Page 1

Installation and Operating Data

Installation and

Operation Manual

Jandy® Laminar Jet

Pulse Controller

LPC4

WARNING

FOR YOUR SAFETY - This product must be installed and serviced by a pro fes sion al pool/spa

service technician. The procedures in this manual must be followed ex act ly. Failure to follow

warning notices and instructions may result in property damage, serious injury, or death.

This manual contains important information about the installation, operation and safe use of

this product. This information should be given to the owner/operator of this equipment.

H0566900A

Page 2

Page 3

Table of Contents

Section 1. Safety Information ...........................4

Section 2. General Information ........................5

Section 3. Solenoid Installation ........................5

Section 4. Control Panel Installation ................6

Section 5. Low Voltage Wiring Installation ......7

Section 6. Control Panel Operation .................8

Section 7. LPC4 Remote Installation ...............8

Section 8. Remote Panel Operation ..................8

Section 9. System Wiring Diagrams .................9

Section 10. Parts List and Exploded View..........13

Page 3

EQUIPMENT INFORMATION RECORD

DATE OF INSTALLATION

INSTALLER INFORMATION

LAMINAR JET MODEL SERIAL NUMBER

CONTROL PANEL MODEL SERIAL NUMBER

LAMINAR PULSE CONTROL MODEL SERIAL NUMBER

NOTES:

Page 4

Page 4

Section 1. Safety Information

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

FOR YOUR SAFETY: This product must be installed and serviced by authorized personnel qual i fi ed in

pool/spa installation and maintenance. Improper installation and/or operation will void the warranty.

WARNING

Risk of Electrical Shock or Electrocution. This Control Panel must be installed by a licensed or certifi ed

electrician in accordance with the National Electrical Code and all applicable local codes and ordinances.

Improper installation will create an electrical hazard which could result in death or serious injury to pool

users, installer, or others due to electrical shock, and may also cause damage to property.

A TTENTION INST ALLER: This manual contains important information about the

installation, operation and safe use of this product. This information should be given to

the owner/operator of this equipment.

Page 5

Section 2. General Information

Page 5

The Jandy® Laminar Jet Pulse Controller (LPC4)

enhances the fi ber optic light option used with the

Laminar Jets. The LPC4 pulses the fi ber optic light

providing a burst of color that travels throughout

the stream of the jet. Because of the unique

microprocessor based electronics, multiple settings

can be achieved from timed bursts of light to random

operation and fi nally to patterns that truly create the

ultimate in backyard water and light fantasy.

The LPC4 can control up to four solenoid valves that

are used to pulse light for up to four Jandy Laminar

Flow Jets (p/n JLJ1001). In other words, one (1)

solenoid valve per Laminar Flow Jet. The LPC4 kit

includes one (1) control panel and two (2) solenoid

valves. The LPC4 can be operated by the Jandy

AquaLink® RS control systems (with Revision L or

newer software) or by the optional LPC4 Remote.

Section 3. Solenoid Installation

1. To install the solenoid, turn the Jandy Laminar

Flow Jet upside down and locate the three (3)

holes molded into the bottom (see Figure 2). The

hole in the center is 3/8” in diameter.

3/8” Hole

for Solenoid

Actuator

Screw Holes to Mount

Solenoid (2)

Figure 2. Laminar Jet Assembly - Bottom View

The LPC4 includes the following parts that can be

installed in up to two Laminar Jets:

• two (2) 24 VAC Solenoid Valves

(model number LPC4-S) with 50 ft cable

(see Figure 1)

• four (4) #10 x 5/8” stainless steel screws

• two (2) adhesive backed 3/8” rubber pads

3/8” Adhesive

Backed Rubber

Pad

(1 pad per Solenoid

Valve Assembly)

Red Plastic

Cap

2. Take the 3/8” rubber pad out of the solenoid

actuator kit and remove the adhesive strip off

the back of the rubber pad. Then press the pad

into the center 3/8” hole. The adhesive on the

back of the pad will secure the pad in the hole.

3. Carefully remove and discard the red plastic

protective plug over the solenoid actuator.

Ensure O-ring is on this end (see Figure 3).

CAUTION

Be sure not to lose the metal striker and spring

assembly.

NOTE The metal striker, spring, and o-ring must be

installed for unit to operate.

Pad

Note: Flat side

Metal

Striker

Spring

towards

Laminar

Note: Pointed end

towards

Solenoid

5/8” Stainless Steel Screws

(2 per Solenoid Valve Assembly)

Figure 1. Solenoid Valve Assembly

O-ring

Solenoid

Figure 3. Solenoid Spring Assembly

Page 6

Page 6

4. Slip the solenoid and striker into the 3/8” hole

and align the two (2) screw holes. Secure in place

with two #10 x 5/8” stainless steel screws (see

Figure 4).

LPC4 Solenoid

Figure 4. Laminar Jet Assembly - Solenoid Mounted

NOTE The control panel should be mounted vertically

on a fl at surface. Locate the control panel at least

one (1) foot (305mm) above the ground and at

least 5 feet away from a pool, spa or fountain.

Ensure that the fi ber optic and LPC4 control wiring

is hardwired to the fi ber optic light source, unless

using an AquaLink RS control system. If using in

an AquaLink RS control system, ensure the fi ber

optic and LPC4 control wiring is connected to the

load side of an AUX relay in the Power Center.

1. Open the cover to the box of the control panel

and remove the two (2) screws holding the

control panel.

2. Remove the green 10-pin terminal bar located

on the printed circuit board (PCB), on back of

the control panel. Set control panel aside.

NOTE This control panel requires listed (for example,

UL, CSA) and properly rated ½” watertight conduit

fittings for all wiring conduits. These conduit

fi ttings are not provided with the product.

3. Locate the knockouts on the bottom of the control

panel. Using a screwdriver, tap out the knockout

on the control panel at desired conduit locations.

Remove any burrs of plastic in opening.

NOTE On the Laminar Jet Deck Box, ensure that conduit

for the fi ber optic/electrical cables is plumbed to

the port marked Electrical.

5. Route the wiring cable from the solenoid

assembly through the Laminar Jet Deck Box

port marked Electrical and through the conduit

to the LPC4 control panel.

Section 4. Control Panel Installation

WARNING

Risk of Electric Shock which can result In

Serious Injury or Death. Before attempting

installation or service, ensure that all power

to the circuit supplying power to the system is

disconnected or turned off at the circuit breaker .

Connect only to a circuit protected by a ground

fault circuit-interrupter (GFCI).

All wiring must be done in accordance with

the National Electric Code (NEC), NFPA-70.

All applicable local installation codes and

regulations must be followed.

NOTE Connect the conduit hub to the conduit before

connecting the hub to the control panel. This

will eliminate any stress placed upon the plastic

controller enclosure from the incoming conduit

and hubs.

4. Install the fi tting securely into control panel

conduit opening, making sure that the fi tting is

seated fl at against the control panel. This will

ensure a watertight seal.

5. Locate the three (3) mounting holes available on

the control panel. Mount the control panel to a

vertical surface.

6. On the lower right-hand side of the control

panel, locate the green ground wire. Connect

the ground wire securely to incoming ground

on the transformer using the provided wire nut.

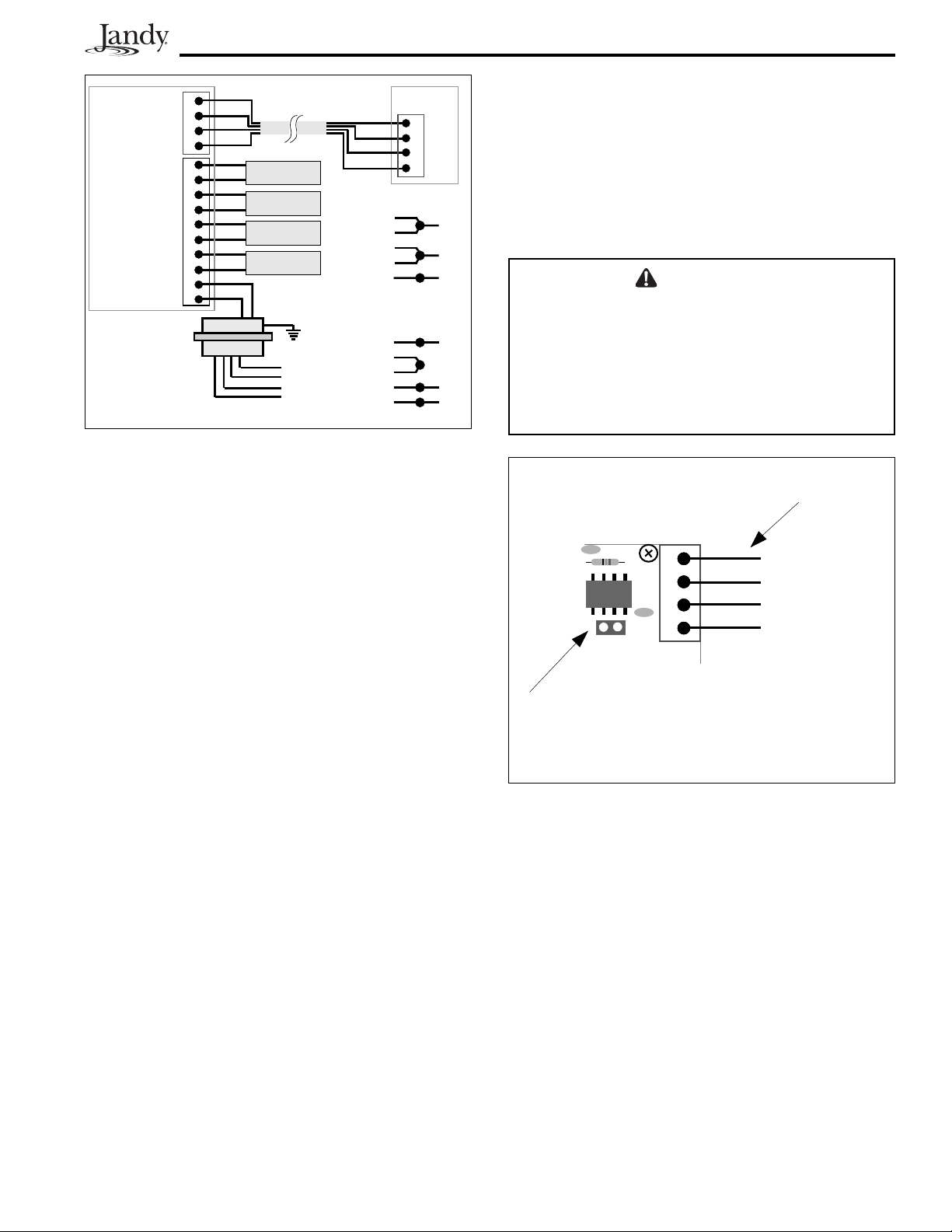

Refer to the wiring diagram in Figure 5.

7. Connect the input power source, either 1 10VAC

or 220VAC, using the wiring diagram in Figure

5 as a reference.

Page 7

Page 7

RED

BLK

YEL

GRN

RED

BLK

GRN

RED

BLK

GRN

Optional

Remote

4321

WHT

BLK

GND

BLK

BLK

GND

LPC4 CONTROL PANEL PCB

4

321

8

765109

4

321

Transformer

GRN

YEL

BLK

RED

BRN

BRN

24VAC

SOLENOID 4

SOLENOID 3

SOLENOID 2

SOLENOID 1

RED

WHT/BLK

WHT/RED

BLK

GRN

Transformer 110VAC

WHT/RED

WHT/BLK

Transformer 220VAC

WHT/RED

WHT/BLK

Figure 5. LPC4 Wiring Diagram

Section 5. Low Voltage Wiring

Installation

Ensure the solenoid valve is installed in the Laminar

Flow Jet prior to starting the following procedure.

1. Route the solenoid cable in the same conduit as

the fi ber optic.

NOTE A jumper is included in the LPC4 Remote Control

Panel (LPC4-R) that allows the control panel

to provide power to the LPC4 Remote. Install

this jumper on the 2-pin header on the control

panel PCB only when connecting the LPC4

control panel to the LPC4 Remote or connecting

multiple control panels to the remote panel (see

Figure 6).

CAUTION

When connecting multiple control panels to the

LPC4 Remote, install the jumper on the header

of only one control panel.

Do not install this jumper if connecting the LPC4

control panel to a Jandy AquaLink RS system.

Red 4-pin

Terminal Bar

C13

C12

D4

GRN

4

YEL

321

BLK

RED

2. Connect the wires of each solenoid into the green

10-pin terminal bar. Refer to Figure 5 for the

connection location for each solenoid wire.

NOTE Use 1/8” screwdriver to tighten terminal screws

fi rmly. Route the solenoid wires on left side of

control panel.

3. If using the LPC4 Remote or a Jandy AquaLink

RS control panel, connect the 4-conductor wire

to the red terminal bar in the control panel. Refer

to Figure 5 for the connection location for each

wire. Tighten the terminal screws fi rmly.

2-pin Header for Jumper

Note: Install Jumper only in the LPC4 Control Board

when connecting the LPC4 Control Panel to

the LPCR1001 Remote Panel.

Figure 6. Jumper Installation in the LPC4 Control

Board - Cut Away View

4. Reconnect the 10-pin terminal bar to the back

of the control panel. Install the top cover using

the two (2) screws removed in Section 4,

Step 1.

Page 8

Page 8

Section 6. Control Panel Operation

R

a

n

d

o

Off

Group

Single

m

P

a

Slow

Fast

Remote

t

t

e

r

n

Fast

d

e

m

Med

i

T

Slow

Off

Figure 7. LPC4 Control Panel Knob

The LPC4 control panel knob has nine (9) operable

settings (see Figure 7). The operating positions are

as follows:

• OFF - Turns off all pulse control to all Laminar

Jets.

• Timed - Provides a synchronous pulse to all

Laminar Jets in any one of the following three

(3) timed settings.

Slow - Pulse occurs every eight (8) seconds

Medium - Pulse occurs every four (4) seconds

Fast - Pulse occurs every one (1) second

Section 7. LPC4 Remote Installation

The LPC4 Remote allows you to operate the control

panel from alternate locations.

1. Remove the four (4) screws located under the

spring-loaded cover on the remote panel.

Remove the cover and set aside.

NOTE The remote panel PCB is located on the back of

the cover.

2. Locate the four (4) mounting holes available on

the remote panel. Mount the remote panel to a

vertical surface.

3. Install a conduit fi tting securely into the remote

panel knockout, making sure that the fi tting is

seated fl at against the remote panel. This will

ensure a watertight seal.

4. Run a 4-conductor 22-gauge, color-coded cable

in a conduit from the LPC4 control panel to the

location for the LPC4-R remote panel.

5. On the remote panel PCB, locate the red, 4-pin

terminal bar. Connect the 4-conductor wire

to the terminal bar on the remote panel (see

Figure 5, page 7). Tighten the terminal screws

fi rmly.

6. Install the remote panel cover using the four (4)

screws removed in Step 1.

• Random - Provides pulse to Laminar Jets at

random time intervals.

Group - All Laminar Jets pulse at random

Single - Each Laminar Jet pulses at random

• Pattern - Provides a pulse sequence to all Laminar

Jets in any one of the following two (2) timed

settings.

Slow - Sequence is time delayed at slow

speed

Fast - Sequence is time delayed at rapid

speed

Remote - Transfers control of all functions to the

•

optional Remote Panel or Jandy AquaLink RS

control panel.

Section 8. Remote Panel Operation

To transfer control to the remote panel or the Jandy

AquaLink RS, turn the LPC4 control panel knob to

the Remote operating position (see Figure 7). The

remote panel can then control the pulse functions of

the Laminar Jets.

Page 9

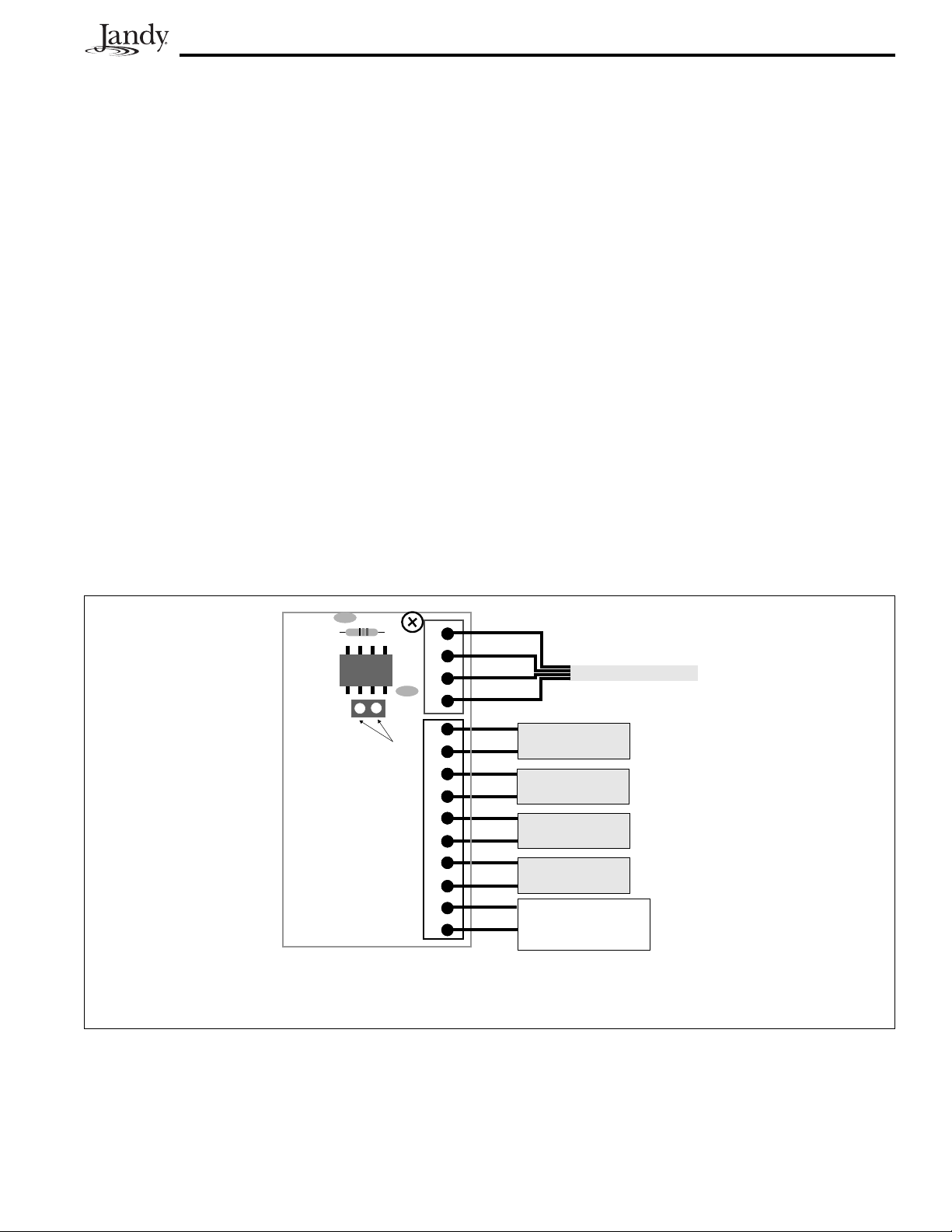

Section 9. System Wiring Diagrams

The LPC4 system can be confi gured for various

system set ups, including the following:

• Single controller

• Single controller with LPC4-R Remote Panel

• Multiple controllers and one LPC4-R Remote

Panel

• Single controller operated by the Jandy AquaLink

RS

Page 9

• Multiple controllers operated by the Jandy

AquaLink RS

NOTE When connecting to a Jandy AquaLink RS, ensure

that the LPC4 control panel PCB is revision

P090r4 or later.

Refer to the wiring diagrams, Figures 8 through 12, on

the following pages to view system confi gurations.

C13

4

321

C12

D4

No Jumper

Installed

8

765109

GRN

YEL

BLK

RED

SOLENOID 4

SOLENOID 3

LPC4 CONTROL PANEL PCB

Note: Install Jumper only in the LPC4 Control Board

when connecting the LPC4 Control Panel to

the LPC4-R Remote Panel.

Figure 8. LPC4 Wiring, Single Controller

SOLENOID 2

4

321

BRN

BRN

SOLENOID 1

24VAC

TRANSFORMER

Page 10

Page 10

LPC4 REMOTE

C13

C12

D4

GRN

4

YEL

321

BLK

RED

RED

BLK

YEL

GRN

4321

Jumper

Installed

8

765109

SOLENOID 4

SOLENOID 3

SOLENOID 2

LPC4 CONTROL PANEL PCB

4

321

BRN

BRN

SOLENOID 1

24VAC

TRANSFORMER

Note: Install Jumper only in the LPC4 Control Board

when connecting the LPC4 Control Panel to

the LPC4-R Remote Panel.

Figure 9. LPC4 Wiring, One Controller with an LPCR1001 Remote Panel

LPC4 REMOTE

RED

BLK

YEL

GRN

GRN

YEL

BLK

RED

4321

LPC4 CONTROL PANEL PCB

C13

Jumper

Installed

4

321

C12

D4

8

765109

4

321

GRN

YEL

BLK

RED

SOLENOID 4

SOLENOID 3

SOLENOID 2

SOLENOID 1

C13

D4

No Jumper

Installed

C12

BRN

BRN

24VAC

TRANSFORMER

LPC4 CONTROL PANEL PCB

Note: Install Jumper only in the LPC4 Control Board

when connecting the LPC4 Control Panel to

the LPC4-R Remote Panel.

When connecting multiple control panels to

the LPC4 Remote, install the jumper on the

header of only one control panel.

Figure 10. LPC4 Wiring, Multiple Controllers with an LPCR1001 Remote Panel

4

321

GRN

YEL

BLK

RED

SOLENOID 4

8

765109

SOLENOID 3

SOLENOID 2

4

321

SOLENOID 1

BRN

BRN

24VAC

TRANSFORMER

Page 11

RED

BLK

YEL

GRN

Dip Switch Settings

Factory Set Optional Set

#OFF

ON

1Aux1

Cleaner

2 spd pump

21spdpump

3Aux3

Spa Spillover

4 Cool Down

Disabled

5 See Manual

See Manual

6 Spare Aux Pool

SpareAux Spa

7 Not Used

Not Used

8 Gas Heater

Heat Pump

artment)

Red

Black

Green

Yellow

Green

Black

Red

4321 654321

ToRemote

ToController

(brown term. bar)

(red term. bar)

Relay Sockets (24 VDC output)

F.Pump Aux. 1 Aux. 2 Aux. 3

Freeze/

White

Brown

Blue

Red

Not Used

Not Used

10987654321

ToSensors, etc.

(green term. bar)

Solar

Sensor

Air Sensor

Water Temp .

Sensor

Return

Voltage

Intake

Black

Red

Black

Low

Heater

JVA

(24 VAC output)

Relay Sockets (24 VDC output)

JVA

Cleaner

JVA

JVASockets

Aux. 7Aux.6Aux. 5Aux. 4

Solar

JVA

Elect.

Heater

Solar

Pump

Relay Sockets

(24 VDC output)

Battery

(9Volt)

Page 11

Jandy AquaLink RS

Remote

Filter Pump Relay

age wire in this comp

Aux. 1 Relay

age Raceway (do not run high volt

Line Two

Line One

Low Volt

Load One

Aux. 3 Relay

Aux. 2 Relay

Load Two

Aux. 4 Relay Aux. 7 Relay

Grounding Bar

Aux. 6 RelayAux. 5 Relay

System Power

120 VAC Power

Wire Nut to

Jandy AquaLink RS

C13

4

321

C12

D4

No Jumper

Installed

8

765109

GRN

YEL

BLK

RED

SOLENOID 4

SOLENOID 3

SOLENOID 2

LPC4 CONTROL PANEL PCB

4

321

SOLENOID 1

BRN

BRN

TRANSFORMER

Figure 11. LPC4 Wiring, One Controller with a Jandy AquaLink RS

CAUTION

Do not install this jumper if connecting the LPC4

control panel to a Jandy AquaLink RS system.

24VAC

Page 12

Page 12

RED

BLK

YEL

GRN

Dip Switch Settings

Factory Set Optional Set

#OFF

ON

Cleaner

1Aux1

2 spd pump

21spdpump

Spa Spillover

3Aux3

Disabled

4 Cool Down

See Manual

5 See Manual

SpareAux Spa

6 SpareAux Pool

Not Used

7NotUsed

Heat Pump

8 Gas Heater

artment)

Red

Black

Yell ow

Green

Black

Red

4321 654321

To Re mo te

ToController

(brown term. bar)

(red term. bar)

Relay Sockets (24 VDC output)

F.Pump Aux. 1 Aux. 2 Aux. 3

Green

White

Brown

Blue

Not Used

10987654321

ater Temp.

Solar

Sensor

age

Freeze/

Air Sensor

W

Sensor

Red

Black

Not Used

Red

Black

Low Volt

ToSensors, etc.

(green term. bar)

Relay Sockets (24 VDC output)

Heater

Intake

JVA

Return

JVA

Cleaner

JVA

JVASockets

(24 VAC output)

Aux. 7Aux. 6Aux. 5Aux. 4

Solar

JVA

Elect.

Heater

Solar

Pump

Relay Sockets

(24 VDC output)

Battery

(9Volt)

Jandy AquaLink RS

Remote

C13

Filter Pump Relay

age wire in this comp

Aux. 1 Relay

age Raceway (do not run high volt

Line One

Low Volt

Load One

Aux. 3 Relay

Aux. 2 Relay

Line Two

Load Two

Aux. 4 Relay Aux. 7 Relay

Grounding Bar

Aux. 6 RelayAux. 5 Relay

System Power

Wire Nut to

120 VAC Power

Jandy AquaLink RS

GRN

YEL

BLKBLK

RED

4

321

C12

D4

GRN

YEL

YEL

BLK

RED

C13

4

321

C12

D4

GRN

YEL

BLK

RED

No Jumper

Installed

8

765109

SOLENOID 4

SOLENOID 3

No Jumper

Installed

SOLENOID 2

LPC4 CONTROL PANEL PCB

4

321

SOLENOID 1

LPC4 CONTROL PANEL PCB

BRN

BRN

24VAC

TRANSFORMER

Figure 12. LPC4 Wiring, Multiple Controllers with a Jandy AquaLink RS

CAUTION

Do not install this jumper if connecting the LPC4

control panel to a Jandy AquaLink RS system.

SOLENOID 4

8

765109

SOLENOID 3

SOLENOID 2

4

321

SOLENOID 1

BRN

BRN

24VAC

TRANSFORMER

Page 13

Section 10. Parts List and

Exploded View

Number Description Part

Number

1 LPC4 Control Panel PCB,

Dead Panel w/Stand-offs,

Knob and Screws

2 Transformer R0410400

3 Control Panel Box,

w/Brackets and Screws

4 Solenoid Spring, Hammer,

and Pad (qty. 4)

5 Remote Panel PCB w/Red

Connector and Knob

6 Solenoid w/50 ft cable,

Spring, Hammer and Pad

7 LPC4 Remote LPC4-R

8 LPC4 Controller and 2

Solenoids

(each Solenoid w/50 ft cable)

R0410300

R0410500

R0410600

R0410800

LPC4-S

LPC4

Page 13

4

6, 8 (x2)

10 ¼

32

1

5

7

8

6¾

"

2¾"

"

10 ¼

5

9

/16"

"

5"

5

/8"

4

5¼"

4

"

5¾

"

Side View Front View

LPC4 Control Panel Dimensions

3½"

37/8"

Side View Front View

LPC4 Remote Panel Dimensions

Page 14

Page 14

NOTES

Page 15

Page 16

LIMITED WARRANTY

Thank you for purchasing Jandy® pool and spa products. Jandy Pool Products, Inc. warrants all parts to be free

from manufacturing defects in materials and workmanship for a period of one year from the date of retail

purchase, with the following exceptions:

AquaLink® RS units installed with Jandy Surge Protection Kits will be covered for two years.

•

NeverLube® valves are warranted for the life of pool and/or spa on which they were originally installed.

•

AquaPureTM Electronic Chlorine Generator Electrolytic Cells carry a 5 year limited warranty on a prorated basis.

•

This warranty is limited to the first retail purchaser, is not transferable, and does not apply to products that have

been moved from their original installation sites. The liability of Jandy Pool Products, Inc. shall not exceed the

repair or replacement of defective parts and does not include any costs for labor to remove and reinstall the

defective part, transportation to or from the factory, and any other materials required to make the repair. This

warranty does not cover failures or malfunctions resulting from the following:

1. Failure to properly install, operate or maintain the product(s) in accordance with our published Installation,

Operation and Maintenance Manuals provided with the product(s).

2. The workmanship of any installer of the product(s).

3. Not maintaining a proper chemical balance in your pool and/or spa [pH level between 7.2 and 7.8, Total

Alkalinity (TA) between 80 to 120 ppm, Total Dissolved Solids (TDS) less than 2000 not including salt ppm].

4. Abuse, alteration, accident, fire, flood, lightning, rodents, insects, negligence or acts of God.

5. Scaling, freezing, or other conditions causing inadequate water circulation.

6. Operating the product(s) at water flow rates outside the published minimum and maximum specifications.

7. Use of non-factory authorized parts or accessories in conjunction with the product(s).

8. Chemical contamination of combustion air or improper use of sanitizing chemicals, such as introducing

sanitizing chemicals upstream of the heater and cleaner hose or through the skimmer.

9. Overheating; incorrect wire runs; improper electrical supply; collateral damage caused by failure of O-Rings,

DE grids, or cartridge elements; or damage caused by running the pump with insufficient quantities of water.

LIMITATION OF LIABILITY:

This is the only warranty given by Jandy Pool Products, Inc. No one is authorized to make any other warranties

on behalf of Jandy Pool Products, Inc. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF FITNESS

FOR A PARTICULAR PURPOSE AND MERCHANTABILITY. JANDY POOL PRODUCTS, INC. EXPRESSLY

DISCLAIMS AND EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL, INCIDENTAL, INDIRECT OR

PUNITIVE DAMAGES FOR BREACH OF ANY EXPRESSED OR IMPLIED WARRANTY. This warranty gives

you specific legal rights. You may also have other rights which vary by state or province.

WARRANTY CLAIMS:

For prompt warranty consideration, contact your dealer and provide the following information: proof of purchase,

model number, serial number and date of installation. The installer will contact the factory for instructions

regarding the claim and to determine the location of the nearest designated service center. If the dealer is not

available, you can locate a service center in your area by visiting www.jandy.com or by calling our technical

support department at (707) 776-8200 extension 260. All returned parts must have a Returned Material

Authorization number to be evaluated under the terms of this warranty.

H0566900A

6000 Condor Drive • Moorpark, CA USA 93021 • 707.776.8200 • Fax 707.763.7785

Litho in U.S.A. © Jandy Pool Products, Inc. 0509

Jandy Pool Products, Inc.

Loading...

Loading...