Installation and Operating Data

FOR YOUR SAFETY - This product must be installed and serviced by authorized personnel, qualified in pool/spa heater installation. Improper installation and/or operation can

create carbon monoxide gas and flue gases which can cause serious injury, property

damage, or death. Improper installation and/or operation will void the warranty.

Installation and

Operation Manual

™

Hi-E2

Model EHE

Gas-Fired Pool

and Spa Heater

WARNING

If these instructions are not followed exactly, a fire or explosion may result,

causing property damage, personal injury, or death.

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

H0205000F

TABLE OF CONTENTS

SECTION 1

General Information

1A Introduction ............................................................1

1B Description.............................................................1

1C Warranty ................................................................1

SECTION 2

Installation Instructions

2A General Requirements ..........................................1

2B Heater Assembly and Preparation......................... 2

2C Heater Location ..................................................... 2

2D Installation Clearances .......................................... 2

2E Outdoor Installation ...............................................2

2F Outdoor Shelter Installation (Canada) ...................3

2G Indoor Installation ..................................................3

2G-1 Preparation of Heater For

Indoor Installation ..................................................3

2G-2 Combustion Air Requirements for

One-Pipe Installation .............................................4

2G-3 Two-Pipe Installation (Direct Vent) ........................ 4

2G-3a Connection of Combustion Air Pipe....................... 4

2G-3b Piping Materials ..................................................... 5

2G-3c Size and Length of Combustion

Air and Vent Piping ................................................5

2G-3d Combustion Air and Vent Pipe Installation ............6

2G-3e Room Ventilation ...................................................7

2G-3f Inspection and Replacement of Existing Vent

System with New Components ..............................7

2H Condensate Disposal ............................................ 7

2I Gas Supply and Piping .......................................... 8

2J Electric Wiring........................................................ 9

2J-1 Electrical Power .....................................................9

2J-2 Bonding ...............................................................11

2J-3 Auxiliary Time Clock Wiring .................................11

2J-4 Remote Operation ...............................................11

2K Water Piping ........................................................ 11

2K-1 Reversal of Heater Water Connections ............... 11

2K-2 Pool/Spa Piping Systems ....................................11

2K-3 Connections at Heater .........................................13

2K-4 Pressure Relief Valve .......................................... 13

2K-5 Automatic Chlorinators (Chemical Feeders)........ 13

2L Start-Up and Adjustment ..................................... 13

2L-1 Normal Operation ................................................ 13

2L-2 Start-Up ............................................................... 14

2L-3 Condensate ......................................................... 14

2L-4 Gas Pressure.......................................................14

2L-5 Adjustment of Water Pressure Switch ................15

2L-6 Water Temperature Rise ..................................... 15

SECTION 3

Operating Instructions

3A Start-Up Procedure.............................................. 16

3B Temperature Controls..........................................17

3C Lighting and Shutdown ........................................17

3C-1 Lighting the Heater ..............................................17

3C-2 Shutdown .............................................................17

3D Water Chemistry ..................................................18

3D-1 Pools ....................................................................18

3D-2 Spas .................................................................... 18

3D-2a Spa Water Chemistry........................................... 18

3D-2b Water Changing ...................................................18

3D-2c Corrosion ............................................................. 18

3D-2d Testing ................................................................. 18

3E Spa/Hot Tub Safety Rules ................................... 18

3F Swimming Pool Energy Saving Tips ....................19

3G Seasonal Care .....................................................19

3G-1 Spring and Fall Operation.................................... 19

3G-2 Winterizing ...........................................................19

3H Periodic Inspection ..............................................20

3H-1 Owner Inspection ................................................. 20

3H-2 Professional Inspection .......................................20

SECTION 4

Maintenance and Service

4A General ................................................................21

4B Induced-Draft Combustion System...................... 21

4C Heater Components and Their Operation ........... 21

4D Combustion Air Filter ........................................... 22

4E Electrical Trouble Shooting.................................. 23

4E-1 115V Electrical Power Supply..............................23

4E-2 Control Circuit Trouble Shooting .........................23

4E-2a Transformer ......................................................... 23

4E-2b Fuse..................................................................... 23

4E-2c Fireman Switch and External Interlocks ..............24

4E-2d Limit Switches......................................................24

4E-2e Water Pressure Flow Switch................................ 24

4E-2f Temperature Control ...........................................24

4E-2g Venturi Pressure Switch ...................................... 25

4E-2h Ignition Control ....................................................25

4E-2i Burner Limit Switch .............................................. 25

4E-2j Vent Limit Switch ................................................. 25

4E-2k Combustion Blower..............................................26

4E-2l Igniter ...................................................................26

4F Venturi Combustion Flow System........................26

4F-1 Pressure Measurement Ports .............................. 26

4F-2 Venturi System Checkout .................................... 26

4F-2a Unfired Venturi Differential Pressure ................... 26

4F-2b Gas Pressure Offset ............................................ 27

4F-2c Gas Orifice Differential ........................................ 28

4F-3 Air Flow Investigation........................................... 28

4F-3a Combustion Air Flow............................................ 28

4F-3b Flow in Heater and Vent ...................................... 28

4F-4 Fuel Gas Type and Gas Orifice Size ................... 28

4F-5 High Elevation Operation .....................................29

4G Combustion Condensate ..................................... 29

4H Major Component Service ................................... 29

SECTION 5

Capacities and Dimensions

5A General Information .............................................29

SECTION 6

Replacement Parts

6A General Information .............................................30

Hi-E2

Page 1

SECTION 1.

General Information

1A. Introduction

This manual contains information for the proper

installation and operation of the Hi-E

pool/spa heater. Certain sections are specifi c to United

States or Canadian installations, and are labeled

United States or Canada. Procedures in this manual

must be followed exactly. To obtain a copy of this

manual contact Jandy Pool Products, Inc. For address

information see back cover.

1B. Description

The Hi-E2 is a very effi cient gas-fi red pool and

spa heater. Its combustion system includes a heat

exchanger which extracts 95% of the energy in the

gas fuel. It has no standing pilot burner. It exceeds the

requirements of energy conservation regulations such

as those in California, Hawaii, New York, Oregon

and other states which require that a pool heater have

intermittent ignition.

The heater is designed to operate in conventional

swimming pool and spa equipment arrangements.

It requires 115V 60 Hz electrical power. It has the

versatile FlexTemp dual-thermostat control system for

pool/spa combinations.

The Hi-E

comply with latest editions of applicable standards.

In the United States, the applicable standard is ANSI

Standard Z21.56 for gas-fi red pool heaters. In Canada,

it is Standard CSA 4.7.

The heater has been designed specifi cally to heat

fresh water swimming pools and spas, and with proper

installation and care, it will provide years of reliable

service. Do not use it to maintain pool or spa water

temperature below 70°F. Do not use it as a heating

boiler or general service water heater or to heat salt

water. For special applications, consult your Jandy

dealer.

2 is certifi ed by CSA International to

1C. Warranty

The Hi-E2 is sold with a limited factory warranty.

A copy of the warranty is included in a plastic

bag inside the heater and on the back cover of this

manual. The home owner should fi ll out the warranty

registration card included in the plastic bag and return

it via mail. The warranty does not cover damage

caused by improper installation, operation, or fi eld

modifi cation; or damage to the heat exchanger caused

by corrosive water. See Section 3D for guidelines on

pool water chemistry.

2 Model EHE

WARNING

Improper installation or servicing can cause property damage, injury or death due to fi re, asphyxi-

ation or carbon monoxide poisoning. For indoor

installations, as an additional measure of safety,

Jandy Pool Products, Inc. strongly recommends

installation of suitable Carbon Monoxide detectors

in the vicinity of this appliance and in any adjacent

occupied spaces.

SECTION 2.

Installation Instructions

2A. General Requirements

All gas-fi red products require correct installation

to assure safe and satisfactory operation. The

requirements for pool heaters include the following:

1. Appropriate site location and clearances.

2. Suf fi cient supply of clean air for combustion and

ventilation.

3. Proper venting of products of combustion.

4. Properly sized gas pipe.

5. Properly sized gas meter.

6. Adequate water fl ow.

7. Provision for disposal of combustion condensate

water.

In the United States, installation must be in

accordance with local codes and the most recent

edition of the National Fuel Gas Code, ANSI Z223.1/

NFPA-54. The Code can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02269

In Canada, install the heater in accordance with

local codes and the most recent edition of the Natural

Gas and Propane Installation Code, CAN/CSA B149.1.

Special Precautions

Liquefi ed petroleum (LP) gas is heavier than

air. Therefore, a pool heater using LP gas is subject

to special installation rules. Consult local codes and

fi re protection authorities about specifi c installation

restrictions.

Fuel gas and its combustion products are known

to cause cancer or harm the reproductive process.

Follow these installation instructions and applicable

codes exactly to avoid this.

Page 2

2B. Heater Assembly and Preparation

The Hi-E2 can be installed in a variety of ways,

some of them requiring preparation or assembly in

the fi eld. In all cases, condensate tubing and fi ttings,

which are provided with the heater, must be connected

and routed. Water connections are provided on the

right side of the heater but can be changed to the left

side by reversal of the water headers.

It is best to handle these preparations before the

heater is in its fi nal location. Instructions are provided

in subsequent sections of this document.

Installation at High Elevation

The Hi-E

2 has a venturi-type combustion system

which does not require modifi cation for operation at

high elevation. In this type of system, air and fuel gas

density changes are automatically compensated for,

assuring proper air/fuel mixture. Heating capacity is

reduced about 3 percent per 1000 feet (305 meters)

above sea level. In general, effi ciency at high elevation

is equal to or better than at sea level.

2C. Heater Location

The Hi-E2 may be installed indoors or outdoors

as outlined in later sections. When installed indoors,

combustion air will often be piped to the heater and

this requirement may affect the choice of location (see

later section on air for combustion and ventilation).

Both indoor and outdoor installations require provision

of means for disposal of combustion condensate per

section 2H.

Install the heater at least 5 feet (1.52 meters)

from the inside wall of the pool or spa unless the

heater is separated from the pool or spa by a fi ve-foot

(1.52 meter) high solid fence, wall or other permanent

barrier.

When pool equipment is located below the pool

surface, a leak from any component can cause large

scale water loss or fl ooding. Jandy Pool Products Inc.

cannot be responsible for such water loss or fl ooding

or resulting damage. Location of the heater below

or above the pool deck affects operation of its water

pressure switch. See sections on water piping and

heater start-up for more information about this.

WARNING

When pool equipment is located below the pool surface, a leak from any component can cause large

scale water loss or fl ooding. Jandy Pool Products,

Inc. cannot be responsible for such water loss or

fl ooding or resulting damage.

Locate the heater in an area where water

leakage will not result in damage to the area around

the appliance or to a structure. If forced to locate

the heater where water leakage may cause damage,

provide a suitable pan with drain under the heater. This

pan must not restrict air fl ow or heater functions.

In selection of a location, disposal of combustion

condensate must also be considered. The heater can

produce three gallons of condensate water per hour

under some operating conditions. Means to drain this

condensate must be available or special provisions,

such as a condensate pump must be provided. See later

section on condensate disposal.

2D. Installation Clearances

Clearances between the heater and combustible

material must be per Table 1.

Surface/Component Minimum Clearance

Inches (mm)

Rear & Blank Side 2 (55)

Piping Side 12 (305)

Front 18 (455)*

Top - Indoors 6 (150)

Top - Outdoors Open (See Note)

Flooring Combustible

Vent 0

* For Canada 24 inches (610 mm) clearance

Table 1. Installation Clearance Requirements.

NOTE: See Outdoor Installation section

regarding roof overhang.

These clearances are the minimum acceptable.

Whenever possible, larger clearances should be

provided to assure adequate room for service

operations. Note that gas piping must be provided

through the left side of the unit and that the

combustion air duct, when provided, also enters

through the left side. See later section on combustion

air, and also the section on water piping.

Do not install the heater on carpeting or similar

material.

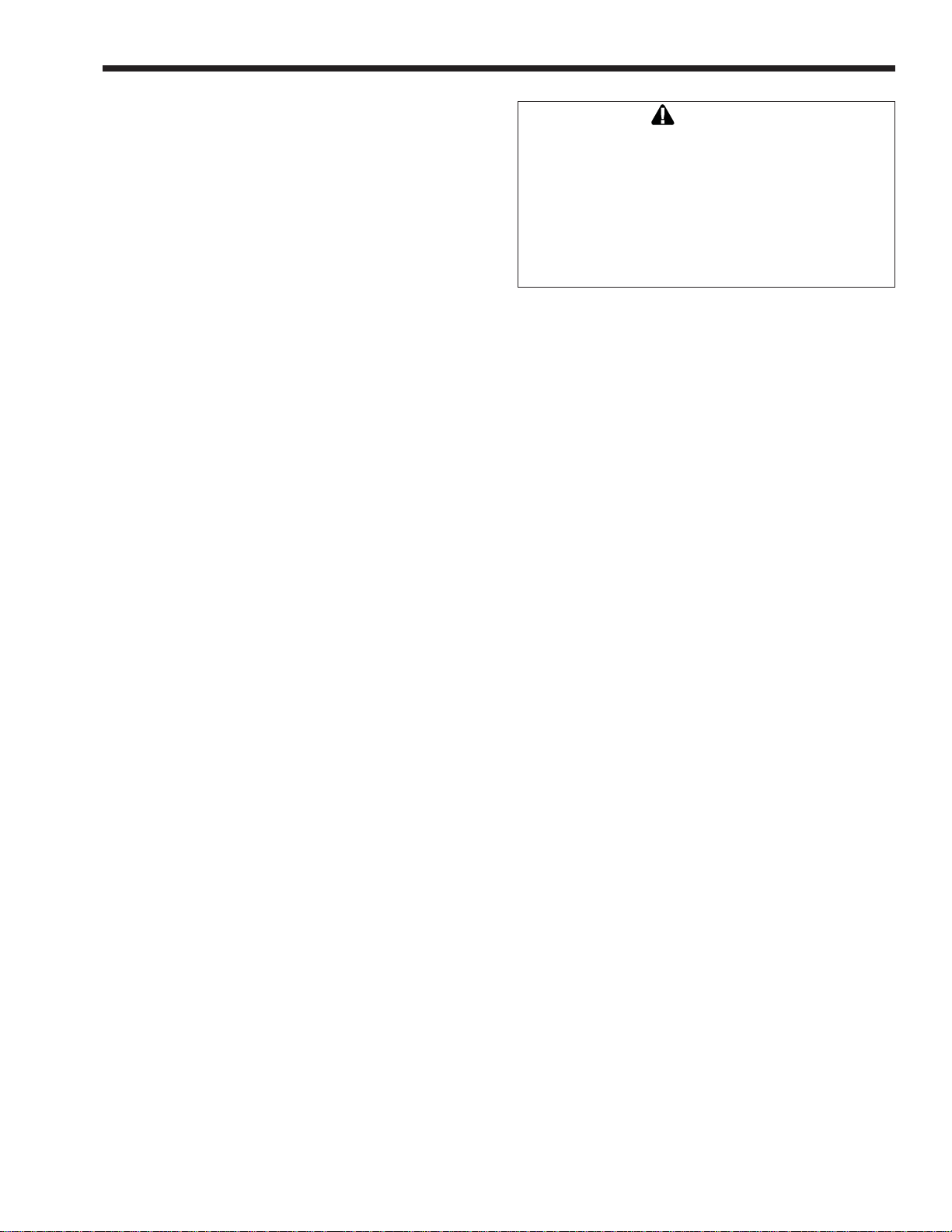

2E. Outdoor Installation

Locate the heater in an open, unroofed area

and maintain the clearances shown in Table 1. Do

not locate the heater below or adjacent to any doors,

windows, louvers or grates, etc., which connect in any

way with an inhabited area of a building, even through

another building such as a garage or utility room (see

Figure 1). Do not locate the heater below an outdoor

deck, unless treated as an indoor installation with

adequate clearances and proper venting to a location

away from the deck.

Hi-E2

Figure 1. Outdoor heater location.

Page 3

If the heater is installed close to a structure,

protect it from rain water runoff by means of gutters,

roof water diverters or similar measures. Do not

locate the heater close to irrigation sprinklers. Water

from sprinklers may damage controls and electronic

components.

Because the Hi-E

2 is very effi cient, combustion

system exhaust gases are moist. Do not locate

the heater such that this exhaust will impinge on

structures or vegetation which may be damaged by

combustion condensate.

WARNING

In United States

Do not install the heater with the vent within 4 feet

(1.22 m) of any opening into a building.

In Canada

Do not install the heater with the vent within 10 feet

(3.05 m) of any opening into a building.

In Florida it is required that the heater be

se cure ly fastened to the equipment pad. Use a size

1/4" x 1-1/2" long stainless steel Tapcon® type

con crete screws and washers at each of the four

tabs located at the base of the heater. Mount ing

the ap pli ance in this manner meets the applicable

requirements of the Florida Building Code.

Mounting screws are not provided with this

heater. After placing the heater on the equipment pad,

drill a hole in the concrete at each of the four tabs

on the feet of the heater. (The correct size drill bit

is usually provided with the concrete screws when

purchased). Place a screw in each of the holes and

fasten the heater to the equipment pad (see Figure 2).

Do not over torque the screws.

2F. Outdoor Shelter Installation (Canada)

An outdoor shelter is an unoccupied enclosure

which does not communicate directly with occupied

areas. The Hi-E

2 may be installed in such a shelter

Figure 2. Anchor heater to equipment pad.

only when the installation is in accordance with local

codes and the most recent edition of the Natural Gas

and Propane Installation Code (CAN/CSA B-149.1).

These codes and standards and Jandy require that the

heater be properly vented as outlined in this manual.

Other requirements also apply, such as provision

of ample uncontaminated air for combustion and

ventilation.

2G. Indoor Installation

The Hi-E2 can be located indoors when

provided with “one-pipe” or “two-pipe” systems for

combustion air and combustion product venting. A

one-pipe installation has only a vent pipe, and air for

combustion must be provided to the room the heater

is located in. A two-pipe system (sometimes referred

to as “direct vent” or “sealed combustion”) has a vent

pipe plus a pipe bringing air directly to the heater's

combustion system.

Section 2G-2 specifi es requirements for

provision of combustion and ventilation air for onepipe installations. Section 2G-3 covers two-pipe

installation.

An important consideration in selecting one or

two pipe installation is the quality of the combustion

air. Indoor air is sometimes contaminated with

various household or pool sanitation chemicals

which can cause corrosion in the heater combustion

system. Unless the indoor air is known to be free

of these materials, two pipe installation is strongly

recommended.

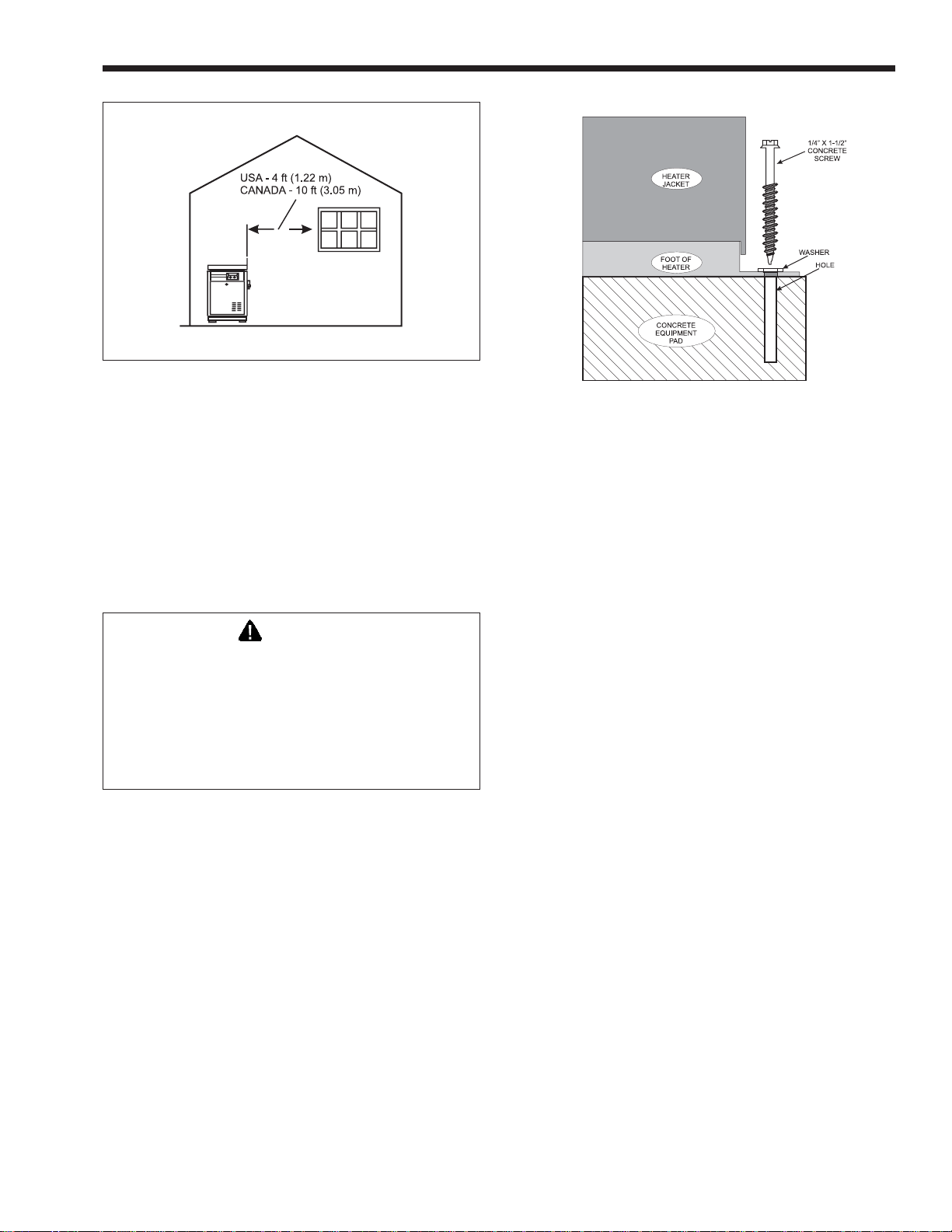

2G-1. Preparation of Heater For Indoor

Installation

If the Hi-E

discharge grille must be converted to an exhaust pipe

confi guration. The necessary vent collar, gasket and

screws are shipped packaged within the heater. The

conversion can be done quite simply as follows (see

Figures 3 and 4):

2 is to be installed indoors, its exhaust

Page 4

Figure 3. Removal of outdoor exhaust grille.

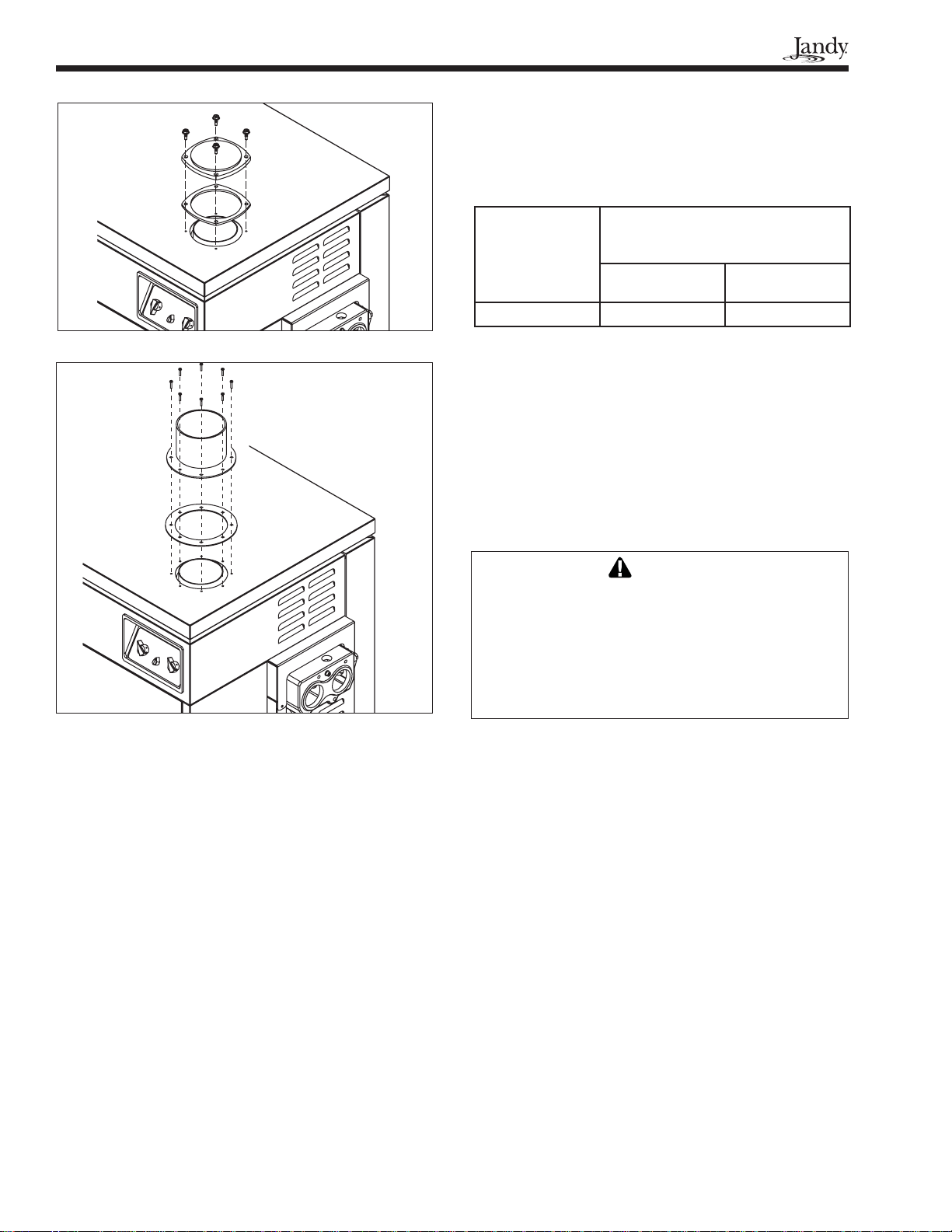

BTU/h of heater input. When air is provided indirectly

through ducts from the outside, the openings and

passages must have at least one square inch of area

per 2000 Btu/h of heater input. These requirements are

interpreted in Table 2.

Required net free area in square

Model

350 88 (570) 175 (1130)

Table 2. Required Net Free Area of Openings for

Combustion and Ventilation Air.

inches (sq. cm) for each of 2 openings

- one near ceiling and one near fl oor

Directly Through

an Exterior Wall

Through Horizon-

tal Ducts

Note that the numbers indicate the net free area

— after allowing for the blockage of grille bars, etc.

See applicable local codes and the previously-cited

national codes for details. Even though codes may

permit it, Jandy does not recommend installations

with only “infi ltration” as the means for provision of

combustion air.

See Section 2G-3c for vent pipe sizing.

Figure 4. Vent collar assembly for indoor installation.

1. Remove the vent exhaust grille by removing

the four screws which retain it. The grille, its

gasket, and the screws may be discarded.

2. Place the vent collar gasket on the top of

the heater aligning its center hole and screw

holes with those in the top of the heater.

3. Place the vent collar over the gasket and

fasten it in place with the screws and

lockwashers provided. Be sure that all

components are properly aligned. Screws

must be tightened enough to assure a sealed

joint without deforming the vent collar.

2G-2. Combustion Air Requirements for

One-Pipe Installation

One-pipe indoor installations must have specifi c

provisions for supply of combustion and ventilation

air to the room in which the heater is located. Two air

openings must be provided — one near the ceiling

and one near the fl oor. When air is provided directly

through an outside wall, each opening must have at

least one square inch (6.5 square cm) of area per 4000

WARNING

Do not store any chemicals, cleaners, or other corrosive material near combustion air openings or in

the room. Avoid location of dryer vents in the vicinity

of combustion air openings. Failure to prevent corrosive materials from mixing with combustion air

can result in reduced heater life and unsafe heater

operation.

2G-3. Two-Pipe Installation (Direct Vent)

This section specifi es installation requirements

for combustion air and vent piping for “two pipe”

installations. A two-pipe system provides isolation of

the Hi-E

2 combustion system from the space in which

the heater is installed. It has not only a vent pipe,

but also a combustion air pipe to provide air directly

from the outdoors. Research studies have shown that

contaminants which may corrode internal heater parts

are typically at much lower levels in outdoor air than

in air from indoors.

2G-3a. Connection of Combustion Air

Pipe

A collar for combustion air pipe connection is

provided in the heater at the inlet of the fi lter box.

As shown in Figure 5, the combustion air pipe is

routed through the side of the heater to the fi lter box

connection. Remove the cover plate from the left side

panel to provide access for the air pipe.

Hi-E2

Page 5

4'

Figure 5. Connection of combustion air pipe to heater.

2G-3b. Piping Materials

Vent piping must be corrosion resistant because

combustion condensate is usually present on its

internal surfaces. Only the following materials are

acceptable for vent piping:

PVC Class 100, Class 125 or Schedule 40

CPVC Schedule 40

®

29-4C

Stainless steel venting materials listed for

venting of condensing gas-fi red appliances.

29-4C® is a trademark of Allegheny Teledyne.

Total Length: 42'

Total Elbows: 5

EHE350

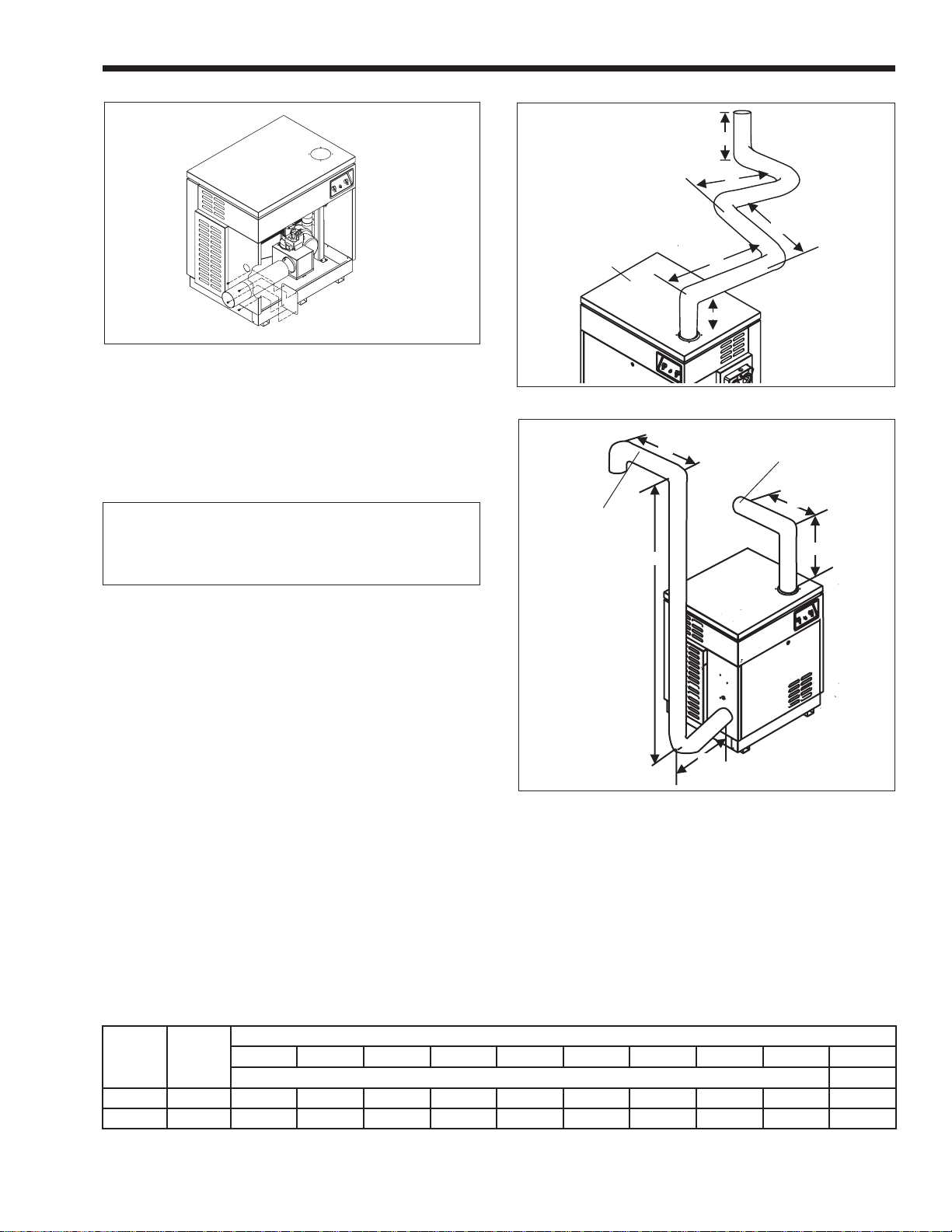

Figure 6. “One-pipe” installation.

Combustion

Air Pipe

7'

10'

2'

4'

8'

18'

Vent

Pipe

4'

5'

Combustion air piping may be single-wall

galvanized steel pipe or any of the above materials.

Comb.

Air Vent Total

Length 13' 9' 22'

Elbows 3 1 4

2G-3c. Size and Length of Combustion

Air and Vent Piping

Piping for combustion air and venting must

be large enough to avoid restriction of the heater

combustion system. Pipe diameter, number of elbows

2'

and length of pipe determine how much it restricts

fl ow to or from the heater. Also, a large heater requires

Figure 7. “Two-pipe” installation.

larger pipe than a small heater because it operates with

higher fl ow of combustion air and exhaust products.

Table 3 specifi es the allowable length of piping for

various situations.

The following examples illustrate use of table 3:

1. A Model 350 heater is to be installed in a onepipe system (see Figure 6). The vent pipe is 42

feet long and has fi ve elbows. Per Table 3, 5"

piping must be used. (Only 16 feet of 4" vent

pipe would be allowable.)

Model Pipe Size

350 4” 61 (18.6) 50 (15.2) 39 (11.9) 27 (8.2) 16 (4.8) NA NA NA NA NA

Inches

(cm)

5” 225 (68.6) 211 (64.3) 197 (60) 184 (56) 170 (51.8) 157 (47.8) 143 (43.5) 130 (39.6) 116 (35.4) 103 (31.4)

123456789

Total Length of Pipe - Feet (m)

Number of Elbows

10

Table 3. Maximum Combined Length of Combustion Air and Vent Piping in Feet.

Page 6

2G-3d. Combustion Air and Vent Pipe

Installation

The Hi-E

2 must be vented to the outdoors.

It must not be vented in common with any other

appliance, even if that appliance is of the condensing

type. Common venting can result in severe corrosion

of the Hi-E2 or of the other appliances or their venting,

or escape of combustion product gases through

such appliances or vents. Do not vent the Hi-E

2 to a

fi replace chimney or building chase.

Combustion air ducting, when provided, must

not be shared with any other appliance or with another

Hi-E

2. Doing so may result in fl ow of air through the

other appliances instead of directly from the outdoors.

The combustion air intake and vent outlet must

be located exterior to the building and in the same

pressure zone - i.e. both through the roof or both

through a side wall. The vent terminal must be located

in accordance with local codes, as applicable, and in

accordance with the following:

1. Locate the vent terminal so that it will not be

damaged by pedestrians and other traffi c, and so

that the discharge is not offensive. The National

Fuel Gas Code requires a through-wall vent

terminal be at least 7 feet (2.13 m) above grade if

located at a public walkway.

2. Locate the vent terminal so the vent exhaust does

not settle on building surfaces and other nearby

objects. Vent products may corrode such surfaces

or objects.

PVC Adapter

when required

4" PVC Pipe

Clamping Connector

with Neoprene,

Nitrile or EPDM

Sleeve

(R0444900)

Hi-E2 Vent Collar

3. Locate the vent terminal at a suffi cient horizontal

distance from any gas or electric metering,

regulating or relief equipment. In the United

States, this distance must be at least 4 feet

(1.21m). In Canada, it must be at least 10 feet

(3.04m).

4. Locate the vent terminal at a suffi cient horizontal

distance from any building opening. Take special

care to assure that combustion products do

not enter a building through windows, doors,

ventilation inlets, etc. In the United States, this

distance must be at least 4 feet (1.21 m). In

Canada, it must be at least 10 feet (3.04 m).

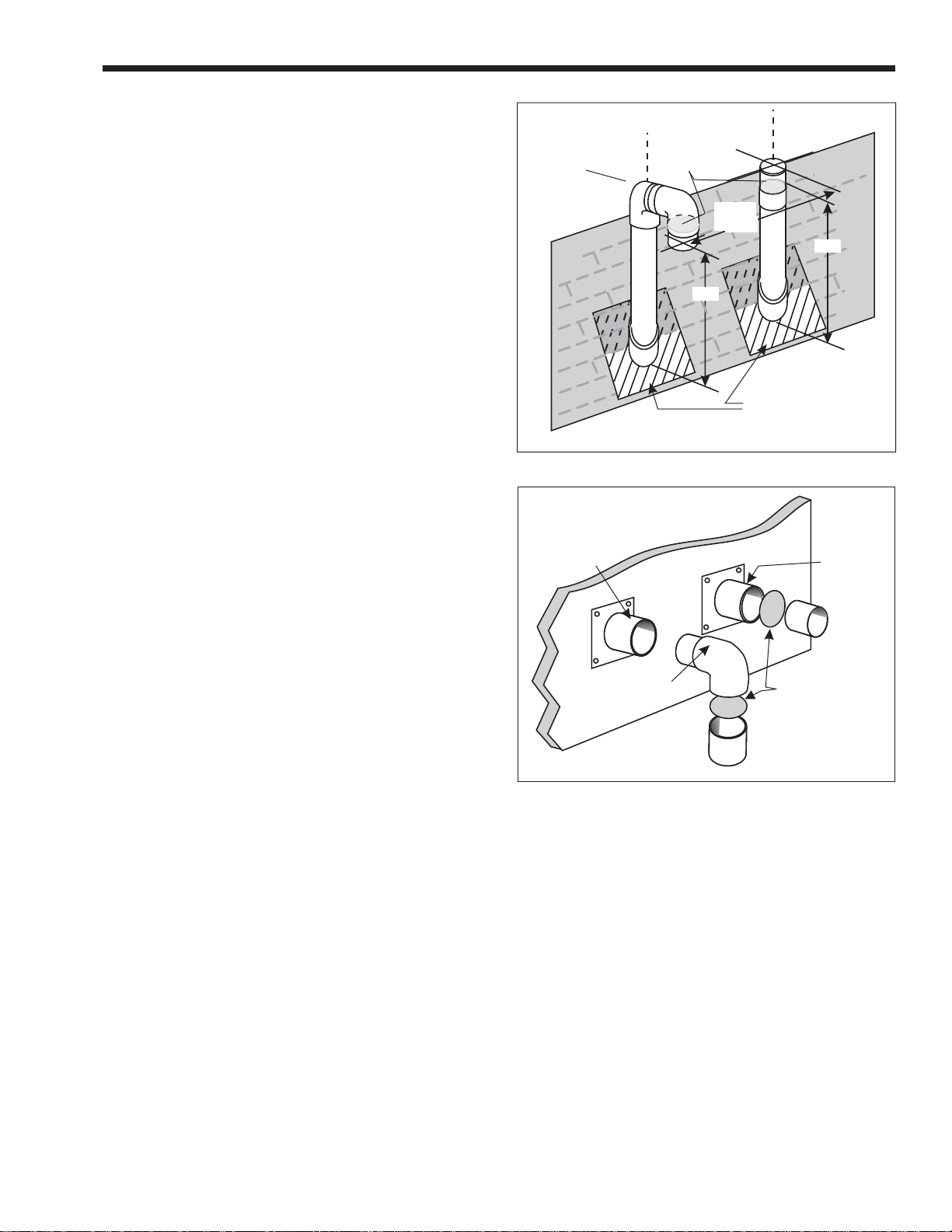

As shown in Figures 9 and 10, the combustion air

intake and the vent outlet must be installed no closer

together than 18" (45.7cm) and no farther apart than

60" (1.5m). The combustion air inlet opening must

face downward to prevent entry of rain or snow. The

vent outlet must discharge away from the combustion

air inlet - normally in a horizontal direction when on

a wall and vertically upward when on a roof. Both

should terminate at least 12" (30.5cm) above the snow

accumulation level. In locations with freezing climate,

extension of the vent pipe outside of the building

should be minimized. The insect screens provided

Figure 8. Indoor vent connection, Hi-E2 pool heater

Special insect screens installed

(see Figure 11)

Vent Exhaust

Combustion

Air Pipe

7" min.

maximum snow level

Figure 9. Vent and combustion air terminals at exterior

wall.

Pipe

18" min.

60" max

12" min.to

6" min.

Grade level

or normal

snow

Hi-E2

Page 7

with the heater must be installed at the combustion air

and vent pipe openings as shown in Figure 11. Insect

screens are sized to fi t the inside of a 5" PVC pipe

fi tting. Trim them as necessary for smaller pipe sizes.

Connect the vent pipe to the heater vent collar

with an air-tight corrosion-resistant clamp. The

connection must not allow leakage of combustion

products into the space but should be removable for

service (see Figure 8).

Connect the combustion air pipe to collar of the

air fi lter box. For this combustion air pipe only, sheet

metal pipe is most convenient and can be screwed

directly to the collar. Seal the joint with silicone sealer

or similar mastic material.

Install vent piping with a continuous rise of at

least 1/4" per foot (20 mm per meter) away from the

heater. This will assure that any condensate forming in

the vent pipe will fl ow back to the heater where it can

be disposed of properly.

Support vent piping with suitable hangers so

its weight does not bear on the heater or building

penetration and so that piping joints are not strained.

Support horizontal runs at intervals no greater than

6 feet (1.82 meters), and closer if necessary to avoid

sagging. Sagging can trap condensate water and block

the vent.

Both combustion air and vent piping joints must

be sealed. Metal combustion air pipe joints should

be fastened with screws and sealed with permanent

sealer or tape. Plastic vent pipe joints must be made

with solvent cement listed for such use. Joints in 29-

®

4C

stainless steel pipe must be sealed in accordance

with its listing. Connection of combustion air and

vent piping to the heater should be serviceable — i.e.

removable for heater service.

2G-3e. Room V entilation

The room a Hi-E

2 is installed in must be provided

with adequate ventilation. Like other gas-fi red

appliances, the Hi-E

2 releases heat to its environment,

and a room with no ventilation may become too warm.

In one-pipe installations, the normal (coderequired) provisions for combustion air also assure

reasonable ventilation of the room. In commercial

applications it is required that a two-pipe system be

used. If a two-pipe system is installed, ventilation must

be provided by other means, such as through grilles or

openings or with a small fan.

2G-3f. Inspection and Replacement of

Existing Vent System with New

Components

If the Hi-E

2 is being installed to replace an

existing pool heater, it is recommended that a new

appropriate venting system be installed with the new

heater. However, if an existing venting system must be

used, be sure to carefully inspect the venting system to

ensure that it is in good condition and continues to be

Vent

Exhaust

Insect Screens

Installed

Elbow

Combustion

Air Pipe

Figure 10. Vent and combustion air terminals at roof.

Combustion

Air Pipe

Figure 11. Installation of insect screens.

(See Fig. 10)

18" min.

60" max

A

Plumbing vent

roof boot

A=Maximum snow ac cu mu la tion level plus 12"

Elbow

Pipe

A

Vent

Exhaust

Pipe

Install special

insect screen

at end of pipe

inside coupling

or elbow. Cut

to size as nec es sary.

appropriate for the Hi-E2 heater. Replace any parts that

are not in good and serviceable condition with new

parts before completing the pool heater installation.

2H. Condensate Disposal

In a high-effi ciency combustion process,

combustion product gases are cooled so much that

liquid water is condensed. Flow of this “condensate”

can be quite high. When pool water is very cold, as

much as two or three gallons of condensate can be

produced in an hour. Condensate is mildly acidic.

Before treatment, its “pH” is typically in the 3.5 to 6.0

range.

Handling and disposal of condensate is not

complicated, but it must be done correctly to prevent

problems or complaints. A trap/neutralizer assembly is

provided with the heater to simplify installation. This

assembly is easily installed in the base of the heater.

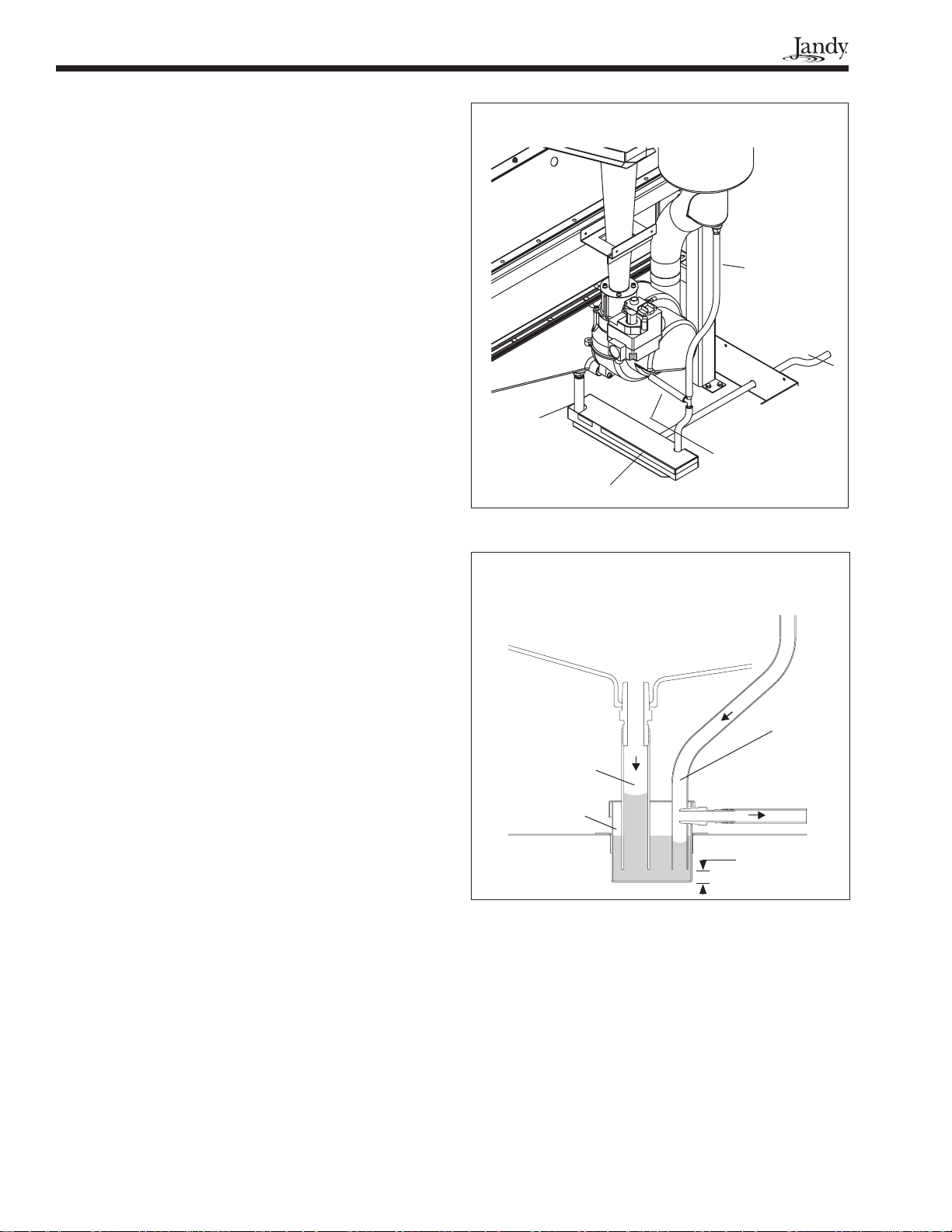

Figure 12 illustrates its installation and the routing of

drain tubes.

Page 8

To install the condensate assembly, fi rst install

the short length of 5/8" I.D. tubing (Collector

Drain) on the barbed fi tting on the bottom of the

condensate collector. Then drop the condensate tray

into the opening in the base pan of the heater, bending

the 5/8" tubing as necessary to get the tube into the

tray. Readjust the 5/8" tubing so that its lower end

is 1/4" - 3/8" above the bottom of the tray. The tray

can be positioned with the outlet fi tting to the right,

as shown in Figure 12, or with the fi tting to the left,

depending on the direction required for condensate

disposal. Connect the piece of 1/2" I.D. tubing to this

outlet fi tting and route it out of the heater through the

hole in the side of the base panel. This tube carries

condensate to the drain. If this disposal tube is routed

to the left, remove the plug button from the hole on the

left side of the base panel and push it into the hole on

the right side.

Connect the remaining short piece of 3/8"

I.D. tubing to the barbed tee fi tting in the tubing

immediately in front of the blower. Position this tubing

so that its bottom end is 1/4"-3/8" above the bottom of

the condensate tray. This tube provides drainage for

the vent duct and blower.

A package of limestone gravel neutralizer

is provided with the condensate assembly. Place

this gravel in the tray after installing and properly

positioning all tubes. Be sure that a limestone pebble

does not plug any of the tubes. Place the cover on the

tray when this is done.

It is important that there be no sagging sections

of tubing to trap water. Drainage to the trap and out

of the trap to the drain must be assured by continuous

downward routing of these tubes. It may be necessary

to elevate the heater to provide downward routing. The

outlet of the disposal tube must be open to the air. PVC

pipe is recommended for long drain tubes.

If a gravity drain is not available, a condensate

pump must be provided in the fi eld. Suitable

condensate pumps are available commercially at air

conditioning equipment distributors.

Incorrect installation of the condensate assembly

or tubing can result in overfl ow or waterlogging of the

vent. In normal operation, water accumulates in the

tray at the level of the outlet fi tting, and this provides

a “water seal” which accommodates combustion

system pressures. Figure 13 illustrates the water seal.

Note that water is “pulled” up toward the condensate

collector pan and is pushed down slightly by the

vent/blower drain. If there is no water seal, air rushes

into the collector drain, preventing normal drainage of

condensate water, until vent drainage provides the seal

(see Section 2L, Start-Up and Adjustment).

The installer must be sure to take whatever

measures are necessary to prevent property damage by

condensate overfl ow. If the heater location is such that

Vent

Drain

To

Disposal

Collector

Drain

Blower

Drain

Trap/

Neutralizer

Figure 12. Condensate drainage components.

Condensate From

Vent/Blower Drains

Condensate

From

Collector

Drain

Water Level

Pushed Down

Water Level

Pulled Up

2"-3"

(50-75mm)

Trap

Figure 13. Condensate drain and trap.

Slightly

Overfl ow

To

Disposal

1/4" - 3/8"

(6-10mm)

this water can directly or indirectly damage a building,

furnishings or other property, an overfl ow pan or other

appropriate preventative measure should be provided.

2I. Gas Supply and Piping

Before installing gas piping, check the rating

plate on the heater to be sure that the heater is for use

with the correct (available) gas. Make sure that gas

supply pressure is adequate per the requirements in

Table 4.

Hi-E2

Supply Pressure Minimum Maximum

Natural Gas 5 inches WC

(125 mm WC)

LP Gas 11 inches WC

(280 mm WC)

Table 4. Gas Supply Pressure Requirements.

10.5 inches WC

(265 mm WC)

14 inches WC

(350 mm WC)

Gas piping must be large enough to provide the

required gas fl ow rate without excessive pres sure drop.

Table 5 specifi es pipe sizes which will limit pressure

drop to 0.5 In WC (125 Pa), based on the National

Fuel Gas Code, ANSI Z223.1/NFPA-54.

Model

350 1-1/4" 1-1/4" 1-1/2" 1" 1-1/4" 1-1/4"

Table 5. Required Gas Pipe Size.

Natural Gas LP Gas

0-50'

(0-15m)

50-100'

(15-30m)

100-200'

(30-60m)

0-80'

(0-15m)

50-100'

(15-30m)

100-200'

(30-60m)

Support gas piping properly so its weight

does not bear on the heater. Install a drip leg, a nonrestrictive shutoff valve and a union on the gas supply

line outside of the heater (see Figure 14).

Before operating the heater, test the gas supply

system, including all connections, for leaks using a

soap solution. Do not use a fl ame or any ignition

source for leak detection. Dis con nect the heater and its

individual gas shutoff valve during pressure testing if

the test pressure is higher than 1/2 psig (3.34 kPa). If

the pres sure is 1/2 psig (3.45 kPa) or lower, close the

manual valve on the heater gas control during testing.

When the heater is started, check the supply

pressure to verify that it is adequate during heater

operation. Undersize piping, a restrictive fi tting or an

undersize gas meter can cause low operating pressure.

High Elevation

To assure good combustion and general

op er a tion, gas appliances are normally de-rated when

installed at high elevation. This is not necessary

with the Hi-E

2 because it has a special venturi-type

combustion system which self-com pen sates for

changes in barometric pressure. Air fl ow through the

venturi pulls the correct fl ow of gas into the burner

regardless of air density. Good quality combustion and

high effi ciency are assured without special adjustment

or changes to the heater.

2J. Electric Wiring

WARNING

ELECTRICAL SHOCK HAZARD. This heater

contains wiring that carries high voltage. Contact with these wires may result in severe injury

or death.

Page 9

From

Supply

To

Heater

Figure 14. Gas piping at heater.

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Verify proper operation after servicing.

2J-1. Electrical Power

Electrical wiring must be in accordance with the

latest edition of the National Electric Code (NEC),

ANSI/National Fire Protection Association (NFPA) 70,

unless local code requirements indicate otherwise; and

in Canada with latest edition of CSA C22.1 Canadian

Electrical Code.

The Hi-E

2 requires electrical power from a 115V,

60 Hz source. Wiring connections must be made

exactly as shown in the wiring diagram (see Figure

16). Grounding must be provided as required by the

prevailing electrical code.

Connect wiring inside the junction box , which is

on the right side of the heater and is accessible through

the door opening. Line voltage con nec tions must be

made within this box. A labeled green grounding screw

is provided in the junction box for a ground ing wire

(see Figure 15).

ATTACH GROUND-

ING WIRE TO

GREEN GROUND-

ING SCREW

Figure 15. Field wiring connections.

Loading...

Loading...