replace the lid of the light source unit.

<<Adjustment of light source mirror for deuterium lamp>>

(1) Turn on the instrument, and light the deuterium lamp.

(2) Select [Environment] from the main menu to display the [Environment] menu.

(3) Select [Single Beam Measurement] from the [Environment] menu to display the single beam

measurement window.

(4) Set parameters as follows.

V-630 measurement parameters V-650/660/670 measurement parameters

Photometric mode Sam Photometric mode Sam

Response Fast Response Fast

Band width 2.0 nm

PMT voltage 300 V

(5) Set the wavelength to 250 nm.

(6) Slide the lid of the light source unit to remove it (see Fig.5.4).

Note: Do not mistakenly loosen other screws instead of the adjustment screw.

(7) Turn the deuterium lamp stopper adjustment screw (Fig. 5.5 or Fig. 5.6) and search for a

position where the value displayed on the monitor is a maximum.

(8) Replace the of the light source unit.

28

Page 42

5.3.2.3 Adjustment of PC type light source mirror

When the light source is replaced, if the beam from the lamp is not incident upon the entrance slit

correctly, problems will occur, such as insufficient light intensity, a non-linear baseline, and

incorrect values for measurements. Whenever the lamp is replaced, be sure to adjust the light

source mirror.

WARNINGS!:

(1) The lamp is hot when lit. Do not touch with bare hands.

(2) Wear glasses (ordinary glasses or sunglasses) during adjustment to

protect your eyes from ultraviolet rays.

(3) Do not touch the wiring either with your hand or with a screwdriver.

Contact with the wiring may cause electric shock.

Note: Never loosen any screws other than those required for lamp replacement.

<<Adjustment of light source mirror for halogen lamp>>

(1) Turn on the instrument.

(2) Start [Abs/%T meter] from the [Spectra Manager] window and appears the [Abs/%T meter]

window.

(3) Set parameters as follows.

V-630 measurement parameters V-650/660/670 measurement parameters

Photometric mode Sample Photometric mode Sample

Response Fast Response Fast

Wavelength 500 nm Band Width 2.0 nm

Halogen lamp Turn on Wavelength 500 nm

HT Voltage 200 V

Halogen lamp Turn on

(4) Slide the lid of the light source unit to remove it.

Note: Do not mistakenly loosen other screws instead of the adjustment screw.

(5) Turn the WI lamp stopper adjustment screw (Fig. 5.5 or Fig. 5.6) and search for a position

where the value displayed on the monitor is a maximum.

(6) Replace the lid of the light source unit.

<<Adjustment of light source mirror for deuterium lamp>>

(1) Turn on the instrument.

(2) Start [Abs/%T meter] from the [Spectra Manager] window and appears the [Abs/%T meter]

windows.

(3) Set parameters as follows.

V-630 measurement parameters V-650/660/670 measurement parameters

Photometric mode Sample Photometric mode Sample

Response Fast Response Fast

Wavelength 250 nm Band Width 2.0 nm

Deuterium lamp Turn on Wavelength 250 nm

PMT Voltage 200 V

Deuterium lamp Turn on

29

Page 43

(4) Slide the id of the light source unit to remove it (see Fig.5.4).

Note: Do not loosen screws other than the adjustment screw for the stopper.

(5) Turn the deuterium lamp stopper adjustment screw (Fig. 5.5 or Fig. 5.6) and search for a

position where the value displayed on the monitor is a maximum.

(6) Replace the lid of the light source unit.

5.3.3 Consumable Parts

Table5.1 gives consumable parts necessary for maintenance. On any order, please quote the

part names and also the part numbers.

Table 5.1 Consumable parts

Part name Part number Description

Halogen lamp (WI) 5330-0099

Deuterium lamp (D2) 5330-0094B

Fuse (2.0 A Time-lag fuse) 5840-H102A 5 fuses/set, V-630, 100 V

Fuse (2.5 A Time-lag fuse) 5840-H103A 5 fuses/set, V-650/660/670, 100 V

Fuse (1.6 A Time-lag fuse) 5840-H106A 5 fuses/set, V-630/650/660/670, 200 V

30

Page 44

6 Troubleshooting

If the spectrophotometer does not operate normally, it may be due to the following causes:

· Erroneous operation

· Deterioration of a consumable parts

· Instrument trouble

Possible causes and corrective actions to be taken against these problems are given below in the

troubleshooting chart. In the event that the trouble cannot be corrected after following the actions

given in the troubleshooting chart, contact your local JASCO distributor and provide the model

name and serial number of your instrument together with a complete description of the problem.

When checking the instrument, observe the following warnings and cautions.

WARNINGS!:

(1) Do not directly look at the light (ultraviolet ray) emitted from the deuterium

lamp as this may cause injury your eyes. Wear glasses (ordinary glasses

or sunglasses) during adjustment.

(2) The lamp is very hot when lit. When the lamp is lit do not touch with bare

hands. Before replacing the lamp, wait for at least 15 minutes after turning

off the lamp until the lamp cools down.

(3) Before checking the electrical system, be sure to turn off the power

switch.

Notes:

(1) Before plugging in the AC power cable, ensure that the power switch is in

the OFF position.

(2) Never touch the mirror or any other optical elements by hands.

31

Page 45

Symptoms Check Possible solutions

The instrument does

not operate at all.

WI lamp does not

come on.

D2 lamp does not

come on.

The baseline is curved

greatly, in excess of

1%.

When the light source

is changed from WI to

D2, the step height of

the baseline is greater

than 1%.

The performance at

wavelengths shorter

than 320 nm is not

stable.

The performance at

wavelengths longer

than 400 nm is not

stable.

Noise is high.

1. Check if the power cable is

securely plugged into the outlet.

2. Remove the power cable from

the outlet and check the fuse in

the main unit. Replace the fuse if

blown.

Check the WI lamp to see if it has

burnt out.

Check the D2 lamp to see if it has

burnt out.

Check if baseline correction is set

to “OFF”.

1. Check if baseline correction is

set to “OFF”.

2. Poor adjustment of light source

mirror.

3. Check if the standard cell holder

is in good contact with the two

positioning pins. The beam may

be incident upon the cell holder.

D2 lamp is “OFF”. Turn the D2 lamp “ON”

WI lamp is “OFF”. Turn the WI lamp “ON”.

1. Check if light is incident upon

the center of the entrance slit.

2. Spectral bandwidth is too small. 2. Increase the spectral

3. The absorption of the solvent

placed on the reference beam

side is too high.

4. Lamp output has deteriorated. 4. Replace the lamp with a

1. Reconnect the cable

securely, if disconnected.

2. Replace the fuse if it

blows. (Refer to Section

5.3.1.) If the fuse blows

immediately after

replacement, the electrical

system is faulty. Contact

your local JASCO

distributor.

Replace the lamp with a new

one if burnt out. (Refer to

Section 5.3.2.)

Replace the lamp with a new

one if burnt out. (Refer to

Section 5.3.2.)

Set it to “ON” if set to “OFF”

(Refer to the Software

manual.)

1. Set it to “ON” if set to

“OFF”. (Refer to the

Software manual.)

2. Re-adjust the mirror

referring to Section 5.3.2.2

or Section 5.3.2.3.

3. Set the standard cell

holder in the correct

position.

(Refer to the Software

manual.)

(Refer to the Software

manual.)

1. If not, adjust the light

source mirror. (Refer to

Section 5.3.2.2 or Section

5.3.2.3.)

bandwidth.

3. Replace the solvent with a

more suitable one.

new one. (Refer to Section

5.3.2.)

32

Page 46

JASCO Corporation

2967-5, Ishikawa-machi, Hachioji-shi

TOKYO, JAPAN

Printed in Japan

Loading...

Loading...