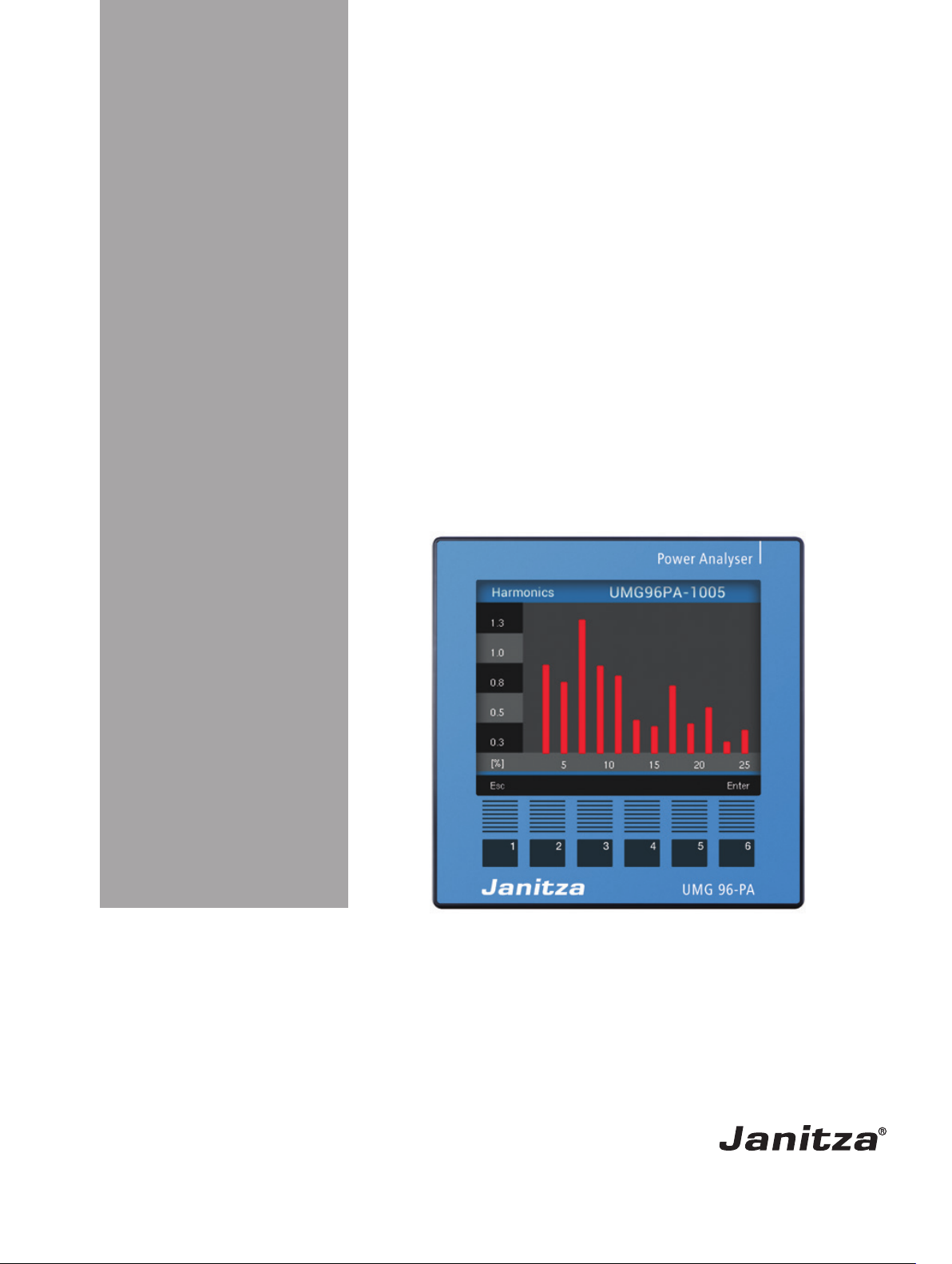

Page 1

Power Quality Analyzer

UMG 96-PA

User Manual and Technical Data

Doc. no. 2.061.015.1b 07/2018

www.janitza.com

Janitza electronics GmbH

Vor dem Polstück 6

D-35633 Lahnau

Support phone number +49 6441 9642-22

Fax +49 6441 9642-30

E-mail: info@janitza.com

Internet: http://www.janitza.com

Page 2

UMG 96-PA www.janitza.de

Content

1. General 6

1. 1 Disclaimer 6

1. 2 Copyright notice 6

1. 3 Technical modifications 6

1. 4 Declaration of Conformity 6

1. 5 Comments on the Manual 6

2. Safety 8

2. 1 Safety Instructions 8

2. 2 Safety Measures 9

2. 3 Qualified Staff 9

3. Intended Use 10

3. 1 Input Check 10

3. 2 Intended Use 10

3. 3 Delivery Contents 11

3. 4 Deliverable accessories 11

4. Product Description 12

4. 1 Measurement Procedure 12

4. 2 Operating Design 12

4. 3 Network Analysis Software

GridVis® 12

4. 4 Performance characteristics 13

4. 5 Product Overview 14

5. Installation 16

5. 1 Installation site 16

5. 2 Installation position 16

5. 3 Securing the device 16

6. Network systems 17

6. 1 Voltage measurement 18

6. 2 Rated voltages 19

6. 2. 1 Three-phase 4-wire network with earthed neutral conductor 19

2

Page 3

www.janitza.de UMG 96-PA

7. Installation 20

7. 1 Connection to a PC 20

7. 2 Circuit breaker 21

7. 3 Supply voltage 21

7. 4 Measured voltage 22

7. 4. 1 Overvoltage 22

7. 4. 2 Frequency 22

7. 4. 3 Connection variants for voltage measurement 24

7. 5 Current measurement 24

7. 5. 1 Current measurement connection variants 25

7. 5. 2 Direction of the current 26

7. 5. 3 Total current measurement 26

7. 5. 4 Ammeter 26

8. Interface 27

8. 1 Screening 27

8. 2 Termination resistors 28

8. 3 Bus structure 29

9. Digital inputs and outputs 30

9. 1 Digital inputs 30

9. 1. 1 S0 pulse input 31

9. 2 Digital outputs 31

9. 3 LED status bar 32

10. Analog output 33

11. Operation 34

11. 1 Key assignment 34

11. 2 Measurement value display

"Overview" 34

11. 3 Option menu 34

11. 4 Overview of menu displays 35

3

Page 4

UMG 96-PA www.janitza.de

12. Configuration 36

12. 1 Language 36

12. 2 Communication 36

12. 3 Measurement 37

12. 3. 1 Rated current 37

12. 3. 2 Current and voltage transformers / Nominal current 39

12. 4 System 40

12. 4. 1 Firmware / Serial number 40

12. 4. 2 Time 40

12. 4. 3 Password 40

12. 4. 4 Reset 41

12. 5 Display 43

12. 6 Colors 44

12. 5. 1 Brightness 44

12. 5. 2 Standby 44

12. 5. 3 Brightness (standby) 44

13. Putting the device into service 45

13. 1 Supply voltage 45

13. 2 Measured voltage 45

13. 3 Frequency measurement 46

13. 4 Rotary field direction 46

13. 4. 1 Phasor diagram basics 47

13. 5 Measurement current 48

13. 6 Measurement range violation 49

13. 7 Checking the power measurement 49

13. 8 Checking communication 50

13. 9 Delete min./max. values

individually 50

13. 10 Harmonics 51

13. 11 Communication in the bus system 52

13. 11. 1 RS485

52

13. 12 Digital inputs/outputs 53

13. 12. 1 Digital

inputs 53

13. 12. 2 Digital

outputs 55

13. 13 Analog output 60

13. 14 “Drag indicator” function 61

13. 14. 1 Internal synchronization 61

13. 14. 2 External synchronization 62

13. 14. 3 Synchronization priority 64

13. 15 Recordings 65

13. 16 Tariff switching 66

4

Page 5

www.janitza.de UMG 96-PA

14. Overview of measurement value displays 68

15. Service and maintenance 74

15. 1 Repairs 74

15. 2 Front film 74

15. 3 Disposal 74

15. 4 Service 74

15. 5 Device calibration 74

15. 6 Re-calibration 74

15. 7 Firmware update 74

15. 8 Battery 75

15. 9 Procedure in the event of an error 76

16. Technical Data 77

16. 1 Function performance characteristics 80

16. 2 Modbus address list of frequently used measurement values: 82

16. 3 Number formats 83

16. 4 Dimension views 84

16. 5 Connection example 1 85

5

Page 6

UMG 96-PA www.janitza.de

1. General

1. 1 Disclaimer

Compliance with the information products

for the devices is a precondition for the safe

operation and for achieving the stated performance and product characteristics. Janitza

electronics GmbH does not accept any

liability for personal injury, material damage

or financial loss incurred as a result of not

complying with the information products.

Ensure that your information products are

kept easily accessible to read.

1. 2 Copyright notice

© 2017 - Janitza electronics GmbH - Lahnau.

All rights reserved.

Any duplication, editing, distribution or other

unauthorized utilization in whole or in part is

prohibited.

All trademarks and their corresponding rights

are the property of the respective owners of

those rights.

1. 3 Technical modifications

1. 5 Comments on the Manual

We welcome your comments. If anything in

this manual seems unclear to you, please let

us know by sending an e-mail to:

info@janitza.de

• Ensure that your device corresponds to the

installation guide.

• First, read and understand the documents

included with the product.

• Keep the product documents available

for the entire life cycle of the product and

provide them to any subsequent users.

• Learn about device revisions and the corresponding updates to the product documentation at www.janitza.de.

1. 4 Declaration of Conformity

The laws, norms and guidelines applied by

Janitza electronics GmbH in the production

of this product can be found in the declaration of conformity at www.janitza.de.

6

Page 7

www.janitza.de UMG 96-PA

7

Page 8

UMG 96-PA www.janitza.de

2. Safety

Please read this user manual as well as all

other publications that must be referred to

for working with this product. This applies

especially to installation, operation and maintenance.

Please follow all safety instructions and warnings. Not following the instructions may result

in personal injury or damage to the product.

Any unauthorized modifications to or use of

this device that exceeds its stated mechanical, electric or other operational limits may

result in personal injury or damage to the

product.

Any such unauthorized modification constitutes "misuse" and/or "negligence" in the

meaning of the warranty for this product,

and therefore invalidates the warranty for the

coverage of possible damages occurring as

a result.

The User Manual:

2. 1 Safety Instructions

Symbols used:

As an addition to the safety in-

c

C

Safety instructions are marked with a warning

triangle and depicted as follows depending

on the degree of hazard:

m

HAZARD!

structions, this symbol indicates

an electrical hazard.

Together with the word "Instructions," this symbol describes:

• Procedures that do not entail

any risk of injury.

• Important information, procedures or actions.

Indicates an immediate hazard

that results in serious or fatal

injury.

• Read before operating the device.

• Keep available for the entire life cycle of

the product and for reference.

Comply with the legal and safety guidelines

required additionally for the specific instance

of application when using the device.

m

WARNING!

m

CAUTION!

Indicates a possibly hazardous

situation that may result in serious or fatal injury.

Indicates a possibly hazardous

situation that may result in minor injury or material damage.

8

Page 9

www.janitza.de UMG 96-PA

2. 2 Safety Measures

When electrical devices are in operation,

certain parts of these devices are necessarily subject to dangerous levels of voltage.

Serious bodily harm or material damage

may therefore result if they are not handled

properly:

c

WARNING!

Serious bodily harm or death may result

from hazardous voltages.

For this reason, please note the following:

• Before making connections, ground

the device on the protective earth terminal, if available.

• Hazardous voltages can occur in any

of the circuits connected to the voltage supply.

• There may be hazardous voltages inside the device even after disconnecting the voltage supply.

• Outfit single-wire leads with ferrules.

• Only connect screw terminals with the

same number of poles that are of the

same make.

• Before starting to work, de-energize

the system.

Risk of injury from electric

voltage!

2. 3 Qualified Staff

This device is to be operated and maintained

only by qualified staff.

Qualified staff are people who are able to

recognize risks and avoid possible hazards

that the operation or maintenance of the

device may cause, based on their specialized

training and their experience.

c

WARNING!

If the device is not operated in accordance

with the documentation, safety is no longer

ensured and the device may pose a risk.

Risk of Injury from

Improper Use

9

Page 10

UMG 96-PA www.janitza.de

3. Intended Use

3. 1 Input Check

Proper transport and professional storage,

installation and assembly, as well as careful

control and maintenance, are all preconditions for the proper and safe operation of this

device.

Perform unpacking and packing with the usual care and without the use of force, and only

use suitable tools.

Perform a visual inspection of the devices to

ensure a proper mechanical condition.

Check the delivery contents for completeness before starting to install the device.

If it is to be assumed that safe operation

is no longer possible, the device is to be

placed out of order immediately and protected against unintended operation. It is to

be assumed that safe operation is no longer

possible if the device e.g.:

3. 2 Intended Use

The device is:

• intended to be built into control cabinets

and small distribution boards.

• not intended to be built into vehicles! The

use of the device in mobile equipment is

considered an exceptional environment

condition, and is only admissible with a

separate agreement.

• not intended to be built into environments

with hazardous oils, acids, gases, fumes,

dust, radiation, etc.

C

ATTENTION!

All of the screw terminals included in

the delivery contents are connected

to the device.

• shows visible signs of damage,

• no longer functions despite an intact power supply,

• has been exposed to longer periods of

adverse conditions (e.g. storage not consistent with the admissible climate limits

without an adjustment of the room climate,

thawing, etc.) or transport stresses (e.g.

fall from a great height even without any

outward visible signs of damage, etc.).

C

ATTENTION!

All of the delivered options and

design variants are described on the

delivery note.

10

Page 11

www.janitza.de UMG 96-PA

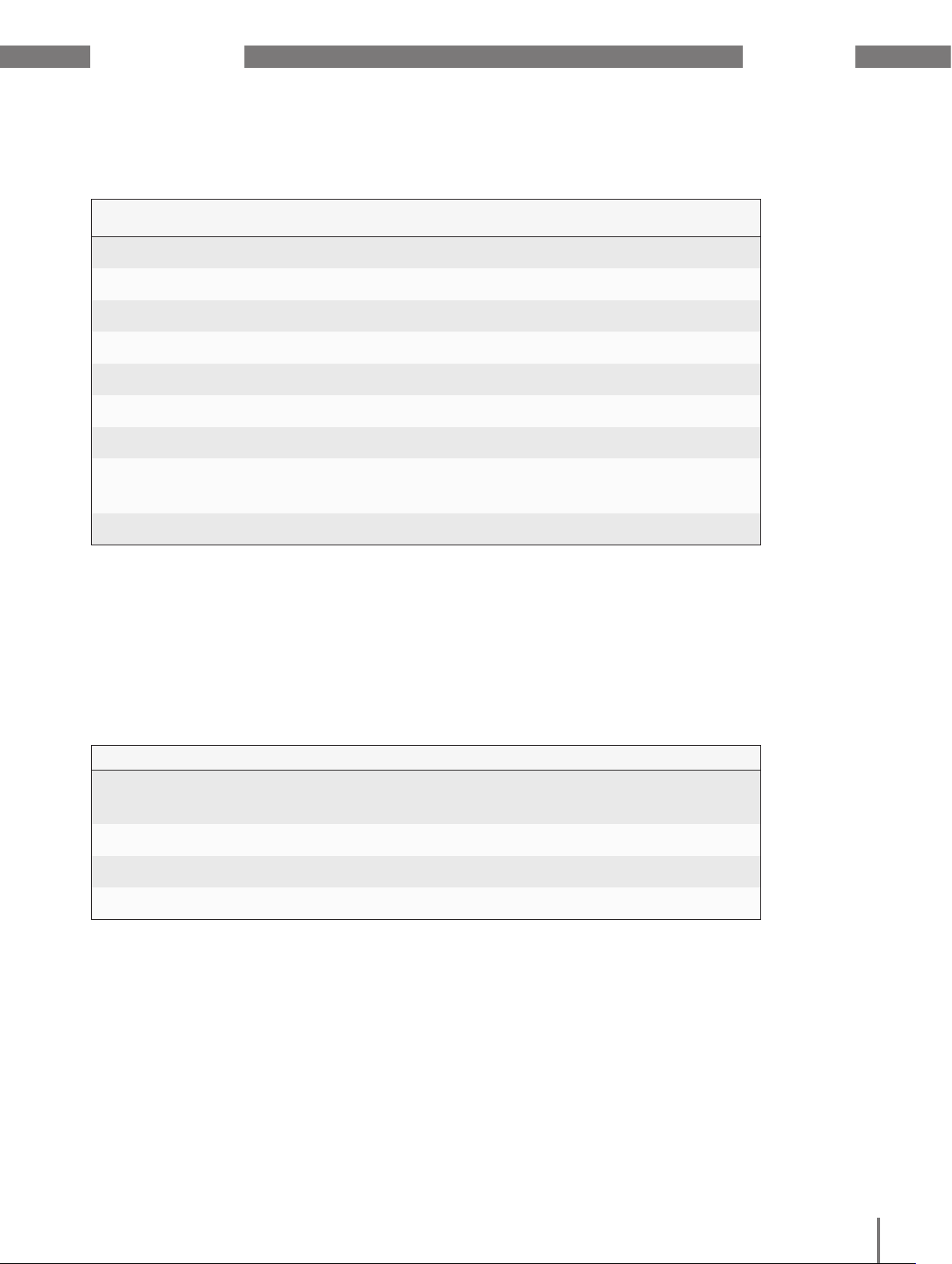

3. 3 Delivery Contents

Number Art. no. Name

1 52.32.xxx

1)

UMG 96-PA

1 33.03.360 Installation Guide

1 33.03.361 "GridVis Software" Quick Start Guide

1 10.01.896 Screw terminal, pluggable, 3-pole (auxiliary energy)

1 10.01.849 Screw terminal, pluggable, 4-pole (voltage measurement)

1 10.01.871 Screw terminal, pluggable, 6-pole (current measurement)

1 10.01.909 Screw terminal, pluggable, 3-pole (RS 485)

1 10.01.865

Screw terminal, pluggable, 10-pole

(digital inputs/outputs, analog output)

1 52.22.251 Mounting Kit

1)

See delivery note for item number

3. 4 Deliverable accessories

Item no. Name

21.01.058

Lithium battery CR2032, 3 V

(Authorization as per UL 1642)

29.01.065 Seal, 96 x 96

15.06.015 Interface converter RS485 <-> RS232

15.06.025 Interface converter RS485 <-> USB

11

Page 12

UMG 96-PA www.janitza.de

4. Product Description

The device is intended for:

• the measurement and calculation of electrical quantities such as voltage, current,

power, energy, harmonics in the building

installation, on distributors, circuit breakers

and busbar distributors.

• the measurement of measuring voltages and currents originating in the same

network.

• measurements in low-voltage networks

in which rating voltages of up to 600 V

conductor to ground and surges of overvoltage category III may occur.

• Measurement in medium and high-voltage

networks usually does not occur through

current or voltage transformers.

• being built into non-mobile control cabinets or small distribution boards. The

position at which it is built in is arbitrary.

• measurement in medium- and high-voltage

networks with current and voltage transformers.

• use in domestic and industrial settings.

• the measurement of current via external

../1 A or ../5 A current transformers.

• Directly on the device using the 6 keys

and the display.

• Via the programming software GridVis®.

• You can change and open data with the

help of the Modbus address list via the

Modbus protocol. You can find this list at

www.janitza.de.

This user manual only describes the 6-key

operation of the device. The network analysis

software GridVis® has its own "Online Help

Guide."

4. 3 Network Analysis Software GridVis®

You can program the device and read out the

data with the network analysis software GridVis® available at www.janitza.de. To do this,

a PC must be connected to the device e.g.

via a serial interface (RS485) or via a gateway

connection.

With the network analysis software GridVis®,

you can:

The measurement results can be displayed

and read out via the device interface for further processing.

4. 1 Measurement Procedure

The device:

• continuously measures and calculates all

effective values over a 200 ms interval.

• measures the real effective value (TRMS)

of the voltages and currents connected to

the measurement inputs.

4. 2 Operating Design

You can program the device in many ways

and/or recall measurement values.

• program the device.

• configure and read out recordings.

• analyze the data you read out.

• save data in the database.

• display measurement values graphically.

• program client-specific applications.

Malfunction can result

c

CAUTION!

If the device is connected improperly, it may

deliver measurement values with errors.

For this reason, please note the following:

• Measurement voltages and measurement currents must come from the

same network.

• Do not use the device to measure

direct current.

• Earth the conducting patch boards.

from an improper

connection

12

Page 13

www.janitza.de UMG 96-PA

4. 4 Performance characteristics

General

• Front board installation device measuring 96 x 96 mm

• Expansion by modules

• Connection via plug-in terminals with screw connections

• Color graphics display 320 x 240 px

• Control via 6 keys

• 3 voltage measurement inputs (600 V, CAT III)

• 3 current measurement inputs (via current transformer)

• 3 digital outputs

• 3 digital inputs

(configured as impulse counters with simultaneous power calculation

• 1 analog output (0 - 20 mA)

• Data storage 4 MByte Flash

• RS485 interface (Modbus RTU, Slave, up to 115 kbps)

• Recording of more than 2,000 measurement values

• Clock and battery

• Operating temperature range -10 °C .. +55 °C

Measurement uncertainty

• Active energy, measurement uncertainty class 0.5S for ../5A transformers

• Active energy, measurement uncertainty class 1 for ../1A transformers

• Reactive energy class 1

Measurement

• Recording of more than 800 measurement values

• Measurement in TN and TT networks

• Measurement in networks with rated voltages of up to L-L 720 Vrms and L-N 417 Vrms

(as per IEC)

• Measurement range for current 0.005 .. 6 Arms

• Real active value measurement (TRMS)

• continuous sampling of voltage and current measurement inputs

• Frequency range of the fundamental oscillation 45 Hz .. 65 Hz

• Measurement of the harmonics 1 to 25 for ULN and I

• ULN, ULL, I, P (drawn/delivered), Q (ind./cap.)

• 2 tariffs (switching via Modbus or digital input 1)

13

Page 14

UMG 96-PA www.janitza.de

4. 5 Product Overview

1

2

Fig. Front view of UMG 96-PA

3

4

5

8

7

6

1 Device Type

2 Description of the function keys

3 Key 1: Configuration menu, Back (ESC)

4 Key 2: Select digit, set option field ()

5 Key 3: Lower digit by 1, select menu item (), set option field ()

6 Key 4: Increase digit by 1, select menu item (), set option field ()

7 Key 5: Select digit, set option field ()

8 Key 6: Open option menu, activate entry, confirm selection (Enter)

14

Page 15

www.janitza.de UMG 96-PA

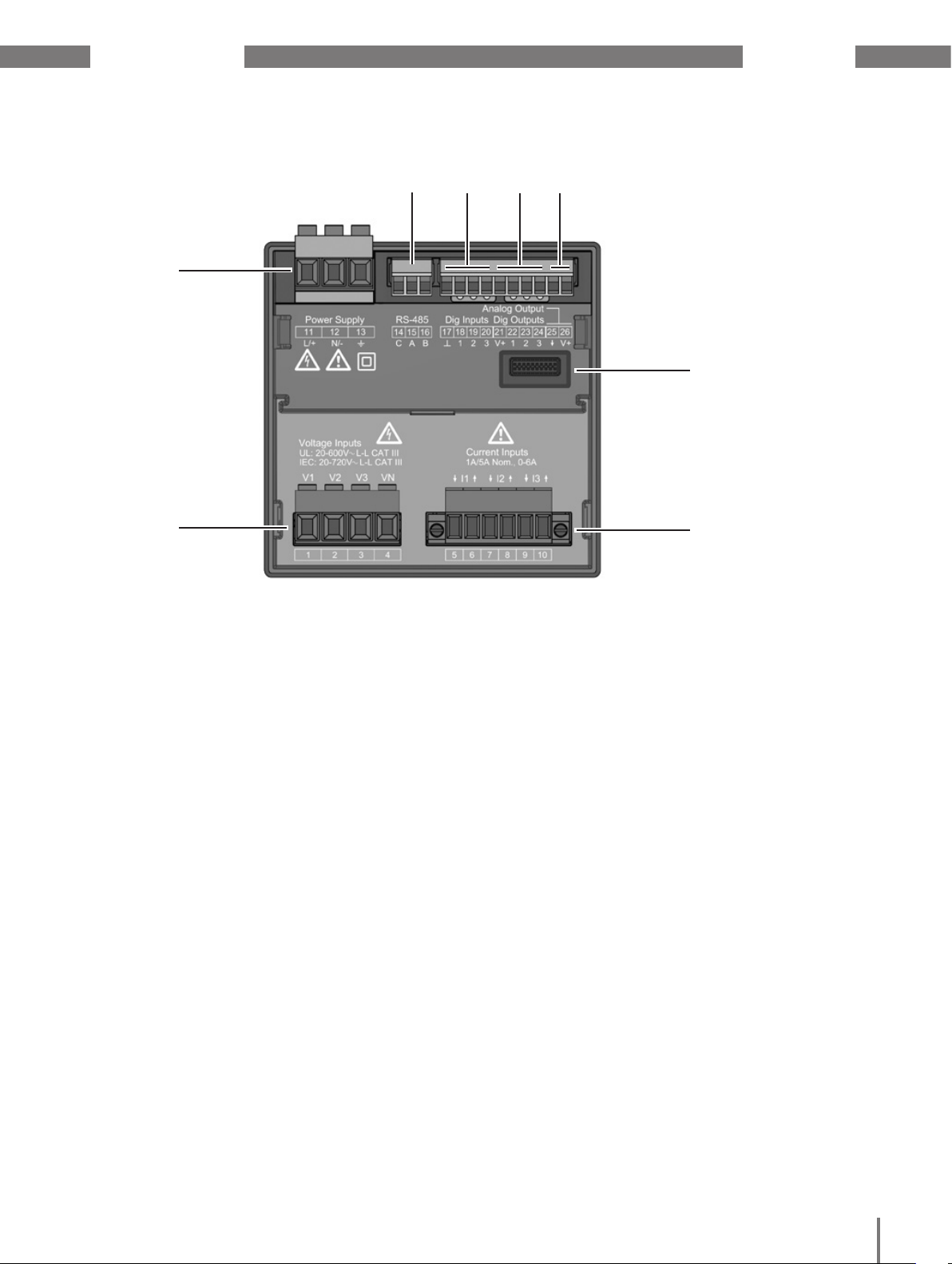

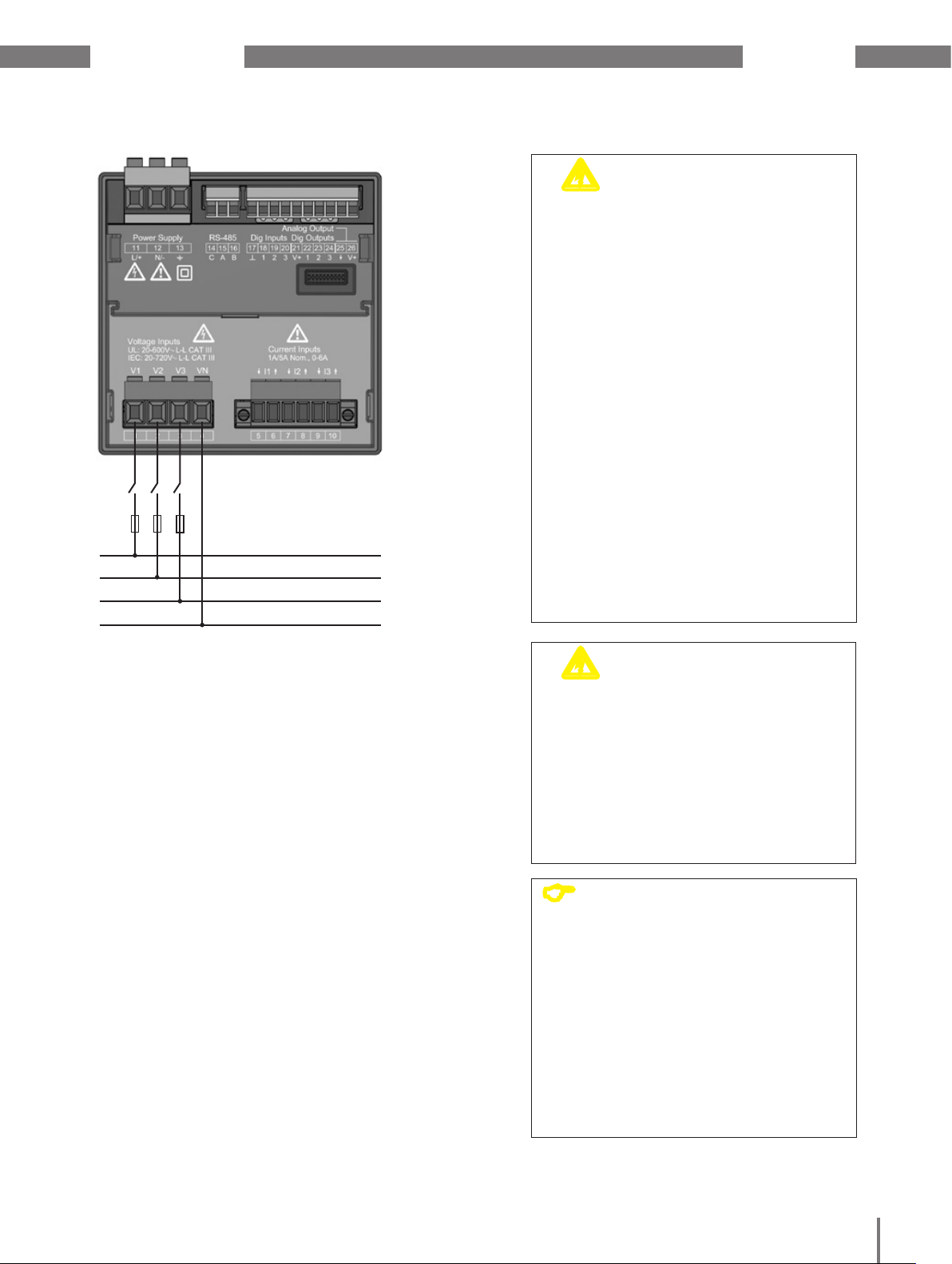

1

8

Fig. Back view of UMG 96-PA

2

3 4 5

6

7

1 Supply voltage

2 RS485 interface

3 Digital inputs

4 Digital outputs

5 Analog output

6 Module connector

7 Current measurement inputs I1 to I3

8 Voltage measurement inputs V1 to V3

15

Page 16

UMG 96-PA www.janitza.de

5. Installation

5. 1 Installation site

The device is suitable for installation in

non-mobile and weather-protected control

panels in indoor environments.

Plan on an earth for conducting control panels.

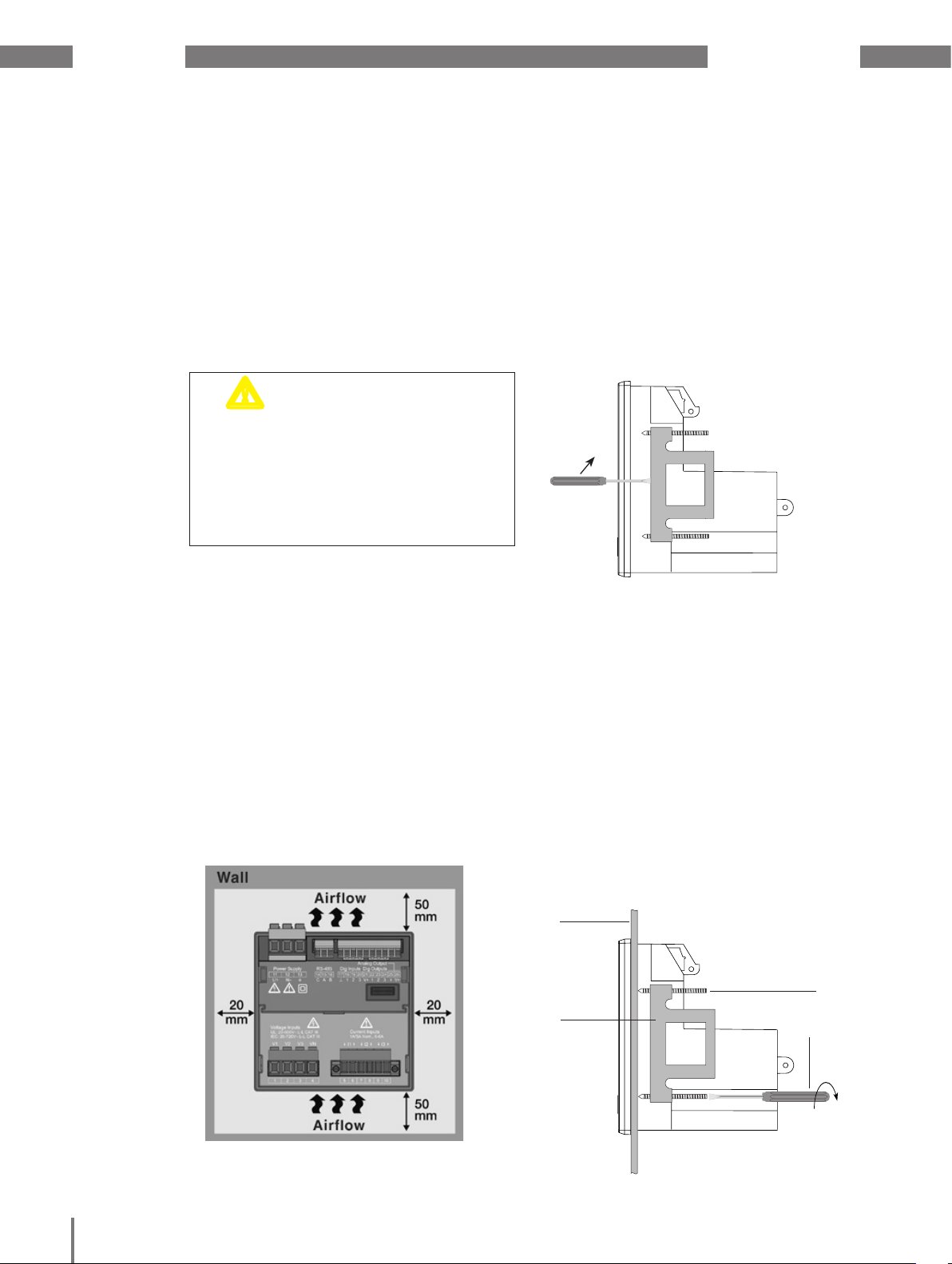

Material damage may

m

CAUTION!

result if the installation in-

structions are not followed!

Not following the installation instructions

may damage or destroy your device.

Comply with the details on the installation

position in sections „Installation“ and

„Technical Data“.

5. 2 Installation position

The cut-out dimensions of the control panel

are 92

+0,8

mm x 92

+0,8

mm.

To achieve sufficient ventilation, take the

following measures:

• Install the device vertically.

• Maintain a minimum clearance of 50 mm

above and below.

• Maintain a minimum clearance of 20 mm

on each side.

5. 3 Securing the device

The device is secured in the control panel

with the side mounting brackets. The brackets are to be removed e.g. using a screwdriver as a horizontal level before the device

is put in.

Fig. Side view of UMG 96-PA with mounting brackets.

The brackets can be loosened by leveraging them horizontally with a screwdriver.

Then slide in and snap the brackets into

place, and finally screw in the screws to secure the device.

• Turn the clamping screws until they just

touch the assembly plate.

• Then tighten the clamping screws with two

more rotations each (the mounting brackets may be destroyed if the screws are

tightened too much).

16

Fig. Back view of the installation posi-

tion of the UMG 96-PA

Assembly plate

Mounting

brackets

Clamping screw

Once the clamping screws

touch the surface of the

assembly plate: use two further

rotations at most to secure

the device

Screwdriver

Page 17

www.janitza.de UMG 96-PA

L1

E

L1

L2

L3

E

N

R

L1

L2

L3

EE

L1

L2

L3

EE

6. Network systems

Network systems and maximum rated voltages as per DIN EN 61010-1/A1:

Three-phase four-wire systems

with earthed neutral conductor

L2

N

L3

IEC U

UL U

L-N

L-N

/ U

417 VLN / 720 VLL

L-L:

/ U

347 VLN / 600 VLL

L-L:

EE

The device can be used in

• TN and TT networks

• domestic and industrial areas.

c

WARNING!

Risk of injury from

electric voltage!

If the device is exposed to measurement

voltage surges above the admissible overvoltage category, safety-related insulations

in the device may be damaged, whereupon

the safety of the product can no longer be

guaranteed.

Only use the device in environments in

which the admissible measurement surge

voltage is not exceeded.

17

Page 18

UMG 96-PA www.janitza.de

6. 1 Voltage measurement

You can use the UMG 96-PA to measure voltage in TN and TT systems.

Voltage measurement in the UMG 96-PA is

designed for the overvoltage category 600V

CATIII (measurement surge voltage 6 kV).

347V/600V 50/60Hz

L1

L2

L3

N

PE

L1

240V

50/60Hz

N

In systems without N, the measurement values that require an N are based on a calculated N.

c

WARNING!

Risk of injury from electric

voltage!

If voltage transformers are used, the connections on the secondary side may not be

short-circuited!

For this reason, please note the following:

• Check that the

voltage transformers have been properly installed. To do this, read the respective information about the voltage

transformers.

V1 V3V2 VN

AC/DC

4M

4M

4M

Voltage measurement

UMG 96-PA

Fig. Principle circuit diagram - Measurement in three-

phase 4-wire systems.

4M

Auxiliary energy

DC

18

Page 19

www.janitza.de UMG 96-PA

6. 2 Rated voltages

The following figures show lists of the networks and the corresponding network rated

voltages at which the device can be used.

6. 2. 1 Three-phase 4-wire network with earthed neutral conductor

U

/ U

L-N

L-L

66V / 115V

120V / 208V

127V / 220V

220V / 380V

230V / 400V

240V / 415V

260V / 440V

277V / 480V

347V / 600V

400V / 690V

417V / 720V

Maximum network voltage of the

network as per UL

Maximum network voltage of

the network

Fig. Network rated voltages as per EN 60664-1:2003

suited for measurement inputs

19

Page 20

UMG 96-PA www.janitza.de

7. Installation

7. 1 Connection to a PC

There are various options for connecting the

device to a PC:

1. Connection via an

interface converter:

PC with GridVis®

UMG 96-PA

RS232

RS232

RS485

RS485

PC with GridVis®

UMG 96-PA

USB

USB

RS485

RS485

2. Use of the UMG 96-PA (slave) via a UMG

(master) with gateway functionality (e.g.

UMG 512)

PC with GridVis®

Ethernet

Ethernet

20

UMG 512-PRO

as gateway

UMG 96-PA

Slave 1

ModbusModbus Modbus

UMG 96-PA

Slave 2

UMG 103

Slave 3

Page 21

www.janitza.de UMG 96-PA

7. 2 Circuit breaker

For building installation, plan for a suitable

circuit breaker for the supply voltage to

de-energise the device.

• The circuit breaker must be installed near

the device and easily accessible to the

user.

• The switch must be marked as the circuit

breaker for this device.

7. 3 Supply voltage

The device needs a supply voltage to operate. The type and amount of supply voltage

required for your device can be found on the

ratings plate.

The supply voltage is connected on the rear

of the device via terminal blocks.

Before connecting the supply voltage, ensure

that the voltage and frequency correspond to

the details on the ratings plate.

Connect the supply voltage through a UL/IEC

approved fuse.

After the supply voltage has been connected, an indicator will appear on the display. If

no indicator appears, check that the supply

voltage is within the rated voltage range.

m

CAUTION!

result from failure to com-

ply with the connection

requirements.

Noncompliance with the connection requirements may result in your device being

damaged or destroyed.

For this reason, please note the following:

• Comply with the details on voltage and

frequency on the ratings plate.

• Connect the supply voltage through a

fuse in accordance with the technical

specifications.

• Do not source the supply voltage on

the voltage transformers.

• Plan for a fuse for the neutral conductor if the neutral conductor connection

to the source is not earthed.

L

N

PE/FE

1.)

Material damage may

1.)

2.)

Fuse

(UL/IEC listed)

2.)

Disconnector

(Circuit breaker)

Functional earth

c

WARNING!

Risk of injury from electric

voltage!

Serious bodily harm or death may result

from:

• Touching bare or stripped wires that are

live.

• Inputs on the device that are dangerous

to touch.

For this reason, please note the

following:

• The inputs for supply voltage are

dangerous to touch.

• De-energise your system before

starting work!

Fig. Connection example for supply voltage

ATTENTION!

C

If the functional earth is not

connected, the device displays a

non-applied residual voltage.

21

Page 22

UMG 96-PA www.janitza.de

Overcurrent protective device for the

line protection of the supply voltage

Recommendation for the overcurrent protective device for the line protection of the

supply voltage, depending on the variants:

• Option 230 V:

6 - 16 A (Char. B)

• Option 24 V:

1 - 6 A (Char. B)

C

Recommendation for the maximum number

of devices on one miniature circuit breaker,

depending on the variants:

• Option 230 V:

• Option 24 V:

ATTENTION!

The circuit breaker serves only as

line protection - it does not provide

protection for the device!

For one miniature circuit breaker B6A,

maximum of 4 devices.

For one miniature circuit breaker B16A,

maximum of 11 devices.

For one miniature circuit breaker B6A,

maximum of 3 devices.

For one miniature circuit breaker B16A,

maximum of 9 devices.

7. 4 Measured voltage

The device has 3 voltage measurement inputs (V1 to V3) on the back of the device.

7. 4. 1 Overvoltage

The voltage measurement inputs are suitable for measurement in networks in which

overvoltage of category 600 V CAT III (voltage

measurement surge of 6 kV) may occur.

7. 4. 2 Frequency

The device:

• requires the network frequency to measure

and calculate the measurement values.

• is suitable for measurement in networks

in which the fundamental oscillation of the

voltage is within the range of 45 to 65 Hz.

The network frequency is derived from the

measured voltage in phase L1. The sampling

rate of the voltage and current measurement

inputs is derived from the network frequency.

If the measurements have severely distorted voltages, it will no longer be possible to

precisely determine the frequency of the

fundamental oscillation of the voltage. I.e. the

corresponding network frequency should be

stipulated for measured voltages that exhibit

severe distortions.

(Voltage distortions occur e.g. in measurements of consumers operated with a phase

angle control). Current distortions do not

affect the determination of the frequency.

22

More information can be found in Section 12

Configuration / Rated frequency"

Page 23

www.janitza.de UMG 96-PA

1.)

Fuse

1) 1) 1)

2) 2) 2)

Fig. Connection example for voltage measurement.

(UL/IEC listed)

2.)

Disconnector

(Circuit breaker)

L1

L2

L3

N

c

WARNING!

Risk of injury from electric

voltage!

Serious bodily harm or death may result

from not complying with the connection

requirements for the voltage measurement

inputs.

For this reason, please note the following:

• De-energise your system before

starting work! Check that it has been

de-energised!

• Connect voltages that are over the

admissible network rated voltages

through voltage transformers.

• The voltage measurement inputs on

the device are dangerous to touch!

• Install a circuit breaker as described in

Section „7. 2 Trennschalter“.

• Use a UL/IEC approved overvoltage

protective device with a rating value

that is measured for short-circuit current at the point of connection.

c

CAUTION!

Malfunction can result from

an improper connection

If the device is connected improperly, it may

deliver measurement values with errors.

For this reason, please note the following:

• Measurement voltages and currents

must come from the same network.

• The device is not suitable for measuring direct current.

ATTENTION!

C

The device can only determine measurement values if there is a voltage

L1-N greater than 20 Veff (4-wire

measurement) or a voltage L1-L2

greater than 34 Veff (3-wire measurement) at the voltage measurement

input V1.

As an overvoltage

protective device for the voltage

measurement, use a line protection

(1 - 10 A) with IEC/UL approval.

23

Page 24

UMG 96-PA www.janitza.de

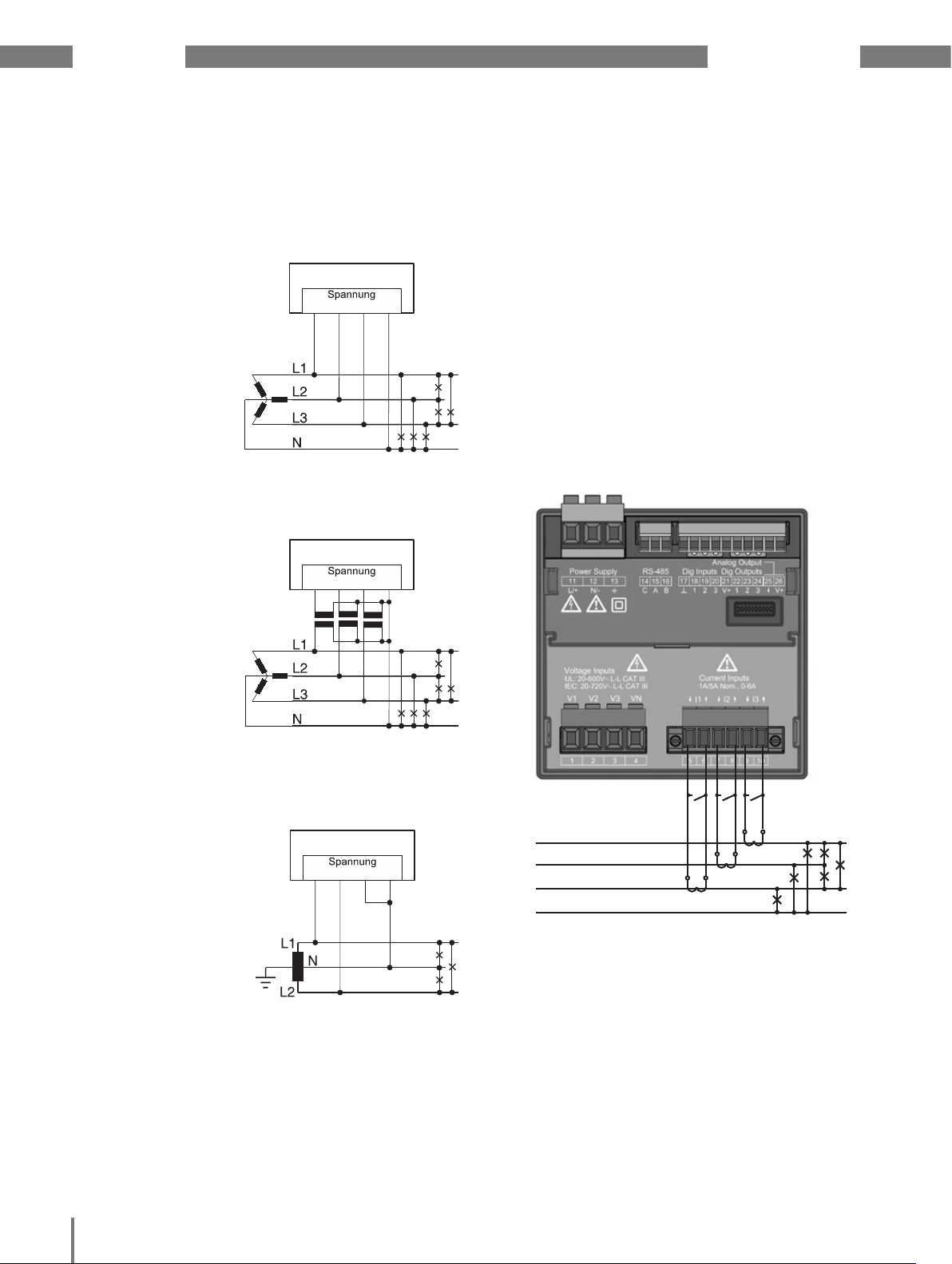

7. 4. 3 Connection variants for voltage measurement

V1

V2

Fig. Voltage measurement in the three-phase

four-wire system

V1

V2

V3

V3

VN

VN

7. 5 Current measurement

The device:

• is designed to be connected to current

transformers with secondary currents of

../1 A and ../5 A.

• is only approved for measuring current

through current transformers.

• does not measure direct currents.

The factory preset current transformer ratio

is 5/5 A, and may need to be adjusted to the

current transformer in use.

Fig. Voltage measurement in the three-phase

four-wire system

V1

V2

Fig. Voltage measurement in the single-phase

three-wire system

V3

VN

L1

L2

L3

N

Fig. Connection example "Current measurement through

a current transformer."

S1 S2

S1 S2

S1 S2

24

Page 25

www.janitza.de UMG 96-PA

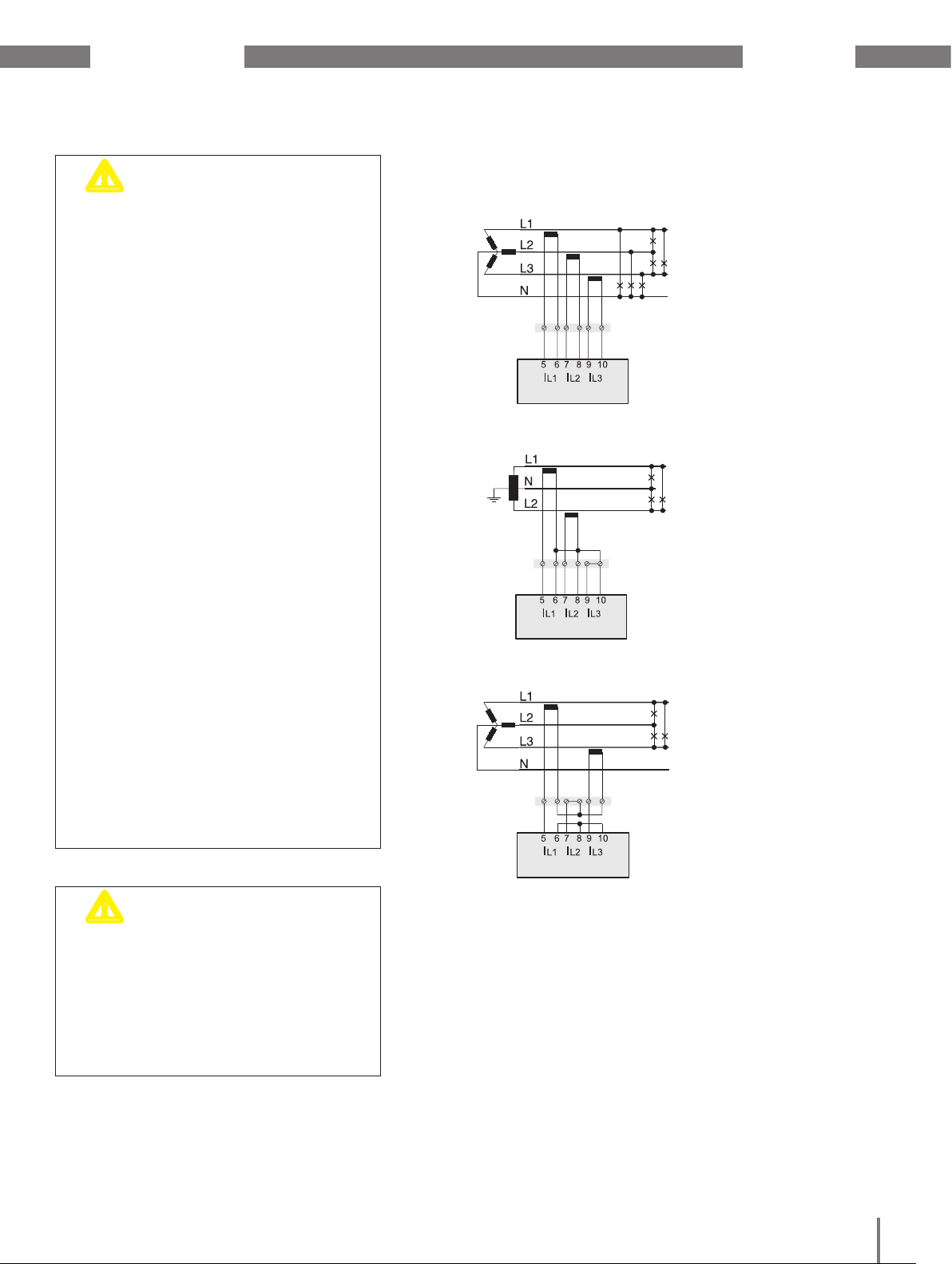

7. 5. 1 Current measurement connection

m

WARNING!

tric voltage on the current

transformers!

Voltage peaks that are extremely dangerous

to touch may occur on current transformers

operated with an open secondary side

that may result in serious bodily harm or

death.

For this reason, please note the following:

• De-energise your system before starting work! Check that it has been de-energised!

• Avoid open operation of the current

transformers.

• Short-circuit uncharged current transformers.

• The secondary terminals of the current

transformer must be short-circuited

before the power supply lines are disconnected.

• If a test switch that automatically

short-circuits the current transformer

secondary leads is available, it is sufficient to put this into the "test" position

provided the short-circuiters have been

checked beforehand.

• Only use current transformers

that have a base insulation as per

IEC 61010-1:2010.

• Ensure that the attached screw terminal is sufficiently secured to the device

with the two screws.

• Even "open-safe" current transformers are dangerous to touch if they are

operated openly.

Risk of injury from elec-

variants

Fig.

Current measurement

via current transformer in three-phase

four-conductor

system

Fig.

Current measurement in

single-phase three-conductor system

Fig.

Current measurement via

2 current transformers in

three-phase four-conductor

system

m

WARNING!

Risk of injury from electric

voltage!

At high measurement currents, temperatures

of up to 80 °C can develop at the terminals.

Therefore, use leads that are designed to

have an operating temperature of at least

80 °C.

25

Page 26

UMG 96-PA www.janitza.de

7. 5. 2 Direction of the current

The current direction can be individually corrected on the device or via the serial interfaces for each phase.

In the case of incorrect connection, the current transformer does not need to be subsequently reconnected.

7. 5. 3 Total current measurement

If the current measurement takes place via

two current transformers, the total transformer ratio of the current transformer must be

programmed on the device. Setting the current transformer ratios is described in Section

„Messwandler“.

Example:

The current measurement is performed via

two current transformers. Both current transformers have a transformer ratio of 1000/5 A.

The total measurement is then carried out

with a total current transformer 5+5/5 A .

7. 5. 4 Ammeter

If you want to measure the current not only

with the UMG but also with the ammeter,

the ammeter must be connected in series to

the UMG.

UMG

I

S2

1

S

A

Einspeisung

Supply

(k)S

1 S2(l)

2(L)(K)P1

P

Fig. Circuit diagram with additional ammeter connected

in series

Verbraucher

Consumer

The device must then be set as follows:

Primary current:

1000 A + 1000 A = 2000 A

Secondary current: 5 A

UMG

I

S

S2

1

Einspeisung 1

Supply 1

1P1

1S1

(K)

(k)

(l)

(L)

1S

1P2

Verbraucher A

Consumer A

2

P1

1S1 1S2 2S1 2S2

Fig. Example of voltage measurement via a total current

transformer

P2

Einspeisung 2

Supply 2

2S1

(k)

(l)

2S2

Verbraucher B

Consumer B

2P

(K)

(L)

2P2

1

26

Page 27

www.janitza.de UMG 96-PA

8. Interface

The RS485 interface in this device is a 3-pole

plug contact that communicates via the Modbus RTU protocol.

Cable types:

• Recommendation: Unitronic Li2YCY(TP)

2x2x0.22 (Lapp cable)

Connection options for the connectors:

• 0.2 - 1.5 mm

(see Section "Technical Data")

e.g.

Connection

to the

UMG 604

as gateway

(master)

A

B

Data GND

2

RS485 bus

A

B

A

B

e.g.

Connection

of further

slave devices

C

CAT cables are not suitable for bus

wiring. Use the cable types recommended for this purpose.

8. 1 Screening

Use a drilled and shielded cable for the connections via the interface, and observe the

following points for the shielding:

• Earth the screens of all cables that lead to

the cabinet where they enter the cabinet.

• Connect the screen over a larger area and

in a manner that will conduct well, to a

low-noise earth.

• Do NOT connect the screen to terminal C

(GND)

• Gather the cables mechanically above the

earthing clamp in order to avoid damage

due to cable movement.

• Use suitable cable glands to feed the cables into the cabinet - for example armored

conduit couplings.

ATTENTION!

Fig. RS485 interface, 3-pole plug contact

RS485 bus

A

B

Data GND

Fig. RS485 interface, 3-pole plug contact with termina-

tion resistor (item no. 52.00.008)

120 Ω

A

B

Cable

Strain relief

Screen braid

of the cable

Earthing clamp

Low-noise earth

Fig. Screening procedure at cabinet entry.

27

Page 28

UMG 96-PA www.janitza.de

m

CAUTION!

Atmospheric discharge may cause transmission errors and hazardous voltages on the

device.

For this reason, please note the following:

• Place the screening on the functional

earth (PE) at least once.

• For larger sources of interference, put

the frequency inverter in the control

cabinet and position the screening as

close as possible on the device to the

functional earth (PE).

• Maintain a maximum cable length of

12000 m at a baud rate of 38.4 k.

• Use screened cables.

• Position interface leads so they are

spatially separated or additionally insulated from the components carrying

network voltage.

Transmission errors and

risk of injury result from

electrical interference.

8. 2 Termination resistors

The cable is terminated with resistors (120

Ohm, 1/4 W) at the beginning and at the end

of a segment.

The device does not contain any termination

resistors.

Correct

Incorrect

Terminal strip in the cabinet.

Device with RS485 interface.

(without termination resistor)

28

Device with RS485 interface.

(with termination resistor on the

device)

Page 29

www.janitza.de UMG 96-PA

8. 3 Bus structure

• All devices are connected in a bus structure (line).

• Each device has its own address within the

bus (see also Parameter programming).

• Up to 32 subscribers can be connected

together in a single segment.

• The cable is terminated with resistors (bus

termination 120 Ohm, 1/4 W) at the beginning and at the end of a segment.

• With more that 32 subscribers, repeaters

(amplifiers) must be used to connect the

individual segments.

• Devices for which the bus connection is

switched on must be under current.

Master

Power supply necessary

Bus terminator on

T

T

Slave

• It is recommended that the master be

placed at the end of a segment.

• If the master is replaced with a bus connection, the bus must be switched off.

• Replacing a slave with a bus connection

that is either switched on or de-energised

can destabilise the bus.

• Devices that are not connected to the bus

can be replaced without destabilising the

bus.

T

Slave Slave Repeater

T

Slave

Fig. Bus structure

Slave

T

Slave Slave

29

Page 30

UMG 96-PA www.janitza.de

9. Digital inputs and outputs

The device has

• 3 digital inputs and

• 3 digital outputs.

External

17

18

Digital

Input 1

19

Digital

Input 2

auxiliary voltage

-

S1

S2

9. 1 Digital inputs

The UMG96-PA has three digital inputs to

each of which you can connect one signal

transducer. When a signal is present, the

corresponding LED lights up green.

An input signal is detected on a digital input if

• a voltage of at least 18 V and maximum 28

V DC (typically at 4 mA) is applied.

• a current of at least 1 mA and maximum 6

mA flows.

UMG 96-PA

Digital inputs 1-3

LED

LEDLED

2k21

2k21

2k21

2k21

24V DC

+

C

Note the correct polarity of the supply voltage.

ATTENTION!

+

-

Fig. Connection of digital inputs

Transmission errors

c

CAUTION!

and material damage

result from electrical

interference.

2k21

2k21

Fig. Example for the connection of external switch

contacts S1-S3 to digital inputs 1, 2 and 3.

20

Digital

Input 3

S3

30

For wiring over 30 m, there is an increased

probability of transmission errors and

damage to the device from atmospheric

discharge.

Use screened wiring for connections to

the digital inputs and outputs.

Page 31

www.janitza.de UMG 96-PA

9. 1. 1 S0 pulse input

You can connect an S0 pulse transducer per

DIN EN62053-31 to any digital input.

This requires an auxiliary voltage with an

output voltage in the range 18 .. 28V DC and

a resistor of 1.5 kOhm.

9. 2 Digital outputs

External

auxiliary voltage

-

UMG 96-PA

Digital inputs 1-3

LED

LEDLED

Fig. Example for the connection of an S0 pulse transducer to digital input 1.

2k21

2k21

2k21

2k21

2k21

2k21

17

18

Digital

Input 1

19

Digital

Input 2

20

Digital

Input 3

1.5k

S0 pulse

transducer

24V DC

+

The device has three digital outputs which:

• are galvanically separated from the analysis electronics using optocouplers.

• have a joint reference.

• are not short-circuit proof.

• require an external auxiliary voltage.

• can be used as impulse outputs.

• can switch between AC and DC loads.

• can be controlled via Modbus.

• can display the results of comparators.

c

CAUTION!

Material damage from

connection errors

The digital outputs are not short-circuit

proof! Connection errors may therefor result

in damage to the connections.

Pay attention to the correct wiring when

connecting to the outputs.

C

Functions for the digital outputs can

be adjusted clearly in the GridVis®

software (see www.janitza.de).

Use of the GridVis® software

requires a connection between the

device and the PC via an interface.

ATTENTION!

m

CAUTION!

Measurement errors in use

as pulse output

When using the digital outputs as a pulse

output, measurement errors may result from

residual ripple.

So use a power adapter whose residual

ripple is less than 5% for the supply voltage (DC) to the digital inputs and outputs.

31

Page 32

UMG 96-PA www.janitza.de

~

Fig. Connection of digital/pulse outputs

UMG 96-PA

21

LED

Digital Ouput 1

22

External

auxiliary voltage

24V DC

+

DC

K1

9. 3 LED status bar

The different statuses of the inputs and outputs are displayed via the LED status bar on

the back of the device.

Digital inputs

The LED assigned to a respective input lights

up green when a signal of at least 1 mA flows

on this interface.

Digital outputs

The LED assigned to a respective output

lights up red when the output is set as

enabled - regardless of whether there is a

continuing connection to this interface.

-

LED status bar

Digital inputs

LED status bar

Digital outputs

LEDLED

Digital Ouput 2

Digital Ouput 3

23

24

Fig. Example for the connection of two

relays to the digital outputs

DC

K2

32

Page 33

www.janitza.de UMG 96-PA

10. Analog output

The device has 1 passive analog output,

which can emit current of 0 - 20 mA. An

external power adapter (24 V DC) is required

for operation.

The connected load impedance may not

exceed a resistance of 300 Ohm.

If the analog output is connected to greater resistance, the output range (20 mA) is

limited.

The measurement value, initial and final values, and the output range 4 - 20 mA or 0 - 20

mA assigned to the analog output can be set

using the GridVis® software (cf. Section 13

"Analog Output")

-

=

+

External

operating voltage

UMG 96-PA

Analog output 1

230 V AC

26

25

+

+

24 V DC

-

Analog inputs

Fig. Analog output connection

33

Page 34

UMG 96-PA www.janitza.de

11. Operation

The device is operated using six function

keys that are assigned to different functions,

depending on the context:

• Selection of measurement value displays.

• Navigation in the menu.

• Control of device settings.

Display title

Measurement

values

Labeling

of the function

keys

Function

Keys

Fig. UMG 96-PA

Measurement value display "Overview"

11. 2 Measurement value display "Overview"

After returning to the network, the device

starts with the measurement value display

"Overview."

This measurement value display includes the

device name and an overview of the important measurement values. In its delivery state,

the device name consists of the device type

and the serial number of the device.

Press key 1 (Esc) repeatedly to open the

measurement value display "Overview."

11. 1 Key assignment

Key

Function

• Option menu

• Leave menu, Back (Esc)

• Press multiple times:

Back to the measurement value display "Overview"

• Select digit

• Set option field ()

• Change (Digit -1)

• Set option field ()

• Select menu item ()

• Change (Digit +1)

• Set option field ()

• Select menu item ()

• Select digit

• Set option field ()

Fig. Measurement value display

"Overview"

11. 3 Option menu

If you are in the measurement value display

"Overview," open the main menu with key 1

(Esc).

Fig. UMG 96-PA Main menu

34

• Open option menu

• Activate entry

• Confirm selection (Enter)

Key 1 (Esc): Main menu

Page 35

www.janitza.de UMG 96-PA

11. 4 Overview of menu displays

Main menu

Summary (start screen)

Voltage

Voltage L-N

Voltage L-L

Linewriter

Current

Current

THD-I

Linewriter

Power

Sum power

Active power

Reactive power

Apparent power

Linewriter active power

Linewriter reactive power

Linewriter apparent power

Energy

Active energy

Reactive energy

Apparent energy

Tariff

Consumption overview

Active energy/month

Reactive energy/month

Apparent energy/month

Active energy/day

Reactive energy/day

Apparent energy/day

Harmonics

Voltage L1

Voltage L2

Voltage L3

Current L1

Current L2

Current L3

Oscilloscope

Voltage L1

Voltage L2

Voltage L3

Voltage L1-3

Current L1

Current L2

Current L3

Current L1-3

Phasor diagram

System

Configuration

Language

Communication

Field bus: Device address

Field bus: Baud rate

Field bus: Framing

Measurement

Measurement

Current transformer

Voltage transformer

Nominal current

Nominal frequency

System

Version

Serial no.

Time

Password

Reset

Display

Colors

Overview COM ports

Comparator 1

Comparator 2

Select menu:

• Select the menu item with the keys 3 () and

4 ().

• Confirm this by pressing key 6 (Enter).

• You can exit the selection by pressing key 1

(Esc).

35

Page 36

UMG 96-PA www.janitza.de

12. Configuration

The device must be connected to a power

supply to configure it. To do so, proceed as

described in „13. 1 Supply voltage“.

• If you are not in the measurement value

display "Overview," switch to this view by

repeatedly pressing key 1 (Esc).

• Open the main menu with key 1 (Esc).

With keys 3 () and 4 (), select "Sys-

tem" and confirm your selection with key 6

(Enter).

• Select "Configuration" and confirm by

pressing key 6 (Enter).

Fig. Main menu,

Selection "System"

• With keys 3 () and 4 (), select the language you want ("German," "English").

• Confirm your selection by pressing key 6

(Enter).

• Exit the configuration with key 1 (Esc).

• Open the main menu with key 1 (Esc).

• Select the measurement value display you

want with keys 3 () and 4 (). Confirm

your selection by pressing key 6 (Enter) or

jump directly to the measurement value

display "Overview" by pressing key 1 (Esc).

12. 2 Communication

Set the parameters for the RS485 interface of

your device in the configuration menu.

12. 1 Language

In the configuration menu, you can set the

language for the measurement value displays

and menus in "Language."

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the item

"Language."

• Confirm by pressing key 6 (Enter).

Fig. Configuration menu,

Selection "Language"

Fig. Configuration menu,

Selection "Communication"

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the menu

item "Communication."

• Confirm by pressing key 6 (Enter).

• With keys 3 () and 4 (), select the parameter you want

- Device address,

- Baud rate

- Data framework.

• Confirm your selection by pressing key 6

(Enter).

• Change the parameter sizes with keys 3

() and 4 ().

Device address: Set the digit position with

keys 2 () and 5 ().

• Confirm by pressing key 6 (Enter).

• Exit the menu "Communication" with key

1 (Esc).

36

Page 37

www.janitza.de UMG 96-PA

• Exit the configuration menu with key 1

(Esc).

• Open the main menu with key 1 (Esc).

• Select the measurement value display you

want with keys 3 () and 4 (). Confirm

your selection by pressing key 6 (Enter) or

jump directly to the measurement value

display "Overview" by pressing key 1 (Esc).

Fig. Menu Communication,

Selection "Device address"

Settings:

• Device address:

Select a device address for the device that

the device will be addressed with in the

bus. This address must be unique within

the bus structure.

Settings range: 1 - 250

Default: 1

• Baud rate:

Select a uniform baud rate for all of the

devices within the bus structure.

Settings range: Auto, 9600, 19200,

38400, 57600, 115200 kbps

Default: Auto

• Data framework:

Select a uniform data framework for all of

the devices within the bus structure.

Settings range:

• "odd" (parity odd with 1 stop bit)

• "even" (parity even with 1 stop bit)

• "1 stop bit" (parity none with 1 stop bit)

• "2 stop bits" (parity none with 2 stop

bits)

• Default: 1 stop bit (no parity)

Material damage may result

m

CAUTION!

Incorrect network settings may cause interruptions in the IT network.

Find out about the correct network settings for your device from your network

administrator.

12. 3 Measurement

In the menu "Measurement," you can set the

ratio of the current and voltage transformers

(primary-to-secondary side), the rated current

and the rated frequency.

12. 3. 1 Rated current

The network frequency is required to measure and calculate the measurement values.

The device is suitable for measurements in

networks that have a frequency range of 45 65 Hz.

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the menu

item "Measurement" from the configuration

menu.

• Confirm by pressing key 6 (Enter).

• With keys 3 () and 4 (), select the item

"Rated frequency" and confirm your selection with key 6 (Enter).

from incorrect network

settings.

Fig. Menu Measurement,

Selection Rated frequency

37

Page 38

UMG 96-PA www.janitza.de

• With keys 3 () and 4 () select the

setting you want, and confirm the selection with key 6 (Enter). You can abort this

action by pressing key 1 (Esc).

• Exit the menu "Measurement" with key 1

(Esc).

• Exit the configuration menu with key 1

(Esc).

• Open the main menu with key 1 (Esc).

• Select the measurement value display you

want with keys 3 () and 4 (). Confirm

your selection by pressing key 6 (Enter) or

jump directly to the measurement value

display "Overview" by pressing key 1 (Esc).

Settings range:

• Auto (45-65 Hz)

• 60 Hz (fixed frequency)

• 50 Hz (fixed frequency)

Default

• Auto (45-65 Hz)

C

C

ATTENTION!

If the network frequency is outside

of the range 45-65 Hz

• no error or warning notification

will be sent.

• the corresponding setting will be

used for the entry of a constant

frequency (50 / 60 Hz).

• The last determined frequency

in the range 45-65 Hz is used for

the selection of the automatic

frequency detection (auto).

ATTENTION!

It takes 10 seconds to determine

the frequency. The frequency does

not represent a 200 ms measurement value!

C

The device can only determine the network

frequency if there is a voltage L1-N greater than 20 Veff (4-wire measurement) or a

voltage L1-L2 greater than 34 Veff (3-wire

measurement) at the voltage measurement

input V1.

ATTENTION!

Devices that use automatic frequency

frequency detection will require

about 5 seconds to determine the

network frequency. During this time,

the measurement values do not

adhere to the guaranteed measurement uncertainty.

38

Page 39

www.janitza.de UMG 96-PA

12. 3. 2 Current and voltage transformers / Nominal current

For the defined operation of the device it

is necessary to set the correct current and

voltage transformer ratios and the nominal

current.

When connecting voltage transformers,

observe the measured voltage on the ratings

plate!

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the menu

item "Measurement" from the configuration

menu.

• Confirm by pressing key 6 (Enter).

• With keys 3 () and 4 (), select the submenu "Rated Measurement" and confirm

your selection with key 6 (Enter).

• With keys 2 to 5 () and 4 () select the

setting you want, and confirm the selection

with key 6 (Enter).

• Set the digit position with keys 2 () and

5 ().

• With keys 3 () and 4 () change the digit

(-1 / +1).

• Confirm by pressing key 6 (Enter) or abort

the action by pressing key 1 (Esc).

• Exit the view "Measurement L1..L3" with

key 1 (Esc).

• Exit the view "Measurement" with key 1

(Esc).

• Exit the configuration menu with key 1

(Esc).

• Open the main menu with key 1 (Esc).

• Select the measurement value display you

want with keys 3 () and 4 (). Confirm

your selection by pressing key 6 (Enter) or

jump directly to the measurement value

display "Overview" by pressing key 1 (Esc).

C

Settings:

• Current transformer (primary):

• Current transformer (secondary):

• Voltage transformer (primary):

• Voltage transformer (secondary):

• Rated current:

ATTENTION!

The adjustable value of 0 for the

primary current transformer doesn't

make any sense and may not be

used.

Settings range: 0 - 32000 A

Default: 5 A

Settings range: 0 - 5 A

Default: 5 A

Settings range: 0 - 32000 V

Default: 400 V

Settings range: 0 - 999 V

Default: 400 V

Settings range: 0 - 999999 A

Default: 150 A

Fig. View "Measurement L1..L3,"

Configuration of the current and voltage

transformer ratios and the rated voltage

39

Page 40

UMG 96-PA www.janitza.de

12. 4 System

Display of device-specific system settings,

password assignment and value reset function.

1

2

3

4

5

Fig. View "System"

1 Firmware version

2 Device serial number

3 Device time / date

4 Password function

5 Reset settings

View of the display "System":

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the menu

item "System" from the configuration

menu.

• Confirm by pressing key 6 (Enter).

12. 4. 1 Firmware / Serial number

Use the firmware version and the device-specific serial number for possible support

requests and to register on the homepage

(www.janitza.de).

12. 4. 2 Time

Shows the current device time. You can

change the settings for Time Synchronization,

Date/Time Zones and Clock Time with the

GridVis® software or via the corresponding

Modbus addresses.

12. 4. 3 Password

You can use a password to block access to

the configuration. Then it is only possible

to change the configuration directly on the

device after entering the password.

The password consists of a 5-digit combination of numbers.

Settings range:

• 1-99999 = with password

• 0 = without password

Default:

• 0 = without password

No password (0) is programmed as the factory preset default setting.

40

Fig. View "Configuration,"

Selection "System"

You must know the current password to

change a previously created password.

Remember and note the password.

Set password:

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the menu

item "System" from the configuration

menu.

• Confirm by pressing key 6 (Enter).

• With keys 3 () and 4 (), select the

submenu "Password" and confirm your

selection with key 6 (Enter).

Page 41

www.janitza.de UMG 96-PA

12. 4. 4 Reset

This area makes it possible to delete and

reset measurement values and device parameters.

Energy

You can delete all of the energy counters in

the device at once. It is not possible to select

Fig. View "System,"

Selection "Password"

• With the keys 2 to 5 (), set the

password you would like to use.Use keys 2

() and 5 () to set the digit position.

With keys 3 () and 4 () change the digit

(-1 / +1).

• Confirm by pressing key 6 (Enter) or abort

the action by pressing key 1 (Esc).

• Exit the view "System" with key 1 (Esc).

• Exit the configuration menu with key 1

(Esc).

• Open the main menu with key 1 (Esc).

• Select the measurement value display you

want with keys 3 () and 4 (). Confirm

your selection by pressing key 6 (Enter) or

jump directly to the measurement value

display "Overview" by pressing key 1 (Esc).

certain energy counters.

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the menu

item "System" from the configuration

menu.

• Confirm by pressing key 6 (Enter).

• With keys 3 () and 4 (), select the submenu "Reset" and confirm your selection

with key 6 (Enter).

• With keys 3 () and 4 (), select the function you want.

C

ATTENTION!

Remember and note the password.

No device settings can be changed

if you do not know the password.

If you lose the password, contact

support!

Fig. View "Reset,"

Reset the energy counters

• Confirm the details by pressing key 6

(Enter).

• With keys 3 () and 4 (), select the option you want "Yes," or "No."

• Confirm by pressing key 6 (Enter) or abort

the action by pressing key 1 (Esc).

• Exit the view "Reset" with key 1 (Esc).

• Exit the view "System" with key 1 (Esc).

• Exit the configuration menu with key 1

(Esc).

• Open the main menu with key 1 (Esc).

41

Page 42

UMG 96-PA www.janitza.de

• Select the measurement value display you

want with keys 3 () and 4 (). Confirm

your selection by pressing key 6 (Enter) or

jump directly to the measurement value

display "Overview" by pressing key 1 (Esc).

Min./Max. values

You can delete all of the minimum and maximum values in the device at once. It is not

possible to select certain energy counters.

ATTENTION!

C

Delete any production-related energy

counter contents, minimum and maximum values, and recordings prior to

putting the device into service.

• Exit the configuration menu with key 1

(Esc).

• Open the main menu with key 1 (Esc).

• Select the measurement value display you

want with keys 3 () and 4 (). Confirm

your selection by pressing key 6 (Enter) or

jump directly to the measurement value

display "Overview" by pressing key 1 (Esc).

Factory settings

In "Factory settings" you can reset all settings, as well as the configuration and the

recorded data back to the factory presets.

Fig. Menu "Reset,"

Delete min./max. values

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the menu

item "System" from the configuration

menu.

• Confirm by pressing key 6 (Enter).

• With keys 3 () and 4 (), select the submenu "Reset" and confirm your selection

with key 6 (Enter).

• With keys 3 () and 4 (), select the function "Min./Max. Values" and confirm your

selection with key 6 (Enter).

• With keys 3 () and 4 (), select the option you want "Yes," or "No."

• Confirm by pressing key 6 (Enter) or abort

the action by pressing key 1 (Esc).

• Exit the view "Reset" with key 1 (Esc).

• Exit the view "System" with key 1 (Esc).

Fig. Menu "Reset,"

Load factory settings

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the menu

item "System" from the configuration

menu.

• Confirm by pressing key 6 (Enter).

• With keys 3 () and 4 (), select the submenu "Reset" and confirm your selection

with key 6 (Enter).

• With keys 3 () and 4 (), select the function "Factory settings" and confirm your

selection with key 6 (Enter).

• With keys 3 () and 4 (), select the option you want "Yes," or "No."

• Confirm by pressing key 6 (Enter) or abort

the action by pressing key 1 (Esc).

• Confirm the warning notification by pressing key 6 (Enter) or abort the action by

pressing key 1 (Esc).

• The device restarts.

42

Page 43

www.janitza.de UMG 96-PA

Restart

To manually restart the device, proceed as

follows:

Fig. Menu "Reset,"

Restart device

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the menu

item "System" from the configuration

menu.

• Confirm by pressing key 6 (Enter).

• With keys 3 () and 4 (), select the submenu "Reset" and confirm your selection

with key 6 (Enter).

• With keys 3 () and 4 (), select the function "Restart" and confirm your selection

with key 6 (Enter).

• With keys 3 () and 4 (), select the option you want "Yes," or "No."

• Confirm by pressing key 6 (Enter) or abort

the action by pressing key 1 (Esc).

• The device restarts.

12. 5 Display

Use this menu item to adjust the display settings on the device:

• Brightness

• Standby after

• Brightness (standby)

Fig. Menu "Display,"

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the

menu item "Display" from the configuration

menu.

• Confirm by pressing key 6 (Enter).

• With keys 3 () and 4 (), select the submenu you want and confirm your selection

with key 6 (Enter).

• Use keys 2 to 5 () to set the display value.

Set the digit position with keys 2 () and

5 ().

With keys 3 () and 4 () change the digit

(-1 / +1).

• Confirm by pressing key 6 (Enter) or abort

the action by pressing key 1 (Esc).

• Exit the menu "Display" with key 1 (Esc).

• Exit the configuration menu with key 1

(Esc).

• Open the main menu with key 1 (Esc).

• Select the measurement value display you

want with keys 3 () and 4 (). Confirm

your selection by pressing key 6 (Enter) or

jump directly to the measurement value

display "Overview" by pressing key 1 (Esc).

43

Page 44

UMG 96-PA www.janitza.de

12. 5. 1 Brightness

Set the display brightness of your device.

• Settings range: 30 - 100

Default: 70

with 30% = dark

100 % = very bright

12. 5. 2 Standby

Set the time in seconds after which the display brightness switched to the set standby

brightness.

• Settings range: 60 - 3600

Default: 900

12. 5. 3 Brightness (standby)

Set the display brightness that the device will

switch to after the standby time has expired.

• Settings range: 20 - 60

Default: 30

with 20% = dark

60 % = very bright

12. 6 Colors

Set the colors that show the current and voltage in the graphical displays.

Fig. Menu "Colors,"

• Open the configuration menu (see Section

12 "Configuration").

• With keys 3 () and 4 (), select the menu

item "Colors" from the configuration menu.

• Confirm by pressing key 6 (Enter).

• With keys 3 () and 4 (), select the option you want and confirm your selection

with key 6 (Enter).

• Set the color with keys 3 () and 4 () .

• Confirm by pressing key 6 (Enter) or abort

the action by pressing key 1 (Esc).

• Exit the menu "Color" with key 1 (Esc).

• Exit the configuration menu with key 1

(Esc).

• Open the main menu with key 1 (Esc).

• Select the measurement value display you

want with keys 3 () and 4 (). Confirm

your selection by pressing key 6 (Enter) or

jump directly to the measurement value

display "Overview" by pressing key 1 (Esc).

44

Page 45

www.janitza.de UMG 96-PA

13. Putting the device into service

This section will explain everything you need

to know about putting the device into service

for the first time.

13. 1 Supply voltage

To connect the supply voltage, proceed as

follows:

1. Connect the supply voltage to a terminal

on the back of the device.

2. After connecting the supply voltage, the

first measurement value display "Overview" will appear on the display a few

seconds later.

3. If no display appears, check whether the

supply voltage is within the rated voltage

range.

Material damage may

m

CAUTION!

Noncompliance with the connection requirements may result in your device being

damaged or destroyed.

For this reason, please note the following:

• Comply with the details on voltage and

frequency on the ratings plate.

• Do not use the device to measure direct voltage.

result from failure to

comply with the

connection requirements.

13. 2 Measured voltage

Voltage measurements in networks with rated

voltages above the maximum stated rated

voltage (cf. Section 6.2 Rated Voltages) are to

be connected via voltage transformers.

To connect the measured voltage, proceed as

follows:

1. Connect the supply voltage to a terminal

on the back of the device.

2. After the measured voltage has been connected, the measurement values displayed

by the device for the voltages L-N and L-L

will have to match those at the measurement input.

3. Consider any utilized voltage transformer

factors.

c

WARNING!

If the device is exposed to voltage surges

above the admissible overvoltage category,

safety-related insulations in the device may

be damaged, whereupon the safety of the

product can no longer be guaranteed.

Only use the device in environments in

which the admissible surge voltage is not

exceeded.

Risk of injury from

electric voltage!

ATTENTION!

C

Delete any production-related energy

counter contents, minimum and maximum values, and recordings prior to

putting the device into service.

45

Page 46

UMG 96-PA www.janitza.de

13. 3 Frequency measurement

To perform this measurement, the device

requires the network frequency, which can be

either supplied by the user or automatically

determined by the device (cf. Section "Configuration").

• The device can only determine the network

frequency if there is a voltage L1-N greater than 20 Veff (4-wire measurement) or a

voltage L1-L2 greater than 34 Veff (3-wire

measurement) at the voltage measurement

input V1.

• The network frequency needs to be within

the range of 45 Hz to 65 Hz.

• If the measurement voltage is not sufficiently high, the network frequency cannot be determined, and subsequently no

measurement can be performed.

More information can be found in Section 12

Configuration / Rated frequency"

13. 4 Rotary field direction

To do this, open the menu display "Phasor

diagram":

• If you are not in the measurement value

display "Overview," switch to this view by

repeatedly pressing key 1 (Esc).

• Open the main menu with key 1 (Esc).

• With keys 3 () and 4 (), select "Pointer

diagram" and confirm your selection with

key 6 (Enter).

Fig. Main menu,

Selection "Phasor diagram"

Check the direction of the voltage rotary field

on the measurement value display of the

device.

• A "right" rotary field is usually available.

UL1-UL2-UL3 = right rotary field

UL1-UL3-UL2 = left rotary field

Fig. Presentation of the phase sequence

according to the rotary field direction.

46

Page 47

www.janitza.de UMG 96-PA

u

i

u

i

u

i

13. 4. 1 Phasor diagram basics

The phasor diagram graphically describes

the phase shift / phase angle between the

voltage and the current. The pointer rotates

around an origin point at a constant speed proportionally to the frequency of the voltage

and the current. The pointer diagram therefore describes the current

status of the quantities in an alternating current circuit.

Representation of Ohmic resistance:

• Voltage and current have the same phase

u

i

Representation of inductance:

• The voltage rushes ahead of the current

• In an "ideal coil," the phase shift is 90°

Representation of capacity:

• The current rushes ahead of the voltage

• In an "ideal condenser," the phase shift is

90°

i

u

In a combination of states, the phase angle

"current to voltage" values can range from

-90° to +90°.

Current: Display with

short pointers

Voltage: Display with

I

long pointers

U

u

i

Example of a phasor diagram (3-phase)

UL2

IL2

UL2

IL1

UL1

IL3

The voltage and the current are pushed

against each other. The current rushes ahead

of the voltage, i.e. the network has a capacitive load.

47

Page 48

UMG 96-PA www.janitza.de

Voltage and current input monitoring in

pointer diagrams:

The phasor diagram can be used to check

for incorrect connections to the voltage and

current inputs.

Example 1

Primarily Ohmic load.

Voltage and Current only

have minor difference

in the phase.

• The current measurement input is assigned

to the correct voltage measurement input.

Example 2

Primarily Ohmic load.

Voltage and Current only

have a difference of about

180° in the phase.

13. 5 Measurement current

The device:

• is designed to be connected to current

transformers with secondary currents of

../1 A and ../5 A.

• does not measure direct currents.

• has current measurement inputs that can

be loaded with 60 A (sinusoidal) for 1

second.

The factory preset current transformer ratio

is 5/5 A, and may need to be adjusted to the

current transformer in use.

1. Short-circuit all of the current transformer

outputs except for one.

2. Compare the current indicated on the device with the attached input current.

• The currents must match when the current

transformer conversion ratio is accounted

for.

• The device must show approx. zero amperes in the short-circuited current measurement inputs.

48

• The measurement current input is assigned

to the correct voltage measurement input.

• In the present current measurement, the

connections k and I are switched or energy

is being fed back into the supply network.

Fig. phasor diagram

C

ATTENTION!

Voltages and currents outside of the

admissible measurement range can

destroy the device.

Page 49

www.janitza.de UMG 96-PA

13. 6 Measurement range violation

The device display shows the warning "Measurement range violation" in the event of a

measurement range violation and indicates

the current/voltage path.

Measurement range violations are displayed

for as long as they continue and cannot be

acknowledged. There is a measurement

range violation if at least one of the voltage or

current measurement inputs is outside of its

specified measurement range.

Thresholds for measurement range violation

(200 ms effective values):

I = 6 A rms

UL-N = 600 V rms

13. 7 Checking the power measurement

Short-circuit all current transformer outputs

except one and check the displayed power

outputs.

• The device may only display one power

output in the phase with the current converter input that is not short-circuited.

• If this does not apply, check the connection of the measurement voltage and

measurement current.

If the amount of effective power is correct but

the sign of effective power is negative, this

may have two causes:

1. The connections S1(k) and S2(l) are

switched on the current transformer.

2. Effective power is returned to the network.

Fig. Warning with measurement range

violations in the current and voltage

paths I1-I3 and U1-U3

Fig. The pointer diagram displays

voltages with long pointers and currents

with shorter pointers

Open the pointer diagram with information on

the power:

• If you are not in the measurement value

display "Overview," switch to this view by

repeatedly pressing key 1 (Esc).

• Open the main menu with key 1 (Esc).

• With keys 3 () and 4 (), select "Pointer

diagram" and confirm your selection with

key 6 (Enter).

49

Page 50

UMG 96-PA www.janitza.de

13. 8 Checking communication

The device counts all received (RX), all sent