Page 1

MODEL J-810

SPECTROPOLARIMETER

Hardware/Function Manual

JASCO Corporation

P/N: 0302-0407A March 1999

Page 2

Safety Cautions

Correct operation and scheduled maintenance are essential for safe use

of the instrument. Read the safety cautions in this manual and fully

understand them before operation.

″WARNING″, ″CAUTION″ and ″Note″ are used throughout this manual

to call operator′s attention to safety.

(1) Meanings of safety notations

WARNING : Failure to comply with this involves the possibility of death

or serious personal injury. Serious personal injury means

loss of sight, injury, burn (high temperature, low

temperature), electric shock, fracture, intoxication, etc.

which can cause sequel or require hospitalization or longterm treatment at hospital.

CAUTION : Failure to comply with this involves the possibility of minor

personal injury or physical damage. Minor personal injury

means injury that does not require hospitalization or longterm treatment, and physical damage means damage to the

instrument itself or damage to objects other than the

instrument, such as buildings, properties, etc. (extended

damage).

Note : This contains care to be taken during operation and

information that will be helpful in operation.

i

Page 3

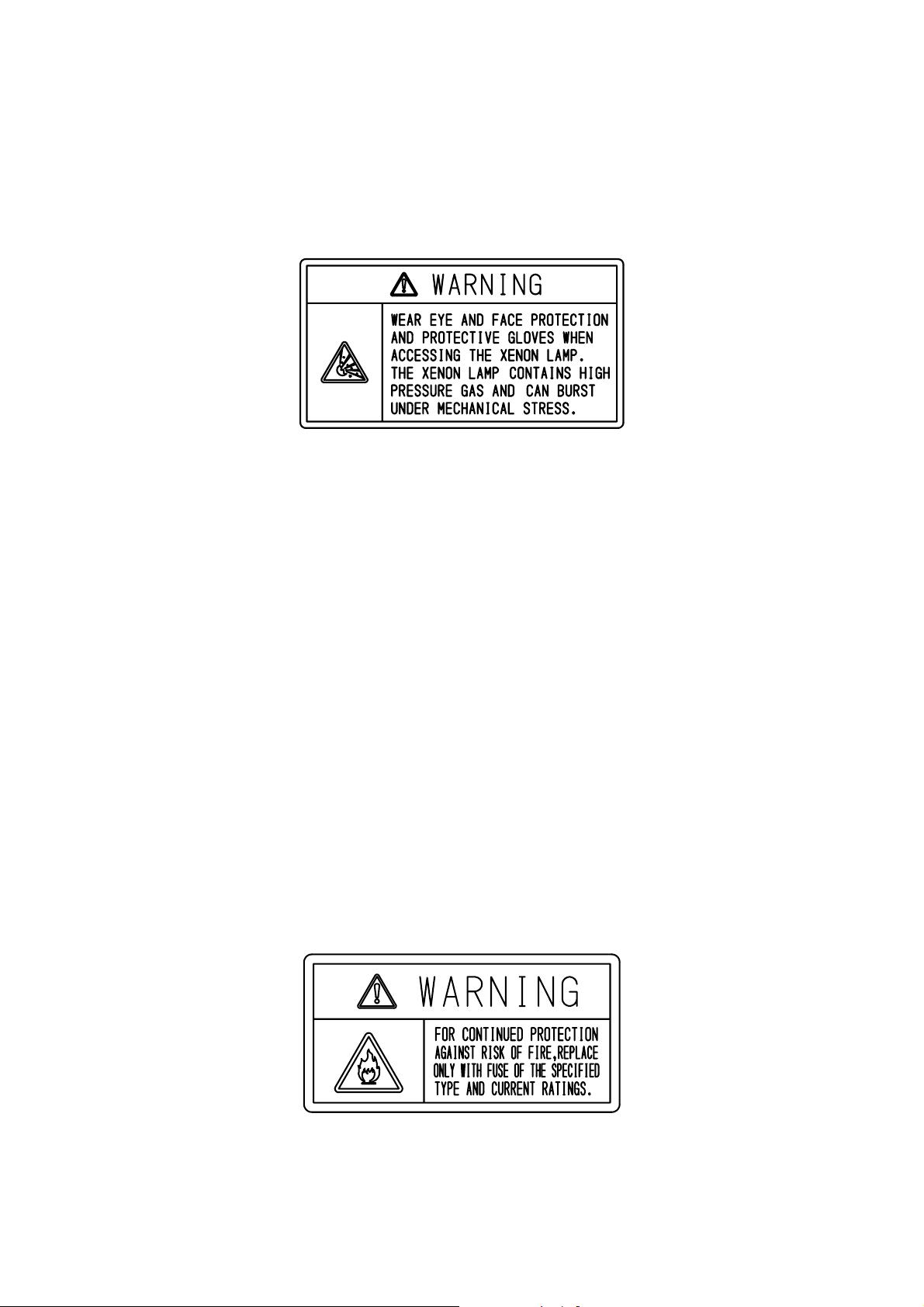

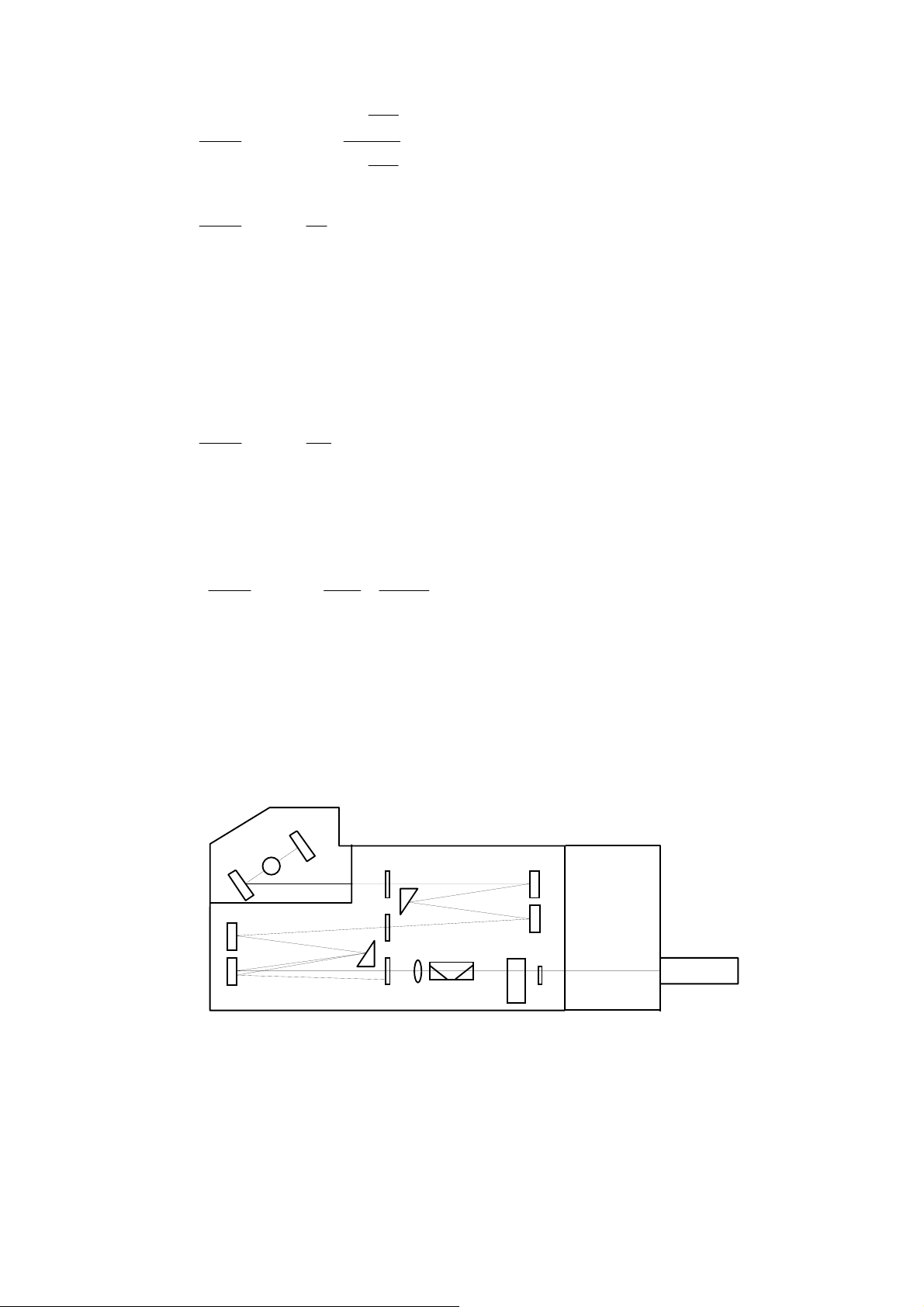

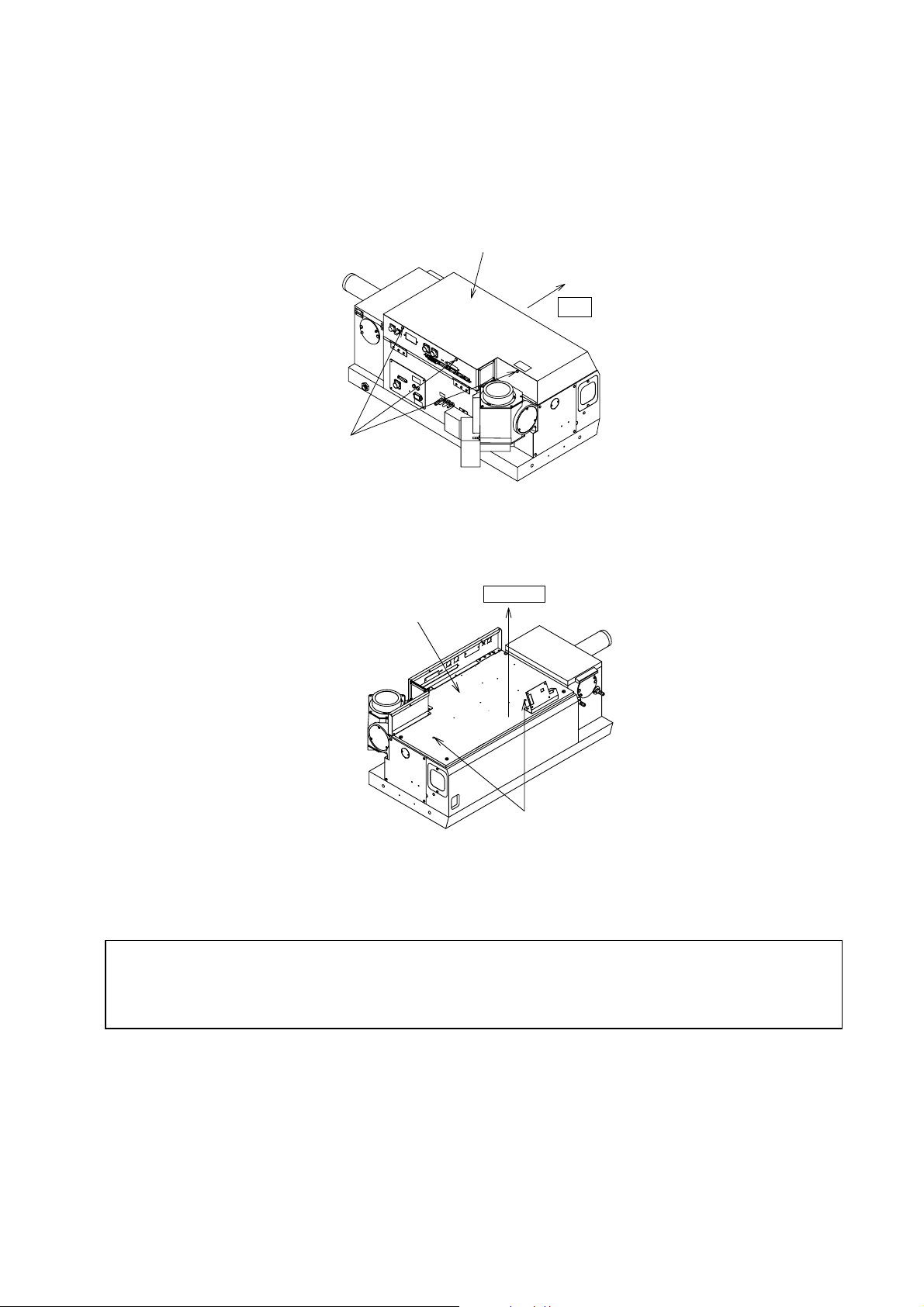

(2) Location of Warning Labels

The instrument is labeled with the following warnings. Use care not to damage or

tear the labels. Should the labels be stained or torn, contact your local JASCO

distributor with its part number.

1) WARNINGS! Handling the Xenon Lamp (①of Fig. 1)

Part number:0822-0127A

. The xenon lamp is made of quartz glass and is filled with high-pressure gas (5 to 10

atm. pressure, about four times when the lamp is lit).

Twisting, bending or impact can burst the lamp, causing danger with glass

fragments. Never open the lid of the light source unit if the lamp is lit or hot.

. When handling the xenon lamp, wear protective clothing such as a thick, long-

sleeved shirt, a mask, thick gloves, etc.

. Before replacing the xenon lamp, turn the lamp off and allow it to cool for about 30

minutes.

When replacing the xenon lamp, be careful not to give an impact to the lamp.

Never twist the lamp by holding it at both ends.

. Do not mistake the mounting direction (polarity) of the lamp. The cathode will be

damaged if the lamp is mounted incorrectly, rendering the lamp inoperable.

. Do not touch the glass portion of the xenon lamp with bare skin.

. If the glass portion of the xenon lamp is contaminated, wipe it with clean gauze

moistened with alcohol.

. After removal and before disposal, place the xenon lamp in its case, and store the

case in a safe place. If the case is not available, carefully wrap the lamp in

foamed plastic or other protective wrapping, and store it in a same place.

. When disposing of the xenon lamp, carefully wrap it in a cloth, smash it with a

hammer, and dispose of it as hazardous material.

WARNING! Fuse Rating (②in Fig. 1)

Part number:0822-0102A

ii

Page 4

Use only fuses of the designated rating to protect both the operator and the

equipment from fire and other hazards. When replacing the fuse, turn OFF the ″

Power″ switch and unplug the power cable from the outlet to avoid electric shock.

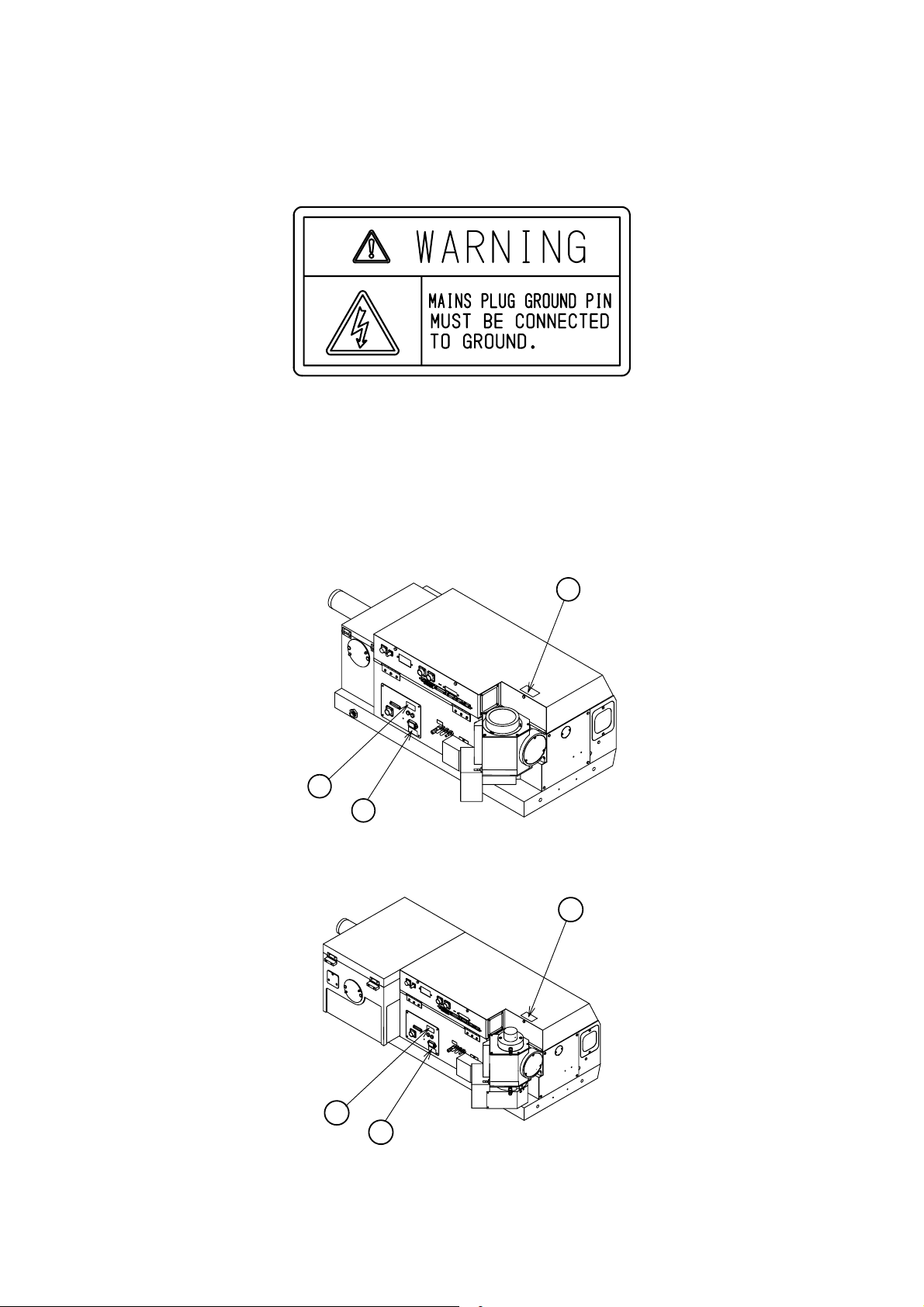

WARNING! Grounding (③in Fig. 1)

Part number:0822-0109A

If the instrument is operated without being grounded properly, the operator may be

subjected to electric shock. Correctly ground the instrument using the grounding

terminal on the switchboard. Do not use gas or water pipes for grounding, because

these pipes are often made of non-conductive material.

150W Light Source, Small Sample Chamber

2

3

450W Light Source, Large Sample Chamber

1

1

2

3

Fig. 1

iii

Page 5

Introduction

This manual is intended to serve as a guide for using the Model J-810

spectropolarimeter, both for experienced and first-time operators.

Prior to operating the instrument, the operator should carefully read and thoroughly

understand the contents of these manuals. In addition, the ″Measurement″,

″Analysis″ and ″ CD-ORD Measurement Method″ instruction manuals should be

understood in full. These three manuals should be kept at your hand at all time

during operation of the instrument. After operation, keep these manuals in your file.

Should the manuals be lost, contact your local JASCO distributor for an additional

copy.

Installation Requirements

Install the instrument in a location where the following conditions are satisfied. The

instrument should be installed in a room that is maintained at a constant temperature

and humidity, because the spectropolarimeter is sensitive to atmosphere fluctuations.

. Room temperature 20 ±5°C

. Humidity lower than 70%

. Not exposed to direct sunlight

. Not in the proximity of harmful or corrosive gas

. Not exposed to a high-intensity light source

. Not in the direct path of air currents emanating from air conditioners or other

equipment

. Relatively free of vibration

. Not in the proximity of a high-intensity magnetic or electromagnetic field

. For the 450W light source, within the proximity of a water supply (flow rate : 2 λ

/min, pressure : 0.5~2.0 kg/cm2). Cooling water piping : 10 m in length, inside

diameter : 12 mm

Note: Do not use water at more than 2.0 kg / cm2 pressure.

. Within the proximity of equipment that supplies nitrogen gas. (flow rate : more

than 3 λ/min). Nitrogen gas tube : 3 m in length, inside diameter : 9.5 mm.

. Within the proximity of nitrogen gas ventilator.

iv

Page 6

Contents

1. Overview and Specifications .........................................................1

1.1 Overview................................................................................................. 1

1.1.1 Principles of operation ...................................................................... 1

1.1.2 Optical system .................................................................................. 2

1.1.3 Electrical system............................................................................... 3

1.2 Specifications.......................................................................................... 4

2. Unpacking and Installation ............................................................7

2.1 Unpacking............................................................................................... 7

2.2 Installation Requirements ....................................................................... 7

2.3 Reassembly ............................................................................................ 8

2.3.1 Removing the cushion from the main unit......................................... 8

2.3.2 Installing the modulation element ..................................................... 9

2.3.3 Installation the detector unit ............................................................ 10

2.3.4 Connecting the cables and tubes.................................................... 11

3. Names of Functions of Components ...........................................14

3.1 Overall View.......................................................................................... 14

3.2 Panels................................................................................................... 17

3.3 Sample Chamber .................................................................................. 20

3.4 Detector Unit......................................................................................... 22

4. MAINTENANCE ..........................................................................23

4.1 Light Source Check and Replacement.................................................. 23

4.2 Energy Check ....................................................................................... 25

4.3 Wavelength Accuracy Check and Adjustment ...................................... 27

4.4 CD Scale Check and Adjustment.......................................................... 28

4.5 Test Signal Check ................................................................................. 30

5. TROUBLESHOOTING ................................................................31

v

Page 7

π

I

I

1. Overview and Specifications

1.1 Overview

1.1.1 Principles of operation

When linearly-polarized light passes through an optically-active substance, its two

circularly-polarized components (right and left circularly-polarized beams of light) travel

at different speeds, and are absorbed in differing degrees by the substance. Thus, the

light passing through the substance is elliptically polarized, and the substance is said to

have ″Circular Dichroism (CD)″. The magnitude of circular dichroism is usually

expressed in terms of molecular elliptically [θ], which is determined according to the

following formula :

4500

θ

=−

where, εL and ε

R

polarized beams of light. The difference (∆ε) between εL and ε

the following formula :

εεε

RL

[]

θ

=

4500

LC

π

In equation (2) and (3), L represents the thickness (cm) of the absorbing layer, and C

represents the molar concentration, I

left circularly-polarized beams of light, respectively, after passing through the substance.

Theoretically, the molecular ellipticity can be derived using equation (3). However, in

practice, determining [θ] with a high degree of accuracy is very difficult using equation

(3), because the value of IR.IL is nearly 1. To avoid this difficulty, we substitute the

following quantities.

1

()

2

S

=−

RL

(5)

Since S/2

Ι

is less than 1, equation (3) can be re-expressed as follows, by substituting

A

the expressions from equations (4) and (5) :

εε

LR e

10( ) log

(1)

are the molecular extinction coefficients for the right and left circularly-

is determined using

R

1

log

=−=∆

LC

log10log

e

III +=

(4)

LRA

I

R

10

10

(2)

I

L

I

R

(3)

I

L

and IL represent the intensities of the right and

R

1

Page 8

S

+

1

4500

[]

=

θ

LC

π

e

log10log

10

−

1

I

2

A

S

(6)

I

2

A

=

4500

LC

π

S

e

log10log

I

A

e

10

Thus, the ratio between IA and S can be approximated with an accuracy sufficient for

practical application.

Given that EA and ES represent the output voltages of the photomultiplier tubes

corresponding to light intensities IA and S respectively, S/IA = ES/EA. By substituting

this expression, equation (6) can be expressed as follows.

4500

[]

θ

= e

π

LC

E

S

e 10

log10log

E

A

(7)

Here, if ES can be amplified independently of EA, equation (7) can be expressed as

follows.

4500

[]

=

θ

LC

π

10log

e

GE

S

E

A

log

e

10

(8)

G

where G represents the amplification factor of ES. Since the value ESG can be brought

very close to the value of E

by choosing an appropriate value for G, [θ] can be

A

determined with a high degree of accuracy.

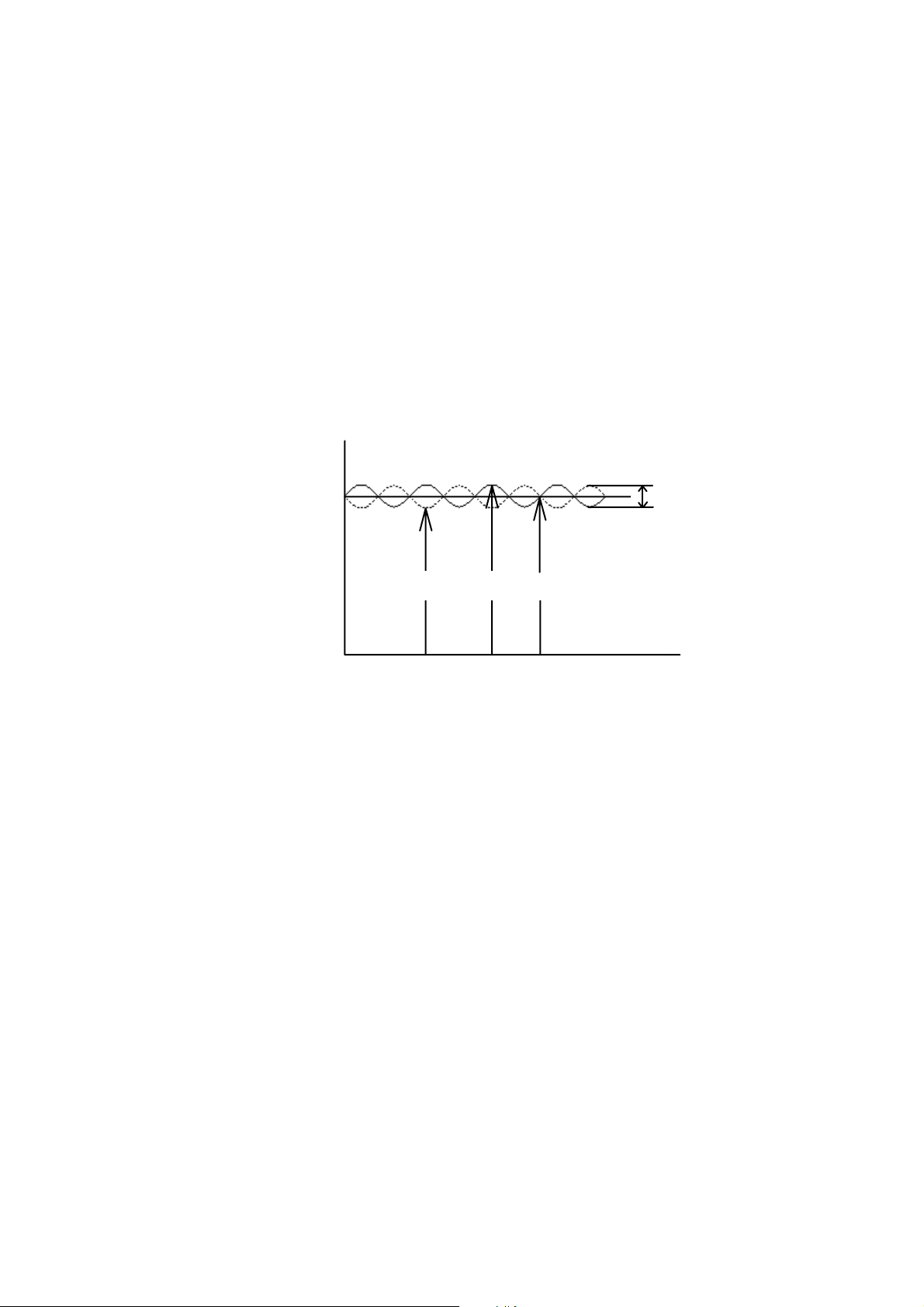

1.1.2 Optical system

Fig. 1.1 shows the optical system of the Model J-810 spectropolarimeter.

M

0

P

O-ray

E-ray

S

2

S

1

S

3

P

1

2

L F CDM

M

M

SH

2

3

PM

M

LS

1

M

4

M

5

M0, M1, Mp, M2 ~ M5 : Mirrors LS : Light source

~ S3 : Slits P1 : First prism (horizontal optical axis)

S

1

P

: Second prism (vertical optical axis) O-ray : Ordinary ray

2

E-ray : Extraordinary ray L : Lens

F : Filter CDM : Modulator

SH : Shutter PM : Photomultiplier tube

Fig. 1.1 Block diagram of optical system

2

Page 9

A xenon lamp is used as the light source. The light emitted from the xenon lamp is

converged by the M1 mirror into the S1 entrance slit. The optical system between the

S1 entrance slit and the S2 intermediate slit is referred to as the first monochromator,

and the optical system between the S2 intermediate slit and the S3 exit slit is referred to

as the second monochromator. Such an optical system, comprised of two

monochromators, is known as a double monochromator. The capability of a double

monochromator reducing stray light makes it indispensable for CD measurement.

The instrument uses crystal prisms (P1 and P2) that have different axial orientations, so

that the light that passes through the monochromator is not only monochromated, but

also linearly polarized, and oscillates in the horizontal direction.

This linearly-polarized light is modulated by the modulator into right and left circularlypolarized beams of light. The modulator subjects quartz to mechanical stress in order

to produce circular polarization in the crystal, based on the principle of the Piezo effect.

When a sample with circular dichroism is placed in the sample chamber, the intensity, I,

of the transmitted light changes as shown in Fig. 1.2 :

Intensity

I

L

I

I

R

A

Time

S

Fig. 1.2 Intensity of transmission light

The relationship between the minimum and maximum intensities and the right and left

circularly-polarized light depends on whether the value E

value E

the dotted line represents the case when E

and S, refer to Section 1.1.1

. In Fig. 1.2, the solid line represents the case when ER is greater than EL, and

L

is smaller than EL. For the definitions of IA

R

″Principles of operation″.

is smaller or larger than the

R

When light with intensity fluctuations such as that shown in Figure 1.2 is incident upon

the photomultiplier tube, the output signal consists of DC components equivalent to I

A

and AC components equivalent to S.

,

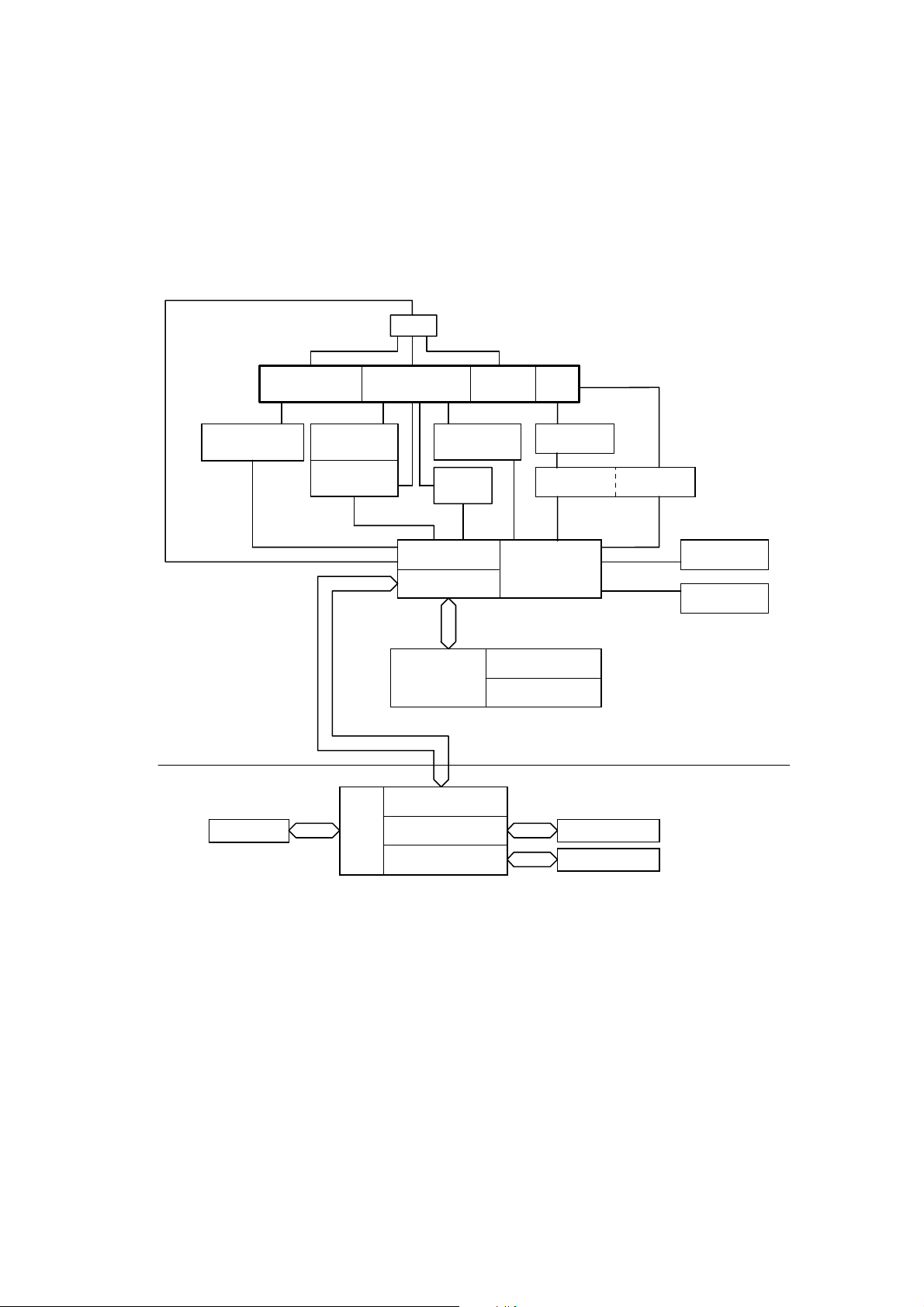

1.1.3 Electrical system

The output signal from the detector (PM photomultiplier tube) consists of an AC

component electrically modulated by the modulator and a DC component that

represents the average intensity of the transmission light. The CD value can be derived

from the ratio between the DC component and the AC component. This instrument

varies the PM voltage in order to maintain a constant DC component, and utilizes the

AC component as the CD signal. Therefore, once the AC signal is calibrated using a

standard sample, the correct CD value can be obtained.

Fig 1.3 shows a block diagram of the electrical system. Since the AC and DC

components can be discussed independently, they are described separately in

reference to Figure 1.3.

3

Page 10

The DC component is separated between the preamplifier and the CD amplifier, and is

compared with the reference voltage in order to control the voltage of the PM power

supply. This voltage is also applied to the PM detector, changing the PM sensitivity.

The AC component is converted to a digital signal after being amplified by the

preamplifier and the CD amplifier.

The main unit and the personal computer communicate through the RS-232C interface.

All parameters of the main unit are designated from the personal computer. The CD

signal and PM voltage are communicated to the personal computer through the RS232C interface after being converted to digital signal and stored in the buffer memory.

Sensor

Light Source

Light Source

Power Supply

Main Unit

PC

Monochromator

Slit Motor

Driver

Wavelength

Motor Driver

Modulator

Driver

Shutter

Driver

I/O

RS-232C I/F

CPU

RS-232C I/F

Sample

Chamber

Buffer Memory

Program Memory

PM

Preamplifier

CD Amplifier

A/D D/A

PM Power

Supply

External

Input 1

External

Input 2

Keyboard

PC

SVGA

Parallel I/F

CRT Display

Printer

Fig. 1.3 Block diagram of electrical system

1.2 Specifications

Light source : 150W air-cooled xenon lamp, or 450W water-cooled xenon

lamp

Detector : Head-on photomultiplier tube

Modulator : Piezoelastic modulator

Measurement wavelength range : 163 to 900 nm (standard detector)

163 to 1100 nm (optional detector)

Wavelength accuracy : ±0.2 nm at 163 to 180 nm

±0.1 nm at 180 to 250 nm

±0.3 nm at 250 to 500 nm

4

Page 11

±0.8 nm at 500 to 800 nm

±2.0 nm at 800 to 1100 nm

Wavelength repeatability : ±0.05 nm at 163 to 250 nm

±0.1 nm at 250 to 500 nm

±0.2 nm at 500 to 1100 nm

Spectral bandwidth : 0.01 to 15 nm

Slit width : 1 to 3000 µm

Response : 0.5 msec to 32 sec

Scanning system : Continuous scan

Step scan (Fixed response and auto response system)

Scanning speed : to 10000 nm/min (continuous scan)

Data interval : 0.025 to 10 nm (continuous scan)

0.1 to 100 nm (step scan)

0.5 msec to 60 min (time change)

CD full scale : ±10, 200, 2000 mdeg

CD resolution : 0.0005 mdeg (at

0.01 mdeg (at

0.1 mdeg (at ±2000 mdeg full scale)

Stray light : Not more than 0.0003% (200 nm)

RMS noise : 185 nm : 0.050 mdeg (150W light source)

0.045 mdeg (450W light source)

200 nm : 0.040 mdeg (150W light source)

0.035 mdeg (450W light source)

500 nm : 0.035 mdeg (150W light source)

0.035 mdeg (450 light source)

(spectral bandwidth 1nm, response 16 sec)

Baseline stability : 0.03 mdeg/hr

(spectral bandwidth 1 nm, response 32 sec, wavelength 290

nm)

UV measurement : Single beam measurement

Photometric range : 0 to 5 Abs

Photometric accuracy :

(0 to 1 Abs, checked using NIST SRM 930D filter)

External input terminal : Two channels (input range : -1 to 1 V DC)

Shutter : Opens and closes in front of sample

Sample chamber : Small sample chamber dimensions :

140mm wide × 300mm deep × 130mm high

Large sample chamber dimensions :

305mm wide

Sample stage can be dismounted and remounted and

accepts various accessories.

Equipped with constant temperature water inlet/outlet ports

Nitrogen gas displacement: Atmosphere in the light source unit, monochromator unit,

and sample chamber is displaced using dry nitrogen gas.

Temperature : 20 ±5°C

Humidity : Less than 70%

Dimensions : Main unit (small sample chamber) :

1115mm wide × 570mm deep × 410mm high

±10 mdeg full scale)

±200 mdeg full scale)

±0.01 Abs

× 420mm deep × 270mm high

5

Page 12

Main unit (large sample chamber) :

1270mm wide × 570mm deep × 410mm high

Weight : Main unit (small sample chamber): 87 kg

Main unit (large sample chamber): 106 kg

Power requirements : 100, 115, 200, 220, 230, 240 V, 50/60 Hz

270 W (150 W light source)

670 W (450 W light source)

6

Page 13

2. Unpacking and Installation

Note: Hold the monochromater bench when you move the main unit.

2.1 Unpacking

After unpacking the instrument, check the parts received against the list of components

(Table 2.1). If any part is missing or damaged, contact your local JASCO distributor.

Table 2.1 List of Components for J-810 Spectropolarimeter

Component

J-810 main unit 1

Modulator element 1

Detector unit 1

Cable 1 set

Nitrogen gas inlet tube 1 3 m

Nitrogen gas outlet tube 1

Nitrogen gas tube band 2

Cooling water tube 1 10 m for the 450W light source

Cooling water tube band 3 For the 450W light source

Sample chamber window 1

Inner sample chamber 1 For large sample chamber

Cell holder 1

Standard samples 1 set Ammonium d-10-camphor sulfonate, etc.

Tools 1 set

Floppy disk 1 set For setup, data, etc.

Instruction manual 1 set For hardware, software, etc.

Tube for accessories 1 set For accessories

Q′ty

Remarks

2.2 Installation Requirements

Install the instrument in a location where the following conditions are satisfied. The

instrument should be installed in a room that is maintained at a constant temperature

and humidity, because the spectropolarimeter is sensitive to atmosphere fluctuations.

. Room temperature 20

. Humidity lower than 70%

. Not exposed to direct sunlight

. Not in the proximity of harmful or corrosive gas

. Not exposed to a high-intensity light source

. Not in the direct path of air currents emanating from air conditioners, or other

equipment

. Relatively free of vibration

. Not in the proximity of a high-intensity magnetic or electromagnetic field

. For the 450W light source, within the proximity of a water supply (flow rate : 2 λ/min,

pressure : 0.5~2.0 kg/cm

mm

Note: Do not use water at more than 2.0 kg / cm

±5°C

2

). Cooling water tube : 10 m in length, inside diameter : 12

2

pressure.

7

Page 14

. Within the proximity of equipment that supplies nitrogen gas. (flow rate : more than 3

λ/min).

. Nitrogen gas tube : 3 m in length, inside diameter : 9.5 mm.

2.3 Reassembly

Note: Reassembly of the instrument is performed by your local JASCO distributor.

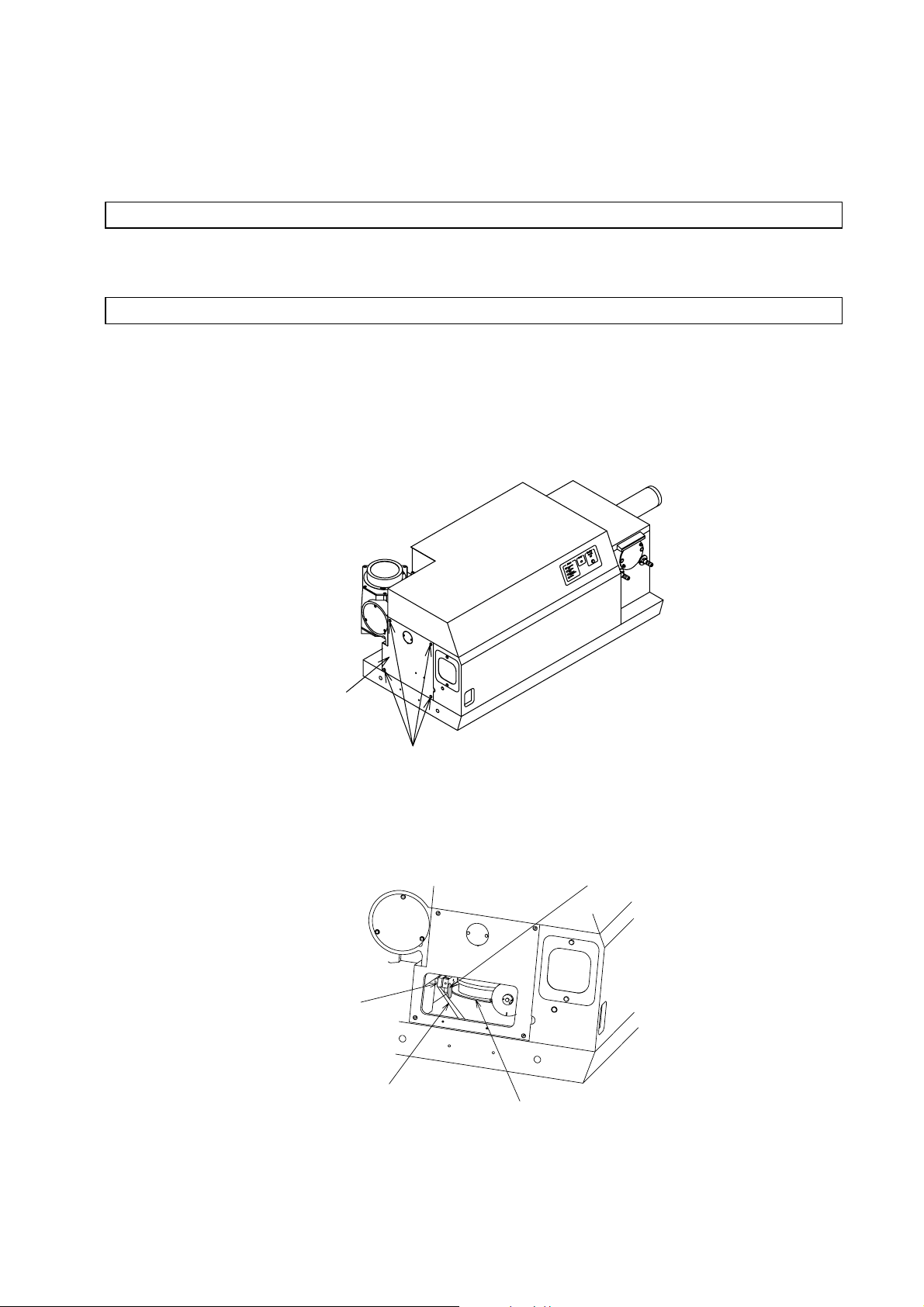

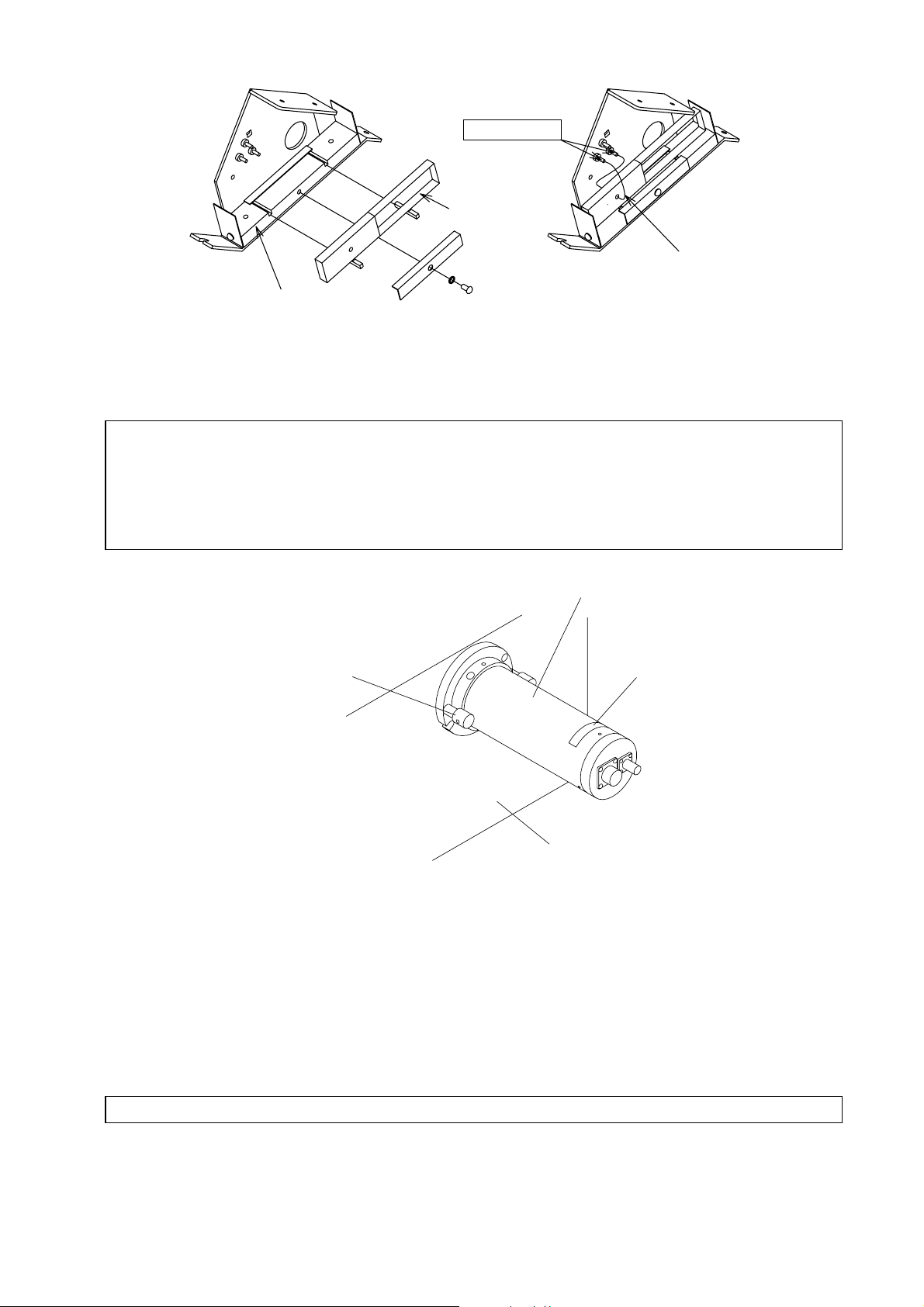

2.3.1 Removing the cushion from the main unit

CAUTION : When removing the cushion, be careful not to give an impact to the cam.

The cam and lever on the bottom of the instrument are separated by a cushion and

secured with a rubber band to protect the cam from damage and the wavelength from

shifting during transit.

Remove the cushion and rubber band after installing the main unit.

(1) Remove the side cover from the main unit.

Side cover

Setscrews

Fig. 2.1 Removing the side cover

(2) Remove the cushion and rubber band.

Wavelength

lever

Rubber band

Fig. 2.2 Removing the cushion and rubber band

Cam

Cushion

8

Page 15

r

2.3.2 Installing the modulation element

The modulation element has been removed from the main unit before shipment to

prevent damage in transit. Install the modulator element in the main unit after installing

the main unit.

(1) Remove the electrical system cover from the main unit.

Electrical system cove

Pull

Setscrews

Fig. 2.3 Removing the electrical system cover

(2) Open the monochromator lid.

Lift

Monochromator lid

Setscrews

Fig. 2.4 Opening the monochromator lid

(3) Mount the modulator element in the holder and mount it in the main unit.Solder the

leads to the terminals.

CAUTION : Be careful not to damage the modulator element or break the leads.

CAUTION : See to it that the leads do not come into contact with the holder, cover or

with each other.

9

Page 16

Solder

Modulator

element

Lead wire

Holder

Fig. 2.5 Mounting the modulator element

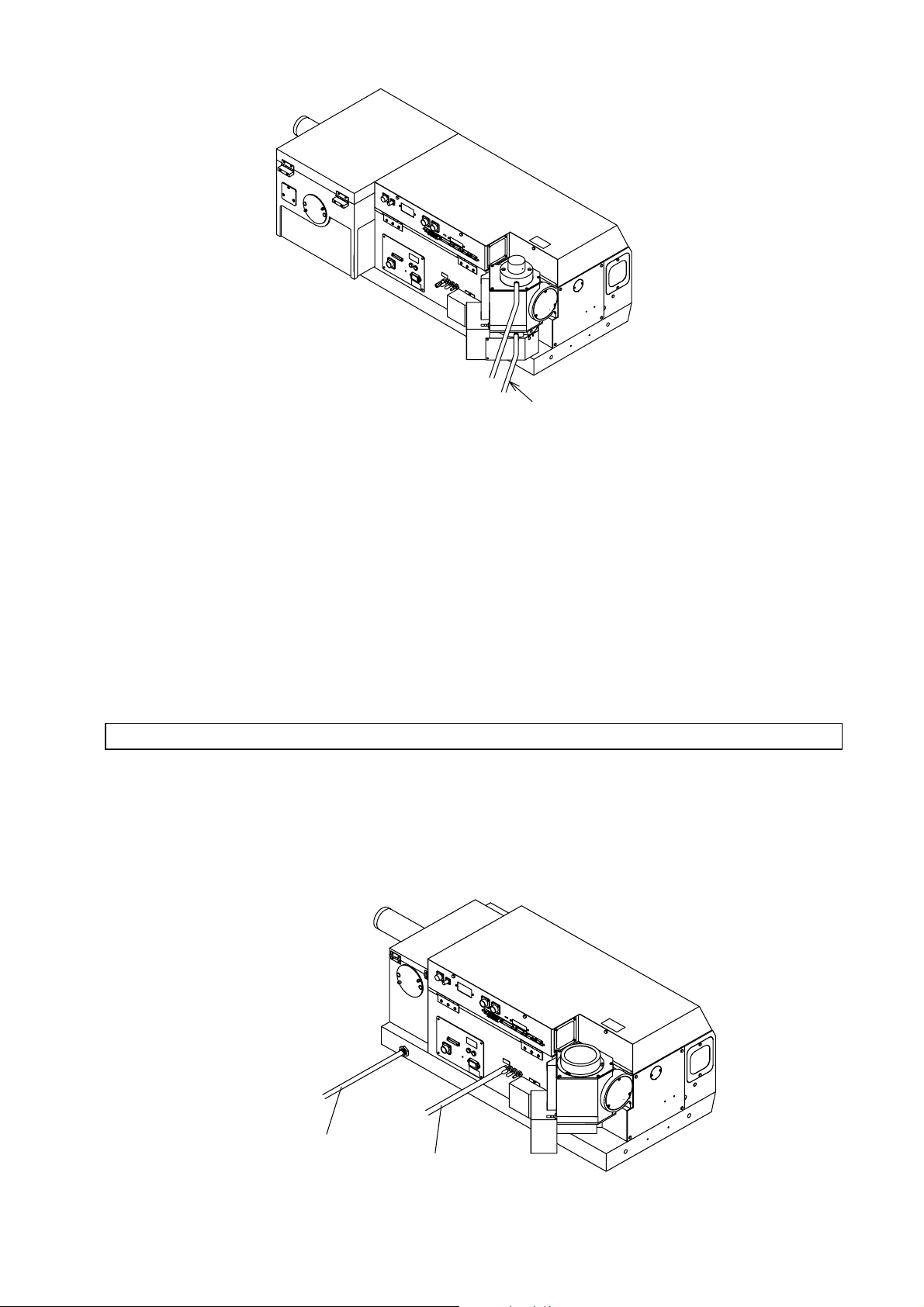

2.3.3 Installation the detector unit

CAUTION : Handle the detector unit with great care. Do not give an impact to the

detector unit.

CAUTION : Do not loosen any screws, except for the lock screw.

CAUTION : Do not expose the detector window to intense light.

Detector unit

Lock screw

Label

Sample chamber

Fig. 2.6 Installation of detector unit

Install the detector unit on the main unit according to the following procedure.

(1) Remove the cover from the detector mounting hole located in the right side panel

of the main unit

(2) Remove the cover from the detector unit

(3) Gently mount the detector unit on the main unit, and secure it using the lock screw.

CAUTION : Install the detector so that the label faces upward.

10

Page 17

2.3.4 Connecting the cables and tubes

Connect the cables and tubes according to the following procedure :

(1) Connecting the cables

1) Using a digital voltmeter, confirm that the supplied line voltage corresponds to

the voltage shown on the rating plate.

CAUTION : The line voltage must be confirmed. An outlet can provide an incorrect

voltage due to faulty wiring.

2) Confirm that the ″Power″ switch on the power supply unit is turned OFF.

3) Plug the cables according to Fig. 2.7.

CAUTION: Ground the grounding terminal of the power cable.

CAUTION: For details regarding the wiring and connections of the personal computer

and printer, refer to their respective instruction manuals.

Detector unit

"CD In"

Amplifier rear panel

"PS In" "Optical Unit" "Serial"

"Amp Unit""PS Out"

Conecting plate of

monochromator

"AC INPUT"

Computer

Line voltage

Fig. 2.7 Connection of cables

(2) Connecting the cooling water tubes (450W light source)

CAUTION : Bind the tube at the water faucet and the water inlet/outlet ports of the light

source unit, using the supplied tube bands.

11

Page 18

Water outlet

Water inlet

Cooling water tube

Fig. 2.8

1) Connect the ″Water Inlet″ of the light source cooling water flow sensor to the

faucet using the tube.

2) Connect the ″Water Outlet″ of the light source cooling water flow sensor to the

″Water Inlet″ of the light source unit.

3) Connect the ″Water Outlet″ of the light source unit to the water drain port.

4) Feed cooling water to confirm that the system is free from leakage.

(3) Connecting the nitrogen gas tube

Connect the nitrogen gas cylinder (flow meter) to the nitrogen gas inlet.

Note : Bind the tube with the tube band, if necessary.

(4) Connecting the nitrogen gas or leak water outlet port.

The outlet tube for nitrogen gas or leaked circulation water is provided at the

bottom of the sample chamber. Connect the tube to the water outlet port, if

necessary.

Outlet tube for nitrogen

gas or leaked water

Notroger gas

inlet tube

12

Page 19

Fig. 2.9

13

Page 20

3. Names of Functions of Components

3.1 Overall View

150W light source. Small sample chamber

2

5

1

4

3

6

8

7

9

10

Fig. 3.1 Overall view (150 kW light source. Small sample chamber)

14

Page 21

450W light source. Large sample chamber

5

2

4

3

1

6

8

7

9

12

11

10

Fig. 3.2 Overall view (450kW light source. Large sample chamber)

15

Page 22

Component Function

① ″Power″ switch

②Sample chamber

③Constant temperature

Power switch of the main unit.

Set sample.

Inlet and outlet ports of constant temperature water.

water ports

④Detector unit

⑤Amplifier unit

⑥Sample chamber leak

Houses the photomultiplier tube and preamplifier.

Houses the amplifier and other elements.

Outlet for the water leaking from sample chamber.

water outlet

⑦Monochromator unit

⑧Connecting plate

⑨Nitrogen gas inlet

Houses the monochromator and modulator.

Connected to the electrical system.

Admits nitrogen gas to displace the air in the

monochromator.

⑩Light source unit

⑪Light source cooling

Houses the light source.

Cooling water inlet to the light source.

water inlet

⑫Light source cooling

Cooling water outlet from the light source.

water outlet

16

Page 23

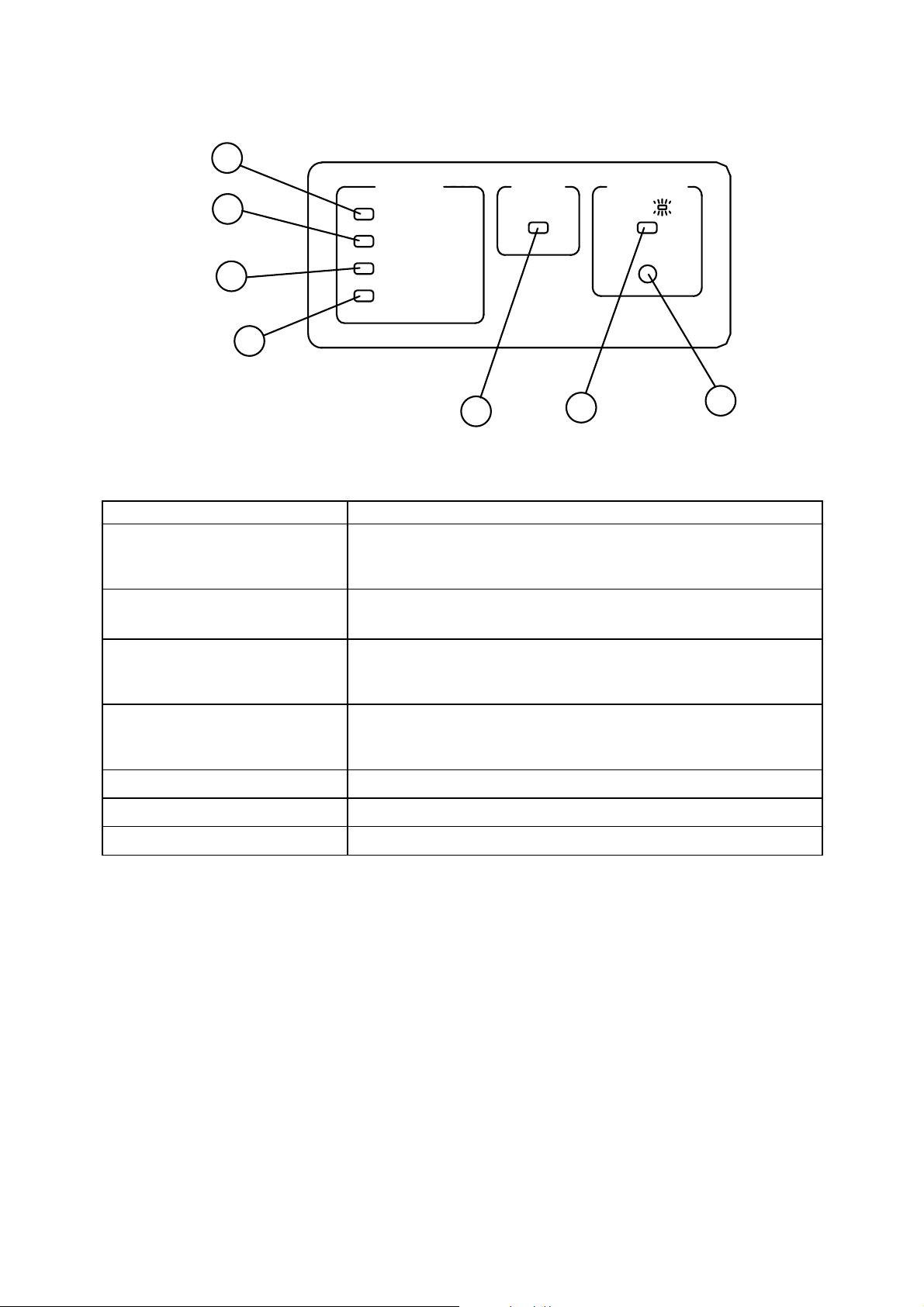

3.2 Panels

1

Alarm

2

3

Temperature

(Lamp)

Water Flow

(Lamp)

Water Leak

(Sample Chamber)

N2 Flow

Lamp

4

5

Fig. 3.3 Front panel of amplifier unit

Component Function

① ″Temperature (Lamp)″

LED

② ″Water Flow (Lamp)″

LED

③ ″Water Leak (Sample

Chamber)″ LED

④ ″N2 Flow″ LED

⑤ ″Lamp″ LED

⑥ ″Shutter″ LED

⑦ ″Shutter″ button

Lights if the light source temperature becomes

abnormally high. The light source is automatically

turned off if an alarm is displayed.

Lights if the cooling water to the 450W light source is

insufficient.

Lights if water leaks in the sample chamber. The use

of the optional constant temperature water stop valve

stops water leak automatically.

Lights if the nitrogen gas flow rate is insufficient. This

alarm is effective when the optional PC-controlled

flowmeter or the flowmeter with sensor is used.

Lights when the light source is turned ON.

Lights when the shutter is open.

Opens/closes the light shield shutter.

6

Shutter

Open

7

17

Page 24

Scale Correction

2

1

CD In

ORD In

7

Offset

CD

9

3

4

CD

8

Accessory

×1

×100

PS In

Scale Correction

LD ORD

Optical unit

10

Fig. 3.4 Rear panel of amplifier unit

Component Function

① ″CD In″ connector

② ″Scale Correction ID″

Connect to the connector on the detector unit.

Trimmer for adjusting the CD scale using a standard

sample.

③ ″Offset CD″ trimmer

④ ″ORD In″ connector

Trimmer for adjusting offset of CD.

Connect the connector for optional ORD unit.

port

⑤ ″ORD Unit″ connector

Connect the connector for optional ORD unit.

port

⑥ ″Scale Correction

LD/ORD″ adjustment

Port for mounting the optional LD/ORD scale

adjustment.

mounting port

⑦ ″Accessory″ connector

Connector for optional accessories.

6

ORD Unit

I/O 1 I/O 2 Serial

11

5

13

12

14

⑧ ″Ps In″ connector Connect to the ″Ps Out″ connector on the rear panel of

the monochromator unit.

⑨ ″X1/X100″ selector

switch

⑩I/O terminals

″Ext1″ terminal

″Ext2″ terminal

″GND″ terminal

″DA1″ terminal

″DA5″ terminal

″DGND″ terminal

″Trig″ terminal

Changes over the ″Ext2″ terminal input voltage gain.

Set it at X100 to amplify the gain by a factor of 100.

Input terminal for analog signal (-1 to 1 VDC)

Input terminal for analog signal (-1 to 1 VDC)

Grounding terminal (for analog signal)

Output terminal for analog signal (0 to 1 VDC)

Output terminal for analog signal (0 to 5 VDC)

Grounding terminal (for digital signal).

Trigger signal input terminal.

⑪ ″Optical Unit″ connector Connect to the ″Amp Unit″ connector on the rear panel

of the monochromator unit.

⑫ ″I/O 1″ connector

⑬ ″I/O 2″ connector

⑭ ″Serial″ connector

Connect to an optional accessory.

Connect to an optional accessory.

Connect to the connector for communication of the

personal computer.

18

Page 25

1

Amp Unit

PS Out

2

4

T6.3A

AC INPUT

T10A

T3.15A

3

Fig. 3.5 Rear panel of monochromator unit

Component Function

① ″Amp Unit″ connector Connect to the ″Optical In″ connector on the rear panel

of the amplifier unit.

② ″PS Out″ connector Connect to the ″PS In″ connector on the rear panel of

the amplifier unit.

③Receptacle

④Fuse

″T3.15A″ label

″T6.3A″ label

Power inlet receptacle

For 200 VAC line voltage.

For 100 VAC (150W light source) or 200 VAC (450W

light source) line voltage.

″T10A″ label

For 100 VAC line voltage.

19

Page 26

3.3 Sample Chamber

Small sample chamber

6

7

Large sample chamber

1

5

8

4

2

9

3

1

4

5

2

6

9

7

3

8

10

Fig. 3.6 Sample chamber

20

Page 27

Component Function

①Cell holder

②Cell holder mount

③Sample stage sub-base (1)

Set the cell.

Set the cell holder.

Remove this when a medium-sized accessory like

Peltier type thermostatted cell holder is mounted.

④Sample stage sub-base (2)

Remove this when a small-sized accessory like

sample changer is mounted.

⑤Light shield plate

Changes over the beam diameter to 8 mm or 13

mm according to the cell to be used.

⑥Detector protective switch

Turns OFF the switch and sets the voltage applied

to the detector to zero when the sample chamber lid

is opened.

⑦Constant temperature

water inlet/outlet ports

⑧Joint

⑨Window plate

Removable joint for constant temperature water.

Attached to the sample chamber window when

measuring a sample that emits harmful gas to

protect the monochromator unit.

⑩Inner sample chamber

Sample chamber to displace nitrogen gas more

efficiently.

21

Page 28

3.4 Detector Unit

1

Fig. 3.7 Detector unit

Component Function

①Lock screw

②Connector

Secures the detector unit to the main unit.

Connect to the ″CD In″ connector located on the rear

panel of the amplifier unit.

③Label

Indicates the wavelength range. Install the detector

unit on the main unit with this label facing upward.

3

2

22

Page 29

4. MAINTENANCE

4.1 Light Source Check and Replacement

The service life of the xenon lamp is 300 to 500 hours, but it differs considerably from

one light source to another. It is therefore difficult to predict life expectancy from

operating hours. It is generally predicted from noise on the measured data. Compare

the current data with the data on delivery (data obtained with a new light source) to

make decision.

Note : Noise may also appear if the line voltage fluctuates abruptly.

Observe the following guidelines in order to maximize the service life of the xenon lamp.

. If the light source is not used for an extended period, turn it off. However, if the light

source will be inactive for an hour or less, leave it on Frequently turning the light

source on and off will shorten its service life.

. Always feed cooling water to the light source (450W light source).

<Procedure>

WARNING : Carefully read the ″Safety Cautions″ at the beginning of this manual.

(1) Turn OFF the ″Power″ switch located on the main unit.

(2) For the 150W light source, remove the light source cover and then remove the

anode holder and the light source. For the 450W light source, remove the anode

holder, and then loosen the cathode fixing screw with a screwdriver through the

hole on the side cover to remove the light source.

Note : The 150W light source is attached to the anode holder.

(3) For the 150W light source, remove the anode holder and cathode adapter from the

light source, and attach them to a new light source.

(4) Mount a new light source in the position of the old light source.

CAUTION : Confirm that the glass protrusion of the Xe lamp does not face the M

M1 mirrors.

CAUTION : Do not mistake the polarity of the Xe lamp.

and

0

23

Page 30

(150W Light source)

Cathode adaptor

M mirror

0

(450W Light source)

Light source cover

Anode holder

Light source

1

M mirror

Anode holder

Light source

M mirror

0

M mirror

1

Cathode fixing screw

Fig. 4.1

(5) Tighten the cathode fixing screw (for the 450W light source)

(6) Mount the anode holder (for the 450W light source).

(7) Start up the instrument.

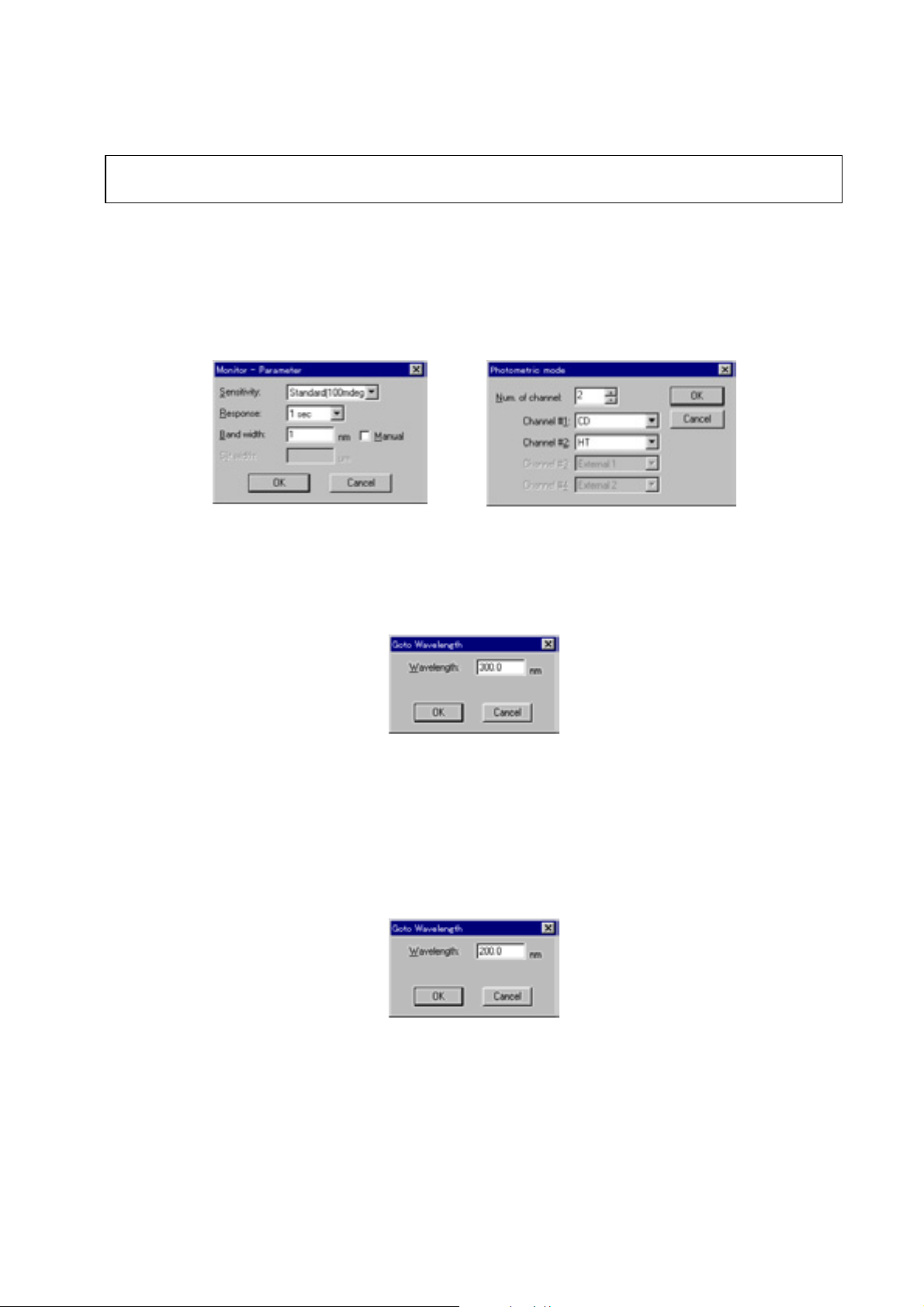

(8) Start up the [Data Monitor] program.

(9) Select the [Parameter...] and [Data Mode...] commands from the [Setting] menu

and designate the monitoring parameters shown in Fig. 4-2.

24

Page 31

Fig. 4.2 Setting parameters (replacement of light source)

(10) Select the [Move Wavelength...] command from the [Setting] menu and set the

wavelength at ″546.1 nm″.

Fig. 4.3 Setting wavelength (replacement of light source)

(11) Remove the cover from the M0 and M1 mirrors. The adjustment screw shown in

Fig. 4.4 will be visible.

Vertical adjustment screw

Horizontal adjustment screw

Cover

Fig. 4.4 Mirror adjustment screw

(12) Adjust the adjustment screws for the M1 mirror to minimize the value of channel 2

(HT voltage) when the sample chamber is empty.

(13) Adjust the adjustment screws for the M0 mirror to minimize the value of channel 2

(HT voltage) when the sample chamber is empty.

Note : Normally, the minimum value is 200 to 300 volts.

(14) Re-install the covers for the M0 and M1 mirrors.

4.2 Energy Check

The energy of the instrument will decrease over time due to the deterioration of the

mirrors and other optical components. This decrease in energy is most apparent in the

25

Page 32

shorter wavelength region (250 nm and less). Check the energy about once a year.

The M0 and M1 mirrors should be replaced every two years, and the M2 through M5

mirrors should be replaced every five years.

Note : If an energy decrease is observed in the long wavelength region, improper optical

alignment or a other trouble is suspected.

<Procedure>

(1) Start up the [Data Monitor] program.

(2) Select the [Parameter...] and [Data Mode...] commands from the [Setting] menu

and designate the monitoring parameters shown in Fig. 4.5.

Fig. 4.5 Setting measurement parameters (energy check)

(3) Select the [Wavelength ...] command from the [Setting] menu and set the

wavelength at ″300 nm″

Fig. 4.6 Setting wavelength (energy check at 300 nm)

(4) Confirm that the value of channel 2 (HT voltage) is 180 to 260 volts when the

sample chamber is empty.

(5) Select the [Move Wavelength...] command from the [Setting] menu and set the

wavelength at ″300 nm″.

Fig. 4.7 Setting wavelength (energy check at 200 nm)

(6) Confirm that the value of channel 2 (HT voltage) is 500 volts or less when the

sample chamber is empty.

26

Page 33

4.3 Wavelength Accuracy Check and Adjustment

Note : Before checking wavelength accuracy, warm up the instrument for about one

hour after turning the light source ON.

Note : Use neodymium glass as the sample.

<Procedure>

(1) Start up the Spectrum Measurement program.

(2) Select the [Parameter...] command from the [Measurement] menu, and designate

the measurement parameters shown in Fig. 4.8.

Fig. 4.8 Measurement parameters (wavelength accuracy check)

(3) Mount neodymium glass in the sample chamber.

(4) Select the [Start] command from the [Measurement] menu in order to perform

measurement.

(5) Using the spectrum analysis program, verify that the peak wavelength of Channel

2 (Fig. 4.9) of the measurement data is 586

±0.8 nm. If the peak wavelength

does not fall within this range, adjust the instrument according to the following

procedure.

100

0

H

T

0

560

Wavelength[nm

586±0.8nm

]

610

Fig. 4.9 HT data of neodymium glass

<Adjustment procedure>

Make adjustment using the adjustment screws on the wavelength lever located at the

bottom of the main unit.

(1) If the main unit is mounted in the optional cabinet, the wavelength cam and

27

Page 34

wavelength lever will be visible from below, as shown in Fig. 4.10. If the main unit

is mounted on a table or bench, bridge the instrument across two tables or

benches to permit access to the adjustment screws.

Fine adjustment screw

Wavelength lever

Coarse adjustment screw

Cam

Fig. 4.10 Adjustment screws

(2) Correct the wavelength by adjusting the fine and coarse adjustment screws

located on the wavelength lever. Turning the screw clockwise shifts the HT data

to shorter wavelengths, and turning the screw counterclockwise shifts the data to

longer wavelengths.

(3) Measure the HT data of the neodymium glass sample to check the wavelength.

Note : If the instrument is moved, gently move it back to its original position, and check

wavelength accuracy again.

4.4 CD Scale Check and Adjustment

Note : Before checking the CD scale, warm up the instrument for about one hour after

turning the light source ON.

Note : Use a 0.06% (w/v) aqueous solution of ammonium d-10-camphor sulfonate as

the sample.

<Procedure>

(1) Start up the [Spectrum Measurement] program.

(2) Select the [Parameter...] command from the [Measurement] menu, and designate

the measurement parameters in Fig. 4.11.

28

Page 35

Fig. 4.11 Measurement parameters (CD scale check)

(3) Fill the 10mm light path cell with 0.06% aqueous solution of ammonium d-10-

camphor sulfonate (solvent : distilled water), and mount the cell in the sample

chamber.

(4) Select the [Start] command from the [Measurement] menu to make measurement.

(5) Using the spectrum analysis program, confirm that the peak value of Channel 1

(Fig. 4.12) is 190.4 ±1 mdeg (291.0 nm). If the peak value does not fall within this

range, adjust the instrument according to the following procedure.

20

0

190.4±1mdeg

C

D

0

250

Wavelength[nm

]

350

Fig. 4.12 CD spectrum of 0.06% ammonium d-10-camphor sulfonate

<Adjustment procedure>

Use the

″Scale Correction CD″ knob located on the rear panel of the amplifier unit (Fig.

3.4).

(1) Select the [Move Wavelength...] command from the [Control] menu and designate

the wavelength shown in Fig. 4.13. Click on the <OK> button.

29

Page 36

Fig. 4.13 Setting wavelength (CD scale adjustment)

(2) Turn the ″Scale Correction CD″ knob located on the rear panel of the amplifier unit

(Fig. 3.4) until the CD value comes within the reference range.

(3) Measure the CD spectrum to check the CD scale.

4.5 Test Signal Check

The test signal is used to check if the electrical system is operating normally. A test

signal can be generated by setting the photometric mode at ″Test Signal″.

<Procedure>

(1) Start up the [Data Monitor] program.

(2) Select the [Parameter...] and [Data mode...] commands from the [Setting] menu

and designate the measurement parameters as shown in Fig. 4.14.

Fig. 4.14 Setting measurement parameters (Test signal check)

(3) Verify that the measurement value of Channel 1 falls within 18 (±10%) mdeg.

(4) After that, set the ″Photometric mode″ at ″CD″.

30

Page 37

5. TROUBLESHOOTING

If the instrument does not operate properly, the following causes are suspected.

. Erroneous operation

. Deterioration of consumable components

. Failure of instrument

The following table describes basic corrective actions for specific symptoms. If the

difficulty cannot be corrected by performing these actions, failure of the instrument is

suspected. In this case, contact your local JASCO distributor with detailed information

about your difficulty, including the model name, serial number, and date of manufacture

of your instrument.

Symptom Check Corrective action

Power cannot be

turned ON

Is the fuse for the power

The light source does

not light.

Is the cooling water supplied

Is the cathode fixing screw

Is a sparking sound heard? Replace the lamp.

HT voltage does not

increase.

Is the photometric mode set

Is the sample chamber lid

HT voltage has risen

and will not lower.

Is the spectral bandwidth

Is the cable correctly

Is the power cable plugged in

to the outlet?

supply unit intact?

Is the check box ″Turn ON

light source at start″ in the

″System Setting″ dialog box

checked?

to the 450W light source

sufficient?

tight, (450W light source) and

are the anode holder and

lamp is contact with each

other?

Is the shutter open? Open the shutter in the

correctly?

Is the ″HT voltage setting″ in

the ″Detector sensitivity″

dialog box set correctly?

completely closed?

Is a sample in the sample

chamber?

setting too small?

connected to the detector unit

and to the connector located

on the back panel of the

amplifier unit?

Correctly plug in the cable.

Replace the fuse.

Turn ON the light source in

the ″Light source control″

dialog box.

Increase the cooling water

flow rate.

Tighten the cathode fixing

screw. Adjust the contact

plate of the anode holder.

″Shutter control″ dialog box.

Set the measurement mode

at ″CD″ (not ″Test signal″).

Set it at ″Auto″ (not

″Manu″).

Completely close the lid.

Remove the sample.

Increase the spectral

bandwidth.

Correctly replug the cable.

31

Page 38

Is the wavelength set to a

value at which the detector is

not sensitive?

Is the nitrogen gas flow rate

high enough when the

Set the wavelength to a

value at which the detector

is sensitive.

Increase the nitrogen gas

flow rate.

wavelength is set below 180

nm?

Is the ″HT″ switch on the subpanel of the amplifier unit in

Set the ″HT″ switch to

″Auto″.

the ″Auto″ position?

Noise is high Is the spectra bandwidth

setting too small?

Does the sample have high

light absorption?

Increase the spectra

bandwidth.

Decrease the sample

concentration, or shorten

the light path of the cell.

Is noise detected in the HT

Replace the Xe lamp.

voltage?

Is the HT voltage at below

250 nm too high?

Any noise source that

generates electromagnetic

waves nearby?

Is any source of mechanical

vibration nearby?

Does line voltage vary

Adjust the M0 and M1

mirrors.

Remove the noise source

from the proximity of the

instrument.

Remove the source of

vibration.

Use stabilized line voltage.

abruptly.

The baseline curves

sharply.

Is the curvature within ±10

mdeg when the baseline is

Perform baseline correction.

not corrected?

CD value is displayed

although sample is not

Is the sample fluorescent? Decrease sample

absorbance to 2 or less.

optically active.

Is the sample a film or liquid

crystal?

Does the cell contain any

False CD signal from the

sample is suspected.

Prepare a new sample.

optically active residue?

The displayed CD

value is smaller than

normal, or no display

Is the ″HT voltage setting″ in

the ″Detector sensitivity″

dialog box set correctly?

Set it at ″Auto″ (not

″Manu″).

appears.

Repeatability of CD

values is low.

Is the photometric value 18±2

mdeg when the photometric

mode is ″Test signal″?

Is the instrument warmed up

sufficiently?

Failure of the electrical

system or modulator

element is suspected.

Before performing Cd

measurement, warm up the

instrument for approximately

one hour after the light

source has lit.

32

Page 39

Is the sample deteriorated by

the light emitted from the light

source?

Is the variation of the peak

Use the shutter function or

narrow the spectrum

bandwidth.

Normal.

value of aqueous solution of

ammonium d-10-camphor

sulfonate (distilled water, 10

nm cell) at 291.0 nm within 2

mdeg/hr?

Are room temperature and

humidity variations normal?

Maintain room temperature

within 20 ±5°C, and humidity

below 70%.

Is the instrument blown with

draft from an air conditioner or

other?

Is the scanning speed too

high?

Install the instrument in a

position outside of the direct

path of air currents.

Slightly lower the scanning

speed.

Is noise too high? Increase response. Or,

refer to the ″Noise is high″

symptom.

Wavelength

repeatability is low.

Is the instrument warmed up

sufficiently?

Measure wavelength

repeatability after warming

up the instrument for

approximately one hour

after the light source is lit.

Are room temperature and

humidity variations too high?

Maintain room temperature

within 20 ±5°C, and humidity

below 70%.

No communication

with the computer.

Is the communication port

Is the RS-232C cable

connected properly?

Reconnect the cable

correctly.

Correctly set the

setting in agreement with the

communication ports.

wiring?

33

Loading...

Loading...