Digital Thermometer

UNI-SENSOR 701A

Operating Instructions

Ver. 2.0

UNI-SENSOR 701A Operating Instructions

Table of Contents

Introduction.......................................................................................................1

1. Precautions...............................................................................................1

2. Features ...................................................................................................2

3. Checking the Thermometer ......................................................................2

4. Specifications............................................................................................2

5. How to Operate the Thermometer and Descriptions of the Functions......3

6. How to Use Each Sensor (Optional).........................................................7

7. Sensor Group for Various Applications .....................................................8

8. Maintenance ...........................................................................................9

1

Introduction

Thanks for purchasing a JAPAN UNIX UNI-SENSOR 701A digital thermometer.

Read the Operating Instructions thoroughly and understand the descriptions well before using

this UNI-SENSOR 701A digital thermometer to operate it correctly.

CAUTION

♦ No p art of this document may be reproduced or photocopied in any form without prior

notice.

♦ The contents of this document are subject to change without notice in the future.

♦ Although we have taken all possible measures to ensure the descriptions of this

document, please do not hesitate to contact us if you find anything wrong such

as an error.

1. Precautions

Before using the UNI-SENSOR 701A digital thermometer, be sure to read the following

cautions and understand them well.

Use the UNI-SENSOR 701A digital thermometer under the environment

that is regulated with the specifications only. Otherwise, it may lower the

reliability of the thermometer or cause the thermometer to malfunction.

If you do not use the thermometer for a long time, the battery may leak.

Please remove the battery from the thermometer.

The case of the thermometer is made of ABS resin. Be careful not to

bring the case to any substance whose temperature is high so that it

cannot be deformed.

Organic solvent such as thinner, benzine and alcohol may deform the

thermometer. Do not apply such solvent to the thermometer.

CAUTION

CAUTION

CAUTION

CAUTION

2

2. Features

This UNI-SENSOR 701A is a product of outstanding safety and reliability. Its main features

are shown below.

① Highest resolution 1.0°C and low cost

High response speed allowing your quick operation

③ Sensor that can be connected to the main unit directly

④ Extension compensating lead wire that allows the thermometer to be used for various

applications

⑤ A wide choice of sensors you can select according to your purpose

⑥ High-precision automatic cold-junction compensating circuit that improves the

performance

3. Checking the Thermometer

Take out the UNI-SENSOR 701A from the package at first. Check the supplied parts one by

one from the following figure to see if you have all parts and if any of them is not damaged. If

you do not have any of them or if any of them is damaged, contact the dealer from which you

have purchased the thermometer.

4. Specifications

Model name UNI-200

Input TYPE/K (CA)

Resolution 1.0°C

Measurement range - 65°C to + 1,000°C

Display precision Display tolerance: ± 0.3 % of rdg ± 2 dig

Temperature coefficient: ± 0.03 % of FS/°C

Sampling frequency 3/second

Cold junction compensating precision ± 0.5°C (at 25°C ± 10.0°C)

Power supply Type 006P battery × 1

Operating time Continuously 100 hours or more

Operation switches ON, OFF, Hold, Battery Low automatic display

Operating environment 0 to 40°C, 20 to 85 %RH (No condensation)

Mass of the main unit Approximately 180 g

Dimensions 185 (W) × 35 (H) × 23 (D) mm

Cover Main unit

UNIX-SENSOR 701A

UNIX-200

POWER

HOLD

MODE

Sensor for the iron tip

UNI-200 UNI-9

3

5. How to Operate the Thermometer and the

Descriptions of the Functions

5.1 How to insert a battery

• Open the battery lid.

• Connect the power cable to the battery.

• Insert the battery.

• Close the battery lid.

CAUTION

If you do not use the thermometer for a long time, the battery may leak.

Be sure to remove the battery from the thermometer.

5.2 Turning on or off the thermometer

• Connect the sensor to the main unit.

When you press the key, all of the display items

light for approximately one second, and the

thermometer starts measuring.

When you press the key again, the thermometer is

turned off.

When you press the POWER key anytime during measurement, the thermometer is turned off.

When you turn on the thermometer, it enters the normal measurement mode.

* In this document, the state into which the thermometer is put at power-on (no function

appears on the left side of the display) is referred as to the “normal measurement mode.”

9V

−

+

−

+

POWER

HOLD

MODE

POWER

POWER

POWER

MAX

MIN

HOLD

AVG

4

5.3 How to measure the temperature of an iron tip

• Melt wire solder with the iron tip, and put the iron tip to

the center of the sensor to measure its temperature.

CAUTION

It takes a while for the temperature to

become stable after solder is melted.

5.4 Detaching the probe

• Push the probe stopper and pull the probe out.

POWER

HOLD

MODE

POWER

HOLD

MODE

Push here.

5

5.5 Various HOLD functions

Selection

(Maximum value HOLD function)

Selection

(Minimum value HOLD function)

Selection

(Average value HOLD function)

Maximum temperature display mode

A normal measurement value is displayed.

Confirmation

Cancel

Confirmation

Cancel

Minimum temperature display mode

A normal measurement value is displayed.

Average temperature display mode

A normal measurement value is displayed.

HOLD function

The current measured temperature data is held

and displayed.

“HOLD” lights on the display.

Maximum value HOLD function (MAX/HOLD)

When “MAX” and “HOLD” are lighting on the display, the

thermometer holds and displays the maximum

temperature data while constantly updating the maximum

temperature data being measured.

If an error occurs, the error message is held and

displayed.

The maximum

temperature is displayed.

Minimum value HOLD function (MIN/HOLD)

When “MIN” and “HOLD” are lighting on the display, the

thermometer holds and displays the minimum

temperature data while constantly updating the minimum

temperature data being measured.

If an error occurs, the error message is held and

A

verage value HOLD function (AVG/HOLD)

This is the function for displaying the average value

obtained during the desired time period.

When “AVG” is lighting on the display, the thermometer

internally holds the temperature data being measur ed .

The actual measurement temperature data is displayed.

A

normal measurement

value is displayed while

the average value is being

obtained.

Average value displayed while “AVG” is lighting

When you press the HOLD key, “AVG” and “HOLD”

light on the display, and the thermometer calculates the

average of the measurement temperature data held with

it internally, and holds and displays the average value.

You can calculate the average value of the measured

temperature data for up to five hours. After a lapse of

five hours or more, this function is cancelled.

If an error occurs during averaging, the error status is

held and displayed.

Confirmation

The minimum

temperature is displayed.

6

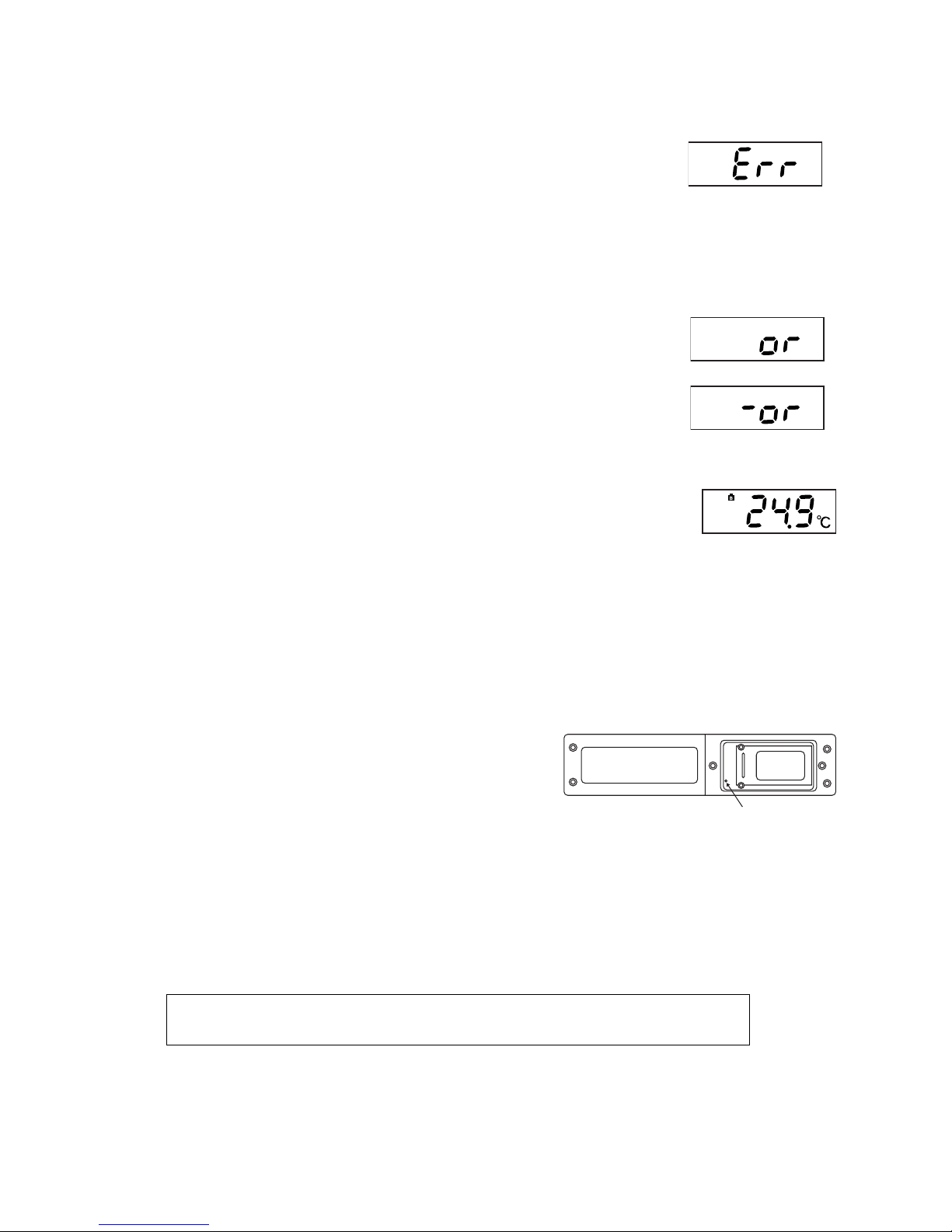

5.6 Error messages

(1) Indication of the broken sensing edge

If the sensing edge of the probe is broken or if the probe is not

connected to the thermometer, “Err” appears on the display as

shown in the right figure.

If this message appears on the display, replace the probe with a

new one or connect the probe to the thermometer.

(2) Over range indication

If the measured temperature exceeds the measurable range, “or” or

“-or” appears on the display as shown in the right figure.

If the sensing edge of the probe is broken, this over range error may

appear also. If the temperature being measured is within the

measurement range clearly , check t he probe. If the indicated value

gets unstable abnormally, check the probe also.

(3) Indication of decrease in the battery power

When the remaining power of the battery decreases, and then the

remaining power level becomes approximately five hours, “B,” which

indicates decrease in the battery power, lights on the display. The

entire display is set to flash when the remaining power level

becomes approximately 30 minutes.

Note that when the battery power decrease indication appears

varies depending on the battery type and/or the used environment.

When the indication of decrease in the battery power lights, replace

the battery with a new one as immediately as possible.

(4) What to do if the thermometer malfunctions

If the display or the thermometer itself

malfunctions, push the reset switch of the battery

storage section with a thin stick or similar tool.

When you press the reset switch, the

thermometer is put into the state in which it is put

at power-on.

If the thermometer does not operate normally

even after you push the reset switch, the

thermometer may have broken down. Contact

a dealer from which you have purchased the

thermometer or us.

CAUTION

When the battery is exhausted completely, the thermometer does not

display the low power indication.

Reset switch

7

6. How to Use Each Sensor (Option)

① How to put the surface sensor to the target

Put the surface sensor to the contact surface of the

target vertically.

Note that the thermometer cannot detect the

correct temperature if the contact surface of the

target is not smooth or flat.

(UNI-1)

② How to connect the extension kit

(UNI-4)

③ How to measure the temperature of a board

Use a heatproof tape to paste the sensor onto the

place of a board whose temperature you want to

measure.

(UNI-8A)

④ How to measure the temperature of a solder bath

Push the sensor through the solder bath to

measure the temperature of the inside of the

solder bath.

(UNI-2)

B

90°

POWER

HOLD

MODE

POWER

HOLD

MODE

HOLD ON OFF

8

7. Sensor Group for Various Applications

Model name Shape Tip of the

sensor

Operating

temperature

Feature/Application

UNI-9

Sensor for an iron tip

(Supplied with the

thermometer))

Normal

temperature to

+ 500°C

• You can measure the

temperature of an iron tip

correctly.

UNI-1

Surface sensor

(optional)

- 50°C to +

200°C

• The certain ground contact

pressure is obtained with the

spring mechanism to allow

the thermometer to detect the

correct surface temperature.

• Durability of the contact

surface of the sensor is

higher than that of the

competitors, and the life is

longer also.

UNI-8A

Pasting type sensor

(optional)

- 30°C to +

200°C

• Use a heatproof tape to paste

the sensor at a position

whose temperature you want

to measure.

• High-sensitive sensor that

can measure the temperature

in real time

• The sensor is film-laminated

and its strength is increased.

UNI-2

Bar type sensor

(optional)

- 100 °C to +

500°C

• Push the sensor through the

solder bath to measure the

temperature of the inside of

the solder bath.

UNI-4

Extension kit

(optional)

• Use this kit to measure the

temperature of a substance

at a high position or narrow

place.

• This kit is useful to measure

the temperature of a

substance whose

temperature or humidity is

high.

* The specifications, design and/or size are subject to change

without notice due to continual improvements.

40

3

150

3φ

Spring

9

8. Maintenance

About storage

When you store the thermometer, avoid places (environment) subjected to:

• Direct sunlight

• High temperature

• High humidity

• Vibration

CAUTION

♦ The case of the thermometer is made of ABS resin. Be careful not to bring it

close a substance whose temperature is very high so that it cannot be

deformed.

♦ Organic solvent such as thinner, benzine and alcohol may deform the

thermometer. Do not use any of them.

HEAD OFFICE

21-25, Akasaka 2-Chome, Minato-ku, Tokyo 107-0052, Japan

URL http://www.japanunix.co.jp.

Loading...

Loading...