Model

SEC 180

Circular Breaking Saw

EQUIPMENT

SELECTION Ordering No.

Model SEC 180 Non–Indexing Depth Gage

Internal Brake

220 V 4004049.

115

External Brake

42 V 4004047.

Model SEC 180 Indexing Depth Gage

Internal Brake

220 V 4004085.

115

External Brake

220 V 4004134.

115

42

V

Model SEC 180 Dual Trigger & External Brake

220 V 4004094.

115

42

V

Balancer 4042002

. . . . . . . . . . . . . . . . . . . . . . . . .

JARVIS

6204012::.

.

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

V

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

V

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

V

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

V

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

4004048.

4004104.

4004133.

4004122.

4004093.

4004092.

TABLE OF

CONTENTS Page.

• Notice to Employer and Safety

Director 2.

• Notice to Operators, Maintenance

and Cleanup Personnel 3.

• Parts Diagram and List 4.

• Special Tools 10.

• Specifications 11

• Installation Instructions 11.

• Operating Instructions 12.

• Maintenance Instructions 13.

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

OWN, CONNECTICUT 06457–4926

Model SEC 180

notice to employer

and safety director

page 2 of 16

Keep hands clear

NOTICE T

1. Remove and

functioning equipment.

2. Ensure

the dangers that may arise if they do not follow procedures outlined in this brochure.

3. Ensure that all employees are instructed not to walk in front of the tool during its use.

4. Enclosed

PERSONNEL.” Post one copy on the employees’ bulletin board; give one copy to the operator(s);

give one copy to the maintenance foreman; and give one copy to the sub-contract cleanup / internal

cleanup foreman. Additional copies will be provided upon request.

5. The

6. Never make modifications or alterations to the tool. Replace any missing or illegible labels.

tool is designed and intended to be powerful. This fact should be obvious to

you must emphasize it to them.

repair

that all employees who use this tool are trained in the proper use of this tool and are aware of

are four (4) copies of

any tool that malfunctions.

O EMPLOYER AND SAFETY DIRECT

AVOID

“NOTICE TO OPERATORS, MAINTENANCE AND CLEANUP

INJUR

All personnel must be instructed to remove any mal

Y

.

OR

your employees, but

-

7. Ensure

(29 CFR 1910.147) to prevent accidental startup or release of stored energy.

8. Follow our installation and maintenance instructions for proper installation and care of the tool.

9. Avoid injury. Do not permit the tool to be misused.

10. If

sheets

request.

JARVIS

6204012::.

that proper procedures are established in accordance with OSHA’s lockout/tagout procedures

you

resell

or

distribute

and tool brochure.

a Jarvis product, you must provide the purchaser with the appropriate safety

Additional copies of

safety sheets and tool br

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

ochur

OWN, CONNECTICUT 06457–4926

es will be pr

ovided upon

notice

to operators, maintenance

and cleanup personnel

page 3 of 16

Model SEC 180

Keep hands clear

NOTICE T

1. Disconnect the power supply in accordance with OSHA’s lockout/tagout procedures (29 CFR

1910.147) before making any blade changes.

2. Disconnect the power supply in accordance with OSHA’s lockout/tagout procedures (29 CFR

1910.147) before performing any repair or maintenance.

3. Disconnect

lockout/tagout procedures (29 CFR 1910.147) before performing any cleanup.

4. Disconnect the power supply when the tool is not being used.

5. Never

tool.

6. Never allow people to walk in front of the tool during its use.

7. Never allow people to hold / restrain the carcass while operating the tool.

O OPERATORS, MAINTENANCE AND CLEANUP PERSONNEL

REMOVE ANY MALFUNCTIONING T

REPORT ANY PROBLEMS TO YOUR SUPERVISOR

the power supply - or have the power supply disconnected - in accordance with OSHA’s

put fingers, hands or other parts of the body on the cutting edge

.

OOL FROM SER

or within the cutting path of the

VICE

8. Test

9. Test

10. Never depress the trigger unless you want to use or test the tool.

11. Never

12. Always

JARVIS

6204012::.

the

tool

prior to use or daily

Release

and the tool should not

either

repair it immediately.

2.5 seconds. If the tool malfunctions, remove it from service and r

or “recoil.” Continue holding the tool with both hands until the saw blade comes to a complete stop.

the trigger and the tool should

start.

trigger and the tool should

the

brake

make modifications or alterations to the tool.

use both hands when starting and operating the tool to avoid the risk of possible “kick back”

prior to use or daily

. For

single trigger tools:

stop. For dual trigger tools:

Depress

both

triggers simultaneously and the tool should

stop.

If the

tool malfunctions, r

. After releasing either or both triggers, the tool should stop within

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

Depr

Report or r

ess

the trigger and the tool should

Depress

emove it from service and r

eport or r

eplace

OWN, CONNECTICUT 06457–4926

each

trigger

epair it immediately.

any missing or illegible labels.

individually

start.

start.

Release

eport or

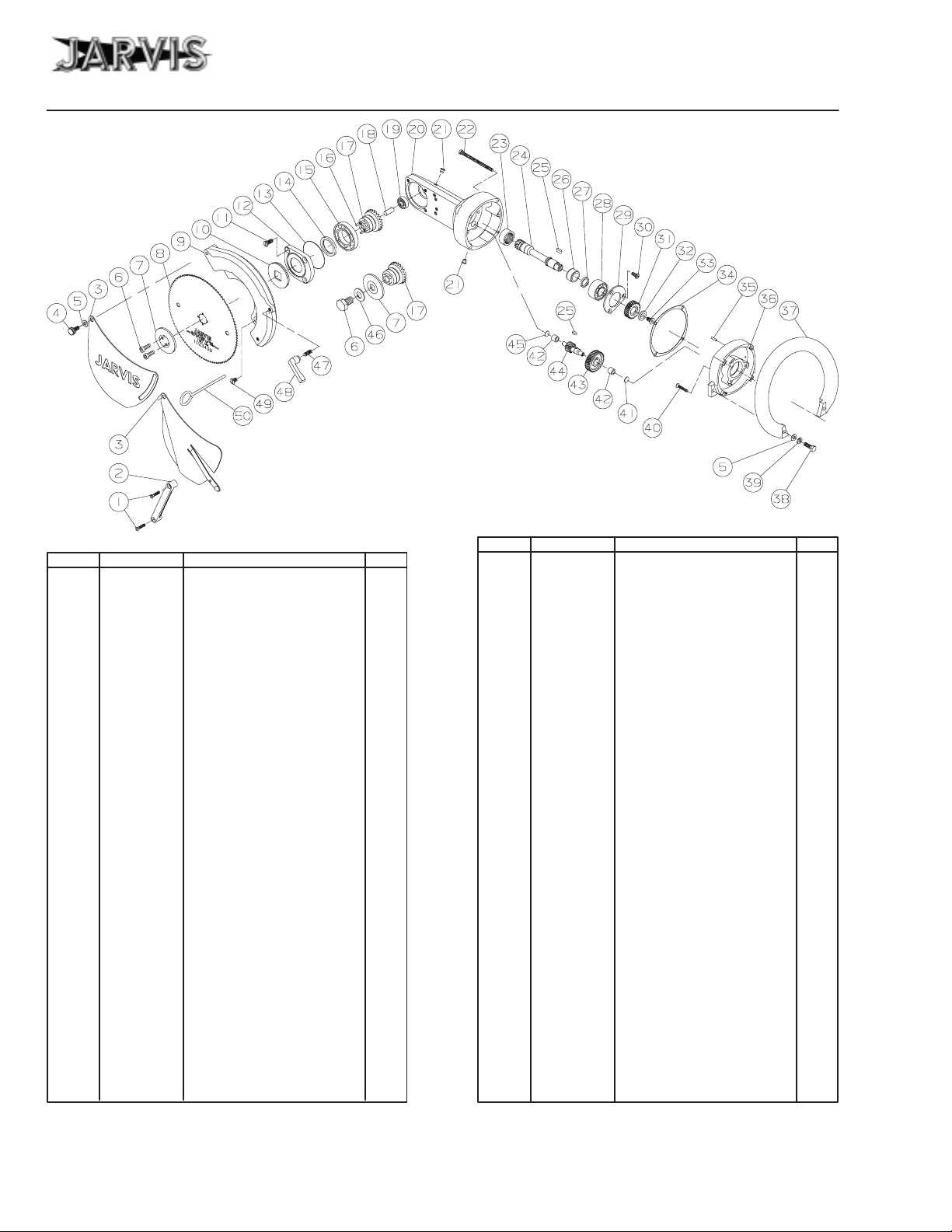

parts diagram and list

Model SEC 180

**

*

*

ITEM PART NO. PART NAME QTY

1 1055901 Oval Head Screw 2

2 1033013 Index Block 1

3 3025011 Depth Gage Assy

1025031

4 1054172 Thumb Screw 1

1055609* Hex Screw

5 1004286* Washer 2

1036222*

6 1055964**

1054139*

7 1004317

1004252*

8 1023439

1023440

1023272*

1023332*

9 1024144

1024169

10 1004258 Slinger 1

11 1055835

12 1002327 Gear Housing Cover 1

13 1035416 O–ring 1

14 1035460

15 1021359

16 1010452

1010446*

17 1026197 Crown Gear with Pins 1

1026192* Crown Gear without Pins

1026158* Crown Gear (one screw) 1

18 1020355

19 1021351

20 3016279 Gear Housing (incls. items 1

21 1038006

Depth Gage, Non–index

Bushing (not shown)

Blade Retaining Screw

Blade Retaining Screw

Blade Retaining W

Blade Retaining W

Saw Blade, 98 T

Saw Blade, 48 T

(with Round Hub and Pins)

Saw Blade, 98 T

Saw Blade, 48 T

(with Square Hub*)

Blade Guard, Non–index

Saw Blade Guard, Index

Flat Head Slotted Screw

Shaft Seal

Ball Bearing

Dowel Pin (with item 17)

Dowel Pin

Gear Shaft (with item 17)

Ball Bearing

21, 23, 42 and 45)

Grease Fitting

* Not used in current tools

For indexing models only

** W

rench 8039146 is provided

For non–indexing models only

, Index

asher 1

asher 1

eeth

eeth

eeth 1

eeth

page 4 of 16

Figure A

*

*

*

ITEM PART NO. PART NAME QTY

22 1055854 Cheese Head Screw 4

23 1021360

24 1026157

1

2

1

1

3

1

1

4

1

1

2

25 1030061 Key 2

26 1021361

27 1029310 Spacer 1

28 1021155

29 1004255

30 1055781 Oval Head Screw 3

31 1026156 Helical Gear 1

32 1004253 Washer 1

33 1055852 Flat Head Socket Screw 1

34 1035468 Gear Housing Gasket 1

35 1010366

36 3002034 Front Motor Cover Assy. 1

37 1019142

38 1055613 Hex Head Screw 6

39 1004231 Split Lock Washer 2

40 1055856 Oval Head Screw 3

41 1004363 Thrust Washer 1

42 1021362

43 1026154 Helical Gear 1

44 1026155 Helical Gear 1

45 1004364 Thrust Washer

1004254* Thrust Washer

46 1014159* Locking Washer 1

47 1027060 Stud 1

48 1006047

49 1055873

50 8039099

3026064

3026060* Two Screws w/o Pins Arbor

3026051* One Screw Arbor

3026052

Needle Bearing

Spiral Bevel Pinion Gear

Needle Bearing Race

Ball Bearing

Bearing Retaining W

Dowel Pin

(incls. items 35, 41 and 42)

Front Handle

Needle Bearing

Gage Locking Lever

Flat Head Slotted Screw

Blade Locking Pin

Spiral Bevel Gear Set

(incl. items 16–18, 24 & 26)

Helical Change Gear Set

(incls. items 25, 31 and 44)

asher 1

, .15 thick

, .03 thick

1

1

1

1

1

1

2

1

1

2

1

1

JARVIS

6204012::.

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

parts diagram and list

page 5 of 16

Model SEC 180

V

Used on internal brake models only

G

Used on external brake models only

♦

Used on models with single cord connections only

Y

Used on models with dual cord connections only

ITEM PART NO. PART NAME QTY

51 3026053 Helical Pinion Gear Assy 1

52 1029309

53 1013150

54 1021363

55 1004297 Washer 1

56 1004256

57 1061560 Fan 1

58 3063100 Armature Assembly

59 1021364

60 1055855 Cheese Head Screw 2

61 1016391

62 1063470 Stator

63 1036197

64 3016281

65 1002326 Brush Cover 2

66 1047012

67 1061559 Brush Holder 2

68 1007296 Hex Nut 4

69 1002330 Rear Motor Cover 1

70 1055914 Hex Head Screw 2

71 1055716 Hex Head Screw 1

72 1024172 T

73 1055895 Pan Head Screw 4

74 1017188

75 1055725 Pan Head Screw 4

76 1035469 Rear Handle Gasket 1

77 1042281

78 1014085 Spring 1

79 1019188

See parts lis

3063194 Armature Assembly

3063195 Armature Assembly

1063801 Stator

1063802 Stator

1047010

1047008

1019141G

1019164G

t on page 6 for part n

(incl. items 25, 43, 52 & 53)

Helical Pinion Spacer

Retaining Ring

Ball Bearing

Bearing Retaining W

(includes items 57 and 59)

Ball Bearing

Fan Housing

, 42 V

, 1

15 V

, 220 V

Motor Housing Bushing

Motor Housing (includes

items 63 and 67)

Motor Brush, 42 V

Motor Brush, 1

Motor Brush, 220 V

rigger Guard

Label Plate

Hanger Bkt. (incl. item 109)

Rear Handle with Brake

Rear Handle A

Rear Handle 42 V

umbers t

, 42 V

, 1

, 220 V

15 V

TD

o i

asher 1

15 V

tems 80–109.

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

1

1

1

1

Figure B

Y

Y

Y

Y

G

G

Y

♦

V

V

JARVIS

6204012::.

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

Model SEC 180

Figure C

Anti–tie Down

Handle Assembly

parts diagram and list

page 6 of 16

V

Used on internal brake models only

G

Used on external brake models only

♦

Used on models with single cord connections only

Y

Used on models with dual cord connections only

See Figure B on page 5 for items 80–109.

ITEM PART NO. PART NAME QTY

80 1055913 Self Tapping Screw

81 1010167

82 1018126

83 1010356

84 1042373

1042282

85 1055834 Pan Head Screw 1

86 1005126

1005104

87 1004257

88 1013220

89 1035414 Handle Cover Gasket 1

90 1002329♦

1002339

1002370Y

91 1017083

92 1011260 Connector

1011328 Connector

93 1001099

1001039 Electric Cord, 42 V

1001081V

94 1063560G

Roll Pin

Switch Actuating Lever

Dowel Pin

V Switch Holder for Brake 1

G Switch Holder

V Electric Switch for Brake 2

G Electric Switch

Ring W

asher 1

Retaining Ring

Handle Cover (incl. item 91)

Y

Handle Cover

Handle Cover

Danger Label

Spiral Cord, 1

Spiral Cord for brake

Rubber Grommet

, 1

15V & 220V

, 42 V

, 1

15 V & 220 V

, 42 V

15 V & 220 V

2

2

1

1

1

1

1

1

1

1

1

ITEM PART NO. PART NAME QTY

95 1063505G

96 1063549

97 1063209

98 1001100

99 1011279

100 1055832 Oval Head Screw 2

101 1035413

102 1063820

1063821

103 1029341

104 1055777 Cheese Head Screw 4

105 1029342 Hex Spacer 2

106 1018162 T

107 1010362

108 1055894 Socket Head Cap Screw 4

109 1036209

110 1044060

111 1014096 Spring 1

112 1018113 T

113 1010395

114 1019163

115 3005017 Switch Assembly 1

116 1035282 O–ring 1

117 1002367 Switch Cover 1

118 1042343 Handle Bracket 1

119 1011309

120 1001050 Electric Cord 1

121 1011310

122 1007303 Locking Nut 1

123 1055746 Socket Head Cap Screw 4

Plug 1

15 V and 220 V

Y

Rubber Grommet

Y

Signal Cord Plug

Y

Spiral Cord

Y Connector

Diaphragm Seal

V

Brake Board, 1

V

Brake Board, 220 V

V

Circuit Board Spacer 2

rigger Lever (incl. item 78)

Dowel Pin

Bushing (with item 77)

Handle Mounting Flange

rigger Lever

Threaded Pin

Front Handle

Strain Relief Connector

Strain Relief Connector

, 42 V and A

15 V

1

1

1

1

TD 1

1

1

1

1

1

2

1

1

2

1

1

1

JARVIS

6204012::.

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

parts diagram and list

page 7 of 16

Remote Electronic Brake

Single Trigger

3063121 (220V)

3063130 (1

Model SEC 180

Figure D

15V)

ITEM PART NO. PART NAME QTY

1

1016445 Electrical Enclosure 1

2

10

1

12

13

14

15

16

17

18

1063393 T

3

1032436

4

1063496 Y

5

1063455 Fuse T

6

1063542 Fuse 1

7

1063494 Gray T

8

1063363 T

9

1055803 Pan Head Screw 2

1004247 Washer 4

1

1011249

1007256 Locking Nut 2

1063362

1063723 Aux. Contact 1

1063089

1063722 Contactor

1063726 Contactor

1063079

1001188 Cord ft

erminal Rail

Mounting Plate

ellow/ Green T

erminal Block

erminal Block

erminal Marker

Cord Connector

End Clamp T

Wire Ring T

Wire Ring T

erminal 1

erminal 2

, 220 V

, 1

15 V

erminal 2

1

1

erm. Block 1

1

5

7

2

1

1

JARVIS

6204012::.

ITEM PART NO. PART NAME QTY

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

1061545 Ferrule 8

1042341 Resistor Bracket 2

1055779 Cheese Head Screw 2

1004241 Lock Washer 2

7800565

1063724 Power Resistor

1063727 Power Resistor

1063619 Brake Board 1

1029302 Spacer 4

1004244 Washer 4

1063725 Fuse 4

1055974 Pan Head Screw 2

1063533

1063506 Outlet 1

1063560 Grommet 1

1017085

1017237

1017238

Insulating T

Fem. Wire T

Danger Label

Conn. Diagram, 220 V

Conn. Diagram, 115 V

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

ubing

, 220 V

, 1

15 V

erminal 2

2.5 in

1

1

1

1

1

Model SEC 180

Figure E

Remote

Electronic Brake

Single Trigger

3063210 (42V)

parts diagram and list

page 8 of 16

ITEM PART NO. PART NAME QTY

1 1011262 Cord

2 1007266 Locking Nut 2

3 1055803 Pan Head Screw 5

4 1004247 External Lock Washer 5

5 1063799

6 1063800 Heater Pack 1

7 1001189 Cord ft

8 1011249

9 1007256 Locking Nut 1

10 1001039 Cord ft

11 1011248

12 1007249 Locking Nut 1

13 1063208 Outlet 1

14 1063623 Black Grommet 1

15 1016514 Electrical Enclosure 1

16 1032485

17 1063362 T

18 1063520 Gray T

19 1063390 Fuse T

Connector

Magnetic Starter

Cord Connector

Cord Connector

Mounting Plate

erminal End Clamp

erminal Block

erminal Block

2

1

1

1

1

1

4

2

JARVIS

6204012::.

ITEM PART NO. PART NAME QTY

20 1063494 Gray T

21 1063495

22 1063554 T

23 1063496 Y

24 1063363 T

25 1063456 T

26 1063814 Fuse 1

27 1063763 Fuse 1

28 1055971 Pan Head Screw 2

29 1004325 Split Lock Washer 2

30 1063812 Power Resistor 1

31 1029302 Spacer 4

32 1004244

33 1063813 Brake Board 1

34 1063528 Auxiliary Contact Block 1

35 1063725 Fuse 1

36 1063816 Suppressor 1

37 1017085

38 1017298

Blue T

erminal Rail

ellow/Green T

erminal Marker

erminal Marker

Internal Lock W

Danger Label

Connection Diagram Label

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

erminal Block

erminal Block

erm. Block 1

asher 4

1

1

1

5

4

1

1

parts diagram and list

page 9 of 16

Model SEC 180

Figure F

Dual Trigger

Remote Electronic Brake

ITEM PART NO. PART NAME QTY

1 1016408 Electrical Enclosure 1

2 1032447

3 1029302 Spacer 8

4 1004244

5 1063533

6 1063089

7 1063079

8 1063723 Auxiliary Contact 1

9 1063722 Contactor 1

10 1004247 Ext. T

11 1055974 Phillips Screw 2

12 1007266 Locking Nut 1

13 1055803 Pan Head Screw 2

14 1063393 T

15 1011248

16 1011249

17 1011306

18 1001188 Cord ft

19 1061545 Ferrule 6

20 1063506 Outlet 1

Mounting Plate

Int. T

ooth W

Female Wire T

Wire Ring T

Wire Ring T

erminal Rail

Cord Connector

Cord Connector

Cord Connector

asher 8

erminal 2

erminal 2

ooth W

asher 4

1

erminal 2

1

1

1

1

JARVIS

6204012::.

ITEM PART NO. PART NAME QTY

21 1063560 Grommet 1

22 1063208 Outlet 1

23 1001014 Cord ft

24 1007249 Locking Nut 1

25 1007256 Locking Nut 1

26 1063496 Y

27 1063455 Fuse T

28 1063542 Fuse 1

29 1063494 Gray T

30 1063363 T

31 1063362 T

32 1063725 Fuse 1

33 1063741 Brake Board 1

34 1063312 Fuse 1

35 1063502 Fork Wire Terminal 8

36 1063296 Anti–T

37 1017085

38 1017252

ellow/Green T

erminal Marker

erminal End Clamp

Danger Label

Connection Diagram

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

3063141 (220V)

erm. Block 1

erminal Block

erminal Block

ie Down Board

1

5

7

1

1

1

1

special tools

Model SEC 180

Figure G

Special Tools

THE FOLLOWING TOOLS ARE RECOMMENDED FOR PROPER AND EFFECTIVE

ASSEMBLY

SAW.

AND DISASSEMBL

Y OF THE JAR

VIS SEC180 CIRCULAR BREAKING

page 10 of 16

BEARING EXTRACTION

T

OOL 80391

BEARING EXTRACTION and

INSTALLATION T

OOL 8039140

11

BEARING EXTRACTION

T

OOL 8039171

BEARING INSERTION

T

OOL 8039170

JARVIS

6204012::.

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

specifications

and

installation instructions

page 11 of 16

Model SEC 180

SPECIFICATIONS

Voltage 220, 115 and 42 V Single Phase

Power Output 1.6 hp 1200 Watts

Blade Speed

Control Handle(s) Single or Dual Trigger Electric

Overall Length 21.7 in 550 mm

Cutting Depth up to 2.6 in 65 mm

Blade Diameter 7.1 in 180 mm

Weight 13.2 lb 6 kg

Vibration less (<) 120 dB < 1 m/sec

Noise ( 1 meter from tool ) 92 dB

1350 rpm

2

INSTALLATION INSTRUCTIONS

ALWAYS DISCONNECT THE POWER SUPPLY IN ACCORDANCE WITH OSHA’S LOCKOUT/TAGOUT PROCEDURES

(29

CFR 1910.147) BEFORE PERFORMING ANY REP

MAINTENANCE.

AIRS OR

ALL WIRING MUST BE DONE IN ACCORDANCE WITH

NATIONAL, STATE AND LOCAL ELECTRICAL CODES.

1 Install the electrical control box in a convenient

location.

2 Wire the electrical control box, if applicable.

Electrical contr

Note:

power

supplies. Y

your

power supply

for control box numbers for SEC 180 external brake

models.

1 below.

For all other SEC 180 models, r

2.1 Attach

3 Install

3.1 The

4 Suspend the SEC 180 from the balancer.

4.1 Adjust

terminals to the appropriately rated

er supply. See wiring diagram inside control

box cover for external brake models or refer to

Figure 1 below.

a balancer

trolley should have suf

the operator access to the entire work area.

the balancer to

ol boxes ar

ou must have

. Refer to Figur

above the work station on a trolley

e differ

the pr

the operator’s preference.

ent for differ

oper contr

es D–F on pages 7–9

ficient travel to allow

ol box for

efer to Figur

ent

pow

e

-

.

Figure 1

Wiring Diagram

JARVIS

6204012::.

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

Model SEC 180

installation

and

operation instructions

page 12 of 16

5 Plug

the SEC 180 into

power

supply outlet.

Power

by Customer

SEC 180 Models with remote brake

Power

Cord

for 42 V models

only

. Supplied by

Customer

the appropriate control box or

See Figure 2 below as a guide.

Control Box

Cord Supplied

Figure 2

(single cord)

Control Box

OPERATION INSTRUCTIONS

1 Plug in the SEC 180.

2 Each day, before you begin operation, perform the

following:

2.1 Make

2.2 Make sure that the control handle or handles

sure that the SEC 180 moves freely on

balancer.

correctly

work

the

trigger and the tool should

trigger

and the tool should stop.

tools: depress each trigger separately and the

tool should not

multaneously

and

the tool should

triggers

functions,

problem

Always

handles. Continue to hold the tool with both

until the saw blade comes to a complete

hands

stop.

. For single trigger tools:

start.

Release

For dual trigger

start; depress both triggers si-

(within one second of each other)

start.

Release

and the tool should

r

emove it fr

to your supervisor immediately

operate the tool with both hands on

om service and r

either

stop. If the tool mal

the

depress

the

or both

eport the

.

the

-

Power Cord

supplied by

Customer

SEC 180 Models with remote brake (dual cord)

and 42 V models

Power

Cord

Supplied by Customer

Plug Connections

Supplied by Customer

SEC 180 Models with internal brake

(single cord)

2.3 Make sure that the electronic brake is working

correctly.

the saw; release a trigger and the saw blade

should

functions, r

problem

3 Make the cut.

3.1 Position the SEC 180 saw.

3.2 Depress

hands when operating the tool. Continue to

hold the tool with both hands until the saw

blade comes to a complete stop.

3.3 When

ger. This will stop the blade.

3.4 Withdraw the SEC 180 from the carcass.

4 Unplug the SEC 180.

Depress

stop within 2.5 seconds.

emove it fr

to your supervisor immediately

the trigger / triggers.

the desired cut is achieved, release a trig

the trigger / triggers to

If the tool mal

om service and r

Always use both

eport the

.

start

-

-

JARVIS

6204012::.

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

maintenance instructions

page 13 of 16

Model SEC 180

MAINTENANCE INSTRUCTIONS

IMPORTANT: ALWAYS DISCONNECT THE POWER SUPPLY

IN ACCORDANCE WITH OSHA’S LOCKOUT/TAGOUT PROCEDURES (29 CFR 1910.147) BEFORE INSTALLING OR REMOVING A BLADE., OR BEFORE PERFORMING ANY REPAIR OR MAINTENANCE.

Refer to Figures A–C on pages on 4–6 for referenced

items.

1 PRIOR TO USE OR DAILY:

1.1 Make sure that the control handle or handles

work

correctly

trigger and the tool should

the

trigger

and the tool should stop.

tools: depress each trigger separately and the

tool should not

multaneously

and

the tool should

triggers

functions, repair or remove it from service immediately .

Always

handles. Continue to hold the tool with both

hands

until the saw blade comes to a complete

stop.

. For single trigger tools:

start.

For dual trigger

start; depress both triggers si-

(within one second of each other)

start. Release

and the tool should

operate the tool with both hands on the

stop.

If the tool mal

Release

either

depr

the

or both

ess

2 AS NECESSARY:

2.1 Inspect

necessary.

dural guide.

2.2 Disassemble,

housing. Refer to sections 5 and 6 as a proce-

dural guide.

2.3 Disassemble, clean and inspect motor housing

assembly.

dural guide.

2.4 Disassemble, clean and inspect rear handle assembly. Refer to sections 9 and 10 as a proce-

dural guide.

3 CIRCULAR BLADE REMOVAL:

3.1 Non–Indexing Gage Models

3.1.1 Remove

-

3.2 Indexing Gage Models

3.2.1 Remove thumb screw (item 4) and washer

3.2.2 Remove depth gage (item 3). Continue to

3.3

Both Gage Models

circular blade and sharpen

Refer to sections 3 and 4 as a pr

clean and inspect right angle gear

Refer to sections 7

the depth gage

48)

and rotate the depth gage (item 3) out of

the way. Continue to step 3.3.

(item 5).

step 3.3.

or replace as

oce-

and 8 as a pr

locking lever (item

oce-

1.2 Make sure that the electronic brake is working

correctly. Depress the trigger to start the saw;

the

release

within

pair or remove it fr

1.3 Check all electrical plugs and cords (over their

entire

if

necessary

1.4 Add

(item 21) on the gear housing (item 20).

trigger and the saw blade should stop

2.5 seconds.

length) for cuts and abrasions, and replace

.

Jarvis

1315 White Gr

If the tool malfunctions, r

om service immediately

ease to grease

fittings

JARVIS

6204012::.

3.3.1 Use Jarvis wrench 8039146 to remove the

blade retaining screws (item 6). Keep the

blade from rotating by inserting the blade

e-

.

locking

blade and guard.

3.3.2 Remove

3.3.3 Remove the saw blade (item 8).

3.3.4 Inspect

essary.

3.3.4.1 Inspect blade for wear and sharpen or

pin (item 50) through the hole in the

the

all parts for wear and replace if nec

replace

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

blade retaining washer (item 7).

as necessary

.

-

Model SEC 180

maintenance instructions

page 14 of 16

4 CIRCULAR BLADE INSTALLATION:

4.1 Reverse

3. See notes below

steps and procedures outlined in section

. Refer to Figur

e 3 below as

a guide.

4.1.1 To

notches

ensure proper fit and safe

on the saw blade (item 8) must align

operation,

with dowels pins (item 16) and the center

hole

of the blade must fit securely

of the crown gear (item 17).

4.1.2 The

holes

in retaining washer (item 7) must

align with the dowel pins (item 16) on the

crown gear (item 17).

4.1.3 The teeth at the bottom of the blade should

point toward the operator and rotate counter–clockwise. Refer to Figure 3 below for

blade rotation direction.

4.1.4 Tighten blade retaining screws with Jarvis

wrench

ing

8039146. Prevent blade from turn

by inserting blade locking pin (item 50)

through one of the outer holes in blade.

Figure 3

Blade Installation

CROWN GEAR

DOWEL

PINS (4)

OUTER

HOLE

HOLES

(4 PLACES)

FOR PINS

NOTCHED

AREA (4 PLACES)

the

on the lip

LIP

5 RIGHT ANGLE GEAR HOUSING DISASSEM-

BLY:

5.1 Remove blade as described in section 3.

5.2 Remove

flat head screws (item 49) and remove

blade guard (item 9).

5.3 Remove cheese head screws (item 22) and remove right angle gear housing assembly from

assembly

motor

5.3.1 Place

the gear

work surface.

5.4 Remove flat head screws (item 11), gear hous-

cover (item 12), o–ring (item 13), shaft seal

ing

(item 14) and

ing.

5.5 Lightly

tap the gear housing on the guard mount

ing area with a nylon mallet until the crown gear

assembly (items 15–19) slides out of the gear

-

housing.

5.6 Place

remove

crown gear (item 17) in an

ball bearing (item

in the threaded hole of the gear and press gear

shaft and ball bearing (items 18 and 19) from

gear. Press gear shaft (item 18) out of ball

crown

bearing (item

5.7 Remove oval head screws (item 30).

5.8 Lightly

ing

tap the gear housing in the face mount

area with a nylon mallet until the pinion gear

assembly (items 24–33) slides out of the gear

housing.

Note:

Never use a metal hammer on the gear housing or

place

it in a vise. The mounting faces ar

chined and must not be damaged.

5.9 Grip the pinion gear shaft in a vise using soft

jaws only. See note below.

.

housing assembly on a clean

slinger

(item 10) from gear hous

arbor press and

15). Place a 7 mm pin

19

).

e pr

ecisely

ma

-

-

-

-

RETAINING

SCREWS

JARVIS

6204012::.

WASHER

SAW BLADE

SAW BLADE

ROTATION DIRECTION

Note: Never grip the pinion gear on the gear teeth or

bearing

with

mounting diameters.

enough force to keep it fr

the flat head screw.

5.10 Remove flat head screw (item 33) and washer

(item 32).

5.11 Remove helical gear (item 31), shaft key

25) and bearing retaining washer

(item

(item 29).

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

Grip only the shaft portion

om r

otating when r

emoving

maintenance instructions

page 15 of 16

Model SEC 180

5.12 Place

5.13 Remove needle bearing (item 23) from gear

5.14 Remove needle bearing (item 42) from gear

5.15 Clean

6 RIGHT ANGLE GEAR HOUSING ASSEMBLY:

6.1 Reverse steps steps and procedures outlined in

6.1.1 Make sure bearing retaining washer

6.1.2 Use removable thread locking compound

6.1.3 When installing needle bearings always

pinion gear assembly in an arbor press and

remove

(item 27). If necessary, also remove needle

bearing inner race (item 26).

housing.

Figure G on page 10.

housing.

Figure G on page 10.

if

section 5. See notes below.

ball bearing (item 28). Remove spacer

Jarvis

tool 8039111 is available.

Jarvis

tool 8039171 is available.

and

inspect all parts for wear and replace

necessary

(item 29)

gear (item 31).

on flat head screw (item 33).

press on the lip with the part number engraved on it. This lip is hardened and will

resist being

Installing

will deform the case and damage the bearing. Jarvis tool 8039170 is available for

installing

ure G on page 10.

.

is in place before installing helical

damaged by the assembly tool.

needle bearings the opposite way

needle bearing (item 23).

See

See

See

Fig

7.7 Remove

5) and front handle (item 37) from the motor

cover (item 36).

7.8 Remove

the

er.

7.9 Remove bearing retaining washer (item 56).

7.10 Remove

washer

8039140 is available.

7.11 Remove retaining ring (item 53).

7.12 Using

(items 54 and 59) from the armature shaft.

7.13 Grip the armature assembly (item 58) so as not

to damage it or the windings, and unscrew the

helical

shaft.

Note:

Do not r

shaft. The motor fan (item 57) is integrally balanced

with the armature and should never be removed.

7.14 Remove

tor housing (item 64).

7.15 Remove socket head screws (item 108) and

hanger bracket (item 77).

7.16 Remove oval and pan head screws (items 100

and 85) and rear handle cover (item 90) from

-

rear handle (item 79).

7.17 Disconnect wiring from motor, switches and

cord.

screws (item

oval head screws (item 40) and remove

armature shaft assembly from the motor cov

the needle bearing (item 42) and thrust

(item 41) from motor cover

a bearing extractor

pinion gear assembly (item 51) from

emove motor

the fan housing (item 61)

38), washers (item 39 and

See Figur

fan (item 57) fr

e G on page 10.

, remove ball bearings

.

Jarvis

tool

the

om armatur

from the mo

-

e

-

7 MOTOR DISASSEMBLY:

7.1 Remove the blade as described in section 3.

7.2 Remove the right angle gear housing as described in section 5, steps 5.1–5.3.

7.3 Remove the helical change gear assembly

(items 25, 31 and 44).

7.4 Remove the gasket (item 34).

7.5 Remove

(item 66).

7.6 Remove the motor front cover assembly (item

36)

plete unit from motor housing (item 64).

the brush

and armature assembly (item 58) as a com

covers (item 65) and brushes

JARVIS

6204012::.

7.18 Remove brake board (item 102) from circuit

board spacers (item 103).

7.19 Remove cheese head screws (item 104). Remove rear handle assembly from motor and set

aside.

7.20 Remove cheese head screws (item 60) and pry

garter

springs on motor leads from brush holders

(item

67). Remove stator (item 62) from motor

housing (item 64).

7.21 Remove pan head screws (item 75) and motor

rear cover (item 69).

-

7.22 Clean

if

necessary

and

inspect all parts for wear and replace

.

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

Model SEC 180

‘

8 MOTOR ASSEMBLY:

8.1 Reverse

7. See notes below.

8.1.1 Ensure correct motor rotation by attaching

8.1.2 Jarvis tool 8039140 is available for instal-

8.1.3 Use

8.1.4 Evenly tighten screws (item 40) into bear-

9 REAR HANDLE DISASSEMBLY:

9.1 Remove rear handle cover (item 90) and rear

handle

tion 7, steps 7.17–7.21.

steps and procedures outlined in section

the garter springs to their original brush

holder.

of needle bearing (item 42) and

lation

washer

ure G on page 10.

ling helical pinion gear (item 51) on shaft.

ing

flat against the outer bearing race.

(item 41) into motor cover.

thread locking compound when instal

retaining washer (item 56) so that is

(item

79) from motor as outlined in sec

thrust

See Fig

rests

maintenance instructions

9.2 Remove

handle (item 79).

9.3 Remove switch and lever assembly (items

82–86).

9.3.1 Remove dowel pin (item 83).

9.3.2 Remove pan head screw (item 85).

9.3.3 Remove switch activating lever (item 82)

-

9.4 Remove internal retaining ring (item 88), ring

-

10 REAR HANDLE ASSEMBLY:

-

washer (item 87) and diaphragm seal (item

101).

9.5 Press

move trigger lever (item 106) and spring (item

78).

9.6 Clean

if

10.1 Reverse

9.

self tapping screws (item 80) from rear

and switches (item 86) from switch holder

(item 84).

dowel

pin (item 107) from handle and re

and

inspect all parts for wear and replace

necessary

.

steps and procedures outlined in section

page 16 of 16

-

JARVIS

6204012::.

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

UNITED STATES OF AMERICA

TEL. 860–347–7271 FAX. 860–347–6978

OWN, CONNECTICUT 06457–4926

Loading...

Loading...