Page 1

Part no. 33.03.217

Power Quality Analyser

UMG 509-PRO

User manual and technical data

Doc. no. 2.059.011.2.g 01/2019

www.janitza.com

Janitza electronics GmbH

Vor dem Polstück 6

D-35633 Lahnau

Support tel. +49 6441 9642-22

Fax +49 6441 9642-30

E-mail: info@janitza.com

www.janitza.com

Page 2

UMG 509-PRO www.janitza.de

1. Contents

1. General 1

1. 1 Disclaimer 1

1. 2 Copyright notice 1

1. 3 Technical changes 1

1. 4 Declaration of conformity 1

1. 5 Comments on the manual 1

1. 6 Meaning of symbols 1

2. Safety 3

2. 1 Safety information 3

2. 2 Safety measures 4

2. 3 Qualified staff 4

3. Proper use 5

3. 1 Inspection on receipt 5

3. 2 Scope of delivery 6

3. 3 Available accessories 6

4. Product description 7

4. 1 Measuring process 7

4. 2 Usage concept 7

4. 3 GridVis® network analysis software 7

4. 4 Features 8

4. 5 Product overview 9

5. Installation 11

5. 1 Installation location 11

5. 2 Installation position 11

5. 3 Mounting 11

6. Network systems 13

6. 1 Three-phase 3-conductor systems 14

6. 2 Three-phase 4-conductor systems 14

6. 3 Rated voltages 15

6. 3. 1 Three-phase 4-conductor network with earthed neutral conductor 15

6. 3. 2 Three-phase 3-conductor network, non-earthed 15

I

Page 3

www.janitza.de UMG 509-PRO

7. Installation 17

7. 1 Connection to a PC 17

7. 2 Ground wire connection 18

7. 3 Disconnectors 18

7. 4 Supply voltage 18

7. 5 Measured voltage 19

7. 5. 1 Overvoltage 19

7. 5. 2 Frequency 19

7. 6 Current measurement 20

7. 6. 2 Current direction 21

7. 6. 3 Total current measurement 21

7. 6. 1 Ammeter 21

7. 7 Connection variants 22

7. 7. 1 Voltage measurement 22

7. 7. 2 Current measurement 23

7. 7. 3 Supporting measurement, input V4 24

7. 8 Residual current monitoring 25

7. 8. 1 Failure monitoring 25

7. 8. 2

Example: Residual current transformer insulation 26

7. 9 Temperature measurement 27

7. 9. 1 Example: Temperature sensor insulation 27

8. Interfaces 29

8. 1 Shielding 29

8. 2 RS485 interface 30

8. 2. 1 Termination resistors 30

8. 3 Profibus interface 31

8. 3. 1 Connecting the bus lines 31

8. 4 Bus structure 32

8. 5 Ethernet interface 33

9. Digital inputs and outputs 35

9. 1 Digital inputs 35

9. 1. 1 S0 pulse input 36

9. 2 Digital outputs 37

10. Operation 39

10. 1 Button allocation 39

10. 2 “Home" measured value indication 39

10. 3 Measured value indication 40

10. 3. 1 Main values 40

10. 3. 2 By-values 40

10. 4 Selecting a measured value indication 41

10. 5 View additional information 42

10. 6 Deleting values 42

10. 7 Transients list 43

10. 8 Event list 44

II

Page 4

UMG 509-PRO www.janitza.de

11. Configuration 45

11. 1 Languages 45

11. 2 Communication 45

11. 2. 1 Ethernet(TCP/IP) 45

11. 2. 2 Field bus 46

11. 3 Measurement 47

11. 3. 1 Measuring transducer 47

11. 3. 2 Transients 51

11. 3. 3 Events 53

11. 3. 4 Mains frequency 54

11. 4. 2 Temperature 55

11. 4 System 55

11. 4. 1 Password 56

11. 4. 3 Reset 56

11. 5 Display 58

11. 6 Colours 59

11. 7 Extensions 59

12. Commissioning 61

12. 1 Connecting the supply voltage 61

12. 2 Connecting the measured voltage 61

12. 3 Frequency measurement 62

12. 4 Phase sequence 62

12. 5 Applying the measured current 63

12. 5. 1 Phasor diagram examples 64

12. 6 Applying the residual current 64

12. 7 Failure monitoring (RCM) 65

12. 7. 1 Alarm status 65

12. 8 Measurement range exceeded 66

12. 9 Checking the power measurement 66

12. 10 Checking the communication 66

12. 11 Communication in the bus system 67

12. 11. 1 RS485 67

12. 11. 2 Profibus 68

12. 12 Digital inputs/outputs 73

12. 12. 1 Digital inputs 73

12. 12. 2 Pulse output 73

III

Page 5

www.janitza.de UMG 509-PRO

13. Device homepage 77

13. 1 Measured values 78

13. 1. 1 Short overview 78

13. 1. 2 Detailed measured values 79

13. 1. 3 Diagrams 80

13. 1. 4 RCM - residual current monitoring 80

13. 1. 5 Events 81

13. 1. 6 Transients 81

13. 2 Power quality 82

13. 3 Apps 83

13. 3. 1 Push Service 83

13. 4 Information 84

13. 4. 1 Device information 84

13. 4. 2 Display 84

13. 4. 3 Downloads 84

14. Service and maintenance 85

14. 1 Repair and calibration 85

14. 2 Front film 85

14. 3 Disposal 85

14. 4 Service 85

14. 5 Device calibration 85

14. 6 Calibration intervals 85

14. 7 Firmware update 85

14. 8 Battery 86

15. Procedure in the event of faults 87

16. Technical data 89

16. 1 Supply voltage 89

16. 2 Voltage and current measurement 90

16. 3 Residual current monitoring 91

16. 4 Temperature measurement input 92

16. 5 Digital inputs and outputs 93

16. 6 Interfaces 94

16. 7 Function parameters 95

16. 8 Dimension diagrams 96

17. Menu guide overview 97

17. 1 Configuration menu overview 97

17. 2 Overview of measured value indications 98

18. Connection example 101

IV

Page 6

UMG 509-PRO www.janitza.de

1. General

1. 1 Disclaimer

Observing the information products

for the devices is the prerequisite for safe

operation and in order to obtain the specified

performance and product features. Janitza

electronics GmbH accepts no liability

for injuries to personnel, property damage

or financial losses arising due to a failure

to comply with the information products.

Ensure that your information products are

accessible and legible.

1. 2 Copyright notice

© 2017 - Janitza electronics GmbH - Lahnau.

All rights reserved.

Duplication, editing, dissemination and other

utilisation, also in part, is prohibited.

All trademarks and the resulting rights

are the property of their respective owners.

1. 3 Technical changes

• Please ensure that your device complies

with the installation manual.

• Please read and understand

the documents enclosed with the product

first.

• Keep the documents enclosed with

the product available throughout the entire

service life of the product and pass them

on to subsequent users if applicable.

• Inform yourself of any new device versions

and the associated updates to the

documentation enclosed with the product

at www.janitza.de.

1. 4 Declaration of conformity

For information on the laws, standards and

directives that Janitza electronics GmbH has

applied for the device, see the declaration

of conformity on our website

(www.janitza.de).

1. 5 Comments on the manual

We welcome your comments. If anything

in this manual seems unclear, please let

us know by sending us an e-mail to:

info@janitza.de

1. 6 Meaning of symbols

This manual uses the following pictograms:

Ground wire connection.

Inductive.

The current lags behind the voltage.

Capacitive.

The voltage lags behind the current.

1

Page 7

www.janitza.de UMG 509-PRO

2

Page 8

UMG 509-PRO www.janitza.de

2. Safety

Please read this user manual and all other

publications that must be consulted to work

with this product. This applies particularly

to installation, operation and maintenance.

Observe all safety instructions and warnings.

Failure to comply with the instructions can

result in personal injuries and/or damage

to the product.

Any unauthorised changes or use

of this device, which go beyond

the mechanical, electrical or otherwise stated

operating limitations, can result in bodily

injury and/or damage to the product.

Any such unauthorised change constitutes

"misuse" and/or "negligence" according

to the warranty for the product and thus

excludes the warranty for covering possible

damage resulting from this.

The user manual:

• must be read before using the device.

• must be kept throughout the entire service

life of the product and be readily available

for reference.

2. 1 Safety information

Symbols used:

This symbol is used as an addition

c

C

Safety information is highlighted by a warning

triangle and is indicated as follows depending

on the degree of danger:

m

DANGER!

m

WARNING!

m

CAUTION!

to the safety instructions and warns

of an electrical hazard.

This symbol with the word note

describes:

• Procedures that do not pose

any risk of injures.

• Important information,

procedures or handling steps.

Indicates an imminent danger

that causes severe or fatal

injuries.

Indicates a potentially

hazardous situation that can

cause severe injuries or death.

Indicates a potentially

hazardous situation that can

cause minor injuries or damage

to property.

Follow additional legal and safety regulations

required for the respective application when

using the device.

3

Page 9

www.janitza.de UMG 509-PRO

2. 2 Safety measures

When operating electrical devices, certain

parts of these devices are invariably

subjected to hazardous voltage. Therefore,

severe bodily injuries or damage to property

can occur if they are not handled properly:

c

WARNING!

Severe bodily injuries or death can occur

due to dangerous voltages.

Therefore, note the following:

• Before connecting connections,

earth the device at the ground wire

connection if present.

• Hazardous voltages may be present

in all switching parts that are

connected to the power supply.

• Hazardous voltages may also

be present in the device even after

disconnecting the supply voltage.

• Provide single core conductors with

sleeves.

• Only connect screw-type terminals

with a matching number of pins

and of the same type.

• If the device is not operated according

to the documentation, protection

is no longer ensured and hazards

can be posed by the device.

• De-energise the system before

starting work.

Risk of injury due

to electric voltage!

2. 3 Qualified staff

This device must only be operated

and repaired by specialised personnel.

Specialised personnel are people who are

qualified to recognise risks and prevent

potential dangers that can be caused

by the operation or maintenance

of the device based on their respective

training and experience.

4

Page 10

UMG 509-PRO www.janitza.de

3. Proper use

3. 1 Inspection on receipt

The prerequisites of faultless, safe operation

of this device are proper transport and proper

storage, set-up and installation, as well

as careful operation and maintenance.

Packing and unpacking must be carried

out with customary care without the use

of force and only using suitable tools.

Visually inspect the devices for flawless

mechanical condition.

Please check the delivered items

for completeness before you start installing

the device.

If it can be assumed that risk-free operation

is no longer possible, the device must

be immediately put out of operation

and secured against being put back

into operation again. It can be assumed

that risk-free operation is no longer possible

if the device, for example:

C

C

NOTE!

All screw-type terminals included

in the scope of delivery are attached

to the device.

NOTE!

All supplied options and versions

are described on the delivery note.

• has visible damage.

• no longer works despite the mains power

supply being intact.

• has been exposed to prolonged

adverse conditions (e.g. storage outside

the permissible climate limits without

being adapted to the room climate,

condensation, etc.) or rough handling

during transportation (e.g. falling from

a height, even if there is no visible external

damage, etc.).

5

Page 11

www.janitza.de UMG 509-PRO

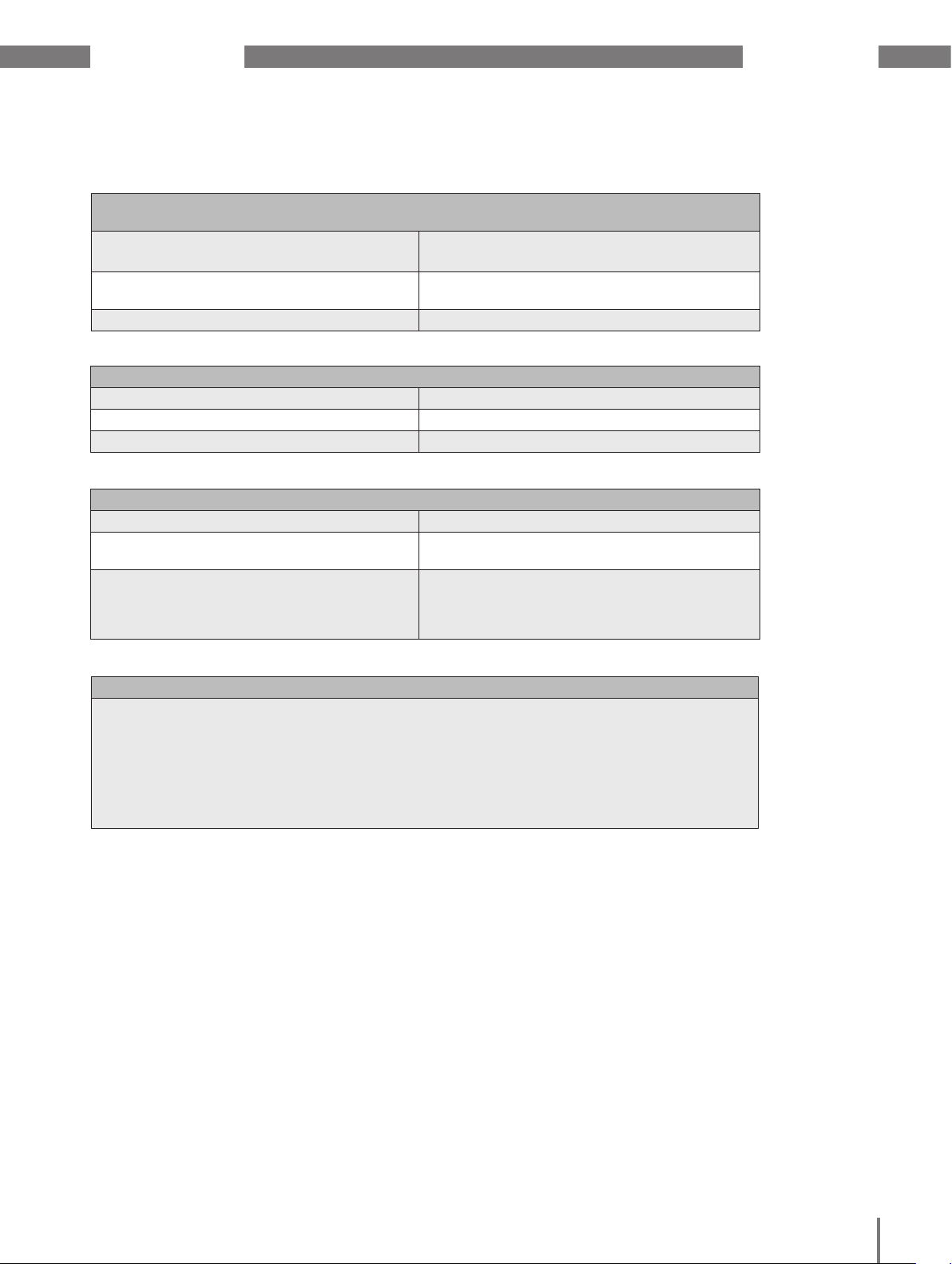

3. 2 Scope of delivery

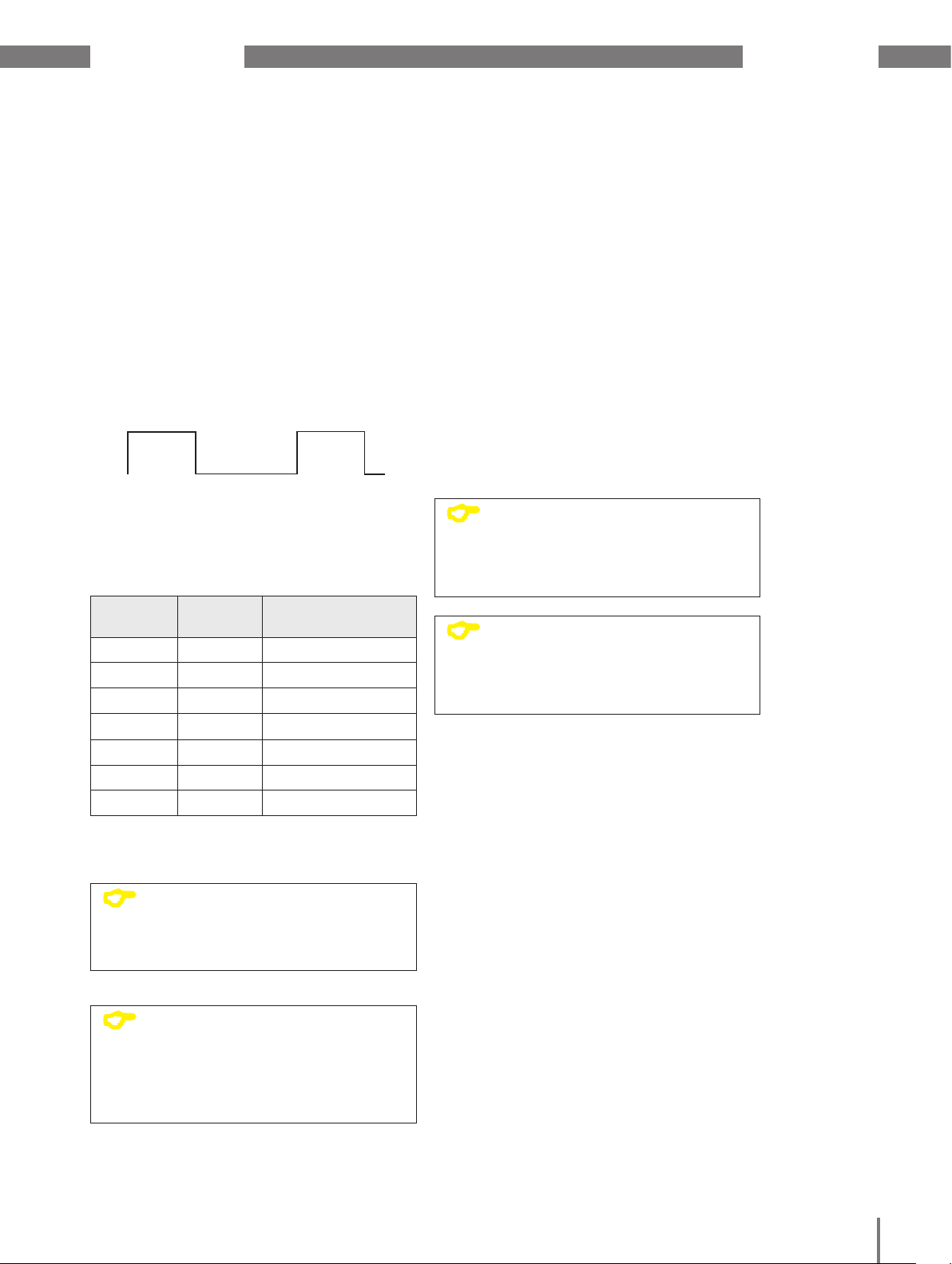

Number Part no. Designation

1 52.26.xxx

1 33.03.320 Installation manual

1 33.03.348 “GridVis software” quick guide

1 10.01.855 Screw-type terminal, pluggable, 2-pin (auxiliary supply)

1 10.01.847 Screw-type terminal, pluggable, 5-pin (voltage measurement 1-4)

1 10.01.853 Screw-type terminal, pluggable, 8-pin (current measurement 1-4)

1 10.01.873 Screw-type terminal, pluggable, 6-pin (digital inputs/outputs)

1 10.01.888 Screw-type terminal, pluggable, 7-pin (RCM, thermistor input)

1)

UMG 509-PRO

1 10.01.859 Screw-type terminal, pluggable, 3-pin (RS 485)

1 08.01.505 2m patch cable, twisted, grey (UMG PC/switch connection)

1 52.19.301 Mounting clips

1)

For the item number, see the delivery note

3. 3 Available accessories

Part no. Designation

21.01.102 CR2450 lithium battery, 3 V (approval according to UL 1642)

13.10.539 Profibus connector, 9-pin, D-SUB

13.10.543 Profibus connector, 9-pin, D-SUB, wound

29.01.903 Seal, 144 x 144

6

Page 12

UMG 509-PRO www.janitza.de

4. Product description

The device is:

• intended for measurement in building

installations, on distribution units, circuit

breakers and busbar trunking systems.

• suitable for installation in fixed

and weatherproof switchboards.

• usable in 2, 3 and 4-conductor networks

and in TN and TT networks.

• provided with external ../1 A or ../5 A

current transformers for current

measurement.

• only suitable for measurements in medium

and high-voltage networks via current and

voltage transformers.

• suitable for use in residential and industrial

applications.

• suitable for residual current monitoring

(RCM) via external residual current

transformers with a rated current of 30 mA.

• suitable for measuring measured voltages

and measured currents that derive from

the same network.

The measurement results can be displayed,

saved, read out and further processed

via the device's interfaces.

4. 1 Measuring process

The device:

• measures continuously and calculates

all effective values over a 200 ms interval.

• measures the real effective value (TRMS)

of the voltages and currents connected

to the measurement inputs.

4. 2 Usage concept

You can program and call up the measured

values via many routes using the device:

This operation manual only describes how

to operate the device using the 6 buttons.

The GridVis® network analysis software

has its own "online help".

4. 3 GridVis® network analysis software

You can use the GridVis® network analysis

software that is available at www.janitza.

de to program the device and read out

data. To do this, a PC must be connected

to the device via a serial interface (RS485/

Ethernet).

You can use the GridVis® network analysis

software to:

• program the device.

• configure and read out recordings.

• analyse the read out data according

to EN 61000-2-4.

• save the data to a database.

• display measured values graphically.

• program customer-specific applications.

c

CAUTION!

If the device is connected incorrectly,

incorrect measured values may be returned.

Therefore, note the following:

• Measured voltages and measured

currents must derive from the same

network.

• Do not use the device to measure

DC current.

• Earth active switchboards.

Malfunctions due

to incorrect connection

• directly on the device via 6 buttons

and the display.

• using the GridVis® programming

software.

• using the device homepage.

• using the Modbus protocol. You

can modify and call up the data using

the Modbus address list. The list can

be called up from www.janitza.de.

7

c

CAUTION!

Residual current monitoring monitors residual

currents via external current transformers

and can trigger a warning impulse

when a threshold value is exceeded.

The device is therefore

not anindependent protective device

against electric shocks.

Risk of injury due

to electric voltage

Page 13

www.janitza.de UMG 509-PRO

4. 4 Features

General

• Front panel integration device with dimensions 144 x 144 mm

• Connection via pluggable screw terminals

• Colour graphic display 320x240, 256 colours

• Operation via 6 buttons

• 4 voltage and 4 current measurement inputs

• 2 residual current inputs with failure monitoring

• 1 temperature measurement input

• 2 digital outputs and 2 digital inputs

• 16-bit A/D converter, memory 256 Mbyte Flash, SDRAM 32 Mbyte

• RS485 interface (Modbus RTU, slave, up to 921 kbps)

• Profibus DP/V0

• Ethernet (web server, e-mail)

• Capture more than 2000 measured values

• Clock and battery

• Working temperature range -10 °C to +55 °C

Measurement

• Measurement in TN and TT networks

• Continuous sampling of the voltage and current measurement inputs at 20 kHz

• Capture transients >50 µs and store up to approx. 330,000 sampling points

• Current metering range 0.001 to 7 Amps

• Real effective value measurement (TRMS)

• Continuous sampling of the voltage and current measurement inputs

• Continuous monitoring of residual currents with failure monitoring

• Temperature measurement

• Working measurement, measurement uncertainty in accordance

with DIN EN50470-3:

- Class C for ../5 A converter

- Class B for ../1 A converter

• Measurement of the harmonics 1st to 63rd for:

- Ull, Uln, I, P (consumption/delivery) and Q (ind./cap.)

• Analysis and evaluation in accordance with DIN EN 50160 with the GridVis®

programming software supplied as standard

• Programming separate applications in Jasic

8

Page 14

UMG 509-PRO www.janitza.de

4. 5 Product overview

1

2

Fig. Front view of UMG 509 -PRO

3

4

5

1 Device type

2 Description of the function keys

3 Button 1: Configuration menu, back

4 Button 2: Select number, switch between main values

5 Button 3: Reduce the number by 1, select menu item

6 Button 4: Increase the number by 1, select menu item

7 Button 5: Select number, switch between main values

8 Button 6: Activate input, confirm selection

8

7

6

9

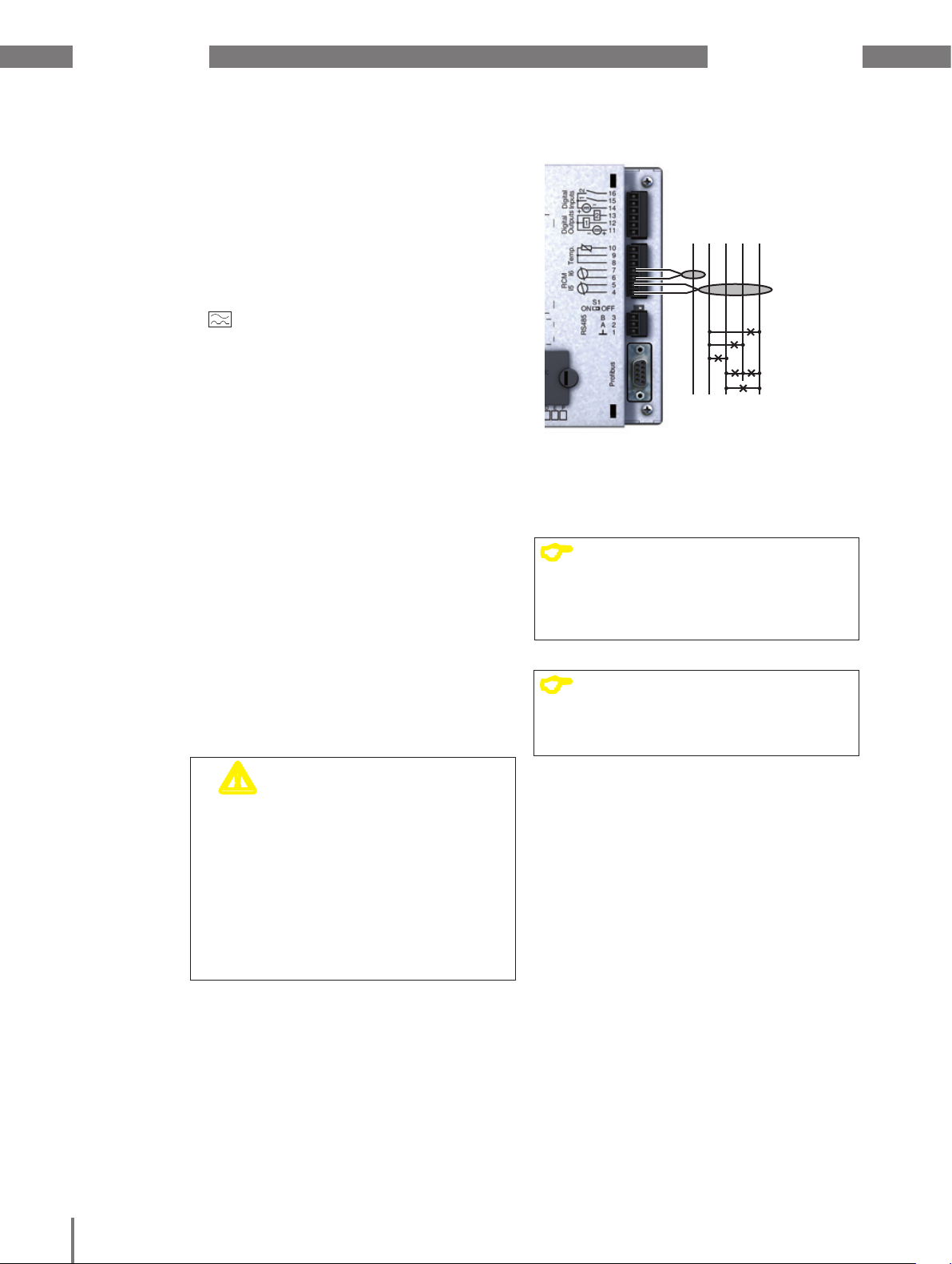

Page 15

www.janitza.de UMG 509-PRO

1

2

5

6

3

7

8

9

4

Fig. Rear view of UMG 509 -PRO

1 Ground wire connection

2 Supply voltage

3 Current measurement inputs I1 to I4

4 Voltage measurement inputs V1 to V4, Vn

5 Digital inputs / outputs

6 Thermistor inputs

7 Residual current monitoring inputs I5 and I6

8 DIP switch S1

9 RS485 interface

10 Profibus interface

11 Battery compartment

10

11

10

Page 16

UMG 509-PRO www.janitza.de

5. Installation

5. 1 Installation location

The device is suitable for installation in fixed

and weatherproof switchboards.

Earth active switchboards.

Damage to property due

m

CAUTION!

to a failure to adhere to

the installation instructions!

Failing to observe the installation instructions

can damage or destroy your device.

Adhere to the specifications for

the installation position in sections „5.

Montage“ and „16. Technische Daten“.

5. 2 Installation position

The cut-out dimension in the switchboard is

138

+0.8

mm x 138

+0.8

mm.

To ensure adequate ventilation, adhere

to the following specifications:

• install the device vertically.

• keep a gap of 50 mm at the top

and bottom.

• keep a minimum gap of 20 mm.

5. 3 Mounting

The device is mounted in the switchboard

with two mounting clips at the top

and bottom. Attach the mounting clips

to the device in advance.

Fig. Arrangement of the mounting clips on thee

UMG 509-PRO

Wall

Airflow

Airflow

Fig. Rear view of the UMG 509-PRO installation position

11

Page 17

www.janitza.de UMG 509-PRO

12

Page 18

UMG 509-PRO www.janitza.de

L1

EE

E

L1

L2

L3

E

N

R

L1

L2

L3

EE

L1

L2

L3

EE

E

L1

E

L1

L2

L3

EE

L1

L2

L3

EE

L1

EE

L1

L2

L3

EE

L1

EE

L1

L2

L3

EE

N

E

L1

L2

L3

E

N

R

L1

L2

L3

EE

L1

EE

L

N

EE

L1

L2

L3

EE

L1

L2

N

EE

E

L1

L2

L3

E

N

R

L1

L2

L3

EE

EE

L1

L2

L3

EE

L1

L2

N

EE

L1

L2

L3

EE

L1

L2

L3

EE

L1

EE

6. Network systems

Network systems and maximum rated voltages in accordance with DIN EN 61010-1/A1:

Three-phase four-conductor

systems

with earthed neutral conductor

L2

N

L3

U

/ U

L-N

L-N

/ U

L-L

L-L

: 417 VLN / 720 VLL

: 347 VLN / 600 VLL

IEC

UL

U

Dual-phase two-conductor

systems

not earthed

L2

Three-phase four-conductor

systems

with non-earthed

Three-phase three-conductor

systems

not earthed

Three-phase three-conductor

neutral conductor (IT networks)

L2

N

R

L3

L2

L3

Only partially suitable for use in non-earthed networks U

Single-phase two-conductor

systems

with earthed neutral conductor

L

N

Separated single-phase

three-conductor system

with earthed neutral conductor

N

L2

Application areas for the device:

• 2, 3 and 4 conductor

• Domestic and industrial

systems

with earthed phase

L2

L3

L-L

600 VLL

networks

(TN and TT networks).

applications.

Only partially suitable for use

in non-earthed networks

c

WARNING!

Risk of injury due

to electric voltage!

IEC

UL

U

U

L-N

L-N

480 VLN

480 VLN

IEC

UL

U

/ U

L-N

U

/ U

L-N

: 400 VLN / 690 VLL

L-L

: 347 VLN / 600 VLL

L-L

If the device is subjected to measurement

voltage surges higher than the permissible

overvoltage category, safety-relevant

insulations in the device can be damaged,

which means that the product’s safety can

no longer be guaranteed.

Only use the device in environments

13

in which the permissible measurement

voltage surge is not exceeded.

Page 19

www.janitza.de UMG 509-PRO

6. 1 Three-phase 3-conductor systems

The device is only suitable to a limited extent

for use in IT networks, as the measured

voltage relative to the housing potential

is measured and the input impedance

of the device creates residual current against

the earth. The residual current can trigger

insulation monitoring in IT networks.

The connection variants with voltage

transformers are suitable for unlimited use

in IT networks.

6. 2 Three-phase 4-conductor systems

The device can be used in three-phase

4-conductor systems (TN, TT networks)

with an earthed neutral conductor.

The bodies of the electrical system

are earthed.

Voltage measurement in the device

is designed for overvoltage category 600 V

CAT III (measurement voltage surge 6 kV).

L1

L2

L3

Impedance

Earthing of

the system

Fig. Schematic diagram, UMG 509-PRO in an IT network

without N.

L1

L2

L3

N

PE

System

earthing

600V 50/60Hz

V1

V4

4M

4M

4M

Voltage measurement

UMG 509-PRO

347V/600V 50/60Hz

V1 V3V2 Vref

V4

4M

4M

4M

Voltage measurement

UMG 509-PRO

4M

V3V2

Vref

4M

4M

Auxilliary power

L1

N

AC/DC

4M

Auxilliary power

240V

50/60Hz

AC/DC

DC

DC

Fig. Schematic diagram, UMG 509-PRO in a TN

network.

14

Page 20

UMG 509-PRO www.janitza.de

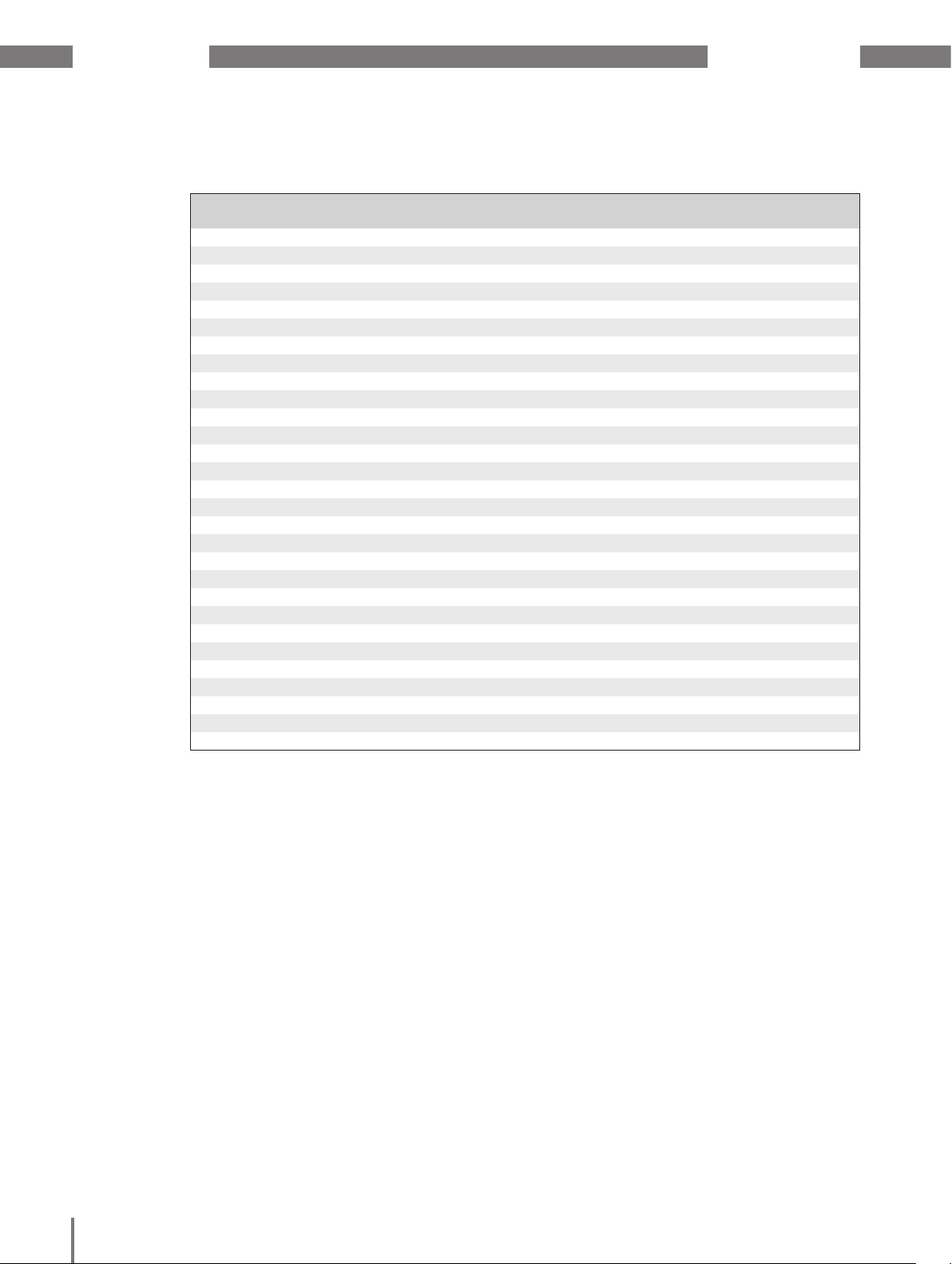

6. 3 Rated voltages

The following illustrations show lists

of networks and the corresponding rated

network voltages in which the device can

be used.

6. 3. 1 Three-phase 4-conductor network

with earthed neutral conductor

U

/ U

L-N

L-L

66V / 115V

120V / 208V

127V / 220V

220V / 380V

230V / 400V

240V / 415V

260V / 440V

277V / 480V

347V / 600V

400V / 690V

417V / 720V

Fig. Rated network voltages that are suitable for

measurement inputs in accordance with EN 60664-1:2003

Maximum network rated voltage

according to UL

Maximum network rated voltage

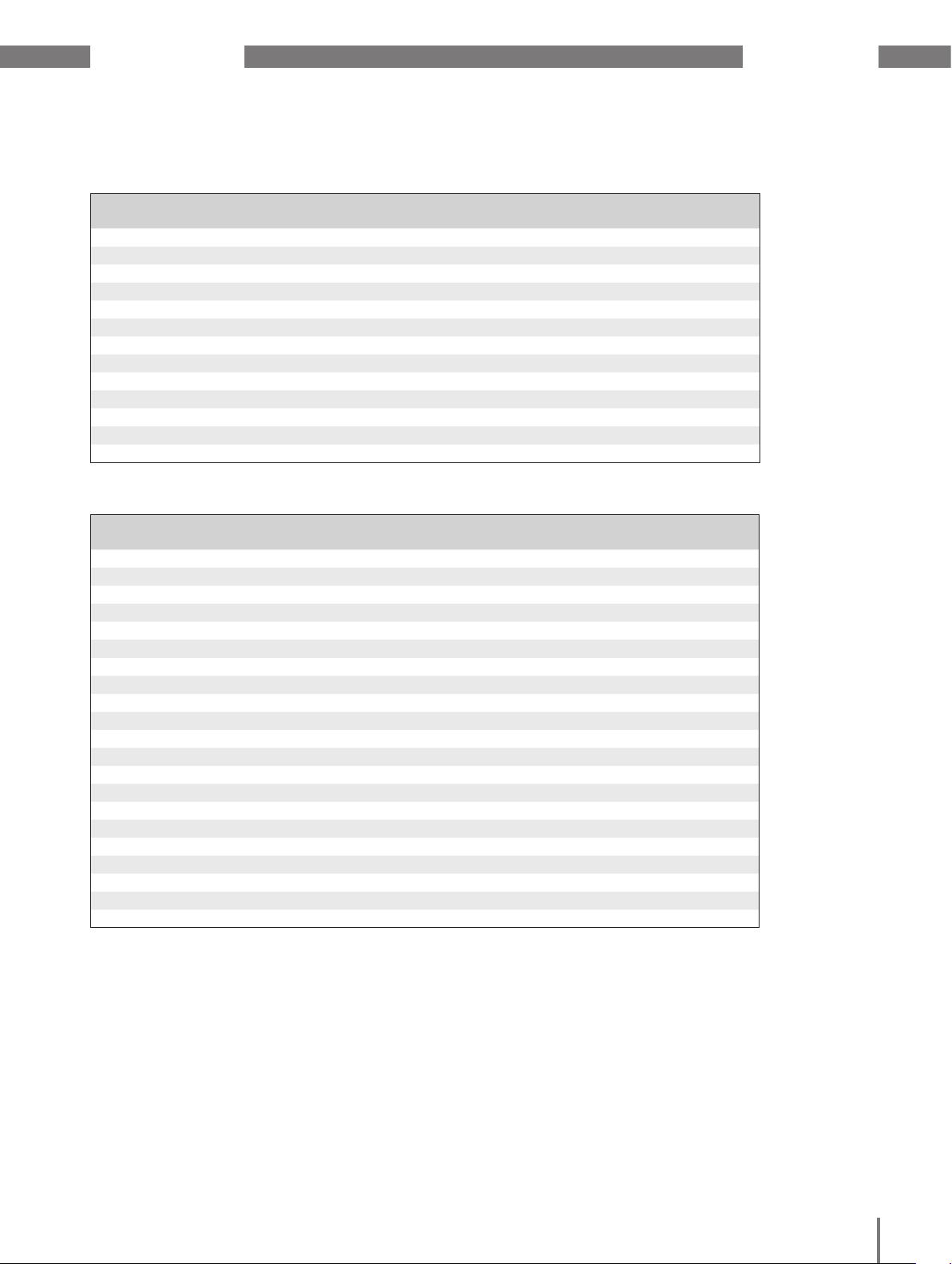

6. 3. 2 Three-phase 3-conductor

network, non-earthed

U

L-L

66V

115V

120V

127V

200V

220V

230V

240V

260V

277V

347V

380V

400V

415V

440V

480V

500V

577V

600V

Maximum network rated voltage

Fig. Rated network voltages that are suitable for

measurement inputs in accordance with EN 60664-1:2003

15

Page 21

www.janitza.de UMG 509-PRO

16

Page 22

UMG 509-PRO www.janitza.com

7. Installation

7. 1 Connection to a PC

You have the following options for connecting

the device to a PC:

1. Connection via an interface converter:

PC with GridVis®

UMG 509-PRO

RS232

RS232

RS485

RS485

3. Connection via the network:

PC with GridVis®

Ethernet

UMG 509-PRO

Ethernet

2. Direct connection via Ethernet: 4. Using the UMG 509-PRO as a gateway

for additional UMGs

PC with GridVis®

UMG 509-PRO

PC with GridVis®

17

Ethernet

UMG 509-PRO

as gateway

Ethernet

UMG 104

Slave 1

Ethernet

UMG 103

Slave 2

ModbusModbus Modbus

UMG 604

Slave 3

Page 23

www.janitza.com UMG 509-PRO

7. 2 Ground wire connection

Use a ring cable lug to connect the ground

wire connection to the device.

7. 3 Disconnectors

During building installation, provide a suitable

disconnector for the supply voltage in order

to disconnect the device from the current

and voltage.

• Install the disconnector close to the device

so that it is easily accessible to the user.

• Label the switch as a disconnection device

for this device.

7. 4 Supply voltage

The device requires supply voltage

to operate. The supply voltage type and level

for your device are specified on the rating

plate.

The supply voltage is connected via terminal

blocks on the rear of the device.

Before connecting the supply voltage, ensure

that the voltage and frequency correspond

to the details on the rating plate.

Connect the supply voltage via a UL/IEC

approved fuse.

m

CAUTION!

Failure to observe the connection conditions

can damage or destroy your device.

Therefore, note the following:

• Adhere to the specifications for voltage

and frequency on the rating plate.

• Connect the supply voltage via a fuse

in accordance with the technical data.

• Do not connect the supply voltage to

the voltage transformers.

• Provide a fuse for the neutral

conductor if the source's neutral

conductor connection is not earthed.

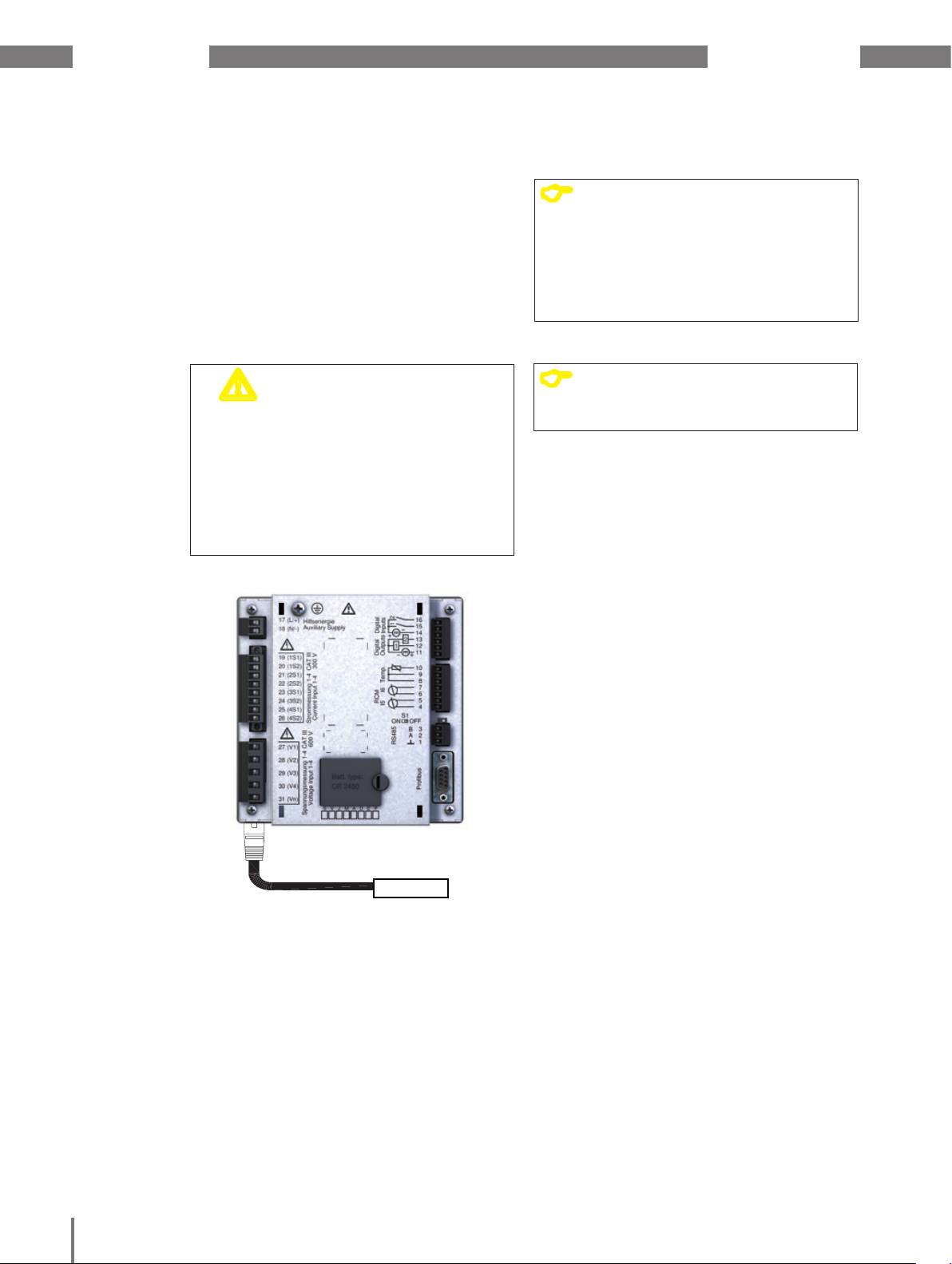

L1 N PEL3L2

Damage to property

due to not observing

the connection conditions

Connection point for the ground wire

Fuse

Isolation device

Ground wire

c

WARNING!

Severe bodily injuries or death can occur

due to:

• touching bare or stripped wires that are

live,

• device inputs that are dangerous

to touch.

Therefore, note the following:

• The inputs for the supply voltage are

hazardous if touched.

• De-energise your system before

starting the work!

• Connect the device’s ground wire

connection to the system earthing.

Risk of injury due

to electric voltage!

Fig. Example connection for the supply voltage

18

Page 24

UMG 509-PRO www.janitza.com

7. 5 Measured voltage

The device has 4 voltage measurement

inputs (V1 to V4) that are located on the rear

of the device.

• V1 to V3 for the baseline measurement.

• V4 for the supporting measurement

The connections are called supporting

and baseline measurement below.

7. 5. 1 Overvoltage

The voltage measurement inputs are suitable for

measurements in networks where overvoltages

of category 600 V CAT III can occur.

7. 5. 2 Frequency

The device:

• is suitable for measurements in networks

in which the fundamental oscillation

of the voltage is in the range of 40 Hz

to 70 Hz.

• only measures the frequency on

measurement inputs V1, V2 and V3.

c

WARNING!

Severe bodily injuries or death can occur

due to a failure to observe the connection

conditions for the voltage measurement

inputs.

Therefore, note the following:

• Do not use the device for voltage

measurement in SELV circuits

(safe extra low voltage).

• Connect the voltages higher than

the permitted network rated voltages

using voltage transformers.

• The voltage measurement inputs

on the device are dangerous

if touched!

• Install a disconnector as described

in “7. 3 Disconnectors”.

• Use a UL/IEC-approved overcurrent

protection with a rated value, which

is suitable for the short circuit current

at the connection point.

Risk of injury due

to electric voltage!

L1 N PEL3L2

10A

(UL/IEC listed)

Fig. Connection example for voltage measurement.

C

C

If the device is connected incorrectly,

incorrect measured values may be returned.

Therefore, note the following:

NOTE!

It is not necessary to configure

a connection schematic for

measurement inputs V4 and I4.

NOTE!

For measurement with the supporting

measurement, a voltage must be

connected to the baseline measurement

for frequency determination.

c

CAUTION!

• Measured voltages and currents must

derive from the same network.

• The device is not suitable

for measuring DC voltage.

Malfunction due

to incorrect connection

19

Page 25

www.janitza.com UMG 509-PRO

7. 6 Current measurement

The device:

• is intended for connecting current

transformers with secondary currents

of ../1 A and ../5 A.

• does not measure DC.

• has current measurement inputs that are

loaded with 120 A for 1 second.

The factory-set current transformer ratio

is 5/5 A and must be adapted to the current

transformer employed if necessary.

L1 N PEL3L2

S1

S2

S1

S2

S1

S2

S1

S2

m

WARNING!

to electric voltage

on current transformers!

On current transformers that are operated

open on the secondary side, high voltage

peaks that are dangerous to touch can

occur, which can cause severe bodily

injuries or death.

Therefore, note the following:

• Avoid operating the current

transformers open.

• Short circuit all unloaded current transformers.

• Connect the earthing connections

provided on the current transformer

to the earth.

• You must short circuit the secondary

connections on the current transformer

before interrupting the power supply.

• If a test switch, which automatically

short-circuits the secondary wires

of the current transformer is available,

it is sufficient to set this to the "Test"

position as long as the short-circuiting

device has been checked beforehand.

• Only use current transformers that

have a basic insulation in accordance

with IEC 61010-1:2010.

• Ensure that the attached screwtype terminal is affixed to the device

sufficiently using the two screws.

• Safe open-circuit current transformers

are also dangerous to touch when they

are operated open.

Risk of injury due

Fig. "Current measurement via current transformers"

connection example.

m

WARNING!

Risk of injury due

to electric voltage!

Temperatures of up to 80 °C can occur on

the connections if there are high measured

currents.

Therefore, use lines that are designed

for an operating temperature of at least

80 °C

20

Page 26

UMG 509-PRO www.janitza.com

7. 6. 2 Current direction

You can correct the current direction

on the device or via the existing serial

interfaces for each phase individually.

If the connection is incorrect, a subsequent

re-connection of the current transformer

is not required.

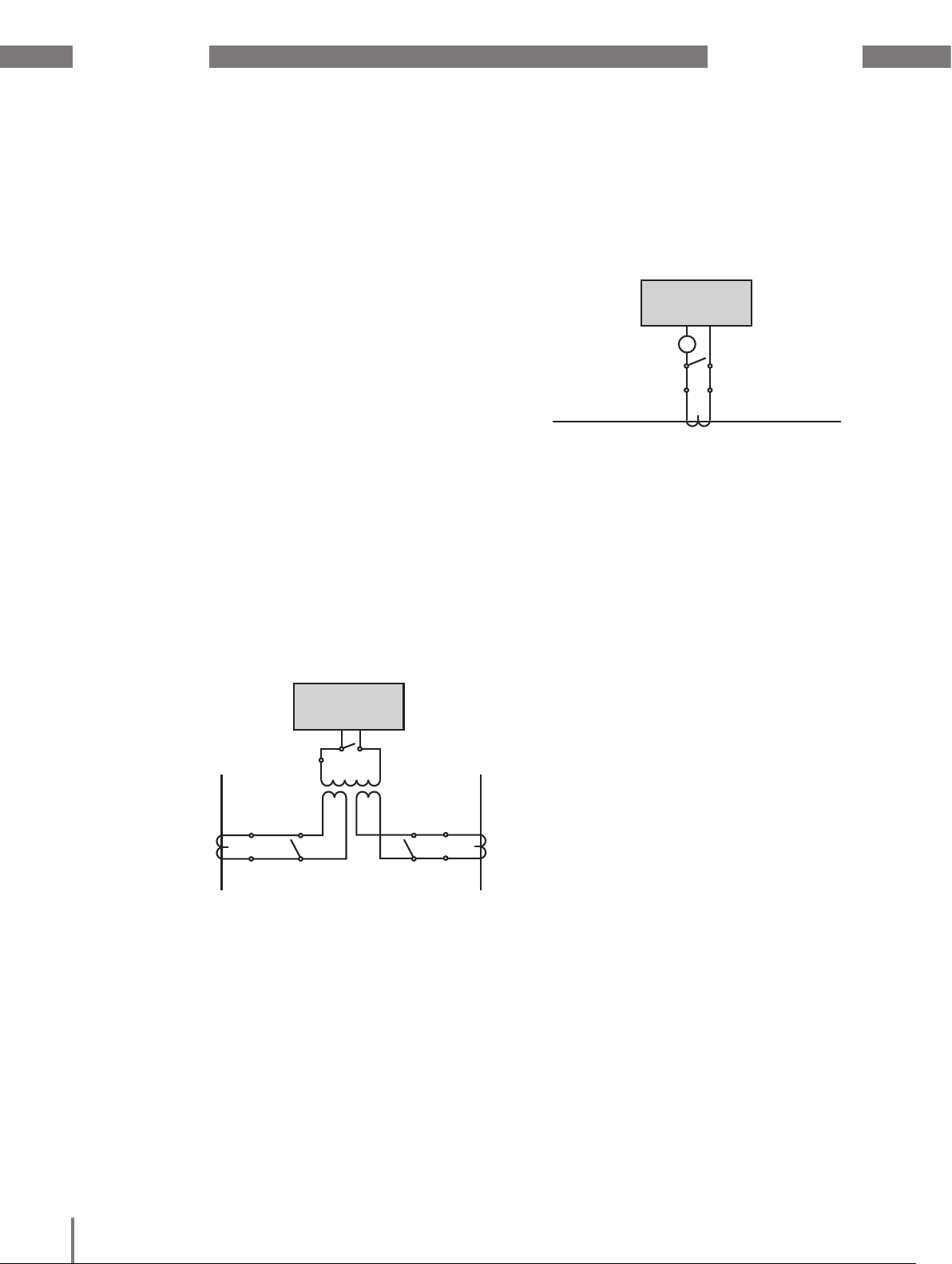

7. 6. 3 Total current measurement

For a summation measurement via two

current transformers, first set their total

transformation ratio on the device. For

information on setting the current transformer

ratios, see “11. 3. 1 Measuring transducer”.

Example:

The current is measured via two current

transformers. Both current transformers

have a transformation ratio of 1000/5 A.

The summation measurement is performed

using a 5+5/5 A total current transformer.

The device must then be set up as follows:

Primary current: 1000 A + 1000 A = 2000 A

Secondary current:

5 A

7. 6. 1 Ammeter

If you wish to measure the current not only

with the UMG but rather with an ammeter

too, connect the ammeter to the UMG

in series.

UMG

I

S2

1

S

A

Einspeisung

Supply

(k)S

1 S2(l)

2(L)(K)P1

P

Fig. Circuit diagram with additional ammeter switched

in series

Verbraucher

Consumer

UMG

I

S

S2

1

Einspeisung 1

Supply 1

1P1

(K)

(L)

1P2

Verbraucher A

Consumer A

1S1

1S

P1

1S1 1S2 2S1 2S2

(k)

(l)

2

P2

Einspeisung 2

Supply 2

2S1

(k)

(l)

2S2

Verbraucher B

Consumer B

2P

2P2

1

(K)

(L)

Fig. Example for current measurement via a total current

transformer

21

Page 27

www.janitza.com UMG 509-PRO

L1

L2

L3

N

V

1 V2 V3 V4 Vref

3p 4wu

L1

L2

L3

N

3p 4w

L1

L2

L3

N

3p 4w

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

L1

L2

L3

N

V

1 V2 V3 V4 Vref

3p 4wu

L1

L2

L3

N

V

1 V2 V3 V4 Vref

3p 4w

L1

L2

V

1 V2 V3 V4 Vref

1p 2w

L1

L2

L3

3p 2i0

L1

L2

L3

N

3p 4w

L1

L2

L3

N

V

1 V2 V3 V4 Vref

3p 4wu

L1

L2

L3

3p 2i0

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

L1

L2

L3

N

3p 4w

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

L1

L2

L3

N

V

1 V2 V3 V4 Vref

3p 4wu

L1

L2

L3

N

V

1 V2 V3 V4 Vref

3p 4w

L1

L2

V

1 V2 V3 V4 Vref

1p 2w

L1

L2

L3

3p 2i0

L1

L2

L3

N

3p 4w

L1

L2

L3

V

1 V2 V3 V4 Vref

3p 3wu

L

L

L

L

N

3p 5w

L

L

L

L

V

1 V2 V3 V4 Vref

3p 5w

N

L1

L2

L3

N

V

1 V2 V3 V4 Vref

3p 4wu

L1

L2

V

1 V2 V3 V4 Vref

1p 2w

L1

L2

L3

3p 2i0

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

L1

L2

L3

N

3p 4w

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

L

L

L

L

N

3p 5w

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

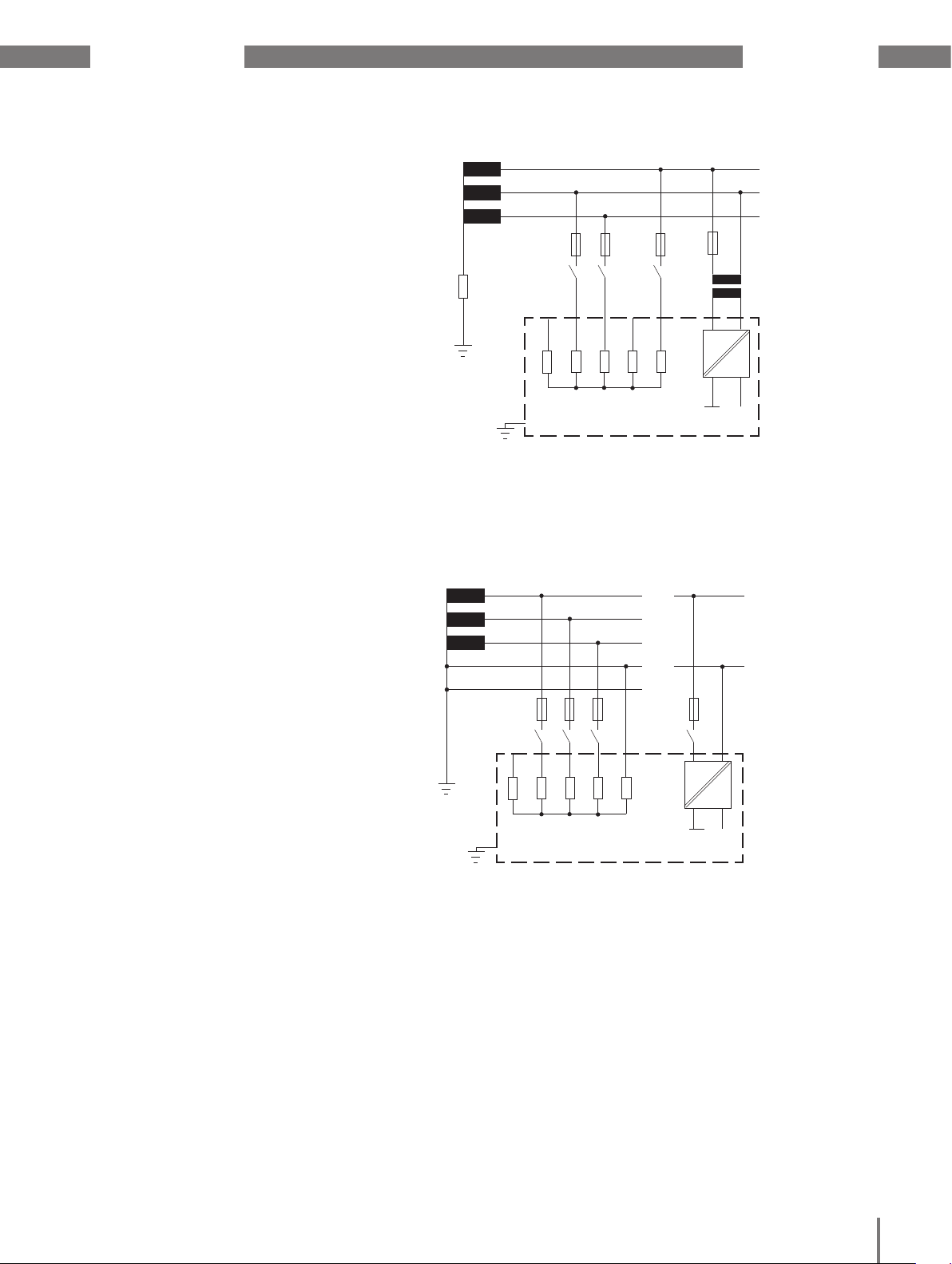

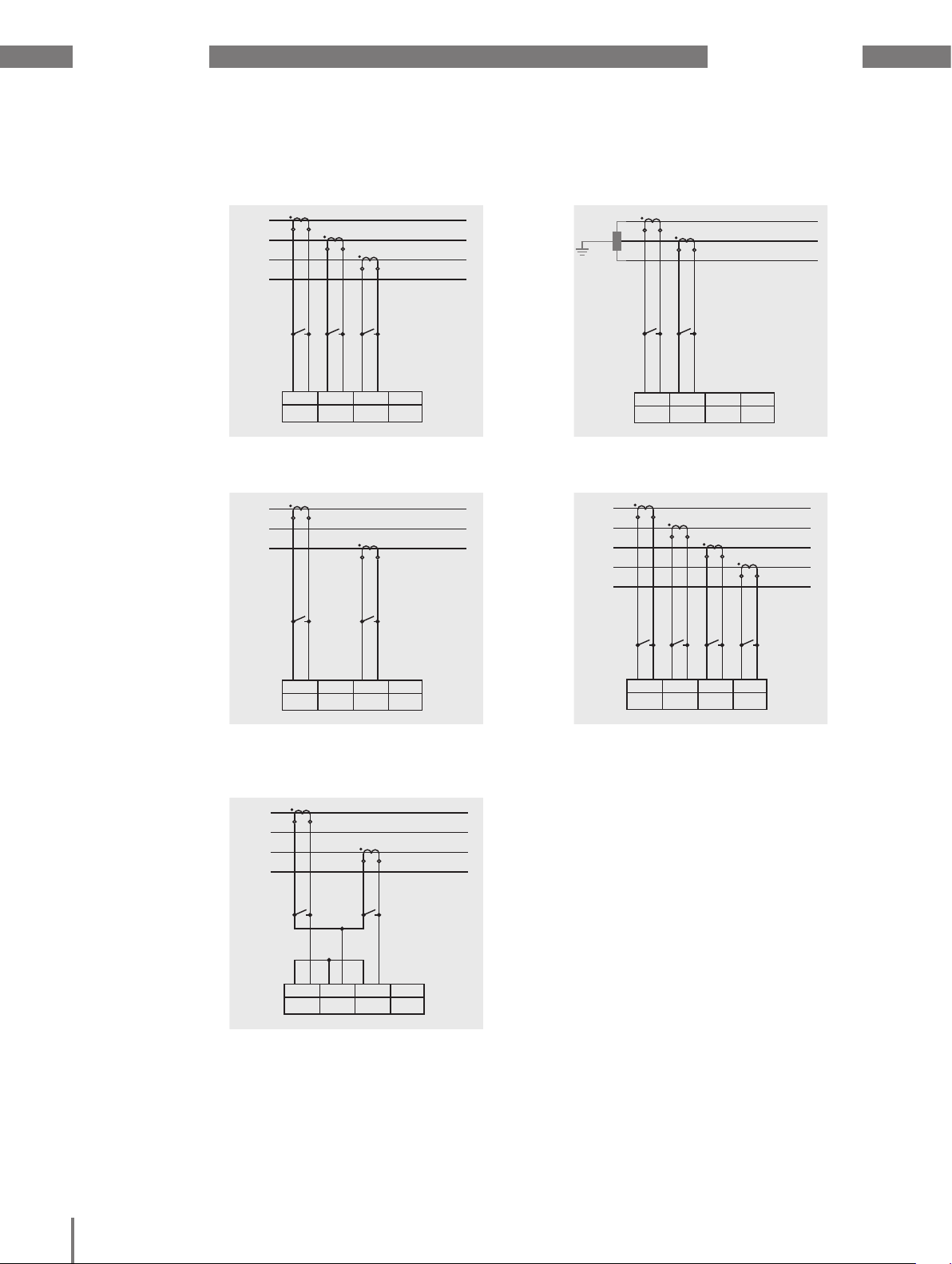

7. 7 Connection variants

7. 7. 1 Voltage measurement

L1

L1

L2

L3

L2

N

1p 2w

L1

L2

L3

3p 3w

V1 V2 V3 V4 Vref

V1 V2 V3 V4 Vref

3p 4w

Fig. Measurement in a three-phase 4-conductor network Fig. Measurement in a single-phase 2-conductor network

V1 V2 V3 V4 Vref

L1

L2

L3

3p 3wu

Fig. Measurement in a three-phase 3-conductor network

without neutral conductor

V1 V2 V3 V4 Vref

Fig. Measurement in a three-phase 3-conductor network

L1

L2

L3

Fig. Measurement in a three-phase 4-conductor network

N

3p 4wu

V1 V2 V3 V4 Vref

L

L

L

N

L

3p 5w

Fig. Measurement in a three-phase 4-conductor network

with an additional conductor

V1 V2 V3 V4 Vref

22

Page 28

UMG 509-PRO www.janitza.com

L1

L2

L3

N

3p 2i

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

L1

L2

L3

N

3p 2i

L1

L2

1p 2i

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

L1

L2

L3

N

3p 4w

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

L1

L2

L3

N

3p 2i

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

L1

L2

L3

N

3p 2i

L1

L2

L3

3p 2i0

L1

L2

1p 2i

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

L1

L2

L3

N

3p 4w

I1 I2 I3 I4

S1 S2 S1 S2 S1 S2 S1 S2

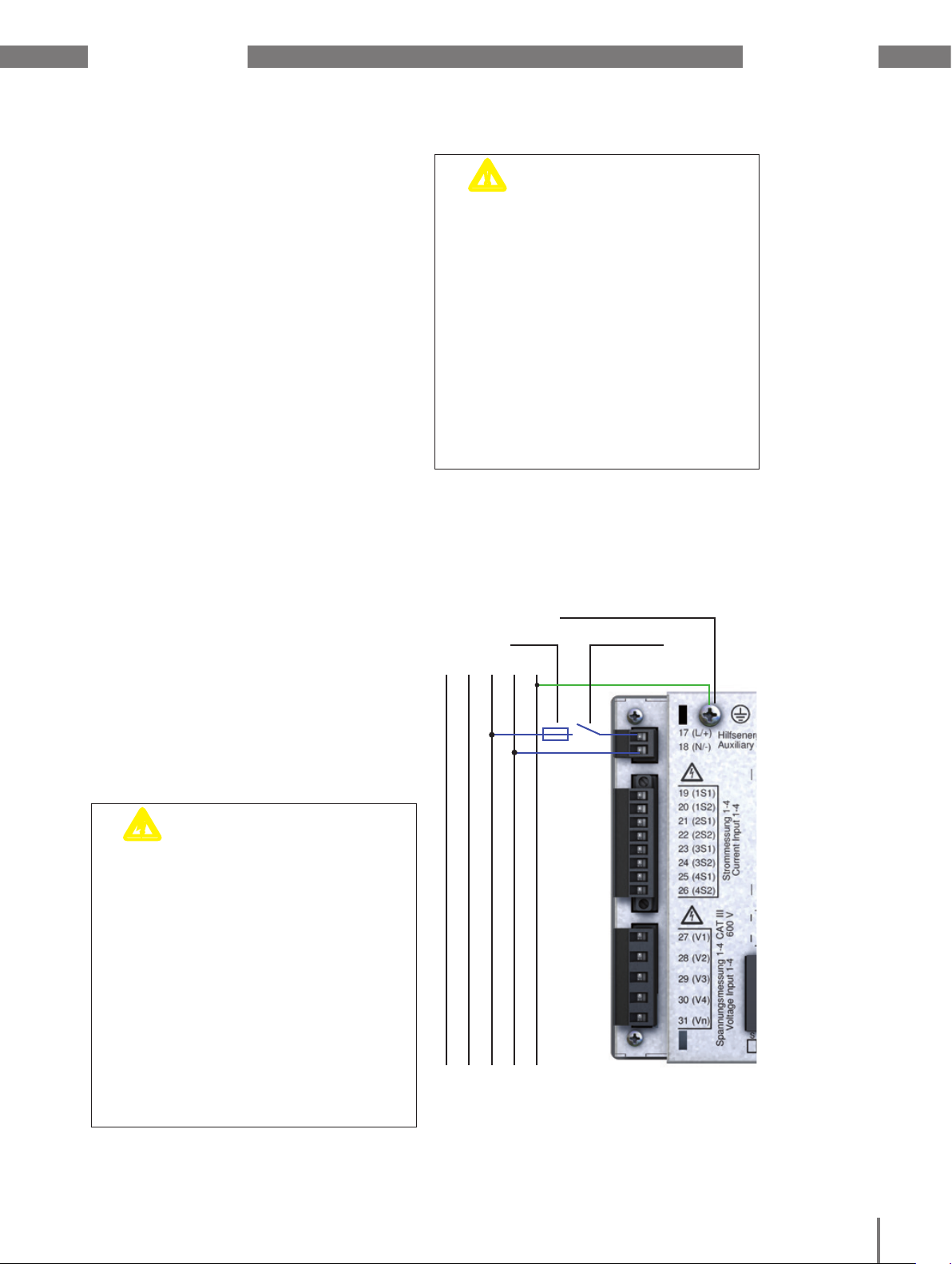

7. 7. 2 Current measurement

L1

L2

L3

N

S1 S2 S1 S2 S1 S2 S1 S2

3p 4w

Fig. Measurement in a three-phase 4-conductor network

via three current transformers

L1

I1 I2 I3 I4

L2

L3

S1 S2 S1 S2 S1 S2 S1 S2

3p 2i0

Fig. Measurement in a three-phase 3-conductor network

via two current transformers

I1 I2 I3 I4

L1

L2

S1 S2 S1 S2 S1 S2 S1 S2

1p 2i

Fig. Measurement in a single-phase 2-conductor network

via 2 current transformers

L

I1 I2 I3 I4

L

L

L

N

S1 S2 S1 S2 S1 S2 S1 S2

3p 5w

Fig. Measurement in a three-phase 4-conductor network

via four current transformers

I1 I2 I3 I4

23

L1

L2

L3

N

S1 S2 S1 S2 S1 S2 S1 S2

3p 2i

Fig. Measurement in a three-phase 4-conductor network

via two current transformers

I1 I2 I3 I4

Page 29

www.janitza.com UMG 509-PRO

L1

L2

L3

V

4 N

3w 1m

I

4

S1 S2

L1

L2

L3

N

V

4 N

4w 1m

I

4

S1 S2

L1

L2

L3

V

4 N

3w 1m

I

4

S1 S2

7. 7. 3 Supporting measurement, input V4

L1

L2

L3

N

4w 1m

Fig. Measurement in a three-phase 4-conductor

network with symmetric loading

3w 1m

V4 N

L1

L2

L3

V4 N

S1 S2

I4

S1 S2

I4

NOTE!

C

If the a baseline measurement

is connected to a three-phase

3-conductor network, the supporting

measurement can no longer be used

as a measurement input.

NOTE!

C

For measurement with the supporting

measurement, a voltage must

be connected to the baseline

measurement for frequency determination.

NOTE!

C

Measured voltages and measured

currents must derive from the same

network.

Fig. Measurement in a three-phase 3-conductor

network with symmetric loading

N

PE

2w 1n

Fig. Measurement of the voltage between N and PE.

Measurement of the current in the neutral conductor

V4 N

S1 S2

I4

24

Page 30

UMG 509-PRO www.janitza.com

7. 8 Residual current monitoring

The device:

• is suitable for use as a residual current

monitoring device (RCM) as well as for

monitoring AC, pulsing DC, and DC.

• can measure residual currents in

accordance with IEC/TR 60755 (2008-01)

of type A.

The connection of suitable external residual

current transformers with a rated current of

30 mA is performed via the residual current

transformer inputs I5 (terminals 4/5) and I6

(terminals 6/7).

7. 8. 1 Failure monitoring

The device monitors the ohmic resistance at

the residual current measurement inputs.

If this is greater than 300 Ohm, residual

current monitoring fails. This can occur due

to a cable break for example

For further information on failure monitoring,

see section “12. 7 Failure monitoring (RCM)”.

PE

Fig. “Residual current monitoring via current trans-

formers” connection variant

NOTE!

C

The transformation ratios for the

residual current transformer inputs

can be configured via the GridVis®

software. (see www.janitza.com)

NOTE!

C

It is not necessary to configure a connection schematic for measurement

inputs I5 and I6!

L2 L3N L1

Load

25

m

CAUTION!

Insufficient insulation of the operating equipment on the analogue inputs (temperature

measurement and residual current monitoring) to the mains supply circuits can cause

hazardous voltages on these inputs.

Ensure that there is reinforced or double

insulation to the mains supply circuits!

Risk of injury due to

high voltage

Page 31

www.janitza.com UMG 509-PRO

7. 8. 2 Example: Residual current transformer insulation

A residual current transformer should measure on isolated mains cables within a 300 V

CAT III network.

The insulation of the mains cables and the

insulation of the residual current transformer

must fulfil the basic insulation requirements

for 300 V CAT III. This equates to a test

voltage of 1500 V AC (duration 1 min.) for the

insulated mains cables and a test voltage of

1500 V AC (duration 1 min.) for the residual

current transformer.

L1

L2

L3

PEN

N

PE

m

CAUTION!

Transmission errors and

damage to property due to

electrical faults

If the line is longer than 30 m, there is an

increased probability of transmission errors

and damage to the device due to atmospheric discharge.

Use a shielded cable for connection to

the residual current transformer.

Residual current transformer

Residual

current

transformer

I6

L1 L2 L3 N I1 I2 I3

UMG 509-PRO

Fig. Example of a UMG 509-PRO with residual current monitoring via measuring inputs I5/I6.

c

WARNING!

Risk of injury due

to electric voltage!

I5

I4

M

3~

The Profibus, RS485, temperature measurement input and residual current monitoring

input are not galvanically separated from

each other.

Therefore, be aware that hazardous voltages on these inputs may have effects on

the other connections.

26

Page 32

UMG 509-PRO www.janitza.com

7. 9 Temperature measurement

The device has a temperature measurement

input that is designed for a maximum total

burden of 4 kOhm (sensor and cable).

The temperature is measured here via terminals 8 to 10.

PT100

Fig. Connection example for temperature measurement

with a PT100

7. 9. 1 Example: Temperature sensor

insulation

A temperature sensor in close proximity to

non-insulated mains cables should measure

within a 300 V CAT III network.

The temperature sensor must be equipped

with reinforced or double insulation for 300 V

Cat III.

VCC

PT100

10

9

8

GND

UMG 509-PRO

Fig. Schematic illustration of the connection example

m

CAUTION!

If the line is longer than 30 m, there is an

increased probability of transmission errors

and damage to the device due to atmospheric discharge.

Use a shielded cable to connect to the

temperature sensor.

c

WARNING!

The Profibus, RS485, temperature measurement input and residual current monitoring

input are not galvanically separated from

each other.

Therefore, be aware that hazardous voltages on these inputs may have effects on

the other connections.

Transmission errors and

damage to property due to

electrical faults

Risk of injury due

to electric voltage!

m

CAUTION!

Insufficient insulation of the operating equipment on the analogue inputs (temperature

measurement and residual current monitoring) to the mains supply circuits can cause

hazardous voltages on these inputs.

Ensure that there is reinforced or double

insulation to the mains supply circuits!

Damage to property due to

short circuit

27

Page 33

www.janitza.com UMG 509-PRO

28

Page 34

UMG 509-PRO www.janitza.de

8. Interfaces

The device has four interfaces that can

be used to connect it to other devices:

• RS485

• Profibus

• Ethernet

8. 1 Shielding

A twisted, shielded cable should be used

for connections via the interfaces. Note

the following when shielding:

• Earth the shields of all cables that lead

to the cabinet and at the cabinet entry.

• Connect the screens over a generous area

and in a manner that will conduct well,

to a low-noise earth.

• Gather the cables mechanically above

the earthing clamp in order to avoid

damage due to cable movements.

• Use suitable cable glands to feed

the cables into the cabinet, for example,

armoured conduit couplings.

Cable

Strain relief

Screen braid of the cable

Earthing clamp

Noiseless ground

Fig. Shielding procedure at cabinet entry.

m

CAUTION!

Atmospheric discharge can cause

transmission errors and hazardous voltages

on the device.

Therefore, note the following:

• Connect the shielding to at least one

functional earth (PE).

• If there are more significant sources

of interference, connect the shield

to the functional earth (PE) as close

as possible to the device.

• Adhere to the maximum cable length

of 12000 m at a baud rate of 38.4 K.

• Use shielded cables.

• Lay the interface lines with a spatial

separation or with additional insulation

to live system parts.

Transmission errors

and risk of injury due

to electrical faults

29

Page 35

www.janitza.de UMG 509-PRO

8. 2 RS485 interface

The RS485 interface on this device

is designed as a 3-pin plug contact and

communicates via the Modbus RTU protocol.

The cables used must be suitable for an

environmental temperature of at least 80 °C.

Recommended cable type:

• Unitronic Li2YCY(TP) 2x2x0.22 (from Lapp

Kabel)

B

A

8. 2. 1 Termination resistors

The cable is terminated with resistors (120

Ohm 1/4 W) at the beginning and at the end

of a segment.

Termination within the device is possible

via the S1 DIP switch on the device.

Correct

Incorrect

Terminal strip in the cabinet.

Device with RS485 interface.

(without termination resistor)

RS485 bus

GND data

Fig. RS485 connection example

c

WARNING!

Risk of injury due

to electric voltage!

The Profibus, RS485 and the temperature

measurement input are not galvanically

separated from each other.

Therefore, be aware that hazardous

voltages on these inputs may have

effects on the other connections.

Device with RS485 interface.

(with termination resistor on the device)

ON

OFF

S1

Fig. Termination via DIP switch activated (ON)

30

Page 36

UMG 509-PRO www.janitza.de

8. 3 Profibus interface

This 9-pin D-sub receptacle RS485 interface

supports the Profibus DP V0 slave protocol.

For a simple connection of inbound

and outbound bus wiring, connect

it to the device via a Profibus plug.

For the connection, we recommend a 9-pin

Profibus connector, e.g. type "SUBCONPlus-ProfiB/AX/SC" from Phoenix, item

number 2744380. (Janitza item no: 13.10.539)

D-sub

receptacle for

Profibus

Fig. Rear view UMG 509-PRO with D-sub receptacle for

Profibus

8. 3. 1 Connecting the bus lines

1. Connect the inbound bus line to terminals

1A and 1B on the Profibus connector.

2. Connect the continuing bus wiring

for the next device in line to terminals 2A

and 2B.

3. If there are no subsequent devices

in the line, terminate the bus line with

resistors by moving the switch on

the Profibus connector to ON.

UMG 509-PRO

Profibus

D-Sub,

9 pin,

socket

Fig. Profibus connector with termination resistors

Transmission

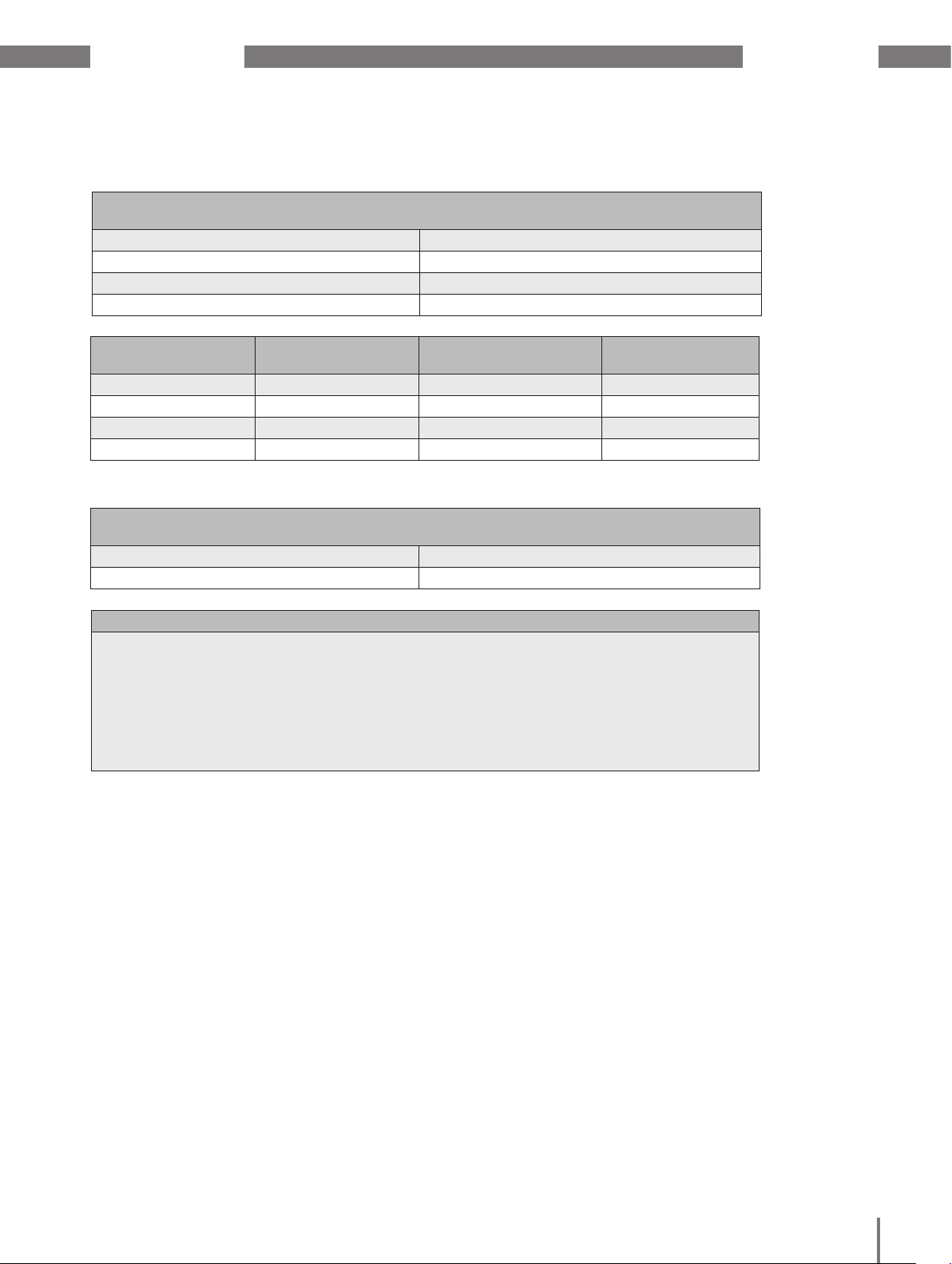

speeds in Kbit/s

9.6, 19.2, 45.45,

Profibus connector (external)

D-Sub,

9 pin,

connector

Terminating resistors

Screw-type terminals

max.

segment length

1200 m

Other

profibus

stations

93.75

187.5 1000 m

500 400 m

1,500 200 m

3000, 6000, 12000 100 m

Table Segment lengths per Profibus specification.

31

NOTE!

C

When using the device in a Profibus

system, define the device address

using the configuration menu

as described in “11. 2. 2 Field bus”!

c

WARNING!

Risk of injury due

to electric voltage!

The Profibus, RS485 and the temperature

measurement input are not galvanically

separated from each other.

Therefore, be aware that hazardous

voltages on these inputs may have

effects on the other connections.

Page 37

www.janitza.de UMG 509-PRO

8. 4 Bus structure

• All devices are connected in a bus

structure (line).

• Each device has its own address

within the bus (also see „11. 8 Profibus

Konfiguration“).

• Up to 32 participants can be connected

together in a single segment.

• The cable is terminated with resistors

(bus terminator, 120 Ohm, 1/4 W) at

the beginning and at the end of a segment.

• If there are more than 32 participants,

repeaters (amplifiers) must be used

to connect the individual segments.

• Devices for which the bus connection

is switched on must be under current.

• It is recommended that the master

be placed at the end of a segment.

• If the master is replaced with a bus

connection, the bus must be switched off.

• Replacing a slave with a bus connection

that is either switched off or de-energised

can destabilise the bus.

• Devices that are not connected

to the bus can be replaced without

destabilising the bus.

Master

T

Slave

T

Slave Slave Slave Slave

Fig. Bus structure illustration

NOTE!

C

CAT cables are not suitable for bus

wiring. Use the recommended cable

types for this.

SlaveSlaveSlave

Speisung notwendig / power supply necessary

Busabschluß eingeschaltet / bus terminator onT

Slave Slave Repeater

T

T

32

Page 38

UMG 509-PRO www.janitza.de

8. 5 Ethernet interface

The Ethernet interface is on the bottom

of the device. When connecting, ensure

that you provide a sufficient connection

area depending on the bending radius for

the Ethernet cable.

This connection area must not be smaller

than 50 mm.

m

CAUTION!

Incorrect network settings can cause faults

in the IT network.

Before connecting the device, obtain

information from your network

administrator about the correct settings

for your device.

Damage to property due to

incorrect network settings

NOTE!

C

The device is factory-set to dynamic

IP address allocation (DHCP mode).

You can change these settings as

described in “11. 2. 1 Ethernet(TCP/

IP)” or using the GridVis® software.

NOTE!

C

We recommend using at least CAT5

cables for connection.

33

Ethernet connection

Patch cable

Fig. Rear view of UMG 509-PRO with patch cable

PC/switch

Page 39

www.janitza.de UMG 509-PRO

34

Page 40

UMG 509-PRO www.janitza.de

9. Digital inputs and outputs

9. 1 Digital inputs

The device has two digital inputs.

An input signal is detected on a digital input if

a voltage of at least 18 V and maximum 28 V

DC (typically at 4 mA) is applied.

There is no input signal for a voltage of 0

to 5 V and a current less than 0.5 mA.

+

-

m

CAUTION!

Transmission errors

and damage to property

due to electrical faults

If the line is longer than 30 m, there

is an increased probability of transmission

errors and damage to the device due

to atmospheric discharge.

Use a shielded cable for connection

to the digital inputs.

UMG 509-PRO

Digital inputs 1-2

2k21

2k21

2k21

2k21

2k21

External

Auxiliary voltage

14

15

Digital

Input 1

Digital

Input 2

S1

16

S2

24V DC

-

+

Fig. Connection of digital inputs

NOTE!

C

Pay attention to the supply voltage's

polarity.

Fig. Example for connecting external contacts S1 and S2

to digital inputs 1 and 2

35

Page 41

www.janitza.de UMG 509-PRO

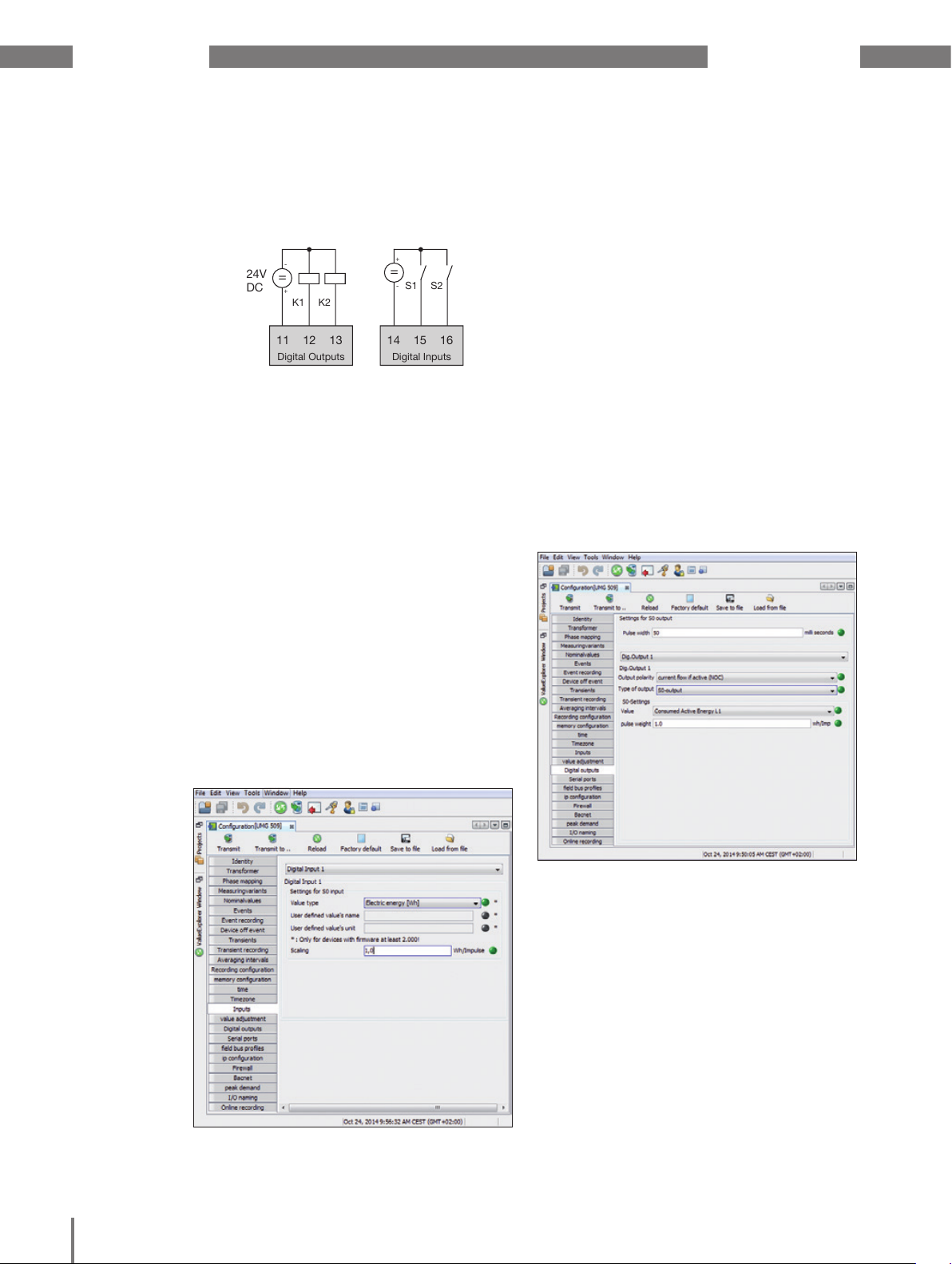

9. 1. 1 S0 pulse input

You can connect an S0 pulse transducer per

DIN EN62053-31 to any digital input.

This requires an external auxilliary voltage

with an output voltage in the range 18 to 28 V

DC and a resistor of 1.5 kOhm.

External

1.5 kOhm

transducer

24 V DC

-

S0 pulse

UMG 509-PRO

Digital inputs 1-2

2k21

2k21

2k21

2k21

2k21

Auxiliary voltage

14

15

Digital

Input 1

16

Digital

Input 2

Fig. Example for connecting an S0 pulse transducer

to digital input 1

+

36

Page 42

UMG 509-PRO www.janitza.de

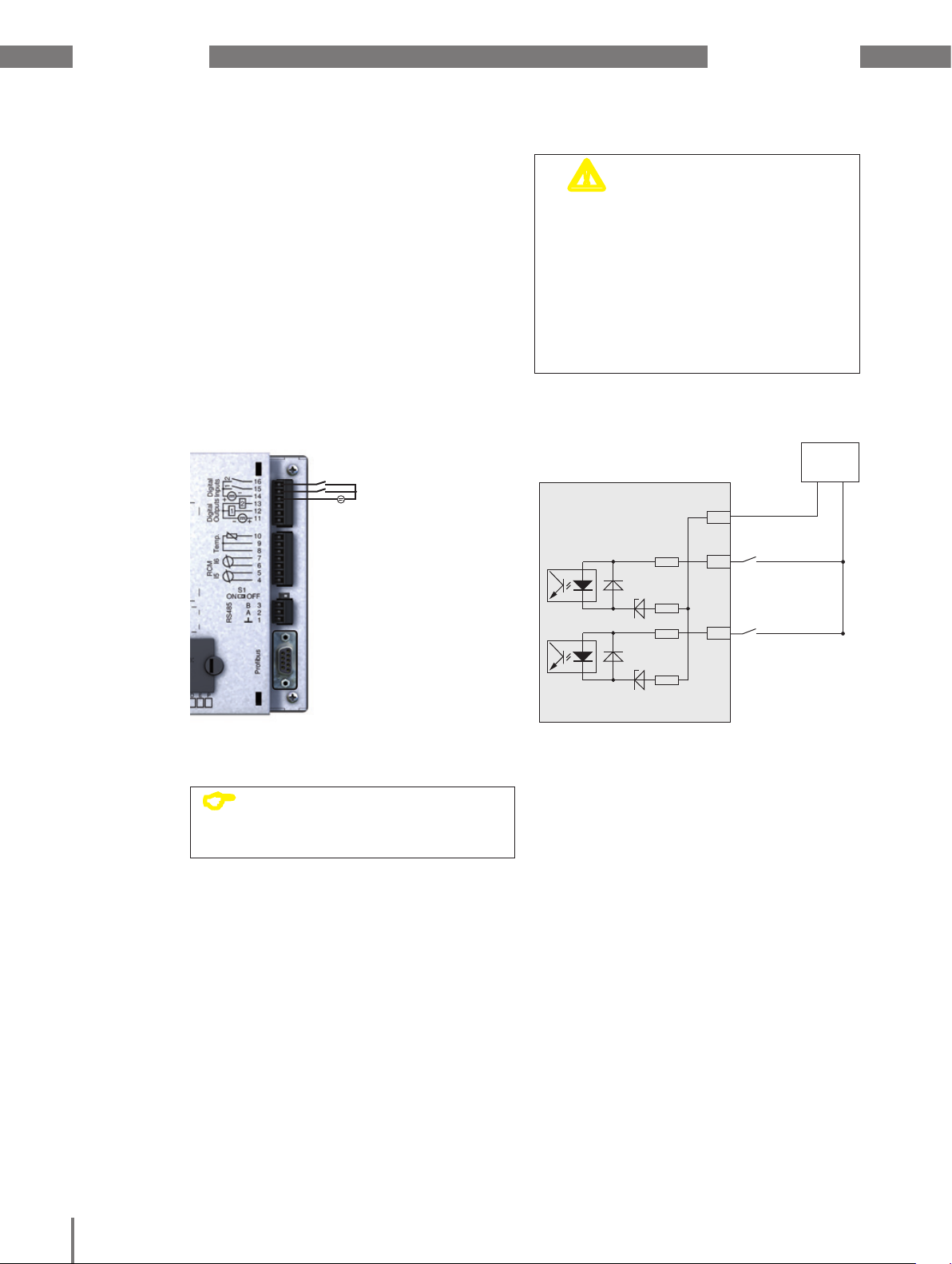

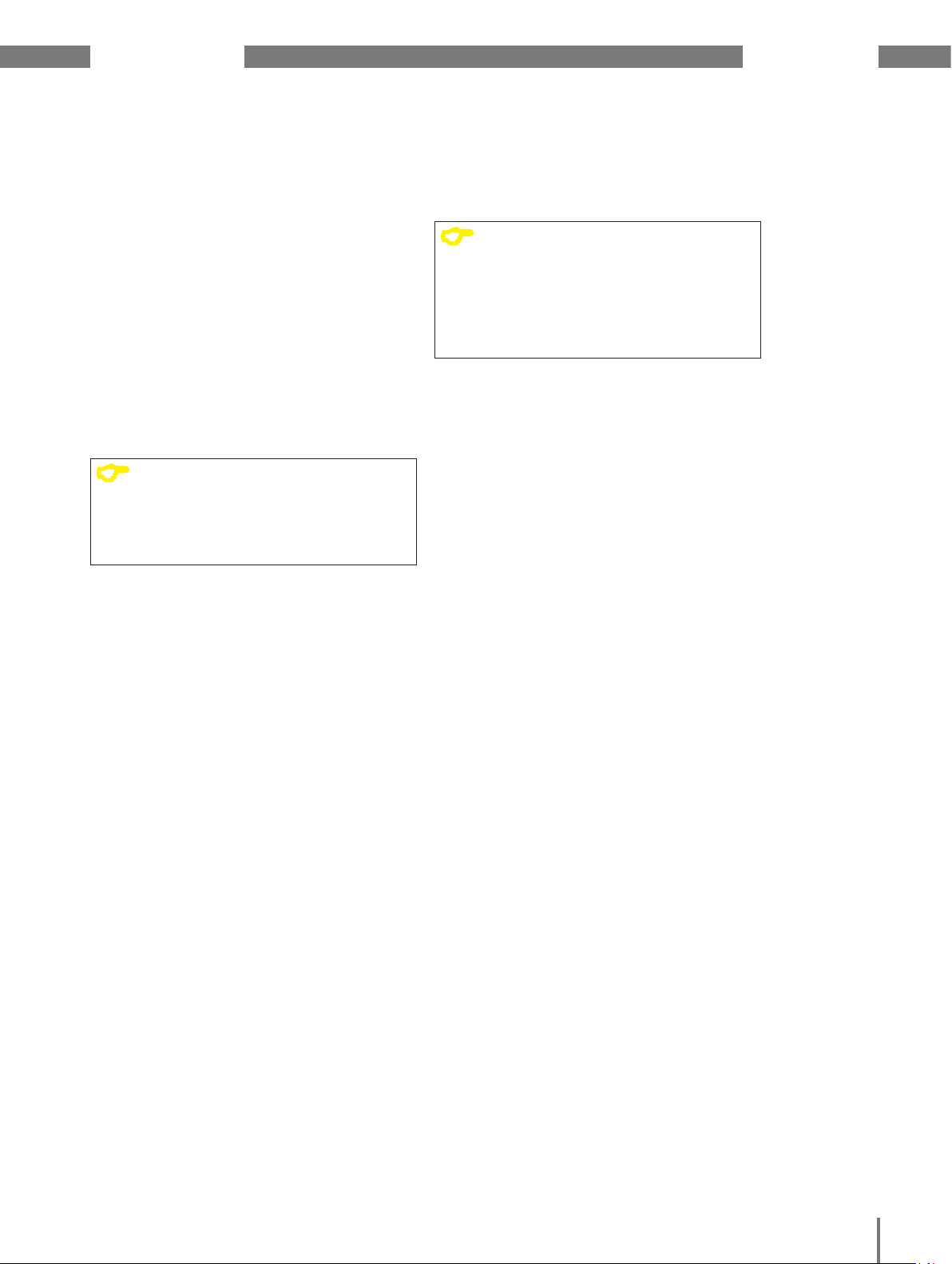

9. 2 Digital outputs

The device has two digital outputs, which:

• are galvanically separated from

the analysis electronics using opto

couplers.

• have a joint consumption.

• can switch DC loads.

• require an external auxiliary voltage.

• can be used as pulse outputs.

~

C

CAUTION!

When using the digital outputs as pulse

outputs, measurement errors may arise due

to the residual ripple.

Therefore, use a mains adapter for

the supply voltage for the digital inputs

and outputs, which has a residual ripple

of less than 5% of the supply voltage.

CAUTION!

The digital outputs are not short-circuit

proof! Connection errors can therefore

cause damage to the connections.

Ensure that the wiring is correct when

connecting the outputs.

NOTE!

You can use the GridVis® software

to set functions for the digital

outputs clearly.

(see www.janitza.de)

m

m

Measurement errors when

using as a pulse output

Damage to property due

to connection errors

Fig. Connection of digital outputs

UMG 509-PRO

Digital outputs 1-2

Fig. Example for connecting 2 relays to digital outputs 1 and 2

Digital Ouput 1

Digital Ouput 2

11

12

13

External

Auxiliary voltage

24V DC

+

DC

K1

DC

K2

-

37

Page 43

www.janitza.de UMG 509-PRO

38

Page 44

UMG 509-PRO www.janitza.de

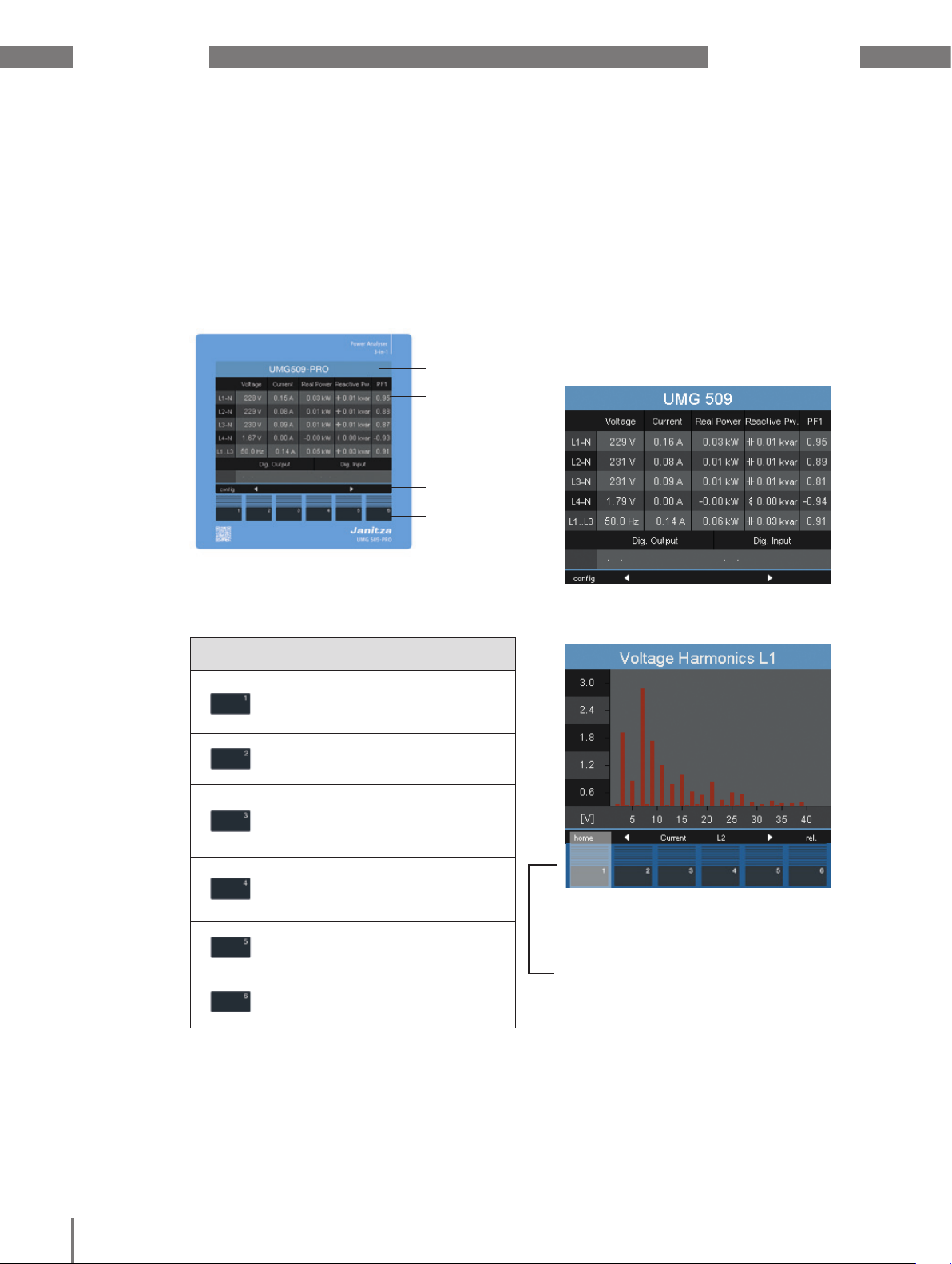

10. Operation

The device is operated via six function keys

that have different functional assignments

depending on the context:

• selecting measured value indications.

• Navigation within the menus.

• Editing device settings.

Display title

Measured

values

Labelling of

the Function keys

Function keys

Fig. UMG 509-PRO "Home" measured value indication

10. 1 Button allocation

10. 2 “Home" measured value indication

After the power returns, the device starts with

the "Home" measured value indication.

This measured value indication contains

the device names and an overview

of important measured values. In its

delivery condition, the unit name consists

of the device type and the serial number

of the device.

Fig. UMG 509-PRO "Home" measured value indication

Button

Function

• Returns to the first screen

(home)

• Exits selection menu

• Selects number

• Selects main values (U, I, P ...)

• Changes (number -1)

• By-values (select)

• Selects menu item

• Changes (number +1)

• By-values (select)

• Selects menu item

• Selects number

• Selects main values (U, I, P ...)

• Opens selection menu

• Confirm selection

Fig. UMG 509-PRO Harmonics of voltage L1

Using the "Home - button 1", you

navigate directly to the first "Home"

measured value indication from

the measured value indications

for the main values

39

Page 45

www.janitza.de UMG 509-PRO

10. 3 Measured value indication

10. 3. 1 Main values

Using buttons 2 and 5, you can scroll

between the main values of the measured

value indications. You can find an overview

of the main values in section “17. 2 Overview

of measured value indications”.

10. 3. 2 By-values

Using buttons 3 and 4, you can select

the by-values of a measured value indication.

These are also provided in section “17. 2

Overview of measured value indications”.

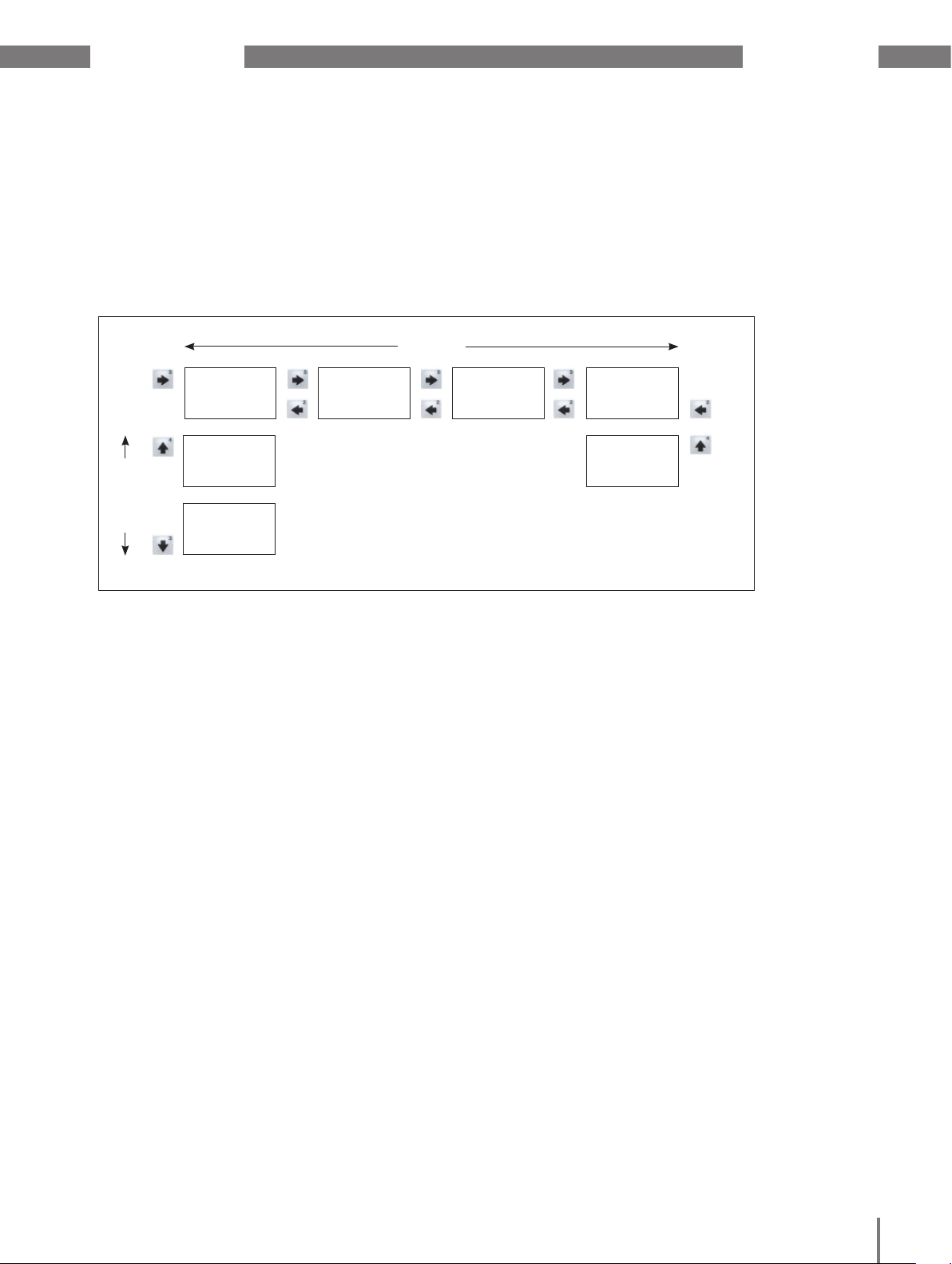

Main values

...

By-values

Display

Oscilloscope L1

Display

Oscilloscope L2

Display

Oscilloscope L3

Display

Communication

Status

Display

Home

Display

Voltage L-N

Display

Voltage L-L

...

40

Page 46

UMG 509-PRO www.janitza.de

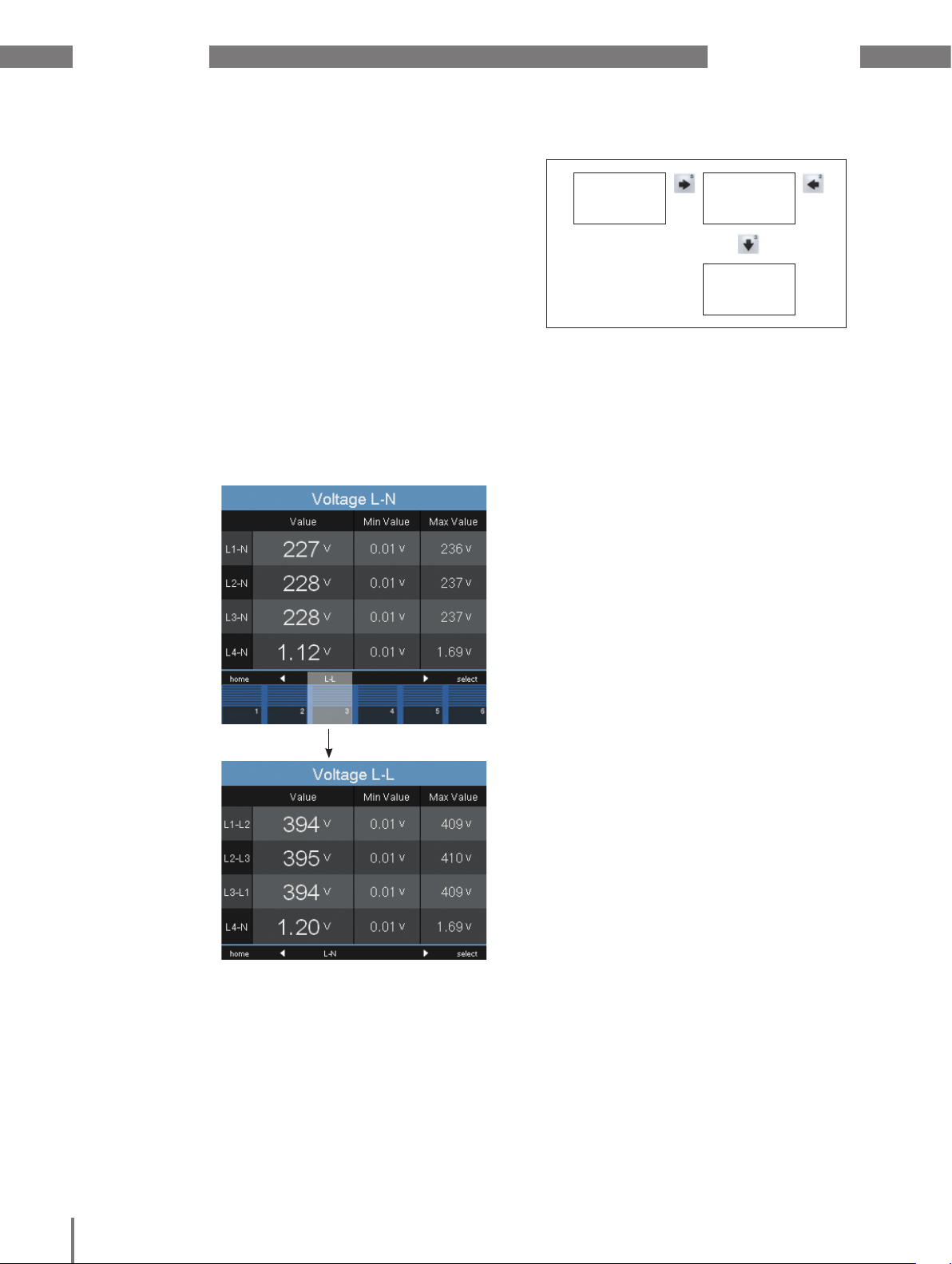

10. 4 Selecting a measured value indication

In order to switch to a measured value

indication with main values, use function keys

2 to 5 to select the required measured value

indications with main values.

Using the 1 (home) function key, you always

navigate to the first measured value indication.

Proceed as follows to switch to a measured

value indication with by-values:

1. Select the measured value indication with

the main values.

2. Use function keys 3 and 4 to select

the measured value indication

for the required by-values.

Display

Home

... ...

Fig. Example: Selecting the voltage by-values.

Display

Voltage L-N

Display

Voltage L-L

41

Fig. Selecting a measured value indication

Page 47

www.janitza.de UMG 509-PRO

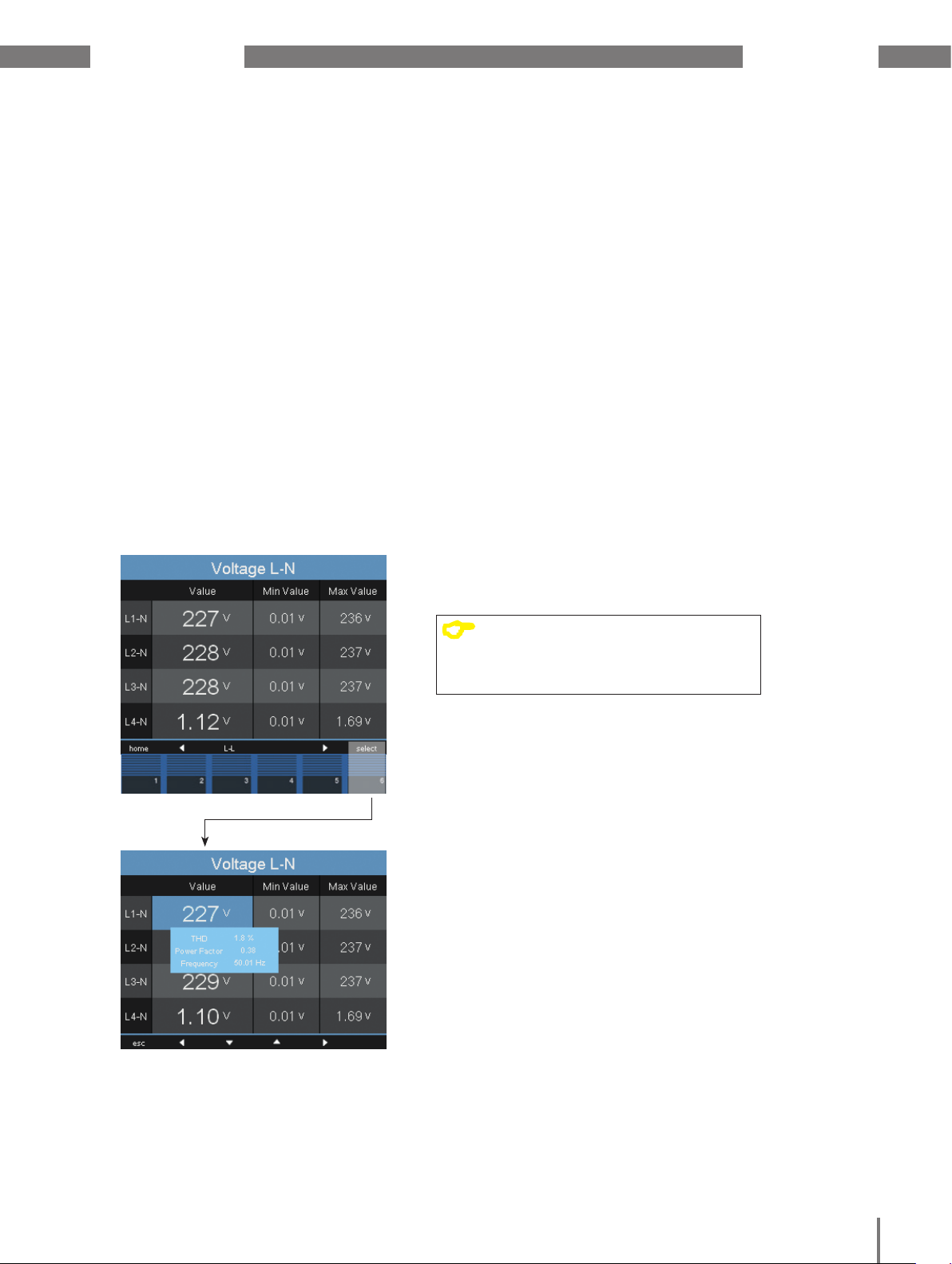

10. 5 View additional information

Proceed as follows to view additional

information such as the power factor

and frequency:

1. Use buttons 2 to 5 to scroll to the desired

measured value indication.

2. Activate the measured value selection

using the 6 key (select).

• The background colour for the measured

value switches from grey to blue.

The additional information is displayed

in an additional window.

3. Use buttons 2 and 5 to select the desired

measured value.

4. End the procedure using the button 1

(ESC) or select another measured value

using buttons 2 to 5.

10. 6 Deleting values

Proceed as follows to delete individual

minimum and maximum values:

1. Use buttons 2 to 5 to scroll to the desired

measured value indication.

2. Activate the measured value selection

using the 6 key (select).

• The background colour for the measured

value switches from grey to blue.

The additional information is displayed

in an additional window.

3. Use buttons 2 to 5 to select the desired

minimum or maximum value.

• The time along with the date and time

of the occurrence are displayed as

additional information.

4. Using the 6 key (reset), you can delete

the selected minimum or maximum value.

5. End the procedure using button 1 (ESC)

or select another minimum or maximum

value with buttons 2 to 5.

NOTE!

C

The date and time for the minimum/

maximum values are specified

displayed in UTC.

Fig. Additional information for L1-N voltage

42

Page 48

UMG 509-PRO www.janitza.de

10. 7 Transients list

Transient voltages:

• are fast impulse transient effects

in electrical networks.

• are unpredictable from a time perspective

and have a limited duration.

• are caused by lightning strikes, switching

operations or by tripped fuses.

A total of 16 detected transients are listed

in the 2-page transients list for the device.

Proceed as follows to display a specific

transient voltage:

1. Use buttons 2 and 5 to scroll

to the "Transients" main value display

2. Select the desired page using button 4.

3. Use button 6 (selection) to access

the transients list.

• The background colour for the date/time

switches from grey to blue.

4. Press button 3 or 4 to select a transient.

5. Use button 6 (select) to display

a transient graphically.

6. Press button 6 (key) again to show or hide

the key.

7. You can exit the transient graph display

using button 1 (ESC).

Fig. Displaying a transient

43

Page 49

www.janitza.de UMG 509-PRO

10. 8 Event list

Events are threshold value violations

of effective current and voltage values.

A total of 16 detected events are listed

in the two-page event list for the device.

Proceed as follows to display a specific

event:

1. Use buttons 2 and 5 to scroll to

the "Events" main value display.

2. Select the desired page using button 4.

3. Use button 6 (selection) to access event

list.

• The background colour for the date/time

switches from grey to blue.

4. Press button 3 or 4 to select an event.

5. Use button 6 (select) to display an event

graphically.

6. Press button 6 (key) again to show or hide

the key.

7. You can exit the event’s graphical display

using button 1 (ESC).

Fig. Displaying an event

44

Page 50

UMG 509-PRO www.janitza.de

11. Configuration

The supply voltage must be connected

to configure the device. Proceed as

described in “12. 1 Connecting the supply

voltage”.

To call the configuration menu, press button

1 on the “Home” measured value indication.

11. 1 Languages

You can set the language for the measured

value indications and menus directly

in the configuration menu.

There are different languages available

for selection. The factory default setting

for the language is "English".

Proceed as follows to change the system

language:

1. Open the configuration menu.

2. Press button 3 or 4 until the language field

has a blue background.

3. Press button 6 (enter) to open

the language selection.

4. Press button 3 or 4 to select the desired

language.

5. Press button 6 (enter) again to confirm

your selection.

11. 2 Communication

You can configure the Ethernet

and RS485 interface for your device

in the communication menu.

Proceed as follows to access

the communication menu:

1. Open the configuration menu. Press button

1 in the “Home menu”.

2. Press button 3 or 4 until

the communication field has a blue

background.

3. Press button 6 to open

the “Communication” menu.

11. 2. 1 Ethernet(TCP/IP)

Select the mode for address allocation and,

if necessary, the IP address, subnet mask

and the gateway in this section. The latter

is allocated automatically in the BOOTP

and DHCP allocation modes.

The device has three types of address

allocation:

• Off - You define the IP address, subnet

mask and gateway, and set them directly

on the device. Select this mode for

straightforward networks without DHCP

servers.

45

• BOOTP - - BootP enables the fully

automatic integration of a UMG 509-PRO

into an existing network. However, BootP

is an older protocol and does not provide

the scope of functions provided by DHCP.

• DHCP - When started, the device

automatically obtains the IP address,

the subnet mask and the gateway from

a DHCP server. DHCP is factory-set.

Fig. "Configuration" menu

Page 51

www.janitza.de UMG 509-PRO

Proceed as follows to adjust the IP address,

subnet mask and gateway:

1. Press button 3 or 4 until the relevant field

has a blue background.

2. Press button 6 to activate the input.

• The font changes to red and a cursor

is displayed.

3. Now press button 3 or 4 to select

the required digit.

4. Use button 5 to move to the next digit.

5. Repeat steps 3 and 4 until you have

completed the required input.

6. Press button 6 to confirm your input.

m

CAUTION!

Incorrect network settings can cause faults

in the IT network.

Obtain information from your network

administrator about the correct settings

for your device.

Damage to property due

to incorrect network settings

11. 2. 2 Field bus

If you connect the device via the RS-485

interface, configure the following settings

in this section:

• Modbus protocol - Here, you can select

whether the device works as a slave or a

master/gateway within the bus structure.

• Device address - Here, you can select

a device address that is used to address

the device in the bus. This address must

be between 0 and 255, and be unique

in the tree structure.

• Baud rate - Select the same baud

rate for all devices in a bus structure.

Possible settings are 9600, 19200, 38400,

57600,115200, 921600 kbps. The factory

default setting is 115200 kbps.

Proceed as follows to make the adjustments:

1. Press button 3 or 4 until the relevant field

has a blue background.

2. Press button 6 (enter) to call the selection

options.

3. Press button 3 or 4 to select the required

value.

4. Press button 6 to confirm your selection.

46

Page 52

UMG 509-PRO www.janitza.de

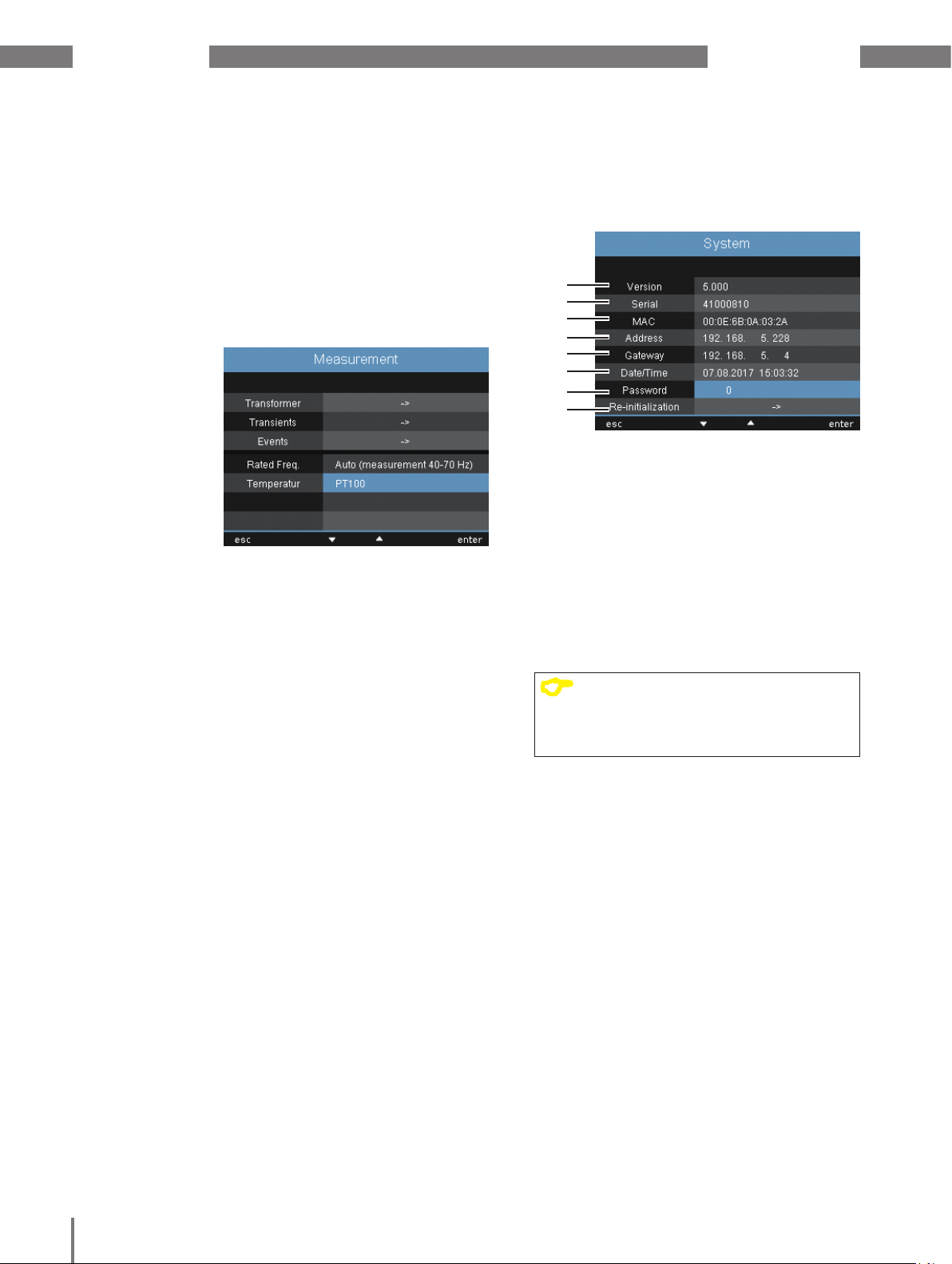

11. 3 Measurement

You can configure the following

in the measurement menu:

• the measuring transducer for current

and voltage measurement.

• recording transients.

• recording events.

• the mains frequency.

• the temperature sensor.

The device has:

• 4 measurement channels for current

measurement (I1 - I4)

• 4 measurement channels for voltage

measurement (V1 - V4 against Vref).

Measured voltage and measured current for

the measurement channels 1-4 must derive

from the same network.

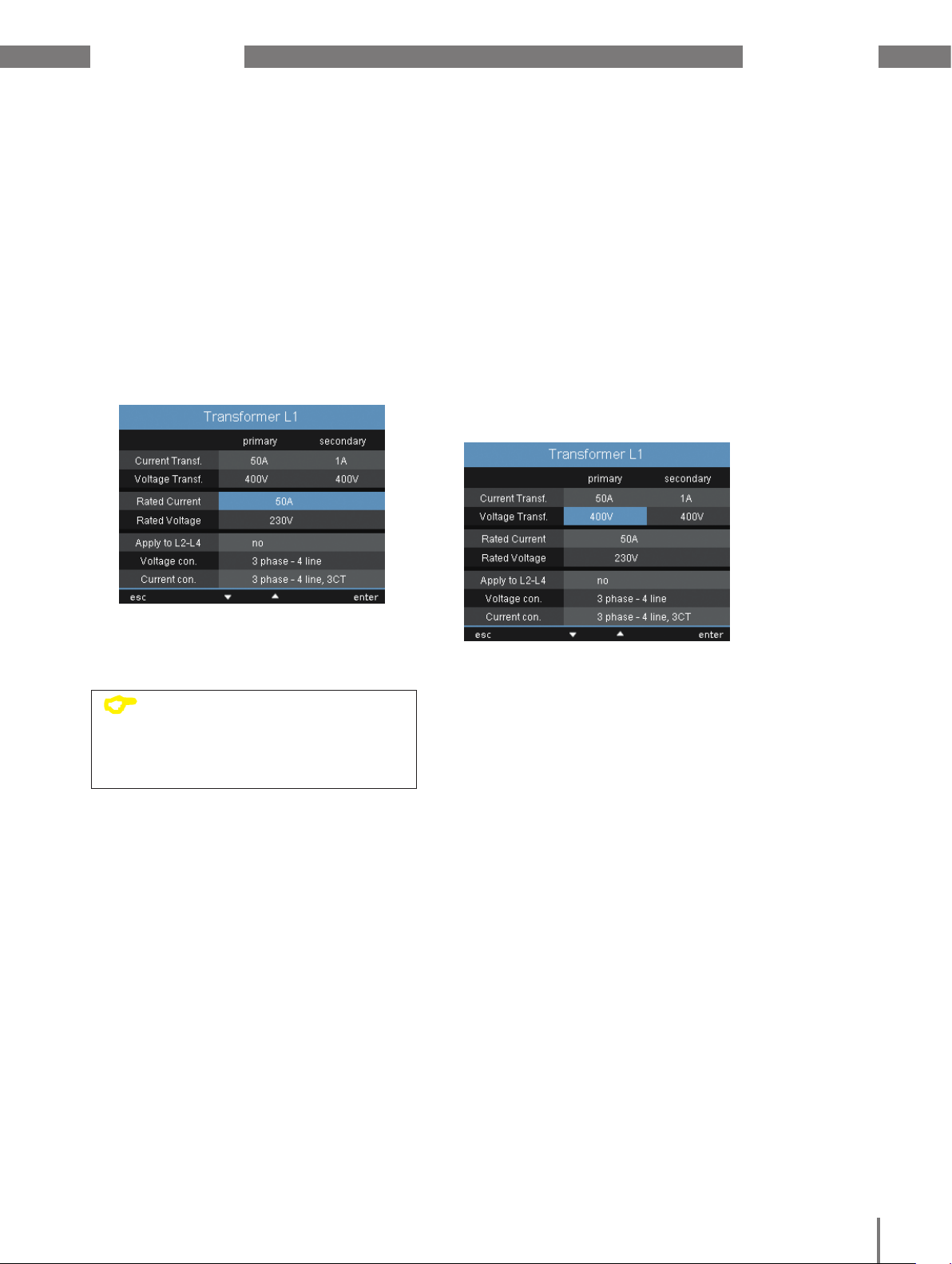

11. 3. 1 Measuring transducer

You can make the following adjustments for

baseline and supporting measurements here:

• current transformer

• voltage transformer

• rated current

• rated voltage

• connection

As well as settings for transformation ratios

and monitoring for the residual current

transformer.

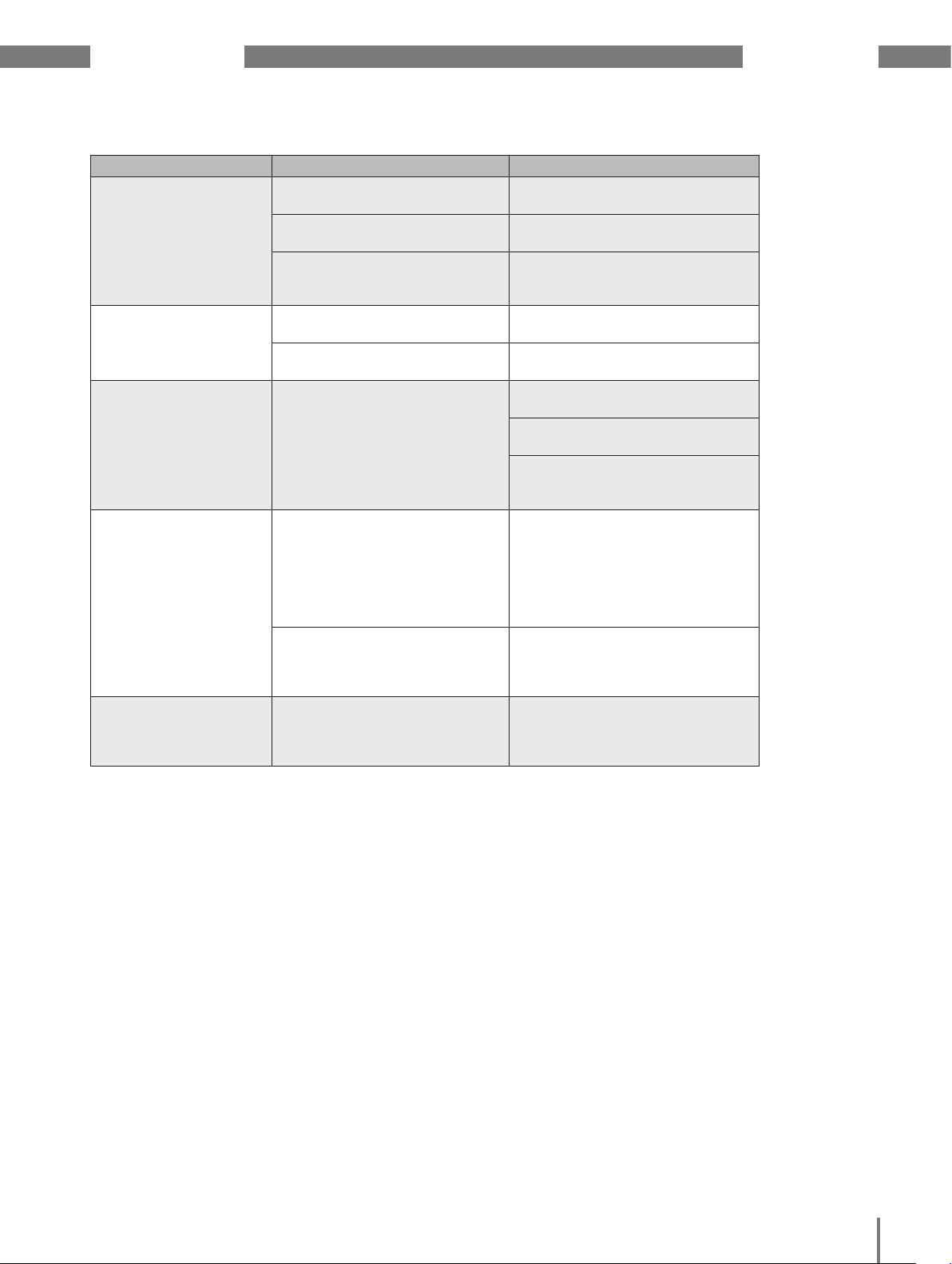

Current transformer

You can assign current transformer

ratios to the baseline measurement and

the supporting measurement.

Select the 5/5 A setting when measuring

currents directly.

Setting range:

Primary 1 to 999999

Secondary 1 to 5

Fig. Measurement configuration

Factory default setting:

Primary 5

Secondary 5

Fig. Configuring current transformer ratios

47

Page 53

www.janitza.de UMG 509-PRO

Rated current

The rated current defines the reference point

for:

• overcurrent

• current transients

• automatic scaling of graphics

Setting range:

0 0 to 999999 A

Fig. Configuring the rated current

Voltage transformer

You can assign voltage transformer

ratios to the baseline measurement

and the supporting measurement.

Select the 400/400 V setting when measuring

without a voltage transformer.

Setting range:

Primary 1 to 999999 V

Secondary 1 to 999 V

Factory default setting:

Primary 400 V

Secondary 400 V

C

Fig. Voltage transformer configuration

NOTE!

You can set the nominal value

for measuring the K-factor and TDD

via the GridVis® software.

(see www.janitza.de)

48

Page 54

UMG 509-PRO www.janitza.de

Rated voltage

The rated voltage defines the reference point

for:

• transients,

• events

• automatic scaling of graphics

Setting range: 0 to 1000000 V

Factory default setting: 230 V

You can also select the primary voltage

as the rated voltage.

Transfer L2 - L4

These settings can be adjusted for each

phase.

You can use the “Transfer L2 - L4” menu

item to transfer the settings from phase L1

to phases L2, L3 and L4, in order to prevent

having to enter everything again.

• No - The settings from phase L1 will not

be transferred to phases L1 to L4.

• Yes - The settings from phase L1 will be

transferred to phases L1 to L4.

Fig. Configuring the rated voltage

Fig. Transferring settings to L2 - L4

Fig. “Transfer setting “deactivated.

49

Page 55

www.janitza.de UMG 509-PRO

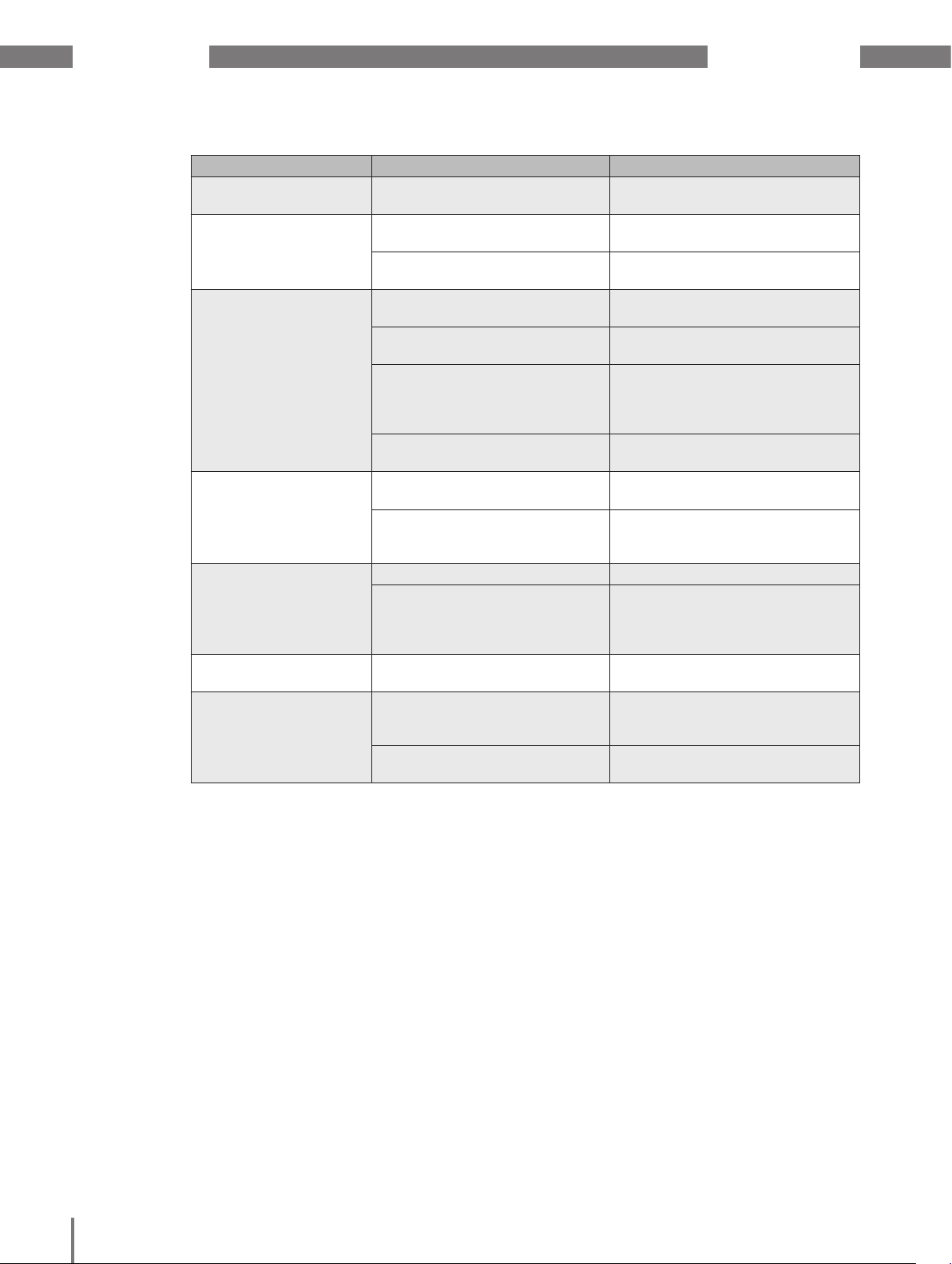

Voltage measurement connection schematic

The following connection schematics can

be selected for voltage measurement:

3p4w 3 phases, 4 conductors

3p4wu 3 phases, 4 conductors

3p3w 3 phases, 3 conductors

For networks without a neutral

conductor and with symmetrical loading

3p3wu 3 phases, 3 conductors

For networks without a neutral

conductor and with symmetrical loading

3p5w 3 phases, 4 conductors

Measurement on an additional

conductor

1p2w 1 phase, 2 conductors (180°)

Factory default setting: 3p4w

NOTE!

C

It is not necessary to configure

a connection schematic

for measurement inputs V4 and I4.

Current measurement connection schematic

The following connection schematics can

be selected for the current measurement:

3p4w 3 phases, 4 conductors, 3 current

transformers

3p5w 3 phases, 4 conductors, 4 current

transformers

The fourth current transformer can be

used for the measurement in the neutral

conductor.

3p2i 3 phases, 4 conductors, 2 current

transformers

For networks with symmetrical loading.

3p2i0 3 phases, 3 conductors, 2 current

transformers

Aron circuit for networks without a

neutral conductor. The third current is

calculated

1p2i 1 phase, 2 conductors, 2 current trans-

formers

Factory default setting: 3p4w

Fig. Configuration of voltage connection schematic

Fig. Voltage measurement connection schematic

Fig. Configuration of current connection schematic

Fig. Current measurement connection schematic

50

Page 56

UMG 509-PRO www.janitza.de

Residual current transformer

When using residual current inputs I5 and

I6, the corresponding transformer ratios

of the used residual current transformer must

be set.

Setting range:

Primary 1 to 1000000

Secondary 1

Factory default setting:

Primary 127

Secondary 1

You can also use this menu to adjust failure

monitoring for the corresponding residual

current inputs:

• Activated - Switches on failure monitoring

for residual current monitoring.

• Deactivated - Switches off failure

monitoring for residual current monitoring.

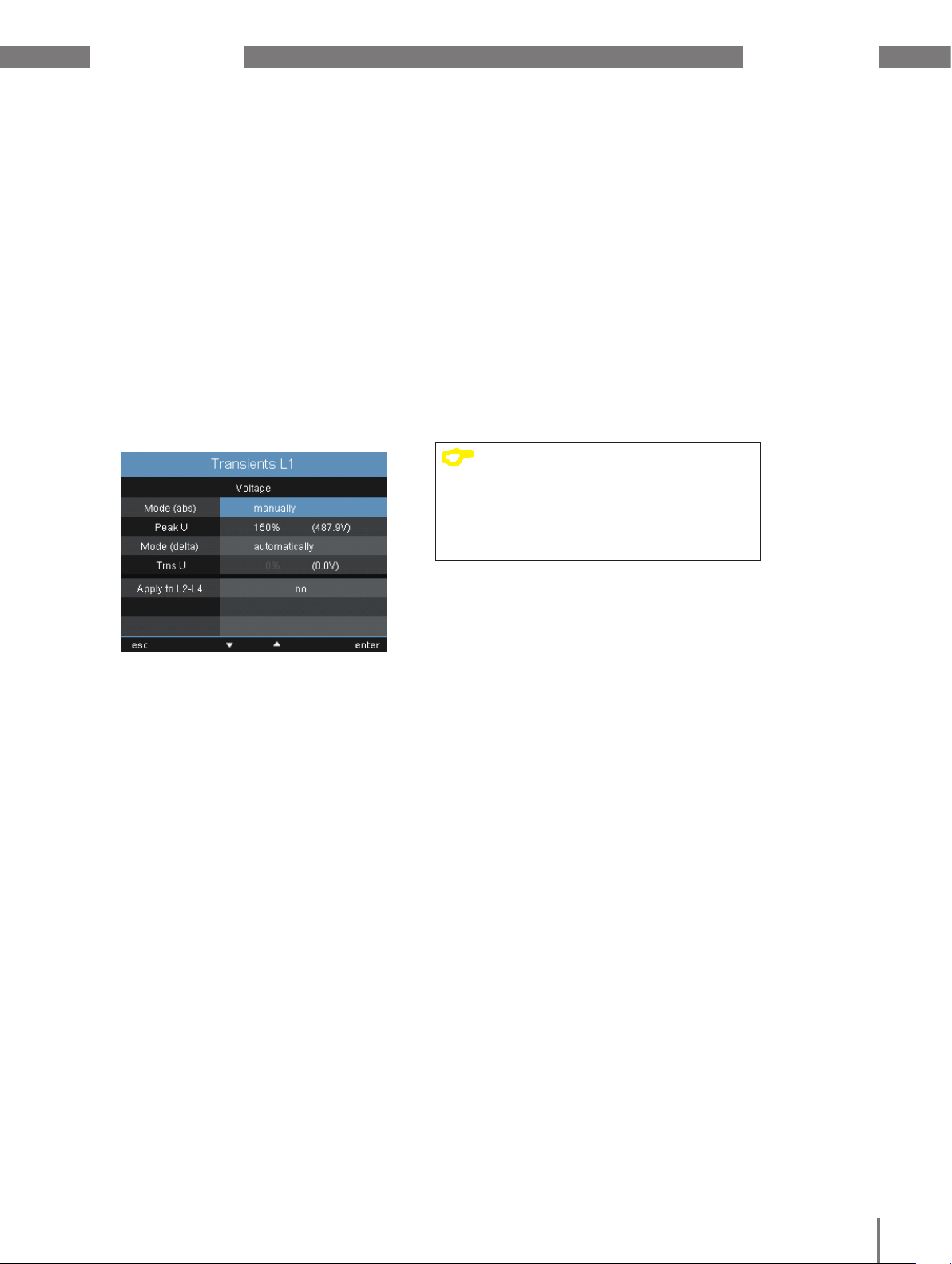

11. 3. 2 Transients

The device:

• monitors the voltage measurement inputs

for transients.

• detects transients that are longer than

50µs.

• can detect transients according to two

different criteria.

• can receive different monitoring settings

for each phase.

If a transient has been detected:

• the wave form is saved to a transient

record.

• the threshold value increases by 20 V

for the next 10 minutes, both in automatic

and in manual mode.

• it will be recorded with 509 points

for a period of 60 seconds per additional

transient.

You can use the GridVis® event browser

to display recorded transients.

Fig. Residual current transformer configuration

Fig. Configuring monitoring for residual current

monitoring

The following modes are available

for recording the transients:

• absolute

• delta

Fig. Configuring transients

51

Page 57

www.janitza.de UMG 509-PRO

Mode (absolute)

If a sample value exceeds the set threshold

value, a transient is detected:

• Off - Transient monitoring has been

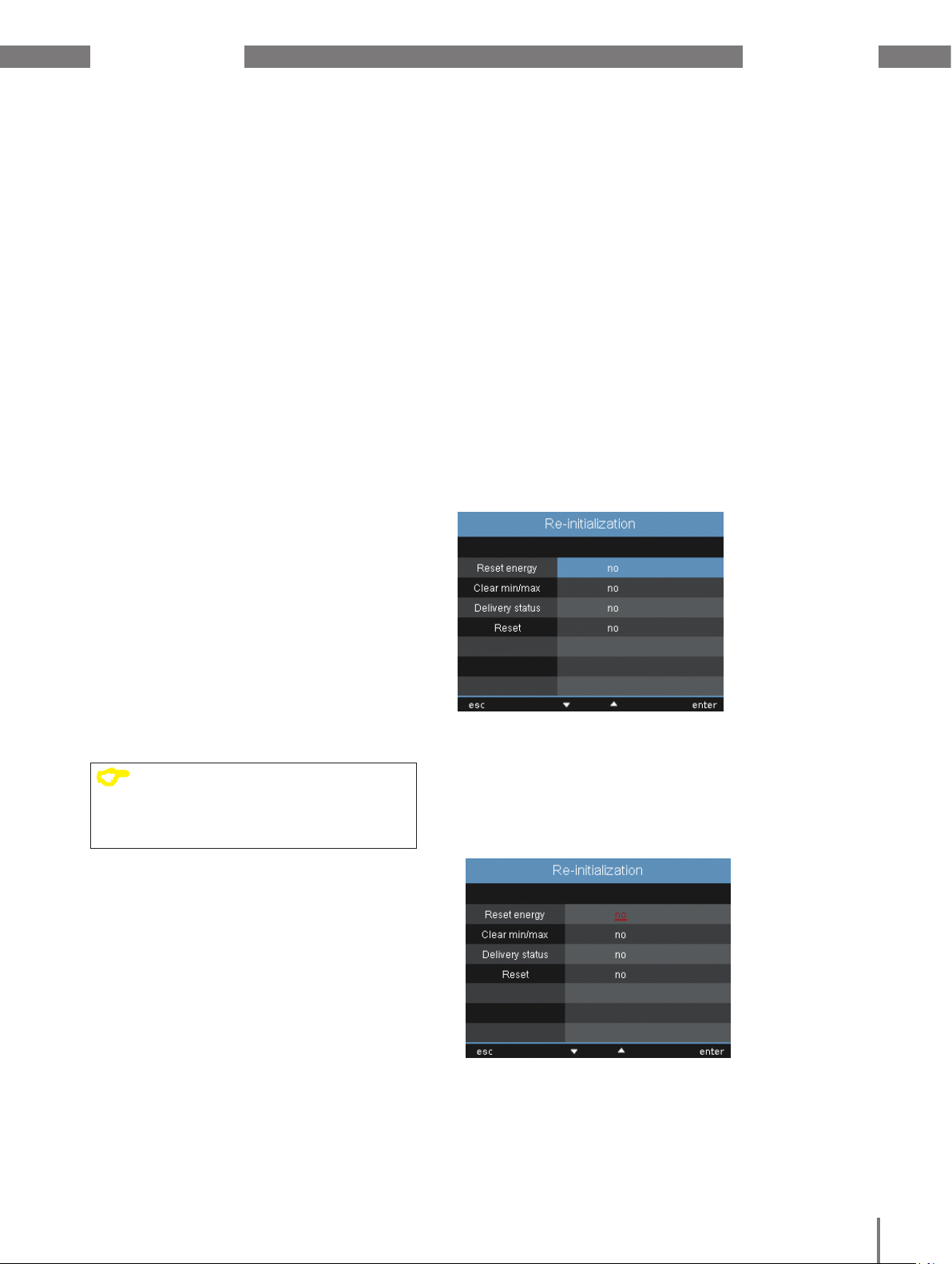

switched off