Page 1

Installation Instructions

Jandy® Sheer Descent

Installation Manual

THIS UNIT MUST BE INSTALLED ACCORDING TO THE MANUFACTURER'S INSTALLATION

INSTRUCTIONS. PLEASE READ AND FOLLOW ALL INSTRUCTIONS. PLEASE SAVE THESE

INSTRUCTIONS.

PREPARATION AND INSTALLATION INSTRUCTIONS

This manual provides easy reference illustrations to help you identify each part of the Sheer Descent Waterfall. Use this

manual to guide you through the routine procedures and adjustments for a trouble free installation. These instructions were

developed with the aid of experienced contractors and has proven to be a simple, yet consistent and trouble free, method of

installation.

During all phases of the installation, care should be taken not to damage the Sheer Descent Waterfall. Keep the unit in the

original packaging until the site is prepared for permanent installation.

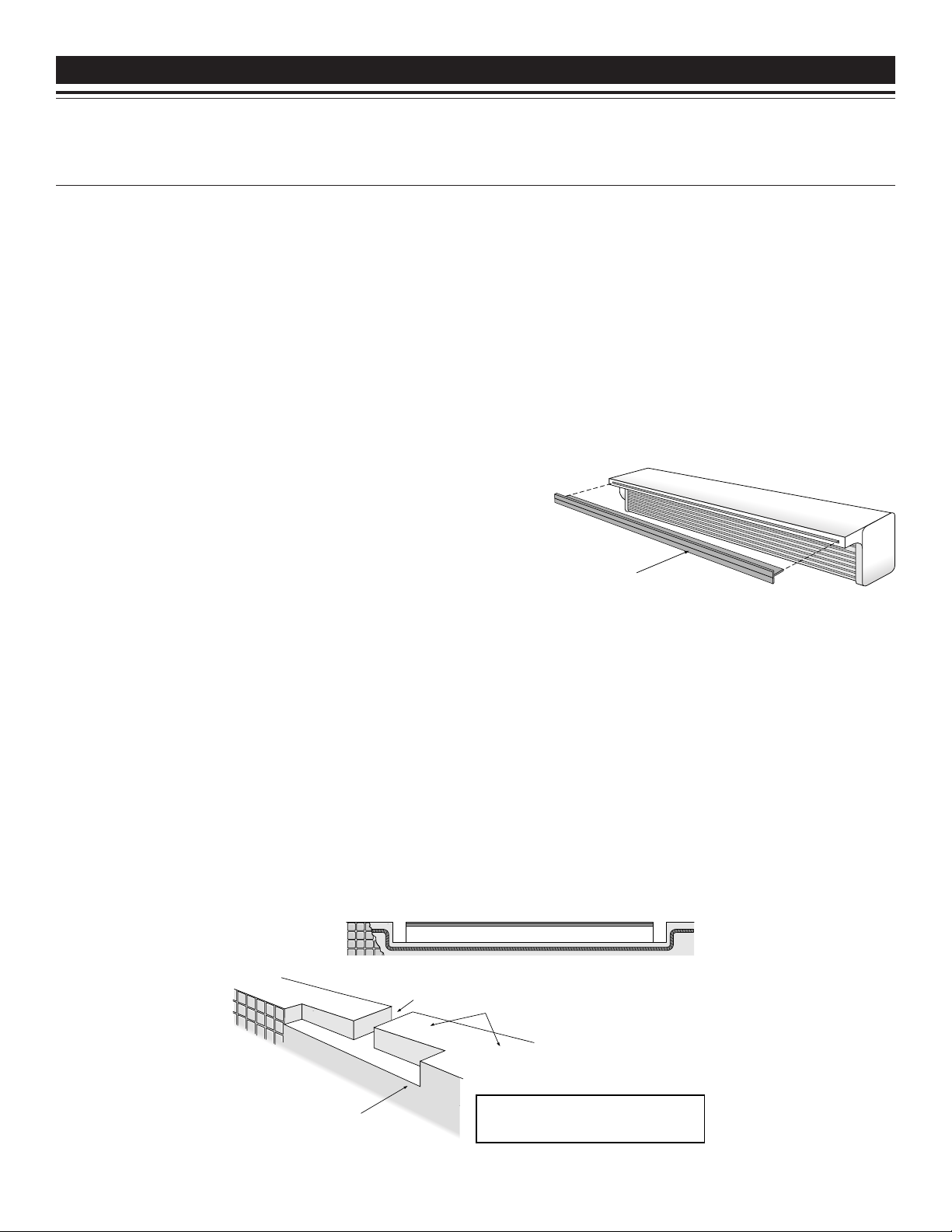

The Sheer Descent Waterfall is available in standard sizes from eight

inches to eight feet in length and is shipped complete with safety

tongue installed in the opening of the waterfall. See figure 1. The

protective tongue keeps the spillway opening clean and damage free.

DO NOT REMOVE THE TONGUE until the start up of the pool

equipment. The safety tongue must be left in the opening during the

entire installation, or damage to the unit, which would effect its ability

to perform, may occur.

Tongue

(Do not remove

prior to start-up)

Figure 1

EXCAVATION & STEEL MODIFICATIONS

It is recommended that the area designated for the Sheer Descent Waterfall be marked off with colored stakes, yellow

construction ribbon, or similar material during the framing process, prior to excavation. In preparation for the installation

of the steel rebar, mark the EXACT area designated for the Sheer Descent Waterfall. To allow room for notching the bond

beam and installing the unit, offset the steel pattern by 3 inches below the original form and 1 inch on both ends of the

Sheer Descent Waterfall. For example, if the Sheer Descent Waterfall is 4 feet in length, offset the steel pattern to measure

3 inches down from the top of the frame and 50 inches in length (this allows 1 inch of space on each side of the Sheer

Descent unit). See figure 2.

Steel off set

Figure 2

Note: Notching of the bond beam is the next

step in the process. The change to the

steel will make the notch a simple procedure.

3½" wide x 3½"

deep notch

Finished notch in beam

2½"

Top of raised bond beam

Page 2

Page 2

Feet of Elevation

Feet of Projection

Gallons per minute per foot

Guideline is for 1ft. to 4ft models

7

1

2

3

12

9101215 20

Manifold

Rock trap

Sheer Descent Waterfall back feed

plumbing for 6, 7, & 8 ft. lengths.

Beam

Center

CONCRETE INSTALLATION AND MODIFICATIONS

As the concrete installation (or similar process) nears completion, a notch must be cut into the inner edge of bond beam in

the same area at which the steel was offset to allow for the installation of the Sheer Descent Waterfall. See figure 3.

CUTTING THE BOND BEAM

FOR SHEER DESCENT WATERFALL SIZES 8" THROUGH 5'

Select the EXACT location for the Sheer Descent Waterfall.

The notch in the bond beam should be cut 3½" deep by

2½" wide and 2" longer than the length of the proposed

Sheer Descent Waterfall (1" per side). For example, if a

Tile

4' model is to be installed, the notch length should be 50"

(48" + 1"+ 1" = 50"). In addition, mark a single slot on

the top of the beam in the center of the proposed notch

Tongue

3½" wide by 3½" deep. The notch will be used to plumb

1½" pipe to the Sheer Descent Waterfall. Mark the bond

beam and proceed with cutting the beam.

FOR SHEER DESCENT SIZES 6', 7', AND 8'

Mark and cut the beam as instructed previously, with the exception that two notches are required on the top of the beam

for piping. Longer waterfalls require more water; consequently, two plumbing lines are required. The top of the beam

should be marked for these units as follows: NOTE: These measurements are from the center of the Sheer Descent

Waterfall unit.

3½" wide x 3½" deep notch

2½"

3½"

Figure 3

Length Plumbing Location

6 foot 1 foot 6 inches to the right and to the left from the center line

7 foot 1 foot 9 inches to the right and to the left from the center line

8 foot 2 feet to the right and to the left from the center line

The notches should be 3½" wide by 3½" deep. See figure 4.

MAKE SURE THE CUTS IN THE BEAM ARE PROPERLY COMPLETED BEFORE PROCEEDING.

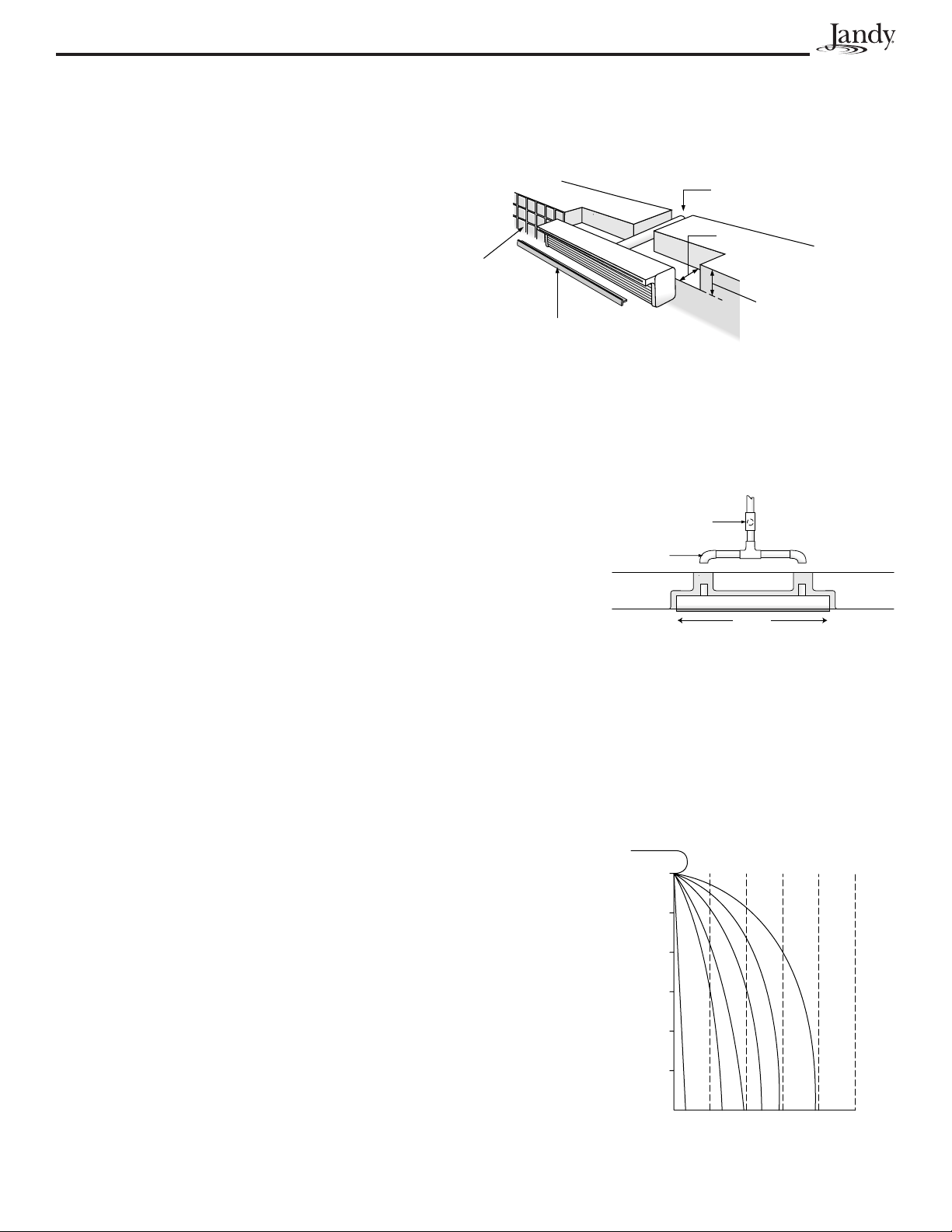

PUMP SIZING AND INSTALLATION OPTIONS

One of the advantages of the Sheer Descent Waterfall is the ability to provide a continuous sheet of water with a minimum

of water flow. A standard four foot model, for example, requires only 40 gallons per minute to operate. In order to size

your pump properly, refer to the Water Flow Requirement Chart. In most

cases, a properly sized standard swimming pool pump will operate the Sheer

Descent Waterfall and filter the pool with little loss of total water turnover. As

a general rule of thumb, the Sheer Descent waterfall requires approximately

10 gallons per minute per foot with little head loss. For more a dramatic effect,

more water gallonage can be applied to project the waterfall further away from

the wall. NOTE: When plumbing multiple falls, add the total length of

waterfalls together to determine GPM required. e.g. When plumbing two

(2) 6' units, you now have 12' of waterfall, which requires 120 gallons per

minute.

Figure 4

EXISTING POOL FILTER PUMP INSTALLATION

The installation of the Sheer Descent Waterfall using the main pool filter pump

is the most common plumbing system, due to the unique low flow aspect of the

waterfall system. Simply plumb a three way valve on the return line, after the

filter, and plumb the waterfall feed line in a minimum of 1½" PVC schedule

40 pipe. Units above 5' in length need a minimum of 2" plumbing.

Page 3

Page 3

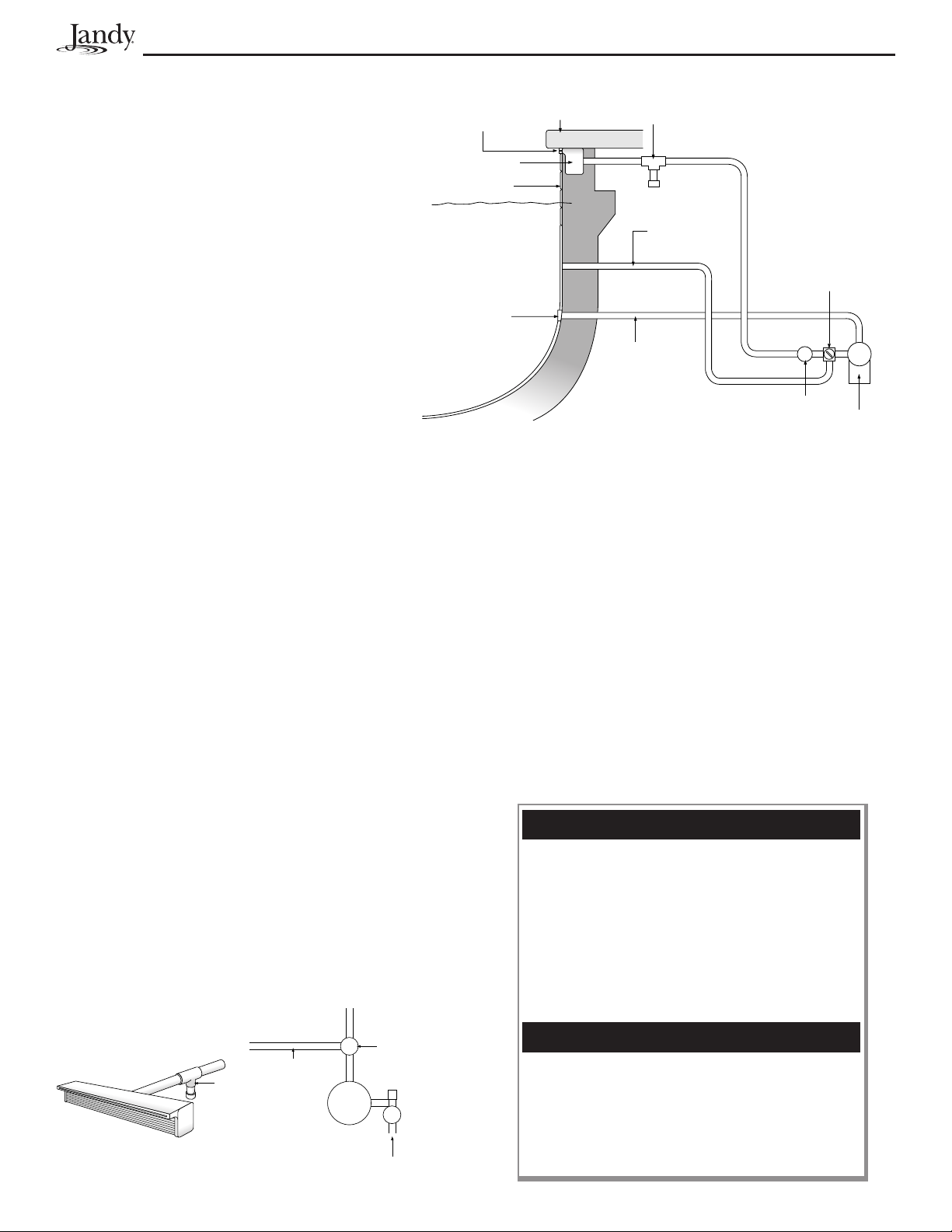

SEPARATE PUMP FOR THE SHEER DESCENT WATERFALL

If multiple waterfalls are being installed, or a Sheer

Descent Waterfall 6' or longer is being installed, we

Cantilever edge

recommend installing a separate pump. When

plumbing a pump dedicated for use by the Sheer

Descent, a separate suction line to the pool must be

Sheer Descent unit

Tile

plumbed. This should be plumbed in a minimum of

2" schedule 40 pipe.

Water line

NOTE: At least one anti-vortex safety suction

cover must be installed at pool side as a safety

precaution. The anti-vortex suction cover is

recommended to be positioned 18 inches above

Anti vortex

cover

the floor of the pool.

Next, a Sheer Descent filter/strainer (part #3456),

or equivalent, must be installed on the return side

of the pump, between the pump and the Sheer

Descent Waterfall. A FILTER IS REQUIRED

for separate pump installations, as large debris

must not be allowed to enter the Sheer Descent

unit. For installations requiring up to 60 gallons per minute, use one Sheer Descent filter. For higher water requirements,

use two or more filters plumbed in parallel. A separate return line, with a three way valve plumbed in such a way that

water can be balanced between the Sheer Descent Waterfall and return back to the pool, is also required. See figure 5.

Conventional

concrete decking

Suction line

Figure 5

Rock trap

Separate return

to pool

Jandy three

way valve

Sheer Descent

filter/strainer

Filter

pump

PLUMBING THE SHEER DESCENT WATERFALL

WATERFALL RETURN LINE PLUMBING

The waterfall feed line, from either the main filter pump or a separate pump, should be plumbed in a minimum of 1½"

PVC pipe. NOTE: Two inch plumbing or larger is suggested for waterfalls over 5 feet in total length. Refer to

Hydraulic Guideline Chart for specifications. The feed line should end near the back of the bond beam near the center of

the waterfall location.

It is important to have a valve located in a convenient location on the feed line to regulate the flow of water to the Sheer

Descent Waterfall. A Jandy three-way valve is suggested to be

used as the "T" from the return line of the pool to the Sheer

Descent Waterfall. A properly plumbed valve in that position will

allow full control of the water to the Sheer Descent, as well as to

the rest of the pool. In most cases, this valve can be located after

the filter near the equipment pad. See figure 6.

NOTE: All water to the Sheer Descent must be filtered.

Those systems using a separate pump must use our separate

filter (part #3456) to prevent debris from entering the Sheer

Descent unit.

Figure 6

Return to pool

Jandy three

Filter

way valve

Pump

Suction

from pool

Rock trap

Water to

sheer descent

H YDRAULIC GUIDELINE CHART

•Use minimum of 1½" pipe.

•Use minimum of 2" pipe for runs in excess of 60

feet or if Sheer Descent unit is over 5 feet.

•Dedicated plumbing lines are recommended.

•Maximum recommended flow for a typical installation:

1½" pipe for 60 GPM

2" pipe for 100 GPM

2½" pipe for 140 GPM

3" pipe for 225 GPM

Typical pump performance at 50 Feet of head

½ HP = 26 GPM

¾ HP = 58 GPM

1 HP = 68 GPM

1½ HP = 93 GPM

2 HP = 106 GPM

3 HP = 140 GPM

Page 4

Page 4

PLUMBING A SINGLE UNIT

All Backfeed Sheer Descent Waterfalls have the equivalent of standard 1½ inch pipe protruding from the back of the unit.

For waterfalls eight inches through five feet in length, this fitting is located in the center of the back of the waterfall.

For Sheer Descent waterfalls 6, 7, and 8 feet in length, two 1½ inch fittings are located as follows:

Sheer Descent Length Plumbing Location

6 foot 1 foot, 6 inches to the right and to the left from the center line

7 foot 1 foot, 9 inches to the right and to the left from the center line

8 foot 2 feet to the right and to the left from the center line

NOTE: A plumbing manifold is included with all Sheer Descent Waterfalls 6, 7, and 8 feet in length, to assist in

proper plumbing. Simply plumb the manifold to the waterfall, install the Rock Trap and the plumbing is complete!

Standard 1½" PVC fittings will glue over the 1½" pipe provided on all Sheer Descent Waterfalls. Make sure the fittings

are properly glued. Also, make sure the Rock Trap is properly installed as close to the waterfall as possible (figure 6).

See page 5 for Rock Trap installation instructions.

NOTE: A flow control valve must be plumbed in a convenient location on the supply line for regulation of the water

supply to the unit. See figure 7.

Ensure plumbing lines to unit are clear of debris.

Rock Trap

Notch in beam

Back Feed plumbing

for units 8"through 5'

Ensure plumbing is properly sized

Manifold

Beam

Rock Trap

Beam

Back Feed plumbing

for units 6', 7', & 8'

Figure 7

PLUMBING MULTIPLE UNITS

Plumbing two or more Sheer Descent Waterfalls together is done in exactly the same way as the installation procedure for a

single unit, explained previously, with the exception that additional two-way valves are required for each Sheer Descent

Waterfall. These valves regulate and balance the amount of water between the various waterfalls. For units 6', 7' and 8'

long, separate minimum 2" lines are required, with valves to regulate the balance. See to figure 8.

Make sure no debris is in any of the plumbing lines in the unit

Rock trap

Jandy

Valve

Sheer Descent Waterfall

back feed plumbing for

eight inch through five feet

Jandy

Valve

Rock trap

Sheer Descent Waterfall

back feed plumbing for

six, seven and eight feet

Figure 8

Page 5

Page 5

From pump

To sheer

descent

Screen

Debris

trap

INSTALLING THE SHEER DESCENT WATERFALL

The Sheer Descent Waterfall is generally installed by the tile installer. NOTE: The Sheer Descent Waterfall must be

installed prior to installing the decks and coping. Place the Sheer Descent Waterfall in the pre-cut notch in the bond

beam. Level the top of the Sheer Descent unit to the upper edge of the

bond beam with tile shims.

Sheer Descent Waterfall

NOTE: The top of the Sheer Descent is where the opening and

tongue are located. Fill the gaps around the unit with concrete

brown coat, or similar material, and surface the face of the Sheer

Descent unit in preparation for tile. The face of the Sheer Descent has

Spillway

Spillway must be

flush with tile or

overhang by 1/8"

(side view)

been designed to allow concrete to "grip" the surface and assure a strong

tile bond. Cut the tile to fit under the "lip" of the unit and secure with

"thin set" or similar compound. See figure 9.

Figure 9

Tile

Water line

Undercoat or browncoat

then thin set and tile

START UP INSTRUCTIONS

After the swimming pool is completed and filled with water, the Sheer Descent Waterfall is ready to be activated.

REMOVE THE TONGUE NOW. This must be done before water is diverted to the waterfall. Also, ensure the opening

is clean and clear of any debris. Turn the pump on. If the waterfall is plumbed with the main pool filter pump, allow the

pump to run a few minutes to clear the lines of debris. Slowly open the regulating valve and supply water to the Sheer

Descent Unit. Adjust the flow of water until the sheet of water extends out onto the pool surface. Allow for air to clear the

lines. This should only take a few minutes. The Sheer Descent Waterfall unit should now provide a clear, continuous sheet

of water.

In the event a separate pump was installed, make sure all valves are open prior to starting the pump. ENSURE ALL

LINES ARE CLEAR OF DEBRIS BEFORE STARTING. Start the pump and allow water to circulate through the

separate filter system and return line. Slowly open the valve to the waterfall and regulate to the desired setting. Allow a few

minutes to purge all air from the lines.

In order to prevent freeze damage to the system, the plumbing to the unit must be installed so water drains easily from the

system. The Sheer Descent Waterfall has been engineered to allow only a minimum of water to stay in the unit as long as

the plumbing is installed properly. For winterizing, blow all lines and follow normal procedure.

♦ Install the Rock Trap as close to the water fixture (waterfall, jets, etc.) as

♦ Rock Trap must be installed with debris collection chamber pointed DOWN.

♦♦

♦ Prior to gluing the Rock Trap, ensure flow arrow is properly aligned.

♦♦

♦♦

♦ NEVER install Rock Trap where debris chamber cannot be pointed DOWN.

♦♦

ROCK TRAP

INSTALLATION

OPTIONS

FREEZE PROTECTION AND WINTERIZATION

ROCK TRAP INSTALLATION INSTRUCTIONS (Rock Trap optional on some models)

possible, to assure maximum protection.

See figure 10.

Right

Rock trap

Wrong

Figure 10

Page 6

Page 6

SHEER DESCENT EXTENDED LIP WATERFALL

The Sheer Descent Extended Lip Waterfall is used for radius cuts or when the lip of the waterfall needs to extend over

wide objects such as brick, glass block, etc. The lip extension is 6" (the standard Sheer Descent Waterfall has a one inch

lip). Operation and installation of both products is identical, with the exception that the steel pattern and notch in the beam

may need to be altered to accommodate the lip width. NOTE: The extended lip must be fully supported. See figure 11.

Mortar will not stick to the plastic parts on the Sheer Descent Waterfall. When using various types of coping material,

consult with your decking contractor for appropriate installation and or modification to the installation.

Sheer Descent Extended Lip Waterfall

Figure 11

NOTE: The tongue must stay in place during entire

Tongue

installation, but make sure it is removed prior to system start

up. All aspects of the installation are the same as the

Brick

Brick

Brick

Over Brick/Rock Installation

Bond beam

Rock Trap

Tile

Bond beam

Over the Beam Installation

Notch back

of beam

standard model Sheer Descent Waterfall.

CUTTING THE LIP FOR CURVES OR CUSTOM INSTALLATIONS

The extended lip Sheer Descent Waterfall can be custom cut in the field to meet specific needs, such as curves, irregular

shapes, etc. In order to custom fit the waterfall, carefully measure the amount of extended lip to be removed. Remember to

leave enough room for tile and thin set, so the deepest edge of the radius cut will not be recessed from the tile line. NOTE:

Never remove more than 4½" of the extended lip, leaving a minimum of 1½" of lip. See figure 12. Remove the

protective tongue prior to cutting the waterfall. Remember to REPLACE THE TONGUE after cutting the radius to

protect the fall from construction debris. An additional tongue is provided in product packaging.

The waterfall must be cut with a coarse tooth saw blade. Running water can be applied to the surface being cut to keep the

blade cool. Caution must be taken to make the cut as smooth as possible to avoid a jagged edge. After cutting the

waterfall, insert the support removal tool (included in product packaging) 1 inch into the waterfall opening. Move the tool

around the opening. If the tool hits a support, use the notch in the tool to remove the support. See figure 13a. Make sure

all supports within 1 inch of lip opening are removed. See figure 13b. DO NOT LEAVE THE LOOSE SUPPORT

SECTION IN THE WATERFALL.

After removing sections of the supports, use a coarse grade of sandpaper to smooth the edges of the waterfall, follow with

a fine grade of sandpaper to get the edge as smooth as possible. A sanding block is recommended to avoid rounding the

edges of the waterfall.

Insert the tongue back into the opening and continue installation, following the installation instructions for the standard

Sheer Descent Waterfall. NOTE: Two tongues are provided with every extended lip waterfall. Use the appropriate

tongue to fully cover the opening. The long tongue can be "V" cut, as shown in figure 13b, to allow for curved

installations. The smaller piece of tongue, which is provided in the packaging, is used to make up any sizing

difference due to the radius cut. When installing the smaller piece, make sure the fit is tight and no debris can enter

the spillway opening.

Convex Curve

Break off lip supports

1" from lip of waterfall

Support

removal tool

Convex Curve

Insert Tongue Assemble

Concave Curve

Break off lip supports

1" from lip of waterfall

1½" minimum

¼"

6"

¾"

½"

Support

removal tool

Concave Curve with Tongue

Insert Tongue Assemble

Figure 12 Figure 13a Figure 13b

Page 7

SHEER DESCENT WATERFALL RADIUS CUT GUIDELINE

Sheer Descent Waterfall

extended lip radius installation

Do not

remove more

than 4½"

NOTE: Never remove more than 4½" of the extended lip, leaving a minimum of

1½" of lip. The top of the beam, where the Sheer Descent unit is to be installed,

should be a minimum of 9" thick. When designing custom curves for the Sheer

Descent Extended Lip models, please refer to the following Minimum Radius Guidelines

Table to select the correct Sheer Descent model. Super Radius models accommodate

very tight radius curves and are available by special order.

MINIMUM RADIUS GUIDELINES TABLE KEY

Sheer Descent Model Abbreviation Customize Cut

Extended Lip EL Field Cut or Factory Cut

Super Radius SR FACTORY CUT ONLY

S

HEER DESCENT WATERFALL LENGTH

1' 1.5' 2' 3' 4' 5' 6' 7' 8'

Radius

1' EL - - - - - - - -

1.5' EL EL - - - - - - -

2" EL EL EL SR

2.5' EL EL EL SR - - - - -

3' EL EL EL SR SR - - - -

3.5' EL EL EL SR SR - - - -

4' EL EL EL EL SR - - - -

4.5' EL EL EL EL SR SR - - -

5' EL EL EL EL SR SR - - -

5.5' EL EL EL EL SR SR - - -

6' EL EL EL EL EL SR SR - -

6.5' EL EL EL EL EL SR SR - -

7' EL EL EL EL EL SR SR - -

7.5' EL EL EL EL EL SR SR - -

8' EL EL EL EL EL SR SR - -

8.5' EL EL EL EL EL SR SR SR -

9' EL EL EL EL EL SR SR SR -

9.5' EL EL EL EL EL EL SR SR -

10' EL EL EL EL EL EL SR SR -

10.5' EL EL EL EL EL EL SR SR -

11' EL EL EL EL EL EL SR SR -

12' EL EL EL EL EL EL SR SR -

12.5' EL EL EL EL EL EL EL SR SR

13' EL EL EL EL EL EL EL SR SR

Page 7

Before proceeding, make sure the pump system is fully functional and activated. Also, ensure all air is purged from

plumbing lines.

Problem «

The Sheer Descent Waterfall is not

completely smooth. A gap in the sheet

of the water is present.

Problem «

Where multiple Sheer Descent

Waterfalls are installed, one of the

waterfalls is stronger than the other.

TROUBLE SHOOTING GUIDE

Cause «

Debris in the plumbing has lodged in

the opening of the waterfall.

Cause «

The water supplied to the units is not

properly balanced.

Solution

Use a credit card or similar object and

gently position it inside the opening

while the waterfall is on. Slide it

along the opening to the point where

the debris is located and gently pull

the debris through the opening.

Solution

Adjust the valves for each waterfall

until the proper effect and balance is

achieved. See figure 8 for valve

location.

Page 8

LIMITED WARRANTY

Thank you for purchasing Jandy® pool and spa products. Water Pik Technologies (manufacturer of Jandy

products, including Laars

®

pool and spa heaters, Air Energy Heat Pumps, and Clormatic Electronic Chlorine

Generators) warrants all parts to be free from manufacturing defects in materials and workmanship for a period of

one year from the date of retail purchase, with the following exceptions:

AquaLink

•

NeverLube

•

AquaPure

•

®

RS units installed with Jandy Surge Protection Kits will be covered for two years.

®

valves are warranted for the life of pool and/or spa on which they were originally installed.

TM

Electronic Chlorine Generator Electrolytic Cells carry a 5 year limited warranty on a prorated basis.

This warranty is limited to the first retail purchaser, is not transferable, and does not apply to products that have

been moved from their original installation sites. The liability of Water Pik Technologies shall not exceed the

repair or replacement of defective parts and does not include any costs for labor to remove and reinstall the

defective part, transportation to or from the factory, and any other materials required to make the repair. This

warranty does not cover failures or malfunctions resulting from the following:

1. Failure to properly install, operate or maintain the product(s) in accordance with our published Installation,

Operation and Maintenance Manuals provided with the product(s).

2. The workmanship of any installer of the product(s).

3. Not maintaining a proper chemical balance in your pool and/or spa [pH level between 7.2 and 7.8, Total

Alkalinity (TA) between 80 to 120 ppm, Total Dissolved Solids (TDS) less than 2000].

4. Abuse, alteration, accident, fire, flood, lightning, rodents, insects, negligence or acts of God.

5. Scaling, freezing, or other conditions causing inadequate water circulation.

6. Operating the product(s) at water flow rates outside the published minimum and maximum specifications.

7. Use of non-factory authorized parts or accessories in conjunction with the product(s).

8. Chemical contamination of combustion air or improper use of sanitizing chemicals, such as introducing

sanitizing chemicals upstream of the heater and cleaner hose or through the skimmer.

9. Overheating, incorrect wire runs; improper electrical supply; collateral damage caused by failure of O-Rings,

DE grids, or cartridge elements; or damage caused by running the pump with insufficient quantities of water.

LIMITATION OF LIABILITY:

This is the only warranty given by Water Pik Technologies. No one is authorized to make any other warranties on

Water Pik Technologies' behalf. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE AND MERCHANTABILITY. WATER PIK TECHNOLOGIES EXPRESSLY DISCLAIMS

AND EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL, INCIDENTAL, INDIRECT OR PUNITIVE

DAMAGES FOR BREACH OF ANY EXPRESSED OR IMPLIED WARRANTY. This warranty gives you specific

legal rights. You may also have other rights which vary by state or province.

WARRANTY CLAIMS:

For prompt warranty consideration, contact your dealer and provide the following information: proof of purchase,

model number, serial number and date of installation. The installer will contact the factory for instructions

regarding the claim and to determine the location of the nearest designated service center. If the dealer is not

available, you can locate a service center in your area by visiting www.jandy.com or by calling our technical

support department at (707) 776-8200 extension 260. All returned parts must have a Returned Material

Authorization number to be evaluated under the terms of this warranty.

A Water Pik Technologies Company

480 S. Service Road West • Oakville, Ontario, Canada L6K 2H4

6000 Condor Drive • Moorpark, CA USA 93021

Sheet #0129, Rev. D

• 707.776.8200 • Fax 707.763.7785

• 905.844.8233 • Fax 905.844.2635

Litho in U.S.A. © Water Pik Technologies 0404

Loading...

Loading...