INSTALLATION AND

OPERATION MANUAL

ENGLISH

Jandy® Pro Series

Water Feature Pump

Model WFTR

WARNING

FOR YOUR SAFETY - This product must be installed and serviced by a contractor who is licensed and

qualified in pool equipment by the jurisdiction in which the product will be installed where such state or

local requirements exist. The maintainer must be a professional with sufficient experience in pool equipment

installation and maintenance so that all of the instructions in this manual can be followed exactly. Before

installing this product, read and follow all warning notices and instructions that accompany this product.

Failure to follow warning notices and instructions may result in property damage, personal injury, or death.

Improper installation and/or operation will void the warranty.

Improper installation and/or operation can create unwanted electrical hazard which can

cause serious injury, property damage, or death.

ATTENTION INSTALLER - This manual contains important information about the

installation, operation and safe use of this product. This information should be given to

the owner/operator of this equipment.

H0320100 Rev B

®

Jandy

Pro Series Water Feature Pump | Installation and Operation Manual

Table of Contents

ENGLISH

Page 3

Section 1. Important Safety Instructions ......... 4

1.1 Safety Instructions .............................................. 4

1.2 Pool Pump Suction Entrapment

Prevention Guidelines ........................................ 6

Section 2. General Description ......................... 7

2.1 Introduction ......................................................... 7

2.2 Description ......................................................... 7

Section 3. Installation......................................... 8

3.1 Plumbing ............................................................ 8

3.2 Electrical Installation ........................................... 9

3.2.1 Voltage Checks .................................................. 9

3.3 Pressure Testing ............................................... 10

Section 4. Operation ........................................11

4.1 Start-up ..............................................................11

Section 5. Service and Maintenance ..............11

5.1 Routine Maintenance ........................................11

5.2 Winterizing Pump ............................................. 12

Section 6. Troubleshooting and Repair ........ 13

6.1 Troubleshooting ................................................ 13

6.2 Service Technician Maintenance ...................... 14

6.2.5 Motor Replacement .......................................... 17

Section 7. Product Specications and

Technical Data .............................. 18

7.1 Replacement Parts List .................................... 18

7.2 Exploded View .................................................. 19

7.3 WFTR Pump Curves ........................................ 20

7.4 PhysicalandOperationalSpecications .......... 21

7.5 Replacement Motor Guide ............................... 22

EQUIPMENT INFORMATION RECORD

DATE OF INSTALLATION

INSTALLER INFORMATION

INITIAL PRESSURE GAUGE READING (WITH CLEAN FILTER)

PUMP MODEL

NOTES:

HORSEPOWER

Page 4

ENGLISH

®

Pro Series Water Feature Pump | Installation and Operation Manual

Jandy

Section 1. Important Safety Instructions

READ AND FOLLOW ALL INSTRUCTIONS

1.1 Safety Instructions

All electrical work must be performed by a licensed electrician and conform to all national, state, and local codes.

When installing and using this electrical equipment, basic safety precautions should always be followed, including the

following:

WARNING

RISK OF SUCTION ENTRAPMENT HAZARD, WHICH, IF NOT AVOIDED, CAN RESULT IN SERIOUS INJURY

OR DEATH. Do not block pump suction as this can cause severe injury or death. Do not use this pump for

wading pools, shallow pools or spas containing bottom drains, unless the pump is connected to at least two

functioning suction outlets. Suction outlet (drain) covers must be certified to the latest published version of ANSI/

ASME A112.19.8.

WARNING

To reduce the risk of injury, do not permit children to use this product.

WARNING

To reduce the risk of property damage or injury, do not attempt to change the backwash (multiport, slide, or full

flow) valve position with the pump running.

WARNING

Jandy Pro Series pumps are powered by a high voltage electric motor and must be installed by a licensed or

certified electrician or a qualified swimming pool service technician.

WARNING

Due to the potential risk of fire, electric shock, or injuries to persons, Jandy Pumps must be installed in

accordance with the National Electrical Code (NEC), all local electrical and safety codes, and the Occupational

Safety and Health Act (OSHA). Copies of the NEC may be ordered from the National Fire Protection Association,

470 Atlantic Ave., Boston, MA 02210, or received by contacting your local government inspection agency.

WARNING

Incorrectly installed equipment may fail, causing severe injury or property damage.

• Do not connect the system to an unregulated city water system or other external source of pressurized water

producing pressures greater than 35 PSI.

• Trapped air in system can cause the filter lid to be blown off, which can result in death, serious personal injury,

or property damage. Be sure all air is out of the system before operating.

WARNING

®

Jandy

Pro Series Water Feature Pump | Installation and Operation Manual

ENGLISH

Page 5

WARNING

To minimize the risk of severe injury or death the filter and/or pump should not be subjected to the piping system

pressurization test.

Local codes may require the pool piping system to be subjected to a pressure test. These requirements are

generally not intended to apply to the pool equipment such as filters or pumps.

Zodiac® pool equipment is pressure tested at the factory.

However, if the WARNING cannot be followed and pressure testing of the piping system must include the filter

and/or pump, BE SURE TO COMPLY WITH THE FOLLOWING SAFETY INSTRUCTIONS:

• Check all clamps, bolts, lids, lock rings and system accessories to ensure they are properly installed and

secured before testing.

• RELEASE ALL AIR in the system before testing.

• Water pressure for test must NOT EXCEED 35 PSI.

• Water temperature for test must NOT EXCEED 100°F (38°C).

• Limit test to 24 hours. After test, visually check system to be sure it is ready for operation.

NOTICE: These parameters apply to Zodiac equipment only. For non-Zodiac equipment, consult equipment

manufacturer.

WARNING

Chemical spills and fumes can weaken pool/spa equipment. Corrosion can cause filters and other equipment to

fail, resulting in severe injury or property damage. Do not store pool chemicals near your equipment.

CAUTION

Do not start pump dry! Running the pump dry for any length of time will cause severe damage and will void the

warranty.

CAUTION

This pump is for use with permanently installed pools and may also be used with hot tubs and spas if so marked.

Do not use with storable pools. A permanently installed pool is constructed in or on the ground or in a building

such that it cannot be readily disassembled for storage. A storable pool is constructed so that it may be readily

disassembled for storage and reassembled to its original integrity.

CAUTION

Do not install within an outdoor enclosure or beneath the skirt of a hot tub or portable spa. The pump requires

adequate ventilation to maintain air temperature at less than the maximum ambient temperature rating listed on

the motor rating plate.

SAVE THESE INSTRUCTIONS

Page 6

ENGLISH

®

Pro Series Water Feature Pump | Installation and Operation Manual

Jandy

1.2 Pool Pump Suction Entrapment Prevention Guidelines

WARNING

SUCTION HAZARD. Can cause serious injury or death. Do not use this pump for

wading pools, shallow pools or spas containing bottom drains, unless the pump is

connected to at least two (2) functioning suction outlets.

WARNING

Pump suction is hazardous and can trap and drown or disembowel bathers. Do not use or operate

swimming pools, spa, or hot tubs if a suction outlet cover is missing, broken, or loose. The following

guidelines provide information for pump installation that minimizes the risk of injury to users of pools, spas, and

hot tubs:

Entrapment Protection - The pump suction system must provide protection against the hazards of suction

entrapment.

Suction Outlet Covers - All suction outlets must have correctly installed, screw-fastened covers in place. All

suction outlet (drain) covers must be maintained. Drain covers must be listed/certified to the latest published

version of ANSI/ASME A112.19.8. They must be replaced if cracked, broken, or missing.

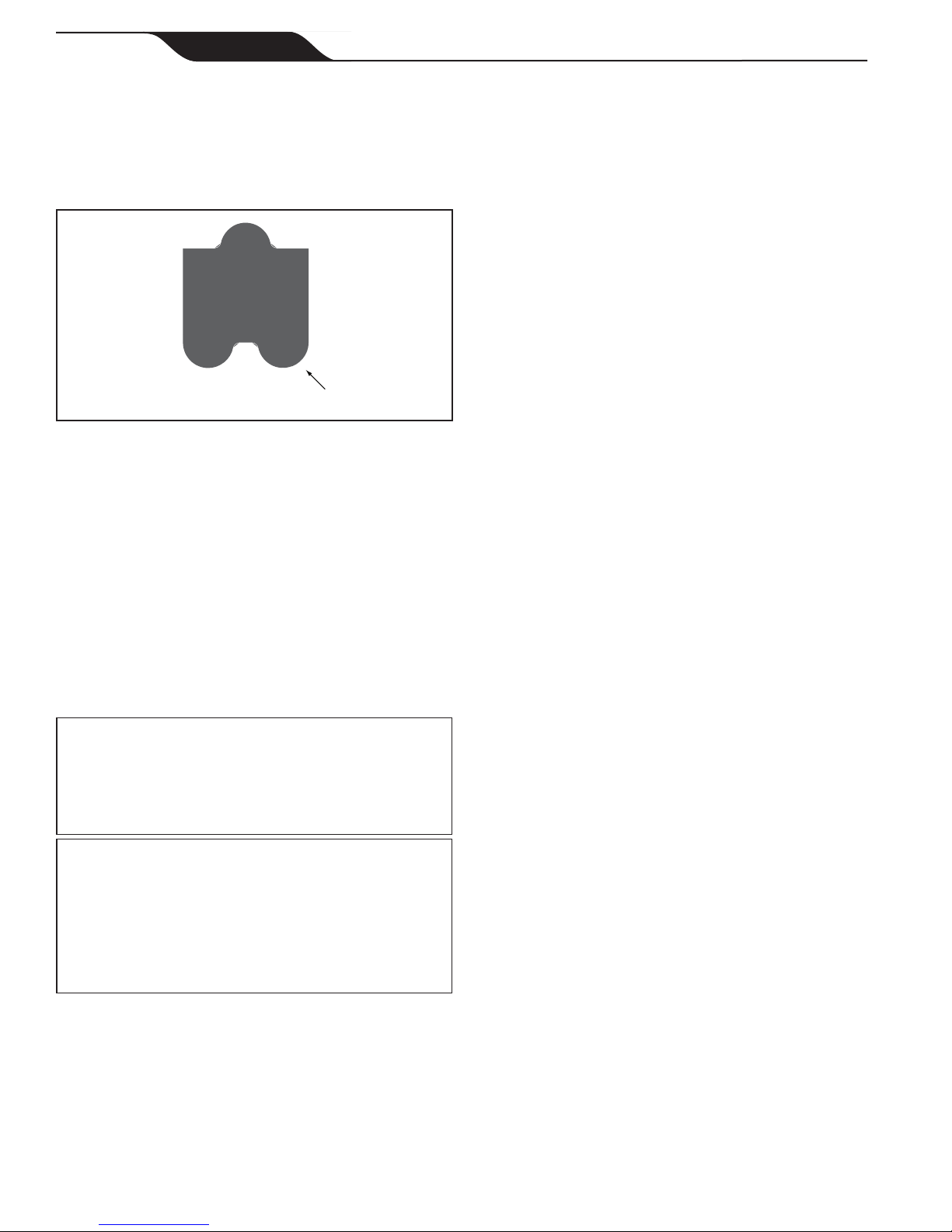

Number of Suction Outlets Per Pump - Provide at least two (2) main drains, with covers, as suction outlets for

each circulating pump suction line. The centers of the main drains (suction outlets) on any one (1) suction line

must be at least 3 feet apart, center to center. See Figure 1 on page 7. For additional details and guidelines, refer

to ANSI/APSP 7, the standard for Suction Entrapment Avoidance in Swimming Pools, Wading Pools, Spas, Hot

Tubs, and Catch Basins.

The system must be built to include at least two (2) suction outlets (drains) connected to the pump whenever

the pump is running. However, if two (2) main drains run into a single suction line, the single suction line may be

equipped with a valve that will shut off both main drains from the pump. The system shall be constructed such

that it shall not allow for separate or independent shutoff or isolation of each drain. See Figure 1 on page 7.

More than one (1) pump can be connected to a single suction line as long as the requirements above

are met.

Water Velocity - The maximum water velocity through the suction fitting or cover for any suction outlet must be

1.5 feet per second, unless the outlet complies with the latest published version of ANSI/ASME A112.19.8, the

standard for Suction Fittings For Use in Swimming and Wading Pools, Spas, Hot Tubs, and Whirlpool Bathtub

Applications. In any case, do not exceed the suction fitting’s maximum designed

flow rate.

If 100% of the pump’s flow comes from the main drain system, the maximum water velocity in the pump suction

hydraulic system must be 6 feet per second, or less even if one (1) main drain (suction outlet) is completely

blocked. The flow through the remaining main drain(s) must comply with the latest published version of ANSI/

ASME A112.19.8, the standard for Suction Fittings For Use in Swimming and Wading Pools, Spas, Hot Tubs, and

Whirlpool Bathtub Applications.

Testing and Certification - Suction outlet covers must have been tested by a nationally recognized testing

laboratory and found to comply with the latest published version of ANSI/ASME A112.19.8, the standard for

Suction Fittings For Use in Swimming and Wading Pools, Spas, Hot Tubs, and Whirlpool Bathtub Applications.

Fittings - Fittings restrict flow; for best efficiency use the fewest possible fittings (but at least two (2) suction

outlets).

Avoid fittings that could cause an air trap.

Pool cleaner suction fittings must conform to applicable International Association of Plumbing and Mechanical

Officials (IAPMO) standards.

®

Jandy

Pro Series Water Feature Pump | Installation and Operation Manual

At Least

3 Feet

ENGLISH

Page 7

Listed/certified to latest

published version of

ANSI/ASME A112.19.8

Anti-entrapment

Cover/Grate or Suction

Fitting, screw-fastened to

Main Drain Sump

Suction Outlet

(Main Drain)

Valves OK between

pump and Tee

Figure 1. Number of Suction Outlets Per Pump

No valves between

Tee and Main Drains

Listed/certified to latest

published version of

ANSI/ASME A112.19.8

Anti-entrapment

Cover/Grate or Suction

Fitting, screw-fastened to

Main Drain Sump

Suction Outlet

(Main Drain)

Pump

Section 2. General Description

2.1 Introduction

This manual contains information for the proper

installation, operation and maintenance of Jandy Pro

Series Water Features (WFTR) Pumps. Procedures in this

manual must be followed exactly. To obtain additional

copies of this manual contact Zodiac Pool Systems, Inc.

at 800.822.7933. For address information, see the back

cover of this manual.

2.2 Description

WFTR Pumps are designed to meet the needs of today’s

more hydraulically demanding pool equipment. The

pump housing, backplate, diffuser, hair and lint pot

(pump debris lter basket), and impeller are all made

from high quality thermoplastic materials. These

materials were chosen for their strength and corrosion

resistance.

The pump is driven by an electric motor directly attached

to the pump impeller. As the electric motor turns, it

causes the impeller to turn, which forces water to ow

through the pump. The water ows through the pump

inlet and then into the lter basket. The basket assembly

pre-strains/traps large particles. The water then enters the

center of the pump housing, ows through the impeller

into the diffuser, and then ows out the pump discharge

port.

Page 8

ENGLISH

®

Pro Series Water Feature Pump | Installation and Operation Manual

Jandy

Section 3. Installation

3.1 Plumbing

3.1.1 Preparation

1. Upon receipt of the pump, check the carton for

damage. Open the carton and check the pump

for concealed damage, such as cracks, dents or a

bent base. If you nd damage, contact the shipper

or the distributor where the pump was purchased.

2. Inspect the contents of the carton and verify

that all parts are included. See Section 7.1,

Replacement Parts List.

3.1.2 Pump Location

1. Zodiac Pool Systems, Inc. recommends installing

the pump within 1 foot above water level. The

pump should not be elevated more than a few

feet above the water level of the pool. A check

valve is recommended on the suction line to the

pump.

5. The pump foundation must have adequate

drainage to prevent the motor from getting wet.

Protect the pump from the rain and sun.

6. Proper ventilation is required for the pump to

operate normally. All motors generate heat that

must be removed by providing proper ventilation.

7. Provide access for future service by leaving a

clear area around the pump. Allow plenty of

space above the pump to remove the lid and

basket for cleaning.

8. If the equipment is under cover, provide adequate

lighting.

3.1.3 Pipe Sizing

3.1.3.1 Suction Pipe

When the pump is located up to 50 feet from the pool, the

recommended Schedule 40 minimum pipe size for the

suction side of the pump is 2" for 1 to 2 HP. For 2.5 HP

pumps, the recommended pipe size is 2½".

NOTE Better self-priming will be achieved if the pump is

installed as close as possible to the water level of the

pool.

2. If the pump is located below water level,

isolation valves must be installed on both the

suction and return lines to prevent back ow

of pool water during any routine or required

servicing.

WARNING

Some Safety Vacuum Release System (SVRS)

devices are not compatible with installation of check

valves. If the pool has an SVRS device, be sure to

confirm that that it will continue to safely operate when

any check valves are installed.

3. Zodiac Pool Systems, Inc. recommends that

the pump and other circulation equipment be

located more than 5 feet from the water. Choose

a location that will minimize turns in the piping.

NOTE In Canada, the pump must be located a minimum of

3 meters (approximately 10 feet) from the water (CSA

C22.1).

4. The pump must be placed on a solid foundation

that will not vibrate. To further reduce the

possibility of vibration noise, bolt the pump to

the foundation, or place it on a rubber mat.

NOTE Zodiac Pool Systems, Inc. recommends bolting the

pump directly to the foundation.

3.1.3.2 Discharge Pipe

When the pump is located up to 50 feet from the pool,

the recommended Schedule 40 minimum pipe size for the

discharge side of the pump is 2" for 1 to 2 HP. For 2.5 HP

pumps, the recommended pipe size is 2½".

NOTE All pipe sizes (Schedule 40) are able to withstand the

pressures the pump will deliver, but not necessarily

the flow. If the pipe is too small for the pump, or if

the pump is elevated above water, the maximum

gallons per minute (GPM) may not be delivered. If

this happens, the pump will develop an air pocket

(cavitation) that will make noise, and the life of the

pump might be shortened.

3.1.3.3 Installation Recommendations

1. If the pump is located below water level,

isolation valves must be installed on both sides

of the pump to prevent back ow of pool water

during any routine or required servicing.

2. To help prevent difculty in priming, install the

suction pipe without high points (above inlet of

pump - inverted “U”s in plumbing commonly

referred to as an airlock), which can trap air. For

installations of equipment up to 100 feet from the

water, refer to the pipe sizing chart in Table 1.

For installations of equipment more than 100 feet

from the water, the recommended pipe size must

be increased to the next size.

®

Jandy

Pro Series Water Feature Pump | Installation and Operation Manual

ENGLISH

Page 9

Table 1. Pipe Sizing Chart for Schedule 40 PVC

Pipe

Size

2" 85 GPM (322 LPM) 105 GPM (397 LPM)

2½" 120 GPM (454 LPM) 149 GPM (564 LPM)

3" 184 GPM (697 LPM) 230 GPM (871 LPM)

Maximum Flow

Suction

(8 feet per second)

Maximum Flow

Discharge

(10 feet per second)

3. WFTR Pumps come equipped with unions

on both the suction and discharge ports. This

feature simplies installation and service, and

it eliminates the possibility of leaks at threaded

adapters.

4.

The WFTR Pump must be connected to at least two

(2) main drains (suction outlets) for each pool pump

suction line. Each drain must be provided with covers

that are listed or certied to the latest published

version of ANSI/ASME A112.19.8. The suction

outlets of the main drains must be at least 3 feet apart

or at different planes. The suction outlets can be a

drain and skimmer, two (2) drains, two (2) skimmers,

or a skimmer with an equalizer line installed. For

additional details and guidelines, refer to ANSI/APSP

7, the standard for Suction Entrapment Avoidance

in Swimming Pools, Wading Pools, Spas, Hot Tubs,

and Catch Basins. Check the local codes for proper

installation requirements. Applicable local codes will

take precedence over other codes.

NOTE To prevent entrapment, the system must be built so

that it cannot operate with the pump drawing water

from only one (1) main drain. At least two (2) main

drains must be connected to the pump when it is in

operation. However, if two (2) main drains run into

a single suction line, the single suction line may be

equipped with a valve that will shut off both main

drains from the pump.

5. The piping must be well supported and not

forced together in places where constant stress

will be experienced.

3.2 Electrical Installation

3.2.1 Voltage Checks

The correct voltage, as specied on the pump data plate,

is necessary for proper performance and long motor life.

The incorrect voltage will decrease the pump’s ability to

perform and could cause overheating, reduce the motor

life, and result in higher electric bills.

It is the responsibility of the electrical installer to provide

data plate operating voltage to the pump by ensuring

proper circuit sizes and wire sizes for this specic

application.

CAUTION

Failure to provide data plate voltage (within 10%)

during operation will cause the motor to overheat and

will void the warranty.

3.2.2 Bonding and Grounding

1. The motor frame must be grounded to a reliable

grounding point using a solid copper conductor,

No. 8 AWG or larger. In Canada, No. 6 AWG

or larger must be used. If the pump is installed

within 5 feet of the inside walls of the swimming

pool, spa, or hot tub, the motor frame must be

bonded to all metal parts of the swimming pool,

spa, or hot tub structure and to all electrical

equipment, metal conduit, and metal piping

within 5 feet of the inside walls of the swimming

pool, spa, or hot tub.

2. Bond the motor using the provided external lug.

WARNING

To avoid risk of property damage, severe personal

injury, and/or death, always disconnect the power

source before working on a motor or its connected

load.

6. Always use properly sized valves. Jandy Pro

Series Diverter Valves and Ball Valves typically

have the best ow capabilities.

7. Use the fewest ttings possible. Every additional

tting has the effect of moving the equipment

farther away from the water.

NOTE If more than 10 suction fittings are needed, the pipe

size must be increased.

8. Every new installation must be pressure tested

according to local codes. See Section 3.3,

Pressure Testing.

WARNING

In order to avoid the risk of property damage,

severe personal injury, and/or death, make sure

that the control switch or time clock is installed in

an easily accessible location, so that in the event of

an equipment failure or a loose plumbing fitting, the

equipment can be easily turned off.

Page 10

ENGLISH

®

Pro Series Water Feature Pump | Installation and Operation Manual

Jandy

CAUTION

The pump must be permanently connected to a

dedicated electrical circuit. No other equipment, lights,

appliances or outlets may be connected to the pump

circuit, with the exception of devices that may be

required to operate simultaneously with the pump,

such as a chlorinating device or heater.to both the

pump and motor and will void the warranty.

3.2.3 Electrical Wiring

WARNING

To avoid risk of property damage, severe personal

injury, or death, always ground before connecting to an

electrical power supply.

1. The pump motor must be securely and

adequately grounded using the green screw

provided. Ground before attempting to connect

to an electrical power supply. Do not ground to a

gas supply line.

2. Wire size must be adequate to minimize a voltage

drop during the start-up and operation of the

pump. See Table 2 for suggested wire sizes.

3. Insulate all connections carefully to prevent

grounding or short-circuits. Provide extra

protection for sharp edges on terminals. To

prevent wire nuts from loosening, tape them

with a suitable, listed (UL, ETL, CSA) electrical

insulating tape. For safety, and to prevent entry

of contaminants, reinstall all conduit and terminal

box covers. Do not force connections into the

conduit box.

4. To congure the pump motor's internal wiring for

the correct voltage, refer to the diagram on the

motor data plate.

3.3 Pressure Testing

WARNING

When pressure testing a system with water, air is often

trapped in the system during the filling process. This

air will compress when the system is pressurized.

Should the system fail, this trapped air can propel

debris at a high speed and cause property damage,

severe personal injury or death. Every effort to remove

trapped air must be taken, including opening the bleed

valve on the filter and loosening the pump basket lid

while filling the pump.

WARNING

Trapped air in system can cause the filter lid to be

blown off, which can result in death, serious injury,

or property damage. Be sure all air is properly

out of system before operating. DO NOT USE

COMPRESSED AIR TO PRESSURE TEST OR

CHECK FOR LEAKS.

WARNING

Do not pressure test above 35 PSI. Pressure

testing must be done by a trained pool professional.

Circulation equipment that is not tested properly may

fail, which could result in severe injury or property

damage.

WARNING

When pressure testing the system with water, it is very

important to make sure that the pump basket lid is

completely secure.

1. Fill the system with water, using care to eliminate

trapped air.

2. Pressurize the system with water to no more than

35 PSI.

3. Close the valve to trap pressurized water in the

system.

Table 2. Recommended Minimum Wire Size for WFTR Pumps

RECOMMENDED MINIMUM WIRE SIZE (AWG) FOR WFTR PUMPS*

Distance from Sub-Panel

Branch Fuse AMPS

Model

WFTR 80 15A 20A 14 10 10 8 8 6 8 4

WFTR 120 15A 20A 12 10 10 6 8 6 6 4

WFTR 160 15A NA 12 NA 8 NA 6 NA 6 NA

*Assumes three (3) copper conductors in a buried conduit and 3% maximum voltage loss in branch circuit. All National Electrical Code (NEC) and

local codes must be followed. Table shows minimum wire size and branch fuse recommendations for typical installation per NEC.

Class: CC, G, H, J, K,

RK, or T

230 VAC 115 VAC 230 VAC 115 VAC 230 VAC 115 VAC 230 VAC 115 VAC 230 VAC 115 VAC

4. Carefully observe the system for leaks and/or

pressure decay.

0-50 FEET 50-100 FEET 100-150 FEET 150 FEET-200 FEET

Voltage Voltage Voltage Voltage

®

Jandy

Pro Series Water Feature Pump | Installation and Operation Manual

ENGLISH

Page 11

Section 4. Operation

4.1 Start-up

CAUTION

Never run the pump without water. Running the pump

“dry” for any length of time can cause severe damage

to both the pump and motor and will void the warranty

If this is a new pool installation, make sure all piping

is clear of construction debris and has been properly

pressure tested. If a lter is installed in the system, it

should be checked for proper installation, verifying that

all connections and clamps are secure according to the

manufacturer’s recommendations.

WARNING

To avoid risk of damage or injury, verify that all power

is turned off before starting this procedure.

1. If a lter is intalled in the system, release all

pressure from the system and open the lter

pressure release valve.

9. If the pump does not prime and all the

instructions to this point have been followed,

check for a suction leak and then repeat Steps 2

through 7.

10. For technical assistance, contact Technical

Support Department at (800) 822-7933.

Section 5. Service and

Maintenance

5.1 Routine Maintenance

Inspect the pump basket for debris by looking through

the clear pump lid. Remove any debris, because as debris

accumulates, it will begin to block the ow of water

through the pump. Keep the basket clean to improve the

performance of the pump.

1. Turn off the power to the pump. If the pump is

located below water level, close the isolation

valves on the suction and discharge sides of the

pump to prevent backow of water.

2. If the pump is located below the water level of

the pool, opening the lid should allow water to

ll the basket area. If a lter is installed in the

system, opening the lter pressure release valve

will prime the pump with water.

3. If the pump is located above the water level of

the pool, remove the lid and ll the basket with

water before starting the pump.

4. To prevent air from leaking into the system,

remove any debris around the lid seal seat.

5. Hand-tighten the lid to make an air tight seal. Do

not use any tools: hand-tighten only. Ensure that

the lid is secure. Make sure all valves are open

and the unions are tight.

6. Restore power to the pump, then turn on the

pump.

7. If a lter is installed in the system, when all the

air has left the lter, close the lter pressure

release valve.

8. The pump should prime. The time it takes to

prime will depend on the elevation and length of

pipe used on the suction supply pipe. See

Section 3.1.3.3, Installation Recommendations

for proper elevation and pipe size.

2. Turn the lid's locking ring counter-clockwise

until the 'START' marking aligns with the ports.

Carefully remove the locking ring and the lid.

CAUTION

A misaligned basket will cause the lid to be improper-ly

seated, allowing an air leak, which could result in pump

damage.

3. Lift the basket out of the pump. Dispose of all

debris and thoroughly clean the basket, making

sure all the holes are open. Using a garden hose,

spray the basket from the outside to help clear the

holes. Remove any remaining debris by hand.

4. Replace the basket in the pump by aligning the

open section of the basket with the inlet pipe. If

aligned properly, the basket will drop easily into

place. Do not force it into place.

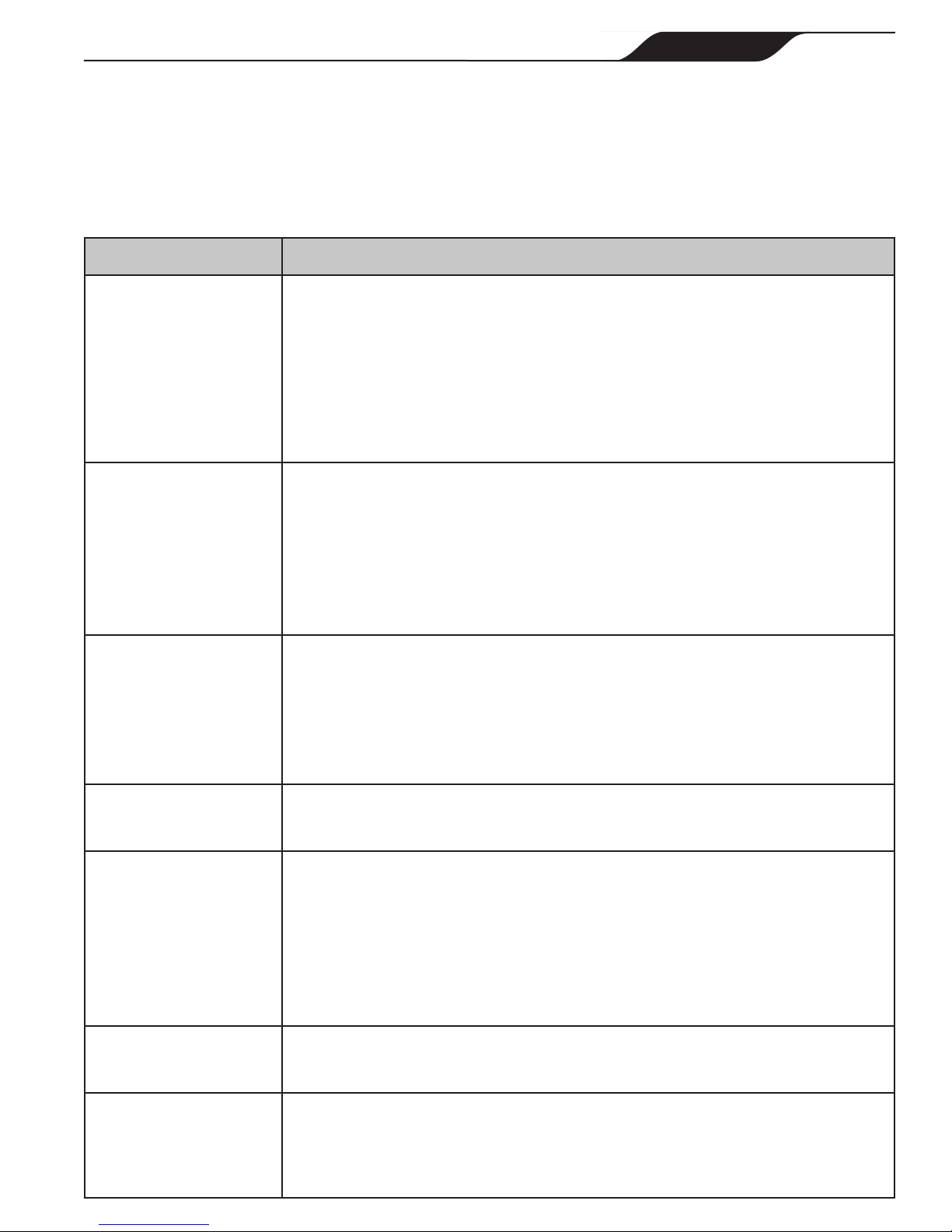

5. Remove the lid seal and remove debris around

the lid groove, as this will cause air leaks in the

system. Clean the lid groove and the lid seal.

6. Note that one (1) side of the lid seal has two (2)

ribs and the other has one (1). Place the side with

two (2) ribs into the groove. See Figure 2.

Page 12

ENGLISH

®

Pro Series Water Feature Pump | Installation and Operation Manual

Jandy

7. Replace the lid with locking ring on the pump

housing. Align 'START' with the ports and turn

the lid's locking ring clockwise until 'LOCKED'

aligns with the ports. Hand-tighten the lid to

make an air tight seal. Do not use any tools to

tighten the lid.

Place side with two ribs into lid groove.

Figure 2. Cross Section of Lid Seal

8. Verify that all valves have been returned to the

proper position for normal operation.

9. If a lter is installed in the system, open the

pressure release valve on the lter, and make sure

it is clean and ready for operation.

NOTE Zodiac Pool Systems, Inc. recommends having a

qualified service technician or electrician properly

disconnect the electrical wiring at the switch or junction

box. Once the power is removed, loosen the two (2)

unions and store the pump indoors. For safety, and to

prevent entry of contaminants, reinstall all conduit and

terminal box covers.

4. When the system is reopened for operation, have

a qualied service technician or electrician make

sure all piping, valves, wiring, and equipment

are in accordance with the manufacturer’s

recommendations. Pay close attention to any

lter and electrical connections.

5. The pump must be primed prior to starting; refer

to Section 4.1, Start-up.

10. Turn on the power to the pump. If a lter is

installed in the system, when all the air has been

evacuated from the lter, close the lter pressure

release valve.

5.2 Winterizing Pump

CAUTION

The pump must be protected when freezing

temperatures are expected. Allowing the pump

to freeze will cause severe damage and void the

warranty.

CAUTION

Do not use antifreeze solutions in the pool, spa, or

hot tub systems! Antifreeze is highly toxic and may

damage the circulation system. The only exception

to this is Propylene Glycol. For more information, see

your local pool/spa supply store or contact a qualified

swimming pool service company.

1. Drain all water from the pump, system

equipment, and piping.

2. Remove the two (2) drain plugs and store them

in a safe place. Reinstall them when the cold

weather season is over. Do not lose the o-rings.

3. Keep the motor covered and dry. Do not cover

the pump with plastic. This creates condensation

that will damage the pump.

®

Jandy

Pro Series Water Feature Pump | Installation and Operation Manual

ENGLISH

Page 13

Section 6. Troubleshooting and Repair

Zodiac Pool Systems, Inc. strongly recommends that you call a qualied service technician to perform any repairs on

the pump system. To locate a qualied technician, check your local yellow pages or visit www.jandy.com and click on

“Product Support.”

6.1 Troubleshooting

Symptom Possible Problem/Solution

The cleaning/circulating

system is not operating

correctly.

Bubbles present in the

pump basket.

Air leaks are still present. Check the suction side piping union. While the pump is running, try to tighten the union.

Verify that skimmer baskets, pump basket and other screens are clean. Clean as necessary.

If a filter is installed in the system, check the filter and clean as necessary.

Check valve positions. Adjust as necessary.

NOTE Multiple pieces of equipment operating at one time (for example, waterfalls, spa

jets, and surface returns) may affect the cleaning system and prevent it from working

properly.

Check cleaning system manual to ensure the system is adjusted according to

manufacturer's recommendations.

Air is in system. Check pool or spa water level to ensure it is at the proper level and air is

not being drawn into suction piping. If water is at normal level, turn off pump. Turn the lid's

locking ring counter-clockwise until 'START' aligns with ports. Remove lid and check for

debris around lid seal seat or improper installation of lid seal, as either of these conditions

will cause air leaks in the system. Clean lid seal and lid groove. Note that one (1) side of

lid seal has two (2) ribs and the other has one (1). See Figure 2. Place the side with two

(2) ribs into lid groove. Replace lid on pump housing. Align 'START' with ports and turn

lid's locking ring clockwise until 'LOCKED' aligns with ports. Hand-tighten the lid to make

an air tight seal. Do not use any tools to tighten the lid. Turn the pump back on.

If this does not stop the air leak, turn off the pump. Loosen both unions and slide the

pump out of the way. Remove, clean, and re-install both union o-rings.

Reposition the pump next to the piping and secure the union nuts to the pump. With

clean union o-rings, hand-tightening of the unions should create a seal. If the unions

still do not seal, gently tighten with a large pair of tongue-and-groove pliers.

Do not over-tighten.

There is no air in the

system, but the pressure

is still low.

There is no debris

blocking the impeller and

the pressure is still low.

The pump is leaking water

between the motor and

pump body.

The pump gets hot and

shuts off periodically.

It is possible that debris is caught in the pump impeller. The pump impeller moves the

water, and the vanes in the impeller can become blocked with debris. See Section 6.2,

Service Technician Maintenance, 6.2.1, Blocked Impeller, for more information.

The pump impeller and diffuser are showing signs of normal wear. Have a qualified

service technician check the impeller and diffuser and replace as necessary.

If the pump is part of a relatively new installation, it could be an electrical problem.

Contact a qualified service technician. Have the technician check for loose electrical

connections and check the voltage at the pump motor while it is in operation. The

voltage must be within 10% of the motor's data plate rating. If the voltage is not within

10%, contact a qualified electrician and/or the local power service provider.

The pump seal is leaking air. Have a qualified service technician replace the seal.

This is caused by a damaged or failed mechanical seal. Replace the seal. See Section

6.2, Service Technician Maintenance, 6.2.4, Mechanical Seal Replacement.

Ensure that there is adequate room around the motor to circulate air and keep motor

cool. Have a qualified electrician check for loose connections and check voltage at the

pump motor while it is in operation. The voltage must be within 10% of the motor's data

plate rating. If voltage is not within 10%, contact a qualified electrician and/or the local

power service provider.

Page 14

ENGLISH

®

Pro Series Water Feature Pump | Installation and Operation Manual

Jandy

6.2 Service Technician Maintenance

WARNING

This pump must be serviced by a professional

service technician, qualified in pool/spa installation.

The following procedures must be followed exactly.

Improper installation and/or operation can create

dangerous electrical hazards, which can cause high

voltages to run through the electrical system, possibly

causing property damage, serious injury, or death.

Improper installation and/or operation will void the

warranty.

6.2.1 Blocked Impeller

WARNING

While servicing the pump, switch off the circuit

breakers at the power source. Severe personal injury

or death may occur if the pump starts while your hand

is inside the pump.

1. Turn off the pump. Switch off the circuit breaker

to the pump motor.

2. Remove the lid and basket.

6.2.2 Impeller Removal

WARNING

While servicing the pump, switch off the circuit

breakers at the power source. Severe personal injury

or death may occur if the pump starts while your hand

is inside the pump.

1. Turn off the pump. Switch off the circuit breaker

to the pump motor. If you are not replacing the

motor, do not disconnect the electrical wiring.

NOTE If you are replacing the motor, Zodiac Pool Systems,

Inc. strongly recommends that a qualified service

technician or electrician properly disconnect the

electrical wiring at the pump motor.

2. Turn off any valves to prevent pool water from

reaching the pump. Drain the water from the

pump by loosening the unions or removing the

drain plugs.

3. Using a 9/16" wrench, loosen the bolts

connecting the pump body to the motor

backplate. See Figure 3.

3. Look inside the pump for debris. Remove any

debris found inside.

4. Replace the basket and lid.

5. Switch on the circuit breaker to the pump motor.

6. Turn on the pump, and see if the problem is

solved.

7. If the impeller is still blocked with debris and it

is not possible to remove the debris using Steps 2

through 4, the pump will need to be disassembled

in order to access the inlet and outlet of the

impeller.

Bolts (8)

Pump

Body

Motor Backplate

Motor Shaft Cover

Figure 3. Remove the Pump Housing

4. Pull the motor and backplate out of the pump

body. Remove the pump body o-ring. The

impeller is connected to the motor shaft.

5. Using a No. 1 Phillips screwdriver, remove the

two (2) screws holding the diffuser. (The diffuser

is the cover over the impeller). Then remove the

diffuser. See Figure 4.

6. Remove any debris from the inlet and outlet of

the impeller.

®

Jandy

Pro Series Water Feature Pump | Installation and Operation Manual

ENGLISH

Page 15

Motor

Motor

Diffuser O-ring

Figure 4. Remove the Diffuser

Backplate

Screws

with

Washers (2)

Pump Body

Diffuser

O-ring

Diffuser

Diffuser

Diffuser O-Ring

Diffuser Screws with Washers (2)

Self Sealing Left

Handed Screw

Backplate

O-ring

Diffuser

Impeller

Mechanical

Seal

Backplate

Figure 7. Diffuser and Impeller Exploded View

7. Remove the motor shaft cover on the back of the

motor by twisting the hex-head screw with a 90°

crescent wrench, see Figure 3. The motor shaft

will be exposed.

8. Hold the exposed motor shaft with a ½" wrench

while removing the impeller center screw using

a No. 2 Phillips screwdriver. Since the impeller

center screw is a left-hand threaded screw, turn it

clockwise to loosen it. See Figure 6.

O-ring Location

for SHP only

O-ring Location

for WFTR/PHP only

Figure 5. Location of Diffuser O-ring

Self Sealing Left

Handed Screw

Backplate

Mechanical Seal

9. Hold the motor shaft with a ½" wrench while

unscrewing the impeller from the motor shaft

with your hand. Since the impeller is a right-hand

thread, turn the impeller counter-clockwise to

unscrew it.

10. Inspect the impeller and diffuser for signs of

rubbing and/or damage.

Impeller

Figure 6. Remove the Impeller

Page 16

• Ceramic Face Seal

• Carbon Face/ Spring

6.2.3 Impeller Replacement

ENGLISH

®

Pro Series Water Feature Pump | Installation and Operation Manual

Jandy

1. Press the carbon face seal half, see Figure 8, on

the motor shaft using a twisting motion. Make

sure the carbon surface is facing toward the

ceramic ring in the backplate.

CAUTION

VERY IMPORTANT! Grasp the lower portion of the

seal (opposite the carbon face) when installing the seal

or it will be damaged.

Backplate

Self Sealing Left

Handed Screw

Impeller

Mechanical Seal

Diffuser

Screws and

Washers (2)

NOTE To assist assembly, only use water or a soap solution

as a lubricant. Any other lubricant will destroy the seal

after a short period of time.

NOTE Take great care to keep the seal and mating parts

clean.

2. While holding the motor shaft with a ½" wrench,

thread the impeller onto the motor shaft. Handtighten the impeller until it is secure.

3. Install the impeller center screw into the center

of the impeller and tighten, using a No. 2 Phillips

screwdriver. Since the impeller center screw

is left-hand threaded, turn the screw counterclockwise to tighten it. Do not overtighten.

4. Replace the motor shaft cover by inserting the

cover tabs into the slots and rotating the cover

90º clockwise.

5. Replace the diffuser over the impeller, using care

to insert alignment pins into the correct holes.

The molded-in arrow must point toward the

handle of the backplate.

6. Replace the two (2) small Phillips-head screws.

Tighten the screws to draw the diffuser against

the motor backplate.

Diffuser O-ring

Figure 9. Backplate, Impeller, Diffuser, and

Mechanical Seal Exploded View

7. Make sure the diffuser o-ring, o-ring groove, and

o-ring seal area are clean and free of debris, which

could cause a leak. If you removed the diffuser

o-ring, make sure you install it into the proper

groove, see Figure 5. If grease is used to retain

the o-ring, it must be silicone based. Do not use

petroleum-based grease. It will destroy the o-ring.

8. Slide the diffuser into the mating hole in the pump

body. While supporting the motor, start two (2)

screws on opposite sides. This will hold the motor

in position while you start the other six (6) screws.

9. Tighten the screws lightly in a crossing “X”

pattern using a 9/16" wrench starting with the

inner (middle) four (4), then the outer (top and

bottom) four (4) to draw the backplate to the

body in a even manner. Once all the screws are

snug, torque in the same order to 18 foot-pounds.

10. If the pump is located above water level of the

pool, remove the lid and ll the basket with water

before starting the pump.

Carbon Seal Surface

• Backplate Seal

Figure 8. Replace the Mechanical Seal

Side of Seal

• Impeller Side of the

Mechanical Seal

11. To prevent air from leaking into the system,

remove debris around the lid seal seat.

12. Hand-tighten the lid to make an air tight seal. Do

not use any tools to tighten the lid.

13. If a lter is installed in the system, open the

pressure release valve on the lter, and make sure

it is clean and ready for operation.

14. Switch on the circuit breaker to the pump motor.

15. Turn on the pump and check the system for

normal operation.

16. If a lter is installed in the system, when all the

air has left the lter, close the lter pressure

release valve.

®

Jandy

Pro Series Water Feature Pump | Installation and Operation Manual

ENGLISH

Page 17

6.2.4 Mechanical Seal Replacement

NOTE This is a two-part replacement process. The

mechanical seal must be replaced as a set.

NOTE Refer to Figure 9 for the location of the mechanical

seal and impeller.

WARNING

Do not damage the ceramic or carbon surfaces of the

seals. If surfaces are damaged, leaks will occur.

1. To access the mechanical seal, comply with the

warning and follow steps 1 through 8 of Section

6.2.2, Impeller Removal.

2. Remove the carbon face seal half from the

motor shaft, see Figure 8. This is a spring-loaded

seal. Grasp the portion of the seal closest to

the impeller body and pull the seal off using a

twisting motion.

3. Remove the motor from the backplate by

complying with the caution and following steps 1

through 3 in Section 6.2.5.

4. Place the backplate o-ring side down and force

the ceramic seal out using a screwdriver or drift.

5. Turn the backplate o-ring side up and insert the

new ceramic seal side into the backplate. Use

great care to press the seal in squarely with your

ngers. The ceramic is easily damaged and must

be pressed in using only your ngers or soft

tools. Do not use any lubricant other than water

and soap solution.

6. Install the motor by complying with the caution

and following the steps in Section 6.2.5, Motor

Replacement.

7. Install the backplate by complying with the

caution and following the steps in Section 6.2.3,

Impeller Replacement.

6.2.5 Motor Replacement

CAUTION

To ensure continued safety and reliable operation,

Zodiac Pool Systems, Inc. requires that you replace

the motor with a motor that has the identical HP

rating and service factor (Zodiac Pool Systems, Inc.

approved only).

Backplate

Bolts and

Washers (4)

Starting

Capacitor

Motor

Figure 10. Backplate Assembly

2. To disassemble the pump housing from the

motor, comply with the warning and follow steps

1 through 8 in Section 6.2.2, Impeller Removal.

3. Place the backplate motor assembly o-ring side

down and unscrew the four (4) 9/16" screws and

remove the motor.

NOTE Before removing the backplate, note the alignment of

the backplate to the motor. See Figure 10.

4. If installing a new motor, remove the protective

plastic cap from the motor shaft. Place the motor

on the backplate so that the opening in the motor

faces the bottom of the backplate. The starting

capacitor on the motor should be at the

12 o’clock position.

5. Replace the four (4) bolts and washers holding

the backplate to the motor.

6. To reassemble the pump after replacing the

motor, comply with the caution and follow

steps 1 through 13 of Section 6.2.3, Impeller

Replacement.

7. Have a qualied service technician or electrician

properly connect the electrical wiring at the

pump motor.

NOTE Zodiac Pool Systems, Inc. recommends replacing the

mechanical seal at the same time that you replace

the motor. See Section 6.2.4, Mechanical Seal

Replacement, for details.

1. Have a qualied service technician or electrician

properly disconnect the electrical wiring at the

pump motor.

Page 18

ENGLISH

®

Pro Series Water Feature Pump | Installation and Operation Manual

Jandy

Section 7. Product Specications and Technical Data

7.1 Replacement Parts List

To order or purchase parts for Jandy Pro Series pumps, contact your nearest Zodiac® dealer. If they

cannot supply you with what you need, contact Zodiac Technical Support at 800.822.7933 or send an

e-mail message to techsupport.vista@zmp-zodiac.com.

Key

No. Description

1 Single-speed Motor and Hardware, WFTR80 1.0 R0479311

1 Single-speed Motor and Hardware, WFTR120 1.5 R0479312

1 Single-speed Motor and Hardware, WFTR160 2.5 R0479314

1 Bolts and Washers (Set of 4) All R0479310-14

2 Backplate Kit w/Hardware, O-ring & Mech Seals, WFTR All R0445200

Impeller & Diffuser w/Screw and O-ring, WFTR 1.0 R0449502

3

Impeller & Diffuser w/Screw and O-ring, WFTR 1.5 R0449503

3

Impeller & Diffuser w/Screw and O-ring, WFTR 2.5 R0449505

3

3 Screw w/O-ring, Self-sealing All R0449501-05

4 Diffuser w/O-ring & Hardware All R0445400

5 Mechanical Seal (Carbon and Ceramic) All R0479400

6 Body, Pump, WFTR All R0448701

7 Motor Mounting Foot Assembly w/ 2 Screws, WFTR All R0445700

8 Locking Ring w/ Lid and Seal All R0448800

9 Pump DebrisFilter Basket All R0448900

10 Drain Plug w/ O-ring All R0446000

11 Tail Piece (2" by 2½") w/O-ring and Coupling Nut (Set of 2) All R0449000

12 Lid Seal and Lid O-ring (Lid O-ring Not Shown) All R0449100

13 O-ring, Backplate All R0446300

14 O-ring, Tail Piece All R0449200

15 Diffuser/Impeller w/ O-rings & Mounting Hardware All R0446500

16 Backplate Bolts and Washers All R0446600

17 Motor Bolts & Washers All R0446700

18 Screws, Motor Mounting Foot All R0446800

Model

No. (HP) Order Part No.

®

Jandy

Pro Series Water Feature Pump | Installation and Operation Manual

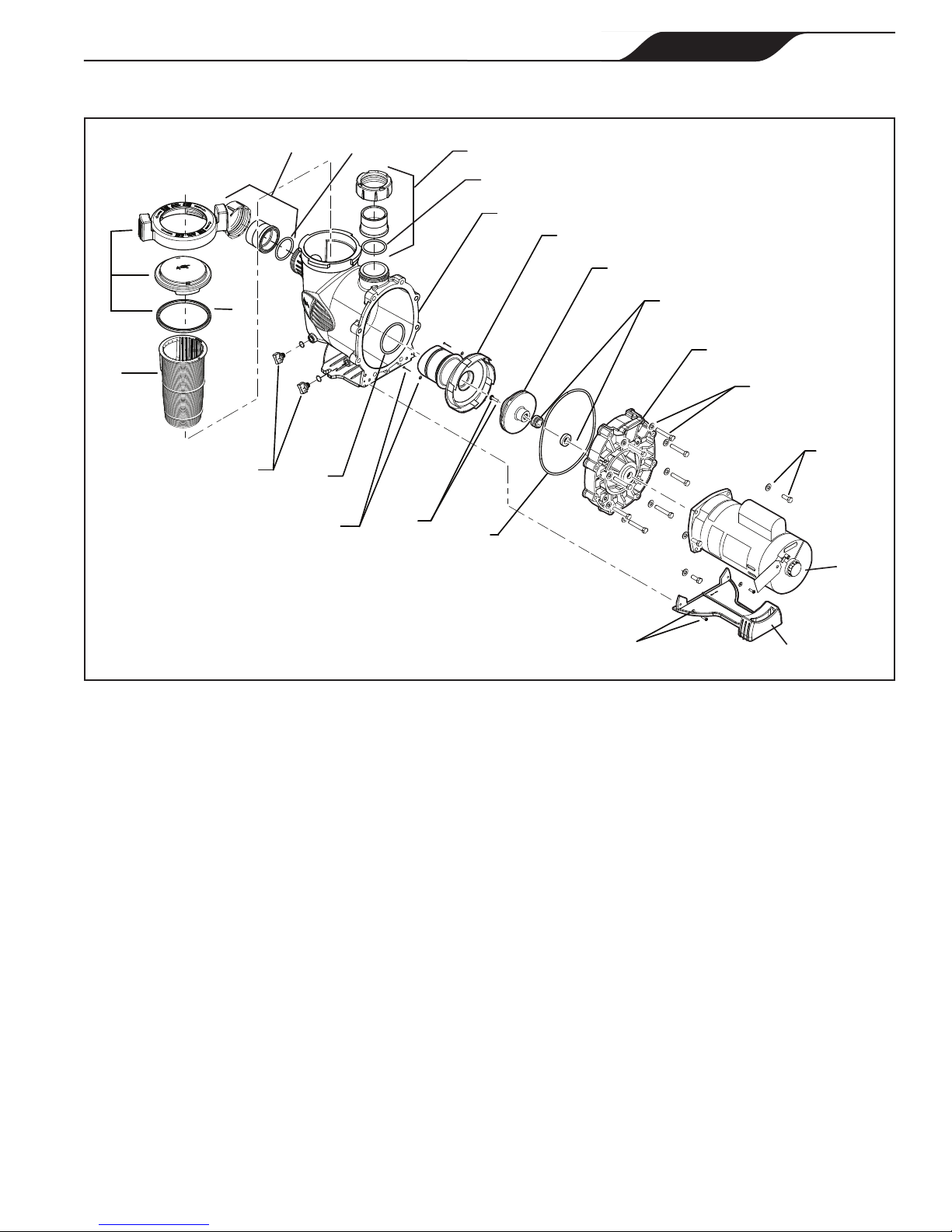

7.2 Exploded View

ENGLISH

Page 19

11

14

11

14

6

3, 4

8

12

3

2, 5

2

9

2 (qty 8)

16 (qty 8)

1 (qty 4)

10 (qty 2)

4, 15

4 (qty 2)

15 (qty 2)

3, 15

2, 13

17 (qty 4)

1

Figure 11. WFTR Exploded View

7 (qty 2)

18 (qty 2)

7

Page 20

ENGLISH

7.3 WFTR Pump Curves

®

Pro Series Water Feature Pump | Installation and Operation Manual

Jandy

Jandy Water Features Series High Head Pumps

(WFTR)

Total Dynamic Head

(Feet of Water)

120

110

100

90

80

70

60

50

40

30

20

10

WFTR80 (1.0 HP)

Pounds Per Square Inch

WFTR160 (2.5 HP)

WFTR120 (1.5 HP)

(PSI)

50

45

40

35

30

25

20

15

10

5

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250

Flow Rate, Gallons Per Minute (GPM)

0

®

Jandy

Pro Series Water Feature Pump | Installation and Operation Manual

ENGLISH

Page 21

7.4 Physical and Operational Specications

7.4.1 WFTR Pump Specications

Model No. HP Voltage Amps Pipe Size Carton Weight Overall Length 'A'

WFTR80 1.00 230/115 7.1/14.2 2-2½" 41.2 28⅞"

WFTR120 1.50 230/115 8.0/16 2-2½" 42.6 29¼"

WFTR160 2.50 230 11.5 2½-3" 48.6 30"

7.4.2 WFTR Pump Dimensions

'A'

91/8"

9"

Bolt Holes,

Center to Center

87/8"

141/8"

87/8"

Front Edge of Union to Center

of Bolt Holes

137/8"

11⅜"

NOTE When installing the pump, leave a minimum of 2 feet of clearance above the pump for removal of strainer

basket.

Page 22

ENGLISH

®

Pro Series Water Feature Pump | Installation and Operation Manual

Jandy

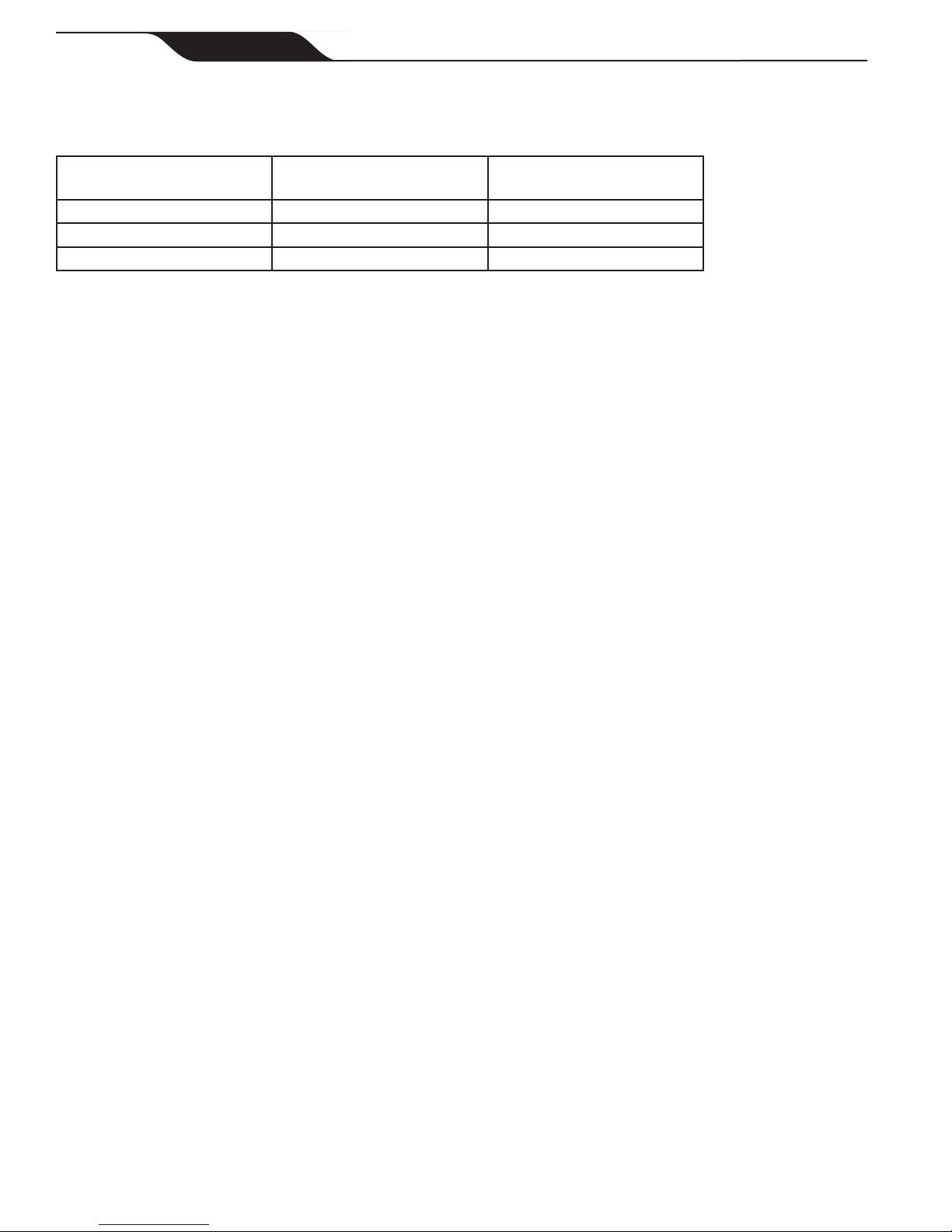

7.5 Replacement Motor Guide

WFTR Replacement Motor Guide

Pump Model A.O Smith /Century Emerson Motor Technologies

WFTR80 B853 EB853

WFTR120 B854 EB854

WFTR160 B840 EB840

®

Jandy

Pro Series Water Feature Pump | Installation and Operation Manual

NOTES

ENGLISH

Page 23

Zodiac Pool Systems, Inc.

2620 Commerce Way, Vista, CA 92081

1.800.822.7933 | www.ZodiacPoolSystems.com

ZODIAC® is a registered trademark of Zodiac International, S.A.S.U., used under license.

All trademarks referenced herein are the property of their respective owners.

©2012 Zodiac Pool Systems, Inc. H0320100 Rev B

CONFORMS TO UL 1081

CERTIFIED TO CSA C22.2 NO 108

Loading...

Loading...