Page 1

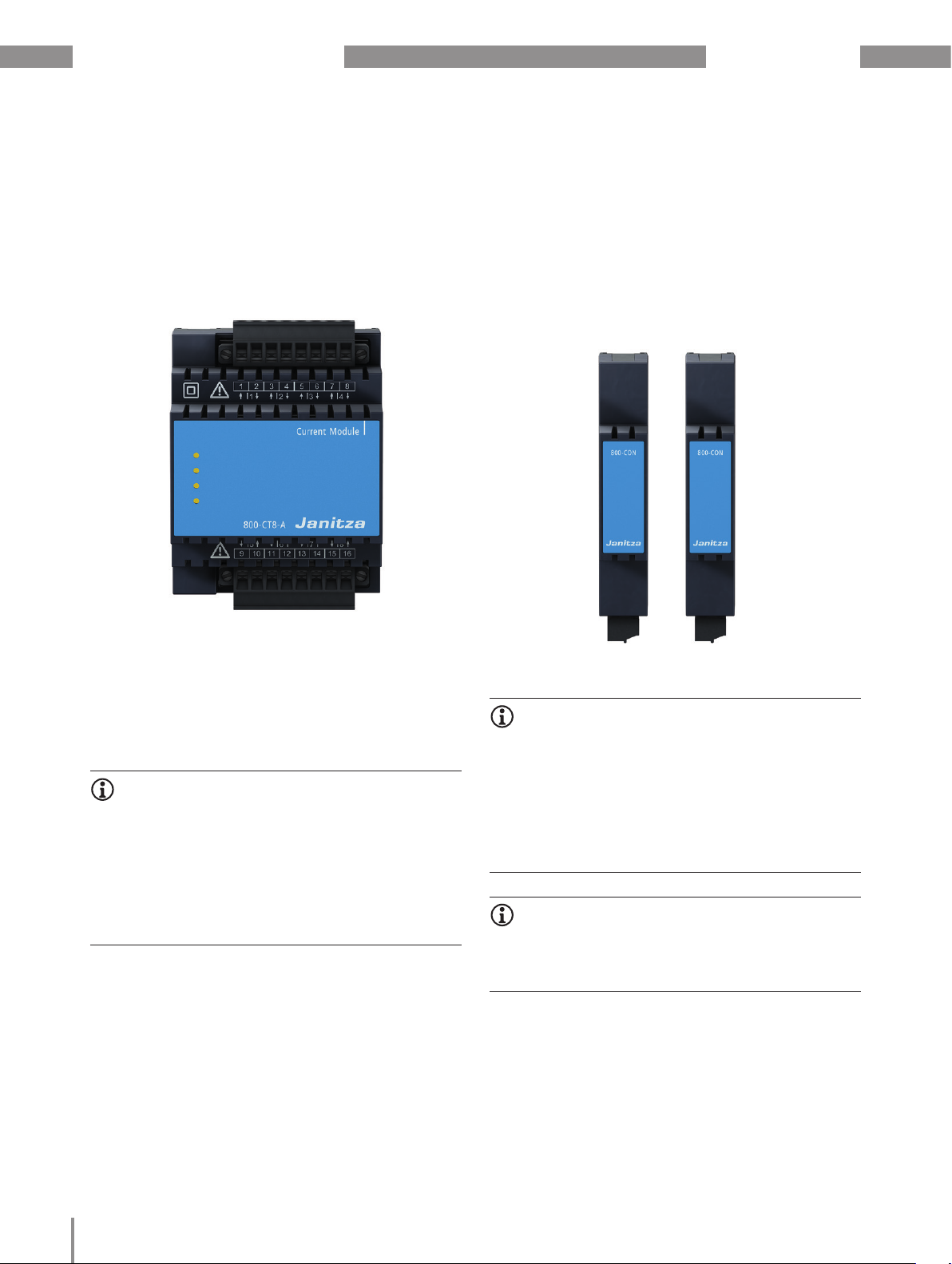

800-CT8-A current measuring module

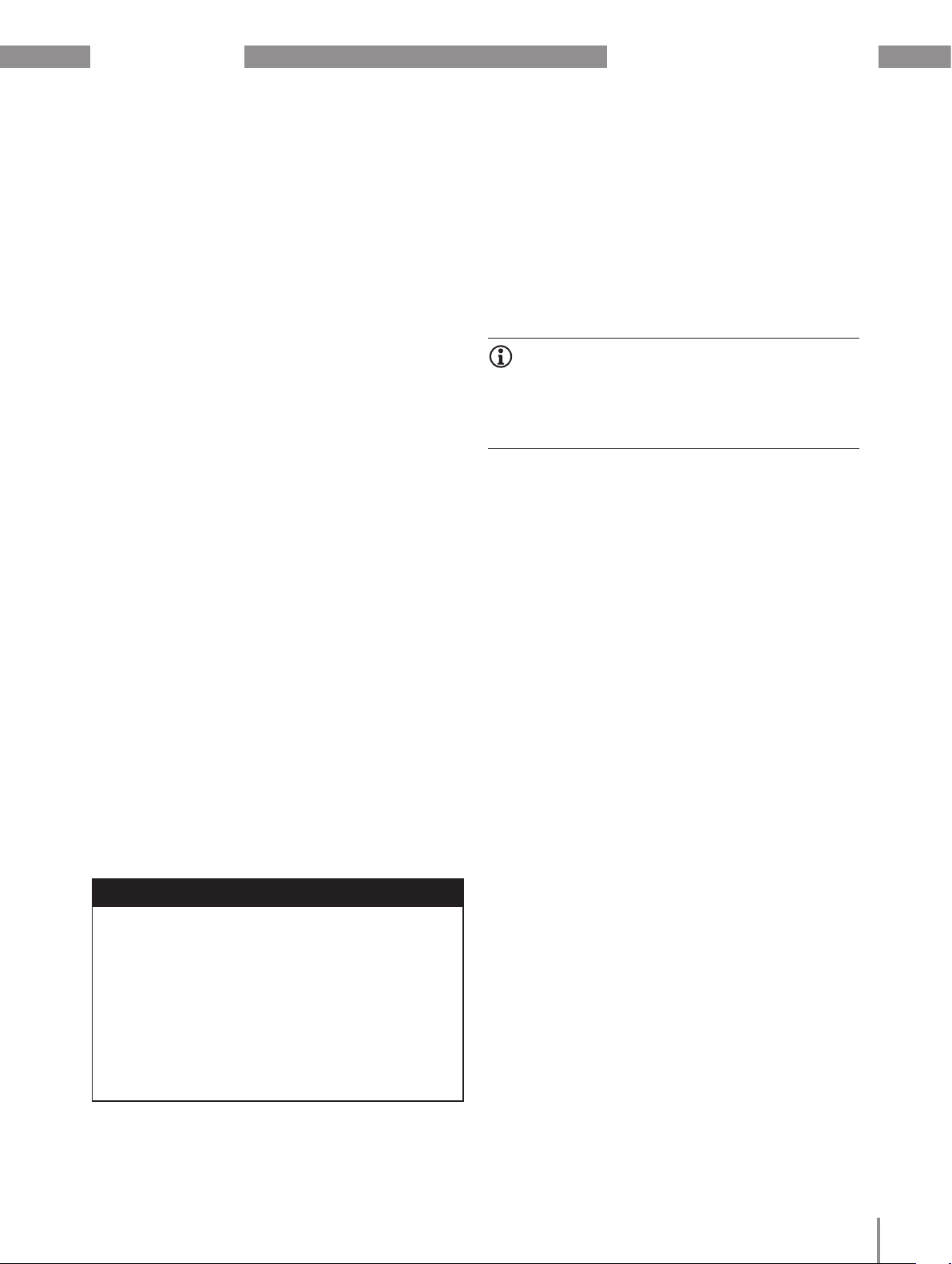

800-CON transfer modules

Extension modules for the UMG 801

User manual and technical data

www.janitza.de

Janitza electronics GmbH

Vor dem Polstück 6

D-35633 Lahnau

Doc. no.: 2.053.023.0a Date: 11/2019

Support tel. +49 6441 9642-22

Fax +49 6441 9642-30

Email: info@janitza.de

www.janitza.de

Page 2

Modules 800-CT8-A | 800-CON www.janitza.de

800-CT8-A

current measuring module

800-CON

transfer modules (set of 2)

Modules for UMG 801

Doc. no.: 2.053.023.0a

Date: 11/2019

The German version is the original edition of the documentation

2

Page 3

www.janitza.de

Modules 800-CT8-A | 800-CON

Subject to technical changes.

The contents of our documentation have been compiled with great care and reflect the current state of the

information available to us. Nonetheless, we wish to point out that updates of this document are not always

possible at the same time as technical refinements are implemented in our products. Please see our website

under www.janitza.de for the current version.

Please see our website under www.janitza.de for the current version.

3

Page 4

Modules 800-CT8-A | 800-CON www.janitza.de

TABLE OF CONTENTS

1. Information on the devices and the user manual 8

1. 1 Disclaimer 8

1. 2 Copyright notice 8

1. 3 Technical changes 8

1. 4 About this user manual 8

1. 5 Defective device/disposal 9

2. Safety 10

2. 1 Display of warning notices and safety information 10

2. 2 Hazard levels 10

2. 3 Product safety 11

2. 4 Hazards when handling the device, components and modules 11

2. 5 Electrically qualified personnel 12

2. 6 Warranty in the event of damage 12

2. 7 Safety information for handling current transformers 12

3. Product description 14

3. 1 800-CT8-A module 14

3. 2 800-CON module (set of 2) 14

3. 3 Incoming goods inspection 15

3. 4 Intended use 15

3. 5 Overview of module functions 15

3. 6 EU conformity declaration 15

3. 7 Scope of delivery, 800-CT8-A current measuring module. 16

3. 8 Scope of delivery, 800-CON transfer module (set of 2) 16

3. 9 Accessories for “800-CON transfer module” 16

3. 10 Operating concept 17

3. 11 GridVis® network analysis software 17

4

Page 5

www.janitza.de

4. Mounting 18

4. 1 Mounting the 800-CT8-A module 18

4. 2 Mounting the 800-CON module 21

4. 3 Connection of device and module series with the 800-CON transfer modules 22

4. 4 Connections/controls on 800-CT8-A module 24

4. 5 Marking of the 800-CT8-A module - rating plate 25

4. 6 Connections/controls on 800-CON module 26

4. 7 Marking of the 800-CON module - rating plate 27

5. Installation 28

5. 1 Current measurement with module 800-CT8-A 28

5. 2 Example schematic diagram “Connection variants for current measurement” 29

5. 3 Data transfer with 800-CON module 30

Modules 800-CT8-A | 800-CON

5. 4 Data cable for connecting the 800-CON transfer modules 31

6. PC connection 32

6. 1 PC connection of the current measuring modules via the basic device (UMG 801) 32

6. 2 PC connection of the basic device (UMG 801) with current measuring module

or your module series via the Ethernet interface 32

7. Operation and button functions of the basic device with module 34

7. 1 Operation and button functions of the basic device with 800-CT8-CON module 34

7. 2 Module-relevant menu items of the basic device with one module 34

8. Module-relevant configurations 36

8. 1 800-CT8-A module - Current transformer configuration on the basic device 36

8. 2 800-CT8-A module - Current transformer configuration in the GridVis® software 37

9. Module-relevant measuring displays 38

9. 1 800-CT8-A module - Measuring displays 38

10. Device views - 800-CT8-A current measuring module 46

5

Page 6

Modules 800-CT8-A | 800-CON www.janitza.de

11. Technical data - 800-CT8-A current measuring module 47

11. 1 Functional performance characteristics of 800-CT8-A current measuring module

(Only valid in conjunction with UMG 801!) 49

12. Device views - 800-CON transfer module 50

13. Technical data - 800-CON transfer module 51

14. Dismounting 52

14. 1 Dismounting the 800-CT8-A module 52

14. 2 Exchanging an 800-CT8-A module 53

14. 3 Dismounting the 800-CON module 54

15. Service and maintenance 56

15. 1 Repair 56

15. 2 Service 56

15. 3 Device adjustment 56

15. 4 Calibration interval 56

15. 5 Firmware update 56

15. 6 Procedure in the event of a malfunction 56

15. 7 Resetting the module to the standard factory settings 56

15. 8 Information on saving measured values and configuration data 57

6

Page 7

www.janitza.de

Modules 800-CT8-A | 800-CON

7

Page 8

Modules 800-CT8-A | 800-CON www.janitza.de

1. Information on the devices and the user manual

1.1 Disclaimer

Compliance with the usage information for the

devices (modules/components) is a prerequisite for

safe operation and attaining the stated performance

characteristics and product features.

Janitza electronics GmbH assumes no liability for

bodily injury, material damage or financial losses

which result from disregard of the usage information.

Ensure that the usage information for the products is

legible and accessible.

1.2 Copyright notice

© 2019 - Janitza electronics GmbH - Lahnau. All

rights reserved.

Any reproduction, processing, distribution or other

use of this usage information, in whole or in part, is

prohibited.

All trademarks and the rights arising from them are

the property of the respective owners of these rights.

1.4 About this user manual

If you have questions, suggestions or ideas for

improvement of the user manual, please let us know

via email at: info@janitza.de.

INFORMATION

This user manual describes the modules for the

UMG 801 and provides information on the operation of

the devices.

Also consult the additional usage information relevant

for this user manual, such as:

· Installation instructions.

· Data sheets.

· The "Safety information" supplement.

· The supplement on mounting the modules.

· Usage information on the basic device.

Moreover, the GridVis® software has an “online help”

feature.

1.3 Technical changes

· Make sure that your device (modules/components)

matches the user manual.

· This user manual applies to the modules for the

UMG 801. Separate validities and distinctions are

marked.

· First make sure you have read and understood the

usage information accompanying the product.

· Keep the usage information associated with the

product available for the entire service life and pass

it on to any possible subsequent users.

· Find out about device revisions and the associated

modifications of the usage information associated

with your product at www.janitza.de.

8

Page 9

www.janitza.de

1.5 Defective device/disposal

Before sending defective devices, modules or

components back to the manufacturer for testing:

· Contact the manufacturer's Support department.

· Send devices, modules or components complete

with all accessories.

· When doing so, please bear the terms for

transportation in mind.

INFORMATION

Please return defective or damaged devices, modules

or components to Janitza electronics GmbH in

accordance with the shipping instructions for air or

road freight (complete with accessories).

Observe special regulations for devices with built-in

batteries or rechargeable batteries!

Do not attempt to open or repair the device (the

module, the component) on your own because

otherwise all warranty claims become invalid!

Modules 800-CT8-A | 800-CON

For the disposal of the device (the module, the

component), please observe national regulations!

Dispose of individual parts, as applicable, depending

on their composition and existing country-specific

regulations, e.g. as

· Electronic waste

· Batteries and rechargeable batteries

· Plastics

· Metals

Engage a certified disposal company to handle

scrapping as needed.

Information on “Service and maintenance” of your

device can be found in chapter 15 on page 56.

9

Page 10

Modules 800-CT8-A | 800-CON www.janitza.de

2. Safety

The chapter on Safety contains information which

must be observed to ensure your personal safety

and avoid material damage.

2.1 Display of warning notices and safety

information

The warning notices shown below

· are found throughout the usage information.

· can be found on the devices themselves.

· indicate potential risks and hazards,

· underscore aspects of the information provided that

clarifies or simplifies procedures.

This additional symbol on the device (module/

component) itself indicates an electrical hazard that

can lead to severe injury or death.

This general warning symbol draws attention to a

possible risk of injury. Be certain to observe all of the

information listed under this symbol in order to avoid

possible injury or even death.

2.2 Hazard levels

Warning and safety information is marked by a

warning symbol, and the hazard levels are shown as

follows, depending on the degree of hazard:

DANGER

Warns of an imminent danger which, if not avoided,

results in serious or fatal injury.

WARNING

Warns of a potentially hazardous situation which, if

not avoided, could result in serious injury or death.

CAUTION

Warns of an immediately hazardous situation which,

if not avoided, can result in minor or moderate injury.

ATTENTION

Warns of an immediately hazardous situation which,

if not avoided, can result in material or environmental

damage.

INFORMATION

Indicates procedures in which there is no hazard of

personal injury or material damage.

10

Page 11

www.janitza.de

2.3 Product safety

The devices, components and modules reflect

current engineering practice and accepted safety

standards, but hazards can arise nonetheless.

Observe the safety regulations and warning notices.

If notices are disregarded, this can lead to personal

injury and/or damage to the product.

Every type of tampering with or use of the devices

and the modules,

· which goes beyond the mechanical, electrical or

other operating limits can lead to personal injury

and/or damage to the product;

· constitutes "misuse" and/or "negligence" under the

product’s warranty and thus voids the warranty for

any possible resulting damage.

Read and understand the user manual and the usage

information on the basic device before installing,

operating, maintaining and using the devices,

components and modules.

Only operate the devices, components and modules

when they are in perfect condition and in compliance

with this user manual and the usage information that

is included. Send defective devices, components

or modules back to the manufacturer in compliance

with proper transport conditions.

Retain the user manual throughout the service life of

your product and keep it at hand for consultation.

When using the device, component or module, also

observe the legal and safety regulations for your

system that are applicable for the respective use

case.

2.4 Hazards when handling the device,

components and modules

When operating electric devices, components

or modules, it is unavoidable for certain parts

of these devices to conduct hazardous voltage.

Consequently, severe bodily injury or material

damage can occur if they are not handled properly.

Therefore, when handling our devices, components,

or modules, always observe the following:

· do not exceed the limit values specified in the user

manual and on the rating plate! This must also be

observed during testing and commissioning!

· Take note of the safety and warning notices in

all usage information that belongs to the device,

components or modules!

Modules 800-CT8-A | 800-CON

WARNING

Risk of injury due to electrical current and voltage!

Severe bodily injury or death can result! Therefore

please abide by the following:

· Do not touch bare, stripped wires or device

inputs that are dangerous to touch on the

devices, components and modules.

· Switch off your installation before commencing

work! Secure it against being switched on!

Check to be sure it is de-energized! Ground and

short circuit! Cover or block off adjacent live

parts!

· During operation and troubleshooting

(especially with DIN rail devices), check the

environment for dangerous voltages and switch

these off if necessary!

· Wear protective clothing and protective

equipment in accordance with applicable

guidelines when working on electrical systems!

· Before making connections, ground the device

/ component / module by means of the ground

wire connection, if present!

· Do not touching bare or stripped leads that are

energized! Equip stranded conductors with wire

ferrules!

· Hazardous voltages can be present in all

circuitry parts that are connected to the power

supply.

· Protect wires, cables and devices with a

suitable line circuit breaker/fuse!

· Never switch off, remove or tamper with safety

devices!

· There can still be hazardous voltages present in

the device or in the component (module) even

after it has been disconnected from the supply

voltage (capacitor storage).

· Do not operate equipment with current

transformer circuits when open.

· Only connect screw terminals with the same

number of poles and design!

· Do not exceed the limit values specified in

the user manual and on the rating plate! This

must also be observed during testing and

commissioning.

· Take note of the safety and warning notices

in the usage information that belongs to the

device, components or modules!

11

Page 12

Modules 800-CT8-A | 800-CON www.janitza.de

2.5 Electrically qualified personnel

To avoid bodily injury and material damage, only

electrically qualified personnel are permitted to work

on the devices and their components, modules,

assemblies, systems and current circuits who have

knowledge of:

· the national and international accident prevention

regulations,

· safety technology standards,

· installation, commissioning, operation,

disconnection, grounding and marking of electrical

equipment,

· the requirements concerning personal protective

equipment.

Electrically qualified persons within the scope of the

technical safety information of all usage information

associated with the device and its components

(modules) are persons who can furnish proof of

qualification as an electrically skilled person.

WARNING

Warning against unauthorized manipulation or

improper use of the device or its components

(modules)!

Opening, dismantling or unauthorized manipulation of

the device and its components (modules) which goes

beyond the mechanical, electrical or other operating

limits indicated can lead to material damage or injury,

up to and including death.

· Only electrically qualified personnel are

permitted to work on the devices and their

components (modules), assemblies, systems

and current circuits.

· Always use your device or component (module)

only in the manner described in the associated

documentation.

· If there is discernible damage, send the

device or the component (module) back to the

manufacturer!

2.7 Safety information for handling current

transformers

WARNING

Risk of injury due to large currents and high

electrical voltage on the current transformers!

Current transformers operated while open on the

secondary side (high voltage peaks pose a hazard

when touched) can result in severe bodily injury or

death.

· Avoid operating the current transformers while

open; short circuit the unloaded transformers!

· Before interrupting the current supply, short

circuit the secondary connections of the

current transformers. Switch any test switches

that automatically short circuit the secondary

lines of the current transformers to the “Test”

status (Check the test switch/short circuiting

connection beforehand)!

· Only use current transformers with basic

insulation to IEC 61010-1:2010!

· Caution, even current transformers rated as

safe for open operation can pose a hazard

when touched during operation while open!

· Make sure that screw terminals for the current

transformer connection on the device are

adequately tightened!

· Comply with the information and provisions

in the documentation of your current

transformers!

CAUTION

Risk of injury or damage to the meter due to high

measurement currents at the connections of the

current transformers!

High measurement currents can cause temperatures

of up to 80 °C (176 °F) on the connections of the

current transformers

· Use wiring that is designed for an operating

temperature of at least 80 °C (176 °F)!

· The current transformers can be hot even after

the power supply has been switched off. Allow

the connections of the current transformers

and the connecting cables to cool down before

touching them!

2.6 Warranty in the event of damage

Any unauthorized tampering with or use of the

device, component or module constitutes "misuse"

and/or "negligence" under the product’s warranty

and thus voids the warranty for any possible

resulting damage. In this regard, please take note of

chap. „3.4 Intended use“ on page 15.

12

CAUTION

Risk of injury or damage to the basic device

(module) and/or your system due to a short circuit!

Inadequate insulation at the current measurement

inputs of the modules with respect to the supply

circuits of the basic device can cause dangerous

voltages at the measuring input or damage to your

device (module)/system.

· Ensure reinforced or double insulation with

respect to the supply circuits!

Page 13

www.janitza.de

Modules 800-CT8-A | 800-CON

13

Page 14

Modules 800-CT8-A | 800-CON www.janitza.de

3. Product description

3.1 800-CT8-A module

The current measuring module

· extends the functional range of the basic device

to include additional current measuring channels

(2 groups of 4 current measuring channels each);

· is suitable for current transformers with transformer

ratios of ../1 A or ../5 A.

3.2 800-CON module (set of 2)

The module set, consisting of 2 transfer modules,

is used to connect remote measurement points.

With the transfer modules, you can implement

meter and module topologies (e.g. UMG 801 with

modules 800-CT8-A) with flexible arrangement of

your DIN rails (for types, see Technical Data) in the

switchboard cabinet or small distribution board.

Fig.: 800-CT8-A module

The basic device (UMG 801) with current measuring

module measures current exclusively via current

transformers. The current transformers require a

basic insulation according to IEC 61010-1:2010 for

the nominal voltage of the circuit.

INFORMATION

When setting up your meter and module topology,

note that:

· The UMG 801 as the basic device allows the

mounting of up to 10 modules.

· The scope of delivery for the module includes the

appropriate bus connector (JanBus interface) for

connection to the basic device.

· The maximum bus length of the JanBus is 100 m.

Fig.: 800-CON module (transfer module,

output / input)

INFORMATION

· Both modules in the set of 2 are suitable as input

or output modules!

· The scope of delivery for the transfer modules

includes the appropriate bus connector (JanBus

interface).

· When setting up your meter and module topology,

make sure that the maximum bus length of the

JanBus is 100 m.

INFORMATION

Please also observe all usage information

associated with the basic device in addition to the

usage information for the modules!

14

Page 15

www.janitza.de

Modules 800-CT8-A | 800-CON

3.3 Incoming goods inspection

The prerequisites for trouble-free and safe operation

of the modules include proper transport, storage,

setup and assembly, as well as proper operation

and maintenance.

Exercise due caution when unpacking and packing

the device, do not use force and only use suitable

tools. Check:

· The modules by performing a visual inspection to

ensure flawless mechanical condition.

· The scope of delivery (see chap. 3.7 and 3.8) with

respect to completeness before beginning with

assembly and installation.

If it must be assumed that safe operation of your

basic device with module is not possible:

1. Switch off the power to your system (your

device)!

2. Secure it against being switched back on!

3. Check to be sure it is de-energized!

4. Ground and short circuit the system (device)!

5. Cover or block off adjacent live parts!

Safe operation is impossible, if, for example, the

basic device with module:

· has visible damage,

· no longer functions despite an intact power supply,

· was subjected to extended periods of unfavorable

conditions (e.g. storage outside of the permissible

climate thresholds without adjustment to the room

climate, condensation, etc.) or transport stress

(e.g. falling from an elevated position, even without

visible external damage, etc.).

3.4 Intended use

The modules/components

· Are intended as expansion or transfer modules for

the basic device UMG 801 in switch cabinets and

small distribution boards.

· Must only be mounted with basic devices that are

disconnected from the power supply (see chap. „4.

Mounting“ on page 18).

INFORMATION

Please note:

More information on certain functions of the basic

device with modules can be found in the usage

information for the basic device.

The basic device and the modules (800-CT8-A and

800-CON) are not designed for installation:

· In vehicles! Use of the basic device with modules

in non-stationary equipment is considered an

exceptional environmental condition and is only

permissible by special agreement.

· In environments with harmful oils, acids, gases,

vapors, dusts, radiation, etc.

· In potentially explosive environments.

3.5 Overview of module functions

800-CT8-A module:

· 8 current measurement inputs (2 groups of 4)

· Measuring category 300 V CAT II

· Nominal current 1 A/5 A configurable

ATTENTION

Improper handling may cause damage to the

module and result in material damage!

The contacts of the bus connectors (Janbus interface)

can bend or break off and destroy the bus connector.

· Never touch or manipulate the contacts of the bus

connector!

· Never force the bus connector into the module!

Please refer to the chapter on this „4. Mounting“

on page 18.

· When handling, transporting and storing

the module, protect the contacts of the bus

connector!

800-CON module:

· JanBus interface (proprietary) via bus connector

and twisted pair, shielded data cable (1:1

connection via shield clamps) to device and module

series (see section „5.4 Data cable for connecting

the 800-CON transfer modules“ on page 31).

3.6 EU conformity declaration

Please see the EU declaration of conformity posted

at www.janitza.de for the laws, standards and

directives applied by Janitza electronics GmbH for

the devices.

15

Page 16

Modules 800-CT8-A | 800-CON www.janitza.de

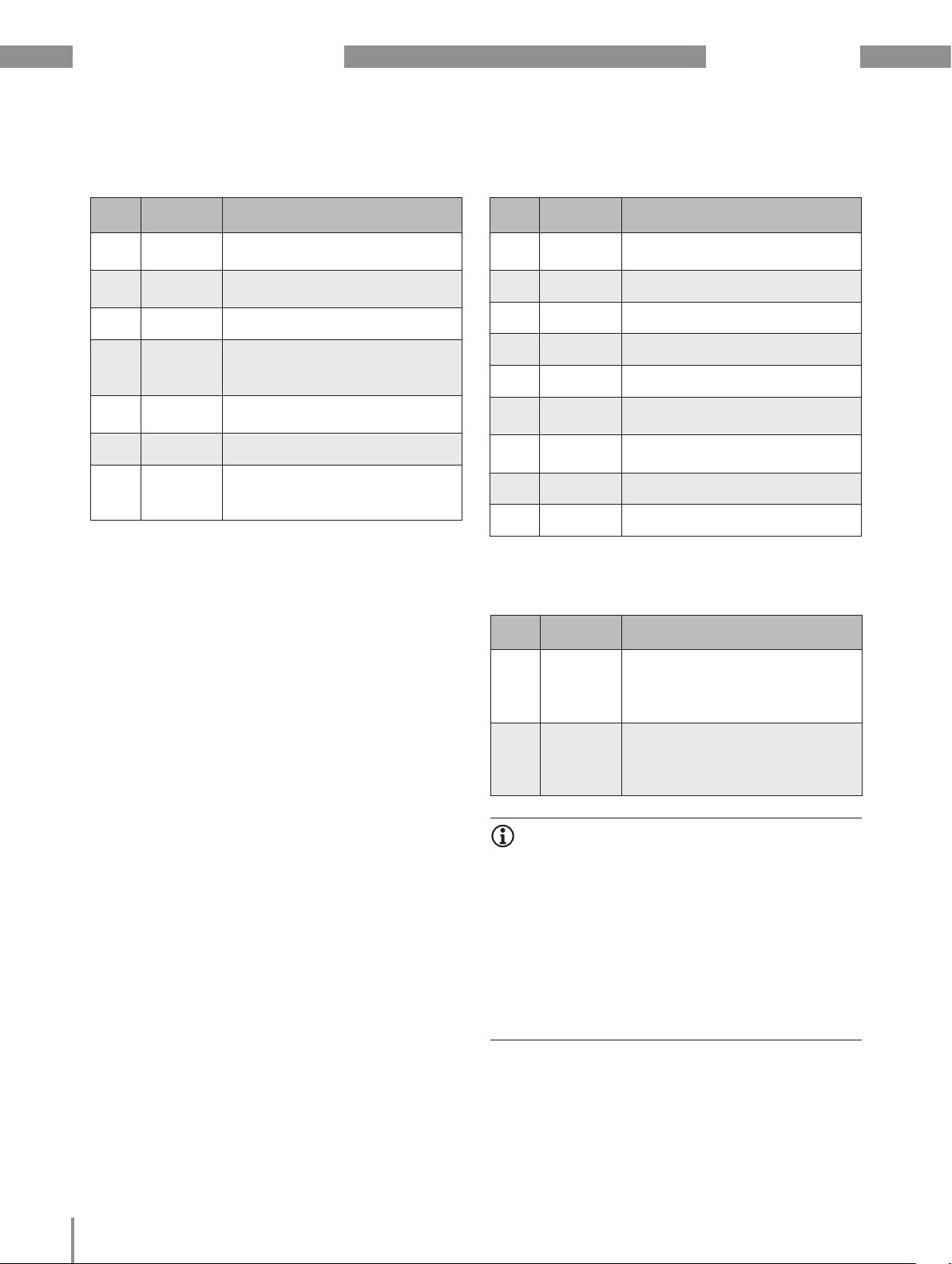

3.7 Scope of delivery, 800-CT8-A current

measuring module.

Quan-

tity

Tab. Scope of delivery, 800-CT8-A current measuring module

Part. no. Designation

1 52.31.201

1 52.31.207

1 10.01.953 End bracket

1 33.03.378

1 33.03.342

1 33.03.059 “Mounting” supplement

1 10.01.853

Module 800-CT8-A

(current measuring module)

Bus connector - Current measuring

module

Installation instructions (DE/EN)

"Current measuring module for the

UMG 801"

"Safety information” supplement

(12 languages)

Screw terminal, plug-in, 8-pole

(current measurement I1..I4 and

I5..I8)

3.8 Scope of delivery, 800-CON transfer

module (set of 2).

Quan-

tity

Tab. Scope of delivery, 800-CON transfer module

Part. no. Designation

1 52.31.210

1 52.31.208 Bus connector - Transfer on right

1 52.31.209 Bus connector - Transfer on left

2 10.02.188 Shield clamps

2 10.01.953 End bracket (Weidmüller)

1 33.03.379

1 33.03.342

1 33.03.059 “Mounting” supplement

2 10.01.938 Screw terminal, plug-in, 8-pole

800-CON module - Transfer module

(set of 2)

Installation instructions (DE/EN)

"Transfer modules for the UMG 801"

"Safety information” supplement

(12 languages)

3.9 Accessories “800-CON transfer module”

Quan-

Tab. Accessories

Part. no. Designation

tity

1 08.02.451

1 08.02.452

Data cable for connecting the

"transfer modules" (1000 mm pre-assembled, twisted pair data

cable)

Data cable for connecting the

"transfer modules" (225 mm pre-assembled, twisted pair stranded hook-up wires)

INFORMATION

· The modules are delivered with the necessary

screw terminals and bus connectors (JanBus

interface) for connection to the basic device or

other modules.

· All supplied options and design variants are

described on the delivery note.

· With the GridVis® network analysis software

available at www.janitza.de, you can configure

your basic device with modules and read out data

for analysis (prerequisite: PC connection with your

basic device).

16

Page 17

www.janitza.de

Modules 800-CT8-A | 800-CON

3.10 Operating concept

Options to configure the basic device with current

measuring module or to read measured values:

· Display and buttons on the basic device (user

interface).

· GridVis® network analysis software.

· RS-485 interface or Ethernet interface.

INFORMATION

Please take note of the documentation of your

basic device (without the module)! Basic or

identical information and chapters, such as

· Commissioning

· Configuration

· Technical data

· Error messages

· Procedure in the event of a malfunction, etc.

can be found in the usage information of your

basic device.

A list of parameters and Modbus addresses with

data on your basic device with module is available

for you as a download at www.janitza.de.

3.11 GridVis® network analysis software

With the GridVis® software, you have the perfect

tool for programming, reading out and visualizing

measurement data (download at www.janitza.de).

Performance characteristics of the GridVis®

software

· Configuration of the device

· Graphic display of measured values

· Online help and tutorials

Connections to the PC (GridVis® software)

Connections for communication between the PC

and the basic device with modules can be found in

chapter 6 on page 32.

INFORMATION

This user manual describes the modules and

provides information on the operation of the

modules via the basic device (UMG 801).

The GridVis® software has an online help with

tutorials.

17

Page 18

Modules 800-CT8-A | 800-CON www.janitza.de

4. Mounting

CAUTION

Disregard of the assembly instructions may cause

property damage or personal injury!

Disregard of the assembly instructions may cause

damage to your basic device with module or destroy

it and/or may also result in personal injury.

· In addition to the installation instructions for

your module, also observe the installation

instructions for your basic device, in particular

the safety and warning information.

· Before installing modules

- Disconnect the supply of power to the system!

- Secure it against being switched on!

- Check to be sure it is de-energized!

- Ground and short circuit!

- Cover or block off adjacent live parts!

· Provide adequate air circulation in your installa-

tion environment and cooling, as needed, when

the ambient temperatures are high.

· Return defective modules to Janitza electronics

GmbH in accordance with the shipping instructions for air or road freight (complete with

accessories).

· All usage information is also available as a

download at www.janitza.de.

2. If this has not yet been done, plug the bus

connector (JanBus interface) included in delivery

into the sockets on the rear of your module.

ATTENTION

Improper handling may cause damage to the

module and result in material damage!

The contacts of the bus connectors (Janbus interface)

can bend or break off and destroy the bus connector.

· Never touch or manipulate the contacts of the

bus connector!

· Never force the bus connector into the module!

· When handling, transporting and storing the

module, protect the contacts of the bus connector!

4.1 Mounting the 800-CT8-A module

Observe the mounting instructions for your basic

device (e.g. check bus connector installation!) and

mount the 800-CT8-A module in the de-energized

system as follows:

1. Press in the bottom bolts on the rear of the

module.

Bottom bolts

Fig.: Module rear view

INFORMATION

press

Bus connector

Bus connector

Twisted

Press the bus connector

contacts into the module

sockets

The following module assembly sequence must be

observed!

18

Fig.: Module rear view.

Page 19

www.janitza.de

Modules 800-CT8-A | 800-CON

3. Press your module with the bus connector

onto the DIN rail (for suitable DIN rail types see

chapter „11. Technical data - 800-CT8-A current

measuring module“ on page 47) until the 4

bottom bolts snap into place.

800-CT8-A module

With bus connector

UMG 801

Bottom bolts

click!

DIN rail

Fig.: Side view, UMG 801 and 800-CT8-A module

INFORMATION

4. Push the contacts of your module bus connector

into the sockets of the basic device bus

connector (or into the sockets of the attached

module) so that the bus connectors (devices) are

coupled.

UMG 801

Fig.: Side view, UMG 801 and 800-CT8-A module

800-CT8-A module

Internal bus connector

5. Then cable your module and apply voltage to the

basic device (system).

INFORMATION

The basic device automatically recognizes the

module during the power-up procedure!

Before coupling the module, check to be certain

your basic device is de-energized! Coupling

while energized can destroy your basic device or

module!

19

Page 20

Modules 800-CT8-A | 800-CON www.janitza.de

Bottom bolts

End bracket

DIN rail

Fig. Assembly example:

Front view UMG 801 (basic device) with 800-CT8-A module

INFORMATION

After installing your module, check the function of

the communication between the basic device and

the module using the display on the basic device

as follows:

· When you are in the Home measuring display

of the basic device, pressing the button 1 ESC

takes you to the Menu window.

· Use buttons 2 (5) and 5 (6) to select the menu

item System information and confirm with button 3

Enter.

· The System information window with the items

Basic device and Module 1 appears.

System information

Main device

Module 1

Bus connector

contacts

JanBus

JanBus

interface

Bus connector

sockets

Bottom bolts

interface

for further

modules

Bus connector

sockets

Error after starting the basic device with module:

INFORMATION

The basic device does not recognize modules

during the power-up procedure!

If there is no communication to modules, the

module functions are not supported (e.g. current

measurements).

· Disconnect your system from the power supply

and check the condition of the bus connectors

and the connections of your modules to the

basic device (JanBus interface). If necessary,

push the contacts of the module bus

connectors into the sockets of the basic device

bus connector or the attached modules so that

the bus connectors (devices) are coupled.

· For remote module series, check the

connection of the transfer modules with the

connection via the shield clamps.

· If necessary, restart the basic device.

· If these measures do not lead to the desired

result, please contact our Support –

www.janitza.de

ESC

Fig.: System information window with the

entries of the basic device and module 1.

· The basic device has detected module 1.

Observe the following:

· The basic device allows the mounting of up to 10

modules!

· The maximum bus length of the JanBus is 100 m.

· Always start and end your device and module series

with end brackets (cf. Fig. "Example of a meter and

module topology” on page 30).

20

INFORMATION

The figure above shows an example of mounting the

800-CT8-A module. Use end brackets to set up your

device and module series on the DIN rails.

Page 21

www.janitza.de

Modules 800-CT8-A | 800-CON

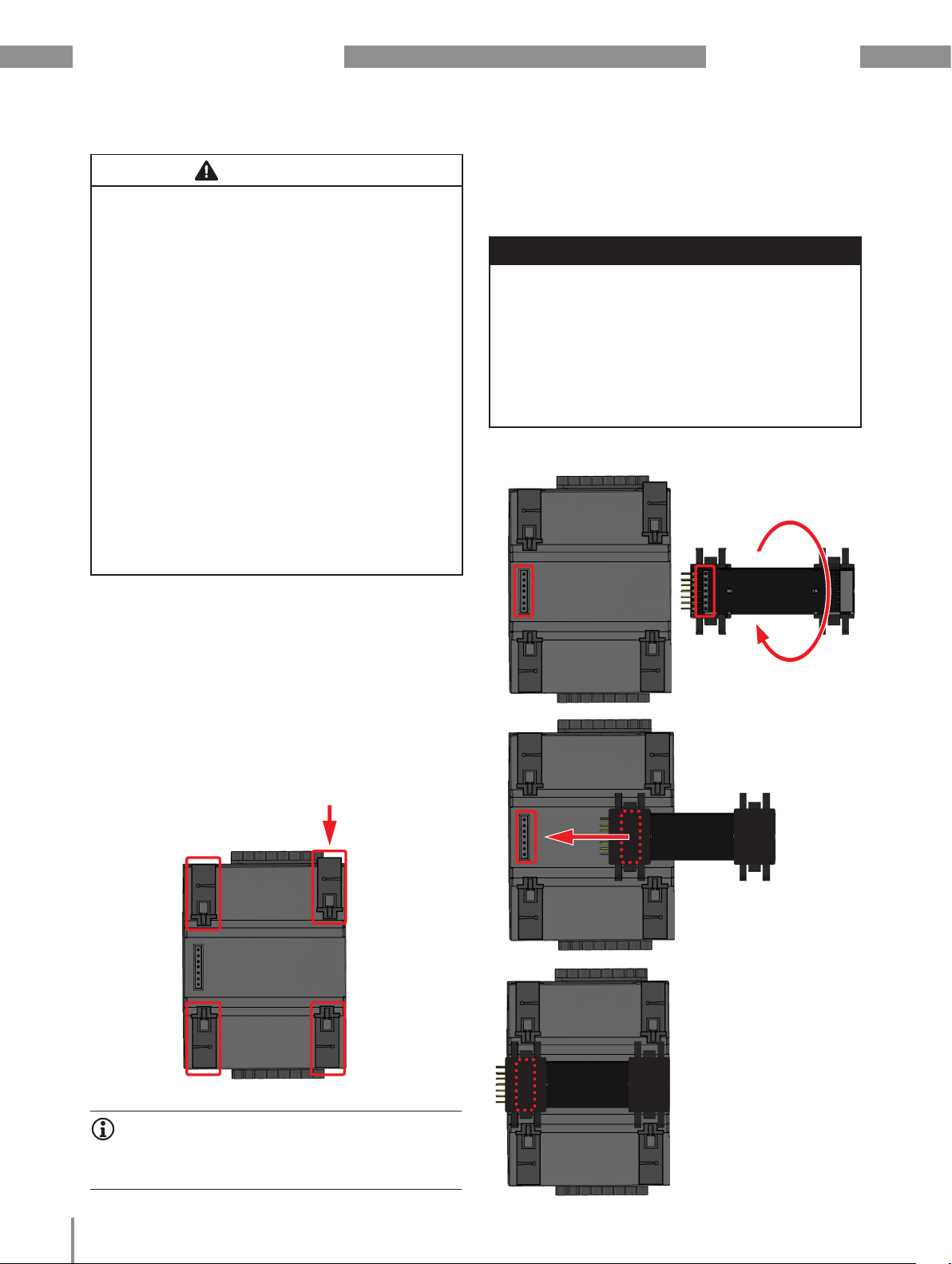

4.2 Mounting the 800-CON module

Observe the mounting instructions of your basic

device (e.g. check bus connector installation!) and

mount the 800-CON module (transfer module) in the

de-energized system as follows:

1. Press in the bottom bolts on the rear of the

module.

Fig.: Module rear view

2. If this has not yet been done, plug the bus

connector (JanBus interface) included in delivery

into the sockets on the rear of your module.

Bus connector

INFORMATION

· The following module assembly sequence must

be observed!

· Always mount components of your JanBus system from the output bus connector to the input

bus connector. This will avoid an incorrect connection of remote JanBus systems! Cf. chapter

„5.3 Data transfer with 800-CON module“ on

page 30.

ATTENTION

Improper handling may cause damage to the

module and result in material damage!

The contacts of the bus connectors (Janbus interface)

can bend or break off and destroy the bus connector.

· Never touch or manipulate the contacts of the

bus connector!

· Never force the bus connector into the module!

· When handling, transporting and storing

the module, protect the contacts of the bus

connector!

Bus connector

rotated

Press the bus connector

contacts into the module

press

sockets

Fig.: Module rear view.

21

Page 22

Modules 800-CT8-A | 800-CON www.janitza.de

3. Press your module with the bus connector

onto the DIN rail (for suitable DIN rail types see

chapter „13. Technical data - 800-CON transfer

module“ on page 51) until the 2 bottom bolts

snap into place.

800-CON module

with bus connector

UMG 801

Fig.: Side view, UMG 801, 800-CT8-A and 800-CON module

800-CT8-A module

click!

DIN rail

4. Push the contacts of your module bus connector

into the sockets of the connected module

(or basic device) so that the bus connectors

(devices) are coupled.

5. End your device and module series with end

brackets (see Fig. Example "Devices and module

series" in chapter 4.3 on page 22).

UMG 801

800-CT8-A module

800-CON

module

4.3 Connection of device and module series

with the 800-CON transfer modules

To ensure trouble-free operation of your device

series with modules and thus your system, connect

your transfer modules via shield clamps. The

shield connection serves as protection against

overvoltages and electromagnetic interference.

Also provide a strain relief during installation

that protects the data cable from being torn out

unintentionally. Connect the transfer modules with

the recommended data cables. Please note the

warnings and information below!

ATTENTION

Incorrect installation of the data cable can destroy

your basic device with modules or your system!

A faulty or incorrectly installed data cable between

the transfer modules can lead to the destruction of

your basic device with modules and thus to material

damage.

· For the connection between the transfer

modules, use a twisted pair, stranded, shielded

data cable with a 1:1 cable connection (cf. Chap

„5.4 Data cable for connecting the 800-CON

transfer modules“ on page 31)!

· Always connect your transfer modules via

shield clamps with a strain relief!

· Protect your system against overvoltages and

electromagnetic interference by connecting the

data cable shield to the shield clamp!

· Always connect the data cable shield (ground)

within the same grounding potentials! With

different ground potentials, connect the data

cable shield at least at one end!

DIN rail

Internal bus connector

Fig.: Side view, UMG 801, 800-CT8-A and 800-CON module

6. Then cable your module and apply voltage to

the basic device (system). The basic device

recognizes the plugged in module automatically.

22

ATTENTION

Improper handling may cause damage to the

module and result in material damage!

The contacts of the bus connector (Janbus interface)

can bend or break off and destroy the bus connector!

· Never touch or manipulate the contacts of the

bus connector.

· Never force the transfer module with bus

connector contacts into the bus connector

sockets!

· When handling, transporting and storing the

transfer module, protect the contacts of the

bus connector!

Page 23

www.janitza.de

Modules 800-CT8-A | 800-CON

800-CT8-A

module

Fig. Example "Device and

module series": Wiring of the

transfer module (output)

800-CON transfer

module

Shield clamp

End bracket

Heat-shrink tubing

INFORMATION

The basic device does not recognize modules

during the power-up procedure!

If there is no communication to modules, the

module functions are not supported (e.g. current

measurements).

· Disconnect your system from the power supply

and check the condition of the bus connectors

and the connections of your modules to the

basic device (JanBus interface). If necessary,

push the contacts of the module bus

connectors into the sockets of the basic device

bus connector or the attached modules so that

the bus connectors (devices) are coupled.

· For remote module series, check the

connection of the transfer modules with the

connection via the shield clamps.

· If necessary, restart the basic device.

· If these measures do not lead to the desired

result, please contact our Support –

www.janitza.de

Shielded

data cable

Strain relief

DIN rail

800-CON transfer

module

Fig. Example “Remote

module series": Wiring of the

transfer module (input)

800-CT8-A

module

Observe the recommended data cables for the

connection between the transfer modules (see

chap. „5.4 Data cable for connecting the 800-CON

transfer modules“ on page 31)!

23

Page 24

Modules 800-CT8-A | 800-CON www.janitza.de

4.4 Connections/controls on 800-CT8-A module

5

4

2

3

1

6

7 7

7 7

INFORMATION

The current measuring module is supplied with the

necessary screw terminals and bus connectors

(JanBus interface) for connection to the basic device

or other modules.

Item Designation Description

4 current measurement inputs in the

1

group, terminals 9/10, 11/12, 13/14,

15/16

2 LED

3 LED

4 2 LEDs Blink “orange" during operation and indicate cyclic data exchange.

4 current measurement inputs in the

5

group, terminals 1/2, 3/4, 5/6, 7/8

6 JanBus interface Connection sockets for the bus connector

7 Bottom bolt For mounting the module on the DIN rail

8 JanBus interface Bus connector insertion into the module

Current measurements I5, I6, I7, I8

Lights "green" if the supply of power via the JanBus interface of the basic

device is correct; the device is ready for operation.

Lights up "red" at power-up and remains so until completion of

initialization (module not yet initialized). Then there is a switchover to cyclic

data exchange (pos. 4).

Current measurements I1, I2, I3, I4

9

8

10

9 Bus connector contacts (JanBus) Connection to the basic device (or connected modules)

10 Bus connector sockets (JanBus) Connection of additional modules

24

Page 25

www.janitza.de

4.5 Marking of the 800-CT8-A module - Rating plate

4 5 6

Modules 800-CT8-A | 800-CON

3

2

1

Item Designation Description

1 Part number Current measurements I5, I6, I7, I8

Symbol for “Danger sign”

2

3 Device type Device designation

4 DataMatrix code Coded manufacturer data

5 Manufacturer’s logo Logo of the device manufacturer

6 CE conformity marking See „3.6 EU conformity declaration“ on page 15

7 Manufacturer-specific data Manufacturer data

8 Hardware version Hardware version of the module

9 Type/serial number Number for identification of the device

800-CT8-A

5231201

Made in Germany • www.janitza.com

01A • 1

4800/0001

7

8

9

10

General hazard symbol.

Be certain to observe the warning notices applied to the device and shown

in the documentation in order to avoid possible injury or even death.

10 Designation of origin/web address Country of origin and manufacturer’s web address

25

Page 26

Modules 800-CT8-A | 800-CON www.janitza.de

4.6 Connections/controls on 800-CON module

INFORMATION

The transfer modules (800-CON) of the set of 2 are

suitable as output or input modules!

However, make sure to mount the correct bus

connectors (output and input)!

Always mount components of your JanBus system

from the output bus connector to the input bus

connector. This will avoid an incorrect connection

of remote JanBus systems! Cf. chapter „5.3 Data

transfer with 800-CON module“ on page 30.

INFORMATION

The transfer modules are supplied with the necessary

screw terminals and bus connectors (JanBus

interface) for connection to the basic device or other

modules.

3 3

1 2

Item Designation Description

1 Screw terminals, 8-pole Output or input module

2 Screw terminals, 8-pole Output or input module

JanBus interface -

3

rear of module

Transfer module

4

output bus connector

Transfer module

5

output bus connector

Transfer module

6

input bus connector

Transfer module

7

input bus connector

Connection sockets for the bus connector (note output/input!)

Plug for insertion into the basic device or an attached module

Connector for insertion into the rear of the module

Connector for insertion into the rear of the module

Sockets for module insertion

1 2

6

7

5

4

26

Page 27

www.janitza.de

4.7 Marking of the 800-CON module - rating plate

4 5

3

2

1

800-CON

5231203

Modules 800-CT8-A | 800-CON

Made in Germany • www.janitza.com

Item Designation Description

1 Part number Current measurements I5, I6, I7, I8

2 Symbol for “Danger sign”

3 Device type Device designation

4 Manufacturer’s logo Logo of the device manufacturer

5 CE conformity marking See „3.6 EU conformity declaration“ on page 15

6 Designation of origin/web address Country of origin and manufacturer’s web address

6

General hazard symbol.

Be certain to observe the warning notices applied to the device and shown

in the documentation in order to avoid possible injury or even death.

27

Page 28

Modules 800-CT8-A | 800-CON www.janitza.de

5. Installation

5.1 Current measurement with module

800-CT8-A

Your 800-CT8-A module in combination with the

basic device (UMG 801):

· measures current exclusively via current

transformers.

· allows the connection of current transformers with

secondary currents of ../1 A and ../5 A for current

measurement inputs I1 to I8.

· has a current transformer ratio of 5 A/5 A (I1 to I8)

as the default setting.

· does not measure DC currents.

L1

L2

L3

N

PE

S1 S2

S1 S2

S1 S2

S1 S2

Consumer

INFORMATION

You can configure the current transformer ratios via

the user interface of the basic device or conveniently

using the "Device configuration" function of the

GridVis® software.

Observe the following:

· For single measurements, the phase assignment

of the current measuring channels is arbitrary.

The measurement of system performance

characteristics requires phase L1 - L3.

· The connection variants for current measurement

in the usage information of your basic device

WARNING

Warning of electrical currents and voltages

Current transformers operated while exposed on

the secondary side (high voltage peaks) can result in

severe bodily injury or death.

Avoid exposed operation of the current transformers

and short circuit unloaded transformers!

S1

L1

L2

L3

N

PE

Fig. Connection variant “Current measurement" with

800-CT8-A module and terminal assignment.

S2

S1

S2

S1

S2

S1

28

S2

Consumer

Page 29

www.janitza.de

Modules 800-CT8-A | 800-CON

WARNING

Risk of injury due to high currents and high

electrical voltages!

Severe bodily injury or death can result from:

· Touching bare or stripped leads that are

energized.

· Inputs of devices, components and modules are

dangerous to touch.

Therefore, please note for your system:

· Disconnect the supply of power before starting

work!

· Secure it against being switched on!

· Check to be sure it is de-energized!

· Ground and short circuit! Use the ground

connection points with the ground symbol for

grounding!

· Cover or block off adjacent live parts!

CAUTION

Risk of injury or damage to the device due to high

measurement currents at the connections of the

current transformers or the current measurement

inputs of the device!

High measurement currents can cause temperatures

of up to 80 °C (176 °F) on the connections of the

current transformers

· Use wiring that is designed for an operating

temperature of at least 80 °C (176 °F)!

· The current transformers can be hot even after

the power supply has been switched off. Allow the

connections of the current transformers and the

connecting cables to cool down before touching

them!

· Make sure that screw terminals for the current

transformer connection on the device are

adequately tightened!

· Ground connections present on the secondary

windings of the current transformers must be

connected to ground!

· Observe the general safety information for

handling current transformers in the chap.

„2.7 Safety information for handling current

transformers“ on page 12.

· Comply with the information and provisions in the

usage information of your current transformers!

5.2 Example schematic diagram “Connection variants for current measurement”

L1

UMG 801

(Basic device)

S1

L2

L3

N

JanBus interface

S2

S1

1 2 3 4 5 6

S1 S2 S1 S2 S1 S2

I

1 I2 I3

Current measurement

S2

S1

S2

S1

7 8

S1 S2

I

4

S2

800-CT8-A module

JanBus interface

Current measurement

I

5 I6 I7

S1 S2 S1 S2 S1 S2

9 10 11 12 13 14

I

8

S1 S2

15 16

Load

JanBus interface

Fig. Example schematic diagram, current

measurement with module 800-CT8-A

L1

L2

L3

S2S1

S2S1

S2S1

N

Load

S2S1

29

Page 30

Modules 800-CT8-A | 800-CON www.janitza.de

5.3 Data transfer with 800-CON module

Your 800-CON transfer module (set of 2) in combination with a basic device (UMG 801) and current

measuring modules serve to connect remote measurement points.

With the transfer modules, you can implement

meter and module topologies (e.g. UMG 801 with

800-CT8-A current measuring modules) with flexible

arrangement of your DIN rails in the switchboard

cabinet or small distribution board (for DIN rail types,

see chapter „13. Technical data - 800-CON transfer

module“ on page 51).

INFORMATION

· When setting up your meter and module topology, bear in mind that the UMG 801 as the basic

device allows the mounting of up to 10 modules.

· Always mount components of your JanBus

system from the output bus connector to the

input bus connector (from left to right). This

will avoid an incorrect connection of remote

JanBus systems!

· Use end brackets and shield clamps with a

strain relief to mount your meter and module

topology on a suitable DIN rail (see chap. „13.

Technical data - 800-CON transfer module“ on

page 51.

· The recommended data cables can be found in

chap. „5.4 Data cable for connecting the 800CON transfer modules“ on page 31.

· When setting up your meter and module topology,

make sure that the maximum bus length of the

JanBus is 100 m.

Fig. Example of a meter and module topology

30

Page 31

www.janitza.de

Modules 800-CT8-A | 800-CON

5.4 Data cable for connecting the 800-CON

transfer modules

Recommendation:

Use the following data cables for smooth communication in your meter and module topology for

connecting the 800-CON transfer modules:

Twisted pair, shielded data cable with color code to DIN 47100 (4 x 2 x 0.25) - Lapp Unitronic LiYCY (TP)

8

7

6

5

4

3

2

1

Blue

Red

Brown

White

Gray

Pink

Green

Yellow

6 mm / 0.24 in

70 mm / 2.76 in

Approx. 20 mm / 0.79 in

approx.

5 mm/

0.2 in

Heat shrink tubing

40 mm / 1.57 in

Approx. 8 mm / 0.31 in

Cable sheath removed up to the braided shield.

1000 mm / 39.37 in

1 : 1 - Cable connection!

Yellow

Green

Pink

Gray

White

Brown

Red

Blue

1

2

3

4

5

6

7

8

Twisted pair stranded hook-up wire, Lapp LiY 0.252, black/blue.

8

7

6

5

4

3

2

1

Blue

Black

Blue

Black

Blue

Black

Blue

Black

6 mm / 0.24 in

225 mm / 8.86 in

Blue

Black

Blue

Black

Blue

Black

Blue

Black

INFORMATION

Ordering information for the data cables can be

found in the chapter page 16.

1 : 1 - Cable connection!

8

7

6

5

4

3

2

1

31

Page 32

Modules 800-CT8-A | 800-CON www.janitza.de

6. PC connection

6.1 PC connection of the current measuring

modules via the basic device (UMG 801)

Configure your current measuring module via

the display and the buttons on your basic device

(UMG 801).

Use the Ethernet interface of the basic device to

connect your module/module series to a PC. The

PC, with the GridVis® software or generic OPC UA

client installed, is used to configure or read out your

modules/module series.

INFORMATION

Further information on PC connections of the basic

device can be found in the UMG 801 user manual.

6.2 PC connection of the basic device

(UMG 801) with current measuring module

or your module series via the Ethernet

interface

Connection to a DHCP server and PC.

The DHCP server automatically assigns IP addresses

to the basic device (with modules) and the PC.

PC with GridVis

DHCP

server

Patch cable Patch cable

Switch/

Router

®

UMG 801 with modules

PC direct connection to the basic device with

modules.

PC and basic device require a fixed IP address.

PC with GridVis

®

Patch cable

UMG 801 with modules

INFORMATION

Detailed descriptions of connection via the Ethernet

interface of the basic device can be found in the

UMG 801 user manual.

32

Page 33

www.janitza.de

Modules 800-CT8-A | 800-CON

33

Page 34

Modules 800-CT8-A | 800-CON www.janitza.de

7. Operation and button functions of the basic device with module

7.1 Operation and button functions of the basic

device with 800-CT8-CON module

The basic device with module has a display

and 6 function buttons to enable installation,

commissioning and configuration without a PC.

INFORMATION

· The configuration of your module and the display

of module-relevant measurement data is carried

out via the basic device.

· For details and information on the display and

button functions of the basic device, refer to the

usage information of the basic device.

· With the GridVis® network analysis software

available at www.janitza.de, you can configure

your basic device with modules and read out data

for analysis (prerequisite: PC connection with your

basic device).

7.2 Module-relevant menu items of the basic

device with one module

INFORMATION

The following graphic shows the module-relevant

menu items of the basic device with one module.

The module-relevant items of the basic device can

contain up to 10 modules!

Menu

Home (UMG 801 start screen,

1st measuring display)

Phasor diagram

Phasor diagram 1-4

Phasor diagram 5-8

Phasor diagram, mod. 1 1-4

Phasor diagram, mod. 1 5-8

Voltage

Voltage L-N

Voltage L-L

Voltage THD

Current

Current

Current 1-4

Current 5-8

Current, mod. 1 1-4

Current, mod. 1 5-8

THD-I

THD-I 1-4

THD-I 5-8

THD-I, mod. 1 1-4

THD-I, mod. 1 5-8

Power

Power summary

Power summary 1-4

Power summary 5-8

Power summary, mod. 1 1-4

Power summary, mod. 1 5-8

Active power

Active power 1-4

Active power 5-8

Active power, mod. 1 1-4

Active power, mod. 1 5-8

34

Page 35

www.janitza.de

Modules 800-CT8-A | 800-CON

Reactive power

Reactive power 1-4

Reactive power 5-8

Reactive power, mod. 1 1-4

Reactive power, mod. 1 5-8

Apparent power

Apparent power 1-4

Apparent power 5-8

Apparent power, mod. 1 1-4

Apparent power, mod. 1 5-8

Power factor

Power factor 1-4

Power factor 5-8

Power factor, mod. 1 1-4

Power factor, mod. 1 5-8

Energy

Active energy

Active energy 1-4

Active energy 5-8

Active energy, mod. 1 1-4

Active energy, mod. 1 5-8

Reactive energy

Reactive energy 1 1-4

Reactive energy 5-8

Reactive energy, mod. 1 1-4

Reactive energy, mod. 1 5-8

Apparent energy

Apparent energy 1-4

Apparent energy 5-8

Apparent energy, mod. 1 1-4

Apparent energy, mod. 1 5-8

Multifunction channels

Current measurement

Temperature

Configuration

Ethernet TCP/IP

IP configuration

IP address

Netmask

Gateway

Fieldbus

Device address

Baud rate

Data frame

Current transformer

Basic device

Current transformer 1..4 prim./sec.

Current transformer 5..8 prim./sec.

Module 1

Current transformer 1..4 prim./sec.

Current transformer 5..8 prim./sec.

Voltage transformer

Voltage transformer 1..4

Display

Language

Brightness

Standby after

System

Time

Password

Reset

Standard factory settings

Restart

Min/max values

System Information

Basic device

Serial number

MAC

IP address

Date

HW version

SW version

SW build

Module 1

Type

Serial number

Position

HW version

SW version

SW build

Module n (up to 10 modules)

35

Page 36

Modules 800-CT8-A | 800-CON www.janitza.de

8. Module-relevant configurations

8.1 800-CT8-A module - Current transformer

Configuration on the basic device

INFORMATION

Before configuring the current transformer ratios,

be certain to connect the transformers in compliance with the specifications on the device rating

plate and the technical data!

· Press function button 1 ESC to open the menu.

· Use buttons 2 “5” and 5 “6” to select the menu

item Configuration and confirm with button 3 Enter.

· The Configuration window appears.

· In the Configuration window, use buttons 2

“5” and 5 “6” to select the menu item Current

transformers and confirm with button 3 Enter.

Configuration

Ethernet (TCP/IP)

Fieldbus

Current Transformer

Voltage Transformer

Display

ESC

Fig. Window Configuration -> item Current transformer

· The Current transformers window appears.

Device

Transformer 1..4

Transformer 5..8

ESC

Fig. Window, Current transformer module 1 -> item

Device

· In the Current transformers window, choose the

item Device and confirm with button 3 Enter.

· The item Device appears marked in “blue."

· Use buttons 2 “5” and 5 “6” to select the item for

your series module Module 1 (up to 10 modules)

and confirm with button 3 Enter.

Current transformer

Module 1

Primary Secondary

5 A 5 A

5 A 5 A

· Use button 5 "6" to go to the setting for the

primary side of the current transformers 1-4 of the

module (current measurement inputs I1..I4).

· The item for the primary side of the current

transformers I1..I4 appears marked in “blue."

· Press button 3 Enter.

· The item for the primary side of the current

transformers I1..I4 “blinks."

· Use buttons 4 () and 6 () to change the position

of the digit to be set and buttons 2 (5) and 5 (6) to

change the digit (-1/+1).

· Confirm your entries with button 3 Enter or end the

action by pressing button 1 ESC.

Current transformer

Device

Transformer 1..4

Transformer 5..8

ESC

Fig. Window, Current transformer module 1 ->

item Primary for current transformer 1..4.

Module 1

Primary Secondary

5 A 5 A

5 A 5 A

· Use button 6 () to go to the configuration of the

secondary side of the current transformers I1..I4 of

the module.

· Configure the secondary side of the current

transformers I1..I4 of the module in the same way.

· Confirm your entries with button 3 Enter or end the

action by pressing button 1 ESC.

· Use the function buttons to configure the Current

transformer ratio 5-8 (I5..I8) – Primary and

secondary side – of the module, as described

above.

· To return to the menu, confirm your entries with

button 3 Enter or end the action by pressing button

1 ESC.

INFORMATION

You can also configure current and voltage

transformer ratios in the device configuration of

the GridVis® page 37). A description of the

configuration can be found in the online help or in

the tutorials for the software.

36

Page 37

www.janitza.de

8.2 800-CT8-A module - Current transformer

Configuration in the GridVis ® software

An assistant in the GridVis® network visualization

software helps with all module-relevant settings. Also

note the usage information of the basic device.

Modules 800-CT8-A | 800-CON

Fig. Current transformer configuration "Module 1" in the GridVis software®.

37

Page 38

Modules 800-CT8-A | 800-CON www.janitza.de

9. Module-relevant measuring displays

9.1 800-CT8-A module - Measuring displays

INFORMATION

The following measured value and instrument displays of the basic device do not show a concrete

application and may differ depending on the connection of your basic device with modules and the

measuring environment! A basic device allows the connection of up to 10 current measuring modules.

Further measured value and instrument displays can be found in the usage information for the basic

device.

Menu (phasor diagram)

Home

Phasor diagram

Volt ag e

Current

Power

ESC

Menu

Phasor diagram

Phasor diagram 1-4

Phasor diagram 5-8

Phasor diagram Mod. 1 1-4

Phasor diagram Mod. 1 5-8

ESC

Phasor diagram Mod. 1 1-4

L1 230.0V

L2

40.0°

L3

52.0°

ESC

Display, Voltage L1, L2, L3; current L1, L2, L3;

phase shift between voltage and current L1, L2, L3.

U1 U2 U3 I1 I2 I3

2.229A45.0°

229.7 V

2.228A

229.7 V

2.228A

Phasor diagram

Phasor diagram 1-4

Phasor diagram 5-8

Phasor diagram Mod. 1 1-4

Phasor diagram Mod. 1 5-8

ESC

Phasor diagram Mod. 1 5-8

L5 229.8V

L6

41.0 °

L7

50.0°

ESC

Display, Voltage L5, L6, L7; current L5, L6, L7; phase

shift between voltage and current L5, L6, L7.

U1 U2 U3 I5 I6 I7

2. 227A44.0°

230.0V

2.229A

229.7 V

2.229A

38

Page 39

www.janitza.de

Menu (Current)

Menu

Home

Phasor diagram

Volt ag e

Current

Power

ESC

Submenu (Current)

Current

THD I

ESC

Current

Modules 800-CT8-A | 800-CON

Current

Current 1- 4

Current 5 -8

Current Mod. 1 1-4

Current Mod. 1 5 -8

L1

L2

L3

L4

ESC

Display, Current (1-4) L1, L2, L3, L4 with mean

and maximum values.

ESC

Current Mod. 1 1-4

Valu e Max.Avg.

1.9 40 A

1.9 40 A

1.9 40 A

0.0 01A

1.9 40 A

1.9 40 A

1.9 40 A

0.0 01A

1.9 40 A

1.9 40 A

1.9 40 A

0.0 01A

Submenu (THD-I)

Current

THD I

ESC

Current

Current

Current 1- 4

Current 5 -8

Current Mod. 1 1-4

Current Mod. 1 5 -8

L5

L6

L7

L8

ESC

ESC

Display, Current (5-8) L5, L6, L7, L8 with mean

and maximum values.

THD I

THD I 1-4

THD I 5-8

THD I Mod. 1 1-4

THD I Mod. 1 5-8

L1

L2

L3

L4

ESC

ESC

Display, THD-I (1-4) - L1, L2, L3, L4 (Total

Harmonic Distortion of the current in %) with

average and maximum values.

THD I

THD I 1-4

THD I 5-8

THD I Mod. 1 1-4

THD I Mod. 1 5-8

L5

L6

L7

L8

ESC

ESC

Display, THD-I (5-8) - L5, L6, L7, L8 with mean

and maximum values.

Current Mod. 1 5 -8

Valu e Max.Avg.

1.930A

1.930A

1.930A

0.0 01A

1.930A

1.930A

1.930A

0.0 01A

THD I Mod. 1 1-4

Valu e Max.Avg.

166. 3%

166 .4%

166 .4%

201 .1%

166. 3%

166 .4%

166 .4%

207.0%

THD I Mod. 1 5-8

Valu e Max.Avg.

166. 3%

166 .4%

166 .4%

209.3%

166. 3%

166 .4%

166 .4%

212. 3%

1.930A

1.930A

1.930A

0.0 01A

166. 3%

166 .4%

166 .4%

222.2%

166. 3%

166 .4%

166 .4%

2 2 7. 6 %

39

Page 40

Modules 800-CT8-A | 800-CON www.janitza.de

Menu (Power)

Menu

Home

Phasor diagram

Volt ag e

Current

Power

ESC

Submenu (Power summary)

Power summary

Active power

Reactive power

Apparent power

Power factor

ESC

Power

Power summary

Power summary 1-4

Power summary 5 -8

Power summary Mod. 1 1-4

Power summary Mod. 1 5-8

ESC

Power summary Mod. 1 1-4

P SQ

L1

0.1 0 k W

-0.00kvar

0.1 0 k W

0.1 0 k W

0.31kW

-0.00kvar

-0.00kvar

-0.00kvar

L2

L3

Σ

ESC

Display, Summary of active, reactive and apparent

power for L1, L2, L3 and their sum.

0.1 9 k VA

0.1 9 k VA

0.1 9 k VA

0.58 kVA

Submenu (Active power)

Power

Power summary

Active power

Reactive power

Apparent power

Power factor

ESC

Power summary

Power summary 1-4

Power summary 5 -8

Power summary Mod. 1 1-4

Power summary Mod. 1 5-8

ESC

Active power

Active power 1-4

Active power 5-8

Active power Mod. 1 1-4

Active power Mod. 1 5-8

ESC

Active power

Active power 1-4

Active power 5-8

Active power Mod. 1 1-4

Active power Mod. 1 5-8

ESC

Power summary Mod. 1 5-8

P SQ

L5

0.11 k W

-0.00kvar

0.11 k W

0.11 k W

0.34kW

-0.00kvar

-0.00kvar

-0.00kvar

L6

L7

Σ

ESC

Display, Summary of active, reactive and apparent

power for L5, L6, L7 and their sum.

0.20 kVA

0.20 kVA

0.20 kVA

0.61kVA

Active power Mod. 1 1-4

Valu e Avg.

L1

L2

L3

Σ

Display, Active power 1-4 for L1, L2, L3 with

average values and sums.

ESC

0.1 0 k W

0.1 0 k W

0.1 0 k W

0.31kW

0.1 0 k W

0.1 0 k W

0.1 0 k W

0.31kW

Active power Mod. 1 5-8

Valu e Avg.

L5

L6

L7

Σ

Display, Active power 5-8 for L5, L6, L7 with

average values and sums.

ESC

0.11 k W

0.11 k W

0.11 k W

0.34kW

0.11 k W

0.11 k W

0.11 k W

0.34kW

40

Page 41

www.janitza.de

Submenu (Reactive power)

Power

Power summary

Active power

Reactive power

Apparent power

Power factor

ESC

Reactive power

Reactive power 1-4

Reactive power 5-8

Reactive power Mod. 1 1-4

Reactive power Mod. 1 5-8

ESC

Modules 800-CT8-A | 800-CON

Reactive power Mod. 1 1-4

Valu e Avg.

L1

L2

L3

Display, Reactive power 1-4 for L1, L2, L3 with average values and sums.

-0.02kvar

-0.02kvar

-0.02kvar

Σ

-0.06kvar

ESC

-0 .01kvar

-0 .01kvar

-0 .01kvar

-0.02kvar

Submenu (Apparent power)

Power

Power summary

Active power

Reactive power

Apparent power

Power factor

ESC

Reactive power

Reactive power 1-4

Reactive power 5-8

Reactive power Mod. 1 1-4

Reactive power Mod. 1 5-8

ESC

Apparent power

Apparent power 1-4

Apparent power 5- 8

Apparent power Mod. 1 1-4

Apparent power Mod. 1 5-8

ESC

Apparent power

Apparent power 1-4

Apparent power 5- 8

Apparent power Mod. 1 1-4

Apparent power Mod. 1 5-8

ESC

Reactive power Mod. 1 5-8

Valu e Avg.

L5

L6

L7

Display, Reactive power 5-8 for L5, L6, L7 with average values and sums.

-0.02kvar

-0.02kvar

-0.02kvar

Σ

-0.06kvar

ESC

-0 .01kvar

-0 .01kvar

-0 .01kvar

-0.03kvar

Apparent power Mod. 1 1-4

Valu e Avg.

L1

L2

L3

Σ

Display, Apparent power 1-4 for L1, L2, L3 with

average values and totals.

ESC

0.1 9 k VA

0.1 9 k VA

0.1 9 k VA

0.58 kVA

0.1 6 k VA

0.1 6 k VA

0.1 6 k VA

0.4 8kVA

Apparent power Mod. 1 5-8

Valu e Avg.

L5

L6

L7

Σ

Display, Apparent power 5-8 for L5, L6, L7 with

average values and sums.

ESC

0.20 kVA

0.20 kVA

0.20 kVA

0.61kVA

0.17kVA

0.17kVA

0.17kVA

0.50 kVA

41

Page 42

Modules 800-CT8-A | 800-CON www.janitza.de

Submenu (Power factor)

Power summary

Active power

Reactive power

Apparent power

Power factor

ESC

Power

Power factor

Power factor 1-4

Power factor 5 -8

Power factor Mod. 1 1-4

Power factor Mod. 1 5-8

ESC

Power factor Mod. 1 1-4

cos(p hi) Power factor

L1

L2

L3

Σ

ESC

Display, Power factor 1-4 for L1, L2, L3 with

cos(phi) and sums.

0.984

0.985

0.985

0.985

0. 513

0. 513

0. 513

0.9 81

Menu (Energy)

Menu

Power

Energy

Multifunctional channels

Configuration

System information

Submenu (Active energy)

Energy

Active energy

Reactive energy

Apparent energy

ESC

Power factor

Power factor 1-4

Power factor 5 -8

Power factor Mod. 1 1-4

Power factor Mod. 1 5-8

ESC

Active energy

Active energy 1-4

Active energy 5-8

Active energy Mod. 1 1-4

Active energy Mod. 1 5-8

ESC

Power factor Mod. 1 5-8

cos(p hi) Power factor

L5

L6

L7

Σ

ESC

Display, Power factor 5-8 for L5, L6, L7 with

cos(phi) and sums.

0.985

0.985

0.985

0.985

0. 513

0. 513

0. 513

0.9 81

Active energy Mod. 1 1-4

Sum L1.. L3

Consumed

1.0kW h

Delivered 1.0 kW h

ESC

Display, Active energy 1-4, sum L1..L3, applied and

delivered.

42

Active energy

Active energy 1-4

Active energy 5-8

Active energy Mod. 1 1-4

Active energy Mod. 1 5-8

ESC

Active energy Mod. 1 5-8

Sum L1.. L3

Consumed

Delivered

ESC

Display, Active power 5-8, sum L1..L3, applied and

delivered.

0.8kWh

0.8kWh

Page 43

www.janitza.de

Submenu (Reactive energy)

Energy

Active energy

Reactive energy

Apparent energy

ESC

Reactive energy

Reactive energy 1-4

Reactive energy 5-8

Reactive energy Mod. 1 1-4

Reactive energy Mod. 1 5-8

ESC

Modules 800-CT8-A | 800-CON

Reactive energy Mod. 1 1-4

Sum L1.. L3

Inductive

Capacitive 0.9kvarh

ESC

Display, Reactive energy 1-4, sum L1..L3, inductive

and capacitive.

0.9kvarh

Submenu (Apparent energy)

Energy

Active energy

Reactive energy

Apparent energy

ESC

Reactive energy

Reactive energy 1-4

Reactive energy 5-8

Reactive energy Mod. 1 1-4

Reactive energy Mod. 1 5-8

ESC

Apparent energy

Apparent energy 1-4

Apparent energy 5- 8

Apparent energy Mod. 1 1-4

Apparent energy Mod. 1 5-8

ESC

Apparent energy

Apparent energy 1-4

Apparent energy 5- 8

Apparent energy Mod. 1 1-4

Apparent energy Mod. 1 5-8

Reactive energy Mod. 1 5-8

Sum L1.. L3

Inductive

Capacitive

ESC

Display, Reactive energy 5-8, sum L1..L3, inductive

and capacitive.

0.4kvarh

0.4kvarh

Apparent energy Mod. 1 1-4

Sum L1.. L3

Tot a l 2.7kVA h

ESC

Display, Apparent energy 1-4, sum L1..L3, total.

Apparent energy Mod. 1 5-8

Sum L1.. L3

Tot a l

0.1 k VA h

Menu (Configuration)

Menu

Power

Energy

Multifunctional channels

Configuration

System informationen

ESC

ESC

ESC

Display, Apparent energy 5-8, sum L1..L3, total.

INFORMATION

The description of the current transformer configuration of the

modules can be found in chapter 8.1 on page 36.

43

Page 44

Modules 800-CT8-A | 800-CON www.janitza.de

Menu (System information)

Menu

Power

Energy

Multifunctional channels

Configuration

System informationen

ESC

System information

Main device

Module 1

Typ e

Serial no.

Position

ESC

ESC

Display, System information 1/2

Module 1 info 1/2

800 CT8 -A

480 0 0111

1

Module 1 info 2/2

HW-Ver si on

SW-Version

SW-Build

1

1.0. 8

ab481eb

190710 0 946 b0

ESC

Display, System information 2/2

44

Page 45

www.janitza.de

Modules 800-CT8-A | 800-CON

45

Page 46

Modules 800-CT8-A | 800-CON www.janitza.de

10. Device views - 800-CT8-A current measuring module

· The figures are for illustration purposes only and are not to scale.

· Dimensions in mm.

Rear view

Bottom view

Socket for

bus connector

Plug for

module insertion

Top view

Bus connector for transfer module - Output

Connector for insertion

into the socket for the bus connector

(rear of device)

Sockets for

module insertion

Front view

46

73 mm/2.87 in

90 mm/3.54 in

6 mm/0.24 in

View from left

26 mm/1.02 in

36 mm/1.42 in

14 mm/0.55 in

Page 47

www.janitza.de

Modules 800-CT8-A | 800-CON

11. Technical data - 800-CT8-A current measuring module

General

Net weight Approx. 220 g (0.49 lbs)