Jandy WPLV3LS100, WPLV5LS100, WWPLV3LS150, WWPLV5LS150, WPLV5LS150 Installation And Operation Manual

...

INSTALLATION AND

OPERATION MANUAL

ENGLISH | FRANÇAIS | ESPAÑOL

Jandy Pro Series

White LED Lights

Underwater Large and Small Light

WARNING

FOR YOUR SAFETY - This product must be installed and serviced by a contractor who is licensed and

qualified in pool equipment by the jurisdiction in which the product will be installed where such state or

local requirements exist. The maintainer must be a professional with sufficient experience in pool equipment

installation and maintenance so that all of the instructions in this manual can be followed exactly. Before

installing this product, read and follow all warning notices and instructions that accompany this product.

Failure to follow warning notices and instructions may result in property damage, personal injury, or death.

Improper installation and/or operation will void the warranty.

Improper installation and/or operation can create unwanted electrical hazard which can

cause serious injury, property damage, or death.

ATTENTION INSTALLER - This manual contains important information about the installation,

operation and safe use of this product. This information should be given to the owner/

H0621300 Rev C

operator of this equipment.

Page 2

ENGLISH

®

Pro Series, White LED Lights | Installation Manual

Jandy

Table of Contents

Section 1. Safety Information .......................... 3

Section 2. Product Description and Model

Numbers .......................................... 4

Section 3. Installing Jandy Light Fixture during

New Construction ........................... 5

3.1 Preparing the Light Fixture for Installation .......... 5

3.2 Installing the Light Fixture ................................. 6

Section 4. Replacing Jandy Light Fixture in an

Existing Pool or Spa ....................... 6

4.1 Preparing the Light Fixture for Replacement ...... 6

4.2 Replacing the Light Fixture ................................ 7

Section 5. Wiring Options for Controlling Jandy

White LED Lights ............................ 8

5.1 Wiring to an AquaLink® RS Control System ....... 8

5.2 Wiring to a Time Clock ....................................... 8

5.3 Wiring to a Switch ............................................... 8

Section 7. Replacing Light Engine (PCB) ..... 10

7.1 Pool Clamp Removal ........................................ 10

7.2 12V Small Light Driver (PCB) Replacement ..... 10

7.3 120V Small LED Board Replacement ...............11

7.4 120V Small Light Driver (PCB) Replacement ....11

7.5 Large Light Driver (PCB) Replacement

(120V and 12V) .................................................11

7.6 Reassemble the Fixture ....................................11

7.7 Reinstall the Jandy Pro Series Light into

Niche Fixture .................................................... 13

Section 8. Twelve (12) Volt Installation ......... 13

Section 9. Exploded View and Replacement

Parts ............................................... 14

9.1 Jandy Large White LED Light ........................... 14

9.2 Jandy Small White LED Light ........................... 15

®

Jandy

Pro Series, White LED Lights | Installation Manual

ENGLISH

Page 3

Section 1. Safety Information

IMPORTANT SAFETY INSTRUCTIONS PERTAINING TO A RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSONS

READ AND FOLLOW ALL INSTRUCTIONS

When installing and using this electrical equipment, basic safety precautions should always be followed, including the

following:

WARNING

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION. This underwater light must be installed by a

licensed or certified electrician in accordance with the National Electrical Code and applicable local codes and

ordinances. Improper installation will create an electrical hazard, which could result in death or serious injury to pool

or spa users, installers, or others due to electrical shock, and may also cause damage to property. Read and follow

the specific instructions below.

WARNING

Before installing this underwater light, read and follow all warning notices and instructions accompanying this light.

Failure to follow safety warnings and instructions can result in severe injury, death, or property damage. To obtain

additional copies of this manual, contact Zodiac Pool Systems, Inc at 1.800.822.7933 or visit

www.zodiacpoolsystems.com

CAUTION

Except when the Jandy Pro Series White LED Lights are installed in an area of the swimming pool that is not used

for swimming and the lens is adequately guarded to keep any person from contacting it, the light shall be installed

in or on a wall of the pool, with the top of the lens opening not less than 18 inches (457 mm) below the normal

water level of the pool

ATTENTION INSTALLER

This manual contains important information about the installation, operation and safe use of this

product. This information should be given to the owner/operator of this equipment.

NOTICE

The Jandy Pro Series White LED Lights are intended for installation in fresh water and salt water swimming pools.

It is important to ensure that the wet niches in which the lights are installed are intended for their appropriate

application, either fresh water or salt water pools.

SAVE THESE INSTRUCTIONS

Page 4

ENGLISH

®

Pro Series, White LED Lights | Installation Manual

Jandy

Section 2. Product Description and Model Numbers

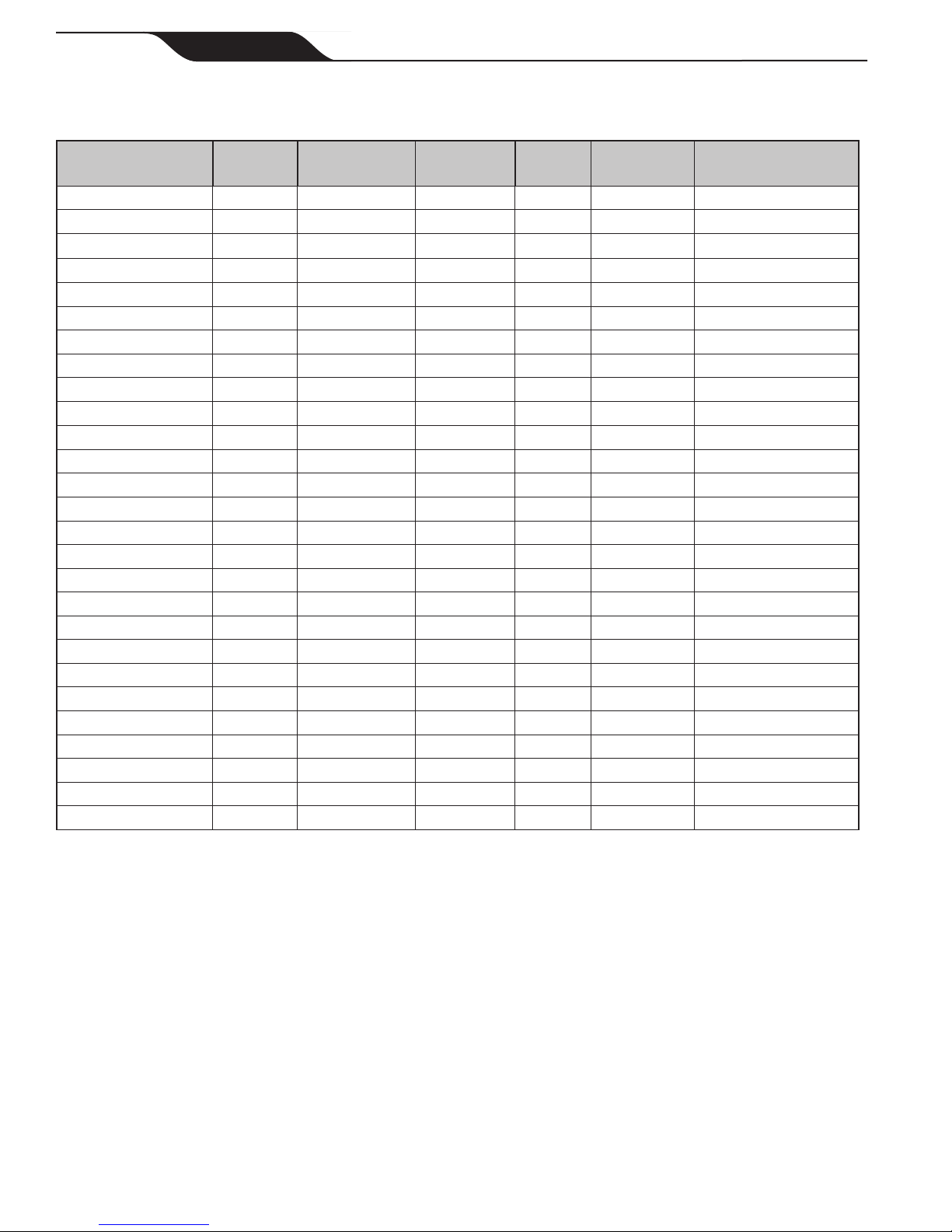

Model # Size Color Temp. Voltage Watts Cord Length Face Ring Material

WWPLV3LS150 Large 2700 12 Volt AC 42W 150 feet Stainless Steel

WPLV3LS100 Large 5000 12 Volt AC 42W 100 feet Stainless Steel

WPLV3LS150 Large 5000 12 Volt AC 42W 150 feet Stainless Steel

WPLV3LS50 Large 5000 12 Volt AC 42W 50 feet Stainless Steel

WWPLV5LS150 Large 2700 12 Volt AC 65W 150 feet Stainless Steel

WPLV5LS100 Large 5000 12 Volt AC 65W 100 feet Stainless Steel

WPLV5LS150 Large 5000 12 Volt AC 65W 150 feet Stainless Steel

WPLV5LS50 Large 5000 12 Volt AC 65W 50 feet Stainless Steel

WWPHV3LS150 Large 2700 120 Volt AC 42W 150 feet Stainless Steel

WPHV3LS100 Large 5000 120 Volt AC 42W 100 feet Stainless Steel

WPHV3LS150 Large 5000 120 Volt AC 42W 150 feet Stainless Steel

WPHV3LS50 Large 5000 120 Volt AC 42W 50 feet Stainless Steel

WPHV5LS150 Large 5000 120 Volt AC 65W 150 feet Stainless Steel

WPHV5LS100 Large 5000 120 Volt AC 65W 100 feet Stainless Steel

WWPHV5LS150 Large 2700 120 Volt AC 65W 150 feet Stainless Steel

WPHV5LS50 Large 5000 120 Volt AC 65W 50 feet Stainless Steel

WPHV5LS250 Large 5000 120 Volt AC 65W 250 feet Stainless Steel

WWSLV1LS150 Small 2700 12 Volt AC 18W 150 feet Stainless Steel

WSLV1LS150 Small 5000 12 Volt AC 18W 150 feet Stainless Steel

WSLV1LS100 Small 5000 12 Volt AC 18W 100 feet Stainless Steel

WSLV1LS50 Small 5000 12 Volt AC 18W 50 feet Stainless Steel

WWSHV1LS150 Small 2700 120 Volt AC 18W 150 feet Stainless Steel

WSHV1LS100 Small 5000 120 Volt AC 18W 100 feet Stainless Steel

WSHV1LS150 Small 5000 120 Volt AC 18W 150 feet Stainless Steel

WSHV1LS50 Small 5000 120 Volt AC 18W 50 feet Stainless Steel

WSHV1LS250 Small 5000 120 Volt AC 18W 250 feet Stainless Steel

®

Jandy

Pro Series, White LED Lights | Installation Manual

ENGLISH

Page 5

Section 3. Installing Jandy

Pro Series Light

Fixture during New

Construction

WARNING

Risk of Electrical Shock or Electrocution. This

underwater light must be installed by a licensed or

certified electrician or a qualified pool serviceman in

accordance with the National Electrical Code and all

applicable local codes and ordinances

Canadian Electrical Code (“CEC” or C22.1) in Canada

Improper installation will create an electrical hazard,

which could result in death or serious injury to pool or

spa users, installers or others due to electrical shock,

and may also cause damage to property.

Always disconnect the power to the light at the

circuit breaker before installing or servicing the light.

Failure to do so could result in death or serious injury

to serviceman, pool or spa users or others due to

electrical shock.

3.1 Preparing the Light Fixture for

Installation

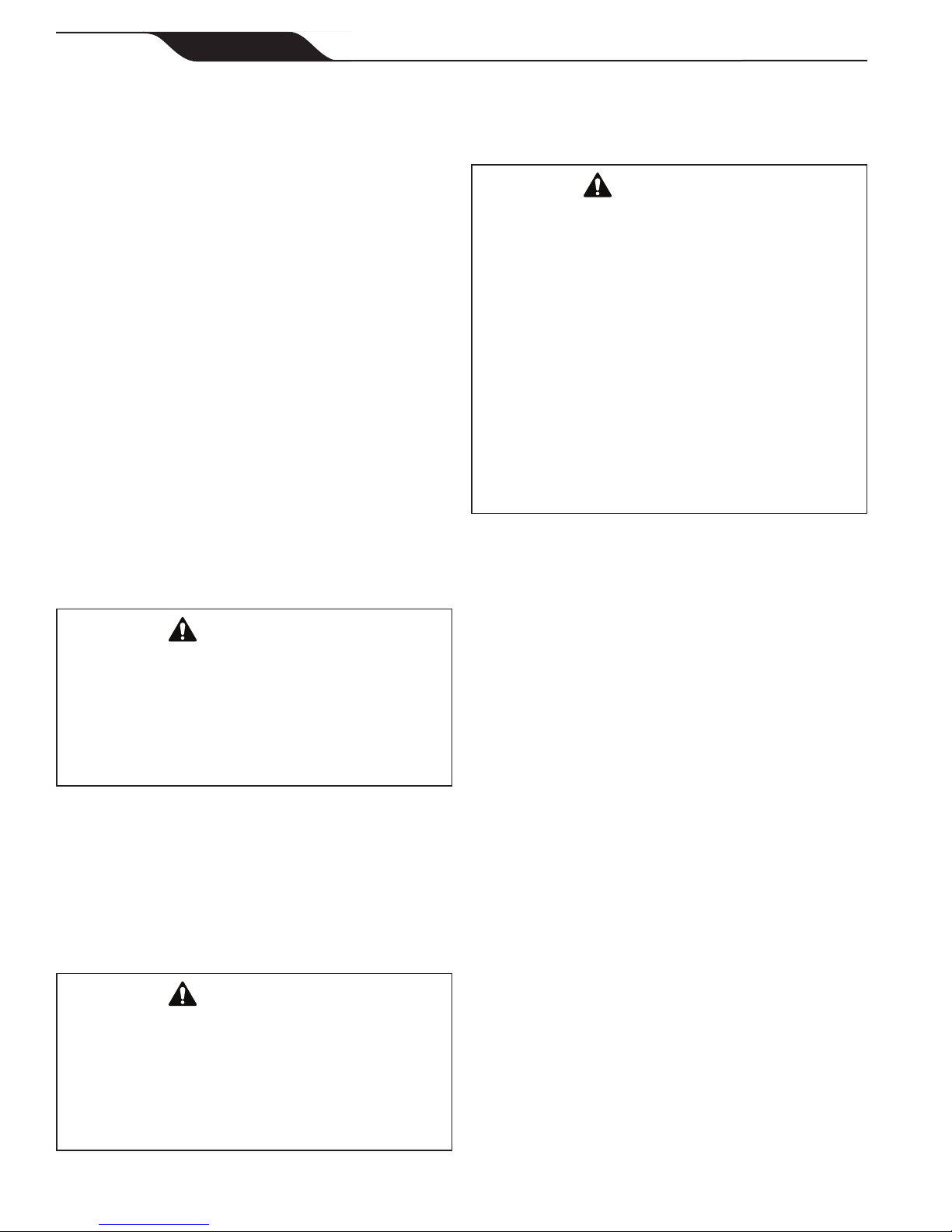

NOTE The electrician must complete preparatory steps

before light fixture is installed. See Figure 1.

Ensure that the pool meets the requirements of the

current National Electrical Code

the US, the Canadian Electrical Code (“CEC” or C22.1) in

Canada

. A licensed or certied electrician must install the

electrical system to meet or exceed those requirements

before the underwater light is installed. Some of the

requirements of the National Electrical Code, which the

pool electrical systems must meet, are as follows:

®

in the US, the

and all local codes

.

in

(5) feet of the pool must be properly electrically

bonded to a reliable point of grounding.

4. The wet niche must be properly installed so that

the top edge of the underwater light’s lens is at

least 18 inches below the surface of the water in

the pool. See Figure 1.

5. The wet niche must be properly electrically

bonded and grounded via the No. 8 AWG ground

connector located at the rear of the niche. See

Figure 1.

NOTE To be certain that the pool’s electrical system meets

all applicable requirements, the electrician should also

consult the local building department.

Use only approved wet niches (see following note) to

ensure a safe and proper installation.

NOTE Jandy Pro Series lights are ETL listed (ETL report/

file 3141154CHI) for installation with only the following

manufacturer’s wet niche fixtures:

Large Niche Model Numbers:

Jandy Pro Series: PLNICLRG, PLNICVFLRG,

WT000002, SSNICLRG1R, SSNICLRG1S

Pentair: 620004, 78210200 thru 700,

78210401, 79206700

Hayward DuraNiche: SP0600U

Sta-Rite: 05161-2352 thru 2369, 05163-2395

thru 2396

Small Niche Model Numbers:

Jandy Pro Series: PLNICSM, SSNICSM,

Pentair: 78241100, 78242200, 78242300

78243100 thru 300, 78244100 thru 300,

79206600

Hayward DuraNiche: SP0601U

Sta-Rite: 05166-1017 thru 1034, 05167-1035

thru 1037

Pentair

®

and Sta-Rite® are registered trademarks of Pentair, Inc.

Hayward® is a registered trademark and DuraNiche™ is a trademark of

Hayward Pool Products, Inc.

WARNING

To minimize risk of Electrical shock or electrocution,

which could result in injury or death, for supply

connection of low-voltage lights use only an isolating

low voltage power supply, evaluated and listed by a

Nationally Recognized Testing Laboratory (NRTL) for

swimming pool use.

1. The lighting circuit must have a Ground Fault

Circuit Interrupter (GFCI) for 120 volt models,

and must have an appropriately rated circuit

breaker.

2. The junction box (or, for 12 volt models, the low

voltage transformer) must be located at least eight

(8) inches above water level, at least four (4)

inches above ground level, and at least four (4)

feet from the edge of the pool. See Figure 1.

3. The light xture and all metal items within ve

To GFCI, Circuit

Breaker and

Power Source.

48"

min.

4" min.

Rigid

Conduit

#8 AWG Ground

Connector bonding

is located at rear

of niche.

16”

8" min. Junction Box or Low

Voltage Transformer, to the

max water level of the pool.

18" min. to top of Lens.

Concrete must be cut

back around Niche to

allow for a compacted

plaster seal.

11.50"

Coil 4 ft. of light cable

around Fixture.

Figure 1. Jandy Pro Series LED Light Installation

Page 6

ENGLISH

®

Pro Series, White LED Lights | Installation Manual

Jandy

3.2 Installing the Light Fixture

NOTE Perform these steps only after the electrical system

requirements are met.

1. Feed cord through conduit to junction box,

leaving at least four (4) feet of cord at the light

xture to coil into the base of the light niche, see

Figure 1. The four (4) feet of cord allows the light

to be serviced after the pool is lled with water.

2. Cut the cord at the junction box, leaving at least

six (6) inches of cord to make connections.

3. Strip six (6) inches of the outer cord jacket to

expose the three insulated wires.

Be careful not to

damage the insulation on the three (3) inner wires.

4. Install strain relief over cord jacket and connect

all three (3) wires to the corresponding circuit

wires in the junction box. Install the junction box

cover.

5. Coil the 4-foot length of cord around the xture

or into the base of the pool niche, and place the

light assembly into the niche.

6. Engage the retainer tab on the bottom of the face

ring, then pivot the top of the xture inward and

tighten the special pilot screw.

WARNING

Use only the special pilot screw provided with this

underwater light. This screw mounts and electrically

grounds the housing securely to the mounting ring

and wet niche. Failure to use the screw provided could

create an electrical hazard, which could result in death

or serious injury to pool or spa users, installers or

others due to electrical shock.

7. Fill the pool until the underwater light is

completely submerged in water before operating

the light for more than 2 minutes. The light will

heat up quickly when operated outside of water.

Turn on main switch or circuit breaker, and the

switch, which operates the underwater light, to

check for proper operation. Refer to Section 6,

Operating Instructions.

Section 4. Replacing Jandy Pro

Series Light Fixture in

an Existing Pool or Spa

WARNING

Risk of Electrical Shock or Electrocution. This

underwater light must be installed by a licensed or

certified electrician or a qualified pool serviceman in

accordance with the National Electrical Code and all

applicable local codes and ordinances

Canadian Electrical Code (“CEC” or C22.1) in Canada

Improper installation will create an electrical hazard,

which could result in death or serious injury to pool or

spa users, installers or others due to electrical shock,

and may also cause damage to property.

Always disconnect the power to the light at the

circuit breaker before installing or servicing the light.

Failure to do so could result in death or serious injury

to serviceman, pool or spa users or others due to

electrical shock.

4.1 Preparing the Light Fixture for

Replacement

Verify that the pool meets the requirements of the current

National Electrical Code

ordinances

or C22.1) in Canada

in the US, the Canadian Electrical Code (“CEC”

must install the electrical system to meet or exceed those

requirements before the underwater light is installed.

Some of the requirements of the National Electrical

Code, which the pool’s electrical system must meet, are

as follows:

1. The lighting circuit must have a Ground Fault

Circuit Interrupter (GFCI) for 120 volt models,

and must have an appropriately rated circuit

breaker.

2. The junction box (or, for 12 volt models, the low

voltage transformer) must be located at least eight

(8) inches above water level, at least four (4)

inches above ground level or pool deck level, and

at least 48 inches from the edge of the pool or spa.

See Figure 1.

®

(NEC) and all local codes and

. A licensed or certied electrician

in the US, the

.

WARNING

Never operate this underwater light for more than

10 seconds unless it is totally submerged in water.

Without total submersion, the light assembly will get

extremely hot, which may result in serious burns or in

breakage of the bulb or lens. This may result in serious

injury to pool or spa users, installers, or bystanders or

damage to property.

3. The light xture and all metal items within ve

(5) feet of the pool must be properly electrically

bonded to a reliable point of grounding.

4. The wet niche must be properly installed so that

the top edge of the underwater light’s lens is at

least 18 inches below the surface of the water in

the pool. See Figure 1.

®

Jandy

Pro Series, White LED Lights | Installation Manual

ENGLISH

Page 7

5. The wet niche must be properly electrically

bonded and grounded via the No. 8 AWG ground

connector located at the rear of the niche. See

Figure 1.

To be certain that the pool’s electrical system meets

all applicable requirements, the electrician should also

consult the local building department.

4.2 Replacing the Light Fixture

NOTE Perform these steps only after the electrical system

requirements are met.

WARNING

Failure to bring the pool’s electrical system up to code

requirements before installing the underwater light

will create an electrical hazard which could result in

death or serious injury to pool or spa users, installers,

or others due to electrical shock, and may also cause

damage to property.

NOTE The light fixture may be replaced without removing

water from the pool.

1. Turn off the main electrical switch or circuit

breaker, as well as the switch, which operates the

underwater light.

2. Unscrew the special pilot screw at top of the

face ring and remove the light assembly from the

niche, and place the assembly on the deck.

6. Cut the cord at the Junction Box, leaving at least

six (6) inches of cord to make connections.

7. Strip six (6) inches of the outer cord jacket from

the cord to expose the three insulated wires. Be

careful not to damage the insulation on the three

(3) inner wires.

8. Install the strain relief over the cord jacket and

connect all three wires to the corresponding

circuit wires in the junction box. Install the

junction box cover.

9. Reinstall the light assembly into the niche and

tighten the special pilot screw.

WARNING

Use only the special pilot screw provided with this

underwater light. This screw mounts and electrically

grounds the housing securely to the mounting ring

and wet niche. Failure to use the screw provided could

create an electrical hazard, which could result in death

or serious injury to pool or spa users, installers or

others due to electrical shock.

10. Fill the pool until the underwater light is

completely submerged in water before operating

the light for more than 10 seconds. Turn on main

switch or circuit breaker, as well as the switch,

which operates the underwater light, to check for

proper operation. Refer to Section 6, Operating

Instructions.

WARNING

Be sure to keep the special pilot screw provided

with this underwater light. This screw mounts and

electrically grounds the housing securely to the

mounting ring and wet niche. Failure to use the screw

provided could create an electrical hazard, which could

result in death or serious injury to pool or spa users,

installers or others due to electrical shock.

3. Remove Junction Box cover, disconnect the light

xture wires and strain relief, and then pull the

cord out of the conduit from the niche.

4. Feed the new light xture cord through the

conduit from the niche to the Junction Box.

NOTE Depending on the length of the conduit, special tools

may be required to pull the cord through the conduit.

5. Leave at least four (4) feet of cord to coil around

the light xture or coiled into the base of the light

niche, see Figure 1. This allows the light to be

serviced after the pool is lled with water.

WARNING

Never operate this underwater light for more than

10 seconds unless it is totally submerged in water.

Without total submersion, the light assembly will get

extremely hot, which may result in serious burns or in

breakage of the bulb or lens. This may result in serious

injury to pool or spa users, installers, or bystanders or

in damage to property.

Section 5. Wiring Options for

Controlling Jandy

Pro Series White LED

Lights

NOTE The Jandy Pro Series White LED Lights will not

operate properly with light dimmers. Do not wire the

Jandy Pro Series Lights to any dimming circuitry.

Page 8

Black

White

Green

Ground

Neutral

120 VAC

Power Supply

Black

White

Green

JUNCTION

BOX

12V

LED

Light

120V/12V

Transformer

Black

White

Green

ENGLISH

®

Pro Series, White LED Lights | Installation Manual

Jandy

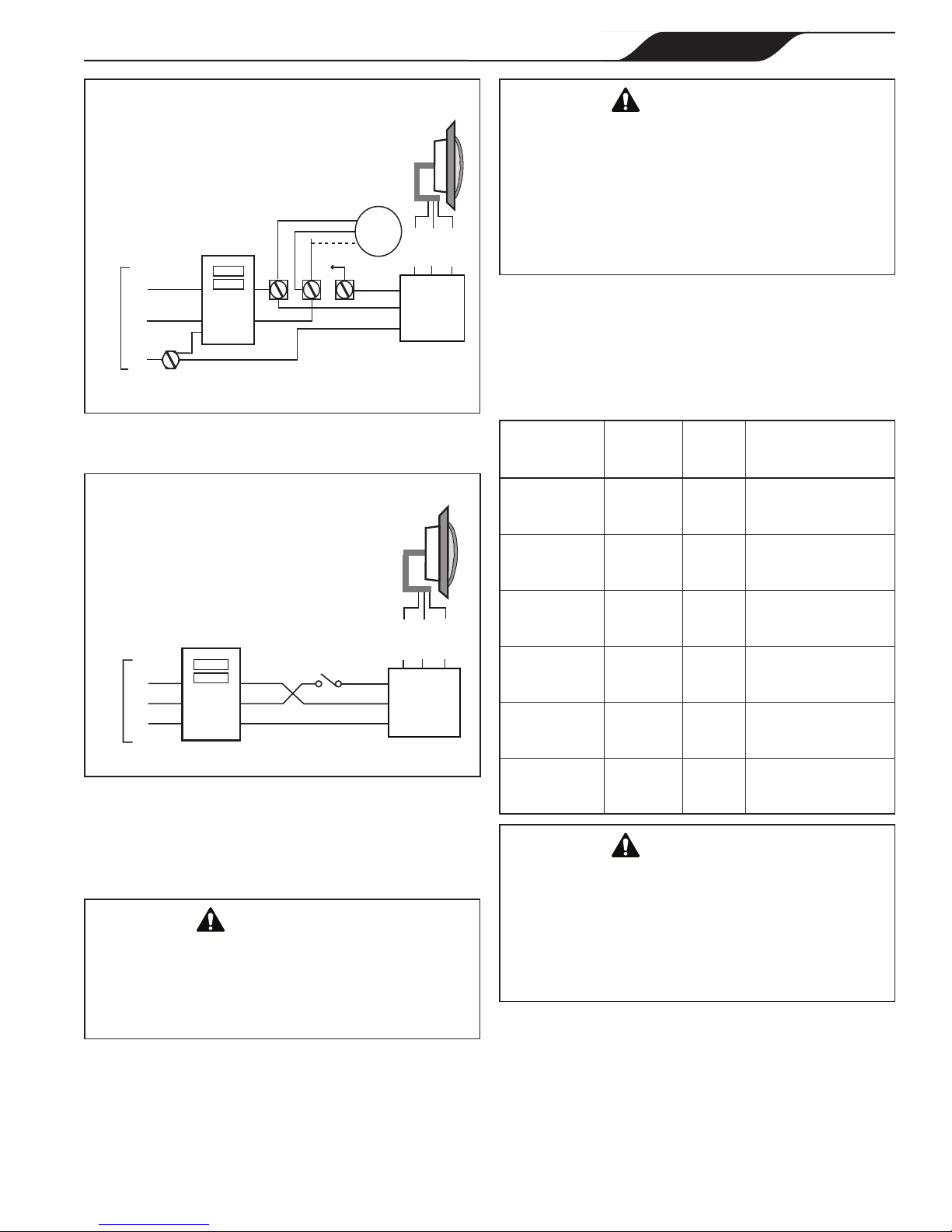

5.1 Wiring to an AquaLink® RS Control

System

The Jandy Pro Series White LED Lights can be wired

into the Jandy Pro Series AquaLink

to provide simplied operation of the lights. Connect the

lights to one of the auxiliary relays in the Power Center.

NOTE It is recommended to connect one light per relay so

each light can be controlled separately. However, up to

four lights can be connected on a single relay. If there

are more than four lights installed on one AquaLink RS

system, ensure there is more than one auxiliary relay

available in the Power Center.

Refer to Figures 2 and 3 to connect the Jandy Pro Series

White Lights to the Power Center.

®

RS control system

WARNING

RISK OF ELECTRICAL SHOCK OR

ELECTROCUTION, which could result in serious

injury or death.

(GFCI) must be provided for 120 volt models. A

Ground Fault Circuit Interrupter (GFCI) for 120

Volt transformers should be used if required by the

transformer manufacturer or if required by the local

applicable code and/or Authority Having Jurisdiction

(AHJ). When a GFCI is used, the conductors on the

load side of the GFCI circuit shall not occupy conduit,

boxes, or enclosures containing other conductors

unless the additional conductors are also protected by

a GFCI. Refer to local codes for complete details.

NOTE The Jandy Pro Series White Lights are available in

120-volt and 12-volt versions. If installing a 12-volt

light, a NRTL certified 120-volt/12-volt step-down (AC)

transformer must be used. For more information about

12-volt installations, refer to Section 8 of this manual.

5.2 Wiring to a Time Clock

The Jandy Pro Series White LED Lights can be wired

into a basic time clock to automatically turn on the lights

at a predesignated time. Refer to Figure 4 to connect the

lights into the time clock.

A Ground Fault Circuit Interrupter

120 VAC

Power Supply

120V

LED

Light

Neutral

Ground

Ground

GFCI

Black

White

Green

JUNCTION

BOX

Black

White

Green

Figure 2. 120-Volt Jandy Pro Series White LED

Light Wiring Diagram

5.3 Wiring to a Switch

The Jandy Pro Series White LED Lights can be wired

into a switch to manually turn on/off the lights. Refer to

Figure 5 to connect the lights into the switch.

Figure 3. 12-Volt Jandy Pro Series White LED Light

Wiring Diagram

®

Clock

Motor

Ground

Ground

Neutral

Line

A

1

2

GFCI

Black

White

Green

Black

White

Green

JUNCTION

BOX

120V

LED

Light

120 V

SUPPLY

Jandy

Pro Series, White LED Lights | Installation Manual

Figure 4. Wiring the Jandy Pro Series White LED

Light to a Time Clock

ENGLISH

Page 9

WARNING

Replace light driver with the same type. Failure to

replace the light driver with the same type will damage

the light assembly and may cause an electrical hazard

resulting in death or serious injury to pool or spa users,

installers, or others due to electrical shock, and may

also cause damage to property. Be sure the power is

switched OFF before removing or installing PCB. Allow

PCB to cool before replacing.

3. To remove the light assembly, unscrew the special

pilot screw at the top of the face ring, remove

light assembly from niche and gently place

assembly on the deck. It is not necessary to drain

down the pool. See Figure 6.

Table 2. Light Specications

Jandy Pro

Series Model

Fixture

Voltage

Watts Light Driver (PCB)

Part Number

SWITCH

120 V

Supply

Neutral

Line

Ground

GFCI

White

Black

Ground

Figure 5. Wiring the Jandy Pro Series White LED

Light to a Switch

Section 7. Replacing LED Board

and Driver (PCB)

WARNING

Always disconnect power to the light at the circuit

breaker before servicing the light. Failure to do so

could result in death or serious injury to installer,

serviceman, pool or spa users or others due to

electrical shock.

1. Turn off the main electrical switch or circuit

breaker, as well as the switch, which operates the

underwater light.

2. Be sure to have the following items:

• A new lens gasket.

• A light driver board. See Table 2 for specication.

Black

White

Green

120V

LED

Light

Black

White

JUNCTION

BOX

Green

White LED

Large Light

White LED

Large Light

White LED

Large Light

White LED

Large Light

White LED

Small Light

White LED

Small Light

12 VAC 65W R0802600

120 VAC 65W R0802700

12 VAC 42W R0802800

120 VAC 42W R0802900

120 VAC R0803200

12 VAC R0803300

WARNING

Be sure to keep the special pilot screw from this

underwater light. This screw mounts and electrically

grounds the housing securely to the mounting ring

and wet niche. Failure to use the screw provided could

create an electrical hazard, which could result in death

or serious injury to pool or spa users, installers or

others due to electrical shock.

7.1 Pool Clamp Removal.

1. Loosen the Phillips head screws (six (6) for small

light, eight (8) for large light) to allow the bottom

clamp to be removed from the face ring assembly.

Do not remove the screws or the retaining rings.

The retaining rings prevent the screws from

falling free from the bottom clamp and also aid in

ease of assembly.

Page 10

1

POOL WALL

Power

Cord

Niche

POOL LIGHT

ASSEMBLY

PILOT SCREW

Push up on

bottom of

light assembly

2

Power

Cord

Niche

SPA LIGHT

ASSEMBLY

SPA WALL

1

PILOT SCREW

Push up on

bottom of

light assembly

2

Unscrew pilot screw

and pull top of light

assembly away from

spa wall

Bonding

cable

Unscrew pilot screw

and pull top of light

assembly away from

pool wall

Bonding

cable

ENGLISH

®

Pro Series, White LED Lights | Installation Manual

Jandy

2 Remove the bottom clamp, the face ring

assembly, the glass lens, and the gasket from

the xture. Remove the silicone gasket from

the lens. Refer to Section 9, Exploded View and

Replacement Parts.

WARNING

To minimize risk of damage to the light and risk of

serious injury, including loss of life, ALWAYS install a

new silicone gasket whenever disassembling the light.

7.2 12V Small Light Driver (PCB)

Replacement

1. Remove both quick disconnect wires from the

PCB. Note that the black wire is connected to

ACN (TP-2) and the White wire is connected to

ACL (TP-1).

2. Remove two (2) nuts and two (2) washers.

3. Remove the light driver from the light xture.

4. Apply thermal grease to the back of the new light

driver board.

5. Place new light driver into the xture with the

orientation shown in Figure 7.

6. Secure the light driver with one (1) washer and

one (1) nut on the right side of the light driver.

Torque to 12 in-lbs.

5. Apply thermal grease to the back of the new LED

board.

6. Place new LED board into the heat sink with the

orientation shown in Figure 7.

7. Secure the LED board with two (2) screws and

two (2) washers.

8. Plug in the board connector.

7.4 120V Small Light Driver (PCB)

Replacement

1. Disconnect power and wait 5 minutes.

2. Remove LED board as instructed in step 7.3

3. Remove 2 screws from the heat sink and remove

the heat sink.

4. Remove both quick disconnect wires from the

PCB. Note that the black wire is connected to

ACN and the White wire is connected to ACL.

5. Remove 2 metal posts from the driver board

6. Remove driver board and place new light driver

board into the xture with the orientation shown

in Figure 7.

7. Insert metal posts back on to the screw studs.

8. Plug in both quick disconnect wires, white onto

the terminal ACL of the light driver and black

onto the ACN.

9. Align heat sink to the metal posts

10. Secure the heat sink with 2 screws

11. Apply thermal grease to the back of the new LED

board.

12. Place new LED board into the heat sink with the

orientation shown in Figure 7.

13. Secure the LED board with two (2) screws and

six (6) washers.

Figure 6. Removing the Jandy Pro Series White

LED Light Assembly for Light Driver

Replacement

7. Place a washer on the other stud and place the

green ground wire terminal on the washer and

secure both with the nut. Torque to 12 in-lbs.

8. Plug in the quick disconnect wire (white) onto the

terminal ACL (TP-1) of the light engine.

9. Plug in the quick disconnect wire (black) onto

7.3 120V Small LED Board Replacement

terminal ACN (TP-2) of the light engine.

1. Disconnect power and wait 5 minutes.

2. Remove two (2) screws and six (6) washers.

3. Unplug the board connector from the light engine.

4. Remove the LED board from the heat sink. If

you are also replacing the driver board, you can

proceed now to step 7.4

14. Plug in the board connector.

7.5 Large Light Driver (PCB) Replacement

(120V and 12V)

1. Disconnect power and wait 5 minutes.

2. Unplug the quick disconnect terminals and the

grounding wire (green) from the light driver.

3. Remove three (3) nuts and washers.

4. Remove the LED board, light driver board and

board connector from the light xture.

5. Apply thermal grease to the back of the new LED

board.

6. Place new LED board and light driver board into

the xture with the orientation shown in Figure 8.

7. Secure the new boards with 3 washers, spilt

washers and nuts. Torque to 12 in-lbs.

8. Plug in the white quick disconnect wire onto the

terminal AC1 (TP-L) of the light driver board.

9. Plug in black quick disconnect wire onto terminal

AC2 (TP-N) of the light driver. Ensure board

connectors are connected to both boards.

®

Fixture Lens

Jandy

Pro Series, White LED Lights | Installation Manual

ENGLISH

Page 11

10. To secure the ground wire, place the at washer,

followed by the ground wire, followed by the split

washer, securing in place with the nut. Torque to

12 in-lbs.

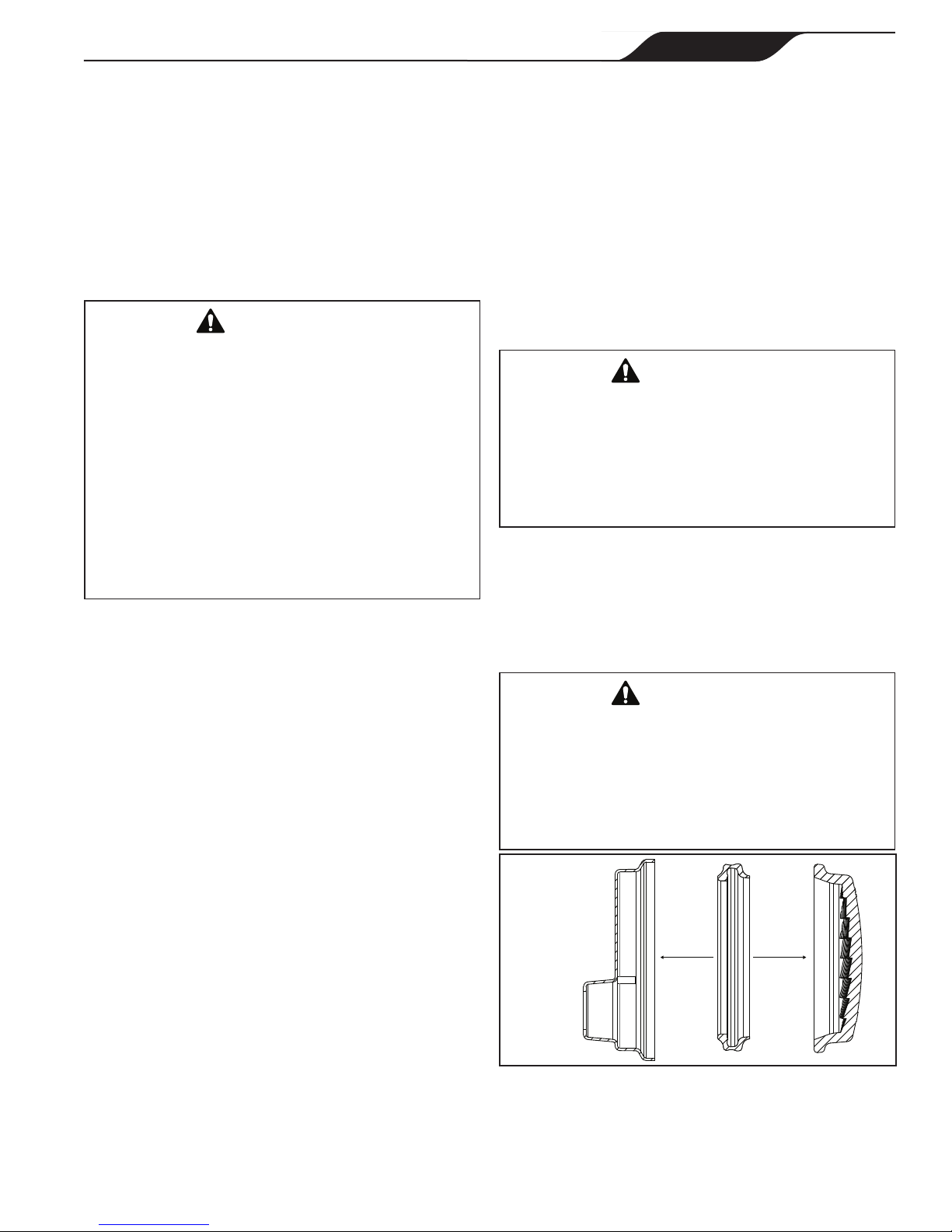

7.6 Reassemble the Fixture.

1. If not already done, remove the gasket from the

glass lens and install a new gasket on the lens. On

the small light, remove the diverger from the lens.

NOTE A new lens gasket must be used each time the light is

reassembled.

WARNING

Risk of Electrical Shock or Electrocution. Always

install a new lens gasket whenever disassembling the

light. Failure to do so may permit water to leak into the

assembly, which could cause:

(a) An electrical hazard resulting in death or serious

injury to pool or spa users, installers, or others due to

electrical shock, or

(b) A malfunction of the Jandy White LED Light,

which likewise could result in serious injury to pool or

spa users, installers, or bystanders, or in damage to

property.

2. While holding the xture upright, place the glass

lens with the gasket on top of the xture. Please

note that the lens gasket is not symmetrical.

Therefore, it must be installed correctly so that

the lens can seal to the xture housing. Place the

gasket on the lens with the orientation shown in

Figure 10. On the small light, replace the diverger

by tucking the tabs between the lens and gasket.

NOTE Be sure to face the dull side of the diverger down

towards the PCB.

3. Position the lens and gasket on the xture. Place

the face ring assembly over the lens and align the

pilot screw with the small arrow mark on the face

of the lens. Note that the small arrow mark on

the face of the lens and the pilot screw of the face

ring must be aligned with the arrow located on

xture label that reads, “Arrow on this label must

line up with the pilot screw on the Face Ring”.

See Figure 9.

4. While holding the aligned face ring assembly and

xture together, turn the assembly upside down

and set it on the old gasket, using the old gasket

as an assembly xture. This will keep the lens

and gasket assembly from being pushed out of the

face ring while you secure it to the light xture.

5. Spread the bottom clamp over the electrical cord

and slide it onto the back of xture to the top

clamp.

6. Tighten the Phillips head screws (eight (8) for

large light and six (6) for small light) on the light

in alternating cross-pattern. Torque screws to

approximately 25 in-lbs.

7. Discard the old gasket.

7.7 Reinstall the Jandy Pro Series Light

Into Niche Fixture.

1. Coil the extra four (4) feet of cord around the

xture or into the base of the niche and place the

light assembly into the niche.

2. Engage the retainer tab on the bottom of the face

ring, then pivot the top of the xture inward and

tighten the special pilot screw.

WARNING

Use only the special pilot screw provided with this

underwater light. This screw mounts and electrically

grounds the housing securely to the mounting ring

and wet niche. Failure to use the screw provided could

create an electrical hazard, which could result in death

or serious injury to pool or spa users, installers or

others due to electrical shock.

3. If pool is empty, Fill the pool until the underwater

light is completely submerged in water before

operating the light for more than 2 minutes. The

light will heat up quickly when operated outside

of water. Turn on main switch or circuit breaker,

and the switch, which operates the underwater

light, to check for proper operation.

WARNING

Never operate this underwater light for more than

10 seconds unless it is totally submerged in water.

Without total submersion, the light assembly will get

extremely hot, which may result in serious burns or in

damage to the light. This may result in serious injury

to pool or spa users, installers, or bystanders or in

damage to property.

Thick molded

side of the

gasket must

mate with

the body of

the housing

Figure 10. Cross Section of Jandy Pro Series White

LED Light

Page 12

Green

ACN (Black)

ACL (White)

LED Board

Connector

LED Board

Connector

Serrated

Washer

Split

Washer

Nut

White (12V)

White (120V)

TP-1 (White)

TP-1

AC1

White

Black (12V)

Black (120V)

TP-2 (Black)

TP-2

AC2

Black

120V Wiring LED Board 120V Wiring Driver Board

12V Wiring LED Board

ENGLISH

®

Pro Series, White LED Lights | Installation Manual

Jandy

Figure 7. Small Light Engine (PCB) Replacement and Wiring

Green

Black (12V)

TP-2 (Black)

TP-2

AC2

Black

12V/120V Wiring

White (12V)

TP-1 (White)

TP-1

AC1

White

Serrated

Washer

Split

Washer

Nut

Figure 8. Large Light Engine (PCB) Replacement

and Wiring

Section 8. Twelve (12) Volt

Align arrow of the

lens with the pilot

screw

Align pilot screw with

the arrow located on

the xture label

Figure 9. Alignment of the Lens, Face Ring, Housing

and Clamps for White LED Lights

Installation

A separate 12-Volt AC Transformer is required on all

12-Volt Models. For Jandy Pro Series White LED Light

use a 150-watt multi-tap 12-volt system per light.

RISK OF ELECTRICAL SHOCK OR

ELECTROCUTION, which could result in serious

injury or death.

lights use only an isolating low voltage power supply

with ungrounded output, evaluated and listed by a

NRTL for swimming pool use.

WARNING

for supply connection of low-voltage

NOTE For optimum performance Jandy Pro Series

recommends to use one transformer per 12-volt light.

To ensure maximum safety, it is strongly recommended

that a transformer that has been listed or recognized by

a Nationally Recognized Testing Laboratory (NRTL) for

the application be used.

®

1

8

5

2

35 467

7

Jandy

Pro Series, White LED Lights | Installation Manual

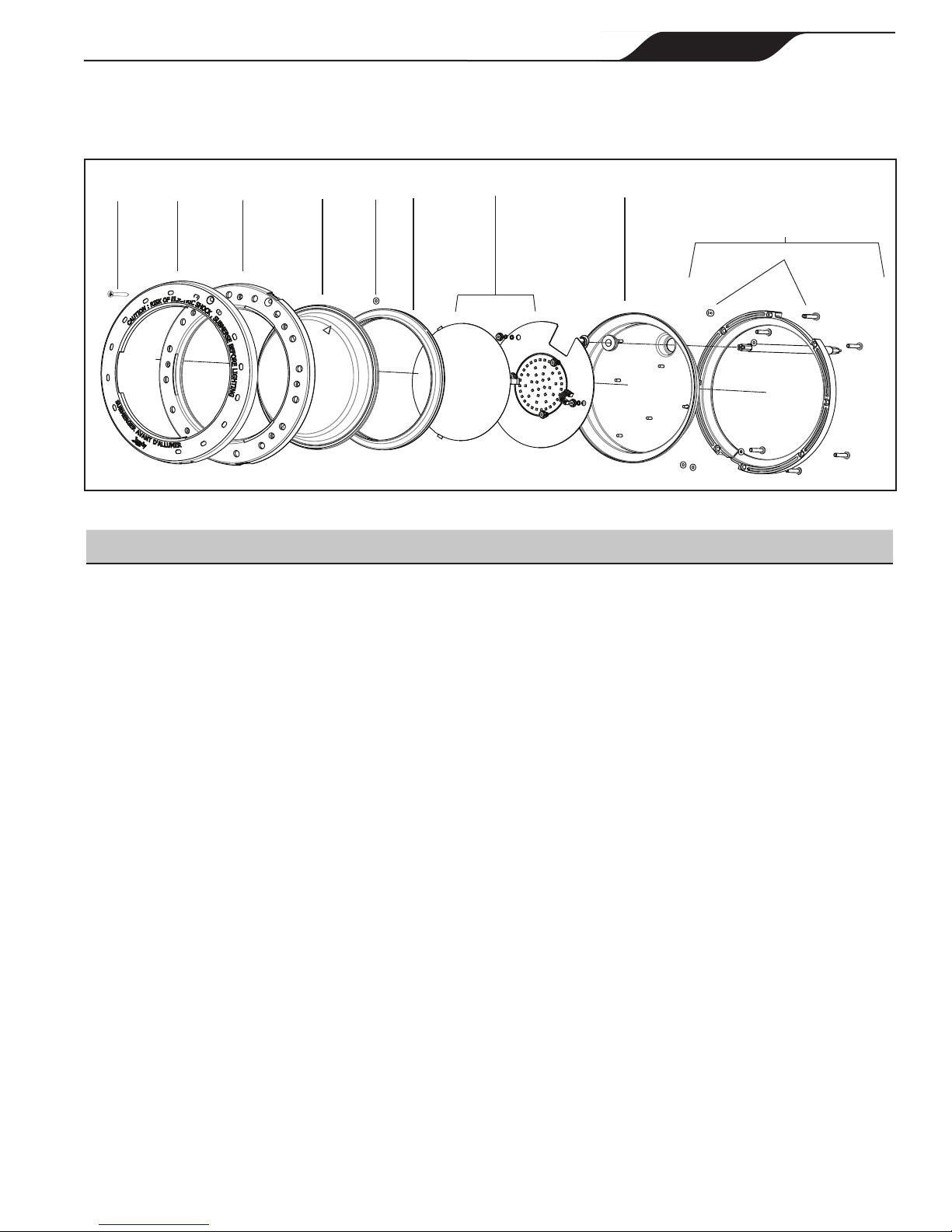

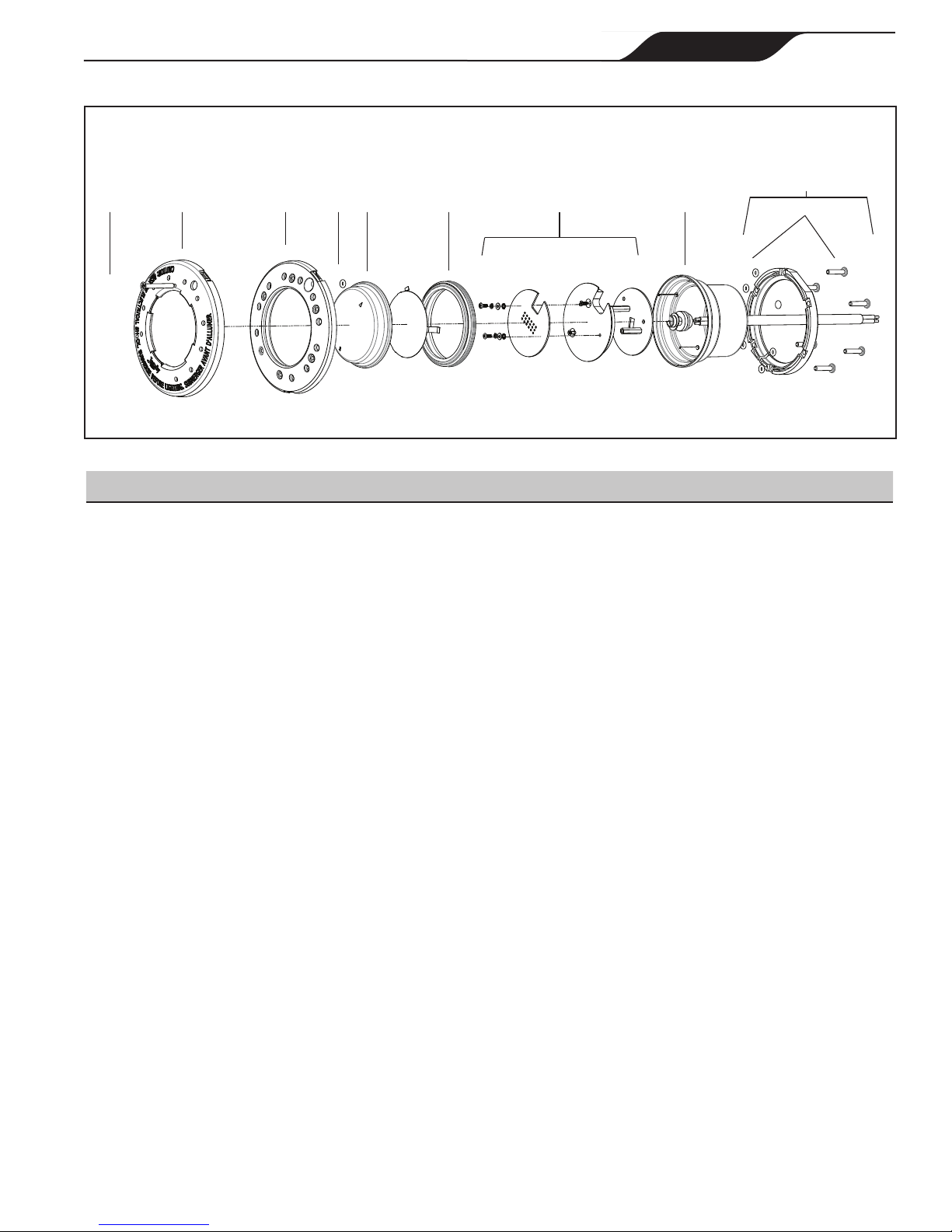

Section 9. Exploded View and Replacement Parts

9.1 Jandy Pro Series Large White LED Light

ENGLISH

Page 13

35 467

7

2

Figure 11. Jandy Pro Series Large White LED Light Exploded View

1

5

8

DWG # Part # Description Field Replaceable

1 N/A White LED Light Housing NO - Purchase New Light

2 R0802600 Light Engine PCB, 12V, 5K, 65W Large LED YES

2 R0802601 Light Engine PCB, 12V, 2.7K 65W Large LED YES

2 R0802700 Light Engine PCB, 120V, 5K, 65W Large LED YES

2 R0802701 Light Engine PCB, 120V, 2.7K, 65W Large LED YES

2 R0802800 Light Engine PCB, 12V, 5K, 42W Large LED YES

2 R0802801 Light Engine PCB, 12V, 2.7K, 42W Large LED YES

2 R0802900 Light Engine PCB, 120V, 5K, 42W Large LED YES

2 R0802901 Light Engine PCB, 120V, 2.7K, 42W Large LED YES

3 R0790500 Silicone Gasket YES

4 R0790600 Glass Lens YES

5 R0790700 Clamp Assembly YES

6 R0790801 Face Ring, Stainless Steel (SS) YES

6 R0790802 Face Ring, Plastic, White YES

6 R0790803 Face Ring, Plastic, Black YES

6 R0790804 Face Ring, Plastic, Gray YES

6 R0790805 Face Ring, Plastic Set YES

7 R0790900 Pilot Screw, with Retainer YES

8 R0791000 Clamp Screws (8 Screws and 8 Retainers) YES

Page 14

1 2

3

5

4

6

7

9

1

4 2

3

6

7

7

9

7

5

8

8

8

8

ENGLISH

®

Pro Series, White LED Lights | Installation Manual

Jandy

9.2 Jandy Pro Series Small White LED 12V Light

8 8

7

6

5

Figure 12. Jandy Pro Series Small White 12V LED Light Exploded View

4 2

3

DWG # Part # Description Field Replaceable

1 N/A White LED Light Housing NO - Purchase New Light

2 R0803300 Light Engine, Small LED Light, 12V YES

3 R0739700 Diverger, Light Shaping, Small LED Light YES

4 R0791100 Silicone Gasket YES

5 R0791200 Glass Lens YES

6 R0791300 Clamp Assembly YES

7 R0791401 Face Ring, Stainless Steel (SS) YES

7 R0791402 Face Ring, Plastic, White YES

7 R0791403 Face Ring, Plastic, Black YES

7 R0791404 Face Ring, Plastic, Gray YES

7 R0791405 Face Ring, Plastic Set YES

8 R0790900 Pilot Screw, with Retainer YES

9 R0791600 Clamp Screws (6 Screws and 6 Retainers) YES

7

1

9

®

1 2

3

5

4

6

7

9

1

4 2

3

6

7

7

9

7

5

8

8

8

8

Jandy

Pro Series, White LED Lights | Installation Manual

9.3 Jandy Pro Series Small White 120V LED Light

ENGLISH

Page 15

8 8

7

6

5

Figure 13. Jandy Pro Series Small White 120V LED Light Exploded View

4 2

3

1

7

9

DWG # Part # Description Field Replaceable

1 N/A White LED Light Housing NO - Purchase New Light

2 R0803200 Light Engine, Small LED Light, 120V YES

3 R0739700 Diverger, Light Shaping, Small LED Light YES

4 R0791100 Silicone Gasket YES

5 R0791200 Glass Lens YES

6 R0791300 Clamp Assembly YES

7 R0791401 Face Ring, Stainless Steel (SS) YES

7 R0791402 Face Ring, Plastic, White YES

7 R0791403 Face Ring, Plastic, Black YES

7 R0791404 Face Ring, Plastic, Gray YES

7 R0791405 Face Ring, Plastic Set YES

8 R0790900 Pilot Screw, with Retainer YES

9 R0791600 Clamp Screws (6 Screws and 6 Retainers) YES

Loading...

Loading...