Page 1

Installation and Operating Data

Installation and

Operation Manual

Jandy® Laminar

Jet with Deck Box

WARNING

FOR YOUR SAFETY - This product must be installed and serviced by a pro fes sion al pool/spa

service technician. The procedures in this manual must be followed ex act ly. Failure to follow

warning notices and instructions may result in property damage, serious injury, or death.

This manual contains important information about the installation, operation and safe use of

this product. This information should be given to the owner/operator of this equipment.

H0565200B

Page 2

Page 3

Page 3

Section 1. General Installation

Requirements

This document gives in struc tions for installing the

Jandy Laminar Jet. Read through the in struc tions

com plete ly before starting the pro ce dure.

The Jandy Laminar Jet is designed to provide a clear

stream of water that arcs up to a maximum of seven

feet (7') high and eight feet (8') out into the water.

Its design provides for the option to light the arc of

water with fi ber optics creating a daz zling nightime

effect. This unique water feature is easily installed and

multiple jets can be com bined to create spec tac u lar

water en ter tain ment.

To properly install this product please review the

following installation and main te nance in struc tions.

1.1 Water Source

The Laminar Jet water supply line must be fi ltered

by a cartridge fi lter (do not use a sand fi lter). If you

are using a dedicated fi lter - it must be a minimum of

20 square feet. For multiple jet installations, use 100

square feet, such as the Jandy CT100.

1.5 Critical Placement Dimensions

The Laminar Jet can project a maximum of seven feet

(7') up and eight feet (8') out into the water. Therefore,

ensure the installation is no more than six feet (6')

from the inside edge of the pool.

NOTE To avoid water spray on the deck in high wind

areas, place the Laminar Jet closer to the edge

of the pool.

NOTE The Deck Box lid can only rotate approximately 30

degrees to the left or the right. Therefore, make

sure that the Deck Box is positioned towards the

desired target location (see Section 2) prior to

completing the installation.

1.6 Bonding

NOTE Only units with metal mounting brackets require

bonding.

The Laminar Jet assembly mounting brackets (metal

only) must be bonded to the pool/spa structure using a

solid copper conductor, No. 8 A WG or lar ger. Prepare

the unit for bonding prior to installation. Bond the

unit using the external lug provided to a steel rod in

the deck frame or metal piping within fi ve feet (5’)

of the inside walls of the pool.

1.2 Pump

Required minimum pump fl ow for each Laminar

Jet is approximately 10 gallons per minute (gpm).

If a dedicated pump is used, a minimum of ½ HP is

required and the pump must produce the required fl ow

at a minimum of sixteen feet (16') of head.

1.3 Plumbing

Each Laminar Jet requires a 1½" to 2" PVC main

feed line with 1" PVC entering the Deck Box. An

adjustment valve and a check valve are also required.

Valves should be placed as far from the Deck Box

as possible to minimize water turbulence (refer to

Figures 1 and 2 and Table 1).

1.4 Conduit/Fiber Optics (Optional)

If installing fiber optics, each Laminar Jet will

require 100 to 150 strand fi ber optic cable. 150 strand

cable is recommended due to the enhanced lighting

effects. Install a 120 VAC line as per the fi ber optic

manufacturer and local code requirements.

Locate the four bonding lugs on the unit. One lug

is mounted on each side of the jet assembly metal

mounting bracket (2 total). One lug is mounted on

the inner wall of the Deck Box above the water inlet

standpipe. The remaining lug is mounted on the outer

wall of the box, directly connected to the inner lug.

Page 4

Page 4

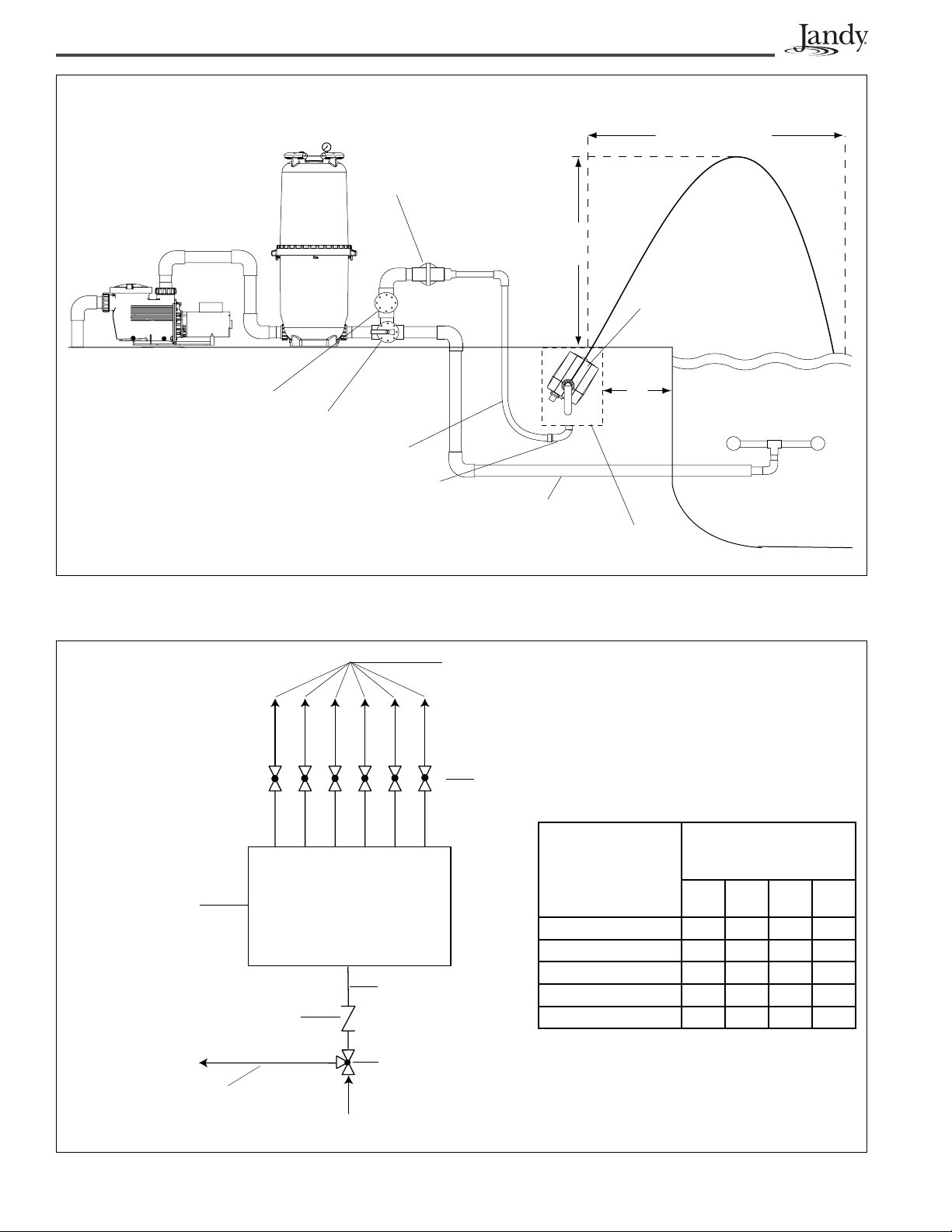

Pump

Filter

Adjustment Valve

(Globe Valve

Recommended)

Water Throw

8' Maximum

Water Height

7' Maximum

Jandy Laminar

Nozzle

Check Valve

Jandy 3-Port Valve

Use 5 feet of 1" PVC flex pipe.

Use 1” sweep elbow.

2" Pipe

Figure 1. Basic Plumbing Diagram for Laminar Jet with Deck Box

"C" -

Inlet Lines to

Laminar Jet Deck

Box

(Maximum 6 Lines

per Plumbing Loop)

Globe Valves

"B" - Plumbing

Loop

"A" - Main Feed Line

Check Valve

6'

max

Laminar Deck Box

Table 1. Multiple Jet Setup

Number of Deck

Jets at rate of 10

GPM

(gallons per

minute)

2 1½" 1"

3 1½" 1½"

4 2" 1½"

5 2" 1½"

6 2" 1½"

Return Lines

Recommended Pipe

Size within 25' of

equipment

ABCD

1"

1"

1"

1"

1"

1½"

1½"

2"

2"

2"

Jandy 3-Port Valve

"A"

"D" - Bypass/Bleed Off Line

(P/N 4715 if

Note: If using a high head pump,

plumb a cartridge filter inline.

Figure 2. Plan View of Plumbing Loop for Multiple Laminar Jets

is 1½" or P/N 4717 if "A" is 2")

Page 5

Page 5

Section 2. Installing the Deck Box

NOTE Prior to installing the Jandy Laminar Jet Deck Box,

locate the jet opening (slot) in the Deck Box cover.

Make sure that this opening is pointing towards

the desired target location in the pool. Use the

water stand pipe as a reference (see Figure 3).

Determining the orientation of the Deck Box will

also establish where to place the plumbing and

fi ber optic conduit.

Water Output

Deck Box

Lid with Slot

Deck Material Deck Material

Laminar

Jet

Assembly

Water Inlet to

Jet Assembly

(2 - 1/2" Unions)

Deck Box Lid

Adjustable Collar

Deck Box

Water

Standpipe

Sweep Elbow

1" Laminar Jet

Water Supply

2. Lift up the Deck Box lid and adjustable

deck lid collar from the Deck Box (see

Figure 4). Notice that the Laminar Jet assembly

is connected to the Deck Box lid as one unit.

Disconnect the two (2) ½” unions located on

the bottom of the Laminar Jet assembly (see

Figure 3). Set the lid/jet assembly aside.

13 ¾"

12"

21"

18"

1" Fiber

Optic Conduit

Figure 3. Laminar Jet Deck Box Schematic

NOTE The Deck Box lid can only rotate approximately 30

degrees to the left or the right. Therefore, make

sure that the Deck Box is positioned towards the

desired target location prior to completing the

installation.

1 1/2" Drain

Line

2.1 In-deck Installation

1. Dig the hole for the Deck Box approximately

twenty-four inches (24”) deep and eighteen

inches (18”) in diameter. This will ensure enough

room for positioning the box and laying out the

plumbing. This depth also allows for the addition

of a layer of pea gravel (1/8 to ¼ size) for stability

and additional drainage.

Figure 4. Deck Box Dimensions

3. Set the Deck Box in the hole. The Deck Box

should sit deep enough so that the upper edge

of the box will be approximately one and one

half to two inches (1½”-2”) below the surface

of the finished deck, after the deck material is

poured.

NOTE T o ensure that the box stays upright while installing

and leveling the unit, place a six inch (6”) length

of one and one half inch (1½”) PVC pipe in the

construction support socket located on the bottom

of the box (see Figure 5).

4. Level the Deck Box. To hold the box in place

while the deck is poured, secure the box by

tying it with tie wire to the steel framework of

the deck.

Page 6

Page 6

5. Plumb the incoming, filtered water supply

to the one inch (1") hub located on the

bottom of the Deck Box marked

Inlet (see

Figure 5). The filtered water supply must

include an adjustment valve and check valve

(see Figures 1 and 2 ).

Construction Support

Socket (1½")

Water Inlet (1")

Drain (1½")

8. (For units with metal mounting brackets only .)

To bond the Laminar Jet, connect one end of a

copper wire to the external lug located on the

box bottom and the other end to the steel frame

of the deck.

9. Verify the Deck Box is level.

10. Place the adjustable deck lid collar back on the

box. This collar allows the installer to make fine

adjustments when leveling the box to be flush

with the deck's finished surface. Set the collar

at the finished deck level and pour the deck.

2.2 Out-of-deck/Planter Box Installation

NOTE Do not install the Jandy Laminar Jet Deck Box in

an area prone to run-off or fl ooding.

NOTE The Deck Box lid can only rotate approximately 30

degrees to the left or the right. Therefore, make

sure that the Deck Box is positioned towards the

desired target location prior to completing the

installation.

Fiber Optic/Low Voltage

Electrial Inlet (1")

Figure 5. Deck Box - Bottom View

Caution

Deck Box is made of ABS. Use Weld-On 793

or 794 ABS-PVC Cement to glue Schedule 40

PVC.

6. Plumb the conduit for the fiber optic cable to

the one inch (1") hub located on the bottom of

the Deck Box marked

Electrical

(see Figure 5). Refer to Section 3 for

Fiber Optic/Low V oltage

fiber optic installation.

NOTE This hub is also used to install the two (2)

conductor, eighteen (18) gauge, stranded cable

for the optional LPC4 light pulse control system.

7. Plumb in the one and one-half inch (1½") drain

line marked Drain. Adequate drainage must be

provided to box.

NOTE Proper drainage to the Deck Box is critical to avoid

damage to the Laminar Jet assembly.

1. Dig the hole for the Deck Box approximately

twenty-four inches (24") deep and eighteen

inches (18") in diameter. This will ensure enough

room for positioning the box and laying out

the plumbing. The dimensions allow for the

addition of a layer of pea gravel (1/8 to 1/4 size)

for drainage, as well as room to pour concrete

around the outside of the box for stability.

NOTE Proper drainage to the Deck Box is critical to avoid

damage to the Laminar Jet assembly.

2. Lift up the lid/jet assembly and adjustable deck

lid collar from the Deck Box. Disconnect the

two (2) ½" unions located on the bottom of the

Laminar Jet. Set the lid/jet assembly aside.

NOTE T o ensure that the box stays upright while installing

and leveling the unit, place a six inch (6") length

of one and one half inch (1½") PVC pipe in the

construction support socket located on the bottom

of the box (see Figure 5).

3. Set the Deck Box in the hole. The box should

be approximately one and one-half to two

inches (1½"-2") above the finished grade in the

planter.

Page 7

Page 7

NOTE Unlike the in-deck installation, the Deck Box cover

cannot be fl ush with the fi nished grade. It must sit

slighty above the surface to prevent water and

debris from seeping into the box.

4. Level the Deck Box. To hold the box in place,

position a six inch (6") length of one and one

half inch (1½") PVC pipe is needed in the

construction support socket located on the

bottom of the box (see Figure 5). In include an

adjustment valve and check valve (see Figures

1 and 2).

5. Plumb the incoming, filtered water supply

to the one inch (1”) hub located on the

bottom of the Deck Box marked Inlet (see

Figure 5). The filtered water supply must include

an adjustment valve and check valve (see

Figures 1 and 2 ).

Caution

Deck Box is made of ABS. Use Weld-On 793

or 794 ABS-PVC Cement to glue Schedule 40

PVC.

2.3 Pressure Test Water Lines

Connect the two (2) ½" unions removed from the

Laminar Jet in Section 2.1, Step 2 (or Section 2.2,

Step 2 for out-of deck installation) together. This

will provide an air/water tight closed loop during the

pressure test.

NOTE This same procedure can be used if you need to

winterize the system or service the unit.

2.4 Flush Water Lines

It is important that prior to reinstalling the Laminar

Jet and Deck Box lid, the installer must turn on the

water source and fl ush the lines of any debris.

6. Plumb the conduit for the fiber optic cable to

the one inch (1") hub located on the bottom of

the Deck Box marked Fiber Optic/Low V oltage

Electrical

. Refer to Section 3 for fiber optic

installation.

NOTE This hub is also used to install the two (2)

conductor, eighteen (18) gauge, stranded cable

for the optional LPC4 light pulse control system.

7. Plumb in the one and one-half inch (1½") drain

line marked Drain. Adequate drainage must be

provided to box.

8. (For units with metal mounting brackets only .)

Connect one end of a copper wire to the external

lug located on the box bottom. Connect the other

end to the steel rod used to stake the Deck Box,

or bond per the National Electrical Code.

9. Fill in the hole surrounding the Deck Box with

concrete or suitable backfill material for stability

in the ground.

10. Place the adjustable deck lid collar back on the

box.

Page 8

Page 8

Section 3. Fiber Optic Installation

3.1 Items Required

Tools

Cable

Illuminator

Additional

Materials

3.2 Installation

1. Remove six inches (6") of the cable jacket.

2. Using black electrical tape, tightly tape over the

exposed fiber leaving approximately ½" exposed

fiber at the end of the cable. The tape prevents the

individual fibers from separating.

Utility knife or hot knife; Heat gun or

propane torch.

Each jet requires 100 to 150 strands

of fiber optic cable. Do not use

more than forty feet (40') of cable

per nozzle as light output will be

diminished.

Use illuminator with sufficient

capacity of lighting effect intended.

Electrical tape; Silicon (RTV)

Section 4. Starting the System

4.1 Install Jet Assembly

1. Disconnect the two unions that were attached

together for pressure testing in Section 2.3.

2. Flush water lines to clear debris. Lines must be

clear of debris before attaching the Laminar

Jet assembly.

3. Connect the two unions to the appropriate

ports of Laminar Jet and Deck Box lid.

4.2 Set up Jet

Recall that the Deck Box lid and Laminar Jet are

attached to each other. To aim the jet, turn the lid

with the slot facing the pool until the stream reaches

the intended target area of the pool.

1. Turn on the water at a reduced rate and slowly

fill the unit. When the unit is filled, increase

the water supply until the jet streams reach

their intended targets.

3. With a heat knife, cut the fiber optic cable so that

the cable end is a flat surface. For best results, heat

knife to cherry red.

NOTE Do not cut the fi ber ends too close to the taped edge.

Leave a ¼" distance between the cable end and the

end of the taped edge. This will prevent adhesive on

the tape from melting and getting on the ends of the

fi ber optic strands.

4. Slide the completed fiber optic cable through the

Heyco waterproof fitting and up the tube (located at

the bottom of the jet) until the cable bottoms out on

the lens inside unit. Secure the fiber by tightening

the waterproof fitting.

NOTE Allow at least two feet (2') of extra fi ber optic cable

in the Deck Box to allow the Laminar Jet to be easily

removed.

5. Fill the electrical conduit between the opening and

the fiber optic cable with RTV silicon to prevent

water from entering the conduit. Let dry . The unit

is now ready for operation.

2. Use the main valve at the equipment pad to

make final adjustments to the overall water

height of the jets.

NOTE Laminar Jets are sensitive to wind, earth

movement and equipment vibration. Secure the

Laminar Jet and Deck Box to minimize vibration.

Periodic stream distortion caused by pump

vibrations and motor electrical fl uctuations is

normal and not indicative of a nozzle defect.

Also, occasionally a nozzle will “burp” due to

pumped air collecting in the nozzle body . This is

normal and will occur until all air is purged from

the piping system. Trapped air can also cause

slight distortion in water action. It is imperative

that all air is removed to ensure proper water

feature operation.

6. Install illuminator and attach fiber optic cable

according to instructions supplied with the

illuminator.

Page 9

Page 9

NOTE To adjust the angle of the jet, lift the Deck Box lid

and move the Laminar Jet up or down to increase

or decrease the angle. The angle can be adjusted

approximately 15 degrees. The Laminar Jet is

installed on two pivots. Loosen the union nuts on

the pivots and adjust the jet angle. Once you are

satisfi ed with the angle and location of the jet,

tighten the union nuts. Secure the Deck Box lid to

the Deck box collar, using two #10 by 1½", Phillips,

fl at head stainless steel screws (see Figure 6). It

is recommended to drill 1/8" pilot holes in the lid.

Then the screws can be threaded into the holes.

This will complete the installation and secure the

jet from movement.

Phillips-head

Screws

Jet Slot

Opening

Deck Box

Lid

Deck Lid

Adjustable

Collar

3. Using a garden hose, place the hose over the jet

nozzle and force water backward through the

unit and out the two ½" open unions. This will

clear debris buildup.

NOTE Avoid damage to the nozzle opening. After clean

up, reinstall the unions and reattach the unit to

the Deck Box.

5.2 Winterization

The Laminar Jet can be winterized in regions that

require winterization.

1. Remove the Deck Box lid assembly and unscrew

the two ½" unions.

2. Attach the two unions to each other to create

an air/water tight system. The Laminar Jet can

then be replaced in the Deck Box or may be

removed to a storage location. If left in the Deck

Box, tape over the slot opening to ensure no

water will enter the system. If fiber optic cable

is used, be sure to remove the retaining nut on

the waterproof fitting on the bottom of the jet

assembly.

Figure 6. Deck Box Lid with Collar

Section 5. General Maintenance and

Troubleshooting

Perform routine maintenance on the fi lter to ensure

trouble-free nozzle operation. Be careful not to allow

debris to enter the inlet plumbing when cleaning

filters. Always flush lines after cleaning and

backwash of fi lters.

5.1 Clogged Nozzle

1. If nozzle becomes clogged with debris, remove

the nozzle by unscrewing the two Deck Box lid

retaining screws.

2. Remove the Deck Box lid assembly and place on

the deck. Disconnect the two ½" unions located

on the bottom of the jet assembly.

Page 10

Page 10

Section 6. Parts List and Exploded

View

Key

No.

Description Qty. Order

Part No.

4, 6

1 Laminar Jet Body

Coupling Nut O-rings

Union O-rings

2 Thermoplastic Brackets

Screws

3 Coupling Nuts

Blank Caps

O-rings

4 Deck Box

Deck Box Lid Screws

1

2

2

2

6

2

2

2

1

2

R0401500

R0401600

R0401700

R0401800

5 Hayco Fitting Complete 1 R0401900

6 Hardware Kit

Laminar Jet Body Screws

Bracket Screws

Deck Box Lid Screws

Union O-rings

Coupling Nut O-rings

Laminar Jet Body

R0411000

8

6

2

2

2

1

O-ring (not shown)

7 Laminar Jet Assembly

1 JLJ1001

w/Deck Box

2, 6

3

9

8

7

6 (x8)

2

1

2, 6

3

8 Deck Box Lid, Pebble

Deck Box Collar, Pebble

9 JLJL Deck Box Lid,

1

JLJL1001

1

1 JLJL1002

Pewter

or JLJL Deck Box Lid, Black 1 JLJL1003

5

4

1, 6

Page 11

Page 11

Page 12

LIMITED WARRANTY

Thank you for purchasing Jandy® pool and spa products. Jandy Pool Products, Inc. warrants all parts to be free

from manufacturing defects in materials and workmanship for a period of one year from the date of retail

purchase, with the following exceptions:

AquaLink® RS units installed with Jandy Surge Protection Kits will be covered for two years.

•

NeverLube® valves are warranted for the life of pool and/or spa on which they were originally installed.

•

AquaPureTM Electronic Chlorine Generator Electrolytic Cells carry a 5 year limited warranty on a prorated basis.

•

This warranty is limited to the first retail purchaser, is not transferable, and does not apply to products that have

been moved from their original installation sites. The liability of Jandy Pool Products, Inc. shall not exceed the

repair or replacement of defective parts and does not include any costs for labor to remove and reinstall the

defective part, transportation to or from the factory, and any other materials required to make the repair. This

warranty does not cover failures or malfunctions resulting from the following:

1. Failure to properly install, operate or maintain the product(s) in accordance with our published Installation,

Operation and Maintenance Manuals provided with the product(s).

2. The workmanship of any installer of the product(s).

3. Not maintaining a proper chemical balance in your pool and/or spa [pH level between 7.2 and 7.8, Total

Alkalinity (TA) between 80 to 120 ppm, Total Dissolved Solids (TDS) less than 2000 not including salt ppm].

4. Abuse, alteration, accident, fire, flood, lightning, rodents, insects, negligence or acts of God.

5. Scaling, freezing, or other conditions causing inadequate water circulation.

6. Operating the product(s) at water flow rates outside the published minimum and maximum specifications.

7. Use of non-factory authorized parts or accessories in conjunction with the product(s).

8. Chemical contamination of combustion air or improper use of sanitizing chemicals, such as introducing

sanitizing chemicals upstream of the heater and cleaner hose or through the skimmer.

9. Overheating; incorrect wire runs; improper electrical supply; collateral damage caused by failure of O-Rings,

DE grids, or cartridge elements; or damage caused by running the pump with insufficient quantities of water.

LIMITATION OF LIABILITY:

This is the only warranty given by Jandy Pool Products, Inc. No one is authorized to make any other warranties

on behalf of Jandy Pool Products, Inc. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF FITNESS

FOR A PARTICULAR PURPOSE AND MERCHANTABILITY. JANDY POOL PRODUCTS, INC. EXPRESSLY

DISCLAIMS AND EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL, INCIDENTAL, INDIRECT OR

PUNITIVE DAMAGES FOR BREACH OF ANY EXPRESSED OR IMPLIED WARRANTY. This warranty gives

you specific legal rights. You may also have other rights which vary by state or province.

WARRANTY CLAIMS:

For prompt warranty consideration, contact your dealer and provide the following information: proof of purchase,

model number, serial number and date of installation. The installer will contact the factory for instructions

regarding the claim and to determine the location of the nearest designated service center. If the dealer is not

available, you can locate a service center in your area by visiting www.jandy.com or by calling our technical

support department at (707) 776-8200 extension 260. All returned parts must have a Returned Material

Authorization number to be evaluated under the terms of this warranty.

H0565200B

6000 Condor Drive • Moorpark, CA USA 93021 • 707.776.8200 • Fax 707.763.7785

Litho in U.S.A. © Jandy Pool Products, Inc. 0508

Litho in U.S.A. © Waterpik Technologies 0401

Jandy Pool Products, Inc.

Loading...

Loading...