INSTALLATION AND

OPERATION MANUAL

Jandy Pro Series

JXi™ Gas-Fired Pool and Spa Heater

Models 200, 260, 330, 400

If these instructions are not followed exactly, a fire or explosion may

WARNING

FOR YOUR SAFETY: This product must be installed and serviced by a contractor who is licensed and qualified in pool equipment by the jurisdiction in

which the product will be installed where such state or local requirements exists. In the event no such state or local requirement exists, the installer or

maintainer must be a professional with sufficient experience in pool equipment installation and maintenance so that all of the instructions in this manual

can be followed exactly. Before installing this product, read and follow all warning notices and instructions that accompany this product. Failure to follow

warning notices and instructions may result in property damage, personal injury, or death. Improper installation and/or operation can create carbon

monoxide gas and flue gases which can cause serious injury, property damage, or death. For indoor installations, as an additional measure of safety,

Zodiac Pool Systems, Inc. strongly recommends installation of suitable carbon monoxide detectors in the vicinity of this appliance and in any adjacent

occupied spaces. Improper installation and/or operation will void the warranty.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Immediately switch off main gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

result, causing property damage, personal injury, or death.

H0404700 Rev D

Page 2

ENGLISH

®

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

Jandy

Table of Contents

Section 1. General Information ....................... 3

1.1 Introduction ......................................................... 3

1.2 Technical Assistance .......................................... 3

1.3 Consumer Information and Safety ...................... 3

1.4 Warranty ............................................................. 4

1.5 CerticationCodesandStandards ..................... 4

1.6 General Operation Description ........................... 4

1.7 Safety Controls ................................................... 4

Section 2. Installation Requirements .............. 5

2.1 Introduction ......................................................... 5

2.2 Materials Installer Must Provide ......................... 5

2.3 Specications ..................................................... 5

2.4 Heater Components ........................................... 6

2.5 Dimensions ......................................................... 7

2.6 Clearances ......................................................... 7

2.7 Field Assembly ................................................... 8

2.8 Location Requirements ..................................... 8

Section 3. Venting ..10

3.1 Combustion Air Supply ..................................... 10

3.2 Exhaust Venting ................................................11

3.3 Vent Pipe Sizing and Installation ......................11

Section 7. Operating Instructions ................. 27

7.1 First-Time Start-Up Procedure ......................... 27

7.2 Starting the Heater ........................................... 27

7.3 Normal Operation ............................................. 28

7.4 Operating the Controller ................................... 28

7.5 Setting up Heater Options ................................ 29

7.6 Operating the Heater ........................................ 29

7.7 Temperature Set Point Lock ............................. 30

7.8 Shutting Down the Heater ............................... 30

Section 8. Maintenance .................................. 32

8.1 Winterizing ........................................................ 32

8.2 Spring Start-up ................................................. 32

8.3 Inspection and Service ..................................... 32

Section 9. Troubleshooting ........................... 33

9.1 Common Problems ........................................... 33

9.2 Service Diagnostic Messages .......................... 35

9.3 Ignition Control LED Service Codes ................. 35

Section 10. Professional Service

and Maintenance .......................... 36

10.1 Gas Pressure Offset Test ................................. 36

Section 4. Gas Connections .......................... 15

4.1 Install Piping and Check Gas Supply ............... 15

4.2 Special Precautions for LP Gas........................ 16

Section 5. Water Connections ....................... 16

5.1 Water Piping Connections ................................ 16

5.2 Pump Sizing ..................................................... 17

5.3 Plumbing Connections ..................................... 18

5.4 Water Pressure Switch Adjustment .................. 19

5.5 Check Valve Installation ................................... 20

5.6 Reversing the Water Connections ................... 20

5.7 Pressure Relief Valve Installation ..................... 20

5.8 Auxiliary Components, Chlorinators,

Ozone Generators,

and Sanitizing Chemicals ................................. 21

Section 6. Electrical Connections ................. 21

6.1 General Information .......................................... 21

6.2 Service Access ................................................. 23

6.3 Main Power ...................................................... 23

6.4 Bonding ............................................................ 24

6.5 Optional Remote Controls ................................ 24

Section 11. Spare Parts ................................... 36

11.1 Ordering Information ........................................ 36

11.2 JXi Major Components ..................................... 37

11.3 Cabinet Assembly Spare Parts List

and Exploded Parts Diagram ........................... 38

11.4 Heat System Spare Parts List and

Exploded Parts Diagrams ................................. 39

11.5 Water System Spare Parts List and

Exploded Parts Diagrams ................................. 42

11.6 Electrical System Spare Parts List and

Exploded Parts Diagrams ................................. 43

Section 12. Water Chemistry .......................... 45

®

Jandy

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

ENGLISH

Page 3

Section 1. General Information

1.1 Introduction

This manual provides installation and operation

instructions for the Jandy Pro Series JXi pool and spa gas

heater product line.

Read the installation and operation instructions

completely before proceeding with the installation.

1.2 Technical Assistance

For technical support or questions, contact your local

Zodiac

800.822.7933 (in Canada: 888.647.4004).

®

distributor or Zodiac Pool Systems, Inc. at

1.3 Consumer Information and Safety

WARNING

Improper installation or maintenance can cause nausea

orasphyxiationfromcarbonmonoxideinuegases

which could result in severe injury, or death. For indoor

installations, as an additional measure of safety, Zodiac

Pool Systems, Inc. strongly recommends installation

of suitable Carbon Monoxide detectors in the vicinity of

this appliance and in any adjacent occupied spaces.

The heater is designed and manufactured to provide

many years of safe and reliable service when installed,

operated, and maintained according to the information

in this manual and the installation codes referred to

throughout. Be sure to read and comply with all warnings

and cautions.

2. The drinking of alcoholic beverages before or

during spa or hot tub use can cause drowsiness

which could lead to unconsciousness, and

subsequently result in drowning.

3. Pregnant women take note! Soaking in water

above 102°F (38.5°C) can cause fetal damage

during the rst three (3) months of pregnancy

(which could result in the birth of a braindamaged or deformed child). If pregnant women

are going to use a spa or hot tub, they should make

sure the water temperature is below 100°F (38°C)

maximum.

4. The water temperature should always be checked

with an accurate thermometer before entering a

spa or hot tub. Temperature controls may vary by

as much as 1F° (1C°).

5. Persons with a medical history of heart disease,

diabetes, circulatory or blood pressure problems

should consult their physician before using a hot

tub or spa.

6. Persons taking any medication which induces

drowsiness (e.g., tranquilizers, antihistamines, or

anticoagulants) should not use spas or hot tubs.

7. Prolonged immersion in hot water can induce

hyperthermia.

Hyperthermia occurs when the internal body temperature

reaches a level several degrees above the normal body

temperature of 98.6°F (37°C). Symptoms include

dizziness, fainting, drowsiness, lethargy, and an

increase in the internal body temperature. The effects of

hyperthermia include:

1.3.1 Spa/Hot Tub Safety Rules

WARNING

The following “Safety Rules for Hot Tubs,”

recommended by the U.S. Consumer Product Safety

Commission, should be observed when using

the spa.

WARNING

The U.S. Consumer Product Safety Commission

warns that elevated water temperature can be

hazardous. Consult heater operation and installation

instructions for water temperature guidelines before

setting temperature.

1. Spa or hot tub water temperature should never

exceed 104°F (40°C). One hundred degrees

Fahrenheit (100°F [38°C]) is considered safe for a

healthy adult. Special caution is recommended for

young children.

• Lack of awareness of impending hazard

• Failure to perceive heat

• Failure to recognize need to leave spa

• Physical inability to leave spa

• Fetal damage in pregnant women

• Unconsciousness resulting in a danger of drowning

1.3.2 Swimming Pool Energy Saving Tips

Zodiac Pool Systems, Inc., offers the following

recommendations to help conserve fuel and minimize

the cost of operating your pool heater without sacricing

comfort.

®

1. The American Red Cross

recommends a

maximum water temperature of 78°F (26°C). Use

an accurate pool thermometer. A difference of 4F°

(2°C), between 78°F and 82°F (26°C and 28°C),

will use as much as 40% more gas.

Page 4

ENGLISH

®

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

Jandy

2. Carefully monitor the water temperature of your

pool in the summertime. You can reduce heater

usage due to warmer air temperatures.

3. Find the proper setting on the pool heater

temperature control and use the Set Point Lockout

feature to discourage further adjustments.

4. Set the pump time clock to start the pump no

earlier than 6:00 AM during the pool heating

season. This is the time when nightly heat loss

balances.

5. If the pool is only going to be used on weekends,

reduce the heater temperature control setting by 8

or 10 degrees during the week. Reset it to the 78°F

(25°C) level a day or so before you plan to use the

pool.

6. During the winter or when on vacation for longer

than a week, shut down the heater by following

the shutdown instructions found on the inside of

the heater.

7. Where possible, shelter the pool from prevailing

winds with well-trimmed hedges or other

landscaping, cabanas, or fencing.

8. Always use a pool cover when practical. Besides

providing a valuable safety feature, a pool cover

will reduce heat loss, conserve chemicals, and

reduce the load on lter systems.

1.4 Warranty

This heater is sold with a limited factory warranty. Details

are included with this heater.

®

Make all warranty claims to a Zodiac

dealer or directly

to the factory. Claims must include the heater serial

number and model (this information can be found on the

rating plate), installation date, and name of the installer.

Shipping costs are not included in the warranty coverage.

The warranty does NOT cover damage caused by

improper assembly, installation, operation or eld

modication. Also, damage to the heat exchanger by

corrosive water is NOT covered by the warranty.

NOTE Keep this manual in a safe place for future

reference when inspecting or servicing the heater.

1.5 CerticationCodesandStandards

The heater is design-certied by CSA (Canadian

Standards Association) compliant with the latest edition of

the Standard for Gas Fired Pool Heaters, ANSI

in the USA and CSA 4.7 in Canada.

All Jandy Pro Series heaters must be installed in

accordance with the local building and installation codes

as per the utility or Authority Having Jurisdiction (AHJ).

In the absence of local codes, refer to the latest edition of

the following national codes for installation:

®

Z21.56

1. In the United States, the National Fuel Gas Code,

®

NFPA

54/ANSI Z223.1. Pay particular attention

to the chapter addressing Venting of Equipment.

2. In Canada, the Natural Gas and Propane

Installation Code, CAN/CSA-B149.1. Minimum

combustion air requirements MUST be

followed for proper and safe operation. The

Jandy Pro Series JXi heater may not operate

properly when installed with only the minimum

combustion air openings allowed in CAN/

CSA-B149.1.

The JXi pool and spa heaters meet or exceed the

requirements of energy conservation regulations, such as

those in California, Hawaii, New York, Oregon and other

states that have disallowed the use of continuously lit pilot

type ignition sources. In addition, the natural gas models

of this heater comply with the California South Coast Air

Quality Management District's (SCAQMD) Rule 1146.2

for Nitrogen Oxide (NOx) emissions.

Any changes to the heater, gas controls, air orice, gas

orices, wiring, draft diverter, or improper installation

may void the warranty. If change is required to any of the

above, consult the factory.

1.6 General Operation Description

In the JXi heater, the blower draws air and fuel through

specially designed orices for both air and gas, then

delivers the precise mixture to the burner located inside

the combustion chamber. The combustion chamber

is completely sealed and contains the heat exchanger,

which surrounds the burner. Once combustion gases pass

through the heat exchanger, the ow is directed through

an exhaust duct located on the side of the combustion

chamber, where it vents to the atmosphere.

1.7 Safety Controls

The JXi heater is equipped with the following safety

controls to protect internal components and prolong the

life of the heater.

Air Flow Switch

The air ow switch monitors the vacuum (negative

pressure) within the blower housing. The air ow switch

is factory set and the ignition module will not operate

unless the air pressure switch and all safety switches are

satised.

Water Pressure Switch

Operating the heater without sufcient water ow may

severely damage the heater. If water ow to the heater is

restricted, the water pressure switch prevents the burner

from ring. The control panel will display an error

message to indicate water ow is insufcient.

®

Jandy

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

ENGLISH

Page 5

NOTE: If the heater is installed below the level of the pool,(or

more than two feet above the pool level), the pressure

switch setting must be adjusted. See Section 5.4

Adjusting the Water Pressure Switch for guidelines.

Water Temperature Control

All heater models are equipped with an electronic control

which senses water temperature by means of a thermistor

and controls heater operation to bring the water to the

temperature selected. It has an option for two (2) separate

thermostat settings which are typically used to set pool and

spa temperatures.

Ignition Control

The ignition control provides energy for ignition of the air/

gas mixture, monitors the ame and controls the gas valve.

When the temperature control calls for heat, the ignition

control initiates the start-up process by rst purging the

combustion chamber gases. The ignition control will

then energize the igniter and open the gas valve when

the igniter surface is sufciently hot. During the start-up

process and after ignition, the ignition control system is

continually monitoring the ame condition. If the control

senses an unstable ame it will close the gas valve as a

safety precaution.

2.2 Materials Installer Must Provide

For ALL Installations

• The correct size gas pipe to supply gas from gas meter to

heater (see Section 4.1).

• Gas shut-off valve to be installed in gas line outside of the

heater jacket.

• Manual gas shut off valve must be installed in an

accessible location, within 6’ upstream of heater.

• A suitable gas union joint to connect heater to gas line

outside of heater.

• Plumbing materials for providing sediment trap (drip leg)

in gas line between the manual gas valve and heater (see

Section 4.1).

• 120 VAC or 240 VAC power supply. (A junction box is not

needed at the heater; connections are made inside of the

heater jacket.)

For Special Installations

• INDOOR INSTALLATIONS: Factory authorized vent

pipe or elbows sized for indoor installations (US) and/or

outdoor shelter installations (Canada).

• PVC PIPE CONNECTIONS: Primer and cement suitable

for cementing CPVC pipe to PVC pipe. Coupling for

connecting factory-supplied CPVC pipe unions to PVC

pool plumbing

Section 2. Installation

Requirements

2.1 Introduction

Install the JXi in accordance with the procedures in this

manual, local codes and ordinances, and in accordance

with the latest edition of the appropriate national code.

See Section 1.5 for certication codes and standards.

All gas-red products require correct installation to assure

safe operation. The requirements for pool heaters include

the following:

• Field assembly (if required)

• Appropriate site location (clearances) and ooring

(see Section 2.6)

• Sufcient combustion and ventilation air

• Properly sized gas meter and piping

• Proper electrical wiring (if required)

• Adequate water ow

This manual provides the information needed to

meet these requirements. Review all applications and

installation procedures before continuing the installation.

See Section 2.7 for NOTE on operating the heater in areas

with below freezing conditions.

2.3 Specications

Installation Location

• Natural Gas (USA) -

Certiedforindoorandoutdoor

• Natural Gas (CANADA) -

Certiedforoutdoorandcoveredshelterinstallations

• Liquid Propane (USA) -

Certiedforindoorandoutdoorinstallations

• Liquid Propane (CANADA) -

Certiedforoutdoorandcoveredshelterinstallations

NOTE: Indoor installation is not recommended for

liquid propane heaters. Review information in Special

Precautions for liquid propane heaters (Section 4.1).

Minimum Clearance from Combustible Material

• 6 inch (15 cm) minimum clearance distance

from all surfaces

See Section 2.6 for more information.

Gas Pipe/Heater Gas Valve Connection

• Natural Gas: 3/4" NPT

• Liquid Propane: 3/4” NPT

• For gas pipe sizing requirements, see Table 4.

Supply Gas Type

• Natural Gas

• Liquid Propane

Page 6

ENGLISH

®

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

Jandy

Inlet Gas Supply Pressure

• Natural Gas:

Minimum 4.0" WC

Maximum 10.5” WC

• Liquid Propane:

Minimum 4.0” WC

Maximum 14.0” WC

Gas Valve Offset Pressure

• Natural Gas: - 0.2" WC (when heater is running)

• Liquid Propane: - 0.2" WC

*NOTE: All readings must be taken while the heater is

operating.

Water Pipe/Heater Connection

• 2" unthreaded slip PVC or CPVC pipe

• Jandy Pro Series union

Water Flow Rate

• Minimum: 30 gpm (76 lpm)

• Maximum: 120 gpm (454 lpm)

Working Water Pressure

• Maximum: 50 psi

• Minimum: 2 psi

Exhaust Vent Connection Size (Category I)

Use type B double-wall gas vent, per table 13.1(a) NFPA 54

• Model 200: 6 "

• Model 260: 7 "

• Model 330: 8 "

• Model 400: 8 "

Exhaust Vent Connection Size (Category III)

See Section 3.0 for information.

Electrical Supply

• 120 VAC

• 240 VAC (factory setting)

High Altitude

• Appliances are normally de-rated when installed at high

elevation. This is not necessary with the JXi heater

because it has a special venturi-type combustion system

which self-compensates for changes in barometric

pressure.Airowthroughtheblowerinletpullsthe

correctowofgasintotheburnerregardlessofair

density.Propercombustionandhighefciencyare

assured without special adjustment or changes to the

heater.

2.4 Heater Components

1. Gas Valve - The gas valve controls gas ow

into the burner. It enables ow only when the

temperature control requires heat and only if

all safety controls enable operation. It is also a

negative pressure regulator, where it maintains a

gas pressure of 0.2” WC below the the air pressure

at the blower inlet. It regulates the gas pressure to

0.2” WC less than the air pressure at the blower

inlet. This is necessary for proper operation of the

burner system and cannot be accomplished with

common (positive pressure) gas valves.

2. Combustion Blower and Air Orice – The

blower pulls air and fuel gas in through their

respective orices and mixes the two gases before

forcing the fuel/air mixture through the burner

for combustion. During normal operation the fan

will turn on before ame initiation to ensure that

the combustion chamber is clear before the igniter

is energized. Additionally, the fan will run after

the ame is extinguished in order to clear the

combustion chamber of exhaust gas.

3. Pool/Spa Water Temperature Control - The

JXi heater models are equipped with an electronic

control, which senses water temperature by means

of a thermistor and controls heater operation to

attain and maintain the water according to the

temperature selected. It has an option for two (2)

separate thermostat settings, which are typically

used to set pool and spa temperatures.

4. Ignition Control - The ignition control provides

energy for ignition of the air/gas mixture, monitors

the ame and controls the gas valve. When the

temperature control calls for heat, the ignition

control provides a pre-purge of the combustion

chamber. Once the pre-purge is complete the

ignition control then applies electrical power to

a hot surface igniter. When the igniter attains

sufcient temperature, the ignition control opens

the gas valve. Immediately after ignition, the

control system will look for characteristics of a

stable ame and de-energize the igniter. If ame

is not detected shortly after opening the gas valve

the control system will close the valve to prevent

further gas release. The ignition control will

attempt to start 2 more times before an ignition

fault is displayed.

5. Igniter - The hot-surface igniter is constructed of

a ceramic material that attains a temperature great

enough to ignite the air/fuel mixture, when an

electric current is applied.

®

Jandy

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

ENGLISH

Page 7

6. High Limit Switches - Two (2) limit switches -

one at the heat exchanger rst pass (135°F/57°C)

and one at the heat exchanger outlet (150°F/65°C)

-- prevent water of excessive temperatures from

being discharged from the heater. If either switch

senses excessive temperature, the gas valve will

close and combustion will stop.

7. Water Pressure Switch - Operating the heater

without sufcient water ow may severely

damage the heater. This control senses whether or

not water is available to the heater by measuring

back pressure at the header inlet. If the pool

water pump fails or the water lter is blocked, the

pressure switch prevents operation of the burner.

The display will indicate a no ow fault to alert

you that water pressure is insufcient.

NOTE: If the heater is installed below the surface level of the

pool,(or more than two feet above the pool level), the

pressure switch setting must be adjusted. See section

5.4 Adjusting the Water Pressure Switch.

8. Vent Temperature Limit (240°C/464°F)- This

is a single use switch, which detects abnormal

temperatures in the vent system. It is mounted

to the exhaust duct. Excessive temperatures

will cause the switch to open. Excessive

temperatures can be caused by inadequate water

ow or a compromised heat exchanger. The vent

temperature limit switch will open the safety

circuit which shuts off the gas valve and shuts

down the heater. If this limit is activated/tripped,

the heater cannot be safely operated without rst

determining the cause and without replacing the

limit switch with an exact replacement.

9. Air Pressure Switch - The air pressure switch

monitors the vacuum (negative pressure) within

the blower housing. This switch veries that air

is owing through the combustion system by

sensing pressure. It shuts off the heater if air ow

is inadequate.

2.5 Dimensions

See Figure 1 for exterior dimensions and dimensions to

critical connections.

2.6 Clearances

In both indoor installations (US) and outdoor shelter

installations (Canada), the heater must be placed to

provide clearances on all sides for maintenance and

inspection, as well as maintain minimum distances from

combustible surfaces.

NOTE Clearances are manufacturer’s tested values. These

are given as minimum values. Where local and national codes

apply, and if the clearance values specified in the applicable

codes are different that those listed in this manual, use the

greater value to ensure safest operation.

2.6.1 Combustible Surfaces

The following minimum clearances must be maintained

from combustible surfaces during operation. See Section

2.6.2 for clearances required for service and inspection.

TOP: 6 inches (15 cm)

EXHAUST SIDE: 6 inches (15 cm) from

surface of the exhaust vent

HEADER SIDE: 6 inches (15 cm)

DOOR PANELS: 6 inches (15 cm)

The dimensions shown in Figure 1 are certied by CSA

for USA and Canada (outdoor shelter). In Canada, 24

inches (60 cm) clearance is required per CSA B149.1,

section 4.14.2.

26.5"

(67 cm)

16.0"

(40.6 cm)

Figure1. GeneralConguration

EXHAUST SIDE

21.0

22.1"

(56 cm)

25.2"

(64 cm)

6.3"

(16 cm) (58 cm)

FRONT

36.5"

(93 cm)

22.9"

*VersaPlumb®

Sweep Elbow Inlet

*Optional Inlet

18.5"

(47 cm)

10.13"

(25.7cm)

5.6"

(14.2 cm)

Outlet

*Union nut, cap, and O-ring

provided for unused inlet. Sweep

Page 8

ENGLISH

®

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

Jandy

2.6.2 Service Clearance

Heater must be installed at least 5 feet (1.5 m) from the

inside wall of a pool unless the heater is separated from

the pool by a solid fence, wall or other permanent solid

barrier. For US installations, at least 18 inches (22.5 cm)

access must be available from at least one door panel

for service, inspection, and repair (see Figure 2). In

Canada, at least 24 inches (30 cm) is required for service,

inspection, and repair (see Figure 2).

If removing the header panel for maintenance, allow at

least 4 feet (1.2 m) access clearance.

If installing in a garage, consult the applicable National

Building Code for proper placement of protective bollards

or posts to prevent the heater from damage.

Min.

vertical

clearance:

36ʺ(45cm).

Min.

clearance

to at least

one door

panel:

18ʺ(22.5cm)US

24ʺ(30cm)Canada

Min. distance to

inside wall of pool (unless

separated by a solid wall):

5 feet (1.5 m)

Min. service

clearance

from header

4 feet (1.2 m)

2.8 Location Requirements

CAUTION

When pool equipment is located below the pool

surface, a leak from any component can cause large

scalewaterlossorooding.ZodiacPoolSystems,

Inc., cannot be responsible for such water loss or

oodingorresultingdamage.

Location of the heater below or above the pool water level

affects operation of its water pressure switch. See sections

on water piping and heater start-up for more information.

All criteria given in the following sections reect

minimum clearances as stated in the national standards.

However, each installation must also be evaluated, taking

into account the prevailing local conditions such as wind

speed and direction, proximity and height of walls that

may block ventilation, and proximity to public access

areas.

2.8.1 Flooring

The heater must be installed on a level, solid, and rm

surface or platform. Although it is always advisable to

install the heater on a non-combustible surface, the JXi-

series has been CSA-certied for installation on solid,

rm, and level combustible surfaces.

2.8.2 Outdoor Installation

The heater is factory congured for outdoor installation.

Figure 2. Service Clearance Requirements

2.7 Field Assembly

The JXi heater is shipped from the factory with an exhaust

vent congured for outdoor installation.

The heater is also design-certied for indoor installations

in the United States and outdoor shelter installations

in Canada. The heater has a ue collar for indoor

installations (see Section 3.3.1 for detailed instructions).

Check specications in Section 2.3 for appropriate vent

connection size (Category I).

Water connections are provided on the right side of the

heater but can be changed to the left side by rotating the

heater 180 degrees, so the water manifold is on the left,

then rotating the top panel so that the control panel faces

the operator.

NOTE: If the heater is to be operated in below freezing

conditions it should be installed in a protected outdoor

shelter (see Section 2.8.3).

WARNING

United States

Do not install the heater with the top of the vent assembly within 4

feet (1.22 m) horizontally, 4 feet (1.22 m) below or less than 1 ft (300

mm) above of any opening into a building. Local codes and installation requirements may vary.

Canada

Do not install the heater with the top of the vent asembly within 10

feet (3.05 m) of any opening into a building. Local codes and installation requirements may vary.

• Locate the heater on a level surface in an open,

unroofed area. If the heater is to be installed inside a

contained area, refer to venting requirements, Section

2.8.3.

• Do not install the heater under a deck.

• Do not locate the heater below or adjacent to any

doors, glass openings, louvers, grills, etc., which

connect in any way with an inhabited area of a

building, even though the access might be through

another structure (e.g., a garage or utility room).

• In Canada, install the heater so that the top of the vent

is at least 10 feet (3.0 m) from any building opening.

See Figure 3.

®

Distance from heater to door, window or other opening:

A - USA 4 ft (1.2m) minimum; Canada 10 ft (3 m) minimum

Distance from heater to forced air inlet or other vented opening:

B - USA and Canada If C is greater than 3 ft (0.9m), any distance OK;

If C is less than 3 ft (0.9m), B must be at least 10 ft (3 m)

Jandy

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

• The top surface of the heater must be at least 3 feet

(0.9 m) above any forced air inlet, or intake ducts

located within 10 feet (3.0 m) horizontally.

• The area under an overhang must be open on three

sides to prevent combustion gases from being diverted

into living areas through doors, windows, or gravity

inlets.

• In the United States install the heater so that there

is at least a three (3) foot (1 m) clearance between

the bottom of the overhang to the top of the heater

exhaust vent.

• If the heater is installed close to a structure, protect it

from rain water runoff with rain gutters on the roof or

other measures.

• Do not locate the heater near irrigation sprinkler

systems that could spray water on it. Water from

sprinklers can damage controls and electronic

components.

• Be sure to divert rain water runoff away from heater

ENGLISH

Page 9

1/4” X 2-1/4”

GALVANIZED OR PLATED

CONCRETE SCREWS (4)

WASHER

“L” BRACKET

HOLE

Figure 4. Anchor Heater To Equipment Pad

NOTE: Other jurisdictions may have similar requirements for

extreme weather. Check your local codes for relevant

details.

2.8.3 Indoor Installations

(and Outdoor Shelter, Canada)

Figure 3. Outdoor Heater Installation

Outdoor Installations in Florida:

Due to the high risk

of extreme weather conditions in Florida, the heater is

required to be securely fastened to the equipment pad

(see Figure 4) to meet the applicable requirements of the

Florida Building Code.

NOTE: Mounting screws are not provided with this heater. Use

size 1/4" x 2-1/4" long galvanized or plated concrete

screws and washers.

1. Place the heater on the equipment pad.

2. Drill a hole in the concrete at each of the brackets

on each corner of the heater. (The correct size drill

bit is usually provided with the concrete screws

when purchased).

3. Place a screw in each of the holes and fasten the

heater to the concrete pad. Do not over-torque

the screws.

WARNING

United States

Do not install the heater with the top of the vent

assembly within 4 feet (1.22 m) horizontally, 4 feet

(1.22 m) below or less than 1 ft (300 mm) above of any

opening into a building. Be sure to consult local codes

and installation requirements as some jurisdications

may have varying and more stringent requirements.

Canada

Do not install the heater with the top of the vent

asembly within 10 feet (3 m) of any opening into a

building. Be sure to consult local codes and installation

requirements as some jurisdications may have varying

and more stringent requirements.

The heater is CSA design-certied for indoor installations

in the US and for outdoor shelter installations in Canada.

To install for outdoor shelter area, you will need to

remove the vent housing and the exhaust grate.

When pool equipment is installed indoors, appropriate

containment and drain should be provided to prevent

property damage in the event of equipment leaks.

NOTE: An outdoor shelter is an unoccupied enclosure which

does not communicate directly with occupied areas.

All outdoor shelter installations (Canada only) must have

uninterrupted openings to outside air for combustion and

ventilation. The installation must be in accordance with

the latest edition of CAN/CSA B149.1.

Zodiac Pool Systems, Inc., does not recommend outdoor

Page 10

ENGLISH

®

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

Jandy

shelter installations that depend on internal air for

combustion (see Table 1).

Due to the higher risks and hazards of Liquid Propane

(LP) gas, Zodiac does not encourage installation of LP gas

heaters indoors. Please be sure to refer to section 4.2 for

additional precautions that must be considered for LP gas.

Section 3. Venting

3.1 Combustion Air Supply

As outlined in the latest edition of ANSI® standard Z223.1

(NFPA

to provide sufcient air supply for proper combustion and

ventilation of the surrounding area.

In general, these requirements specify that the room in

which a heater is installed should be provided with two

permanent air supply openings:

• one within 12 inches (305 mm) of the ceiling

• one within 12 inches (305 mm) of the oor

All indoor installations must have openings to outside

air for combustion, ventilation, and dilution of ue

gases from inside the building. Do not, under any

circumstances, install this product in an indoor location

which does not provide combustion air to the appliance

from outside the building.

In addition, the heater must be completely isolated

and protected from any source of corrosive chemical

fumes such as those emitted by trichlorethylene,

perchloroethylene, chlorine, etc.

®

54), the heater location must be properly vented

Model

200

260

330

400

Table 1. Air Openings to Outside

NOTE: If using screens and/or metal louvers, compensate by

Direct from outside Duct from outside

2

in

50 323 100 645

65 419 130 839

83 535 165 1065

100 645 200 1291

adding 50% additional area to each opening. If using

wood louvers, each opening must be at least four

times the area indicated in the table above.

cm

2

in

2

cm

2

For special conditions, refer to Section 9.3.3.1 NFPA 54

ANSI Z223.

The information in Table 1 is not applicable in

installations where exhaust fans or blowers of any type are

used. Consult a Professional Engineer (P.E.) to ensure that

installations where exhaust fans or blowers are used are

designed and installed in accordance with all applicable

local and national installation codes.

Outside Air Supply: When combustion air is supplied

directly through an outside wall, each opening should

have a minimum free area of 1 square inch per 4,000

BTU/h (1.2kW) input of the total input rating of all

appliances in the enclosed area.

If air is provided through horizontal ducts, each opening

and duct must provide 1 square inch of ow area for

each 2000 BTU/h (0.6 kW). These requirements are

summarized in Table 1.

WARNING

Do not store any chemicals, cleaners, or other corrosive material near combustion air openings or in the

room. Avoid locating appliance vents in the vicinity of

combustion air openings. Failure to prevent corrosive

materials from mixing with combustion air can result in

reduced heater life and unsafe heater operation.

Minimum Net Free Open Area* for Combustion

Openings (square inches/centimeters)

*Area indicated is for one of two openings:

one12inchesfromoorlevel,one12inchesfromceilinglevel.

Exhaust Fans or Vents: Any equipment which exhausts

air from the room where the heater is installed can

deplete the combustion air supply or reverse the natural

draft action of the venting system. This could cause ue

products to accumulate in the room. Additional air must

be supplied to compensate for such exhaust.

The information in Table 1 is not applicable in

installations where exhaust fans or blowers of any type

are used. Such installations must be designed by a

Professional Engineer (P.E.).

3.2 Exhaust Venting

When converted to indoor and outdoor shelter venting

conguration, the JXi has a ue collar for attachment to

the venting for category I vertical venting and category

®

Jandy

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

ENGLISH

Page 11

III vertical and horizontal venting. The only correct

procedure for vent pipe sizing is to do so in accordance

with Table 2 (Section 3.3.2 of this manual) and the

applicable installation code as stated in the following

warning and Table 13.1(a) and 13.1 (b) per NFPA 54

for category I and Table 3 for Category III.

WARNING

Vent pipe materials, sizing, and installation must be

as required by the National Fuel Gas Code NFPA 54/

ANSI Z223.1 or the Canadian Installation Codes for

Gas Appliances CAN/CSA-B149.1. Undersized pipe

can result in inadequate venting and oversize pipe

can result in vent condensation. Improper selection

of vent pipe material, incorrect sizing of the pipe, and

misinstallation of vent piping can result in release of

combustion products to the indoors. This can cause

serious injury or death by Carbon Monoxide poisoning

or asphyxiation.

Note that with horizontal Category III type vent

installations, the venting diameter is four (4) inches and

AL29-4C

vent pipe and elbows. See Section 3.3.1 for procedure to

connect vent pipe and elbows.

®

stainless steel. The JXi ue collar ts 4-inch

resistant and suitable for the specic installation being

considered

• Do not locate the vent terminal where ue products

could strike against building materials and cause

degradation.

• Vent opening should be well away from trees or other

obstructions that would prevent free air ow to and

from vent terminal.

• Do not terminate the vent under decks, stairways, or

car ports.

3.3.1 Vent Pipe or Elbow Increaser Installation

(Category I and Category III)

1. Remove the exhaust body.

2. Remove the exhaust rain shield (see Figure 5).

Exhaust Vent

Rain Shield

3.3 Vent Pipe Sizing and Installation

The JXi may be installed with venting as a Category I or

Category III appliance.

• Category I: A Category I appliance is a vented

appliance that operates with a non-positive vent static

pressure and with a vent gas temperature that avoids

excessive condensate production in the vent. Category

I installations are vented vertically and terminate at

the roof.

• Category III: A Category III appliance is a vented

appliance that operates with a positive vent static

pressure and with a vent gas temperature that avoids

excessive condensate production in the vent. Category

III installations can be vented via a side wall.

In all installations (Category I and Category III):

• Avoid terminating heater vents near air conditioning

or air supply fans. Fans can pick up exhaust ue

products from the heater and return them inside the

building, creating a possible carbon monoxide or

other health hazard.

• Selection of vent pipe type and material must be

carefully considered depending on the type of

installation. Zodiac strongly recommends using high

quality vent pipe materials, which are corrosion

Figure 5. Remove Exhaust Body and Rain Shield

3. Category I:

Install a 4 inch double-wall appliance adapter and

an increaser to meet the vent size requirements per

Table 2. (See Figure 6.)

Category III:

Install vent connector or elbow to the ue collar

according to the specic installation instructions

from the vent connector or elbow component

manufacturer.

Page 12

ENGLISH

®

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

Jandy

4 inch double-wall

appliance adapter

Increaser

Figure6. CategoryIInstallationConguration

4. Wipe the socket of the vent body with rubbing

alcohol using a clean cloth or paper towel, then.

dry with a different clean cloth.

5. Connect the 4 inch double-wall appliance adapter

for category I or vent connector for category III to

the ue collar and fasten with three (3) sheet metal

screws, as shown in Figure 7).

NOTE: It is important to position the three screws so the seal

in the flue collar is not compromised. Begin with first

screw at 3 o’clock position from top of the flue collar

seam. Install screws 2 and 3 in positions 120 degrees

apart (as shown in Figure 7).

Fasten three

screws, positioned

at 120° intervals

from top seam in

vent collar

screw

(3)

120°

screw

(2)

Start with

screw (1) at

3 o’clock position

seam

120°

120°

screw

(1)

Apply RTV at seal after connecting.

Use minimum 600°F (315°C)

temperature rated RTV.

Figure 8. Seal Connection with RTV

3.3.2 Vertical Venting (Category I)

All indoor installations and outdoor shelter installations

require an approved 4 inch double-wall appliance adapter

and increaser to be connected to the JXi 4-inch ue collar

for Type B installations. Increasers are available in steps

up to a maximum of four sizes larger. 4 inch doublewall appliance adapters and increasers can be obtained

®

from manufacturers such as Amerivent or Duravent

(see Section 2.3 for detailed specications). All vent

installations must be made in accordance with local, state,

or provincial codes and with:

®

• National Fuel Gas Code ANSI

Z223.1 (NFPA® 54),

latest edition; pay particular attention to the chapter

addressing “Venting of Equipment.” Applicable

provisions of additional applicable local building

codes may also need to be followed.

• Canada CAN/CSA B149.1.

Vent the JXi heater vertically in a negative pressure (nonpositive draft) system in accordance with the National

Fuel Gas Code NFPA 54 / ANSI Z223.1 or the Canadian

Natural Gas and Propane Installation Code, CAN/

CSA-B149.1. A type B double-wall vent connector is

required. The heater must not be used to support the vent

pipe.

Figure 7. Correct positioning of screws

on vent collar

6. Apply high temperature silicone RTV at the

connection to seal, as shown in Figure 8.

NOTE: Use a minimum 600°F (315°C) temperature rated RTV.

Note that the tables for fan-assisted appliances include

both maximum and minimum vent loading gures in the

NFPFA 54. The primary purpose of the maximum ratings

are to ensure that the vent operates with negative pressure

throughout its length. The minimum rating refers to the

ring rate.

1. Determine the correct vent size for your heater

according to Table 2.

®

Jandy

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

ENGLISH

Page 13

Notes:

1. Use approved

roof jack.

ADEQUATE AIR

SUPPLY TO ROOM

TOP AND BOTTOM

Figure 9. Indoor Installation Venting (USA) or Outdoor Shelter (Canada) for Category I

1)

Figure 10. Side Wall Vent Terminals for Category III (US installations). Refer to CSA B149 for

requirementsspecictoCanadianinstallations.Checklocalinstallationcodeswhichmay

require greater minimum distances from windows and doors to be maintained.

Page 14

ENGLISH

®

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

Jandy

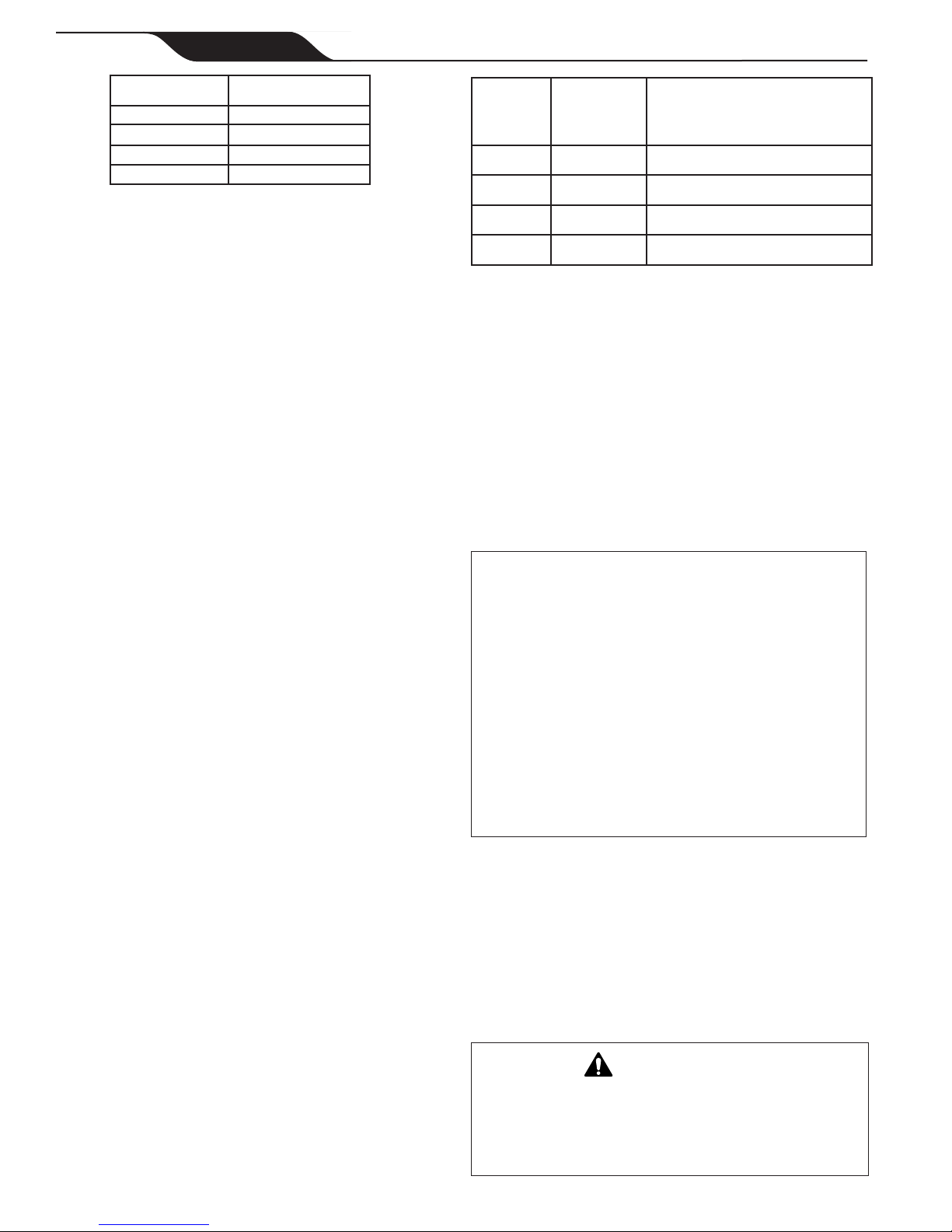

Heater Size Vent Size

200 6" (15cm)

260 7" (18cm)

330 8" (20cm)

400 8" (20cm)

Table 2. Category I Vent Pipe Sizing Table

2. Install a 4 inch double-wall appliance adapter and

an increaser (see Section 3.3.1).

3. Following the vent connector’s manufacturer

instructions attach the vent pipe to the increaser

and further secure them with sheet metal screws.

Before connecting, wet a clean cloth or paper

towel with rubbing alcohol and wipe the socket

of the vent body. Dry with a different clean cloth.

Vent piping must be adequately supported with no

low spots or sagging that could allow condensate

to collect. The heater must not be used to support

the vent pipe. Horizontal runs must be sloped

upwards away from the heater to a vent terminal

at a minimum of 1/4 " per horizontal foot (2

cm/m).

4. Install the vent pipe so it can expand and contract

freely with temperature changes.

Note: Do not run the heater vent into a common

vent with any other appliance.

3.3.3 Vertical or Horizontal Venting

(Category III)

When the installation requires horizontal venting in excess

of what is allowed for Category I installations or calls

for horizontal discharge, the JXi may be installed with a

Category III venting system.

Vent the heater either vertically or horizontally

®

using Al29-4C

manufacturers such as Z-Flex

stainless steel components. Consult

®

or Heat Fab® to obtain

approved components. Venting materials must comply

®

with UL

1738 for Category III, Special Gas Vent.

In Canada, the venting materials must be ULC S636

compliant. Vent piping must be adequately supported with

no low spots or sagging that could allow condensate to

collect.

The heater must not be used to support the vent pipe.

Horizontal runs must be sloped upwards away from the

heater to a vent terminal at a minimum of 1/4 inch per

horizontal foot (2 cm/m).

Heater

Size

200 4" (10cm) TBD (m)

260 4" (10cm) 50ʹ(15m)

330 4" (10cm) TBD (m)

400 4" (10cm) 50ʹ(15m)

Table 3. Category III Vent Pipe Sizing Table

Vent Size

Special Gas Vent

Length (vertical or horizontal)

in feet (metres)

Side wall vents must be installed and located in

®

accordance with the National Fuel Gas Code NFPA

®

54 / ANSI

Z223.1 or the Canadian Natural Gas and

Propane Installation Code CAN/CSA-B149.1. In addition,

always consult your local installation codes. Some local

installation codes may have requirements that exceed

those of the the national codes. The product must be

installed in accordance with the codes being enforced by

the local Authority Having Jurisdiction (AHJ).

See Figure 9 for side wall vent terminations.

IMPORTANT NOTE In the Commonwealth of

Massachusetts, additional requirements, covered in

document CMR 248 5.00, which supersede some of

the requirements of ANSI Z223.1 (NFPA 54) apply to

Side Wall Horizontally Vented appliances. If installing

this product using an approved side-wall horizontal

vent system in the Commonwealth of Massachusetts,

be sure to adhere to these additional requirements.

These requirements include verbiage that says that

the property owner is to ensure that Carbon Monoxide

Detectors are installed in the vicinity of the appliance

and also on all levels of the dwelling in which the

appliance is installed.

For further instructions, contact Zodiac Pool Systems,

Inc., Technical Support Department at 800.822.7933

(in Canada: 888.647.4004)

1. Install the vent connector or elbow

(see Section 3.3.1).

2. Install the vent pipe so it can expand and

contract freely with temperature changes. Before

connecting, wet a clean cloth or paper towel with

rubbing alcohol and wipe the socket of the vent

body.

3. Follow installation instructions from the

manufacturer of the special gas vent components.

It is recommended that vent runs over 18 feet be insulated

to reduce condensation and/or use a condensate trap in

the vent run close to the heater, especially in certain cold

climate installations.

See Table 3 for recommended vent size and run lengths

without elbows. For each elbow installed, reduce the run

length by 12 feet (3.7m)

WARNING

Incorrect design and installation of heater vents and

ducts can result in personal injury, damage to property,

or death. To avoid such hazards, the heater must

beinstalledonlybyaqualiedprofessionalservice

technician.

®

Jandy

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

Precautions Against Common Venting:

Seek the assistance of a Registered Professional Engineer

for proper design of a common venting system.

Zodiac Pool Systems, Inc. does not recommend using

a common vent to vent multiple appliances through a

common duct. However, if no other option is deemed

available by the installer, each appliance must have its

own vent temperature limit switch. All vent limit switches

must be wired in series so as to prevent any appliance

from ring in the event of a blocked vent. An outside

draft inducer must be installed to pull and create negative

®

pressure in the vent system. Refer to ANSI

Z223.1 or

in Canada CAN/CSA B149.1 for more information on

common venting multiple appliances. Do not connect

vent systems of different categories to the same venting

system.

WARNING

Improper installation or maintenance can cause nausea

orasphyxiationfromcarbonmonoxideinuegases

which could result in severe injury, or death. For indoor

installations, as an additional measure of safety, Zodiac

Pool Systems, Inc. strongly recommends installation

of suitable Carbon Monoxide detectors in the vicinity of

this appliance and in any adjacent occupied spaces.

3.3.4 Inspection and Replacement of Existing Vent

System with New Components

When replacing an existing pool heater with the JXi, it

is recommended that a new appropriate venting system

is installed with the new heater. However, if the existing

venting system must be used, be sure to carefully inspect

the existing system to ensure that it is in good condition

and appropriate for the JXi heater. Replace any parts that

are not in serviceable condition before completing the

installation.

Section 4. Gas Connections

4.1 Install Piping and Check Gas Supply

Gas piping installation must be in accordance with the

latest edition of ANSI Z223.1 and all local codes. In

Canada, the installation must be in accordance with CAN/

CSA B149.1 and all local codes that apply.

The heater must be isolated from the gas supply piping

system by closing the individual manual shut off valve

during any pressure testing of the gas supply piping

system at test pressure equal to or less than 1/2 psi

(3.5kPa).

The heater and its individual shut off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psi (3.5 kPa).

ENGLISH

Page 15

WARNING

The JXi pool and spa heaters are designed for use

with either natural gas or LP gas. Check the rating

plate on the front of the combustion chamber to be

sure that the heater is designed to use the type of gas

being supplied. DO NOT ATTEMPT TO CONVERT

THIS HEATER FOR USE WITH ANY OTHER TYPE

OF FUEL OTHER THAN THE FUEL TYPE FOR

WHICH IT WAS CONFIGURED AT THE FACTORY

AND WHICH IS MARKED ON THE NAMEPLATE.

CAUTION

Permanent damage to the gas valve will occur if the

installation procedures are not followed correctly.

1. Refer to Table 4 for correct gas inlet piping length

from the gas meter to the heater. When sizing gas

lines, calculate three (3) additional feet of straight

pipe for every elbow used.

Distance from Gas Meter

Heater

Size

200

260

330

400

Notes:

• Numbers are for natural gas (0.65 Sp. Gr.) based on 1/2

inch (3.45 kPa) water column pressure drop. Check supply

pressure with a manometer, and local code requirements

for variations. For LP gas, reduce pipe diameter by one

size, but maintain a minimum 3/4 inch diameter.

• Check supply pressure and local code requirements before

proceeding with installation.

• Considerpipettingswhendetermininggaspipesizing.

• Table shows the minimum supply gas pipe size required.

Larger pipe size can be used if required by local code or

if desired.

• It is critical that the incoming gas supply pressure at the

heater is within the maximum and minimum pressure

requirements. If the range of acceptable supply pressure

is not provided, the gas supply system to the heater must

bemodiedtomeetpressurerequirements.

Table 4. Supply Gas Pipe Size Requirements*

0-50 feet

(0-15 m)

in. mm in. mm in. mm

1 25 1-1/4 32 1-1/4 32

1-1/4 32 1-1/4 32 1-1/4 32

1-1/4 32 1-1/4 32 1-1/2 38

1-1/4 32 1-1/2 38 1-1/2 38

2. Check the gas meter to make sure it will supply

enough gas to the heater and any other appliances

using the same heater.

NOTE: The gas line from the meter is usually larger than

the gas valve. Therefore, you will need to reduce

connecting pipe as necessary. Make this reduction as

close to the heater as possible.

3. Install a manual gas shutoff valve for service and

safety.

50-100 feet

(15-30 m)

100-200 feet

(30-60 m)

Page 16

3-way

ENGLISH

®

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

Jandy

4. Install a sediment trap and union ahead of the gas

controls and outside the heater panels, as shown

in Figure 11. Do not use a restrictive gas cock.

DO NOT USE FLEXIBLE GAS PIPING, it will

restrict the gas ow to the heater.

PIPE

UNION

SEDIMENT TRAP

Figure 11. Manual Shut-off Valve and Sediment Trap

NOTE: Close shutoff valve and disconnect the heater to

isolate the heater before pressure testing the gas

supply system.

5. Connect a manometer to the supply pressure port

on the gas valve. While the heater, and when

possible, while all other gas burning appliances

supplied by the common gas delivery system,

are operating, conrm the gas supply pressure is

correct according to Table 5.

8. Test gas offset pressure. See Section 10.

Professional Service and Maintenance.

WARNING

Failure to replace the 1/8 inch NPT gas valve plugs on

inlet, gas offset pressure ports, and cap on the manifold pressure adjustment screw, can result in property

damage, severe injury, or death.

4.2 Special Precautions for LP Gas

Under the same environmental conditions, liquid

propane (LP) gas is more dense than air and will more

readily collect in enclosed areas if there is not adequate

ventilation. It is not recommended to install LP gas

heaters in enclosed areas such as pits. Locate heaters a

safe distance from LP gas cylinders and lling equipment.

Consult the National Fuel Gas Code (NFPA

Z223.1, latest edition), the Liqueed Petroleum Gas Code

(NFPA 58, latest edition), the Natural Gas and Propane

Installation Code in Canada (CAN/CSA B149.1, latest

edition), and any other local codes and re protection

authorities about specic installation restrictions in your

area.

For ALL installations the combustion air openings

requirements and NFPA54 / ANSI Z223.1 MUST be

followed for safe and proper operation.

Section 5. Water Connections

®

54/ANSI®

Gas Pressure Natural Propane

Inches W.C.

Maximum inlet 10.5 14

Minimum inlet 4 4

Gas Offset – 0.2 – 0.2

Notes:

• All readings must be taken while the heater is operating.

• Any adjustments or readings made while the heater is off

will result in poor performance and problems.

Table 5. Gas Supply Pressure Requirements

6. If the gas supply pressure is less than required,

check for undersized pipe between the meter and

the heaters, a restrictive tting, or an undersized

gas meter.

7. Before operating the heater, test the complete gas

supply system and all connections for leaks using

a soap solution. Do not use an open ame to test

for leaks.

CAUTION

Some leak test solutions (including soap and water)

may cause corrosion or stress cracking. Rinse the

piping with water after testing.

5.1 Water Piping Connections

Install pool system components with connections as

illustrated in Figure 12.

Pool

main

drain

3-way

valve

Spa

valve

Pump

Filter

3-way

valve

Figure12. TypicalWaterPipingConguration

Chlorinator

Heater

check

valve

®

Jandy

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

ENGLISH

Page 17

Any conguration other than as illustrated in Figure 12

can affect the operation of the water pressure switch.

Locating the heater above or below the pool water surface

can also affect operation of the switch.

NOTE: When pool equipment is located below the pool

surface, Zodiac Pool Systems, Inc. is not responsible

for any large scale water loss, flooding or damage

caused by a leak.

The heater must be protected from back-siphoning of

water, which can result in dry starts. If there is any chance

of back-siphoning, provide a check valve between the

pool and the lter pump inlet.

5.2 Pump Sizing

The internal ow bypass within the heater manifold

will accommodate ows delivered to the heater from a

minimum of 30 gallons per minute (gpm) to a maximum

ow of 120 gpm, depending on the heater model. A

manual bypass valve should be installed when the pump

ow exceeds 120 gpm.

To install a manual bypass valve:

1. Connect ball valve valve between water inlet and

outlet (Figure 13).

Model Min gpm (lpm) Max gpm (lpm)

200 30 (114) 120 (454)

260 30 (114) 120 (454)

330 30 (114) 120 (454)

400 30 (114) 120 (454)

Table 6. Recommended Flow Rate Adjustment

3. Remove the valve handle to avoid tampering.

Pump Sizing for New Pool Construction:

When sizing a pump for the system, the head loss for

all system components must be added together when

determining the design ow rate. Component “Head

Loss at Flow” curves are available from equipment

manufacturers.

NOTE: In order to properly establish head loss at flow for a

filter, remember that a “dirty” filter can typically add 10

psi of additional head loss (23 extra feet of head). This

must be considered when sizing a pump for a new

pool system.

Pump Sizing for Replacement in an Existing Pool:

Heater

IN OUT

Handle

Ball Valve

Figure 13. Install Manual Bypass Valve

IMPORTANT

The system water pump must be capable of providing

no less than 30 gpm of flow through the heater.

Flow rates at less than 30 gpm may cause nuisance

operation causing the heater to turn off or damage to

the heater.

2. Adjust the valve to bring the ow rate within the

acceptable range (see Table 6).

If the JXi heater replaces a different model of heater,

determine if the existing pump is capable of providing the

minimum ow of no less than 30 gpm indicated in Table

6 for the specic model. JXi heaters are high efciency

heaters. Heaters typical of this construction may have

higher head loss characteristics than the one being

replaced.

IMPORTANT

Heater failure due to insufficient water flow is not

covered under warranty. See measurements in the

Head Loss Chart, Figure 14.

Page 18

Head Loss - JXi Heaters

Design Pressure Drop (psi)

Design Head Loss

ENGLISH

®

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

Jandy

30

28

26

24

22

20

18

16

14

12

10

(ft head)

8

6

4

2

0

NOTE: Head Loss

Data for Models 200

and 330:

TBD

12

10

8

6

4

2

0

Flow Rate (gpm)

Figure 14. Head Loss Chart

5.3 Plumbing Connections

The heater has a standard 2 inch water header and coupling

design. With this feature, only nominal two inch PVC

or CPVC may be connected to the heater. However, by

installing the appropriate pipe adapters and two (2) short

pieces of two-inch plastic pipe (supplied by the installer),

any size existing pipe may be tted to the heater.

Optional Water Inlet Piping

The water inlet can be piped in one of two possible

congurations. The heater comes with a Zodiac

Sweep Elbow for increased hydraulic performance and

efciency. The sweep elbow also provides the advantage

of its exclusive interface with the Zodiac AquaLink

temperature sensor. The sweep elbow may be installed in

the top inlet connection, and the cap and plug with O-ring

installed to close off the unused side port (see Figure 15).

This conguration may be preferred for Versa Plumb

piping to mating components

®

®

RS

®

SWEEP

ELBOW

(provided)

SWEEP

ELBOW

Figure 15. Top Inlet Piping Using the Versa Plumb

Sweep Elbow

®

Jandy

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

ENGLISH

Page 19

Optionally, the top inlet opening may be capped with the

union nut and cap, and plug with O-ring provided, then

the water inlet port on the side directly above the outlet

port may be used. (See Figure 16.)

(union nut, cap

and O-ring provided)

IN

OUT

Figure 16. Optional Side Inlet Piping

WARNING

To avoid an electrical shock hazard, which can result

in serious injury or death, ensure that all electrical

power to the system is turned off before approaching, inspecting or troubleshooting any leaking valves

or plumbing that may have caused other electrical

devices in the surrounding area to get wet.

WARNING

Followallltermanufacturer’s

instructions. NEVER attempt to

assemble, disassemble or adjust the

lterwhenthereispressurizedairin

the system. Starting the pump while

there is any pressurized air in the

systemcancausethelterlidtobe

blown off, which can cause death,

serious personal injury or property

damage.

2. After the glue is cured, close the pressure relief

valve on top of the lter.

3. Return all valves to their operating positions.

4. Turn on power to the heater.

5. Turn on the pump to check for water leaks.

6. Restore the gas supply to the heater.

7. Start the system and check for proper water ow.

5.4 Water Pressure Switch Adjustment

CAUTION

The water pressure switch should be adjusted to turn

the heater off when the pump is off. Setting the switch

tocloseattoolowowcandamagetheappliance.

Adjust the switch to turn the heater off, not on.

The pressure switch is preset at the factory for activation

at 2 psi (14 kPa). If the heater is installed below the

surface level of the pool, more than two feet above the

pool level, or any time the pressure is measured at 1 psi

or greater with the system pump off the pressure switch

setting must be adjusted.

Location of the heater above or below the pool water

surface can also affect the operation of the switch. The

factory installed switch can accommodate elevations not

exceeding 6 feet above the pool water surface or 11 feet

below pool water surface. If the heater water connections

are outside this range Consult your local Zodiac

representative for recommendations.

Make sure the pool lter is clean before making any

pressure switch adjustment. A dirty lter will restrict the

water ow and the pressure switch cannot be adjusted

properly.

To adjust the water pressure switch:

NOTE: It is recommended that a Pressure Release Valve

(PRV) be installed prior to taking any of the steps

below. See section 5.7

To install the Sweep Elbow:

1. Clean the cut ends of the pipe and both ends of

the sweep elbow(s) with an appropriate NSF

approved All Purpose cleaner/primer. Glue the

sweep elbow(s) onto the cut pipe ends using an

appropriate All Purpose NSF approved adhesive/

glue.

NOTE Zodiac Pool Systems, Inc. recommends Weld-On

724TM PVC to CPVC Cement to glue Schedule 40

PVC.

1. Set the heater control to the “OFF” mode.

2. Remove the header side panel to access the water

®

pressure switch.

3. Start the lter pump and conrm by means of a

voltmeter that the pressure switch closes (if the

switch fails to close, replace it with a switch that

has a lower minimum setting).

4. Set the heater control to either POOL or SPA.

®

Heater should start.

5. With your ngers, turn the adjustment sprocket

very slowly clockwise until the heater goes off.

(See Figure 17.)

Page 20

Slowly turn adjustment

sprocket clockwise until

heater goes off

Figure 17. Adjust Pressure Switch

ENGLISH

®

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

Jandy

6. Slowly turn the pressure switch adjustment

sprocket counterclockwise one-quarter turn. The

heater should come back on.

7. Check the adjustment by turning the lter pump

OFF. The burners should shut off immediately.

If they do not, restart the lter pump and repeat

Steps 6 and 7. Check the adjustment again.

8. Return the pool temperature control to the desired

temperature.

It may be necessary to repeat these steps to get a proper

setting. The switch must be set so that the heater will not

re unless the pump is running. If a proper setting cannot

be reached, contact the factory service department.

5.5 Check Valve Installation

When any equipment is located below the surface of the

pool or spa, back-siphoning can occur, which is when the

pump stops and a pressure-suction differential is created.

Check valves should be installed in the piping system to

isolate the equipment from the pool or spa if there is any

chance of back-siphoning. Always install a check valve

if there is a chemical feeder installed in the system (see

Section 5.8).

outlet line is downstream of the heater and a positive seal

noncorrosive check valve is installed between the feeder

and the heater.

5.6 Reversing the Water Connections

The JXi heater is shipped with water connections on the

right side, but the top panel can be rotated to adapt to leftside water connections. This procedure involves turning

the heater and then removing and rotating the top panel of

the heater. The heater wiring procedure must be done only

by a trained service technician.

5.7 Pressure Relief Valve Installation

A pressure relief valve (PRV) is recommended in all

installations, and is mandatory in any installation in which

the water ow can be restricted between the heater outlet

and the pool/spa.

A pressure relief valve is not supplied with the JXi heater.

However, it is recommended that a pressure relief valve

be installed and may even be required by local codes.

Be sure to check any applicable installation codes in

your area to determine whether a pressure relief valve is

required.

The maximum working pressure of this heater is 50 psi.

Be sure to take into consideration the maximum allowable

pressure of the other components in the system when

selecting a PRV. Any pressure relief valve installed must

comply with provisions of the standard described in

®

ANSI

To install a pressure relief valve:

Z21.22 for the United Sates or CSA 4.4 in Canada.

1. Locate the threaded boss on the outlet port of the

in/out header (beside the “out” arrow). See Figure

18.

2. Note the dimple at the center of the blind bottom

of the boss. Using the dimple to center the

drill bit, drill a 1/4" diameter hole through the

bottom of the boss, taking care not to damage

he surrounding plastic threads. (TIP: Drilling a

1/8" diameter hole rst will help prevent thread

damage.)

WARNING

A check valve can interfere with the proper operation

of certain Suction Vacuum Release System (SVRS)

products. To avoid possible entrapment hazard,

serious injury, or death, make sure to review the

operation/owners manual of your particular SVRS

product before installing the check valve.

Do not install any shutoff valve in the piping between

the heater outlet and the pool, unless it is being used as a

diverter valve. Always use care when installing chemical

feeders so that there is no back-siphoning of chemical

into the heater, lters, or pump. Make sure the feeder

WARNING

Drilling through plastic can often cause the drill bit to

‘grab’, causing the drill motor to twist in your hand.

Holddrillrmlytoavoidpotentialinjury.

NOTE: The fittings must be installed immediately after the

outlet with no valves or other components inbetween.

The pressure relief valve must be installed at the outlet

port. Do not install at either of the header inlet ports.

3. Install a brass 3/8 NPT x 3/8 NPT x 3" long pipe

nipple into the boss, using 5 to 6 wraps of Teon

tape on the threaded end. Do not overtighten. See

Figure 18.

®

®

Jandy

Pro Series, JXi™ Gas-Fired Pool & Spa Heater | Installation & Operation Manual

CAUTION

UseTeon® tape only on the threads of the pipe nipple

attachment to the plastic header. Do not use any pipe

compound or pipe dope on the threads or any part that

comes into contact with the plastic headers. These

compounds may damage the header over a period of

time.

3/4-inch

NPT PRV

Heater

Water

Out

2-inch

Tee

3/8-inch

NPT

nipple

3/8-inch

NPT

3/4-inch NPT

to 3/8-inch

NPT reducer

ENGLISH

NOTE: To ensure the continued proper operation of the

pressure relief valve, the valve should be tested once

a year. To test, lift the lever with the circulation system

running to ensure that water will pass through. When

the lever is down, there should be no leaks from the

outlet.

Page 21

5.8 Auxiliary Components, Chlorinators,

Ozone Generators, and Sanitizing

Chemicals

The JXi heater is manufactured with materials that are not