FOR

QUICK

REFERENCE

AND SPARE

PARTS

NUMBER

ORDERING,

WITH

RECORD ENGINE

PREFIXES

HERE

Jfr

INDUSTRIAL

ENGINES

MODELS,

Reference

412, 413, 5

TYPE

Book, Diagraffis,

I

A 6

Printed by East Cheshire

Pri

Spare

Parts

Lists

sBiP/04

61ffi

JD

MODE,LS

412,413,,5€d6

INDT]STRIAL

E,NGINE,S

Genera,

TYPE,

1

I DescriPtion,

Running

',fl,

I nstructions

and Spare

a,nd

M aintenance

with

Pa,rts

Diagrams

List.

GENERAL DESCRIPTION

The crankcase

a rigid

a

each revolution.

aluminium

trough into

through metering

The

crankshaft is

roller

or

rod assembly

The

big-end is split and

The piston

rings,

fitted

oil

ball bearings of large

connecting-rod is

one o{

in

scraper rirq

bottom ring groove

gudgeon

The

in

gudgeon

the

The

cylinder is

circumferr:ntial

The cylinder

assist

cooling.

joint

thc

The

camshait

gears.

spur

'lhe

pinion

The inlet

adjustment

tappet

heads.

Lubrication is

and

-very

crankcase is- provided

crankcase release,

The

th.rottle

choke,is

A

centrifugal governor

shlft and. operates.the

and

starting

Peen 2

is made

which the

are

is of die

rvhich is a

top

the

pin

bosses.

madc

fins of

head

It is

betrveen

is

is rnachined

and

exhaust,cams

is effected

fhc

by

eihcient,

is operated

fitted

to

lever is

base rvhich

This

holes

made of high quality

very carefully

fitted

cast aluminium

groove

above

is located

is made

the

made

whole of

JAI'

_affording

ensuring a

facilitate

fitted,

from high-grade

forms the oil

dippcr on

trough is

kept at

which connect to

dimensions.

balanced.

stcel

with a phosphor

with

white metal steel

aluminium.

the end of the

constant level

the

steel, and is

The

bronze small-end

alloy.

special

with the fåce

the

from

special

detachable and

cylinder ancl head.

from meehanite

from steel

by

pa.tcuted

with the

by a centrifuga,l governor.

is driven

throttle by

taper chrome-plated

gudgeon pin.

by

a circlip at

close

shape for

marl<ed TOf

grained

Drain holes åie

each end and ls {ully floating

cast iron and

cooling.

from an aluminium

fitted

alloy,

and meshes

operate

the fitting of

the cam gear

ample

directly on

dipper

system

supply to all

difierent

is encloscrl

well-known

clean

engine and

starting

when engine is

by a spur wheel

which is operated

simple

mechanism.

sump. In the

It is mounted

connecting rod dips at

main

crankshaft and

backed shells.

It is fitted

alloy,

with a

and is driven

with

and is

]AP

economy in oil.

meshing

against

by

sump.

carried

with compression

ring and

uppelmost, and an

drilled in the

is provided

deeply {rnned

§asket-wirich

the camshaft.

the tappets.

thicknå§s

and running

entirely automatic

working

vacurrru

A

hand operated

cold.

with

A slow running

the governor

is

base

oil

fltted

bein[ fed

on

taper

connecting-

bush. The

must be

forms

by heavy

Tappet

discs uiråer

in oil.

parts.

System

cam-

the

arrn.

on

with

to

'fhe

and

The flywheel

The

cooling

cylinder head

for

The

of

The

Attached

purpose.

this

cowl is designed

the cylinder and cylinder

oil filler cap on the side

is a

Ian

air is

and

dipstick,

is of

supplied

portions of the cylinder, which are

These

iron

cast

by this

fins should be kept clean for efficient cooling.

give

to

a cooling

head.

having high level mark.

tsOTTOM END INDICATES

is fitted

and

fan,

directly

creates a

which

draught to

of the crankcase is

DANGER LEVEL.

on

cranksheft.

the

draught

over tho

correctly

necessary portiont

the

of

the

screwed

THE DIPSTICK

ALWAYS

flnned

type.

XNBP MOVE THE

CAP

WHEN THE

The engine base

A carburetter has been

jets

the

It

smooth running

Jets,

water.

22 to 25

The damper on the

should not

is correctly

fi,lters,

This

for

etc.,

can

maintenance

ENGINE

must

be

specially designed for each engine. The setting

be interfered

at the works,

set

of the

engine.

may

be simply

governor arm is

standing

occasionally require cleaning to remove dirt

friction on the spindle. Great

ing

lVhen commerclal

this,

as

much friction will

too

petrol

§poon of eng,lne otl wlth

mlxed.

COLD

(")

fully

(å)

(r)

(d)

(r)

§TARTING.

petrol filter tap by

Open

Each filter

in for

the slow

Slip

Push the carburetter

only.

Turn

When

wpwørds

OFF,

is

or

fitted

fully

with a tap

running lever into

engine slowly until compression is felt.

compression

direction.

is felt,

IMPORTANT.-Always

do not attempt

When engine

U)

(g)

engine commencss

When

choke lever forward to

to start

has

started

HOT STARTING.

To facilitate restarting

a hot

inlet pipe. When starting difficulty

a

crankshaft

rich

The air

tap still open, crank engine

the

started and

has

mixture.

the

slowly

mixture. During this operation the

should be

choke

is running evenly, close the tap to

times to clear the induction system

few

left

IS RUNNING.

level

when checking or re-filling

with except by an experienced engineer.

and any slight alteration may upset the

done by blowing

and

carburetter

to

care, however, must be exercised in adjust-

prevent

ls used,

gallon

one

turning in anti-clockwise direction.

which

out for ON, to ensure

position

air choke levcr to close choke

give

the starting

pull

starting

continuous turniag.

by

release the slow running

pick

to

open choke.

a release tap has been

engine

open

occurs, open the tap

at all times for starting

to start in the usual

air

through them. See

parts list.

prevent hunting

the throttle

lt le

advlsable

putting extra

by

opening

to

add

one table-

of fuel. Thta should be well

requires to be screwed

to

proof

leak

partly

close the throttle.

operation.

for cold

handle a

handle up smartly to start;

up speed,

puli

sharp

lever.

the Carburetter air

provided

and rotate

of

excessively

throttle should be left wide open.

hot

engines. With

manner. A{ter engine

prevent

weakening of

oil.

pages

fully.

either

starting

pull in

on the

the

Pecn 3

of

or

(

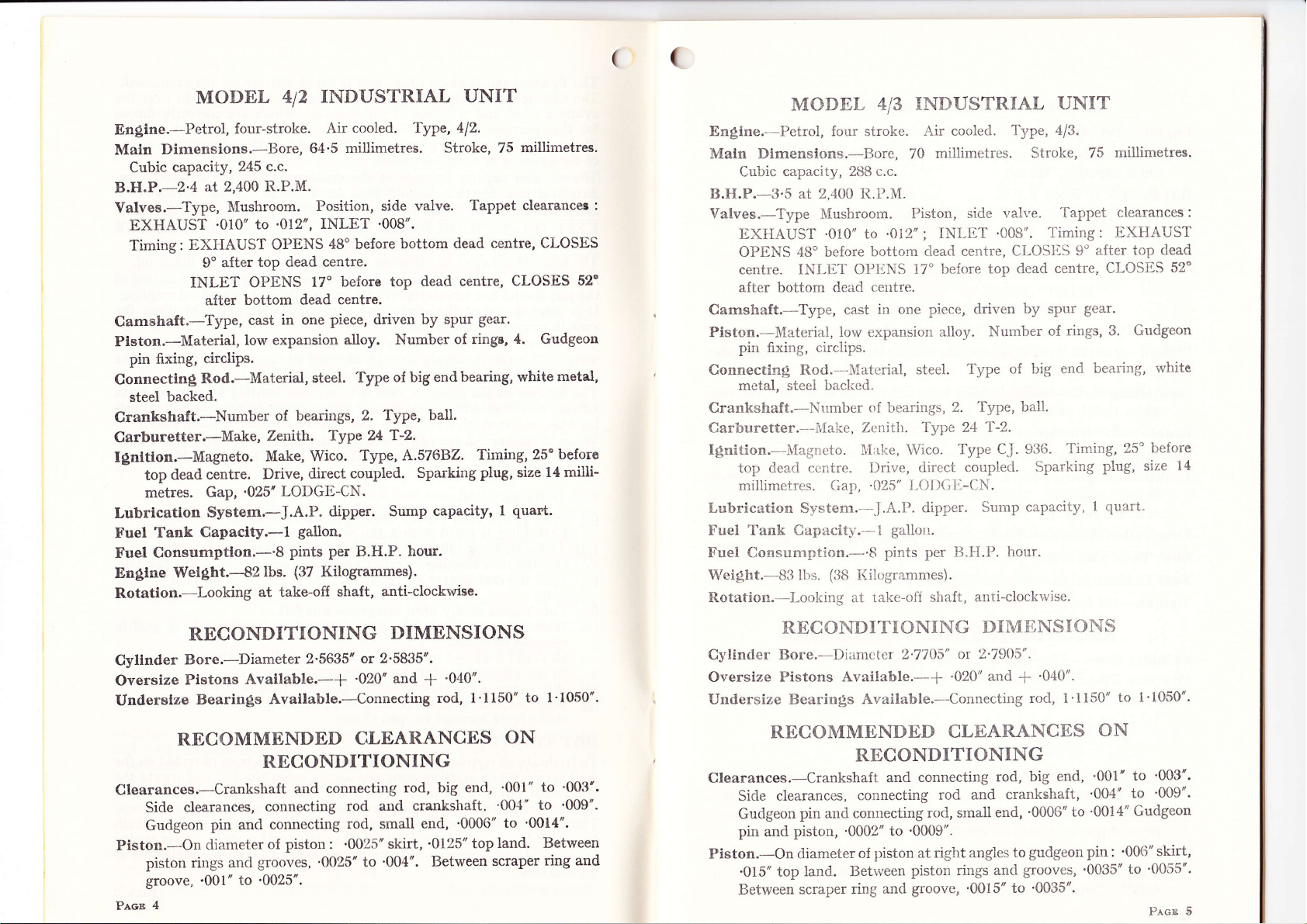

MODEL

Engtne.-Petrol,

Maln

Dimensions.-Bore,

Cubic

capacity,

B.H.P.-2'4

Valves.-Type,

EXHAUST

Timing:

Camshaft.-Type,

Pieton.-Material,

pin fixing,

Connectin§,

backed.

steel

Crankshaft.-Number

Carburetter.*Make,

Ignttton.-Magneto.

dead

top

metres.

Lubricatlon

Tank

f,'uel

Consumptlon.-'8

Fuel

Engtne

Wel§ht.--{2

Rotatlon.-Looking

four-stroke.

245

at 2,400

I\{ushroom.

to

'0l0"

EXHAUST

after top

9"

INLET OPENS

bottom

after

cast

low expansion

circlips.

Rod.-Material,

centre.

Gap,'025'

Syetem.-J.A.P.

Capaclty.-l

at take-ofi

INDUSTRIAL

412

Air

millimetres.

64'5

c.c.

R.P.M.

Position, side

'012',

INLET

OPENS

in one

48' before

dead centre.

before top

17'

dead centre.

piece,

alloy. Number

steel. Type

of bearings,

Zetith. Type

Make, Wico.

direct

Drive,

LODGE-CN.

dipper. Sump

gallon.

per

pints

(37

lbs.

Kilogammes).

shaft,

UNIT

cooled. Type, 412.

Stroke,

valve.

'008".

dead

by

capacity'

hour,

dead centre,

centre, CLOSES

spur

of ringe,

bottom

driven

of big endbearing,

Type, ball.

2.

24 T-2.

A.57682.

Type,

coupled. Sparking

B.H.P.

anti-clockwise.

millimetres.

75

Tappet clearancer

CLOSES

52'

gear.

4.

Gudgeon

metal,

white

size

quart.

beforo

14

milli-

Tirning, 25"

plug,

I

INDUSTRIAL

MODEL

Engine.-Petrol, four stroke.

Maln Dimensions.-Bore, 70

capacity, 288 c.c.

Cubic

:

B.H.P.-3.5 at

Valves.-Type

EXIIAUST

OPENS 4Bo bcfore

centre. INLET Ol'IiNS

after bottom

Camshaft.-Type, cast

Piston.-Material, Iow

2,400

Mushroom.

'010" to

413

It.P.Nt.

'012"

bottom

dead centre.

in one

expansion alloy.

Air coolcd.

millimetres.

Piston,

17"

side

INI-IiT

;

clead centre,

be{ore top

piece, driven

1'ype,

val.ve. Tappet

'008'.

Number

UNIT

,t/3.

Stroke,

Timing:

CI-OS}iS

dead centre,

by spur

9"

rings, 3. Gudgeon

of

millimetres.

75

clearances

IIXHAUST

after top

CLOSES

gear.

:

dead

52'

pin fixing, circiips.

25o

whito

before

siz;e

14

Connectln§ Rod.--'Material,

metal, steei backed"

Crankshaft.-Number

Carburetter.--1,{ake,

of

Zcnitir.

steel.

bearings,

Type 24'l-2.

Ignition.--ltagneto. l'I;rl<e, Wico.

dead ccntre. I)rive,

top

millimetres. Gap,'025"

Lubrication S-v*stem.-.J .A.I'].

Fuel Tank Capacity.--l

Fuel Consumption.--'8

Weight.--S3 lbs.

(i38

I(ilogrammes).

Rotation.-I-ooking at rake-olI

direct

I-riI)Gtt-CN.

dipper.

gallon.

per u.H.P.

pints

shaft,

Type

2. fype,

Type CJ.

couplecl.

Sump

anti-clockrvise.

of big

ball.

936.

Sparking

capacity,

hour.

en<l bearing,

Timing,

plug,

quart-

I

RECONDITIONING

Cyltnder

Oversize

Underslze

Bore.-Diameter

Pietons

Bearin§s

Avallable.-+

Avatlable.-Connecting

RECOMMENDED

RECONDITIONING

Clearances.-Crankshaft

clearances,

Side

Gudgeon

Piston.-On

rings ancl

piston

groove,

4

Pecn

pin and connecting

diameter

.001'

connecting

of

grooves, '0025' to

to'0025".

2'5635'

or 2'5835'.

'020'and

CLEARANCES

and connecting

rod

rod,

piston

'0025'skirt,

:

DIMENSIONS

'040'.

f

rod, l'1150"

rod, big end,

and crankshaft'

small end,

'004'. Between

'0006" to

'0125" top land'

to l'1050".

ON

'001"

'001'

'0014'.

scraper

'003'.

to

to

'009'.

Between

ring and

RECONDI']TIONING

Cylinder Bore.-DiiLmcter

Oversize

Undersize Bearings

Pistons Available.-

Available.-Connectirrg

RECOMMENDED

RECONDITIONING

Clearances.-Crankshaft

clearances,

Sicle

Gudgeon

pin and

pin and connecting

piston, '0002" to

Piston.-On rliameter

'015" top

Between

land. Betrveen

scraper ring

connecting

piston at right

of

and

2'77O5"

connecting

and

rod, small

'0009".

pistorr rings

groove,

DIMI'NSIONS

2'7905".

or

+

'020'

and

+

'040".

rod, 1'1150"

CLEARANCES

rod, big

and cranksha{t,

rod

'0006"

end,

gudgeon pin: '006"

to

angles

grooves, '0035'to

and

'0015" to

'0035'.

end,

to

t'1050".

to

ON

to

'001'

'004' to

'0014"

Gudgeon

'003'.

'009".

skirt,

'0055'.

Pr,cn 5

(

MODEL

En§lne.-Petrol,

Maln

Dlmenslone.-Bore,

capacity,

Cubic

B.H.P.-4'5

Valves.-Type,

EXHAUST

Timing

-

Camshaft.-Type,

Pleton.-Material,

pin fixing,

Connectln5i

white

Crankshaft.-Number

Carburetter.-Make,

Ignttlon.-Magneto.

dead

top

millimetres.

Lubrlcatlon

Tank

Fuel

Consumptlon"-'9

Fuel

Wetght.-122

four-stroke.

412 c.c,

at 2,200

R.P.M.

Mushroom.

'020';

EXHAUST

I

CLOSES

INLET

circlips.

Rod.-Materia.l,

metal, steel

OPENS

after

52'

cast

low expansion

backed.

Zenith.

Make,

centre.

Gap,'025"

System.-J.A.I'}.

Capacity.-l

(55'5

lbs.

INIÆT

in

of bearings,

Drive,

RECONDITIONI}{G

Cyllnder Bore.-Diameter

Overelze

Underelze

Plstons

Bearing,s

Avallable.-+

Avallable.-Connecting

RECOMMENDED

RECONDITIONING

Clearances.-Crankshaft

clearances,

Side

Gudgeon

pin and

Plston.-On

skirt,

'017'

'0055'. Between

6

Prae

pin and connecting

piston,

diameter

connecting

'0002'to

of

top land,

scraper

INDUSTR.IAL

5

Air-cooled.

millimetres,

80

Position,

OPENS

after

9"

17'

bottom

piece, clriven

one

side

'010'.

48" before

toP

before

dead

alloy'

steel.

ton

40-45

Type,

2'

24

Type

direct

Typ" CJ,

coupled'

Wico.

LODGTI-CN.

dipper. Sump

gallon.

per

pints

Kilogrammes).

3'170"

ts.H'P.

or 3'190'.

'020' and

CLDARANCES

and connecting

and

rod

small

rod,

'0009'.

piston at right

Between

ring and

piston rings and

groove, '0015'to

UNIT

Model

Type,

stroke,

valve'

bottom

centre.

dead

dead

top

centre.

spur

by

Number

Type

taper

T-2.

936.

Sparl<ing

capacity,

hour.

DIMENSIONS

f

rod, 1'1150"

rod,

big-end

crankshaft,

end '0005'to

to

angles

5.

82

Tappet

dead

centre,

gear.

rings, 3. Gudgeon

of

of

big

roller.

Timing,

plug, size

2

'040".

ON

'001' to

'004" to

'0014" Gudgeon

gudgeon

grooves,

'0035'.

millimetres.

clearances:

centre,

CLOSES

bearing,

end

belore

20o

pints.

to l'1050".

'0025'.

'009'.

pin

'008'

:

'0035'

14

to

Type,

Stroke,

valve'

centre'

dead

top

by

big

of

taper

936'

CJ'

capacity,

hour'

f

rod,

UNIT

Model

102

Tappet

centre;

gear'

spur

rings,

of

bearing'

end

roller'

Timing'

Sparking

'040"'

1'3655'

6'

4' Gudgeon

plug'

pints'

3

ON

INDUSTRIÅL

MODEL

Engine.-Petrol,

Dimensions.-Bore,

Maln

Cubic

capacitY

B.H.P.-5'5

Valves.-Type,

EXHAUST

Timing:EXHAUSTOPtrNS48'beforebottomdeadcentre;

-

Camshaft.-Type,

Piston.-Material,

pin

fixing,

Connectln§

metal,

Crankshaft.-Number

Carburetter.--Make,

Ignttlon.-I\fagneto.

top dead

millimetres.

Lubricatlon

Tank

Fuel

Consumptlon.-'9

Fuel

Wel§ht.-l72

four-stroke.

at 1,800

Mushroom.

'020';

INLET

circliPs.

Rod.-Material,

backed.

steel

centre.

GaP,

System.-J.A.P.

CaPacitY.-l

lbs.

RECONDITIONING

Cylinder

Overslze

Underslze

Bore.-Diameter,

Plstons

Bearings

RECOMMENDED

6

cooled'

Air

millimetres.

85.7

c.c.

5BB

R.P.M.

Position,

INLET '010''

after

CLOSES

52'

cast

low

(88 Kilogrammes)'

Available.-+

9"

before

OPENS

after

in

expansion

l7o

bottom

piece,

one

alloy.

steel'

of bearings,

Zenith.

Make,

Drive,

'025' LODGE-CN'

Type

Wico.

direct

dipper'

gallon.

per B-H'P'

pints

3'3955'

Available.-Connecting

CLEARANCES

side

dead

toP

centre'

dead

driven

Number

Type

Type,

2.

T-2'

24

Type,

coupled'

Sump

DIMENSIONS

or 3'4155"

and

'020"

RECONDITIONING

'001'

end,

big

rod,

to

'0055"

to

rod,

small

'0009''

skirt,

end,

'0185"

Between

'0005'

top

land'

scraper

connecting

Clearances.-Crankshaft

and

Sideclearances,connectingrodandcra.rrkshaft,.004"to.009,.

Gudgeon

Gudgeon

Piston.-On

piston rings

groove,'0015'

pin and

pin and

diameter

and

to'0035'.

"or.r""iing

piston,

piston

oI

grooru=,

'0002'

:

'0035'

'006"

millimetres.

clearances:

CLOSES

white

20'before

size

1'3555''

to

to

'003"

'0015"

to

B.etween

ring

P.n-cr 7

14

and

(

(

ROUTINE

1. DRY

is

It

essential

the felt pad,

14.

OIL BATH

It is

essential

bowl

using

and wash

filter

bowl and

MAINTENANCE.

TYPE dIR

periodically

to

also

dry if necr:ssary.

fi1l

to

clean

the

engine

element in petrol

replenish

2. FLYWI{EEL

Never operate

as this

This

engine may

3.

An engine.which

when

4.

Do not

minute

5.

Keep

will allow

part is

COVER

not in

OVER.LO,{I}ING

overload

or

CLEANLINESS

the sparking plug

the

the engine

absolutclv

be properly

FOR.

is exposed

use.

a cold

two.

FILTER

clean the

ÅIR. FILTEId

and maintain

lubricating

with

FAN

engine rvith

necessary

cooled.

oil

or paraffin,

fresh lubricating

CASING

any part of

lo overheat

ENGINO.

to

th,. u,eather must

TEI}T }.INGINE.

engine. r\lways

OF SPARKING

clean

and a

(Where

element by removing

Carefully

firted)

replace the

(trVhere

to the indicated

oil.

Occasionallv

allorv

to drain,

oil.

the fan

and

to rlircct

allorv it

the

the

piston

alr

always

to run

PLUG.

o{

.025".

gap

and

shaking

ilement.

fitted)

level on

remove the filter

casing removed,

florv

the filter

clean out the

to score.

so tliat the

be covered

light for

up

The oil circulation is

necting

rod, and

vital irnportance

in the

sump below

damage

may be caused

at an excessive

important

danger

to keep the oil

of the dipper

It is important

re-filling

Check the oil level with

dipstick,

reading.

All

sealed in

After

condltions,

flush out tlie oil

then refill

has

oil left in

oil.

rest the

parts

are lubricated,

a dust-light

every 50

and preferably

with fresh lubricating

been run

through, to make

the sump.

8. TAPPET

For

method of adjustment

IF

a

9.

(o)

(å)

(c)

(d)

COMPRESSION IS

tappet

Check

cylinder

Check

Examine

Inspect piston

valve seatings.

maintained

works with

is

to see that

the bottom

angle

missing

that

the engine

cap on top

to the

due to

sump

the oil

the filler

a minimum

the engine

end of

engirre.

uneven or

base is standing

of

including

cover.

hours' running,

when the

sump with flushing

oil

sure

ADJUSTMENT.

paragraph

see

clearances.

head nuts,

and piston

and tighten

rings.

by splash

from

a dipper on

of

attention.

never

runs

the dipstick,

In the

case of

sloping ground,

topped right

and starving

cap unscrewed,

the oil Iiller

tappets

an engine

up, so

the

level

when

remove

boss

to obtain

and valves;

but more frequently

engine

(paraffin

oil

after a

there are no

is hot,

should

small quantity

traces of

(a),

Page

POOR.

if necessary.

One point

with

the oil level

otherwise

it

that there

engine.

checking

cap and

these

under

drain

not

be used),

of

the flushing

12 (Valve

the con-

of

serious

working

is

most

is no

or

wipe

correct

are

due§

oil,

the

fresh

oil

Gear).

6.

DECARBONISING.

Decarbonise

7.

LUBRICATION

It is important

for

these engines

Prrcn 8

every 400

to use

working hours. (See

OF ENGINE.

good

lubricating

are'-

SUMMER_CASTROL

WINTER

-CASTROLITE

paragraph (a),

oil, and

XL

the most

Page

suitable

l0).

oils

10. TO INSPECT

See that rings

or broken, that all

holes in

When replacing

fitted

before removal.

1I.

MAGNETOS.

e. 576F..2. (Ref.

fyp"

Pages

18 to

move freely

ring grooves

the bottom ring grooves

see that the piston

2l).

PISTON

in

Pages

their

are

are

16 and

grooves

and rings

AND

and are

clean, also

clear.

are replaced

1Z).

RINGS.

not cracked, worn

see

that the oil

Type

CJ.9B6. (Ref.

as

they were

drain

Prcn

I

MAINTE}dANCE

ENGINE.

DISMANTLING

1.

(a) Decarbonlsing.

Iead.

Remove

unscrewing

bolts,

joint.

cylinder

that this

of

with

cylinder,

piston

unscrewing

collar

NorB.-It

on

ports

crown

damage

paste to

Twist

for

position.

wash

a few

line

Mal<e

correctly.

tappet

4

paragraph

H.T.

the carburetter

washers

Remove

head.

is replaced the

cylinder

head,

Carburetter.

the

tal<ing

not foul

does

fixing bolt.

remove cotter.

and

is advisable

correct seatings'

their

and cylinder

and clean,

the surface.

ttre

valve

a short

Remove

clean

with

times.

round.

all

sure

Replace

head

'l

and

to

,

(a).

valve

in a

while,

Withdraw

that

and

method

(b) Ptston.

Inspect

respective

Inspect

see that

Prcn

l0

piston rlngs

€(rooves,

piston ring

oil drain

and base

nuts

Remove

and not

care

paraffrn and

If not, repeat

OF'

Remove

nuts.

and bolts

gasket.

correct

overlapping

Remove

to draw

of connecting

side

Hold

mark

to

head. AIso

taking

Apply

seat and

semi-rotary

occasionally

and wipe

valve

and see

valves

valve

and their

cylinder

stem. For

of obtaining

and see

that they

groove.s

in

holes

sparking

banjo.

Detach

holding

Norri.-When

way,

cylinder

cylinder

valve down

the valves,

carbon

Clean

remoYe carbon

great

care not to

a small

place in

motion,

lifting

face

dry. Replace

if both

process until

the

on engine

correct

that

are not worn,

and carefully

pistorl are

OF

E,NGINE

plug. Remove

Remove

i.e.,

on one side.

off evenly,

component

them,

they

cowl

throttle

cylinder

down

replacing

to conform

base

and that

Remove

rod.

seat,

on

so that

deposit

deposit

scratch,

quantity of fine

position

using

valve

and seat clean'

valve

and

are

dear.

for

very light

a

and turning

and

valve

and

this

check clearances

clearances

valve

see

{ree to

cracked,

clean

pipe

petrol

by unscrewing

link from

to

Take

nuts and

valve cover

press

they

from

bottom

Lift

head'

gasket,

inside shape

off inlet

remove

in removal,

up spring

are

valves,

from

or otherwise

carborundum

grinding in."

"

pressure,

to

Thoroughly

on seating

turn

seat show

result

parts are

a bright

obtained.

is

replaced

between

see Pages

gear,

Page 12,

in

move

or broken.

necessary.

if

by

top

off

see

pipe

by

ground

valve

pistou

a

fresh

Nos.

thelr

Also

To remove

{oliows: Insert a sharp

piston

from connecting rod, first remove circlip as

pointed

tool, such

tool, into one end of the transverse slots in

under tail of circlip. Lever circlip

rag

in front to

injury.

Lift

Remoual

To

tool may be used. If this

narrow

and piston.

their

Push

piston

ønd

remove piston rings

strips

respective

prevent

out the gudgeon

of connecting rod.

clear

Replacentent

of metal and insert

Work

circlip

af

from their

these strips round until all rings stand clear of

grooves.

frorn its groove, holding

flying

pin

in the direction of removed circlip.

Pistun

is

available, obtain

not

these

rings

The

by sliding in an upward direction,

serviceable, or

dure of

(c) Blg

and Small Ende.

The small-end bush

to size after fitting to connecting rod.

a special drawbolt or by

Reverse the above

The

big-end

if a new ring or rings are fitted, reverse the

removal.

is

is a

procedure

backed. The

steel

press

pressing out

in

fit

when

in working position by bolts and self-locking

(d)

Matn

Bearlnge.

The main bearings

centre

portions, which

on crankshaft

The outer

case and

Noru.-The

races

are a

centre

from crankshaft

placement is necessary.

(e)

Crankshaft.

To remove

frorn

crankshaft from crankcase proceed as follows: Remove

driving end

Withdraw splitpin from

Unscrew bolts

securing nut.

special

in

until flywheel is free

Remove

bolt into centre of starting boss

draw

flywheel

are

situated

carry the rollers and cages

journals.

are carried

press

fit.

portion

journals,

of crankshaft any coupling device,

starting pin and knock out starting

and remove starting

lteplace starting

on taper,

clear of craakshaft. Now

on either end

in housing plates on either end

of

main bearings

and should not be

boss and fixing screws.

as

a scriber or similar

and

out

Rings.

grooves,

a piston ring expanrling

betrveen back of

gudgeon

causing any

pin

boss and

a

personal

several thin and

piston

may now be easily removed

clear of piston. If rings are

the connecting rod

It

may be

hydraulic

with

and

removed

hand

or

is reamed

by using

f,tting new bush.

2 halves of

are not easily removable

boss.

taking

care not to lose the key.

bearing

nuts.

of

removed

Next

and

remove nuts holding

are

crankshaft. The

press

are

a

of

unless re-

also its key.

remove flywheel

Screw

continue

to screw

piece

rinp

proce-

press.

secured

cran-k-

pin.

the

Pecr I 1

of

fit

crankcase to engine base and lift top half of engine

Inspect

nuts and bolts, then remove big-end

into cylinder as far as it will

plate, first removing nuts and dralu housing plate

Turn crankshalt until it rvill clear camshaft and

VALVE

2.

(a)

Yalves.

When

a new valve

valves on their seats and

With

end of valve stems and top of tappet caps with feeler

correct

fitting tempered steel shims betrveen

The shims are of various thicknesses.

Timing

Timing marks are

magleto driving wheel when the engine is erected.

the engine, care must be taken to ensure that

with each

marks corresponding, then revolve the

on the camwheel

wheel bush.

corresponding

timing see

(b) Camshaft

(i)

R.emovtng and Replactng.

'fo

with crankshaft

camsha{t

will

axle.

Repløcement

Reverse operation of removal and replace

half of engine

top

and remove connecting rod

go.

GEAR.

"

valves have been

or

valves are fitted, they must

clearances are as Ref. Pages

other.

First

points

Now insert

with the mark on

Pages 4

to 7.

Drive.

remove camshaft, the

axle

toward

remove the

Camshaft

of

C

ground

cold engine, check clearances

stamped

on crankshait pinion,

mesh

the camwheel and pinion

towards the centre of

magneto

the

the camrvheel. For correct

crankshaft

removed, proceed

flywheel

sealing

may novr

ømshøft.

disc

be

caps. Push connecting rod

remove

Next

"

in

after

4 to 7,

of ta.ppet

top

crankshaft until the mark

driving wheel with its marks

must

as follows:

side of engine. This operation

and allow free exit of camshaft

withdrawn.

of

clear

base.

big

engine main bearing

off crankshaft.

withclraw crankshaft.

decarbonising or when

adjusted as

be

and

are obtairred

and tappet cap.

A{ter dismantling

marks

these

follows:

between

gauge.

camwheel and

The

coincide

with their

magneto

the

driving

valve

first be removed

Drive out

sealing disc.

end

by

3. GOVERNOR.

(a)

AdJusting.

To adjust

speed,

engine speed, turn in anti-clockwise

nut

(b) Repatring.

To

parts,

the 4 securing nuts and

weights

fulcrum pins, remove

until small end of

Remove

driving shaft.

Norr.-If replacement of the

and

are drilled and reamed in position

remove

necessary

sliding magneto sideways

To remove the

pull

4. FUEL

Fuel is fed

is fitted

;

this by washing in petrol.

Each filter is fitted

in

fully

governor

turn the knurled

spring, slack ofi locking nut.

adjuster in

a clockwise direction. To decrease

direction. Tighten locking

when correct adjustment has been obtained.

gain

access

to the

disconnect throttle

withdraw

plug,

drive out taper

magneto shaft complete must

governor

link

remove

governor

actuating rod,

weights.

fixing pin is opposite

taper

repair

for

governor

from

governor

To remove

pin

and slide

gear

wheel

fitted as

be

or

cover. To

drive

gear

gear

is necessary,

for correct timing relation. To

magneto driving

to remove

CJ. type

magneto

the

magneto by

magaeto,

fonvard to disengage magaeto driving

on the "

shaft

unscrewing

to disengage

unscrew the two

A

magneto

SYSTEM.

to the carburetter by

with a fine mesh filter and it

with

for

or fully out for

OFF,

gravity

a

tap which

ON,

from tank. The

is

important to

requires

to

ensure

increase

To

renewal

control arrn, remove

the

gear

of component

remove

governor

out

wheel, turn engine

plug

wheel

wheel and shaft

engine

governor

weight

in crankcase.

off magneto

gear

wheel

" type magtreto it is

the 3 fixing bolts

driving

fixing nuts and

plate.

petrol

periodically

to be screwed either

leak proof operation.

and

plate.

filter tap

clean

(lt) Adjusting.

No means of adjustment

are

Ptcs, 12

provided,

as

both

between

components

camrvheel

on

work

and driving

fixed centres.

pinion

Peor

13

t07

(

(

t04

t03

I

&

67

64

58

65

56

98

t2r

63

62

57

t12

99

tt

il7-

t00

t05

4n

r06

42=/-

4.7

il

ez-W

eø'$f,.

,æ

93

92

a7

73

72

-/

?

lt9

r29

t20

5P

6

5

94

t0t

35

36

33

.1

.4

,3

9

-'/-

t§.'

-'=/'

::)-:-:.^-å

r25

25

69

7

44

54

53

-/

I

t0

q

80

I

9l

1

t0?

77

PAGB

14

SEE PAGES

26

-1-O

37

FOR, DESCRIPTIONS!

gEE

PAGES

26 TO

37

FOR

DESCRIPTIONS

Pecr

15

(

(

SDRVICE

Installatlon

Slowly

the normal

approximately

on,the

valves

magneto

the

the

rotation

t-o separate.

the

rn

engirre

illhe

ed, the

Just

Tlmln§

the

as

leaving

sparh

the.

contre.

Lubrlcatlon

The

spring

one

ovcrfiowing

1,000

the

tho pad

a Summer

grease

used

grease.

Impulse

The

a spark

automatically-

r.p.m.

contlnuously

would

wear

The

spark

ing

the

stops.

turn

compression

are

contact

magneto

brcakcr points

until

engine

coupling

posltron.

To re-checl<

over

on thc

magneto

magneto

atter

top

No

adjustment

magneto,

the magueto

the

occurs

running

magneto

oilers.

of

these

hours

carn

it

oil,pad.

and squeezing

grade

which

at the

factory.

coupllnE

impulse

of high

The

cause

on the

irnltulsc

for

starting,

it

as tlre

enginc

retarded

PÅcB

I8

INSTRUCTIONS

and tlrnln§

thc ongirre

marrner

before top

;["

strolie (i.e.

closed).

breaker

in

a clockwise

close,

the

breal<er

'Ihen

fit the

and

the

timine,

cornprcssion

has

becri

impulse

dead centre.

is

provided

which

is

works,

just

with

enslne

correcfly

so that-flre

after

spark

25.

is pror.irlcd

Once

ejery 200

oilors

should

Castrolite.

is

trecessary

This is

of motor

will

closelv

Do not

coupling

density

cuts

out

should

below

thls

unnecessary

lrnpulse

pror.icles

also

aritonratically

spoccls

position

cranl<shaft

rrntil

tlre

Then

remove

cover

rotation

then rcversc

points

coupling

sccrrre the

slowly

corrcctly

tvill

is

.,n,,"""..r.y]

top

duad

belorc

]rorrrs

ire

After

to ru-lubricate

dirne

by removing

and

woririrrg

transnrission

resemble

usc

is

designed

for

§tarting.-

at

not

speed,

straln

parts.

rrp, rciurning

wlren

the en§ine

MAGNETO

piston

deåd

centre

when

both

and

turn

until

just

bcgirr

on-to

daqneto

pull

s[ro'ke,

u;rd

position-

give

a clic)r

for

timing

sct

bcfoie

startii.rg

ccltrc

anå

top

tlcrd

with

two

eithcr

Iilk.rl

every

into

that

ordinary

give

to

about"

165

be run

as thls

and

a retarded

advanc-

ilre

ilre

thc

to

to

FOR

in

is

ii

It

WICO TYPE

Cleanlng

If

.

dirt,_

or

action,

with

parallin

housing.

Replacernent

-

fixed

placed

To rernove

breaker

clarnping

lrre:rl<cr

assembly

frxcrl

thc lrrcakol

{ixed

Romoval

Rcrnove

arrn spring.

from

scrcws

Rernoval

breal<er

{rom

lead

earth

holding

magncto

longer

housing,

The

If

the

{orce

from

In replacing

that,

the housing,

earthing

the primary

the coil

Breaker polnt

The

.015'.

loosen

contact

headed

oI points

securely.

of

the impulse

and

the

dlscngagc,

it

should

paraffin,

to work

If

points

the

and moviug points

at the sarne

arm clarnp

washcr,

arrrt terminal

olf the

corrtact

arrn pivot,'alter

contact

of condenser

screw

thc Ilrcakcr

f:rstcniug

of coll

Ilemove

box

the

driving

loosening

by

stud.

down

slialt

grips

pull

coil is

held

coil is

may

be necessary

the core.

ground

the

stud is

core

correct

When readjustmånt

the screw

plate

screw

is

obtained.

lmpulse

becomes

trip

arm fails

or

the impulse

flushed

be

taking

care not

its

way

of breaker

need

replacing,

time.

the

breaker

screw,

together

scrclv

breal<er

rn.ry

1,llatc

screw.

holding

-Ihe

condenser

box

by rernoving

it

dovrn.

the

top

cover.

Viewing

end,

rcleaie

remove

the core

until the

the

coil

the

coil

on the

to

be replaced,

the

coil and

surface

the primary

propeily

lead

screw.

the right

core

and

of the

'Ihcn

that

earth

clamp

openlng

breaker point

which

and

turn

until

the

Then

A.57682.

clogged

io

is sluggish

out thoroughly

to

allowåny

into

the magrrcib

polnts

both

should

arrn,

take o1I the

lock-washer

with

and pull the

arm pivot.

thcn

bl takelr

rorrroving

down

the

is then

cover

and

the

magneto

the

pri"mary

irair<1

the

trvo screws

magnetism

to the

the coil

by a we<1ge.

cånsideralle

coil

core,

core is

lead

located

opening is

is

,i"."rråry,

locks

the

the

eccentric-

correct

lock

'furn

core free.

and

opening

thå plat6

clanps.

core

to removc

is fastened

with

engage

the

be re-

and

the

The

the

breakcr

taken

the two

the

sia"e

tht:

main

the coil

be sure

against

[o ttre

that

under

fixed

no

otf

in

raxt2tc

x

xlø

xtst

SPARE

H.r,

1,,,

øt2a

x2l15

raI

cra2 I

sls

PARTS

LIST

Peoe

17

(

(

SDRVICE INSTRUCTIONS F'OR WIPAC

TYPE CJ

IN§TALLING

Slowly turn the engine crankshaft in

the normal manrler untii the

to rise

whea

agaemblo the steel floating couplinq on to

on

both

the engine coupling. Iiinally take the

magneto

anti-clochwise until the impulse

enuages the irnpulse stop, then siorvly turn

the magneto

until the trvo

with the two free

atrd

secure

re-check the

ovor on the cornpression

magneto has

tho

magneto impulse

jurt

before

TIMING

No

adjustment

the

magneto,

the

magneto

the

works, eo that the starting sparl

just

occurr

the running spark in

on Pages

details

LUBRICATION

Tho

only

the

field

re-lubricated

be

This is done

squeezing and

grado

oI motor trangmissiou

will

closely resemblo that used

factory.

aB thlo wlll

polnts

cauelng

startlng.

The main bc.aring

end of

the magneto is

before

leaving

rertewed

servicecl.

impregnateci

fol'

rirops of lubri<;aring oil

me.

t

Pacr

M,dGNEI'O

piston

begins

the cornpression

valves

are ciosed). Next

stroke

(i.e.

and turn the magneto shaft

pav.

in

shaft

the

driving

slots

the magneto in

timing, slowly

correctly

been

top

dead centre.

is

which

ia

correctly

before top

Nos. 5, 6 and 7.

part

is

requiring attention in

the canr oil

opposite

dogs

in the steel coupliDg

stroke, and

will

provided

is unnecessary, ae

set before

dead centre arrd

pad

direction

in line

are

position.

pull

the

positioned,

give

a

engino

i{ the

click

for timing

Ieaving

accordance u'ith

which should

after every 1,000 houre.

to

the

grease

the

pad

and

Surnmer

a

which

the

at

gtease

trreaker

dlfflcult

tire

at

rear

with grease

by

working

Do

not

splash on

renroving

into it

uee

ordlnary

ml8flrlng and

situated

packed

the v'orks and should

oirly u'henever the rnagneto ie

'lhe

flont

main

and slrr.ruld only

bearing is oil

require

at the same

lt)

To

936

be

a

MAGNETO

IMPULSE

The

give

It

automatically cuts out

r.p.m.

continuously

would cause

on the impulse

'IIte

spark for

ing it

to the retarded

Btops.

CLEANING

II

dirt, and

disengage, or

action,

rvith

any

magneto housing.

BREAI(ER POINT

Itemove

obtain access

Ihe correct

.015'.

loosen the

contgct

until the correct opening of

obtained, then

REPLACEMENT

POINTS

The

assembly

point,

COUPLING

impulse coupling is designed to

a sparh of high

'fhe

engine

below this

unnecessary strain and

parts.

impulse

also

starting,

as the engine

the

position

IMPULSE

OF

inrpulse becomes

the

trip arm fails to engage or

the

impulse

density

provides

automatically advanc-

speeds

at about

should

speed, as thio

up, returning

when tho

clogged with

is sluggish in

for

not

a

starting.

retarded

it should be Ilushed out thoroughly

parafi&n,

paralfin

taking care

to

work

not to ellow

its way into the

OPENING

cover acrows

to the

breaker

breaker

When re-adjustrnent is necessary,

screrv *'hich

plate

and

point

raise or lower the

cover to

and

points.

opening

locks tho fixed

points

lock the

breaker

points

including the fixed and movoable

the die-cast back

plate

OT'

are

recuroly.

BREAKER

supplied

plate

and

be

$,ear

engino

plate

ae

pad. To rcmove the original assembly

loosen the breakor arm

screw and

from

the

plato

When

assembly

in

an approximate

the

slightlv

release

the coil

trvo screws securing

the main housing.

to

and

condenser,

fitting the new breaker

secure the die-cast back

breaker

point

lnoceri

the

apring retainer

the

two leads

tho dio-cast

position

opening to

lrvo

back

coming

then removc

back

point

plato

and adjuct

'015',

then

pl,ato

rcrawl

165

run

an

oil

and tuln

the

breaker pornts

when the

the

core larninations

Finally

1l»'.

reconnect

and condenser,

RDMOVAL

'Ihe

of

the main housing

the

breaker

nuts

securing

earthing

out

of

part

nurnber

thie

it is

magneto

load

can

housing

REPLACEMENT

The

coil

by

in

hole

rvire

around

refitting

or

ia

plate

the

rvithin

begiu to open

rotor larninations

tighten the

tl're

two leads {rorn

OF'

CONDDNSII,R

condenser

is housed in

points.

the

immediatelv

Remove the hexagon

connecting lead

strip. Unscrew

its housing,

advisable first to

cover so that the

be

out

of

00146,

pushed

the

way of the

using a special

back into the ruain

Or

H.T. Iead is

passing

the coil

secured

the

rvire through the

tab

II.T.

tab.

this

a new H.T. lead

its

slots until

and

itave

by

apitroximately

trvo screws

lelt

ancl

the coil

the

base

below

and

the condcnser

but before doing

tool,

rernove the

connectin(

tool.

II,T.

LEAD

the

to

II.T.

and twisting the

When rernoving,

srna.'!l

exercise

the greatest

is

done

Never

tab

it is possible

nection. This

be

apparent, but the

the coil

paratively

care to ensure

to the

coil.

solder the FI.T.

because even

to sever

to breali

period.

short

that no

lead

with the greatest

the internal

would

not immediately

defect would

down within

damagt

to

a com-

RI'T{OVAL OF COIL

Remove

the

and release the

remove the two hexaqon posts

dos'n

releasc tlie earth

magncto shaft until the magnetism

longer

housing, pull

froe.

hr replacing the coil

sure

fastened under the

posts

tl.re

covor

breaker

thc

grips

and H.T. Iead.

spring retaining

arm

primary

lead. Thon

core clarnps, this

prirnary

the coil

lead. Turn

core to the

the coil and the

will

coil coro

and coil core

that the primary

earth

coil coro hexagon

the insulated

and

breaker arm spring rotaining

primary

Loosen

ecrew

holding

lead ia

lead to

acrew,

the

caro

con-

cause

also

tho

no

main

bo

h

Plcr

19

(

01,O,

Cov.r Unit

0t080

StoD Unlt

01,O,

Coll Unit

ot{0.t

Cond.nr.r Unit

0t{o3

Co66ct Brsakat

H.T, Lod GrcuD

ahDult. Stop Unit

iotor Unit

lhpulr.

Unlt

w

0ll9t

0l{00

06ll2

Unit

ComponGnE åod

H.T. L..d Slccvin8

R.rc G.rl.t

Erll

B.ll R..e Unit

Oil

Pl.t.

Stop

StoD Pht. Firitrg

Fl.ng.

O.ieon

O.iv.

Drivr

LcL

Sob

0t il8

0t330

Rotot

0l

ot4t7

06579

S€.1

06680

0568 r

o

t,t2 I

06lgo

SDtint

01419

Cup S..

063r8

Nur sct

SPARE

P.r$

ia Explod.d

YI.w

Pnrt

086i17

01107

01080

0L422 CoiI Clamp

0140, Coil

01408

"t

"il

109

S.t

S.t

S6t

S.t

I

,J

0r{04

011o5

01298

0r381

ot322

00466

0r ll8

01330

01409

0r417

01393

06679

06680

06e€l

01400

01421

06180 Drivo Spring

01419

06398

06182

PARTS LIST FOR WIPAC

NG

Cover Fixing Scrow

Cover

Stop

Coil Unit...

Condenser Uoit

Contact Breakcr

Outlet Block

Main Housing Unit

Bearing

H.T. I-oad Group

H.T,

Rotor

Ball Raco

BaIl Racc Unit

Rotor Unit

Oil

Impulao

Impulso Stop Plato

Impulee Stop Unit

Driven

Drlvo

LocLnut Sst

Impulec

Unit

Unit

Set

Group

Bueb

I-oed Sleoving

Gasktt

Soal ...

Stop Plato

Flugo Set

Cup Sot

Unit

Deccrlptlon

. ..

Unit

...

Sot

Fixing Sct

...

C.J. 936

MAGNETO

No.

off

I

I

2

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

t

EXPLODIiD DRAWING

OF

WIPAC

CJ 936 MAGNI''IO

Plcr 20 Ptoz 27

(

(

ZENITH

4/'

41

Engine Model

(Petrol)

(Paraffrn)

(Petrol)

(Paraffin)

Ptos

412, 413,5

412,413,5 c/s

6

6

22

CAR.BT]RE,TTER.

24T-2

- cls

-

53

m/m.

STANDARD SDTTING

Choke Main

Tube

c/s 1406

1425

l4O7

cls

1426

13

13

16

l6

flange

centres

Jet Jet

62

70

82

95

Air

S.R.

Jet

r.75

50

1.75 50

1.50

1.50

50

50

Needle

Seating

1.5 m/m

1.5 m/m

1.5

m/m

1'5 m/m

ZENITI{ Carburetter Spare Parts

Ref.

Throttle

I

0

Screw Fixing Throttle

3

Screw Fixing

4

Spring Washer

D

Throttle Spindle

Spring for

6

7

Air Regulating Screw

8

Fibre

I

Petrol

10

Filter Gauze

1l

Filter Plug, Fixing

Throttle Stop 013111

t2

13

Throttle Lever

t4

Spring

Nut

15

Washer for Needle Seating 09619

16

t7

Needle and

18

Float

19

Slow Running Tube*

2,0

VYasher

Main

2l

22

Washer for Plug

oq

Plug over Main

24

Needle Valve

23

Packing Nut for

28

Packing

27

Adaptor for Main

(Items

28

Drain

?,9

Carburetter Bowl

30

Nut for Strangler Spindle

Spring Washer for do.

3l

32

Spring

38

Spring

g4

Sleeve

35

Strangler Flap

36

Screw

37

Spring

38

Strangler Lever

39

Bearing

40

Strangler

Air

4t

42

Choke

43

Gasket

44

Carburetter Barrel

45

Throttle Stop Screwrnrottre

,tB

Spring

Air Regulating

Washer for Plug

Elbow or Banjo

Washer for'l'hrottle

for

Throttle Spindle...

for

(State

Jet*

for

24 to

Valve Plug

A-nchor Plate

for

Strangler

for

Strangler

Fixing Strangler

for Strangler Lever

for

Spindle

(State

Jet*

Tube*

(Bowl

btop

for

I

IMPORTANT.-§tate

Deecrlptlon

(2

Bowl to

Seating

Main

for

do.

27 used for cls

Barrel

for do.

(Supplied

Jet

(5

or

Petrol Pipo ... 06098

(1.5

(State

Jet

size)

over

Main

(used

Main

Jet

Main

Jet

Acljustruent

Jet

(used

for c§

(Ass'mb'd

Spindle

Spindle

Flap

Strangler

Lever

...

size)

(State

size)

to Barrel)

do.

olI)

(5

off)

off)

Screw

Elbow

by

m/m)r

(2 off)

Prestwich) ...

A.

J.

Lever

(State

size) 09121

size) 015408

... 04625

Jet

for

c/s

1406

and

1407

only)

Adjustment.

Adjustment...

and 1426 only).

1425

1425

and

with itemr

(Autom*tic)

(2

otr)

alze

only)

1426

37, 38 & 39) 016314

requlred

List

Part No.

0r2465

16776

012405

04691

0r2628

09846

09845

06101

08103

06100

04691

05581

012318

06167

013121

012650

013603

P-12803

P-1503

012850

F-1410

05581

04691

013110

0r3109

013I08

012449

t6776

013107

014335

013104

0131

012773

013119

012631

013073

05923

04611

Pro* 23

14

'fhe

21'l-2

section is

ight

Stationary

Mobilo

is ofi-set

to

anglo

or

tako all

invariably

feature

condltion!

reliablo

thc upper

lowor

is

as siEple

jet

is arranged

a correct

engine

ple,

plug

(15).

is controlled

is

uotlced

aad

maln

Fuel

rtomlsed

sir lntakc

mixturo

(10)

chaEber

a vertical

Commercial

Agricultural

ia order

tho main

operation

stalling.

sir through

ls called

servlce are

The carburetter

bowl

shown (8).

as

and

a slow running

mixturc strength

operation. The

or mail

(l).

Thc

teke! Irom

that thls air lssues

(6),

at high engine

dischargo

metered

by an alr supply

aDd controlled

i$suer through

and

tho

coDtains a normal

PAes.

SECTION CARBURETTER

GENDRAL

Industrial

The lustrument

protccted

close

or barrel

portion

possiblo

Carburetter

instrument

Vehicles,

Plaqt and various

equipnent.

to keep

discharge

in any

the

by an

Ior

when working

to

the

to be

consists of

portlon

by 6ve

Itr order

we

DESCRIPTION

to atomiso the

jet

The slow

air

by

24

drawlng

(2)

covered by

running

bleeding to

jet

the air

tho main air

speeds

(7)

tube

by thc slow

tho ldle

progresrion

ALf

TRNATIV€

showu

in

Marine

'fhc

it ar closc

tube, thus

direction

without

caq be arranged

uain intako

air

ground,

if

obtalned.

two maia

being

acrews,

to keep thl3

hÅve

uscd

jet.

Suitable alr

luel and

under

all condltionr

rhowr the

thc largo

jet

the maln

(14),

and thb

lntaks.

lrom

thc holer

whcn tho

Ialls

to ltt

runnitrg

tsken through

by the

serew

dlrcharge

(11).

orlåce

typo float (10)

above

general

types

float

ar

ensuriog

flooding,

which lr

cleaner,

under

long

lile

castingr,

secured

ono of

carburettcr

princlplo

ono

bleeding

to tnaintalo

hexagon

lr

sko shorvu

jet

air

It

fuel iu

lowest level.

jet

thc

(12).

Ttc

ead

VARIABII

in

cross

use on

Engines

of

chamber

possible

high

to

Thtl

dusty

and

to the

which

of

princl-

$yttem

3upply

will

be

({),

(6)

thc

(lS)

ir

malu

Tht.

channcl

doat

thc

MAIN

JET

TYPE

2{7.2,

usual

combined

correct

Iuel

of

the

is

level is

the

float

position

usually

catr

bc used

the fuel

size

with

part

washer

to reduce

MAIN

The

comblnation

jet

alr

will be

the itrstrument

to

alter

running

results.

driver

damage

The mair

pa$lng

flow of fuel lnto

direction as

jct

will be

the

adjuster (22)

dlrection

the full luel

Do

not screw the needle

lorce,

&ud tho correct settiug

packing

The

slightly if

must

carbur€tter.

Tbis should

hot, tho rniuirnum

sround 550/600 r.p.m.

rrow lr

Iound

is

parts

these

trouble.

Takc speclal

when rcmoving

to

the thread

jet

adjuster

into

the main

the

far as

coDpletely

more

flow of

as this

will

nut

the luel drips

alwayE be used

SLOW RUNNING

be carried

provided

needle

seating

autouatically

chaDrbcr

and the

of

the ncedle

fitted

with

iI it is

lcvel

in

the iloat

ADJUSTMENT

of choke

corrcct

fitted and

than about

of the adjuster

when

Cleanliness

cåre to

the

in

jet

jet.

lVhen

possible,

cut-o{I.

is

opened

the main

into

damage

specified

from

between

it

main

the

(22).

orificc

all fuel

up ln

the taper

ADJUSTMENT

out

ruuning

A apring-loaded

close

to

valve (lg),

provided.

float,

seating,

one

washer,

desired

for

chambcr,

tube,

main

for

the

engine

should

not

deallng

with

is the

keynote

use a

suitablo

in

order

Jet

carburetter

is a

tapered

and

controlling

turoed

ln a

flow

On

the other

an anti-clockwise

two

coruplete

jet

rvill

be

jet

the

with

of

will no longor

should

the adjuster,

the two

halver

vhen the

speed ls

the throttlo

together

the

but

anv reason

jet

to

be

uecessary

ortliuary

for

prevent

to

casting.

clockrvise

to

the

haqd,

provided.

ercessive

tho

needle

apply.

be

tighteDed

gasket

A

engine

usually

adjustlDs

lever

The

by

latter

two

antl

which

good

screw_

Deedlo

naln

turn8,

oI

the

set

thc

by

the

means

of which the

adjustqd

for idling.

be turned

uicc o./sø.

provide

direction

air,

running,

idling,

one-half

usual

the fully

slightly

clockwise

The slow running

a richer

by reduciog

On the

i.e.,

this

turn

setting

home

frorn

COLD

The rich

mixture

provided

is

and

at the

of its

3). As soon

will open

the

engioe

must

sarnc time

third

page

flap

as

strangler

HOT

When

the

not

lcquired,

irnportant.

respond

check

tap ln

ment.

is

\Vhen

disDratrtled

to

belore any

ou

"

The carburetter

Consequently,

essential

if

the

for cleanitrg

clean

the outside

exact throttle

The

to increase

idle n:ixture

the

other

hand if there

black

smoke

screw

should be

in

an anti,clockwise

is

about

one corlpletc

position,

orre

cngine to

STARTING

necessary

by closing

full movement

the

set

as

the

engine is mnuing

autoulatically

warms

up

be rnoved

§TARTING

etrgine is

II

satisfactory

cornplete

dismautling

hot

and

the throtde position

thc

engine

the

usual details,

"

Ilosition,

GENERAL

is

an accurate

absolute

instrument

of

head of ilris

but

the control

to the futly

opening

scre\y should

the idle specd and

mixture

screw

if turned itr a clockwise

supply oI

lrom the

atroflrer.

choke

the throtile

opcn.

to

(seo

slow

is evldenco of rich

exhaust when

given

a

direction.

turn open from

of course

(see

page

also

to nteet

this conditlon

or air strangler

to about

(See

SIARTING,

adrnit air; however,

operatiDg

open

page

also

or warm, the

does not

such as pctrol

etc.

netering

intcrnal

resuits

are

to

be obtained,

takes

is rerrroved

it is

place.

purposes,

the carburetter

cau be

(12)

rvill

running

quarter,

The

this varies

3)

one

the

strangler

the

position,

3)

choke

is

not

Inrncrliately

lnstru-

cleanliness

and

good

plan

a

tholoughly

parts

The

or

(3)

ls

should

bo carefully

and

the main

air if

its

spindle

anchoring

the closed

finger.

to is secured

anchor

adjusted.

l2 o'clock

"

choke valves

closerl

lever is rnoved

replacing

flange

out cirusing

this

would allow

with a flange

ttsual

start

etter,

atrd also

parts

travel,

The

setting lor

mlxturo

3,000 feet

8t higher

to deal wiUr

loss

of

will

bo found Dost

ruDning

wise direction

bo found

by the carburetter,

Servico Dcpartment

Servico

castings

this

available.

should move quite

spring

positioa

It rvill be

in

plate,

and the

The standard

notch.

"

the

against

the air intake

to

the carburetter

as a thick

Basket

the flange on

in this way

nlanner

with a file.

the

engine,

good

it is a

the choke cootrol

work corrcctly,

etc.

l{aker's

adjustment

tlre main

strcngth

altitucle

altitudes

8yDptoms

power.

In these

exhaust.

one-quarter

eflectlve in

Station should

set out

on a clean

blown

The strangler

when the

and

the flap is

noted that

one of

strangler

straogler flap

æ air leak

subsequent to

plan

for all

above

Turning

the light

the notches

spring loading

position

IR commoD

the fuUy closed

take care to

gasket

the oarburetter

to occur.

it can

to

check the

to make

giving

oI the

jet

adjuster

conditions

sea level.

it may

sometimes

of rich running

cases, the rnain

useful in

the

of a

weakening

In

any casc

or

the nearest

be consulted.

sheet

out with

freely

bore

Before

the full

the rnixture

compressed

flap complete

against

lever is

pushed

spring referred

of

the spling

can

be readily

is

the top or

rvith all

nust be

may

refitting the

adjuster in a clock-

turn at a

of difficulty

air

cornpletely

when the extemal

position.

use a thin

tend to

to bend and

When dealing

be trued up in the

atternpting

throttle cotrtrol

quite

sure these

amomt of

carburetter and

gives

up to about

Wherr operating

bo necessary

and

jet

obtaining

tinre will

delivered

Zenith Carburetter

papor

of

with

the light

held in

with the

intake

When

squeeze

carbur-

correct

possibly

adjustcr

clean

a

our orvn

to

if

is

Prcu 26

(

(

Illuc.

Part

No.

No.

18572

I

2 13054

3 19926/r

4 19915

5 16,590

5A2765

6

7

3730

I 14695

I 284

13962

l0

ll 16894

12 19671

13

13023

x{A31.12

-

13961/r

t5

28s

16

19517

t7

SA2912

I8

21

194115

l9 19749

20 673r/l

25 18479

28

18474

27 18546/r

22748

65'27

8316

I

18540

I1669

12864

6374

4085

19137

10010

l'7690

14630

14662

14630

14662

to quoto

to the

do this

12

-

28 22342

29

30 18674/2

8t 285

32 1455s

33

34 1B61 1

35

36 6627

37 12222

38 16163

39 69311

40

42

13

44 18346

46

47 14605/r

48 18346

49

It is essential

owing

Failure to

Customers' Patternr

P.rce 26

MODtsL 4/2

Ilare-Engine...

Gasket

.

Oil Trough ......

,,

Filler

Drain

Fixirig Stud

.

Stud-Cowl !ixing

.

Carusha{t

Carburetter

Spindle

.

.

"

.

Conrod

Liner--I3ig

Ilolt-

.

Cowl

Crankca.se

different Engine

may

not returned

Bush-Snrall Iind

Ilase Fixing Nut

,,

fop fixing'nolt

.

Tappet i3ush

Bu!å--lfagnetoi)rive

PIug...

Stud--Cylinder

.

.

,,

Vacuurr

Bearing-Itlywhecl