Page 1

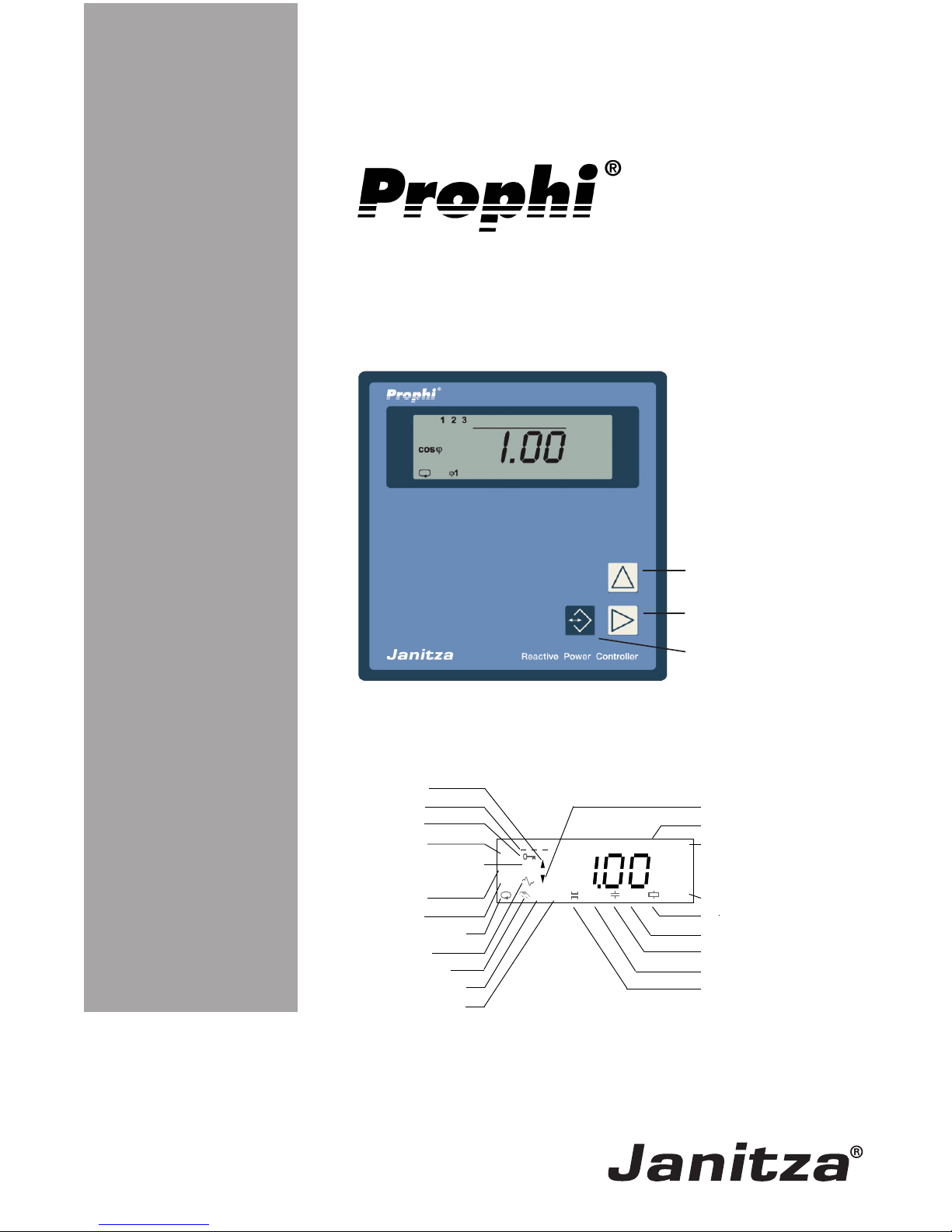

Key 3

Key 2

Key 1

www.janitza.com

Doc no. 1.020.009.m

Serie II

Prog

Janitza electronics GmbH

Vor dem Polstück 6

D-35633 Lahnau

Support Tel. +49 6441 9642-22

Fax +49 6441 9642-30

e-mail: info@janitza.com

Internet: http://www.janitza.com

w

Reactive Power Controller

Operating instructions

Brief instructions see last page

Peak value

Fix stages

Password

Capacitive

Required capacitive

power

Cosinus ϕ

Inductive

Automatic mode

Harmonics

Manual mode

Target cos(phi1)

Target cos(phi2)

Lowest value

Capacitive stage active

Alarm output active

Expanded programming

Number of stages

Stage ratio

Power of 1st stage

Learning of configuration

CT ratio

cap

cos

ϕϕ

ϕϕ

ϕ Qc

ind

1 2 3 4 5 6 7 8 9 10 11 12 Error

ϕϕ

ϕϕ

ϕ1

ϕϕ

ϕϕ

ϕ2 learn 1:1... Prog

Article no. 33.03.027

Page 2

Page 2

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Expanded programming 25

Fix stages 25

Discharge time 26

Disconnection pause 26

Power station service 27

Stage power 28

Choke degree 28

Voltage transformer ratio 29

Harmonic thresholds 30

Switching frequency 31

Alarm output 32

Alarm call 32

Give a receipt for alarms 32

Lower voltage (1) 33

Overvoltage (2) 33

Underscoring of the measurement current (3) 33

Exceeding of measuring current (4) 33

Insuff icient capacitor output (5) 33

Supply of real power (6) 33

Harmonic thresholds (7) 33

Overtemperature (8) 33

Averaging time for the mean value cos(phi) 34

Averaging time of reactive power 34

Ventilator control 35

Ventilation control 35

Upper temperature limit 35

Lower temperature limit 35

Switching output 35

Overtemperature disconnection 37

Upper temperature limit 37

Lower temperature limit 37

Pause time 37

Indication in manual mode 38

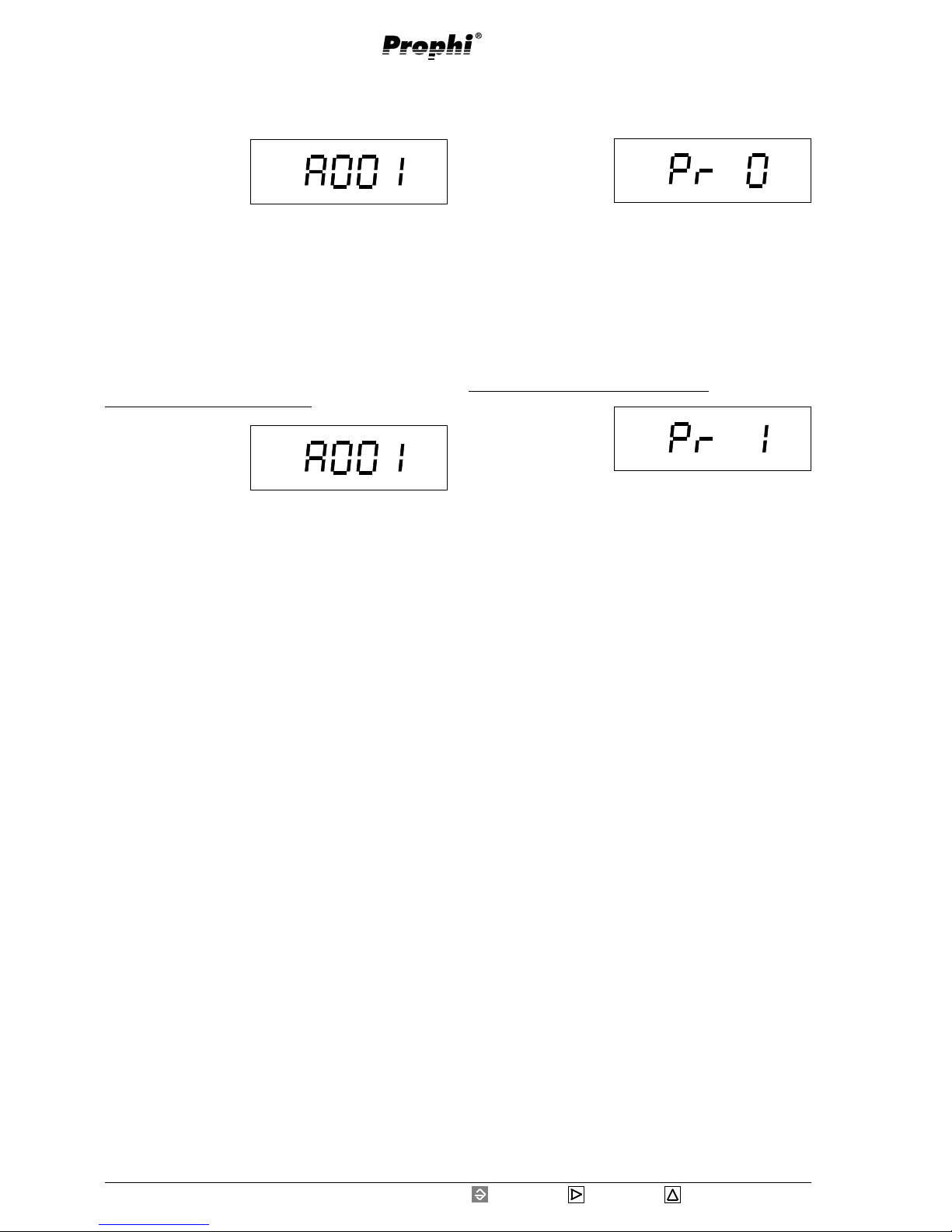

Password 39

Program password 39

Enter password 39

Change password 39

Contrast 40

Reset programming 41

Connection conf iguration 42

Correction angle 42

Software release 43

Serial number 43

Serial interface (Option) 44

Device address 44

Transmission protocol 44

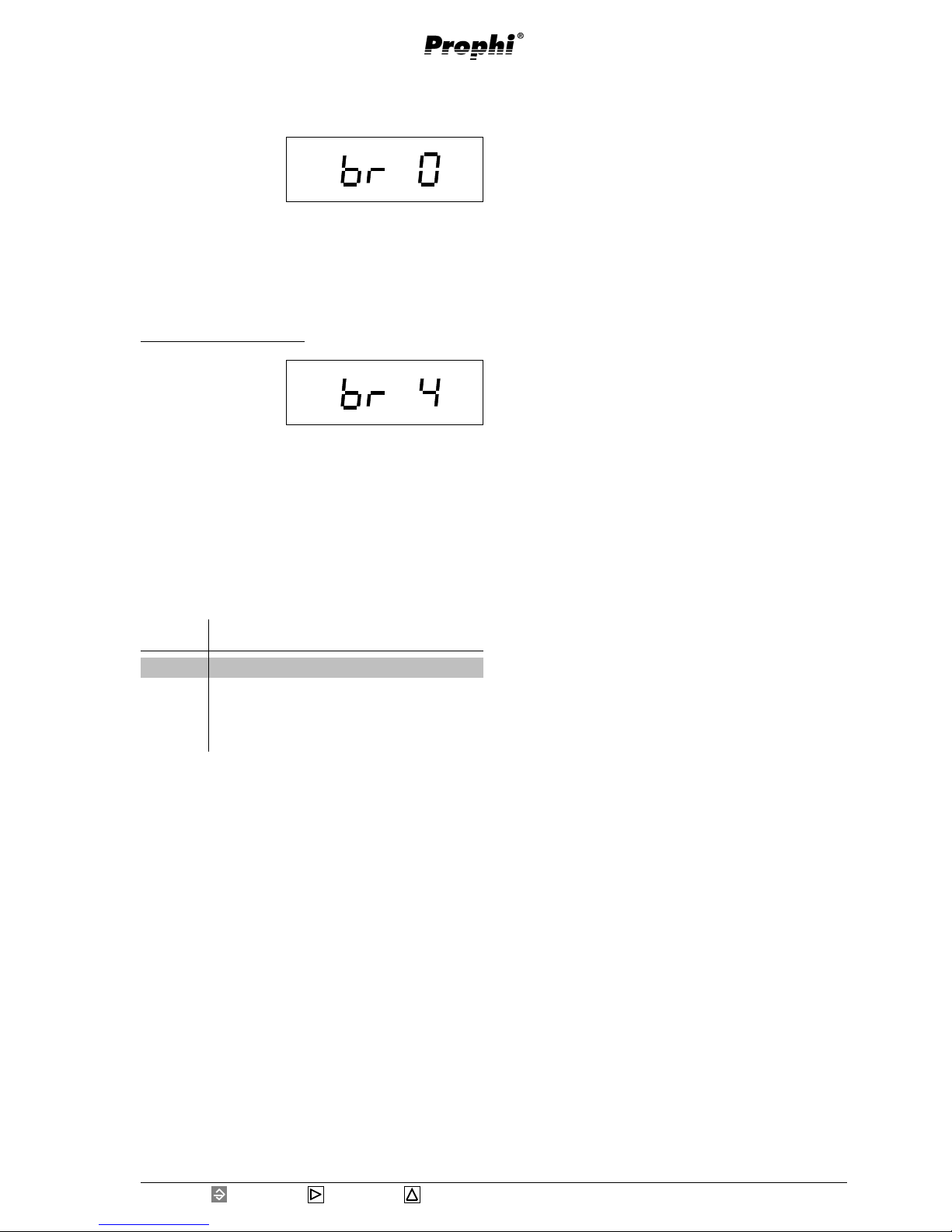

Baud rate 45

Modbus RTU 45

Profibus DP V0 45

Table Modbus 46

Table Profibus 47

Contents

Receipt Control 4

Meaning of the symbols 4

Hints for usage 4

Product description 5

Intended use 5

Data protection 5

Hints for maintenance 5

Repairing and calibration 5

Front foil 5

Waste management 5

Funktional description 6

Measurement 6

Switching of capacitor stages 6

Switching outputs 6

Net return 6

Hints for installation 8

Mounting place 8

Measurement and supply voltage 8

Sum current measurement 9

Current measurement 9

Installation and putting into service 10

Measurement and supply voltage 10

Current measurement 11

Real power 11

Switching outputs 12

Transistor outputs 12

Target-cos(phi) changeover 13

Alarm output 13

Check alarm output 13

RS485 Interface (Option) 14

Transmission protocols 14

Bus structure 14

Shielding 14

Cable length 14

Terminal resistors 14

Removal of errors 15

Service 16

Display and use 17

Automatic mode 17

Manual mode 17

Key functions 18

Standard programming 19

Target cos(phi) 19

Current transformer ratio 20

Learning of the configuration 21

Stage power 22

Stage ratio 22

Switching outputs 23

Delete peak and lowest values 24

Page 3

Page 3

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Display overview 48

Measured value indications 48

Display in standard programming 50

Display in expanded programming 51

Configuration data 53

Setting range 53

Manufacturer's presetting 53

Technical data 54

Ambient conditions 54

Inputs and outputs 54

Measurement 54

Measurement accuracy 54

Back Side 55

Side view 55

Short manual 56

All rights reserved. No part of this manual may be reproduced or duplicated without the written permission

of the author. Any contraventions are punishable and

will be prosecuted with all legal means.

No liability can be taken for the faultless condition of

the manual or damage caused by the use of it. As failures cannot be avoided completely, we shall be very

grateful for any advice. We will try to remove any failures as soon as possible. The mentioned software and

hardware descriptions are registered trademarks in the

most cases and are subjected to the regulations by law.

All registered trademarks are property of the corresponding companies and are fully recognized by us.

Page 4

Page 4

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Receipt Control

In order to ensure a perfect and safe use of the device, a

proper transport, expert storage, erection and mounting

and careful usage and maintenance are required. When

it may be supposed, that a safe operation is no longer

possible, the device has to be put out of service and be

protected against unintentional putting into service.

A safe operation can no longer be assumed, when the

device

• shows visible damage,

does not work in spite of intact net supply,

has been exposed to disadvantageous conditions for a

longer time (e.g. storage out of the allowed climate

without adaption to the room climate, dew etc.) or transport use (e.g. falling from great height, even without

visible damage).

Please test the contents of delivery for completion, before starting the installation of the device. All delivered

options are listed on the delivery papers.

In the attached description doc. no.: 1.020.030.x all delivery types and options for the reactive power controller Prophi are listed.

Hints for usage

Safe and failure free operation can only be granted,

when the device is operated according to this manual!

This device may be put into service and used by qualified personnel according to the safety regulations and

instructions only. Please mind the additional legal and

safety regulations for the respective application.

Qualified personnel are persons, familiar with erection, mounting,

putting into service and usage of the product and having the qualifications such as:

education or instruction / entitlement to switch, release, ground or characterize current circuits and devices according to the standards of safety techniques.

education or instruction in the care and usage of suitable safety equipment according to the standards of

safety techniques.

Warning of dangerous electrical voltage.

This symbol shall warn you of possible dangers, which can occur during maintenance, putting into service

and while usage.

Protective wire connection

c

m

Meaning of the symbols

Attention!

This manual also describes options and

types, which were not delivered and therefore, do not belong to the contents of delivery.

m

Page 5

Page 5

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Product description

Intended use

The reactive power controller Prophi together with external capacitor stages, serves for step by step controlling of the phase shift angle cos(phi) in 50/60Hz low

voltage networks. Depending on the type of the reactive power controllers Prophi, contactors or semi conductor switches can be controlled directly.

Additionally, the following electrical quantities are measured and indicated:

- Voltage L2-L3,

- Current in L1,

- Frequency,

- Sum real power (Consumption/supply),

- Sum reactive power (ind./cap.),

- uneven current harmonic waves 1. - 19. in %,

- uneven voltage harmonic waves 1. - 19. in %.

The harmonic contents are related to the rated voltage

or rated current.

The connection is carried out on the back side via touch

proof spring power terminals.

Measurement and supply voltage are taken from the

measurement voltage and must be connected to the

building installation via a separation (switch or power

switch) and an overcurrent protection (6,3A).

The current measurement is carried out via a ../5A or

../1A current transformer in one outer conductor.

The relay outputs are suitable for contactor control, the

transistor outputs are provided for the control of fast

switching thyristor modules, switching at zero crossing.

Hints for maintenance

Before delivery the device is tested in various safety

checks and marked with a seal. If the device is opened,

these checks must be repeated.

There is no guarantee for devices, which are opened

out of the manufacturing works.

Repairing and calibration

Repairing and calibration work can be carried out in the

manufacturing works only.

Front foil

The cleaning of the front foil must be done with a soft

cloth using a common cleansing agent. Acid or acidic

agents may not be used for cleaning.

Waste management

The device can be disposed as electronical waste according to the legal regulations and recycled.

Data protection

The data protection is carried out in a none volatile

memory (EEPROM).

Changed programming data are saved immediately.

Page 6

Page 6

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Switching of capacitor stages

Prophi calculates the required reactive power to reach

the set target-cos(phi) from the current from one outer

conductor and the voltage between two outer conductors. If the cos(phi) deviates from target cos(phi), external capacitor stages or transistor outputs are switched

on or off.

In automatic mode the capacitor stages are switched in

or off, when the required reactive power is higher or

equal to the smallest stage power.

If the power of the first capacitor stage is three times as

high as the measured real power, all capacitor stages

are switched off.

Switching outputs

Depending on the variety of Prophi, relay or transistor

outputs serve as switching outputs.

The relay outputs are suitable for controlling contactors

and the transistor outputs can switch thyristor modules,

that switch in zero crossing of voltage.

For relay outputs the time between two connections or

disconnections is set to two seconds. Transistor outputs

have no limitation of the switching period.

Net return

After net return, the set discharge time runs for the

relay outputs. The transistor outputs do not mention the

discharge time.

Funktional description

Measurement

The measurement is suited for 3 phase systems with or

without neutral conductor for frequencies of 50Hz or

60Hz. The electronical measurement system records and

digitalizes the effective values of voltage between L2

and L3 (L-N Option) and the current in L1.

In each second several snap check measurements are

carried out. As the current is only measured in one

outer conductor, and the voltage only between two outer

conductors, the measured values, which are related to

all three outer conductors, are exact for equal loaded

outer conductors only.

The following electrical quantities are calculated:

Current and current harmonics

Voltage and voltage harmonics

Real power, sum

Apparent power,sum

Reactive power, sum

Reactive power for each stage

Reactive current for each stage

Cos(phi),

Net frequency.

The following information can be indicated:

Number of switchings of each stage,

total connection time of each stage and

the inner temperature.

Prophi measures the frequency of the measurement and

supply voltage and shows the average over 10 seconds.

Page 7

Page 7

Reactive Power Controller

= Key 1 = Key 2 = Key 3

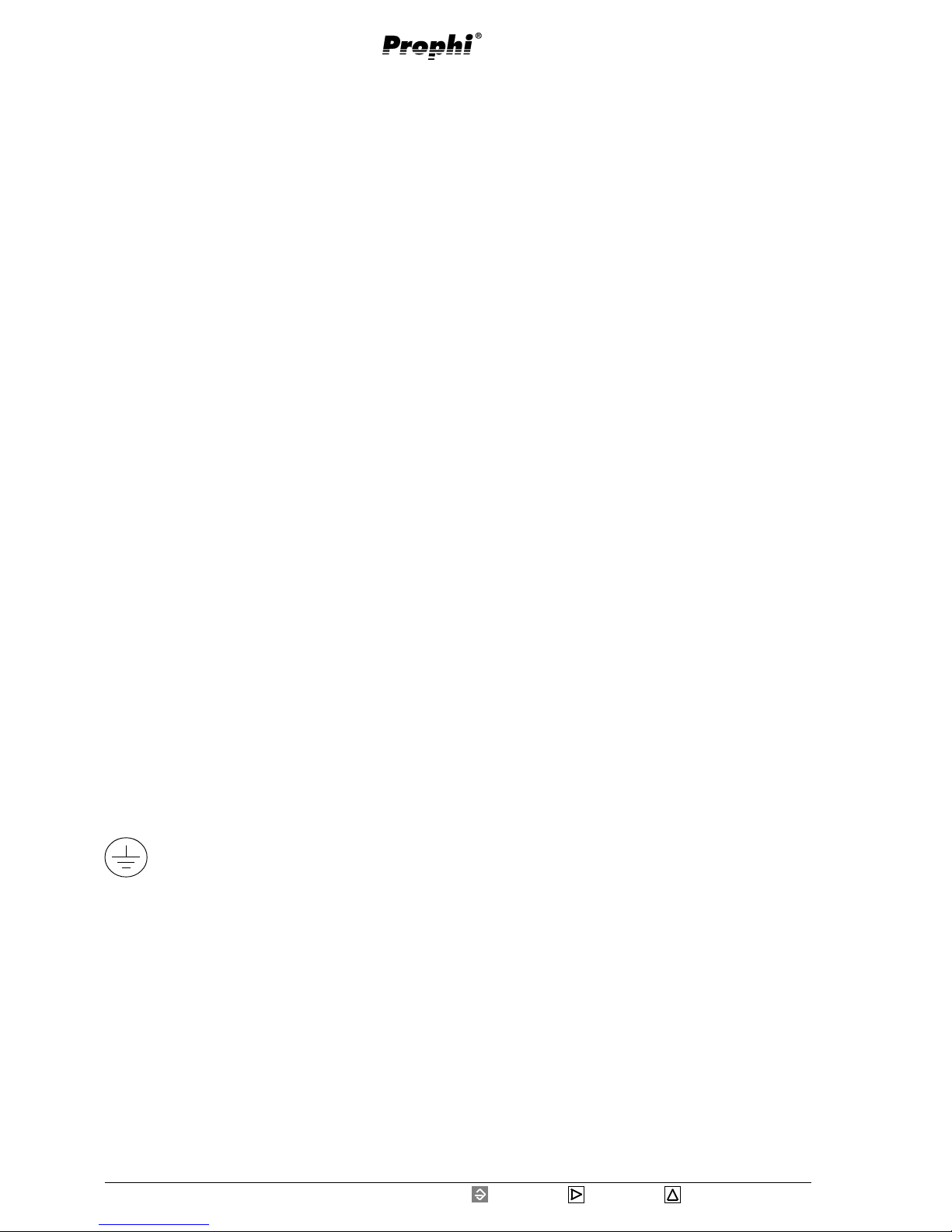

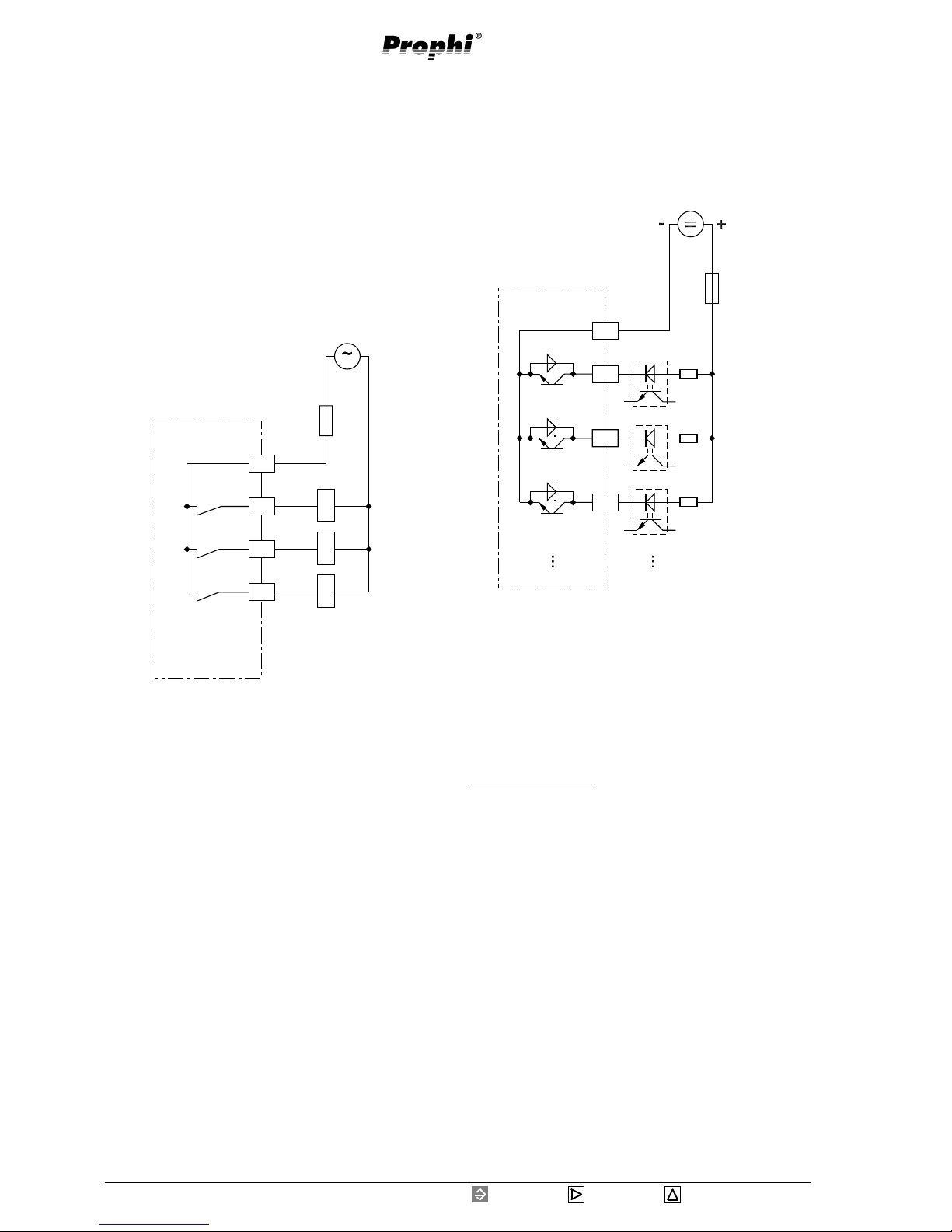

Diagr.: Connection example, power factor controller with measurement and supply voltage L2-L3,12 relais outputs,

target cos(phi) changeover and alarm output.

Prophi

Diagr.: Connection example, power factor controller with measurement and supply voltage L-N,12 relais outputs,

target cos(phi) changeover and alarm output.

Page 8

Page 8

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Hints for installation

Mounting place

The reactive power controller Prophi is suited for mounting and operation in reactive power compensation systems.

The connection is carried out on the back side via touch

proof spring power terminals.

Measurement and supply voltage

The measurement is suited for 3 phase systems with or

without neutral conductor. Measurement and supply

voltage are taken from the measurement voltage and

must be connected to the building installation via a

separation (switch or power switch) and an overcurrent

protection (2A...10A).

The reactive power controller measures and supervises

the voltage between two outer conductors. If one of

those two fails, the reactive power controller gets no

more measurement and operating voltage, and switches

on the capacitive stages after net return according to

the programmed times.

If the third outer conductor is missing, this will not be

recognized by the reactive power controller. If the contactors are supplied by this outer conductor, the contactors can attract simultaneously and without consideration of the discharge time after net return.

Falsch

False

Einspeisung

Supply

Verbraucher

Consumer

EVUMessung

ElectricityMeter

Prophi

Einspeisung

Supply

Verbraucher

Consumer

EVUMessung

ElectricityMeter

Prophi

Falsch

False

Einspeisung

Supply

EVUMessung

ElectricityMeter

Prophi

Falsch

False

Verbraucher

Consumer

Richtig

Correct

Einspeisung

Supply

Verbraucher

Consumer

EVUMessung

ElectricityMeter

Prophi

Attention!

The operating voltage for the contactors

should be taken from an outer conductor connected to the reactive power controller.

m

Abb.: Anschluss der Mess- und Hilfsspannung zwischen

L2-L3 und der Strommessung über Stromwandlers.

Prophi

Messung

Measurement

0,01 .. 5A

L/L

siehe Typenschild

see type label

../5(1)A

L1

L2

L3

PE

k l

2 .. 10A

Verbraucher

Consumer

kl L2L3

Page 9

Page 9

Reactive Power Controller

= Key 1 = Key 2 = Key 3

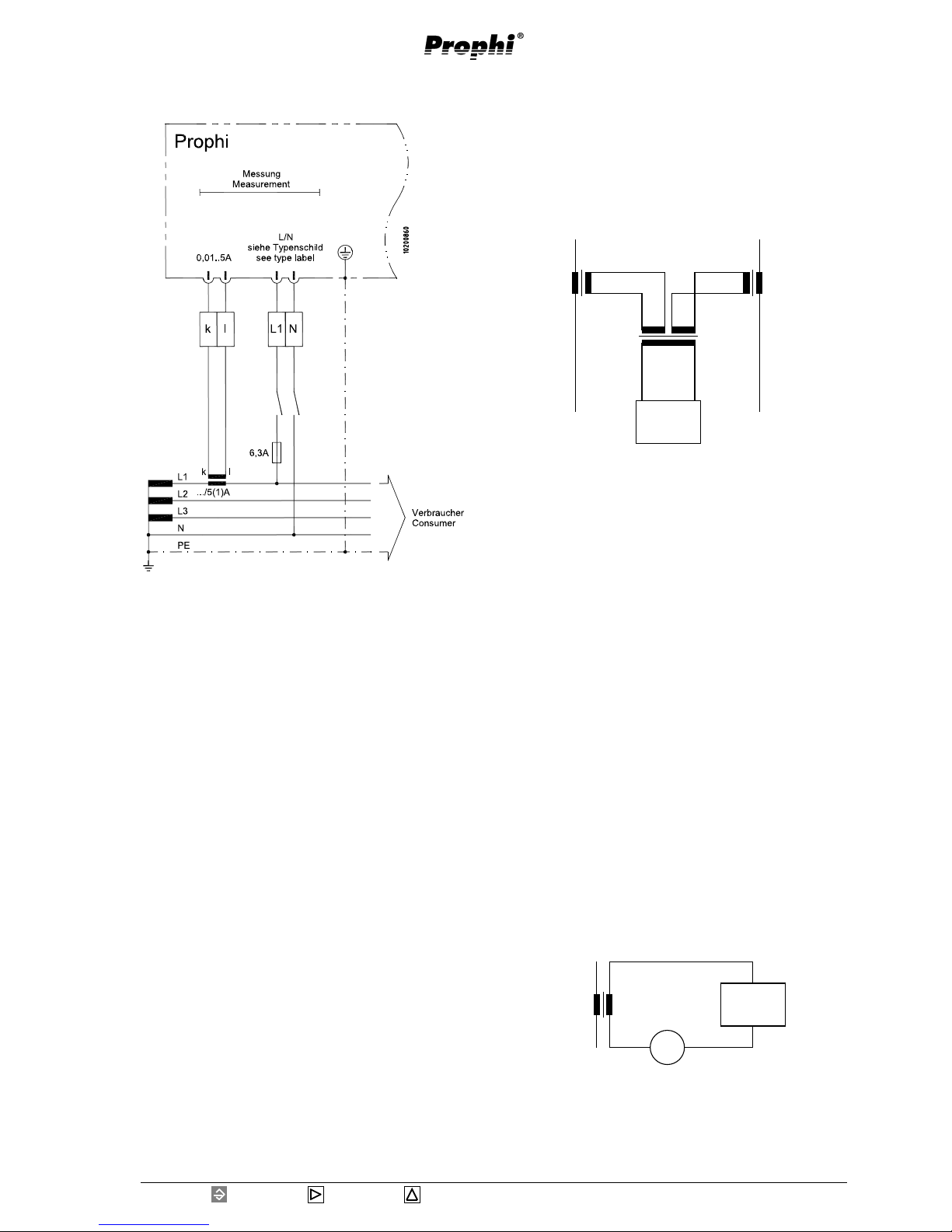

Diagr. Measurement with Amperemeter in series

Diagr. Measurement via sum current transformers

Current measurement

The current measurement is carried out via ../5A or ../

1A current transformers.

If the current must be measured with an Amperemeter

additionally to Prophi, it must be connected in series.

Sum current measurement

If Prophi is connected to a sum current transformer, the

total transformation ratio must be programmed.

Attention!

For unequal load of the outer conductors, the

current should be measured in the outer conductor, which is loaded most heavily.

Verbraucher 1

Consumer 1

Verbraucher 2

Consumer 2

Einspeisung 1

Supply 1

Einspeisung 2

Supply 2

Prophi

L l

k K

l L

K k

AK AL BK BL

kl

kl

Verbraucher

Consumer

Prophi

Einspeisung

Supply

L l

K k

A

k

l

m

Abb.: Anschluss der Mess- und Hilfsspannung zwischen

L1-N und der Strommessung über Stromwandlers.

Page 10

Page 10

Reactive Power Controller

= Key 1 = Key 2 = Key 3

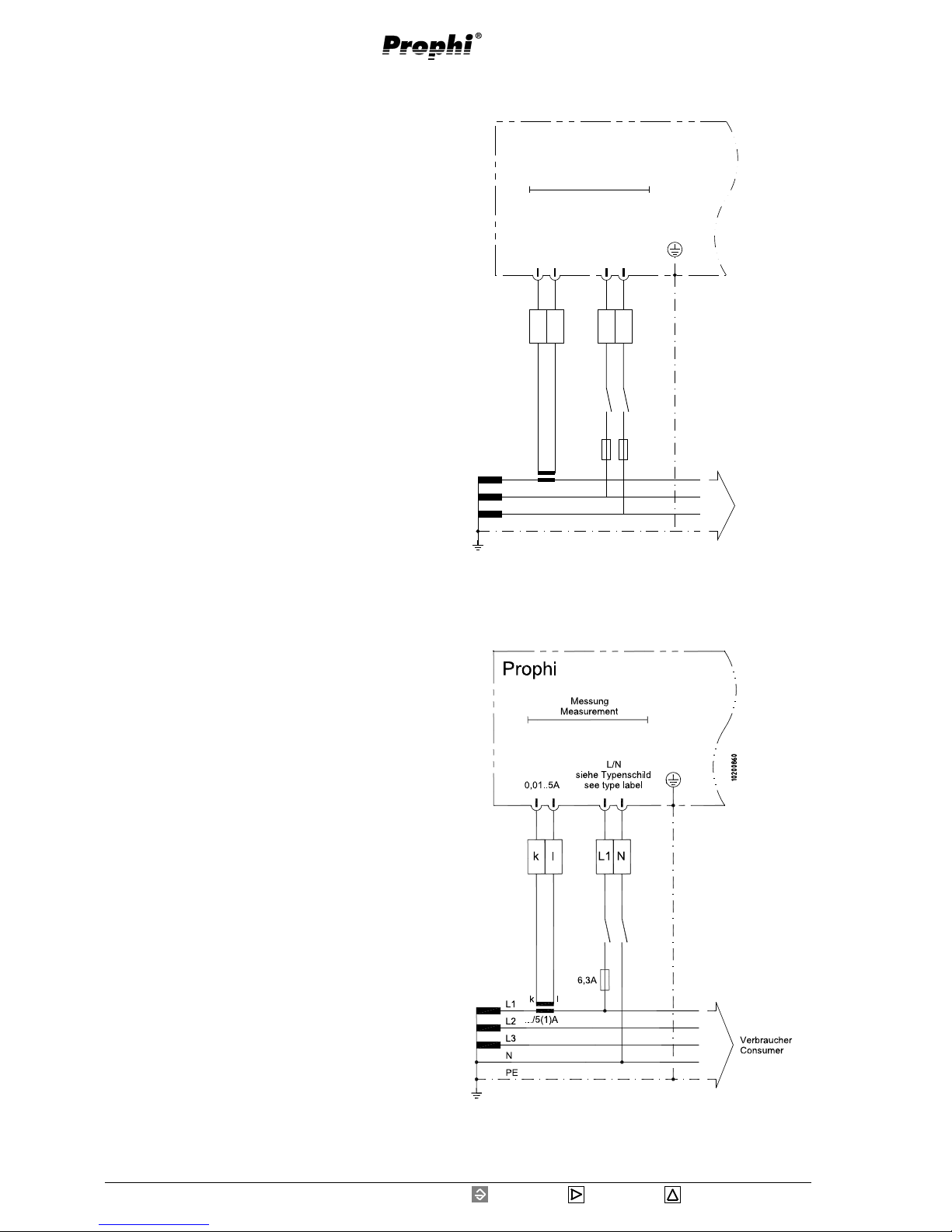

Installation and putting into service

Measurement and supply voltage

The controller Prophi can be delivered in two connection varieties for the measurement and supply voltage.

In the version measurement L-L, the measurement and

supply voltage must be taken from two outer conductors. In version measurement L-N, the measurement

and supply voltage must be taken between outer conductor L and neutral N.

Before connection, please ensure, that the local net conditions match the data on type plate. The range of the

measurement and supply voltage is given by the type

plate and is connected via a fuse (2…10A, time lag type)

Diagr.: Connection of measurement and supply voltage

(L2-L3) and current transformer.

c

c

Prophi

Messung

Measurement

0,01 .. 5A

L/L

siehe Typenschild

see type label

../5(1)A

L1

L2

L3

PE

k l

2 .. 10A

Verbraucher

Consumer

kl L2L3

Diagr.: Connection of measurement and supply voltage

(L1-N) and current transformer.

If the measurement and supply voltage is within the

allowed range, Prophi indicates the voltage on the terminal.

While measuring via voltage transformers, the voltage

transformer ratio must be programmed.

Attention!

The measurement and supply voltage must

come from the low voltage net, which is supervised.

The connected measurement and supply voltage may

not exceed the voltage, mentioned on type plate for

more than 10% or underscore for more than 15%.

To ensure, that the connected measurement and supply

voltage is within the allowed range, please check the

voltage at the terminal with a voltmeter.

Attention!

Voltage, which is out of the indicated range

on type plate can destroy the instrument.

c

Attention!

The operating voltage for the contactors should

be received from an outer conductor connected

to the controller.

Page 11

Page 11

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Current measurement

The current transformer is connected to the clamps k

and l (/5A or /1A) from the outer conductor L1.

Please ensure during the installation of the current transformer, that the current transformer is passed by the

consumer current but not by the compensation current.

The current can be measured by an Amperemeter to

compare it with the current indicated by Prophi to check.

Please note, that the factory's presettings of the current

transformer ratio is set to 10 and must be adapted to the

existing current transformer.

If you should short-circuit the current transformer, the

indicated value on Prophi must decrease to 0A.

Examples for the setting of the current transformer

Example 1

Current transformer 200A/5A

Set Prophi to 40

Example 2

Current transformer 500A/1A

Set Prophi to 500

Example 3

Sum current transformer 1000A+1000A/1A

Set Prophi to 2000

Attention!

For unequal load of the outer conductors, the

current should be measured in the outer conductor, which is loaded most heavily.

Real power

If current and voltage are connected to Prophi according to the connection diagram, a positive real power is

displayed in case of real power consumption. Real power

with a negative sign in the indication points to the supply of real power or an error of connection.

Possible error:

- Voltage and current are measured in the wrong outer

conductor.

- The current transformer clamps (k-l) are exchanged.

m

m

Attention!

None earthed current transformer clamps can

be live.

Page 12

Page 12

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Switching outputs

The reactive power controller Prophi can be equipped

with up to 12 switching outputs. The switching outputs

can be equipped either with relay or transistor outputs.

If a device is equipped with relay or transistor outputs

it is not shown on display. The equipment can be seen

in the connection diagram on the back of Prophi.

Relay outputs

Capacitor contactors can be connected to the relay outputs according to the connection example "Relay outputs".

Transistor outputs

Semi conductor switches, switching at zero crossing,

must be connected to the transistor outputs of the reactive power controller.

The transistor outputs switch the voltage of an external

d.c. net supply to the semiconductor switches.

Check switching outputs

Please switch in the capacitor stages in manual mode:

The inductive reactive power is decreased by the power

of the respective capacitor stage.

Please switch off the capacitor stages in manual mode:

The inductive reactive power is increased by the power

of the respective capacitor stage.

Possibility of errors:

The outputs do not switch

- Relay output defective.

- Transistor output defective.

The change of the reactive power is faulty

- The current is measured incorrectly.

- A wrong current transformer ratio is set.

- The current is measured in the wrong outer

conductor.

- The voltage is measured in the wrong outer

conductors.

- The current transformer clamps k-l are exchanged.

The reactive power does not change

- The current transformer is installed at the wrong

place.

- Switching outputs faulty.

- The wrong control voltage is connected to the

switching outputs.

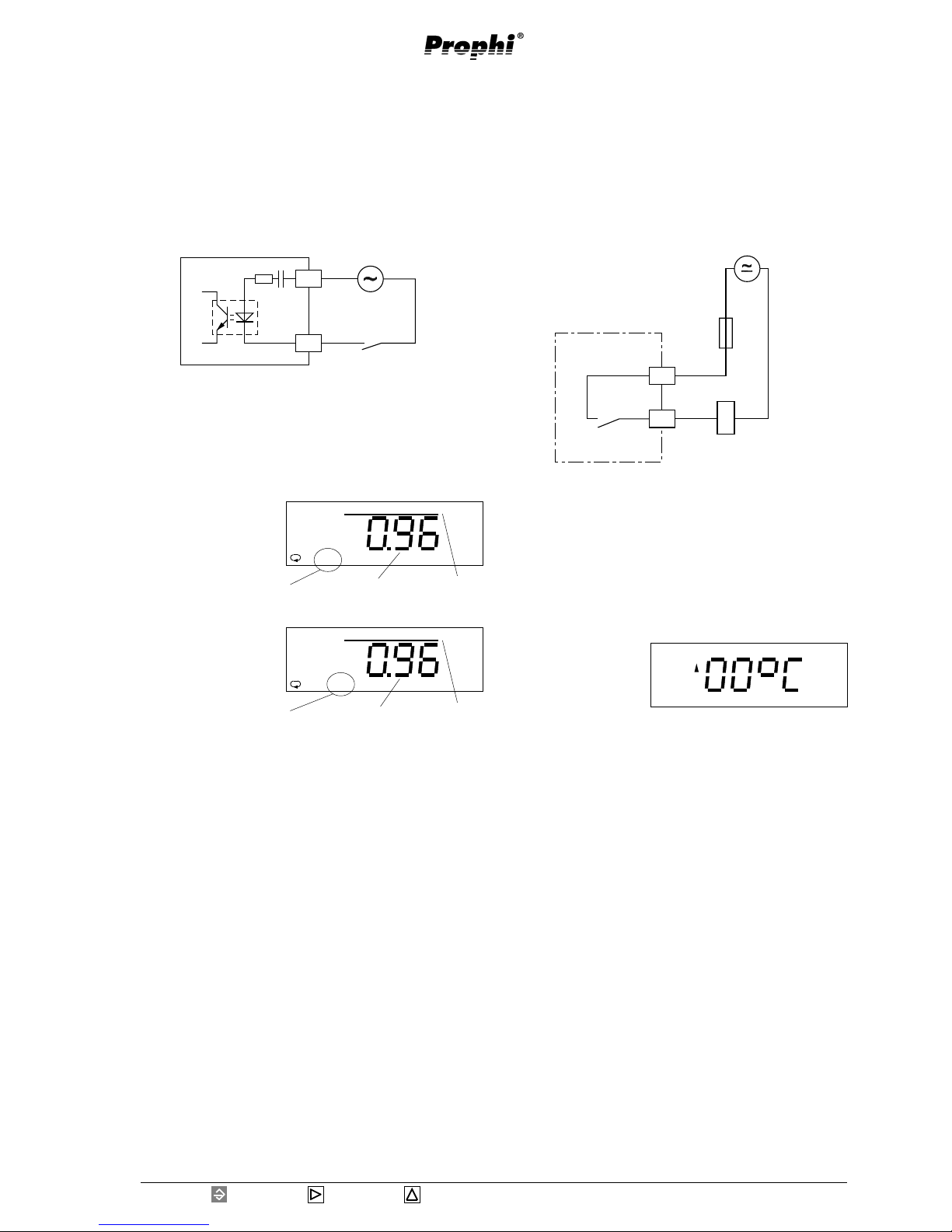

Diagr.: Connection example "Transistor outputs"

Attention !

For devices with relay or transistor outputs,

there are different control voltages applied

to the switching outputs.

15-30VDC

F0,2A

Prophi

1

2

3

C1

Diagr.:Connection example "Relay outputs"

Attention!

The relai and transistor outputs are live.

c

m

Prophi

C1

1

2..10A

max. 250V

2

3

Attention!

If a switching frequency of 50Hz is programmed

for the transistor outputs, the serial interface

does not work!

m

Page 13

Page 13

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Target-cos(phi) changeover

Via the input target-cos(phi) changeover it can be

changed over between target-cos(phi1) and target-

cos(phi2).

If there is no voltage at the input, the target-cos(phi1)

is active. If there is a 85 bis 265V AC connected to the

input, the target-cos(phi2) is active.

In the standard display (please see example), apart from

the active channels and the actual cos(phi) also the active target-cos(phi) is indicated.

Target-cos(phi1) is active.

cos

ϕϕ

ϕϕ

ϕ

ind

1 2 3

ϕ1ϕ1

ϕ1ϕ1

ϕ1

Actual cos(phi) mean

value

Target-cos(phi2) is active.

cos

ϕϕ

ϕϕ

ϕ

ind

1 2 3

ϕ2ϕ2

ϕ2ϕ2

ϕ2

Actual cos(phi) mean

value

Diagr.: Connection diagram target-cos(phi) changeover

85 - 250V AC

15

16

ϕ1

ϕ2

Prophi

Alarm output

The alarm relay attracts in undisturbed operation, and

the contact of the alarm output is closed. If a disturbance occurs, the alarm relay releases and the contact is

opened. Various events can be assigned to the alarm

output via OR-logic interconnections. Each event is assigned to an alarm number, an alarm delay and alarm

duration.

Check alarm output

If there is no alarm, the alarm relay attracts immediately. In order to trigger off an alarm, the threshold for

overtemperature can be set to zero, for instance, and

the alarm relay releases immediately.

Diagr.: Connection diagram alarm output

13

14

T6,3A

max. 250V

Error

Prog

Page 14

Page 14

Reactive Power Controller

= Key 1 = Key 2 = Key 3

RS485 Interface (Option)

Transmission protocols

Two tran smiss ion pr otoco ls are availa ble fo r the c onnec tion to an existing field bus system:

0 - Modbus RTU (Slave) and

1 - Profibus DP V0 (Slave) .

Wi th Mod bus pro tocol you can have ac cess t o the da ta of

table 1, and with Profibus protocol you can have access

to the data of table 2.

Bus structure

All devices are connected in bus structure (line). In one

segment up to 32 participiants can be assembled. At the

end and the beginning of each segment, the cable must

be terminated by resistors. In

Prophi

you can activate

these resistors with two plug-ins.

For more than 32 participiants you must use a repeater

(line amplifier) to connect the single segments.

Shielding

For connections via RS485 interface, you need a protected and twisted cable. To achieve a sufficient protection result, the shielding must be connected at both ends

extensively to the housing or parts of the cabinet.

Cable specifications

The maximum cable length depends on cable type and

transmission speed. We recommend cable type A.

Cable parameter Type A Typ B

Impedance 135-165Ohm 100-130Ohm

(f = 3-20MHz) (f > 100kHz)

Capacity < 30pF/m < 60pF/m

Resistance < 110 Ohm/km Diameter >= 0,34mm2 >= 0,22mm2

(AWG22) (AWG24)

Cable length

The following table shows the maximum cable length in

meters (m) for various transmission speed

.

Baud rate (kbit/s)

Cable type 9.6 19.2 93.75 187.5 500 1500

Type A 1200 1200 1200 1000 400 200

Type B 1200 1200 1200 600 200 70

Terminal resistors

If

Prophi

is connected to the end of the bus cable, the

bus cable must be terminated at this point with resistors.

The required resistors are integrated within the

Prophi

and are activated in position ON.

Diagr. Connection RS485 interface

1

0200740

392R 221R 392R

23

22

21

A

B

+5V

OFFON

GND

GND

Termination

Prophi

Page 15

Page 15

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Removal of errors

Possible cause

- Wrong measurement and supply voltage

connected.

- Prefuse (10A time-lag type) has triggered.

- Current measurement in the wrong outer

conductor.

- Wrong current transformer ratio.

- Current out of measuring range.

- Current transformer clamps are bridged.

- One current transformer line is interrupted.

- A current measuring device is connected

parallely.

- Wrong voltage transformer ratio.

- Uneven load of the outer conductors.

- Wrong voltage transformer ratio.

- Voltage and/or current are measured incorrectly.

- Voltage and current are measured in the

wrong outer conductors.

- Voltage and/or current are measured incorrectly.

- The current transformer connection (k-l) is

exchanged.

The measuring current is smaller but 10mA.

The measuring voltage is interrupted.

The current transformer clamps are bridged.

- Voltage is measured incorrectly.

- Current is measured incorrectly.

- Real power is measured incorrectly.

The current transformer is installed after the

measurement of the energy supplier.

Current and voltage are connected in-correctly.

The capacitor current is not detected by the

current transformer.

Capacitive stages are faulty.

The measurement and operating voltage is

exceeded by more than 10%.

Current measurement in wrong phase.

L1 and L3 are exchanged.

The device is defective.

Remedy

Please check measurement and supply voltage.

Please check current measurement.

Please check voltage measurement.

Please check current and voltage

measurement.

Please check current and voltage

measurement.

Please check current measurement.

Please check current and voltage

measurement.

Check and correct connection.

(Please see hints for installation)

Check and correct connection.

(Please see hints for installation)

Check and correct mounting position of the current transformer.

Check capacitive stages.

Check measurement and operating

voltage.

Check measurement and operating

voltage.

Send the device to the manufacturer

with an exact description of the error.

Description of the error

No indication.

Current

too little / too high.

Voltage

L2-L3 too little / too high.

Real power

too little / too high.

Real power supply/consumption exchanged.

Cos(phi) = 0.00

Cos(phi)

too high / too little.

Cos(phi) does not change,

although all capacitor

stages were switched in.

Cos(phi) is indicated capacitive on Prophi, but,

nevertheless, the reactive

power meter measures reactive power.

Prophi only connects

stages, but does not disconnect.

The outputs can only be

disconnected.

Prophi shows a cos(phi) of

0,2 - 0,4 capacitive.

It does not work.

Page 16

Page 16

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Service

If certain questions appear, which are not mentioned in

this handbook, please call us directly.

To be able to support you, we require the following

information:

- Device description (see type plate),

- Serial number (see type plate),

- Software Release,

- Measurement and supply voltage and

- Exact description of the error.

You can reach us:

Monday to Thursday from 07:00 to 15:00

and on Friday from 07:00 to 12:00

Janitza electronics GmbH

Vor dem Polstück 1

D-35633 Lahnau

Support:

Tel. (0 64 41) 9642-22

Fax (0 64 41) 9642-30

e-mail: info@janitza.de

Page 17

Page 17

Reactive Power Controller

= Key 1 = Key 2 = Key 3

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2 learn 1:1... Prog

Display and use

In the front side of Prophi there is a digital indication

and three keys, with which you can question data and

program the device.

If you are in automatical mode, you can change between the operating modes using key 1:

automatic mode,

manual mode,

standard programming and

expanded programming

automatic mode

manual mode

standard programming

expanded programming

In standard programming often needed settings are carried out such as current transformer ratio or the number

of stages.

In expanded programming those settings are carried out,

which are used not as often, such as discharge time or

choke degree.

To reach the expanded programming from automatic

mode, leaf through the standard programming using key

1 until the symbol "Prog" appears. Confirm selection

with key 2, and you are in expanded programming.

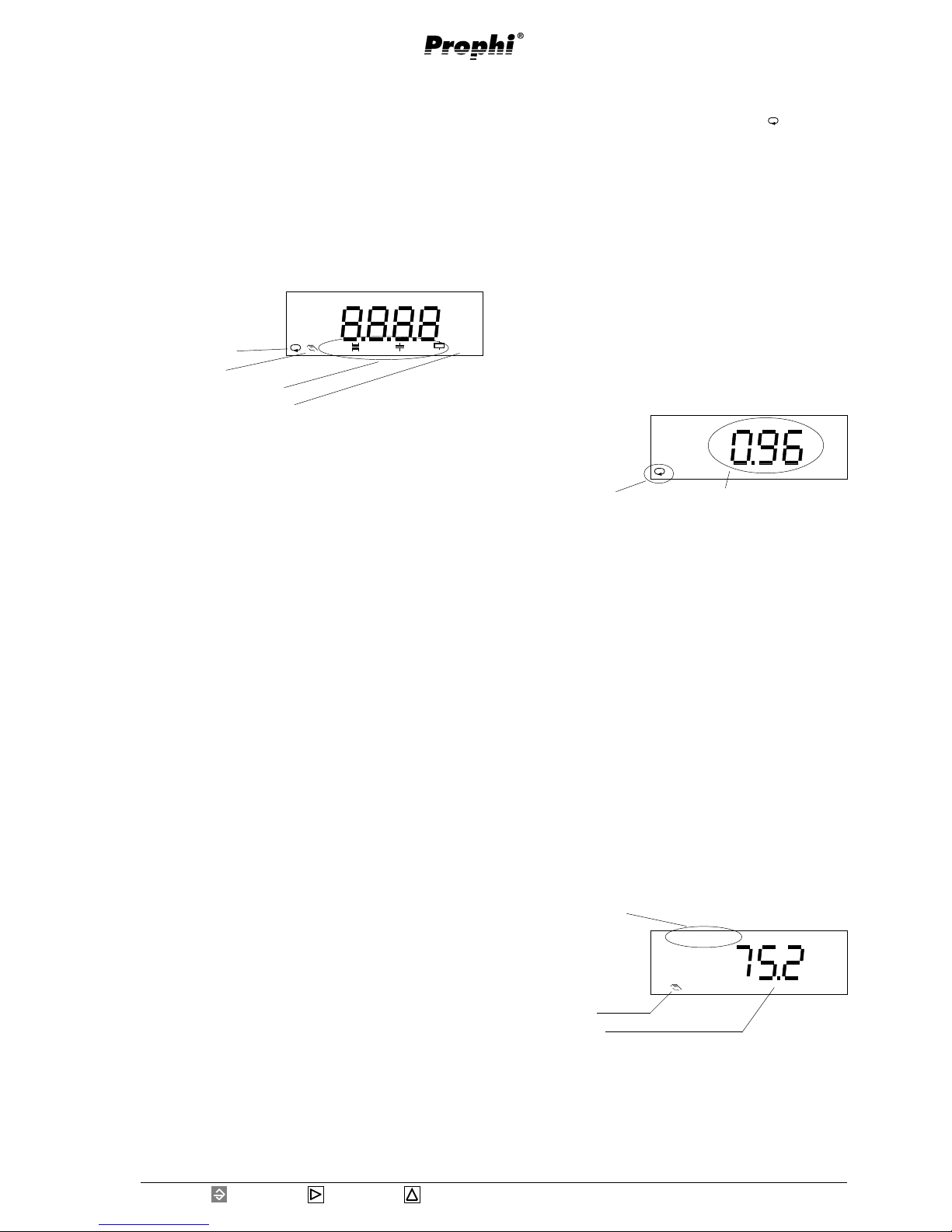

Automatic mode

Automatic mode is marked by the symbol .

In automatic mode, there is:

- the switching condition of capacitive stages,

- the actual value of cos(phi) indicated,

- Connection and disconnection of capacitive stages,

- all 15 minutes saving of

peak and lowest values,

number of switchings of the capacitor stages and

the switching times of capacitor stages.

- Indication of measured values using key 2 and 3.

There are three possibilities to reach automatic mode:

- after net return,

- pressing key 1 for about 2 seconds,

- pressing no key in programming mode for

1 minute.

Automatic mode

cos

ϕϕ

ϕϕ

ϕ

ind

1 2 3

ϕ1ϕ1

ϕ1ϕ1

ϕ1

Actual value cos(phi)

Manual mode

In manual mode, you can switch in capacitor stages

using key 3, and switch off capacitor stages using key

2. The time between two switchings is only limited by

the programmed discharge time. If one stage shall be

connected in manual mode and a discharge time is running, the number and capacitor stage is flashing.

If no capacitors are switched in manual mode, an

automatical jumpback to automatical mode is carried

out after 15 minutes.

Manual mode

Reactive power

Connected stages

k VAr

ind

1 2 3 4 5

Page 18

Page 18

Reactive Power Controller

= Key 1 = Key 2 = Key 3

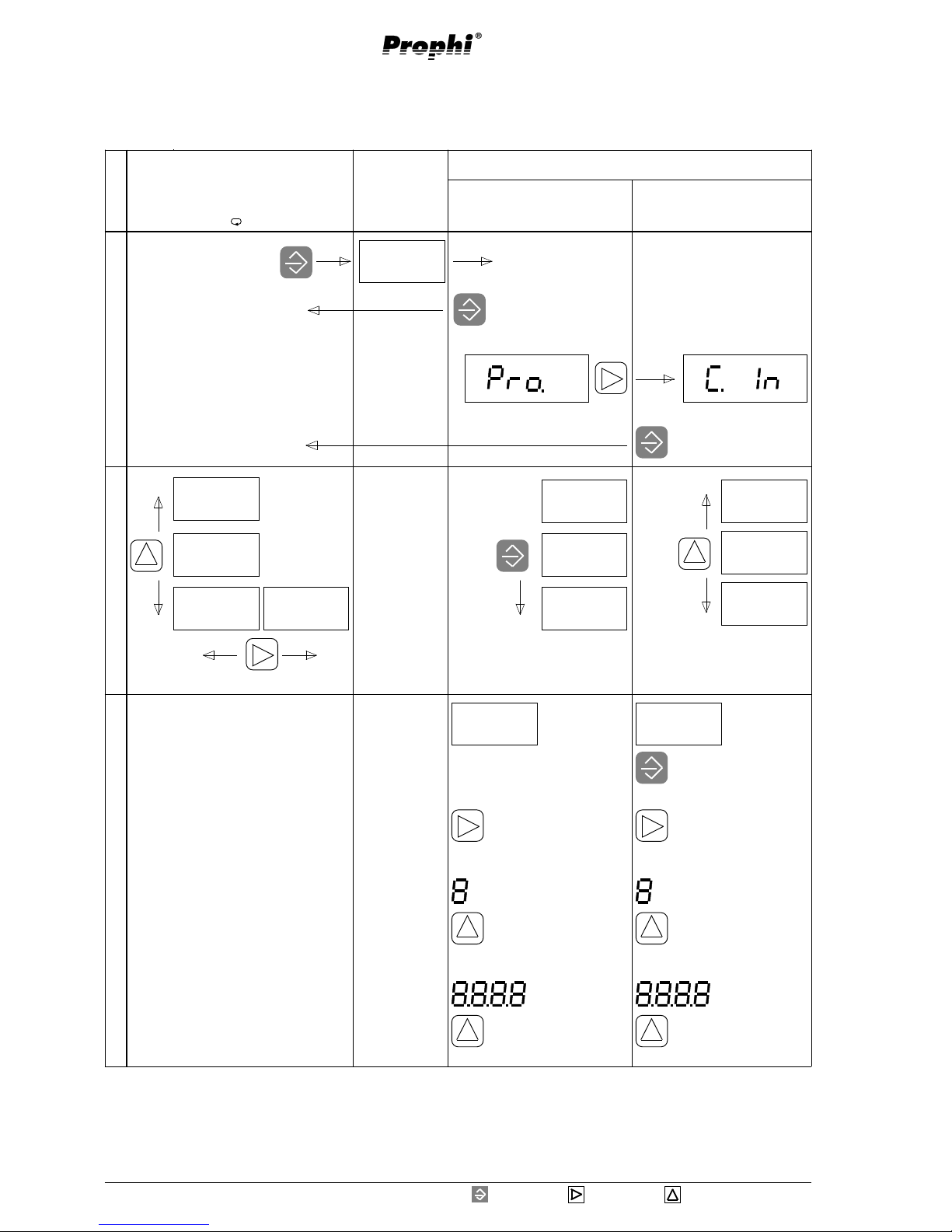

Change mode

LeafProgramming

Expanded programming

Automatic mode

Manual mode

Standard programming

Password

Meas. values

Meas. values

Meas. values

Meas. values

Programming

Menue

2 seconds

short long

long short

short

Programming

Menue

Programming

Menue

Programming

Menue

Confirm selection

Select number Select number

short value *10

long value /10

short number +1

long number -1

short number +1

long number -1

short value *10

long value /10

Programming

Menue

short

Key functions

Prog

Programming

Menue

Programming

Menue

short long

Programming

Menue

Prog Prog

2 seconds

Page 19

Page 19

Reactive Power Controller

= Key 1 = Key 2 = Key 3

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2

learn 1:1... Prog

Target cos(phi)

In automatic mode

Prophi tries to reach

the set target power

factor by switching in

or off the capacitor

stages.

It is possible to set a target-cos(phi1) and a targetcos(phi2). Devices without target-cos(phi) changeover

always use the target-cos(phi1). Devices with an input

for target-cos(phi) changeover switch to target-cos(phi2),

whenever the input is active.

Range 0.80cap. - 1.00 - 0.80ind.

The active target-cos(phi) is indicated in the measured

value indication for the actual-cos(phi).

Example:

cos

ϕϕ

ϕϕ

ϕ

ind

ϕ1ϕ1

ϕ1ϕ1

ϕ1

cos

ϕ

ϕ

ϕϕ

ϕ

ind

ϕ1ϕ1

ϕ1ϕ1

ϕ1

Programming

Press key 1 for about

2 seconds to select automatic mode.

Press key 1 to leaf to

manual mode until indication target cos

(phi).

Select the number to be

changed using key 2.

The selected number

flashes.

Change the selected

number by pressing

key 3.

Target-cos(phi1) is active.

ϕ1ϕ1

ϕ1ϕ1

ϕ1

Standard programming

In the standard programming, the settings needed frequently are carried out, such as:

- target-cos(phi1),

- target-cos(phi2),

- current transformer ratio,

- learning of configuration,

- power of the first capacitive stage,

- stage ratio,

- number of stages,

- delete peak values (no indication).

Standard-Programming

Automatic mode

cos

ϕϕ

ϕϕ

ϕ

ind

1 2 3

ϕ1ϕ1

ϕ1ϕ1

ϕ1

Automatic mode

Manual mode

Ta rget cos(p hi1 )

Press key 1 for about 2 seconds. You return to automatic mode, and the changes are saved immediately.

In delivery condition no password is programmed. The

change from automatic mode into standard programming is carried out without password protection.

If a password is programmed by the user, the change

from automatic mode to standard programming is carried out only after password clearance.

Change from automatic mode to standard programming

and back:

Password

2 seconds

short

Standard

Programming

Automatic mode

cos

ϕϕ

ϕ

ϕ

ϕ

ind

1 2 3

Page 20

Page 20

Reactive Power Controller

= Key 1 = Key 2 = Key 3

ϕϕ

ϕϕ

ϕ1

ϕϕ

ϕϕ

ϕ2 learn 1:1... Prog

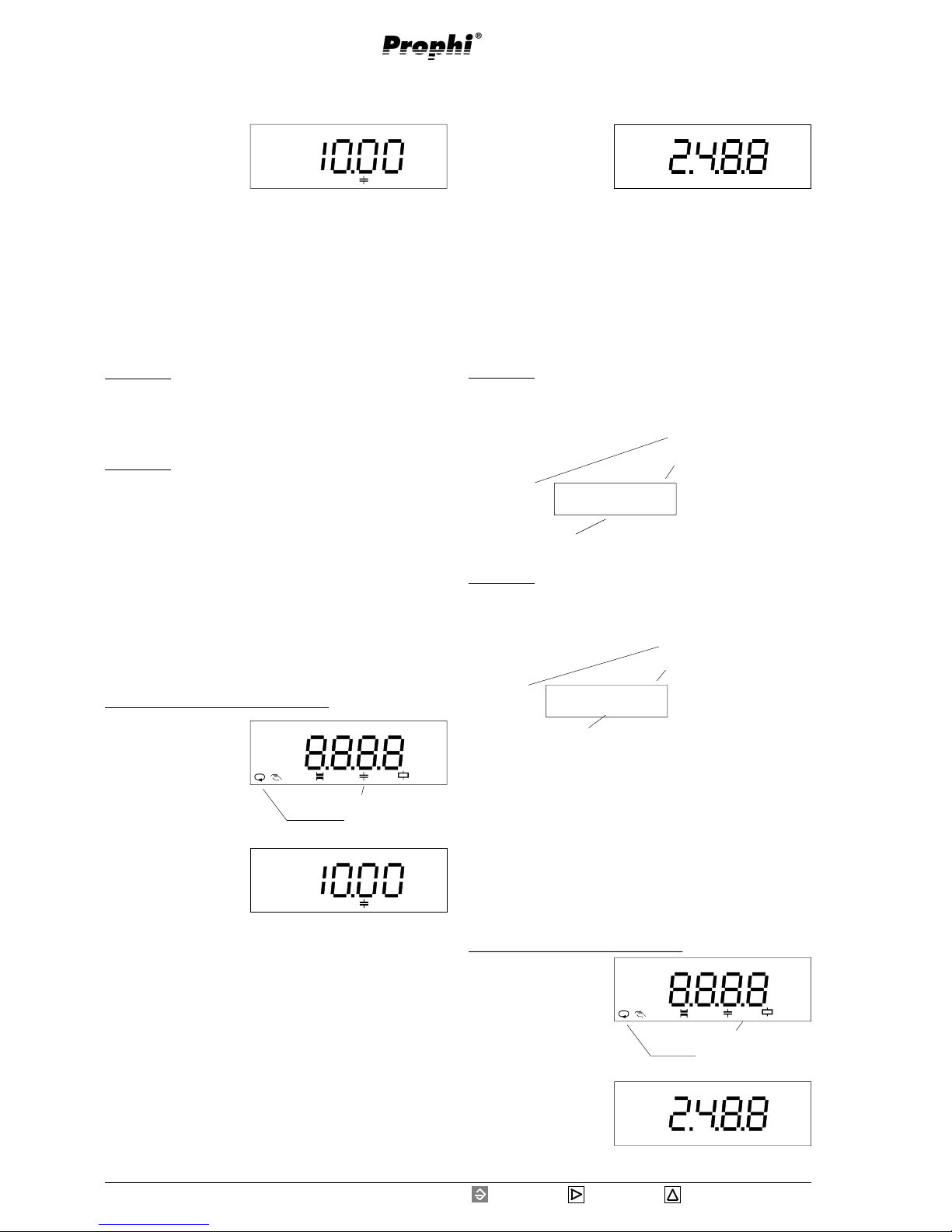

Current transformer ratio

At the measuring input of the current

measure-ment either /

5A or /1A current

transformers can be

connected. In order to get a correct current and power

indication, the current transformer ratio of the connected

current transformer must be set to Prophi. If the current

is measured via a sum current transformer, the total

current transformer ratio must be set.

Example 1: Current transformer 500A/5A

The current transformer ratio is now calculated to

500A : 5A = 100

A ratio of 100 must be set on the device.

Example 2: Current transformer 200A/1A

The current transformer ratio is calculated to

200A : 1A = 200

A ratio of 200 must be set on the device.

Example 3: Sum current transformer

Transformer 1 200/5A

Transformer 2 400/5A

Sum current transformer 5+5/5A

The current transformer ratio is calculated to

(200A + 400A) : 5A

600A : 5A = 120

CT ratio

Automatic mode

Programming

Example: Current transformer ratio 1000

Select indication for

current transformer ratio using key 1.

The automatic symbol

disappears.

Select the digit to be

changed. The selected

digit is flashing.

Change the selected

digit pressing key 3.

Current transformer ratios of more but 1000 are indicated with a decimal point automatically.

Example: Current transformer ratio = 1200 = 1.200k

Indication on display "1.200k"

k

Page 21

Page 21

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Learning of the configuration

After installation of the

controller there is the

possibility to learn and

save the configuration

with the function

"learn".

Important requirements are:

- The discharge time for capacitors is set to 60 seconds,

when the device is delivered. For capacitors with longer

discharge times, the discharge time must be checked

and changed before using the "learn" function.

- The current transformer must be flown through by

consumer and compensation current.

- The measurement and supply voltage may not be taken

from phase to N.

- The compensation system must be ready for operation.

The learning function of the controller is devided into

two steps:

Step 1 - Learning of the connection configuration

Here the correction angle between current transformer

and measurement and supply voltage is detected.

Step 2 - Learning of the capacitor stages

Here the number of outputs and the stage power of

each stage is detected.

The following requirements are neccessary:

- The switching of a capacitor stage must cause a change

of current of at least 50mA at current input.

- The stage power of the stage to be learned must be

bigger than 1% of the measuring range of the controller.

Attention!

After learning, the saved configurations must be checked,

if they are plausible.

The following actions can be carried out:

oFF - No learning.

1 - Step 1, learning of the connection configuration.

2 - Step 2, learning of capacitor stages.

3 - Step 1 + 2, learning of the connection

configuration and capacitor stages.

learn

Prog

Start learning

Go to symbol learn using key 1. Select action

(oFF, 1, 2, 3) with key

3. Start learning with

key 1.

The symbol learn flashes. The controller learns.

During the learning the capacitor stages are switched

for several times. The learning can only be interrupted

by switching off the power factor controller.

The duration of the learning procedure depends on the

net conditions, the number of capacitor stages and the

set discharge time for the capacitors.

When the learning

procedure is finished,

the detected correction

angle, in the example

270°, is indicated.

The learned characteristics are saved.

After 60 seconds the controller changes to automatic

mode. Pressing key 1 for 2 seconds, you reach automatic mode at once.

learn

Page 22

Page 22

Reactive Power Controller

= Key 1 = Key 2 = Key 3

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2 learn 1:1... Prog

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2 learn 1:1... Prog

Stage ratio

The stage ratio states

the ratio of the stage

power of the various

capacitor stages. The

power of the first capacitor stage serves as a reference. The stage ratio is

programmable for each stage up to the fifth stage.

Setting range : 0 - 9

In the display only the stage ratio for the capacitor

stages 2, 3, 4 and 5 are indicated. The stage ratio for

the first capacitor stage is always 1.

Example 2

The stage ratio is programmed to 1:2:0:2:2:2.... In the

4-digit display only the part "2:0:2:2" is indicated.

Example 1

The stage ratio is programmed to 1:2:4:8:8:8..., and in

the four digit-display, only the part "2:4:8:8" is indicated.

Stage power

The stage power is the

power of a capacitor

stage. In the standard

programming the stage

power can only be programmed for the first stage. In the expanded programming you can set the stage power for each capacitor

stage. If you only enter the stage power for the first

capacitor stage, the other stages are fixed by the stage

ratio. The stage power of each capacitor stage can be

calculated from the first stage and the corresponding

stage ratio.

Ratio 0var - 9999kvar

Example 1

Power of the first capacitor stage = 10kvar

Stage ratio = 1:1:1:1:1....

All following stages have the power: 10kvar

Example 2

Power of the first capacitor stage = 20kvar

Stage ratio = 1:2:4:8:8....

The stages have the power:

1. Stage = 20kvar

2. Stage = 40kvar

3. Stage = 80kvar

4. Stage = 160kvar

5. Stage = 160kvar

etc.

1:1...

Please select the indication for stage power

using key 1.

The automatic symbol

disappears.

Select the digit to be

changed using key 2.

The selected digit is

flashing.

Change the digit by

pressing key 3.

Example: Programming stage power

Stage power

Automatic

k VAr

If all numbers are flashing, the decimal point of the set

number is moved.

Please select the indication of the stage ratio using key 1.

The automatic symbol

disappears.

Please select the digit

to be changed using

key 2. The selected

digit is flashing.

Change the selected

digit by pressing key 3.

Example: Programming stage ratio

1:1...

Stage ratio

Automatic

If the first capacitor stage has a power of 10kvar, the

following stages have the power:

1. Stage = 10kvar

2. Stage = 20kvar

3. Stage = 0kvar

4. Stage = 20kvar

5. Stage = 20kvar

etc.

1 . 2 . 4 . 8 . 8 . 8....

Indicated on display.

1. capacitor stage

5. capacitor stage

1 . 2 . 0 . 2 . 2 . 2....

Indicated on display.

1. capacitor stage

5. capacitor stage

k VAr

Page 23

Page 23

Reactive Power Controller

= Key 1 = Key 2 = Key 3

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2 learn 1:1... Prog

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2ϕ1 ϕ2

ϕ1 ϕ2 learn 1:1... Prog

The switching outputs can be equipped with either relay or transistor outputs.

If a device is equipped with relay or transistor outputs

it cannot be read on display. The equipment can only

be seen on the back side of Prophi in the connection

example.

Example 2: Prophi with 3 transistor outputs

Please check, if 3 transistor outputs are programmed.

The programming and indication of the switching outputs is carried out in the menu standard programming.

Please go to the indication of the number of

stages.

The automatic symbol

disappears.

Only two stages are

programmed!

Select the digit to be

changed using key 2.

The selected digit is

flashing.

Change the selected

digit using key 3.

Prophi is available in three varieties regarding the

switching outputs.

1. Only relay outputs

2. Only transistor outputs

3. Relay and transistor outputs mixed

In the menus of the standard programming, only the

variations 1 and 2 can be programmed.

In mixed operation the switching outputs with smaller

numbers are always the relay outputs.

The relay outputs in mixed operation are programmed

in the menu of standard programming, and the transistor outputs are programmed in the menu of expanded

programming. The programming of the transistor outputs is carried out indirectly via the stage power of the

switching outputs. For transistor outputs, to which no

semiconductor switch is connected, a capacitor power

of 0kvar is set.

Please select the indication of the switching

outputs using key 1.

The automatic symbol

disappears.

Please select the digit

to be changed using

key 2. The selected

digit is flashing.

Change the selected

digit by pressing key 3.

Example 1: Prophi with 12 relay outputs

10 of the 12 existing outputs shall be engaged.

The programming and indication of the switching outputs is carried out in the menu standard programming.

Switching outputs

Automatic

Switching outputs

Automatic

Switching outputs

Variety 1 2 3 4 5 6 7 8 9 10 11 12

3R R R R

3T T T T

6R R R R R R R

6T T T T T T T

6R6T R R R R R R T T T T T T

12R R R R R R R R R R R R R

12T T T T T T T T T T T T T

T= Transistor outputs

R= Relay outputs

Diagr. Varieties of the switching outputs

Switching outputs

The reactive power

controller Prophi can

be equipped with up to

12 switching outputs.

Switching outputs

Page 24

Page 24

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Prog

Example 3: Prophi 6R6T with 6 transistor outputs and

6 relay outputs

Two transistor outputs and 6 relay outputs shall be programmed.

The programming of the relay outputs is carried out in

the menu standard programming, and the programming

of the transistor outputs is carried out in the menu expanded programming.

1. step: Programming of the relay outputs.

In standard programming you move to the

indication of the

number of stages using

key 1. 6 stages are programmed, so no change is required.

2. step: Programming of the transistor outputs.

The programming of the transistor outputs is carried

out in the expanded

programming.

Please move to the expanded programming

using key 1. Now press

key 2.

In the expanded programming appears the

menu point "Fix

stages".

Prog

Prog

Using key 3, you reach

the indication stage

power.

Here the stage (7) is selected by pressing key

2. Please confirm with

key1. One digit for the

stage power is flashing.

k VAr

1

Prog

If this stage is engaged, the required stage power must

be programmed by pressing the keys 2 and 3.

Select the digit to be changed using key 2. The selected

digit is flashing. Now change the digit using key 3.

If all ciphers are flashing, the shown digit can be multiplied by 10 using key 3. Also the dimension of the unit

can be changed.

Delete peak and lowest values

Peak and lowest values

of various measured

values are saved every

15 minutes.

The peak values and

lowest values can only be deleted altogether.

The following values are not deleted:

Peak temperature value,

Switching time of the capacitor stages and

Number of switchings per stage.

Example: Delete peak values

Move to indication for

peak and lowest values

by pressing key 1.

The automatic symbol

disappears.

Select delete with key 3.

Text "on" is flashing.

With key 1 you move

to the expanded programming and activate

deletion.

VAr

7

flashing

Automatic

Page 25

Page 25

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Prog

Fix stages

The first three capacitor stages can be fixed

switched in alternatively. Fix stages are

marked by a line below the number of the capacitor stage.

Fix stages cannot be included in the controlling. Nevertheless they are considered in the stage ratio, so that in

the stage ratio in the most disadvantageous case (three

fix stages) in the standard programming only two stage

ratios are available. To get a better solution of the stage

power, the capacitor power must be set for every single

stage in the expanded programming .

Prog

1. capacitor stage (Fix stage)

2. capacitor stage (Fix stage)

3. capacitor stage (Fix stage)

controllable capacitor stages

Example 1: Indication of stage ratio

Example: Programming of fix stages

Please select the fix

stages by using key 1.

The first three stage

numbers are flashing.

1 2 3

Prog

cos

ϕϕ

ϕϕ

ϕ

ind

1 2 3 5 6 12

ϕ2 ϕ2

ϕ2 ϕ2

ϕ2

The fix stages 1, 2 and

3 are switched in

Target-cos(phi2) is active.

Capacitor stages 5,6 and 12

are switched in

The actual mean cos

(phi) is 0.96ind.

Example 2:Indication of fix stages in automatic mode

Indicated on display

Expanded programming

In the expanded programming those settings are carried out,

which are required

very rarely.

With key 3 you can change between the indications.

With key 1 the selected indication can be chosen for

changing.

The following settings and readings can be carried out in

expanded programming:

Fix stages,

Discharge time,

Disconnection pause of relay stages,

Power station service,

Stage power, 1. - 2. stage,

Choke degree,

Voltage transformer ratio,

Harmonic table,

Switching frequency of transistor stages,

Alarm calls,

Averaging time for reactive power,

Averaging time of the mean value cos(phi),

Fan control,

Overtemperature disconnection,

Indication in manual mode,

Password,

Contrast,

Reset of programming,

Connection configuration,

Software release and

Serial number.Power station service,

Stage power, 1. - 2. stage,

Choke degree,

Voltage transformer ratio,

Harmonic table,

Switching frequency of transistor stages,

Alarm calls,

Averaging time for reactive power,

Averaging time of the mean value cos(phi),

Fan control,

Overtemperature disconnection,

Indication in manual mode,

Password,

Contrast,

Reset of programming,

Connection configuration,

Software release,

Serial number and

RS485 interface.

1 : 2 : 4 : 8 : 8 : 8....

All three fix stages

are switched on.

1 2 3

Prog

With key 3 you switch

in the fix stages.

With key 2 you disconnect the fix stages.

Confirm selection with

key 1 and continue with expanded programming using

key3.

Page 26

Page 26

Reactive Power Controller

= Key 1 = Key 2 = Key 3

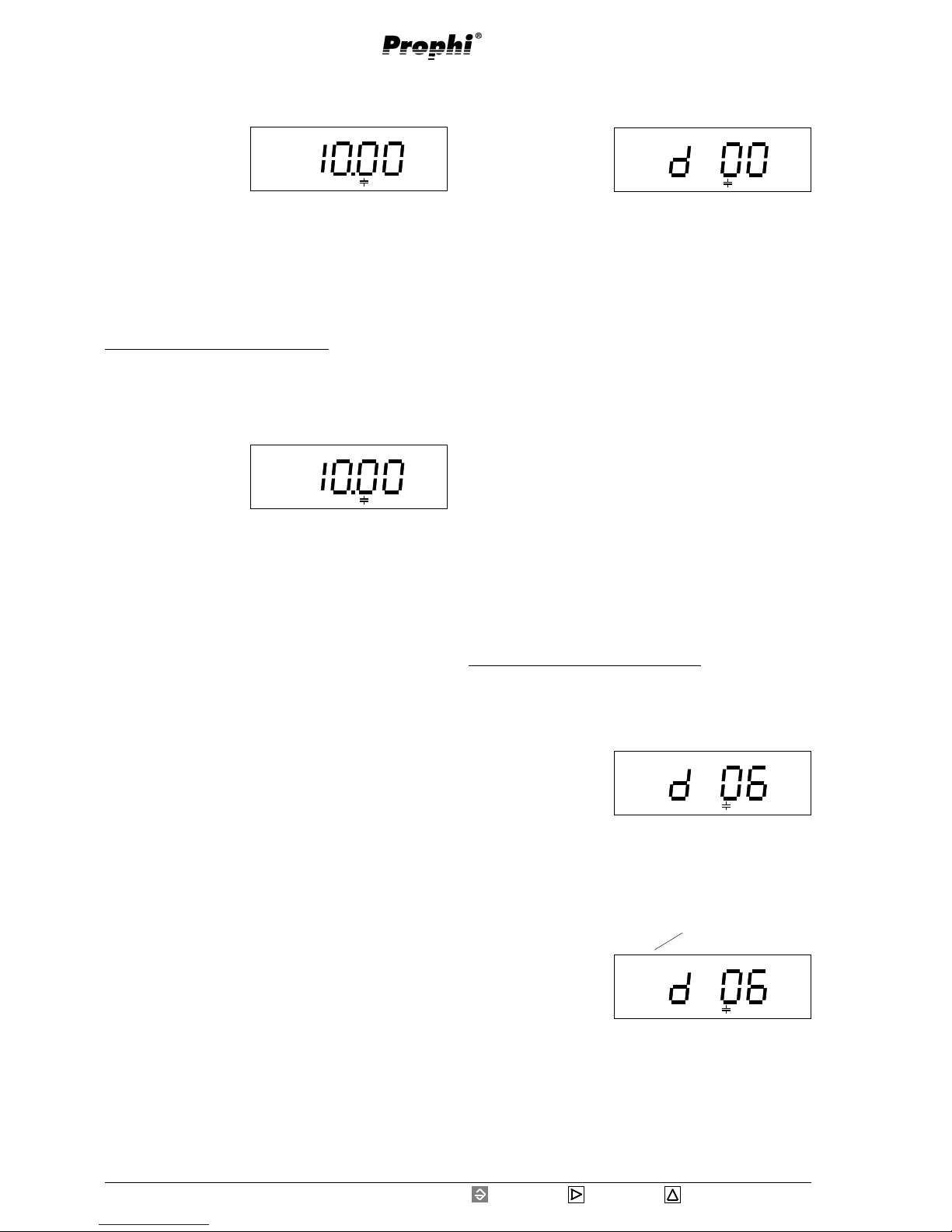

Discharge time

The discharge time

means the time, which

each capacitor stage

has got for discharge.

Setting range : 0 - 1200 seconds

The discharge time will be started after a net return and

after switching off a capacitor stage.

Capacitor stages controlled by transistor outputs must

not consider the discharge time, as the therewith controlled semiconductor switches in the zero crossing of

voltage.

Example: Programming discharge time

With key 3 you can leaf to the discharge time in the

expanded programming. With key 1 you get into programming mode. In this example a discharge time of

60 seconds is indicated.

Select the digit to be

changed using key 2.

The selected digit is

flashing.

Change digit using key

3.

Pressing key 1 you leave the programming mode and

with key 3 you can continue leafing through the expanded programming.

Disconnection pause

The disconnection

pause means the time

after the connection of

a capacitor stage, in

which it is forbidden to

disconnect the next stage.

Setting range : 0 - 1200 seconds

The disconnection pause is not valid for capacitor stages,

switched via transistor outputs.

Example: Programming of disconnection pause

With key 3 you leaf to the disconnection pause in expanded programming. Please press key 1. In this example a disconnection pause of 15 seconds is indicated.

Select the digit to be changed by using key 2. The

selected digit is flashing.

Change the selected

digit using key 3.

Pressing key 1 you leave the programming mode and

with key 3 you can continue leafing through the expanded programming.

s

Prog

s

Prog

Prog

s

Prog

s

Page 27

Page 27

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Confirm selection with

key 1.

Text "on" flashes.

Set function "power

station service" to "oFF" using key 2 and to "on" using

key 3.

Confirm with key 1 and continue with expanded programming pressing key 3.

Power station service

By setting "power station service" the reaction of the controller at

small currents is controlled.

Presetting: Power station service = "oFF"

Power station service= "oFF"

If no or a very small current is flowing through the

current transformer, all connected capacitor stages are

switched off one after the other.

Power station service = "on"

If delivery (power station service) and consumption is

possible, connected stages must remain connected to

the net, even if no current is measured.

Programming

Example: Power station service

Go to power station service in expanded programming

using key 3.

If real power is generated in a certain application, the

following situations can arise:

Case a.

The generated real power is smaller than the demand.

Additionally real power is delivered by the energy supplier.

Case b.

The generated real power is bigger than the demand.

Real power is supplied.

Case c.

The generated real power corresponds to the demand.

In all cases the required reactive power is supplied by

the energy supplier, or even better, by a compensation

system.

The following situation can come into being. The needed

real power is completely generated (case c.) by the generator, and the reactive power is completely supplied

by a compensation system.

There is no current flowing through the current transformer. If the power station service, by mistake, is on

"oFF", the capacitor stages are disconnected. Then a

reactive current is flowing again through the current

transformer. The controller detects a need for compensation, and connectes the stages again. The reactive current is compensated. Again, no current is flowing.

The problem is, that the number of switchings is increased.

For power station service, especially in case c, the power

station service should be set to "on".

Diagr.: Connection example power station service

reactive power

Blindleistung

real power

Wirkleistung

L1

Prophi

MG

reactive power compensation system

Blindleistungs-Kompensationsanlage

consumer

Verbraucher

generator

Generator

L2

L3

k l

10200610

Prog

Prog

Page 28

Page 28

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Choke degree

The choke degree must

be set for choked or

combined choked compensation systems. The

choke degree is needed

for the exact determination of the capacitor current.

With the choke degree you lay down the switching order in combined choked compensation systems. Capacitor stages with a high choke degree and low choke

degree are switched alternatingly. Capacitor stages with

a high choke degree are switched in first.

If more but two different choke degrees are set, the

capacitor stages with the middle choke degrees are

switched as unchoked capacitor stages.

Attention!

To reduce the programming expenditure, the programming of the first capacitor stage is taken over for all the

following capacitor stages. Nevertheless, the choke degree can be changed for the following capacitor stages

afterwards.

The choke degree is given for each capacitor stage in

percent.

Setting range : 0 - 15%

Stage power

The stage power is the

capacitive reactive

power of a capacitor

stage. The stage power

can be set in the expanded programming for each stage. In the standard

programming, the stage ratio 0:0:0:0 is indicated.

Setting range 0 var - 9999kvar

Example: Programming stage power

With key 3 you can leaf to the stage ratio in expanded

programming. Please press key 1 to confirm. In this

example, a stage power of 10kvar is indicated for the

first capacitor stage.

Select the digit to be

changed using key 2.

The selected digit is

flashing.

Change the selected digit using key 3.

Pressing key 1 you leave the programming mode and

with key 3 you can continue leafing through the expanded programming.

Example: Programming choke degree

Please leaf to the choke degree in the expanded programming using key 3. In this example, for the first

stage a choke degree of 5,7% is needed. For the programming, 6% was selected.

Pressing key 1 you leave the programming mode and

with key 3 you can continue leafing through the expanded programming.

%

1

Prog

Select the digit to be

changed using key 2.

The selected digit is

flashing.

Change the selected

digit by pressing key

3.

If the choke degree for the second capacitive stage must

be programmed, you leaf to the desired capacitor stage

pressing key 2.

The selected capacitor stage is confirmed by pressing

key 1.

%

2

Prog

2. capacitor stage

k VAr

1

Prog

k VAr

1

Prog

1

Prog

%

Page 29

Page 29

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Voltage transformer ratio

If the measurement and operating voltage for Prophi is

taken from a voltage transformer, the voltage transformer ratio can be set. This ratio is build by number 1

and number 2 .

Programming number 1

Leaf to number 1 for voltage transformer ratio in expanded programming using key 3. Confirm with key 1.

In this example,

number 1 = 1.

Select the digit to be

changed by pressing

key 2. The selected digit is flashing.

Change the selected digit using key 3.

With key 1 you can leave programming mode and with

key 3 you continue expanded programming.

number 1

Voltage transformer ratio =

number 2

Attention! If a wrong voltage transformer ratio is set,

all voltage as power is indicated incorrectly.

The setting ranges for the numbers 1 and 2 are:

number 1 : 1 - 9.999k

number 2 : 1, 10, 100, 110, 200, 230, 400

In this example, the

presettings are indicated with

number 1 = 1 and

number 2 = 1.

Programming number 2

Leaf to number 1 for voltage transformer ratio in expanded programming using key 3. Change to number 2

with key 2. In this example a value of 1 is

indicated for number 2.

Confirm selection with

key 1.

The value flashes.

With key 2 and key 3

the needed value can

be selected for number

2 from a list of values

(1, 10, 100, 110, 200,

230, 400).

Confirm selection with key 1. The selected value does

not flash anymore.

Continue expanded programming with key 3.

Number 1

Number 1 is indicated with a decimal point automati-

cally, when the value gets bigger than 1000.

Example: Voltage transformer ratio = 1200

1200 = 1.200k

Indication "1.200kV"

Example: Programming voltage transformer ratio

A voltage transformer has a primary of 20000V and a

secondary of 100V.

The result is a ratio of

20000V

= 200

100V

The measurement and supply voltage mentioned on type

plate of Prophi must be 100V.

To set the ratio of 200, several combinations of number

1 and number 2 are possible.

e.g. number 1 200

= = 200

number 2 1

or number 1 2000

= = 200

number 2 10

kV

Prog

V

Prog

Number 2

V

Prog

V

Prog

Prog

V

V

Prog

Page 30

Page 30

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Harmonic thresholds

In order to avoid resonance in the net and to

protect capacitors from

overload, a threshold

row should be selected

from the threshold table. If a harmonic threshold is

exceeded, capacitive stages are switched off for the duration of the discharge time.

Setting range 0 - 10

In order to avoid too much switchings of capacitor

stages, the capacitor stages are only switched on, when

the harmonic threshold of a lower threshold row is exceeded.

If the threshold row is selected for 0, no capacitor

stages are switched off. The thresholds of threshold

row 0 are only taken as the lower threshold row for

threshold row 1.

Harmonic thresholds in % of nominal voltage

Threshold row number

1 2 3 4 5 6 7 8 9 10

3. 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0

5. 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0

7. 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0

9. 1.2 1.2 1.5 1.5 2.0 4.0 4.5 5.0 5.5 6.0

11. 2.5 3.0 3.0 3.5 4.0 5.0 5.5 6.0 6.5 7.0

13. 2.0 2.1 2.5 3.0 4.0 5.0 5.5 6.0 6.5 7.0

15. 1.0 1.2 1.5 1.5 1.8 2.0 2.2 2.5 2.0 2.3

17. 1.5 1.5 2.0 2.0 2.3 2.0 2.5 3.0 3.5 4.0

19. 1.0 1.2 1.5 1.5 1.8 2.0 2.2 2.5 3.0 3.5

Harmonic number

Example: Programming threshold row

Leaf to the harmonic table in the expanded programming using key 3. Confirm with key 1. In this example

the threshold row 1 is indicated.

Select the digit to be

changed by pressing

key 2. The selected

digit is flashing.

Change the selected

digit by pressing key 3.

Pressing key 1 you leave the programming mode and

with key 3 you can continue leafing through the expanded programming.

V

Prog

V

%

Prog

Page 31

Page 31

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Switching frequency

The switching frequency determines,

how often per second

a transistor output may

be switched at maximum.

Possible switching frequencies are:

0,1Hz, (preset)

0,2Hz,

0,5Hz,

1,0Hz,

10,0Hz and

50,0Hz.

The delay time between two switchings of transistor

outputs is fixed to a minimum of 70ms, except for

"50.0Hz".

Switching frequency 0,1Hz

If a switching frequency of 0,1Hz is set, a transistor

output is switched in and off within 10 seconds one

time at maximum.

Switching frequency 10Hz

If a switching frequency of 10Hz is set, a transistor

output is switched in and off 10 times per second at

maximum.

Switching frequency 50,0Hz

The time from a change in signal frequency till a

switching of a transistor output takes a maximum of 20

ms. The time between two switching’s takes a maximum

of 50 ms. If a switching frequency of 50 Hz is adjusted

then the serial interface is out of operation

Example: Programming switching frequency

Go to the switching frequency using key 3 in expanded

programming. Change to programming mode with key

1. In this example, a switching frequency of 10,0 Hz is

indicated.

The set frequency is

flashing.

Now select the needed

frequency with key 2

and 3.

Pressing key 1 you leave the programming mode and

with key 3 you can continue leafing through the expanded programming.

Attention!

If a switching frequency of 50Hz is programmed

for th e transistor outp uts, the serial interf ace d oes

not work!

m

Hz

Prog

Hz

Prog

Page 32

Page 32

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Alarm output

In undisturbed ope-ration, the alarm relay attracts, and the contact

of the alarm output is

closed. In case of a disturbance, the alarm relay releases and the contact is

opened. Various events can be assigned to the alarm

output via or-conjunctions. One alarm number, one

alarm delay and one alarm duration are assigned to

each event. The alarm call can be activated or

deactivated for each event.

"on"/number = Alarm call is activated.

"oFF" = Alarm call is deactivated.

The following events can be assigned to the alarm output:

Alarm call

If one or more alarms occur, Prophi changes to an alarm

indication. In the alarm indication, the errors are shown

by their number. In the following example, the errors

"lower voltage" and "compensation power" occurred.

The time and dimension of the error is not saved.

Give a receipt for alarms

If you confirm the alarm message with key 3, you reach

the last measured value indication. The error symbol

"Error" remains within the measured value indications

until the errors are not valid anymore.

1 5 Error

Low voltage Compensation power

If other error messages appear after the confirmation of

an error message, the alarm indication appears again

with new error messages. Older errors, which are not

valid anymore, are flashing.

Example: Programming compensation power

Leaf to the first alarm in the expanded programming

with key 3. Please leaf to compensation power (5) with

key 2 and confirm with key 1.

Pressing key 1 you leave the programming mode and

with key 3 you can continue leafing through the expanded programming.

With key 3 the alarm "compensation power" is activated (on), with key 2 the alarm "compensation power"

is deactivated (oFF).

Alarmnumber Event Condition

1 Lower voltage oFF/number

2 Overvoltage oFF/number

3 Underscoring of meas.current oFF/number

4 Exceeding of meas. current oFF/number

5 Insufficient capacitor output off/on

6 Supply of real power off/on

7 Harmonic thresholds oFF/number

8 Overtemperature oFF/number

Example: Alarm message

VAr

5 Error

Prog

V

%

1 Error

Prog

cos

ϕϕ

ϕϕ

ϕ

ind

2 3 Error

ϕ1ϕ1

ϕ1ϕ1

ϕ1

Error symbol

Page 33

Page 33

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Lower voltage (1)

A lower voltage is recognized, when the measurement

and supply voltage is smaller or equal to the rated voltage given on type plate.

If lower voltage occurs, it is recognized after 100ms

latest, and the alarm output is active for at least 1 minute.

The threshold for lower voltage is programmable in 1%

steps in the range of 85% and 99%.

Example

Selected threshold : 85%

85% of the rated voltage of 400V make 340V.

If the voltage of 340V is underscored, the alarm relay

releases.

Attention!

If the measurement and operating voltage falls below

85% of the rated voltage, all capacitor stages are

switched off after about 20ms.

Overvoltage (2)

Overvoltage is recognized, when the measurement and

supply voltage is higher or equal to the rated voltage

given on type plate.

If overvoltage occurs, this will be recognized after

100ms latest. The alarm output will drop out for at least

1 minute and connected capacitor stages will be

disconnected in steps of 10 seconds.

The threshold for overvoltage can be programmed in

the range of 96% up to 110% of the rated voltage in

1% steps.

Example

Selected threshold : 110%

110% of the rated voltage of 400V make 440V.

If the voltage of 440V is exceeded, the alarm relay

releases.

Underscoring of the measurement current (3)

The rated current of a measuring input is 5A. If the

selected threshold for the measurement current is underscored, after 100ms maximum the alarm relay releases for at least 1 minute.

The threshold for underscoring the measuring current

can be programmed in the range of 0% up to 28% of

the rated current in 2% steps.

Example

Selected threshold : 10%

10% of the rated current of 5A make 0.5A.

If the current of 0.5A is underscored and the alarm

relay releases.

Exceeding of measuring current (4)

The current of current measurement input is 5A. The

rated current of the current measuring input is 5A. If

the preset threshold for the measurement current is exceeded, the alarm relay releases after 100ms latest for

at least 1 minute.

The threshold for exceeding the measurement current

can be set in the range of 50% up to 120% of the rated

current in 5% steps.

Example 1

Selected threshold : 95%

95% of the rated current 5A make 4.75A.

If the current of 4.75A is exceeded, the alarm relay

releases.

Insufficient capacitor output (5)

If the required compensation power is not reached for

one hour, the alarm relay releases for at least one minute.

Supply of real power (6)

If more real power is supplied than consumed (power

station service), the alarm relay releases after 100ms

latest for at least 1 minute.

Harmonic thresholds (7)

If a value in the selected harmonic threshold table is

exceeded, the alarm relay releases after 100ms latest

for at least 1 minute.

Overtemperature (8)

The reactive power controller is laid out for the operating temperature range between -10°C and +55°C. The

inner temperature of the reactive power controller is

about 2°C higher than the temperature within the cabinet.

If the programmable threshold for the controller inner

temperature is exceeded, the alarm relay releases after

100ms latest for at least 1 minute.

Setting range for the temperature : 0..99°C

Attention!

For inner temperatures of more than 70°C the

alarm will always be raised.

m

Page 34

Page 34

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Averaging time for the mean value cos(phi)

Prophi measures real

and reactive work

within the averaging

time and calculates the

mean value cos(phi).

Setting range: 0.25h

0.50h

1.00h

2.00h

12.00h

24.00h (presetting)

Example: Programming of the averaging time for the

mean value cos(phi).

Go to averaging time for the mean value cos(phi) in

expanded programming with key 3.

Confirm selection with key 1.

In this example, an averaging time of one

hour is indicated and

flashes.

With key 2 and 3 the

desired averaging time can be selected.

Press key 1 for confirmation and with key 3 you can

continue leafing through the expanded programming.

Averaging time of reactive power

The measured reactive

power is summarized

within the averaging

time and the mean

value of reactive power

is calculated.

Setting range: 0,1 Sec.

0,5 Sec.

1,0 Sec.

5,0 Sec.

10,0 Sec.

30,0 Sec.

60,0 Sec. (Presetting)

VAr

s

Prog

VAr

h

Prog

VAr

h

Prog

Example: Programming of the averaging time for reactive power.

Go to averaging time for the mean value reactive power

in expanded programming with key 3.

Confirm selection with

key 1.

In this example an averaging time of 5 seconds is indicated and flashing.

Now the desired averaging time can be selected with

key 2 and key 3.

Press key 1 for confirmation and with key 3 you can

continue leafing through the expanded programming.

VAr

s

P

rog

Page 35

Page 35

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Ventilator control

With the temperature

feeler, inserted in

Prophi, and a ventilator, a simple ventilator

control can be established.

Therefore, an

upper temperature limit, a

lower temperature limit and a

switching output

must be fixed.

Please note, that the inner temperature of the Prophi is

about 2°C over the outer temperature.

A relay output or the alarm output (option) serves as

ventilator output.

If the switching output 0 is assigned to the ventilator

control, the ventilator control is not active.

An upper and lower temperature limit can be set. The

temperature limits can be set in the range of 0°C and

98°C in 1° steps. While programming, you can only set

an upper limit, when it is at least 1°C over the lower

limit.

Attention! If an output is programmed for ventilator

control, and if it is also programmed for a fix stage or

alarm output, the ventilator control has higher priority.

Prog

Obere Grenztemperatur

Attention!

If one output has been programmed for ventilation control, and additionally, it is programmed

as a fix stage or alarm output, the ventilation

control has priority.

m

Prog

Upper temperature limit

(Ventilation control)

Prog

Upper temperature limit

(Ventilation control)

Lower temperature limit

If temperature is below

the lower limit, the

ventilation is switched

off.

Switching output

One of the relay outputs or the alarm output can be used as

switching output of

Prophi.

If output 0 is assigned

to the ventilation control, the ventilation control is inactivated.

Prog

Lower temperature limit

(ventilation control)

Upper temperature limit

If the upper limit is exceeded, the ventilation

is switched on.

Ventilation control

Using the temperature

sensor, which is inserted within Prophi, a

simple ventilation control can be built.

To reach this goal, an

Upper temperature limit, a

Lower temperature limit and

A switching output

must be determined.

While programming of temperature limits, please mind,

that the inner temperature of Prophi is about 2°C above

the outer temperature.

The temperature limits can be set in the range of 0°C

and 98°C in1°C steps.

While programming, it is only possible to set the upper

temperature limit, when it is at least 1°C above the

lower limit.

Prog

No output selected

Page 36

Page 36

Reactive Power Controller

= Key 1 = Key 2 = Key 3

Prog

Upper temperature limit

Prog

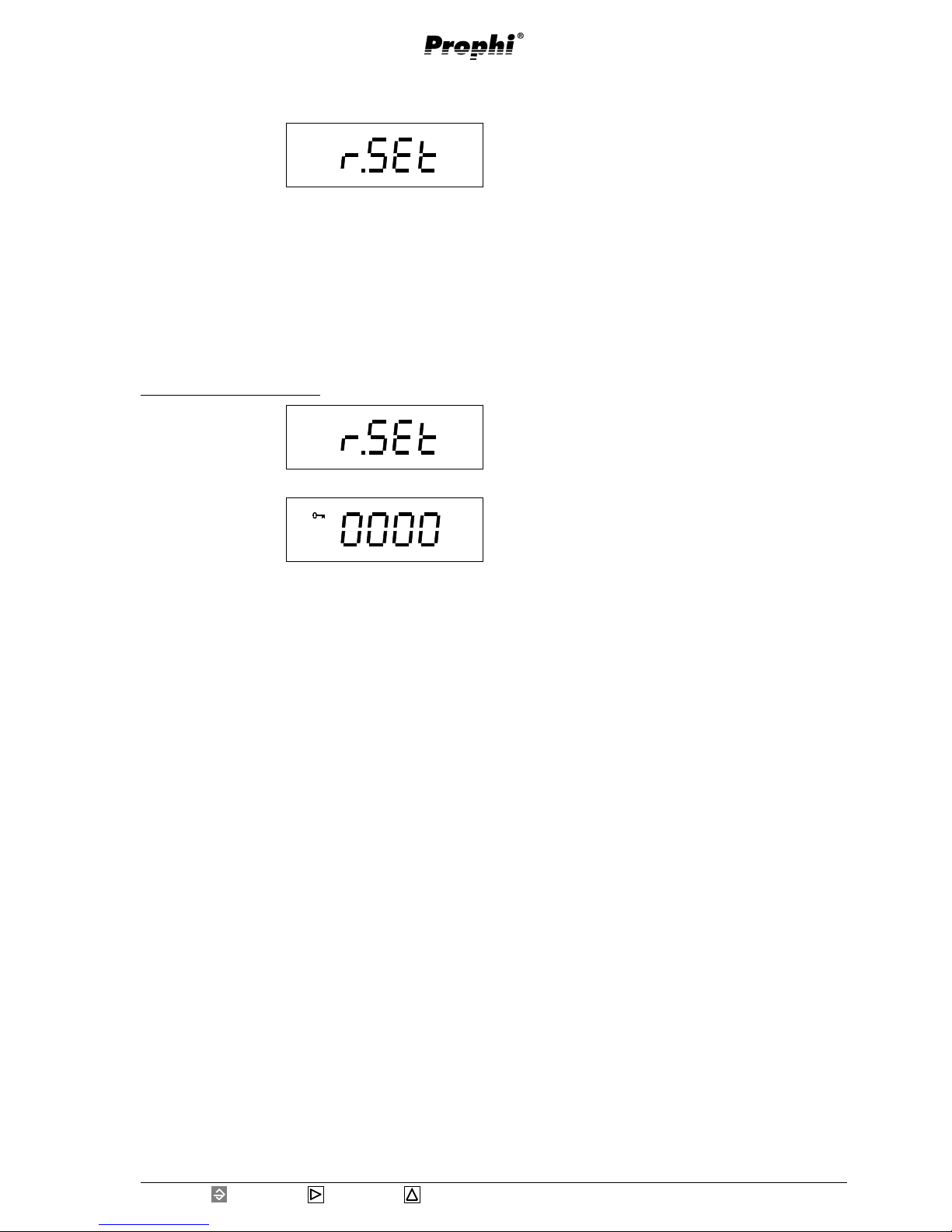

Lower temperature limit