Page 1

Installation and Operating Data

Installation and

Operating Manual

Jandy® Valve Actuator

Model JVA2444

WARNING

FOR YOUR SAFETY - This product must be installed and serviced by authorized personnel,

qualied in pool/spa installation. Improper installation and/or operation can create an unwanted

electrical hazard which can cause serious injury, property damage, or death. Improper

installation and/or operation will void the warranty.

This manual contains important information about the installation, operation and safe use of

this product. This information should be given to the owner/operator of this equipment.

H0570800C

Page 2

Page 3

Table of Contents

Page 3

Section 1. Safety Information ............................ 4

Section 2. General Information ......................... 5

2.1 Introduction ..................................... 5

2.2 Description ...................................... 5

Section 3. JVA Mounting Positions ................... 5

3.1 Standard JVA Position..................... 5

3.2 Actuator Mounting .......................... 6

Section 3. Synchronization ................................ 7

3.1 Synchronization Methods ............... 7

3.2 Resetting the Cams ......................... 7

Section 4. Manual Operation ............................. 9

4.1 Manual Override ............................. 9

4.2 Manual Override, Power On ...........9

4.3 Manual Override, Power Off .......... 9

Section 5. Maintenance ..................................... 10

5.1 Actuator .......................................... 10

5.2 Valve ...............................................10

Section 6. Troubleshooting .................................. 11

6.1 Troubleshooting .............................. 11

Section 7. Wiring Diagrams................................. 12

7.1 JVA Wiring Schematic 2444 ........... 12

7.2 JVA's with Toggle Switch ............... 12

Section 8. JVA Exploded View and

Replacement Kits .............................13

Section 9. Jandy NeverLube Valve Exploded

View and Replacement Kits .............14

9.1 3 Port NeverLube Valve ................. 14

9.2 2 Port NeverLube Valve ................. 14

EQUIPMENT INFORMATION RECORD

DATE OF INSTALLATION

INSTALLER INFORMATION

INITIAL PRESSURE GAUGE READING (WITH CLEAN FILTER)

PUMP MODEL

FILTER MODEL

CONTROL PANEL MODEL SERIAL NUMBER

NOTES:

HORSEPOWER

SERIAL NUMBER

Page 4

Page 4

Section 1. Safety Information

IMPORTANT SAFETY INSTRUCTIONS PERTAINING TO A RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSONS

READ AND FOLLOW ALL INSTRUCTIONS

When installing and using this electrical equipment, basic safety precautions should always be followed,

including the following:

WARNING

This product must be installed and serviced by authorized personnel, qualified in pool/spa installation.

Improper installation and/or operation can create an unwanted electrical hazard which can cause serious

injury, property damage, or death. Improper installation and/or operation will void the warranty.

WARNING

This manual contains important information about the installation, operation and safe use of this product.

This information should be given to the owner/operator of this equipment.

SAVE THESE INSTRUCTIONS

Page 5

Page 5

Section 2. General Information

2.1 Introduction

This manual contains information for the proper

installation and operation of Jandy® Valve

Actuators (JVA). Procedures in this manual must

be followed exactly. To obtain additional copies of

this manual contact 707-776-8200, ext. 237. For

address information see back cover.

2.2 Description

Jandy Valve Actuators are designed to meet the

needs of today's more advanced, automatic pool

equipment. These fully adjustable actuators offer

versatile pool/spa automation with easy setups.

All actuators work with the Jandy AquaLink® RS

Control Systems and are available in 24 volt units.

JVA 2444 Specifications

Voltage 24 VAC

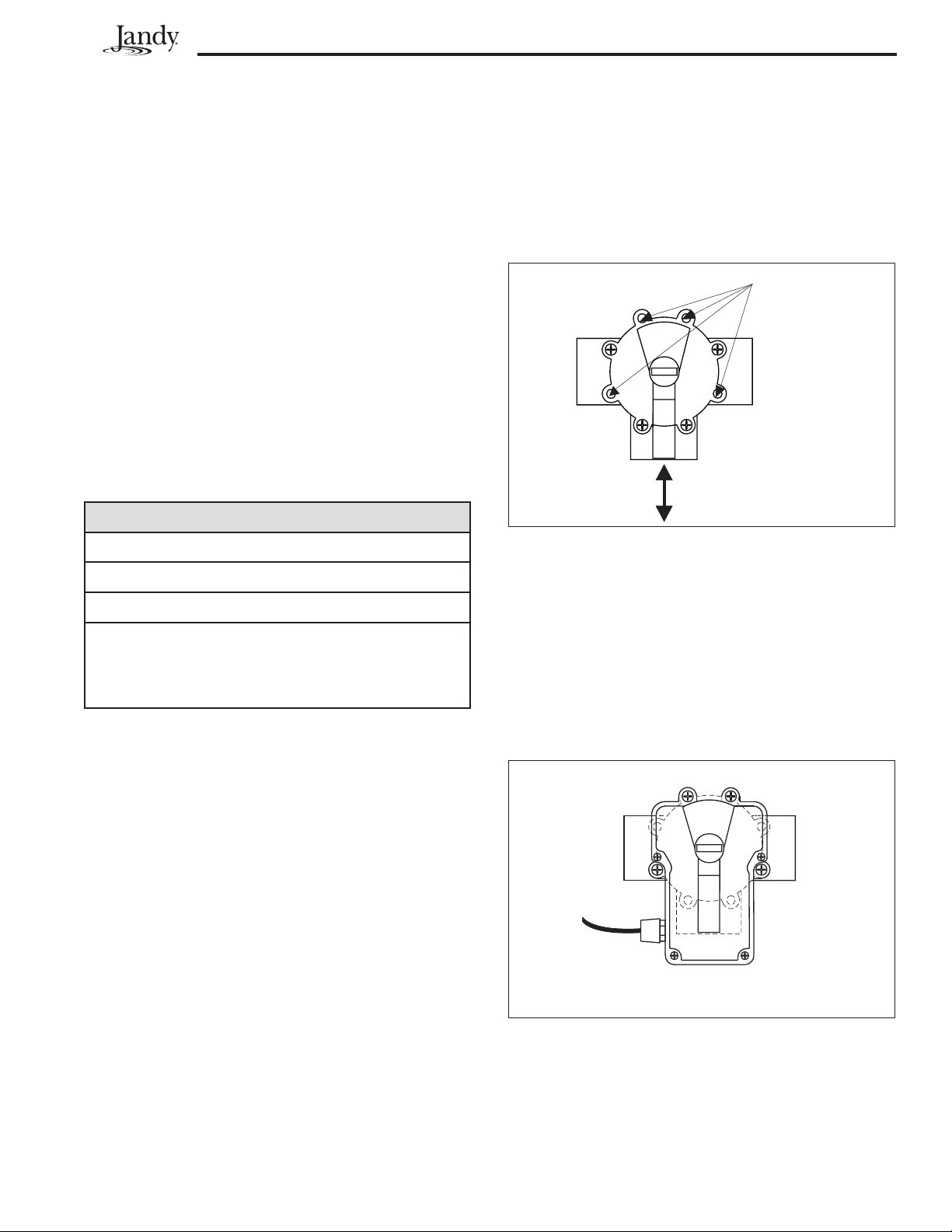

Section 3. JVA Mounting Positions

3.1 Standard JVA Position

Standard Plumbing position is with the middle

port (B) as the incoming or common port to the

valve (see Figure 1).

Remove these

four (4) screws for

Standard Position

A

Water ow into or

out of the valve

Figure 1. Standard Plumbing

B (Common Port)

C

Amperage 0.75 AMPS

Cycles 60 Hz

Wire

Black

Red

White

3-conductor

Common

Switch Leg

Switch Leg

Standard Mounting position is with the main

body of the actuator over port B (see Figure 2).

NOTE If the valve(s) are plumbed with port B as the

common port (Standard Plumbing) and the

main body of the actuator(s) are mounted over

port B (Standard Mounting), there is no need to

adjust the actuator cams.

A

B (Common Port)

C

Figure 2. Standard JVA Mounting

Page 6

Page 6

3.2 Actuator Mounting

JVA’s mount directly on all full-size Jandy Valves

(8 screws on lid) and can be adapted to mount on

Jandy Space Saver Valves (4 screws on lid). Jandy

recommends motorizing Jandy NeverLube® Valves

only.

JVA’s may be mounted onto valves in any of the

four (4) positions in Figure 3.

III

A

A

B

III

A

C

B

IV

C

C

3. Turn the actuator over so you can see into

the clear actuator shaft. There are four (4)

"teeth" on the inside of the shaft. Locate the

smallest "tooth" and align this "tooth" with

the smallest slot on the valve (see Figure 5).

Place actuator on valve so smallest tooth

aligns with smallest slot.

Smallest Slot

Figure 5. Actuator Mounting

Smallest Tooth

Actuator

Bottom

A

B

B

Figure 3. JVA Mounting Positions.

1. Unscrew the locking knob by turning

the knob counterclockwise. Remove the

locking knob and valve handle (see Figure

4).

2. Remove the four (4) large Phillips head

screws from the valve. The location of the

screws you remove will determine how the

actuator will be mounted (see Figure 4).

Remove Locking

Knob and Handle

Remove the 4 Large

Phillips Head Screws

C

4. Place the actuator onto the valve.

5. Rotate the actuator while keeping the two

shafts engaged until the screw holes on the

actuator legs align with the empty screw

holes (from step 2) in the valve (see Figure

6).

6. Use the four (4) large 2" Phillips head

screws (included with the JVA) to secure

the JVA to the valve.

7. Put the valve handle on the actuator shaft.

Put the knob on the shaft and tighten

(nger tighten only).

Rotate valve or actuator

to align screw holes

Rotate

valve

Figure 4. Remove Locking Knob and Lid Screws

Rotate

actuator

Figure 6. Actuator Mounting

Page 7

Section 3. Synchronization

ON 1

OFF

ON 2

Page 7

WARNING

Improper cam settings can result in dead heading

of the water flow which can cause injury or

property damage. Improper cam settings and/or

operation will void the warranty.

3.1 Synchronization Methods

If the valve is plumbed in the Standard Plumbing

position and the actuator is mounted in Standard

Mounting position, you do not have to change the

cam settings from the factory settings. However,

you may have to synchronize the cams.

One of the following will occur when the actuator

is out of synchronization:

• the actuator will rotate in the wrong direction

in relation to its controller (as in a solar heating

system)

• one actuator will rotate incorrectly in relation to

another actuator (as in pool/spa combination)

On the actuator that is out of synchronization, flip

the toggle switch located on the bottom of the

actuator to the ON 2 position (see Figure 8). The

toggle positions are marked on the actuator top

cover. Retry the system.

On/Off Switch is

located on the

bottom of the JVA

Figure 8. JVA Synchronization, Toggle

3.2 Resetting the Cams

NOTE Before resetting cams, if the valve is plumbed in

Standard Plumbing position and the actuator

is in Standard Mounting position there is no

need for resetting the cams (see Figure 9). If a

port other than "B" is plumbed as the common

port or if the actuator is mounted other than

Standard Mounting, the cam setting must be

changed so the actuator shaft and the valve

diverter rotate properly. Refer to the Cam

Setting Chart on page 8 for proper settings.

Figure 7 illustrates an example of the valves and

actuators of a pool/spa combination that are out

of synchronization. The valve on the left of the

illustration (suction) is plumbed with the spa line

on the left side of the valve and the pool line on

the right; whereas, the valve on the right of the

illustration (return) is plumbed with the pool on

the left side of the valve and the spa on the right.

In this configuration, if the actuators are activated,

one will turn to spa while the other will turn to

pool. The actuators will have to be synchronized.

Suction Return

Spa SpaPoolPool

I

A

B

III

A

B

Figure 9. JVA Mounting Positions.

C

C

A

A

II

B

IV

B

1. Turn OFF actuator power. Unscrew

the locking knob by turning the knob

counterclockwise. Remove the locking

knob and valve handle.

C

C

Figure 7. JVA Synchronization, Example

2. Remove the four (4) Phillips head screws

that secure the actuator lid and then remove

the lid.

Page 8

Page 8

0

0

3. Important - Rotate the actuator shaft so

the arrow mark on the top cam aligns with

the microswitch actuator (bottom cam

arrow mark should also align with the

bottom microswitch actuator, see Figure

10). Locate the mounting position for the

actuator (as per Figure 9, the mounting

position will be either I, II, III, or IV). Next,

determine what valve port is the common or

inlet port (as per Figure 9, the common port

will be either A, B, or C). Then refer to the

Cam Setting Chart below to determine what

the cam settings should be. For example, if

the actuator is in JVA mounting position "I",

and the common port on the valve is port

"A", the cam settings would be 90° for the

top cam and 180° for the bottom.

Final minor adjustments may be necessary

Lower

Cam

Upper

Cam

180°

NOTE The cam is marked with the arrow at "0", a long

hash mark at the 180° position, and 2 short

hash marks at the 90° and 270° positions.

4. To set the cams, rotate the cam(s) until the

arrow mark on the cam(s) align with the

microswitch actuator (see Figure 11).

NOTE The upper cam stops counterclockwise rotation

and the lower cam stops clockwise rotation.

5. Turn power ON to the actuator and use the

toggle switch located on the bottom of the

actuator to check rotation. Move the toggle

switch to either ON 1 or ON 2. Allow the

actuator shaft to move until it stops. Check

valve diverter position*, if the position is

correct ip the toggle switch in the opposite

direction and allow the shaft to stop again.

If the stop positions are correct, go to

step 6. If they are not, reset the cams until

correct.

NOTE If the actuator does not move in either direction,

refer to Section 6, Troubleshooting.

6. Replace the lid and tighten screws. Replace

the handle and locking knob.

270°

Left

Microswitch

Figure 10. JVA Cams

NOTE Before resetting cams, always rotate the actuator shaft so the arrow mark on each cam aligns with the pointer

above its microswitch.

Actuator

Mounting

*III A 90 180 B C

*IV A 0 270 B C

*Two Port Valve Settings

90°

0°

Water Enters Port

Common Port

*I A 90 180 B C

I B 90 270 A C

I C 180 90 A B

*II A 180 90 B C

II B 0 0 A C

II C 90 180 A B

III B 270 90 A C

III C 0 270 A B

IV B 180 180 A C

IV C 270 0 A B

Right

Microswitch

Cam Setting Chart

Cam Setting

Top Cam Bottom Cam

NOTE The end of the handle which has the word OFF

embossed on it exactly duplicates the shape of

the valve diverter. When the handle is placed on

a valve or actuator shaft the word OFF will be

directly over the center of the valve diverter.

Water Exits Valve

Port or Port

Page 9

4.3 Manual Override, Power Off

ON 1

OFF

ON 2

Page 9

Rotate Cams

Figure 11. JVA Cam Adjustment

Section 4. Manual Operation

4.1 Manual Override

It is sometimes necessary to rotate a valve(s)

without using the system controller. This occurs

when the controller is not accessible/operational

or when the spa or pool/spa combination require

filling or draining.

1. Move toggle switch located on the bottom

of actuator to the OFF (center) position.

2. Unscrew (counterclockwise) the locking

knob above the handle four (4) full turns.

3. Push down on the locking knob (not the

handle). This will disengage the gear train

and allow the handle, and thus the valve

diverter, to be moved to any position.

4. To return the actuator to automatic position,

pull up on the handle while turning it

clockwise or counterclockwise until you

feel the shaft slide up into the gear train.

Turn the locking knob down (clockwise)

until snug.

5. Put toggle switch back to the original

position.

There are two (2) methods of manually rotating

the JVA; one with power on (system operational)

and one with power off (no power to the control

system).

4.2 Manual Override, Power On

1. Move the toggle switch located on the

bottom of the actuator to the opposite

position (ON 1 switch to ON 2 or vice

versa). This will rotate the motor to the

opposite position.

2. Return the toggle switch to the original

position after use.

On/Off Switch is

on Bottom of JVA

Figure 12. JVA Synchronization, Toggle

CAUTION

To prevent damage to your equipment and to

minimize the possibility of any injury resulting from

such damage, make sure that the pool ltration pump

is OFF BEFORE rotating the valve handle.

Page 10

Page 10

JV

A

2444

MAXIMUM

T

ORQUE

Section 5. Maintenance

5.1 Actuator

The JVA has three seals which should be lubricated

once a year. One o-ring is located on the bottom

of the actuator where the plastic shaft exits the

housing and two (2) O-rings located in the top

cover near where the shaft exits the top of the

housing. Use the following steps to lubricate the

seals:

1. Turn OFF power to the actuator.

2. Remove the locking knob and handle (see

Figure 13).

Unscrew Locking

Knob and remove

handle

7. Turn handle once around to spread the

lubricant.

8. Pull up on the handle and tighten locking

knob.

5.2 Valve

NOTE This section does not apply to Jandy NeverLube

Valves and non-positive seal valves. NeverLube

Valves and non-positive seal valves can be

identified by the absence of a grease cap.

NeverLube Valves can also be identified by the

name "NeverLube" on the handle.

Since the actuator rotates the valve diverter which

redirects the flow of water, it is imperative that

the seals and the O-rings within the valve body be

lubricated often (at least every three (3) months).

Use the following procedure to lubricate the valve

diverter seals:

1. Turn off all pool/spa equipment.

Lubricate Here

Figure 13. JVA Shaft Seal

3. Spread a small amount of Jandy Lube or

other silicone base lubricant around the

actuator shaft just above the lock out ring

(see Figure 13).

4. Reinstall handle and locking knob. Only

tighten knob one (1) turn.

5. Push down on the locking knob to force the

actuator shaft into manual.

2. Rotate valve handle so the OFF on the

handle is over the word GREASE on the

valve body.

3. Unscrew (counterclockwise) and remove

the black cap of the grease tting.

4. Fill cap with lubricant (Jandy Lube).

5. Replace cap on tting and turn in

(clockwise) until all of the lubricant has

been forced into the valve.

6. Use manual operation to move the handle

from side to side to spread the lubricant

across the seal.

7. Reset the valve handle to its original

position and start the equipment.

Once a year the valve should be disassembled and

the O-ring and valve body inspected for damage.

Thoroughly lubricate the square seal and the Oring. Reassemble the valve.

6. Wipe a small amount of lubricant around

the actuator shaft where it protrudes from

the bottom of the actuator.

Page 11

Page 11

Section 6. Troubleshooting

6.1 Troubleshooting

All major components, including the power cord, are replaceable without replacing the entire actuator. Each

item may be replaced as a separate piece allowing easy infield repair. See Section 8, Exploded Views and

Replacement Kits, for actuator replacement part numbers.

Problem Cause Solution/Check

Actuator handle oscillates. Lack of valve seal lubrication.

Obstruction in valve body.

Actuator motor works but the valve

diverter does not turn.

NOTE On a pool/spa combination,

the problem would be spa draining or

overowing.

Actuator motor does not turn. A) No power to the actuator.

Actuator rotates in one direction but

not back again.

Water inside valve actuator. Damaged seals. Replace top lid and grease seals.

A). Actuator shaft broken.

B). Valve diverter broken.

C). Actuator in manual position.

D). Gear train damaged.

B) Toggle switch in OFF position.

C) Motor has failed.

D) Failed or broken microswitch.

E) Both cams in contact with their

microswitches.

A) Broken or damaged micro-

switch.

B) Bad connection(s).

C) Bad control relay switch.

D) Broken wire.

Lubricate valve.

Remove actuator and valve lid and

inspect.

A). Replace actuator shaft. Refer to

Shaft Replacement Kit

instructions for disassembly.

B). Replace valve diverter.

C). Pull up on the handle while

rotating counterclockwise.

D). Refer to Gear Replacement Kit

instructions for disassembly.

A) Check voltage between black

(common) wire and each switch

leg (red then white)

B) Move toggle switch to AUTO

position.

C) Replace motor.

D) Replace microswitch.

E) Check Cam Setting section.

A) Replace microswitch.

B) Check all connections.

C) At the power source check the

operation of the control relay or

switch.

D) Check red and white wires.

Page 12

Page 12

RED

WHITE

BLACK

OFF

JVA 2444

MAXIMUM TORQUE

JandyValve Actuator

Normally Closed

Normally Open

Common

1 amp

fuse

120 VAC

Transformer*

Secondary

(24 VAC)

Primary

(120 VAC)

Single Pole/

Double Throw

Relay

Coil Voltage: 120 VAC

Neutral

Line

Load

Time

Clock

Neutral

Ho

t

PCB Header for

Motor Wiring

Wiring for Toggle

Switch Underneath

Circuit Board

Top Cam

Motor

Connector to

PCB Header

Bottom Cam

Motor

Connector to

PCB Header

OFF

JVA 2442444

RED

WHITE

BLACK

WHITE

BLACK

MAXIMUM TORQUE

JandyValve Actuator

OFF

JVA 2444

MAXIMUM TORQUE

JandyValve Actuator

Normally Closed

Normally Open

Common

2 amp

fuse

RED

120 VA C

Transformer*

Secondary

(24 VAC)

Primary

(120 VAC)

Double Pole/

Double Throw

Toggle Switch

Section 7. Wiring Diagrams

7.1 JVA Wiring Schematic 2444

WARNING

Disconnect power to the system at the main circuit

breaker before servicing to avoid risk of electric shock

which can result in property damage, severe injury or

death. All wiring must be done in accordance with the

National Electric Code (NEC), NFPA-70. In Canada,

all wiring must be done in accordance with the

Canadian Electric Code (CSA C22.1). All applicable

local installation codes and regulations must be

followed.

CAUTION

To avoid damage to the equipment and minimize

risk of injury, use a properly sized, listed Class 2

transformer for connection to the power supply.

7.2 JVA's with Toggle Switch

This diagram is for two (2) JVA 2444s.

To operate more JVA's, additional poles and a higher

amperage fuse are needed. Do not double lug the JVA

switch leg wires (red and white wires).

* Transformer must be sized for the number of JVA's.

Each JVA requires .75 amp. at 24 VAC.

7C. JVA's with Time Clock

This diagram is for a single JVA 2444.

To operate more JVA's, additional poles and a higher

amperage fuse are needed. Do not double lug the JVA

switch leg wires (red and white wires).

* Transformer must be sized for the number of JVA's.

Each JVA requires .75 amp. at 24 VAC.

Page 13

Section 8. JVA Exploded View and Replacement Kits

Page 13

Dwg.

#

1 R0409600 JVA Gasket and Screw Kit

2 R0411500 Top Housing Kit

3 R0408700 Center Plate Kit

4 R0411600 Gear Kit

5 R0411800 Cable Kit, 20'

5 R0411900 Cable Kit, 75'

6 R0441700 PCB w/Toggle Switch Kit

7 R0408500 Motor Kit

8 R0408600 Cam and Microswitch Kit

Kit # Description Qty.

Gasket

O-ring,

Screw, #14 x 2"

Screw, #8 x 5/8"

Gasket

O-ring

Screw, #8 x 5/8"

Housing, Top

O-ring

Screw, #8 x 5/8"

Bridge

Top Cam (Clear)

Bottom Cam (Textured)

Microswitch

Center Plate

Output Shaft, Threaded

Spring, JVA

Primary Gear

Secondary Gear

Large Pinion Gear

Output Gear

Housing, Bottom w/3 Pins

O-ring, Strain Relief

Washer, Strain Relief

Cap, Strain Relief

Power Cord, 20' w/3-pin

Connector

O-ring, Strain Relief

Washer, Strain Relief

Cap, Strain Relief

Power Cord, 75' w/3-pin

Connector

PCB Sub-Assy, 24V w/PCB,

w/Toggle Switch, Lock

Washer and Nut

Screw, #8 x 5/8"

Motor 24V, w/Wire and

Connector

Top Cam (Clear)

Bottom Cam (Textured)

Microswitch

1

1

2

4

4

1

2

4

1

2

8

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1, 2

1, 2, 3 3

3, 7

7

6

3

3

4

4

6

2

1, 2

3

3, 8

5

3,8

3

3

3

Page 14

Page 14

Section 9. Jandy NeverLube Valve

Exploded View and

Replacement Kits

9.1 3 Port NeverLube Valve

1

2

3

Dwg.# R-Kit# Description

1 1298 Screw, #14 x ¾", Valve Housing

2 4603 Knob, ABS, Black

3 4733 Handle, NeverLube, Black

4 4606 Cover, 3 Port, Black

5 1132 O-ring, -151, Valve Cover

6 1307 O-ring, -116, Valve Shaft

7

or

8 4720 NeverLube Diverter Kit

4728

4730

Housing, 1½"-2", 3 Port, Black

Housing, 2"-2½", 3 Port, Black

4

6

5

8

7

9.2 2 Port NeverLube Valve

Dwg.# R-Kit# Description

1 1298 Screw, #14 x ¾", Valve Housing

2 4603 Knob, ABS, Black

3 4733 Handle, NeverLube, Black

4 4734 Cover, 2 Port, Black

5 1132 O-ring, -151, Valve Cover

6 1307 O-ring, -116, Valve Cover

7

or

8 4720 NeverLube Diverter Kit

4727

4729

Housing, 1½"-2", 2 Port, Black

Housing, 2"-2½", 2 Port, Black

1

2

3

4

6

5

8

7

Page 15

NOTES

Page 15

Page 16

LIMITED WARRANTY

Thank you for purchasing Jandy® pool and spa products. Jandy Pool Products, Inc. warrants all parts to be free

from manufacturing defects in materials and workmanship for a period of one year from the date of retail

purchase, with the following exceptions:

•

AquaLink® RS units installed with Jandy® Surge Protection Kits will be covered for two years.

•

NeverLube® valves are warranted for the life of pool and/or spa on which they were originally installed.

•

AquaPureTM Electronic Chlorine Generator Electrolytic Cells carry a 5 year limited warranty on a prorated basis.

This warranty is limited to the first retail purchaser, is not transferable, and does not apply to products that have

been moved from their original installation sites. The liability of Jandy Pool Products, Inc. shall not exceed the

repair or replacement of defective parts and does not include any costs for labor to remove and reinstall the

defective part, transportation to or from the factory, and any other materials required to make the repair. This

warranty does not cover failures or malfunctions resulting from the following:

1. Failure to properly install, operate or maintain the product(s) in accordance with our published Installation,

Operation and Maintenance Manuals provided with the product(s).

2. The workmanship of any installer of the product(s).

3. Not maintaining a proper chemical balance in your pool and/or spa [pH level between 7.2 and 7.8, Total

Alkalinity (TA) between 80 to 120 ppm, Total Dissolved Solids (TDS) less than 2000 not including salt ppm].

4. Abuse, alteration, accident, fire, flood, lightning, rodents, insects, negligence or acts of God.

5. Scaling, freezing, or other conditions causing inadequate water circulation.

6. Operating the product(s) at water flow rates outside the published minimum and maximum specifications.

7. Use of non-factory authorized parts or accessories in conjunction with the product(s).

8. Chemical contamination of combustion air or improper use of sanitizing chemicals, such as introducing

sanitizing chemicals upstream of the heater and cleaner hose or through the skimmer.

9. Overheating; incorrect wire runs; improper electrical supply; collateral damage caused by failure of O-Rings,

DE grids, or cartridge elements; or damage caused by running the pump with insufficient quantities of water.

LIMITATION OF LIABILITY:

This is the only warranty given by Jandy Pool Products, Inc. No one is authorized to make any other warranties

on behalf of Jandy Pool Products, Inc. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF FITNESS

FOR A PARTICULAR PURPOSE AND MERCHANTABILITY. JANDY POOL PRODUCTS, INC. EXPRESSLY

DISCLAIMS AND EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL, INCIDENTAL, INDIRECT OR

PUNITIVE DAMAGES FOR BREACH OF ANY EXPRESSED OR IMPLIED WARRANTY. This warranty gives

you specific legal rights. You may also have other rights which vary by state or province.

WARRANTY CLAIMS:

For prompt warranty consideration, contact your dealer and provide the following information: proof of purchase,

model number, serial number and date of installation. The installer will contact the factory for instructions

regarding the claim and to determine the location of the nearest designated service center. If the dealer is not

available, you can locate a service center in your area by visiting www.jandy.com or by calling our technical

support department at (707) 776-8200 extension 260. All returned parts must have a Returned Material

Authorization number to be evaluated under the terms of this warranty.

6000 Condor Drive • Moorpark, CA USA 93021 • 707.776.8200 • Fax 707.763.7785

Jandy Pool Products, Inc.

H0570800C

Litho in U.S.A. © Jandy Pool Products, Inc. 0508

Loading...

Loading...