Page 1

Instruction Manual

PLEASE READ CAREFULLY AND KEEP

THIS MANUAL FOR FUTURE REFERENCE

- Elda - Cuistot - Chief -

Wood stove with cooking capability

July 13 2017 Printed in Canada

Certified and tested according to

Canadian Safety: ULC S627-00

United States Safety: UL 1482-2011

Emission: EPA Method 28R, ASTM2510

Efficiency: CSA/B415.1.10

490, rue de l'Argon

Québec, CANADA G2N 2C9

Tél.: 418-849-8095 Fax : 418-849-0077

www.jaroby.com

Page 2

TABLE OF CONTENTS

INTRODUCTION .................................................................................. 3

LISTING AND CODE APPROVALS ..................................................... 3

Appliance certification ...................................................................... 3

Mobile home approved .................................................................... 3

BTU & Efficiency Specifications ....................................................... 3

WARNING ............................................................................................ 3

APPLIANCE DIMENSION .................................................................... 4

SPECIFICATIONS ............................................................................... 4

INSTALLATION .................................................................................... 5

Fire Prevention ................................................................................ 5

Floor protection................................................................................ 5

Floor protection plate minimum dimensions ................................ 5

Clearances of the stove until the floor plate protection ................ 5

Minimum clearances to combustible material ................................... 6

Warmer Assembly (Cook, Cuistot, Cicero and Chief only)........... 7

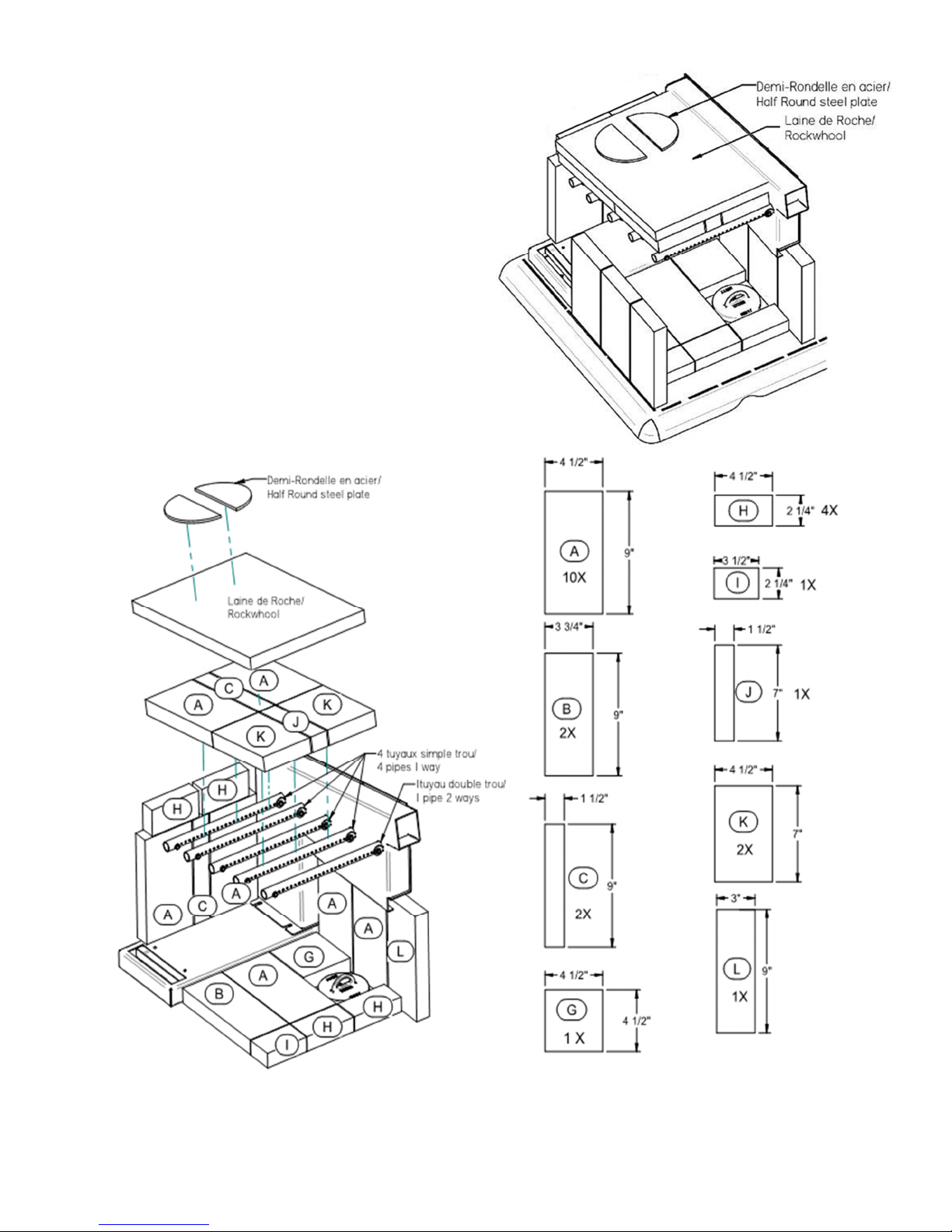

Firebrick installation ......................................................................... 8

Side firebrick installation ............................................................. 8

Back firebrick installation ............................................................ 8

Floor firebrick installation ............................................................ 8

Firebrick installation on the pipes ................................................ 8

Firebrick installation on the pipes (suite) ..................................... 9

GENERAL STOVE INSTALLATION STEPS ....................................... 10

Considering a location ................................................................... 10

General installation steps .............................................................. 10

Chimney pipe installation ............................................................... 11

How to set the pipe sections ..................................................... 11

Mobile home installation ................................................................ 12

CHIMNEY INSTALLATION STEPS .................................................... 13

Inside Masonry Chimney, Vertical Installation ........................... 14

Outside Vertical Installation ....................................................... 14

Cathedral Vertical Installation ................................................... 15

Offset Installation ...................................................................... 15

Vertical Installation .................................................................... 16

EXTERNAL COMBUSTION AIR SOURCE ......................................... 17

Exterior Air Intake pipe .................................................................. 17

Installation of Air Intake Pipe ..................................................... 17

Air Intake Obstruction ............................................................... 17

STAINLESS STEEL TUBES REPLACEMENT ................................... 18

Stainless steel tubes Installation .................................................... 18

How to install the tubes ............................................................. 18

OPERATING INSTRUCTIONS ........................................................... 19

Burning regime control ................................................................... 19

Lightning fire .................................................................................. 19

First fire ......................................................................................... 19

Keeping a fire ................................................................................ 20

Fuel Selection ................................................................................ 20

Moisture Meter Information ....................................................... 20

Things not to burn ..................................................................... 20

Wood storage ................................................................................ 20

Draft .............................................................................................. 20

Usage of cooking area and oven ................................................... 21

Cooking Area ............................................................................ 21

Use of cooking holes ................................................................. 21

Lids above the firebox ............................................................... 21

Lids above the oven .................................................................. 21

Optional cooking plate .............................................................. 21

Oven usage .............................................................................. 22

Thermometer ............................................................................ 23

Cleaning of the creosote build-up .............................................. 23

Clean up procedure .................................................................. 23

MAINTENANCE ................................................................................. 24

Ash Removal ................................................................................. 24

Ash Disposal ................................................................................. 24

Creosote Formation ....................................................................... 24

Chimney Inspection ....................................................................... 24

Chimney Sweeping ........................................................................ 24

Door maintenance ......................................................................... 25

Air tight Adjustment........................................................................ 25

Door adjustment (right side) ...................................................... 25

Cleaning up glass ..................................................................... 25

Disassembly and reassembly of the door .................................. 25

Replacing broken glass ............................................................. 25

Fiberglass rope replacement ..................................................... 26

IN CASE OF CHIMNEY FIRE ............................................................. 26

APPENDIX 1 ...................................................................................... 27

Exploded diagram of doors ............................................................ 27

APPENDIX 2 ...................................................................................... 31

MANUEL D’INSTALLATION ET D’UTILISATION DU RÉSERVOIR À

EAU OPTIONNEL .............................................................................. 31

INSTALLATION AND OPERATION MANUAL OF THE OPTIONAL

WATER TANK .................................................................................... 31

INSTALLATION DU RÉSERVOIR ...................................................... 32

INSTALLATION DU RÉSERVOIR ...................................................... 32

FILLING OF THE WATER TANK ........................................................ 33

WATER TANK’S USAGE ................................................................... 33

CLEANING OF THE WATER TANK ................................................... 33

REMPLISSAGE DU RÉSERVOIR ...................................................... 33

UTILISATION DU RÉSERVOIR ......................................................... 33

NETTOYAGE DU RÉSERVOIR ........................................................ 33

APPENDIX 3 ...................................................................................... 34

Replaceable parts .......................................................................... 34

J. A. ROBY LIMITED LIFE WARRANTY ............................................. 35

July 13, 2017

2

Page 3

INTRODUCTION

This manual describes the operation and installation of J.A.

Roby cook stove model: Cuistot. This appliance meets the 2020

U.S. Environmental Protection Agency's emission standard with

Douglas-fir crib wood. The capacity of this appliance is from

9806 to 21782 BTU/h.

Read all instructions carefully before installing your new J.A.

Roby Cuistot cook stove. A good installation is very important

for a safe and effective use of this appliance. If you have doubts

about how to install your appliance correctly, we suggest to call

a professional installer. A wrong installation may result in a fire,

burns or even death.

When this stove is not properly installed, it may result in fire. To

reduce the risk of fire, follow the installation instructions. Contact

local building or fire departments about restrictions and

requirement about installation in your area.

Keep these instructions for future reference.

This appliance must be connected to:

• A HT type factory-built chimney approved UL103 or ULC

629 with 6 inches diameter (15.24 cm);

• A code-approved masonry chimney with a flue liner with a

6 inches diameter (15.24cm). The masonry chimney liner

must be made of stainless steel and meet the standards

for masonry chimney with inner sleeve

LISTING AND CODE APPROVALS

Appliance certification

The Cuistot cook stove meets the 2020 U.S. Environmental

Protection Agency's emission standard with Douglas-fir crib

wood.

This appliance also meets:

• UL 1482-2011 Standard for Solid-Fuel Type Room Stoves;

• ULC S627-00 Standard for Space Heaters for use with

Solid Fuels;

• (UM) 84-HUD, Mobile Home approved.

THIS WOOD STOVE HAS A FACTORY MINIMUM AND

MAXIMUM BURN RATE SETTING THAT MUST NOT BE

ALTERED.

IN THE UNITED STATE IT IS AGAINST FEDERAL

REGULATIONS TO ALTER THIS SETTING OR OTHERWISE

OPERATE THIS WOOD STOVE IN A MANNER

INCONSISTENT WITH INSTRUCTIONS IN THIS MANUAL.

This wood stove needs regular inspection and repair for proper

operation (see pages 19-20, 26-28). It is against U.S, federal

regulations to operate this wood stove in an inconsistent

manner with the operating instructions in this manual.

Mobile home approved

This appliance is approved for mobile home installation. The

structural integrity of the mobile home floor, ceiling, and walls

must be maintained and respect construction code.

When installed in mobile home, the appliance must be properly

grounded to the frame of the house and use only a listed

double-wall steel pipe.

The appliance must be fixed on the floor by the bottom notch of

legs or by the opening at the bottom of base.

DO NOT INSTALL IN A SLEEPING ROOM.

Fresh air intake is mandatory for mobile home use.

BTU & Efficiency Specifications

• Average efficiency 64.47%

• Particle emission 1.9g/h

• Minimum Heat Output* : 9806 BTU/h

• Maximum Heat Output* : 21782 BTU/h

• Cord Wood Load : 70 000 BTU

• Vent size 6"

• Firebox size 1.69 ft3

• Recommended wood length: 20 inches

• Fuel Orientation: front to back

• Fuel: Seasoned cord wood.

* BTU outputs are based on the EPA official test in reference to

particle emission using Douglas-fir crib wood with controlled

dimension, humidity and volume.

WARNING

If this appliance is in an area where children can reach it, it

is recommended to place a fire guard in front of the

appliance.

THE APPLIANCE GETS HOT WHILE IN OPERATION. KEEP

CHILDREN, CLOTHINGS AND FURNITURES AWAY,

CONTACT MAY CAUSE BURNS.

N.B: BE WARNED THAT THE LOCAL CODES AND RULES

CAN HAVE MORE SPECIFIC REQUIREMENTS THAN THIS

MANUAL. YOU CAN CONSULT A PROFESSIONAL

INSTALLER, FIRE DEPARTMENTS OR LOCAL AUTHORITY

ABOUT INSTALLING SOLID FUEL APPLIANCE IN YOUR

AREA.

YOU MIGHT NEED TO OBTAIN A PERMIT FOR INSTALLING

THE CHIMNEY AND THE STOVE.

DO NOT CONNECT THIS APPLIANCE TO A CHIMNEY FLUE

ALREADY SERVING ANOTHER APPLIANCE.

DO NOT CONNECT TO OR USE IN CONJUNCTION WITH

ANY AIR DISTRIBUTION DUCTWORK WHICH ARE NOT

APPROVED FOR SUCH INSTALLATIONS.

THIS APPLIANCE IS BUILT FOR BURNING SEASONED

CORDWOOD ONLY. USE OF ANY OTHER TYPE OF FUEL

SUCH AS COAL, CONSTRUCTION WOOD, TREATED

WOOD, FLAMABLE LIQUID, TRASH CAN OVERHEAT AND

DAMAGE THE STOVE.

DO NOT OBSTRUCT THE SPACE BENEATH THE STOVE.

July 13, 2017

3

Page 4

kg)

APPLIANCE DIMENSION

SPECIFICATIONS

Elda Marmiton Cuistot Cook Chief Cicero

Combustible Firewood Firewood Firewood

Dry cord wood load

Recommended surface area 1000-1 800ft²(167 m²) 1000-1 800ft²(167 m²) 1000-1 800 ft² (167 m²)

Capacity

Flue pipe diameter 6 in (15.2 cm) 6 in (15.2 cm) 6 in (15.2 cm)

Minimal chimney height 12 ft (366 cm) 12 ft (366 cm) 12 ft (366 cm)

Exterior height 37½ in (95.25 cm) 58½ in (148.6 cm) 58½ in (148.6 cm)

Exterior width 41⅝ in (105.7 cm) 41⅝ in (105.7 cm) 51¾ in (131.4 cm)

Exterior depth 26¼ in (66.7 cm) 26¼ in (66.7 cm) 26¼ in (66.7 cm)

Door opening

Interior height 11⅝ in (29.5 cm) 11⅝ in (29.5 cm) 11⅝ in (29.5 cm)

Interior width 12 in (30.5 cm) 12 in (30.5 cm) 12 in (30.5 cm)

Interior depth 20 in (50.8 cm) 20 in (50.8 cm) 20 in (50.8 cm)

Maximum log length 20 in (50.8 cm) 20 in (50.8 cm) 20 in (50.8 cm)

Average combustion time 3-6h 3-6h 3-6h

Weight

70 000 BTU

(73 800 KJ)

21 782 BTU/h

(6.4 Kw/h)

9 x 9⅛ in

(22.9 x 23.2 cm)

468 lb

(212 kg)

(203 kg)

448 lb

70 000 BTU

(73 800 KJ)

21 782 BTU/h

(6.4 Kw/h)

9 x 9⅛ in

(22.9 x 23.2 cm)

532 lb

(241 kg)

(231 kg)

510 lb

70 000 BTU

(73 800 KJ)

21 782 BTU/h

(6.4 Kw/h)

9 x 9⅛ in

(22.9 x 23.2 cm)

567 lb

(257

546 lb (247

kg)

Efficiency 64.47% 64.47% 64.47%

July 13, 2017

4

Page 5

INSTALLATION

Fire Prevention

To prevent risk of fire, serious consideration should be given to

the following:

1. Install at least one smoke detector on each floor in your

home. They should be located within a reasonable

distance from the heating appliance and close to

bedrooms. Follow the smoke detector manufacturer

instructions regarding placement and installation and

check regularly if they work properly.

2. Keep a Class-A fire extinguisher within reach in case of

small fires on the floor resulting from burning embers.

3. Install a CO detector in the room with the appliance.

4. Make an evacuation plan with at least two exits. All the

occupants must know this plan.

5. A procedure in case of chimney fire:

a. Close all the air intakes of the appliance if possible.

b. Evacuate the house immediately

c. Notify local fire department.

Floor protection

Your stove must be installed on a non-combustible material

plate to protect the floor and avoid fire that might be caused by:

• Projections of sparks when opening door or loading logs;

• The heat radiation from the stove which might cause an

auto-ignition to the floor or to the floor covering;

• Possible flow of creosote when there is a fire chimney.

The coating used for the protection must be non-combustible

and approved according to UL1618 standard for the USA or to

the local codes (Example: cement, brick, ceramic tiles, etc.)

HORIZONTAL VENTING MANDATORY PROTECTION: Noncombustible floor protections must extend beneath the flue

pipe when installed with horizontal venting and it should extend

2 inches (51 mm) beyond each side of the pipe projection on

the floor.

You can extend the protection plate while respecting the

clearances of each side of the stove.

Floor protection plate minimum dimensions

The following dimensions are the minimum values and they

can be greater.

• Width: 57 ⅝ inches (146.4 cm)

• Depth: 51 inches (129.5 cm)

• Thickness: 3/8 inches (1 cm)

In the United States, the depth can be less than the value

above.

• Depth: 49 inches (124.5)

Clearances of the stove until the floor plate

protection

The following dimensions are the minimum values and they

can be greater.

Canada:

• 8 in (20.3 cm) rear

• 8 in (20.3 cm) side

• 18 in (45.7 cm) from the door glass

United States:

• 8 in (20.3 cm) rear

• 8 in (20.3 cm) side

• 16 in (40.64 cm) from the door glass

July 13, 2017

5

Page 6

Minimum clearances to combustible

material

With these reduced clearances, this appliance takes a

minimum installation space. Whether in the living room or in

the dining room, this appliance will complete your decor by his

originality and warmth.

Here is the minimum clearance for different certified flue pipes:

Double wall flue pipe distance:

Single wall flue pipe with shield:

Single wall flue pipe:

To know how to reduce those dimensions, you have to

contact your local authority for installing an heat shield on

a wall. Installations with reduced clearances must comply

with NFPA211 or CAN/CSA-B365 standards.

Minimum Ceiling Height

July 13, 2017

6

Page 7

Warmer Assembly (Cook, Cuistot, Cicero

and Chief only)

At this point, you need to know which type of smoke pipe you’ll

use: single wall pipe or double wall pipe.

For the single smoke pipe, it’s not necessary to remove the precut metal part.

For the double smoke pipe, you must remove the pre-cut metal

part on the top and inside the warmer (1), as well as the

decorative faceplate (2).

2) Place and align the warmer with the corresponding

holes on the top of the stove. You will have two bolts on

each extremity (3) and they can be accessed under the

top by the lids. Two other screws are located on each

side of the flue collar (4), and can be access by the collar

or by the round cooking hole for a total of 6 screws

(3&4).

1) Open the installation opening at the bottom right of the

warmer by removing the screws (5) and the plate (4)

3) Fix the warmer with the lock washers (2) and the nuts(1).

July 13, 2017

7

Page 8

Firebrick installation

Side’s firebrick installation

Put 4 bricks « A » and 2 bricks « B » as shown.

Back’s firebrick installation

Put 2 bricks « A » and 1 brick « C » in the back and place the 2

bricks «H» on top. Screw in the triangular firebrick retainer ( I )

Firebrick installation on the pipes

The firebricks must be put on the 5 pipes on the front of

combustion chamber. Bricks keep the maximum heat inside the

combustion chamber and help the air from the tube burn the most

of the gas from wood which wouldn’t be burnt in any other

manner.

The rockwool above the brick prevents leakage between the

bricks and keeps a maximum heat inside combustion chamber.

It must cover up all the bricks and the air corridors of both sides.

IMPORTANT: The rockwool must not obstruct the smoke path.

Check the rockwool by removing the left top lid hole in the hob

and make sure that it is in a good position. Place the two halfround steel plate on the rockwool as illustrated.

1.

From the hole in the hob, put 2 bricks « A » and 1 brick

« C », over the whole length of 3 the pipes in the back.

Push the bricks against the back bricks with a slight angle

as shown in the image.

2.

Place 2 bricks « K » and 1 brick « J » over the whole length

of the 3 pipes at the front in the same manner as step1

Floor’s firebrick installation

Put 2 bricks « A », 2 bricks « H », 1 brick « I », 1 brick « G » as

shown in the image below.

July 13, 2017

8

Page 9

Firebrick installation on the pipes (suite)

3.

Insert the rockwool over the bricks and check from the hole

in the hub that the smoke path is not obstructed. There

must be 1 inch (2.54 cm) or more between the rockwool

and the deflector.

4.

Put the two half-round steel plates over the rockwool near

the rear deflector already in place. Be sure to put them

under the rear deflector to maximise the clearance between

the rockwool and the rear deflector. Make sure the

rockwool is not obstructing the space by looking under the

cooking lid on the hub.

WARNING: Obstructing the smoke path under the deflector

can force smoke to exit by the door when it’s open and it

will cause the stove not to work properly.

July 13, 2017

9

Page 10

GENERAL STOVE INSTALLATION STEPS

Considering a location

We recommend to install this appliance by a certified installer.

Consideration must be given to:

Safety;

Passage frequency;

Convenience;

type of chimney and required chimney pipe;

Draft.

Drawing your installation plan on paper is a good way to avoid

mistakes.

Write on the plan:

• Exact dimensions for clearances to combustible material;

• Exact dimensions of the floor protection;

• Measurements of the chimney location. (If not already

installed. Be sure to have all the clearances recommended

by the factory-built chimney manufacturer for the floor,

ceiling and roof).

We recommend that a qualified building inspector and your

insurance company representative review your plan before and

after installation.

General installation steps

1) Read the entire installation manual before installing and

using your stove.

2) Choose a spot where to install your stove. Read the

section about the dimensions of the floor protection plate,

the localisation of the stove over the floor protection plate

and the combustible material clearances (page 5). Once

you have decided where to install the stove, mark the

floor at the center of the chimney.

To make sure that the vertical center of the

chimney, use a plumb line and mark the center on

the floor.

3) Check if it is possible to pass the chimney without

damaging the structure of your house. You might have to

move the location of the stove while keeping the

minimum clearances. If you have to cut a joist, be sure to

respect the building code in effect to keep the structural

integrity of your house.

We recommend installation of this appliance by a

certified installer.

Note This appliance have to be connected to 6 inches

(15.24 cm) factory build chimney HT UL 103 or CAN/ULC

S629 compliant or a 6 inches (15.24 cm) masonry chimney

with a homologated sleeve inside. The masonry chimney

liner must be made of stainless steel and meet the

standards for masonry chimney with inner sleeve.

4) Install the chimney following the manufacturer

instruction.

5) Put the stove directly on the floor aligned vertically with

the center of the chimney, and trace the 4 sides of the

stove on the floor. After tracing, remove the stove.

6) Trace the protection plate dimensions on the floor. There

must be 8 inches (20.3 cm) clearance from the side and

the back of the stove. From the door opening, there must

be a front clearance of 16 inches (40.6 cm) in US and 18

inches (45 cm) in Canada.

7) Install the floor protection plate according to the mark (It

must be non-combustible).

8) Put the stove on the protection floor plate and respect the

edge clearance set at step 6 as well as the center the

stove under the chimney. We recommend to fix the stove

to the floor with bolt in the slot made for this purpose in

the legs. In a mobile home, it is mandatory to fix the

stove.

9) If you have a stove with a fresh air intake, you must use

a 4 inches (10.16 cm) inlet tube with an fireproof

insulated coating . The pipe must be installed towards

outside and must be airtightly sealed with a thermally

resistant sealant. It is also necessary to use an air inlet

fitted with an approved screen for this purpose.

10) Install the chimney pipe on the stove. The pipe must be

fixed with at least 3 screws on the stove collar and for

each chimney pipe and the chimney collar.

Note The single wall or double wall chimney pipe must be

made of steel with a 6 inches diameter and a minimum

thickness of 24 gauge (0.025 inches 0.64 mm). The

chimney pipe must have been approved for solid fuel. Do

not use galvanised steel chimney pipe.

July 13, 2017

10

Page 11

Chimney pipe installation

The chimney pipe is a set of single wall or double wall flue pipes

and installed in-between the stove collar and the chimney

thimble. The single wall chimney parts are sold at most

hardware store but these are not approved nor certified. It is

therefore recommended to follow the minimum clearances to

combustible (see page 6). Moreover, there is a series of rules

which can be found in the installation codes for solid fuel

appliance.

Double wall chimney pipe

The stove was designed and tested with a single wall

chimney pipe with an heat shield. However, it is possible

to install a 6 inches (15.2 cm) double wall certified chimney

pipe.

ATTENTION

• For the minimum clearance between combustible

materials and double wall chimney pipe, see the

manufacturer manual.

Single wall chimney pipe

Single wall chimney pipe sections must have a 6 inches

diameter which corresponds to the diameter of the flue

collar and they must be made of steel with a minimum

thickness of 22 gauge 0.029 inches (0.85 mm). to reduce

the clearance of 50% (18’’ to 9’’) it is recommended to

Install a metal heat shield covering straight and elbow

sections with a space of 1 inch (25.4 mm) between the

shield and the pipe.

ATTENTION

• If an heat shield is not installed, you must move away

the stove to keep an 18 inches (45.7 cm) clearance

between combustibles materials and the chimney pipe.

The horizontal section must have an upward slope of at

least 1/4 inch (6.35 mm) by feet (30 cm) and must not

exceed 36’’ of total horizontal length (91.4 cm).

• Clearance to combustible (for example plaster board

roof) must be 18 inches (45.7 cm) or more for single wall

chimney pipe.

• Clearance to combustible must follow the pipe

manufacturer indication’s for approved double wall

chimney pipe,.

ALL PIPE SECTIONS MUST BE CLEAN AND IN GOOD

CONDITION, AND THEY MUST BE APPROVED FOR

CORDWOOD FUEL.

How to set the pipe sections

Make an installation overview of all sections and elbows (if

necessary) to ensure that you meet the clearances and the

horizontal sections inclination. Check if you have all the

necessary parts for the final installation.

For direct vertical installation, you will need:

• 1 vertical section of 24 inches or more to go above

the warmer oven head;

• 1 telescopic chimney pipe section of the right length

allowing you to connect the last chimney pipe

section to the chimney collar.

Note Additional sections can be used for higher roof.

For horizontal run installation you will need:

• 1 vertical section of 24 inches or more to go above

the warmer oven head;

• 1 x 90° elbow or 2 x 45°elbows.

• chimney pipe section(s) of the right length. The

total length of the section(s) must be less then 36’’

inches.

Note For better draft performance, two 45 degrees

elbows are preferable, with or without straight section

in between.

1. Disassemble everything and restart screwing the pieces

by starting from the stove to the roof chimney collar.

2. Insert the flue pipe entirely into the stove collar up to the

rolled rim.

3. Screw the pipe on the stove collar with a minimum of 3

screws in the holes provided for this purpose.

ATTENTION It is mandatory to fix the pipe on the stove

collar and at each joint with a minimum of 3 screws.

4. Install all the next sections up to the roof chimney support

and screw every chimney pipe parts with 3 screws.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE

SERVING ANOTHER APPLIANCE.

CONNECTOR PIPES SHOULD NEVER PASS THROUGH

THE CEILING, THROUGH A WALL, IN A CLOSET, IN AN

ATTIC OR OTHER ENCLOSED AREAS THAT COULD

CAUSE HEAT BUILD UP. IF YOU NEED TO PASS

THROUGH COMBUSTIBLE MATERIALS, MAKE SURE

THAT YOUR INSTALLATION COMPLIES WITH

CAN/CSA-B365.

July 13, 2017

11

Page 12

Mobile home installation

DANGER

WARNING THE STRUCTURAL INTEGRITY OF THE MOBILE

HOME FLOOR, WALL, AND CEILING/ROOF MUST BE

MAINTAINED.

VAPOR BARRIER EFFICACITY AROUND THE CHIMNEY

AND FRESH AIR INTAKE MUST BE KEPT IN GOOD

CONDITION.

1) Follow the «General stove installation» (p.10) from steps

2) The following requirements are MANDATORY for

DO NOT INSTALL IN BEDROOM.

1 to 10.

mobile home installation.

a. The stove must be fixed permanently on the mobile

home’s floor with bolts and nuts.

b. The exterior air intake must be installed.

c. The stove must be electrically-grounded to the mobile

home’s chassis. In the USA, electrical grounding with

8 gauge wire using star washers and certified

terminals is mandatory.

d. All of the following equipment must be certified and

approved for mobile home installation.

• Double wall chimney pipe;

• The chimney system;

• The roof flashing;

• The Storm collar;

• Chimney cap with fire screen;

• Firewall;

• Chimney ceiling support;

• Decorative collar.

e. If the chimney is exposed outside from a wall and

placed lower than 7 feet (213 cm) above the ground

level where the mobile home is situated, a guard

must be installed around the chimney at the height

of 7 feet (213 cm). If openings are made in the

guard, they must be less than ¾ inch (19.5 mm)

wide. guard openings must be kept at least 4 inches

(10.2 cm) away from the chimney surface in order to

avoid contact.

f. The chimney must exceed of at least 3 feet (91.4 cm)

the highest point of the opening made in the roof and

it must also exceed of 2 feet the highest point of the

roof inside a 10 feet distance from the chimney.

g. Be sure to seal correctly the flashing of the roof, the

firewall and the exterior air intake with sealant. You

should also pay attention to the efficacy of the vapor

barrier is not compromised.

3) Always keep the door closed. Open it only when adding

wood or when starting a fire.

4) To close the exterior air intake when the stove is not in

use, a damper must be installed in the air intake pipe.

5) Don’t forget to open the damper when you operate your

stove so that smoke will not fill the house.

6) Always use certified parts for mobile home. Never use a

substitute for replacement.

July 13, 2017

12

Page 13

CHIMNEY INSTALLATION STEPS

Use only approved chimneys, the same size as the stove collar,

6 inches in this case. The chimneys used must be tested

according to CAN/ULC S629 M87 in Canada and to UL 103

(Type HT chimneys in Standard for Chimneys, Factory-Built,

Residential Type and Building Heating Appliance) in USA. The

stove can be installed with a masonry chimney according to ULC

S635, ULC S640 and UL 1777. The masonry chimney must be

equipped with a stainless steel sleeve and meet the standards

for masonry chimney with inner sleeve.

Provide a place for sweeping.

It is preferable, if possible, to avoid a chimney built outside of

the house or of an exterior wall, especially in cold regions.

Outside chimneys generally have a less efficient draft. In some

conditions, they can even have an reverse draft because and it

can be hard to heat them enough so that they can reach their

operating temperature. A greater accumulation of creosote, a

less efficient draft and a lesser performance are some

characteristics of cold chimneys. Draft is proportional to the total

chimney height as well as its temperature. It is therefore possible

to get a better draft by increasing the chimney's height and by

reducing the heat loss with an insulated lining. Make sure that

all smoke pipe joints are really airtight. A leak reduces the

efficiency of the appliance and could even make its use

dangerous.

NOTE This is a general chimney installation method.

Always refer to the chimney manufacturer’s manual for a

more detailed method for your chimney.

1) Determine the total length necessary for your chimney.

2) Cut the holes in all the floors and in the roof.

3) If you need to cut a joist, be sure to strengthen the

adjacent joists and frame the hole respecting the

minimum dimensions between combustible materials

and the firewall. Follow the manufacturer's instructions

in the manual provided with the firewall. Never cut a

structural beam.

4) Frame the holes on each floor and attic respecting the

minimum distance recommended by the

manufacturer's manual of your chimney. Install

firewalls on each floor.

5) Frame the hole in the roof.

6) Install the chimney support and firewall in the ceiling

where the stove is installed.

7) Stack and lock the factory built chimney section on

the support and above the roof.

• The chimney must exceed of at least 3 feet (91.4 cm)

the highest point of the roof opening.

• The chimney must also be 2 feet over the highest point

on the roof within a 10 fts (304 cm) radius around

chimney.

• The minimum length of chimney is 12 feet (365.8 cm).

ATTENTION Be sure the chimney section are attached

together properly and locked onto the chimney support.

NOTE A good length of chimney can help to obtain

effective performances of your stove. Try the minimum

length first then add section if you need more draft.

8) Put the roof flashing over the chimney and seal it with

roof caulking.

9) Nail the roof flashing, and reinstall the roof covering.

10) Slide the storm collar over the chimney and seal it

with high temperature caulking.

11) Lock the chimney cap and install the fire screen if

necessary

Note

• Chimney performance may vary.

• Chimney temperature, the appliance’s location in the

house, the house aerodynamic, buildings, trees, roof

lines and wind conditions can cause backdraft in the

chimney,

• Chimney height might need adjustment if backdraft or

overdraft occurs.

July 13, 2017

13

Page 14

Inside Masonry Chimney, Vertical

Installation

The wood stove must be installed in accordance with the

applicable local laws or the CAN/CSA-B365, NFPA211 (USA)

norms regarding the installation of chimney. Follow the chimney

manufacturer’s instructions.

The masonry chimney must have a certified stainless steel

sleeve inside covering up all the chimney height. The sleeve

must be at the same diameter as the flue collar. The connection

must be tight and sealed to avoid fume to go indoor.

To pass into a wall between the stove and the masonry chimney,

installation methods have been set to prevent fire. Contact your

local authority to find the latest information in terms of

construction standards.

To install a stove with a chimney serving a masonry fireplace,

you must have a certified stainless steel sleeve inside covering

up all the chimney height. The sleeve must have the same

diameter as the flue collar. The connection must be tight and

sealed to avoid fume to go indoor. Don’t forget to add an opening

for sweeping.

Outside Vertical Installation

The wood stove must be installed in accordance with the

applicable local laws or the CAN/CSA-B365, NFPA211 (USA)

norms. Regarding the installation of chimney, follow the chimney

manufacturer’s instructions.

To pass into a wall between the stove and the masonry chimney,

the installation method has been set to prevent fire. Contact your

local authority to find the latest information in terms of

construction standards.

July 13, 2017

14

Page 15

Cathedral Vertical Installation

The wood stove must be installed in accordance with the

applicable local laws or the CAN/CSA-B365, NFPA211 (USA)

norms. Regarding the installation of chimney, follow the

chimney manufacturer’s instructions.

Always pass chimney between joists. If a joist need to be cut,

refer to the Local Building code to know how to do it safely.

Otherwise, ask a carpenter or a certified Installer.

Always frame around chimney. Keep the minimal clearances

as written in your chimney manual.

Do not fill the space between the frame and the chimney.

Nothing must be in contact with the chimney.

Always install a firewall at each level, floor, ceiling, attic and

roof.

Always pass into a level joist with a straight section.

The chimney should be supported by the cathedral roof. Build

a support frame around the chimney to support its weight. The

weight of the chimney must never be supported by the stove.

Offset Installation

The wood stove must be installed in accordance with the

applicable local laws or the CAN/CSA-B365, NFPA211 (USA)

norms. Regarding the installation of chimney, follow the

chimney manufacturer’s instructions.

Always pass chimney between joists. If a joist need to be cut,

refer to the local building code to know how to do it safely.

Otherwise, ask a carpenter or a certified Installer.

Always frame around chimney. Keep minimal clearances as

written in your chimney manual.

Do not fill the space between the frame and the chimney.

Nothing must be in contact with the chimney.

Always install a firewall at each level, floor, ceiling, attic and

roof.

A special firewall need to be install in the attic. It allows to keep

the insulation layers away from the chimney.

Always pass into a level joist with a straight section.

Chimney weight has to be supported by the lower floor and the

ceiling support.

The weight of the chimney must never be onto the elbows.

Install a support strip to hold the upper straight section over the

elbow.

The weight of the chimney must never be supported by the

stove.

Some restrictions are indicated regarding the maximum angle

and length of the angular section. See the chimney manual or

local building code.

July 13, 2017

15

Page 16

Vertical Installation

The wood stove must be installed in accordance with the

applicable local laws or the CAN/CSA-B365, NFPA211 (USA)

norms. Regarding the installation of chimney, follow the

chimney manufacturer’s instructions.

Always pass chimney between joists. If a joist need to be cut,

refer to the Local Building code to know how to do it safely.

Otherwise, ask a carpenter or a certified Installer.

Always frame around chimney. Keep minimal clearances as

written in your chimney manual.

Do not fill the space between the frame and the chimney.

Nothing must be in contact with the chimney.

Always install a firewall at each level, floor, ceiling, attic and

roof.

A special firewall need to be install in the attic. It allows to keep

the insulation layers away from the chimney.

Always pass into a level joist with a straight section.

Chimney weight has to be supported by the lower floor with a

ceiling support.

The weight of the chimney must never be supported by the

stove.

Attic firewall

July 13, 2017

16

Page 17

EXTERNAL COMBUSTION AIR

SOURCE

In a conventional house, the natural fresh air supply is

sufficient to operate the wood stove properly.

However, in new energy saving houses, some of them could

be too air-tight and the fresh air supply might not be sufficient

for the stove to operate properly. It is therefore recommended

to install an outside combustion air duct to avoid smouldering

fire that can cause smoke spill out. This negative pressure in

the house can be also caused by some ventilators in motion

such as a tumble dryer, cooking fan, bathroom fan, etc.

If there is no outside combustion air duct, it is recommended to

open a window slightly in the room where the appliance is

placed in order to avoid the negative pressure caused by the

appliances mentioned above.

A mobile home on a foundation is considered as a

conventional house.

Exterior Air Intake pipe

This appliance has an outdoor air intake.

We recommend using a 4 inches (10.7 cm) diameter aluminum

fireproof flexible pipe with a fireproof insulating coating, an

outside cap and a weatherproof grate.

The grate openings must be smaller than ¼ x ¼ inches (6mm x

6mm).

In case of using air ducts made of other materials, they must

complied with ULC-S110 norms or UL-181 Class1 norms. They

must also be equipped with fireproof insulation and be

corrosion resistant.

THE STOVE MUST BE FIXED TO THE STRUCTURE WHEN

AN EXTERIOR AIR INTAKE IS INSTALLED.

Installation of Air Intake Pipe

You can find external air intake head and grating in hardware

store. (The back panel is removed in the following picture only

to show the flue collar)

1) Find the air intake under the appliance

2) Fix the flexible or rigid pipe to the air intake collar with

a pipe clamp (A).

To install the outdoor air intake through a wall or a floor, follow

the air intake manufacturer installation instructions. Be sure to

seal the edge of the hole correctly too prevent loss of your

vapour barrier efficacy.

To avoid cold air entering in the stove constantly, we

recommend installing a damper which closes the pipe near the

outdoor air intake. Install a small rigid section of tube inside the

outdoor air intake and put a damper inside the rigid section to

close the air Intake. This damper is to reduce the cold air

circulation in the stove when it is not in use.

Connect the flexible air intake pipe onto the damper section.

Put a fireproof thermal insulation around the pipe if the pipe is

not insulated.

Air Intake Obstruction

If the stove extinguishes after closing the door, it’s possible that

the outdoor air inlet is obstructed by something, or that the

damper of the air intake is closed.

After a long period of disuse, insects or animals can build a

nest inside the air intake.

After a storm in winter, snow can accumulate over the air

intake and obstruct it.

Before the heating season, always inspect the air intake pipe to

be sure nothing is obstructing it.

July 13, 2017

17

Page 18

STAINLESS STEEL TUBES REPLACEMENT

Although the tubes are in stainless steel, because of the

extreme temperatures and conditions inside the firebox, the

tubes could eventually corrode and perforate depending of

operating conditions. In that scenario, your stove becomes less

effective in terms of combustion quality and the tubes will need

to be replaced to ensure the performance of your appliance.

Stainless steel tubes Installation

There are three types of tubes to install.

The three tubes in the back (1) are perforated from a single

side, and the second tube in the front (2) is also perforated

from a single side but with bigger holes than the other tubes.

The first tube in front (3) is perforated on both side with smaller

holes as on the 1,2 & 3. tubes

How to install the tubes

1) Insert the tube on either end into the round hole of the

hot air channel.

2) Insert the other end in the corresponding hot air

channel hole.

3) Center the tube and align the holes with the tabs.

Screw the tube to the side tabs at both ends by using

the bigger tube‘s holes intended for that purpose.

.

4) Install the next tube.

To remove the tubes, do these steps in the reverse order.

July 13, 2017

18

Page 19

OPERATING INSTRUCTIONS

OPERATE ONLY WHEN DOOR IS CLOSED: KEEPING

THE DOOR OPEN MIGHT RESULT IN A RUNAWAY

AND CAUSE PERMANENT DAMAGE TO THE STOVE

OR A CHIMNEY FIRE.

A WOOD BURNING PRODUCES CARBON DIOXIDE

(CO2) AND CARBON MONOXIDE (CO) WHICH ARE

TOXIC AND LETHAL. IT’S RECOMMENDED TO

INSTALL A CO, CO2 DETECTOR IN THE SAME ROOM

WHERE THE STOVE IS LOCATED.

INSTALL ALSO A SMOKE DETECTOR IN THE SAME

ROOM WHERE THE STOVE IS LOCATED. THE SMOKE

DETECTOR MIGHT GO ON WHEN THERE IS SMOKE

LEAKING OUT.

THIS APPLIANCE IS NOT DESIGNED FOR OTHER

FUEL THAN SEASONED CORDWOOD. FUELS SUCH

AS COAL, CARDBOARD, ETC. COULD PRODUCE

MORE POLUTANT EMISSIONS OR OVERHEAT THE

APPLIANCE AND DAMAGE IT.

NEVER SLAM THE DOOR.

NEVER BURN INFLAMMABLE LIQUID: INFLAMMABLE

LIQUID PRODUCES VERY INTENSE HEAT AND ITS

COMBUSTION IS HARD TO CONTROL. IT MIGHT

CAUSE RUNAWAY AND OVERHEATING OF THE

STOVE. THIS CAN CONSEQUENTLY CAUSE DAMAGE

TO THE STOVE, A CHIMNEY FIRE OR A HOUSE FIRE.

ALWAYS VERIFY IF THE AIR INTAKE IS NOT

OBTRUCTED BEFORE LIGHTING A FIRE.

NEVER ELEVATE FIRE WITH A GRATE OR ANDIRON.

ALWAYS MAKE FIRE DIRECTLY AT THE BOTTOM OF

THE STOVE.

Burning regime control

When the handle under the front stove apron is pushed

completely backward, the air admission is reduced. In that

configuration, air will only comes out from the secondary air

tubes. On the other hand, when the handle is pulled forward,

the air admission increases. This air is coming from the

openings above the door. This is what we called “primary air

admission”.

Warning Operating your stove with the door partially or

fully open for a long period of time can damage the stove.

IT IS PROHIBITED TO MODIFY AIR ADMISSION TO

OBTAIN A BRISKER FIRE OR FOR ANY OTHER REASON.

MODIFICATIONS CAN VOID WARRANTY.

Lightning fire

After installing the stove correctly by following the instructions

of the manufacturer, you are ready to light it up.

1) Pull the handle under the front table of the stove

forward to let the air admission enter in the

combustion chamber.

2) Put paper and kindling wood in the combustion

chamber and light the fire in your preferred way.

3) Close the door partially keeping a slight opening.

When the chimney is hot enough, close completely

the door and leave the air admission handle in the

pulled position so that your fire kindle steadily.

4) Once you have a glowing ember bed, it’s time to add

logs. Follow now the instruction section on how to

keep a fire.

DO NOT FILL THE STOVE OVER THE UPPER BRICK.

You can control the combustion process by opening or closing

the air intake. The wood will burn more rapidly with more

primary air admission. Otherwise, the wood will burn slower

and more efficiently with the air intake handle set to secondary

air(minimum).

NEVER LEAVE THE STOVE UNATTENDED WHEN

THE DOOR IS SLIGHTLY OPEN FOR LIGHTING.

ALWAYS CLOSE THE DOOR AFTER LIGHTING.

ALWAYS LEAVE THE DOOR CLOSED WHEN

OPERATING THE STOVE.

NEVER USE CHEMICAL PRODUCTS OR

INFLAMMABLE LIQUID TO START THE FIRE OR

REVIVE THE FLAME.

NEVER USE GASOLINE, GASOLINE-TYPE

LANTERN FUEL, KEROSENE, CHARCOAL LIGHTER

FLUID, OR SIMILAR LIQUIDS TO START OR

’REVIVE’ A FIRE IN THIS STOVE. KEEP SUCH

LIQUIDS AWAY FROM THE STOVE WHILE IT IS IN

USE.

DO NOT BUILD FIRE NEAR THE DOOR GLASS.

KEEP ANY INFLAMMABLE PRODUCTS AWAY

FROM THE APPLIANCE.

First fire

During the first hours of operation, you must heat the stove

gradually in order to allow an appropriate baking of the paint

and to facilitate its adhesion to the metal. Do not heat the

appliance with a brisk fire so as to avoid a thermal shock which

could lift up the paint or fade the color.

Make sure that the room is well ventilated in order to eliminate

odours and smoke coming from the paint during the first hours

of use. This nuisance is merely temporary.

This special paint is conceived to tolerate temperatures up

to1200°F (650°C).

July 13, 2017

19

Page 20

Keeping a fire

To add wood in the stove and keep a fire:

1) Pull the handle under the apron of the stove forward and

wait a few seconds to let the fire adjust to the new

conditions.

2) Open the door handle to the previous position and wait

some time so that the fire has time to adjust

3) Turn the door handle completely and leave the door halfopen and let the fire set up.

4) Open the door completely.

5) Move embers near the door with poker to supply it with

oxygen and make it burn completely.

6) Add firewood over the ember, keeping it away from the

glass door to avoid flame touching the ceramic glass.

ATTENTION

DO NOT FILL THE STOVE OVER THE UPPER

BRICK.

DO NOT BUILD A FIRE NEAR THE WINDOW.

THIS APPLIANCE IS DESIGNED TO BURN DRY

CORDWOOD. WE DON’T RECOMMEND ANY OTHER

TYPE OF WOOD.

7) Close the door slightly and let the wood burn.

8) Once the fire gets stable, close and lock the door.

9) Push the air admission knob to the desired condition.

RISK OF OVERHEATING: NEVER LEAVE THE STOVE

UNATTENDED WHEN THE DOOR IS SIGHTLY OPEN.

ALWAYS CLOSE THE DOOR AFTER ADDING A LOAD.

DO NOT USE ANY INFLAMMABLE LIQUID TO REKINDLE

THE FIRE.

Fuel Selection

This stove is designed to burn only firewood. Using firewood

dried properly will result in an higher efficiency and a lower

pollutant’s emission compared with using softwood or fresh

wood.

Moisture Meter Information

Firewood is ready to use at 10‐25% moisture content.

Fresh cut logs can have a moisture content of 80% or more,

depending on species. During the drying process, wood might

shrink, split, twist or change shape. In general, wood must be

dried before use. Air drying, i.e. ‘seasoning’ is the most

common method used for cordwood.

Season wood outdoor in summer for at least 6 months before

use. Properly seasoned wood is darker, has cracks at the

ends, and sounds hollow when one piece is smacked against

one another.

In most parts in the North America, the minimum moisture

content that can be generally obtained by air drying is about 12

to 15 percent.

Things not to burn

1) Garbage;

2) Lawn clippings or yard waste;

3) Materials containing rubber;

4) Plastic materials;

5) Waste containing petroleum products, paints or solvent;

6) Materials containing asbestos;

7) Construction or demolition debris;

8) Railroad ties or pressure-treated wood;

9) Manure or animal remains;

10) Salt water driftwood or other previously salt water

saturated materials;

11) Unseasoned wood;

12) Paper products, cardboard, plywood, or particleboard.

The prohibition against burning these materials does not

prohibit the use of fire starters made from paper, cardboard,

saw dust, wax and similar substances. Burning these materials

may result in release of toxic fumes or make the stove

ineffective.

Wood storage

The cordwood must be stored in a dry place, away from bad

weather.

It should not be stored under or near the stove.

If any wood is stored next to the stove, the minimum

clearances must be respected to avoid self-ignition

temperature.

• 48 inches (122 cm) front

• 10 inches (25.4 cm) rear

• 20 inches (50.8 cm) sides

Draft

Draft is the force which moves air from the appliance up

through the chimney. The amount of draft in your chimney

depends on its length, local geography, nearby obstructions

and other factors. Too much draft may cause excessive

temperatures in the appliance and may damage the appliance.

An uncontrollable burn or excessive temperature indicates

excessive draft.

Insufficient draft will cause the appliance to leak smoke into the

room through the appliance and chimney pipe joints.

July 13, 2017

20

Page 21

Usage of cooking area and oven

Cooking Area

It is not recommended to cook directly on the stove’s top (on the

paint). However, the stove‘s top part is an excellent cooking area

to work with kitchen utensils such as pots and pans. On the other

hand, you need to bring a special attention to aluminum

components which can melt if left unattended or in contact with

the hottest part of the stove. Temperature above the stove can

largely equal that of an electric element.

We recommend using pots and pans made of cast iron, steel, or

stainless steel when you use the circular lids above the fire.

Elsewhere on the surface area, it is possible to use aluminium

pots and pans.

Use of cooking holes

To cook food on the hobs and to get the direct combustion gases

heat from the holes, use the handle provided with the unit. To do

so, insert the handle in the matching lid hole (1-2) then tilt the

handle and lift the lid (3). Place the lid directly on the stove.

Do not leave the holes in the hob uncovered without pot or pan

for a long period of time. If you do otherwise, air will engulf in the

opening and it will cool down the chimney and diminish the draft

inside the stove. Moreover, smoke might come out from the

openings if the draft in the chimney diminishes too much.

Optional cooking plate

J.A. Roby offer two enameled cooking plates for your device.

They can be bought at any J.A. Roby’s retailers.

One of those cooking plates is intended to be placed above the

fire(1) and the bigger cooking plate is to be put above the

oven(2).

The first one can be used to sear meet or food directly on the

stove while the second one is more suitable for slower cooking.

Both plates offer the additional advantage of reducing the oven

heat loss which ends up rising the oven temperature.

It is recommended to clean-up the enameled plates with water

and vinegar while they are still hot. Rinse the plate with water

before drying it.

Lids above the firebox

Above the firebox there are two lids nested in one another. One

is 7 inch diameter and the other is 10 inch diameter. ( 1 )

Before removing the 10 inch lid, it is strongly recommended to

remove the 7 inch one to reduce the weight.

Lids above the oven

Above the oven there are 2 lids. One is 6 inches and the other

is 7 inches ( 2 ). To improve the temperature above the oven

lids the oven damper must be set to the cooking setting.

July 13, 2017

21

Page 22

Oven usage

On the stove’s top there is an handle to turn the oven damper.

When the flame logo is facing front, the damper is in the ignition

position and smoke doesn’t turn around the oven and goes

straight to the chimney. To direct smoke around the oven, it is

necessary to turn the damper perpendicularly to the front of the

stove, in other words, the logo is turned sideways so that we

don’t see it.

The oven doesn’t work as a conventional electric oven. It

requires a preheating time of 30 to 60 minutes. preheating time

and oven temperature vary according to the room temperature,

the chimney set-up, and atmospheric conditions.

In case of an unheated environment, for example without

electricity, it is possible that the preheating time might takes

longer on a cold start since smoke is considerably cooler.

Mastering cooking with your wood cook stove needs time and

experience. Each wood cook stove’s owner develops their own

method and learns how to stabilize the oven temperature.

The operation of wood cook stove is unique for each installation

as described earlier. You might need more/less preheating time

depending on your installation before adding woods or before

adjusting the air admission to control the cooking temperature.

Cooking with wood fire needs much more attention than electric

stove.

The temperature in the oven is directly related to the fire

intensity. The stronger the fire, the higher the oven temperature

gets.

The chimney is the essential part governing the combustion in

the stove. The draft is created by the chimney when it gets hot

enough. It is therefore important to respect the minimum

chimney length according to the standard to get the optimal

performance. You can refer to the section of the chimney

installation in this manual regarding the minimum chimney

length.

Note Each stove installation is different and certain variables

can nevertheless affect the chimney draft and improve/impair

the stove performance even if all the regulations are respected.

Here are examples of factors which can affect the efficiency of

the stove: horizontal/vertical length of chimney, chimney size,

number of elbows, the presence of a liner inside a masonry

chimney, chimney installation located indoor/outdoor, air leaks

from the sweeping hole inside a brick chimney, leaking from

pipes and joints between chimney sections, etc. Even the drying

quality of the wood is important, since wood moisture takes

away the heat to evaporate water which result in a lesser heat

output for your stove.

After starting the fire in your stove, leave the damper handle in

the ignition position until the chimney gets hot enough to warm

up the oven.

When the chimney is not hot enough, there will not be enough

draft to increase the combustion rate and it might prevent the

oven from reaching its optimum performance. It will also make

the preheating time longer. You can get a flue thermometer for

this purpose sold at a hardware store to know the chimney

temperature. To turn the damper handle to the oven heating

position, the chimney temperature should reach at least 350°F

(175°C).

To warm up the oven evenly, it is recommended to leave the

damper handle in the oven heating position and to control the

temperature by changing the burn rate with the handle

underneath the firebox.

July 13, 2017

22

Page 23

Thermometer

The temperatures of the thermometers on the oven and warmer

are approximate and can’t be used for accurate cooking

temperature. We recommend using a cooking thermometer

instead.

Since it is a wood cook stove, It is also possible that the oven’s

cooking time might takes longer than the one indicated in a given

recipe. Spending more time using it and getting experience with

it, you will be able to estimate the cooking time with your oven.

Cleaning of the creosote build-up

When the stove is burning, smoke travels around the oven. Fly

ash and creosote might form deposit on the inside wall along the

smoke travel path. This mixture of ashes and creosote functions

as an insulating layer and might inhibit the heat transfer from the

smoke to the oven. It is therefore necessary to clean up that area

once in a while.

This stove is calibrated for very low particulate emissions.

However, if ashes and creosote build-ups appear quickly, it is

possible that:

• You burn other fuels then wood,

• The wood you use is frozen or too moist/dry with humidity

level above 20% or under 10%,

• You completely close the door too early/late after the

ignition to maintain a clean combustion,

• You have a chimney draft issue (see chimney

installation.)

• There is a leak around the door gasket, a problem with

the air intake or the air flow under the baffle is blocked

For the stove maintenance, there are 4 access points:

1) The 2 round lids on the hob which allow the cleaning of

the oven top

2) The little rectangular hatch located on the top right corner

of the hob which allows access to the right side of the

oven

3) A rectangular hatch is located directly under the oven

door which allow access to the bottom part of the stove.

This door is also convenient to remove creosote deposits

that might have fallen while cleaning up.

4) The chimney collar allows to reach the back of the oven.

Clean up procedure

Make sure the stove is cold. Remove the two circular lids (1) on

the hob and scratch the oven top surface. While doing so, try

pushing the creosote debris on the stove’s right side. You can

let the debris fall at the bottom of the unit’s right side since you

will be able to reach the fallen creosote debris by the access

hatch located under the oven door.

Open the rectangular top access hatch (2) Clean up the

creosote accumulated on the right side and let it fall at the

bottom.

In order to access more easily the back of the stove for cleaning,

it is recommended to reach the back from the flue collar (4). It

will therefore be necessary to remove the chimney section

connected to the stove.

Once the 3 oven’s sides have been cleaned, unscrew the two

nuts (5) holding the bottom access hatch (3) under the oven door

and open it up. Clean up the bottom part of the oven and remove

all the dirt buildup that might have previously fall there.

You can use a vacuum cleaner to remove the creosote debris.

It is recommended to change the filter or keep one filter

exclusively for cleaning creosote/ashes.

July 13, 2017

23

Page 24

MAINTENANCE

Ash Removal

Wood burning doesn’t usually completely transform wood into

combustion gas. The leftover residues are called ashes and

they must be removed from the combustion chamber to help

oxygen circulation.

The ashes have to be removed periodically up to every 2 or 3

days during intensive burning period. Never leave excessive

accumulation in the combustion chamber because it can

reduce the firebox volume and prevent the air supply from

reaching the logs. As a result, this can affect considerably the

performance of your stove.

Remove ashes excess when it gets 3 to 4 inches deep in your

firebox. Note that the fire must have been put out and the stove

must be cool enough for cleaning. You can leave an ash bed

approximately 1 inch deep at the bottom of the firebox to help

maintain a hot charcoal bed.

The best time to remove ashes is after a long heating period

like in the morning when the stove is relatively cold enough to

manipulate ashes and the chimney is still hot. The hot chimney

draft will then vacuum the dust inside the stove.

To clean ashes from the combustion chamber, you must have

the following tools.

• Ash shovel;

• Ash brush;

• A metal bucket with an airtight lid or other container

made for this purpose.

Some embers are mixed with ashes and they could still catch

fire in a few minutes or a few days. It is very important that the

metal lid is airtight. The bucket must be put on a noncombustible tile or brick.

Ash Disposal

Some embers can still catch fire long after the fire is deemed

quenched. If embers have enough oxygen, they can stay lit for

minuts or even for a few days.

It’s mandatory to store ashes:

• In a metal container with an airtight metal lid and

firmly closed;

• Outside the house on a non-combustible material

such as gravels, concrete and bricks;

• Far enough from any combustible material;

• Far enough from any inflammable liquid and vapor.

Before the ashes are discarded or buried in the soil, they

should be retained in a closed container until they get

thoroughly cooled and completely extinguished.

NEVER PUT TRASHES IN THE ASH CONTAINER.

Creosote Formation

When wood is incompletely burned, it produces tar and other

organic vapors, which condensate as creosote. The creosote

vapor condenses on the relatively cold flue walls. As a result,

creosote residue accumulates on the flue lining. The creosote

could be in forms of tarry liquid, dust, soot or crystallized

deposit. This creosote makes an extremely hot fire when

ignited and it is the principal cause of chimney fire.

The chimney pipe and chimney should be inspected at least

once a week during the first several months to determine the

sweeping frequency

Contact your local fire authority to know how to handle a

chimney fire.

Chimney Inspection

Wood moisture, wood type, combustion quality are some

factors that can influence the creosote buildup speed in the

chimney pipes.

The chimney and the chimney pipes must be inspected at least

once every two months during the heating season. You can

contact a chimney sweeper to evaluate the sweeping

frequency required. You can sweep the chimney yourself. To

do so, extinguish the wood stove and wait until it cools down.

Thereafter, remove the chimney collar screws and the stove

collar screws to inspect the chimney pipe. Look inside the

chimney with a flashlight. For a masonry chimney, it is possible

to inspect inside the flue by removing at first the bottom steel

flue plug. Afterward, you should be able to insert a small mirror

in the chimney lookout to conduct your inspection. Don’t forget

to put back the flue plug. For an outdoor factory built chimney,

open the chimney cap at the bottom of the chimney. It is better

to do an inspection during the daytime during a sunny day.

If there is a creosote buildup of 1/8 inch (3 mm) or more , if the

chimney diameter appears smaller and/or if you cannot see the

chimney cap, It’s a sign of an important creosote accumulation

which will require a chimney sweeping.

Chimney Sweeping

Chimney sweeping needs special tools such as fiberglass rod

and a chimney brush of proper diameter.

In order to sweep the chimney, you will need to climb on the

roof top to remove the chimney cap. If the chimney is taller

then 5 feet above the roof it might be necessary to remove a

chimney section.

If you are not comfortable doing it, we recommend calling a

professional chimney sweeper certified by the APC in Quebec,

the WETT in the rest of Canada or by the NFI in the United

States.

July 13, 2017

24

Page 25

Door maintenance

The door is the mobile element that needs a special attention.

Its tightness is essential. When the braided fiberglass rope is

worn out, you will see the white soot sticking on the glass

where the air leaks.

• IT'S IMPORTANT TO KEEP ALL DOOR AND OPENING

CLOSED WHILE IN OPERATION.

• IT'S IMPORTANT TO KEEP ALL GASKET TIGHT,

SEALED AND IN GOOD CONDITION.

Air tight Adjustment

If the braided fiberglass rope still seems in good condition but

little flattened, it needs probably to be tighten.

Door adjustment (right side)

The adjustment on the right side can be done with the screw

under the door near the hook hole.

1) Unlock and open the door.

2) With a square screwdriver, turn the adjustment screw

clockwise by a quarter turn.

3) Put a piece of paper between the stove front and

fiberglass rope. Close and lock the door.

4) If the paper slides easily when you pull it, repeat steps

1 to 3 again.

5) If the screws are tightened completely but the piece of

paper comes off easily, the braided fiberglass rope

need probably to be changed.

Cleaning up glass

To clean the glass, J.A. Roby Inc. recommends using products

sold for this purpose or an oven cleaner. Take care not to

enter in contact with other stove surfaces than the glass when

using this kind of products.

Avoid cleaning the glass when it’s hot or by using abrasives.

Cleaning the glass when it’s hot can cause a thermal shock

which can break it.

Disassembly and reassembly of the door

To disassemble the door, keep the lower hinge tighten.

1) Open the door.

2) Unscrew the upper hinge nut (C) with a spanner

partially or completely so that you can liberate the

upper part of the door.

3) Remove the tilted door from the lower hinge by lifting

it

To reassemble the door:

1) Put the door on the bottom hinge and align the top

part of the door straight

2) Screw back the top hinge bolt assembly (A, B, C)

inside the door hinge as shown and make sure the left

side of the door is pressed evenly against the

appliance front wall before tightening the hinge bolt

definitely. check if the door is straight.

Replacing broken glass

To avoid braking the glass;

• DO NOT HIT THE GLASS,

• DO NOT SLAP THE DOOR,

• NEVER BUILD FIRE NEAR THE GLASS,

• NEVER PUT WATER ONTO THE GLASS TO AVOID A

THERMAL SHOCK,

• NEVER OPERATE THE STOVE WHEN THE GLASS IS

BROKEN OR CRACKED.

Replace only with a 4 mm ceramic glass with the right shape.

Contact your retailer to get a replacement glass.

DO NOT USE SUBTITUTE.

How to replace broken glass

1) Loosen partially the screws retaining the four glass

supports.

2) Remove all pieces of broken glass and clean the

door.

3) There is a fiberglass rope around the glass to seal it.

If not, you need to install it without pulling it too much

so that the rope remains thick. The rope has a selfadhesive side to stick onto the door glass.

4) Install the new glass and put the lower support first

and gently tighten the screws. If the screws are

tighten too much, it will create pressure points and it

might break the glass when it gets hot. The fiberglass

rope will be pressed gently around the glass against

the door.

5) Install the top support and gently tighten the screws.

6) Verify if all the screws are tightened properly.

If you cannot replace the glass with the door in vertical

position, you may have to remove the door by following the

instructions of this manual.

July 13, 2017

25

Page 26

Fiberglass rope replacement

When it is impossible to adjust the door because of the

flattened fiberglass rope, it is the time to change it. When the

rope is damaged, you also have to replace it.

Use a ½ inch (12.7mm) braided round fiberglass rope

(available in some hardware store).

To install the new fiberglass rope, we recommend detaching

the door from the stove. Please see the section « Disassembly

and reassembly of door » in this manual.

Fiberglass rope preparation

1) Remove the worn fiberglass rope and take care

cleaning the groove of any leftover pieces of fiber or

latex.

2) Take the frayed end of the fiberglass rope and push

the loose fiber inside the end of the rope to put it

together

3) Add a small amount of high temperature latex or

silicone at the end of the fiberglass rope to make a

clean end.

4) Starting from the lower corner near the hinge, put the

fiberglass rope around the groove without giving any

tension and measure the length of the rope.

5) Add ½ inch to the length measured in step 4 and

repeat the step 2 & 3 for the new rope end.

IN CASE OF CHIMNEY FIRE

CONTACT YOUR LOCAL AUTHORITY TO KNOW WHAT TO

DO IN CASE OF CHIMNEY FIRE AND BE SURE TO KNOW

PROCEDURE IN CASE OF CHIMNEY FIRE.

1. Close all door, the air intakes and the damper.

2. Water the combustible materials around the stove.

3. Trigger an alarm and leave the house, if necessary, call

the fire department.

4. Don’t interact with the pipes before the fire is completely

extinguished.

Do not use the chimney before inspection or necessary repairs.

.

Fiberglass rope installation

1) Put high temperature latex inside the clean groove in

order to glue the fiberglass rope.

2) Starting from the lower corner near the hinge, put the

fiberglass rope into the groove without giving any

tension.

3) Align the two fiberglass rope ends perpendicularly and

put some high temperature latex in between.

4) Let dry the high temperature latex for at least 48

hours. Put the door back on the hinges and readjust

the tightness.

July 13, 2017

26

Page 27

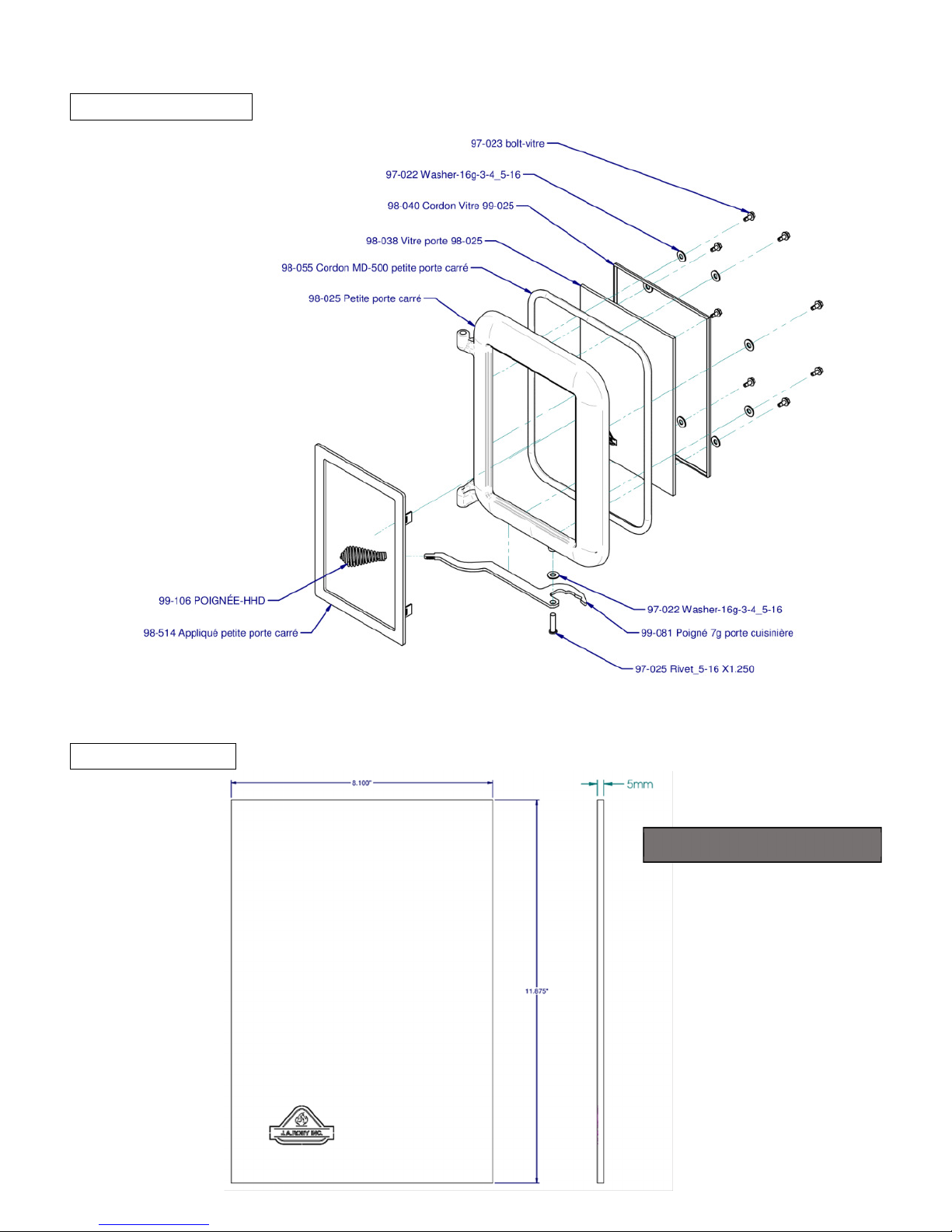

APPENDIX 1

Exploded diagram of doors

Oven door

Glass dimension

Order Code:CB-VPF

July 13, 2017

27

Page 28

Order Code: CB

-

VPC

Square Stove door

Glass Dimension

July 13, 2017

28

Page 29

Arc Stove door

Glass dimension

July 13, 2017

29

Page 30

Order Code : CB

-

VPR

Reservoir Door

Glass

dimension

July 13, 2017

30

Page 31

APPENDIX 2

MANUEL D’INSTALLATION ET D’UTILISATION DU RÉSERVOIR À EAU OPTIONNEL

INSTALLATION AND OPERATION MANUAL OF THE OPTIONAL WATER TANK

Le réservoir décoratif de J.A. Roby ajoute

une touche d’esthétisme à votre cuisinière

tout en complétant votre ensemble de

cuisine. Comme attendu, le réservoir permet

de garder une source d’eau chaude à portée

de main pour votre maisonnée.

Note : Le réservoir n’est pas conçu pour

faire bouillir l’eau ni pour réchauffer l’eau

rapidement. Il ne sert qu’à maintenir la

température de l’eau sur une période

prolongée.

Attention : Pour remplir le réservoir d’eau

chaude J.A. Roby préconise l’utilisation

d’une bouilloire conventionnelle en métal

placée directement sur le dessus du

poêle

The J.A. Roby’s decorative water tank

adds a touch of aesthetic to your cook

stove while completing your kitchen set.

As expected, it also provides an handy

source of warm water for your household.

Note: The water tank is not conceived

to boil water nor to warm it up quickly.

It’s only purpose is to maintain the

temperature of the water on an

extended period.

Attention: To fill the water tank, J.A.

Roby recommends using a standard

metal kettle placed directly atop of the

cook stove hob

July 13, 2017

31

Page 32

INSTALLATION DU

RÉSERVOIR

1)

Visser partiellement les 4 vis

(A) fournies avec le réchaud

de façons à laisser

suffisamment de jeu pour

pouvoir accrocher ce dernier

les vis

2)