Page 1

HPC

Page 2

About This Manual 1

Revision 2.0c – 30 August 2013 HPC User Manual

EMC COMPLIANCE

This product is approved for use in Europe and Australia/New Zealand and conforms to the following

standards:

European Norms Australian / New Zealand Standards

EN 55015 AS/NZS CISPR15

IEC 60439-1

IEC 60439.3

AS/NZS 3439.1

AS/NZS 3439.3

IEC 60950 AS/NZS 60950

To ensure continued compliance with EMC Directive 89/336 and the Australian Radiocommunications

Act 1992, use only high quality data cables with continuous shield, and connectors with conductive

backshells. Examples of such cables are:

DMX: Belden 8102 100% Aluminium foil screen, 65% Copper braid.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation. Changes or

modifications not expressly approved by the manufacturer could void the user's authority to operate

the equipment.

DISCLAIMER

Information contained in this manual is subject to change without notice and does not represent a

commitment on the part of the vendor. JANDS PTY LTD shall not be liable for any loss or damage

whatsoever arising from the use of information or any error contained in this manual.

It is recommended that all service and repairs on this product be carried out by JANDS PTY LTD or its

authorised service agents.

JANDS PTY LTD cannot accept any liability whatsoever for any loss or damage caused by service,

maintenance or repair by unauthorised personnel, or by use other than that intended by the

manufacturer.

JANDS HPC Series products must only be used for the purpose they were intended by the

manufacturer and in conjunction with this operating manual.

Disconnect mains power when not in use.

Designed in Australia

JANDS PTY LTD ACN 001 187 837

40 Kent Rd Locked Bag 15

Mascot NSW 2020 MASCOT NSW 1460

Sydney Australia Sydney Australia

Phone: +61-2-9582-0909 Email: info@jands.com.au

Fax: +61-2-9582-0999 Web:

www.jands.com.au

JANDS PTY LTD 2013 Revision 2.0c

All rights reserved 30 August 2013

Page 3

About This Manual 2

Revision 2.0c – 30 August 2013 HPC User Manual

Table of Contents

Table of Contents ...................................................................................................... 2

1.0 About This Manual .......................................................................................... 3

1.1 Important Safety Information ................................................................................... 3

2.0 Introduction ..................................................................................................... 4

2.1 Features ..................................................................................................................... 4

3.0 Equipment Description ..................................................................................... 5

3.1 Front Panel Layout ..................................................................................................... 5

4.0 Getting Started ................................................................................................. 6

4.1 Connecting Power ...................................................................................................... 6

4.2 Powering Up .............................................................................................................. 6

4.3 Connecting Loads ....................................................................................................... 6

4.3.1 Changing the Channel Configuration ................................................................. 6

4.4 Connecting Control Input .......................................................................................... 7

4.4.1 Changing the DMX Address................................................................................ 7

4.4.2 DMX Termination ............................................................................................... 7

5.0 Operation ......................................................................................................... 8

5.1 Menu and Setting Adjustment .................................................................................. 8

5.1.1 Root Menu ......................................................................................................... 8

5.1.1.1 Changing the DMX Address ........................................................................ 8

5.1.1.2Displaying the Software Version ................................................................. 8

5.1.2 Cap Function .................................................................................................... 11

5.1.3 Preheat Function .............................................................................................. 11

5.1.4 DMX Termination ............................................................................................. 11

5.1.5 DMX Data Loss ................................................................................................. 11

5.1.6 DMX Source ...................................................................................................... 11

5.1.7 Automatic Relay Control – Bypass Relay ......................................................... 12

5.1.8 Automatic Relay Control – Isolate Relay .......................................................... 12

5.2 Deep Clear ................................................................................................................... 12

5.3 RDM Facility ................................................................................................................ 13

6.0 Fault Diagnosis ................................................................................................. 14

6.1 Output protection .................................................................................................... 14

6.2 Thermal Protection .................................................................................................. 14

6.3 Neutral-Earth Detection .......................................................................................... 14

6.4 Fault Finding Guide .................................................................................................. 15

7.0 Installation ....................................................................................................... 16

Page 4

About This Manual 3

Revision 2.0c – 30 August 2013 HPC User Manual

7.1 Ventilation ............................................................................................................... 16

7.2 Supply Wiring ........................................................................................................... 16

8.0 Maintenance .................................................................................................... 17

8.1 External Cleaning ..................................................................................................... 17

8.2 Internal Cleaning ...................................................................................................... 17

8.3 Routine Maintenance .............................................................................................. 17

9.0 Technical Data and Specifications .................................................................... 18

9.1 DMX Connector Pinouts .......................................................................................... 19

9.2 RDM Implementation .............................................................................................. 19

9.2.1 Root Device PIDs .............................................................................................. 19

9.2.2 Sub Device PIDs ................................................................................................ 21

1.0 About This Manual

This manual provides general information about HPC dimmer product fitted with

software version 2. Product diagrams within this manual may differ from the actual

unit provided.

1.1 Important Safety Information

o This product is NOT rated for outdoor use. Ensure the HPC is protected from

moisture and is not used in wet areas.

o Output sockets may have dangerous voltages present even when the channels

are driven off. Switch off the channel circuit breaker before connecting and

disconnecting loads or replacing load lamps.

o The HPC should be properly mounted on a flat stable surface.

o Provide adequate ventilation during use. Do not obstruct airflow around the

vents.

o Do not run the power cables under carpet or other thermally insulating

materials. Arrange the cables away from traffic areas and where they may

become a tripping hazard.

o Inspect the unit for damage prior to each use. If the unit is dropped or damaged

in any way, it must be inspected by a qualified person before use.

o High voltages are present inside the unit. Do not operate with the lid removed.

o Disconnect from mains supply when not in use.

o No user serviceable parts inside.

Page 5

Introduction 4

Revision 2.0c – 30 August 2013 HPC User Manual

2.0 Introduction

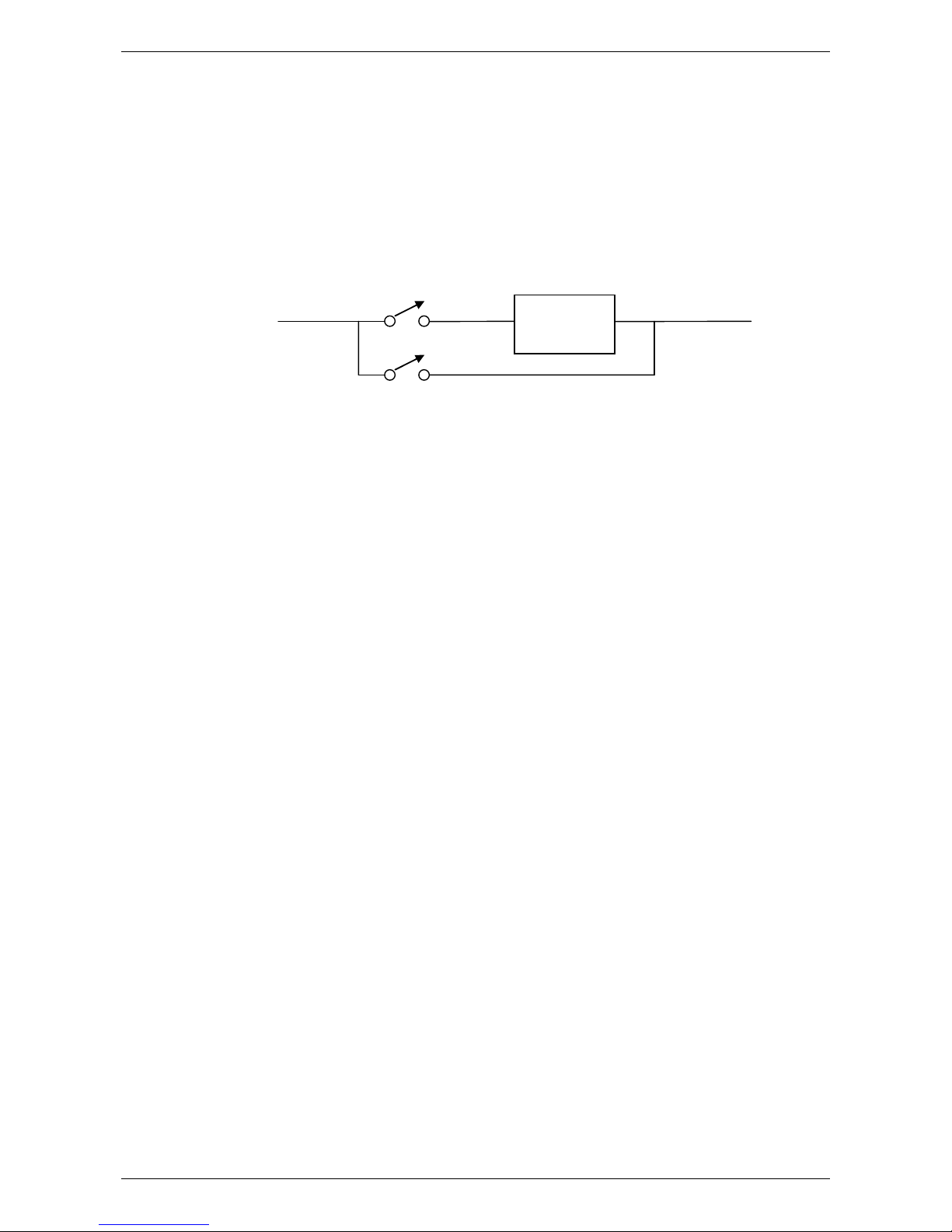

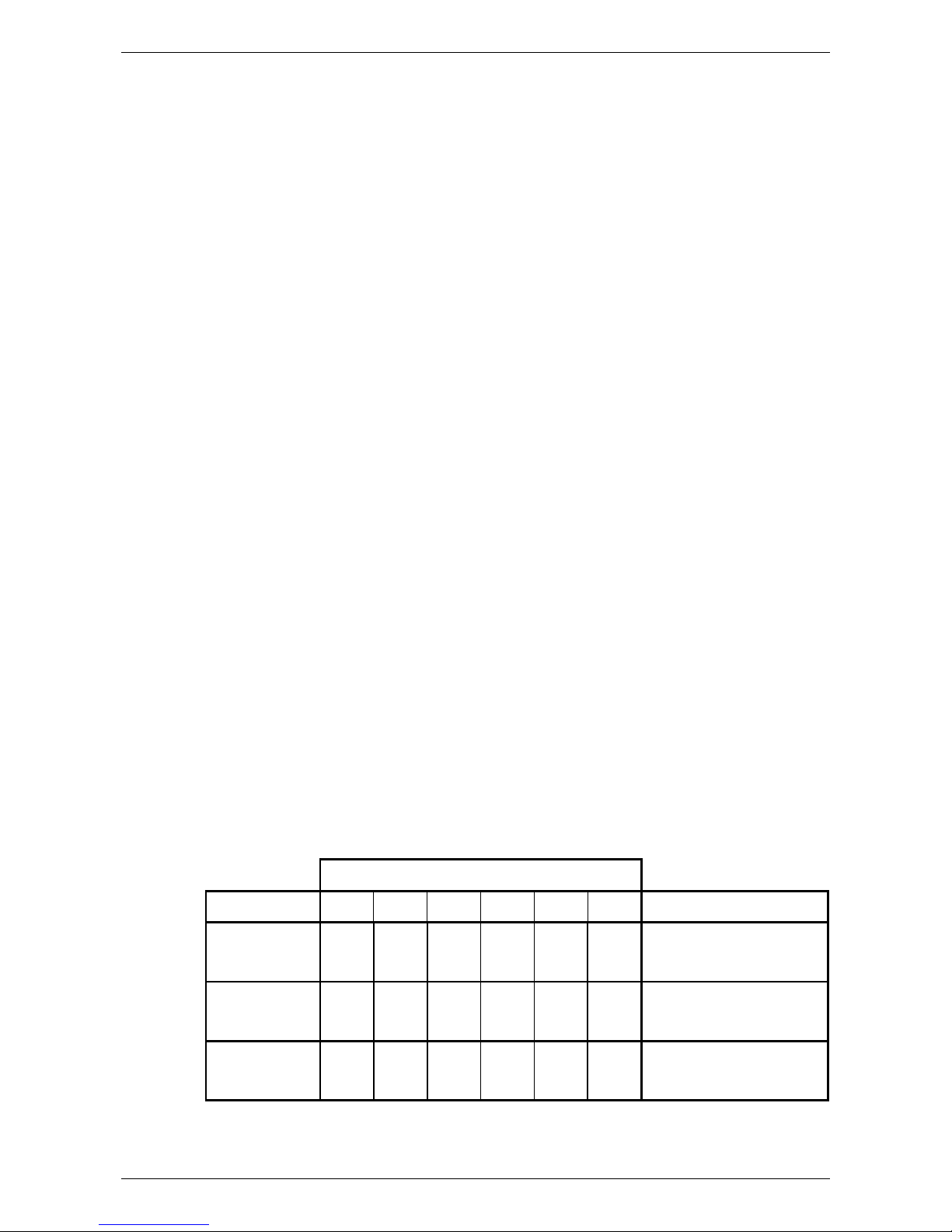

The HPC is a professional power control product designed primarily for use in

performance spaces, but has many additional applications. Each of the 12 channels

incorporates a full power dimmer circuit and two high current relays connected as

shown in Figure 1.

Isolate Relay Dimmer

Input Output

Bypass Relay

Figure 1: Channel Organisation

The “Isolate” relay ensures the output can be fully switched off with a real “air gap”

between the input and output, while the “Bypass” relay completely bypasses the

dimmer circuitry ensuring a clean undistorted mains output. Hence each channel can

be used to safely switch power to non-dimmable loads such as moving lights, LED

fixtures, video screens and walls, gobo rotators, fog machines, and other accessories,

or alternatively smoothly dim conventional incandescent loads. Channels may be

individually set to On, Remote Switch, Remote Dim, or Off.

The HPC is controlled using DMX-512-A via a standard 5-pin socket on the front panel.

RDM functionality is provided to enable remote configuration and status readback via

a suitable RDM controller. The dimmed outlets and power entry are located on the

rear panel. The HPC provides easy to use in-built test functions and facilities.

2.1 Features

o Relay pair per channel allows full control of all loads, both dimmable and non-

dimmable. Automatic relay control optimises safety and efficiency.

o DMX-512 address by start channel

o RDM functionality allow remote configuration and status readback

o Inbuilt DMX-512 terminator

o Two DMX snapshots (scenes)

o Dimming curve set for linear relationship between control input and output

power

o Multiple phase power operation modes

o Dual temperature-controlled DC fans

o Temperature monitor and soft thermal cut-out

o Operates from wide mains supplies 100V to 240VAC, 40 to 66Hz

Page 6

Equipment Description 5

Revision 2.0c – 30 August 2013 HPC User Manual

3.0 Equipment Description

3.1 Front Panel Layout

Refer to Figure 2 for a description of the front panel controls.

1. Channel output sockets (rear panel): The output sockets are located on the back

panel.

2. Channel circuit breakers: If a breaker trips during use ensure the fault has been

cleared before resetting.

3. + and - buttons: These buttons select the DMX-512 start channel, are used to move

through menus and select functions and change values.

4. EXIT and MENU/ buttons: These buttons are used to navigate through the menus

and set DMX address.

5. 3-Digit Display: Indicates currently selected DMX-512 start channel, the menu

position, and the various function options.

6. SIGNAL LED: Indicates the presence of DMX-512 signals.

7. ERROR LED: Flashes in the presence of a fault. In normal operation this LED should be

off.

8. IC LED: The Internal Control LED Illuminates when control is internal, ie. not from the

DMX-512 input.

9. TERM LED: Illuminates when the Terminate function is active.

10. PHASE LEDs: Three blue LEDs (one for each phase) indicate that the mains supply is

available. Note that all three LEDs should illuminate when power is available regardless

of the type of the mains supply used to power the HPC.

11. DMX IN SOCKET: Standard 5-pin AXR connector accepts DMX-512 signals from the

controller.

12. DMX LOOP SOCKET: Standard 5-pin AXR connector links the DMX-512 signals to other

dimmers or devices.

13. Channel “Mode” Switch: A switch per output channel is used to change the mode of

operation of that channel.

14. Channel LED: A multicolour LED per output channel is used to indicate the mode and

drive level of that channel.

2

1

(REAR)

4

3

Figure 2: HPC front panel layout

5

6, 7, 8, 9

10

11, 12

13

14

Page 7

Getting Started 6

Revision 2.0c – 30 August 2013 HPC User Manual

4.0 Getting Started

The HPC would normally be rack mounted before any wiring is terminated. Refer to

Section 6.0 Installation for installation details.

4.1 Connecting Power

The HPC dimmer may be supplied with a mains inlet cable and multipin connector,

mains inlet cable and no connector, or with no inlet cable fitted. Refer to Section 7.2

for details on mains termination connection methods. Always connect to a supply that

is protected by fuses or circuit breakers at not more than the specified maximum.

Refer to Section 9.0 Technical Data and Specifications.

4.2 Powering Up

Turn on the power and check that the three blue phase power indicator LEDs A, B, and

C are illuminated before connecting any loads. If any of the phase LEDs are dim or off,

power down and remedy the fault before trying again.

If all is well, power down and connect loads.

4.3 Connecting Loads

Switch off the channel circuit breaker before connecting and disconnecting loads.

Ensure any plugs are pushed firmly into their sockets. The HPC dimmer circuit will drive

most incandescent loads as well as pinspots, fans, and dimmable fluorescent tubes.

Un-dimmable loads should not be driven from channels configured to dim (see section

4.3.1).

4.3.1 Changing the Channel Configuration

Each HPC channel may be independently configured to dim, switch, turn fully on, or be

fully off. To change a channel’s configuration:

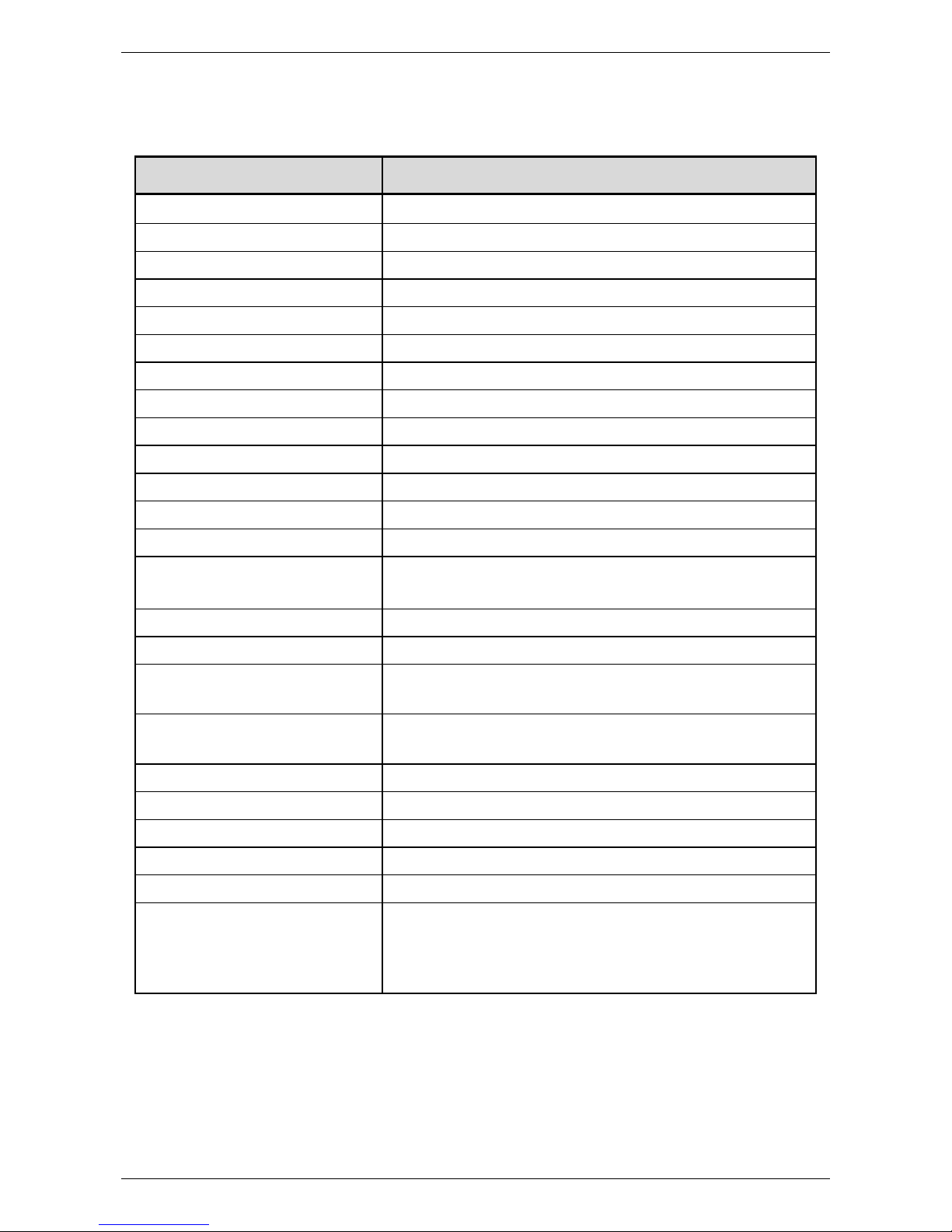

LED colour

Function

Green

Dimmer

Orange

Switch

Red

Channel fully On

Off

Channel fully Off

Table 1: Channel Indicator functions

Page 8

Getting Started 7

Revision 2.0c – 30 August 2013 HPC User Manual

1. Press the Channel Switch for the channel to be reconfigured. All of the Channel

LEDs now flash to indicate the current mode of operation as shown in Table 1.

2. Continue to press the channel Switch until the required function is indicated by

the LED/s.

3. Press and hold the channel switch to record the new setting.

To record multiple channel configurations at once, repeat steps 1 and 2 until all

channels have been configured, then press and hold any channel button to store all

channels.

4.4 Connecting Control Input

Where DMX control is to be used, the input signal to the HPC should conform to the

specified standard for DMX and RDM. Plug the DMX-512 signal to the “DMX IN” socket.

The DMX signal may be daisy-chained to the next DMX receiver via the LOOP

connector.

The SIGNAL LED indicates the presence of control data.

The DMX-512 input is protected against extreme over-voltages across any input pins

and from any input to chassis. The “terminating” resistor is not protected against overvoltages.

Where the Ethernet option is fitted, plug the Ethernet data into the front panel

connector. The source of control for DMX and RDM must be manually selected via the

menu between the front panel DMX connector and the Ethernet connector – refer to

Section 5.1.6.

4.4.1 Changing the DMX Address

The DMX-512 address is the DMX-512 channel number that will be used to control HPC

dimmer channel 1. HPC dimmer channels 2 and up are controlled from the next DMX512 channel upward.

To change the DMX-512 address:

1. At the root menu adjust the displayed value using the + and – buttons until it

matches the required start channel.

2. Press MENU/ to confirm.

4.4.2 DMX Termination

In any DMX-512 system the signal should be terminated at the last dimmer or receiver

in the chain - the HPC can provide this function. Refer to Section 5.1.4.

The TERM LED indicates when the Termination function is active. Note that when

termination is active no signal is present at the LOOP connector.

Page 9

Dimmer Operation 8

Revision 2.0c – 30 August 2013 HPC User Manual

5.0 Operation

This section assumes the HPC has been correctly connected to the mains power supply

and a source of DMX-512 control signal.

5.1 Menu and Setting Adjustment

• Pressing MENU/ at any time moves up a menu level or confirms a new setting.

• Pressing the EXIT button at any time moves back a menu level with no setting

change.

• When adjusting a setting, the display will flash briefly once per second for three

seconds. If the MENU/ button is pressed within that three seconds, the new

value is retained and subsequently takes effect. If no button is pressed within

that 3 seconds, or if the EXIT button is pressed within 3 seconds, the setting

reverts to the previous value.

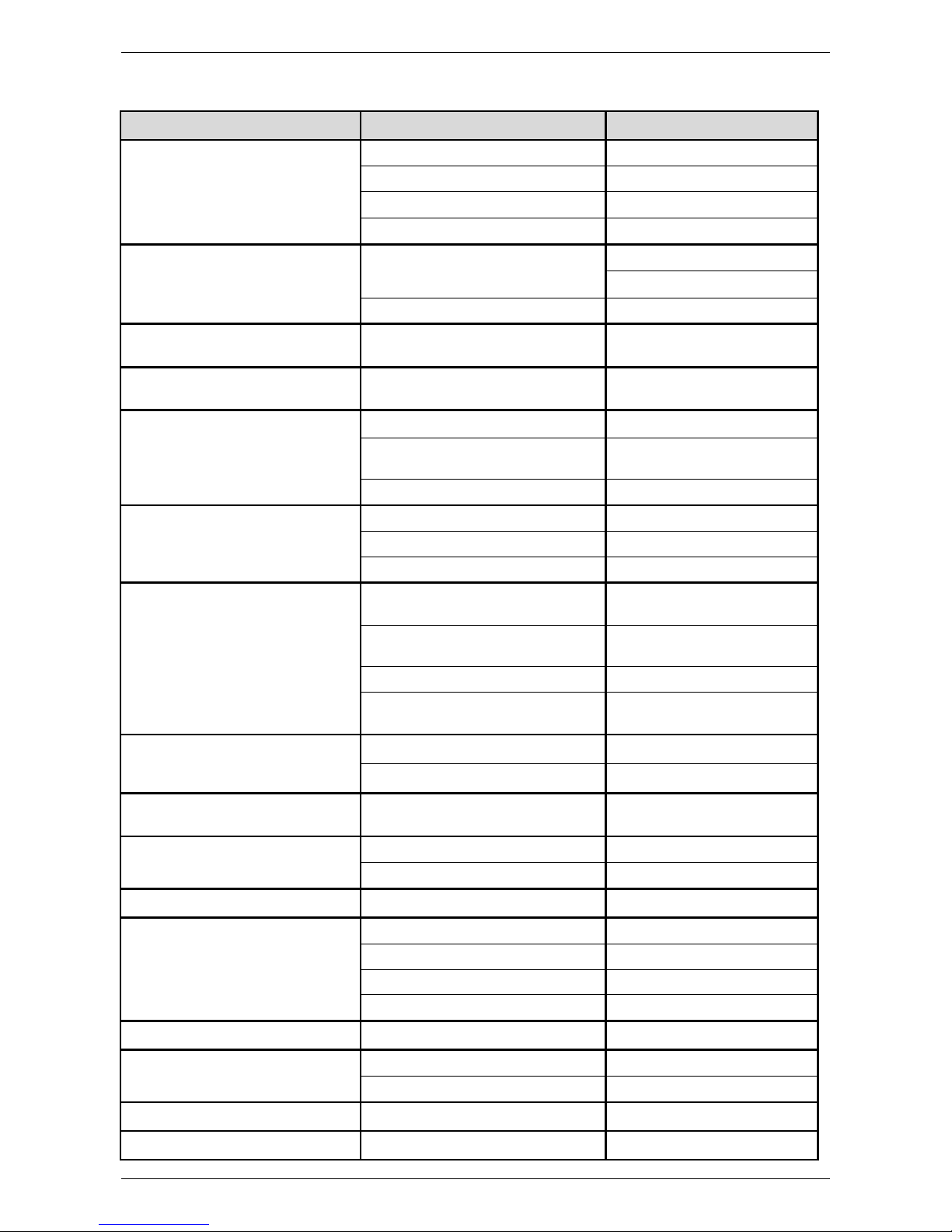

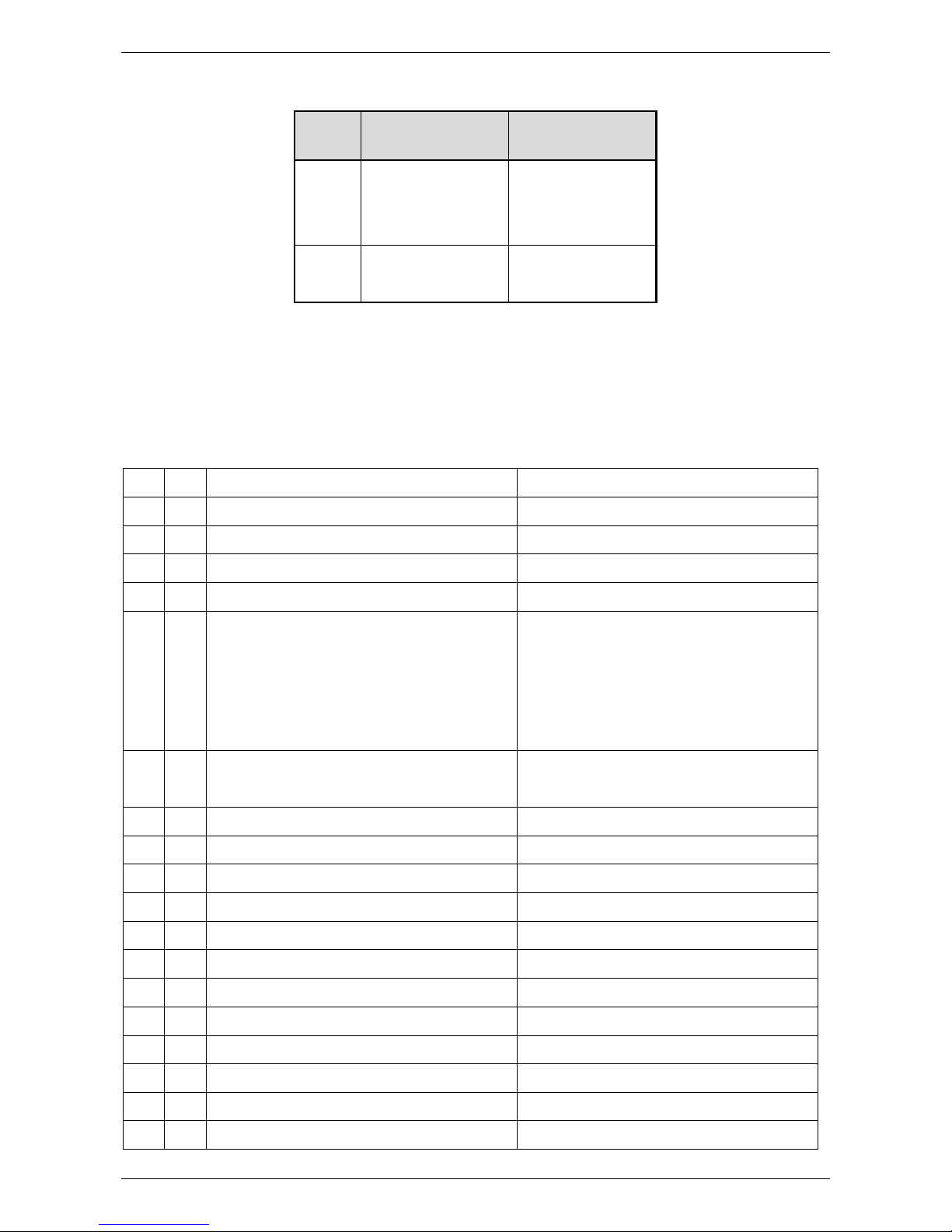

The menu tree is shown in Figure 2. The function of each menu option is described in

Table 2.

5.1.1 Root Menu

The root menu is displayed when the Exit button has been pressed sufficient times

such that the DMX-512 start channel is displayed. A number of functions are available

at the Root Menu as detailed in the following sections.

5.1.1.1 Changing the DMX Address

The DMX address is the DMX-512 channel number that will be used to control HPC

dimmer channel 1. HPC dimmer channels 2 and up are controlled from the next DMX512 channel upward.

To change the DMX address:

1. At the root menu adjust the displayed value until it matches the required start

channel. level

2. Press MENU/ to save the new setting.

5.1.1.2 Displaying the Software Version

To display the software version press and hold the EXIT button while the Root Menu is

displayed. While the Exit button is held the display scrolls with th following data:

• The software version and date

• The internal PCBs found

• The RDM UID

Additionally when EXIT is pressed the channel configuration is indicated on the channel

LEDs.

Page 10

DMX Address Test Channel Select Channel

Use Channel Select buttons

to activate channels

NE Protection

Activate Chase

NE Protection ~ *

+ -

DMX Setups

Output Cap

Terminate ~ *

Signal Loss ~ *

Drive All Chans

Cap Value ~ *

+ -

Scene Control

Mains Freq *

Phases Present *

Select Scene ~ *

+ -

Select Speed

+ -

Select Drive Level

+

-

Change DMX ~ *

+ -

Sets dimmer to

hold data when

DMX is lost

Sets dimmer to

fade to Scene 1

when DMX is lost

Fade to Scene 1

Hold Output

Sets NE fault

detector on or off

Toggles DMX

Termination

function

Sets cap value

Hold to record

the selected

Scene

Press to

activate the

Chase

+ -

+ -+ -

+ -

+ -

+ -

+ -

E

+

-

+

-

E

E

E

E

E

E

E

E

E

E

Hold

(Menu)

E (Cancel/Exit)

* RDM functionality

** Appears when Ethernet option fitted

~ Affected by Deep Clear

+ -

+ -

Global Preheat Preheat Value ~ *

+ -

+ -

Sets preheat

value

System Checks

+ -

E

Signal Source ~ **

DMX / Ethernet

DMX / DMX

Ethernet / DMX

Ethernet /Ethernet

Set DMX and

RDM connection

sources

Press to

activate the

selected Scene

Press

E

Packets/Sec *

Temperature *

Automatic Relay

Control

Auto Isolate ~ *

+ -

+ -

Enable/disable

Automatic bypass

Function

Auto Bypass ~ *

+ -

Automatic

Isolation ~ *

+ -

Automatic

Bypass ~ *

E

E

E

E

Enable/disable

Automatic Isolate

Function

+ -

Page 11

Dimmer Operation 10

Revision 2.0c – 30 August 2013 HPC User Manual

First

Level

Second

Level

Third

Level

Description

Chn

Use channel select buttons drive channel/s to full

n-E

On-off

When ON the N-E fault detector is enabled

SIG

no.S

HLd

Set the HPC to hold the current output upon loss

of DMX data

SIG

no.S

Sc.1

Set the HPC to fade to Scene 1 upon loss of DMX

data

SIG

End

Toggle the DMX terminate function. The TERM LED

indicates when the terminate function is active.

SIG

Src

D d

Level and RDM via DMX connector

SIG

Src

D e

Level via DMX connector and RDM via Ethernet

connector

SIG

Src

E D

Level via Ethernet connector and RDM via DMX

connector

SIG

Src

E e

Level and RDM via Ethernet connector

CAP

240-100

Cap the maximum output voltage. 240 = 240V

nominal operation.

Pre

OFF-50

Set the Preheat level

Rlc

byp

---

Some channels have Bypass enabled and some

don’t

Rlc

Byp

On

Relay bypass will automatically activate

Rlc

Byp

Off

Relay bypass will not automatically activate

Rlc

iso

---

Some channels have Isolate enabled and some

don’t

rlc

Iso

On

Relay Isolate will automatically activate

rlc

iso

Off

Relay Isolate will not automatically activate

Chc

24.C

Display the internal measured temperature in

degrees Celsius

CHC

D.21

Display the DMX packet rate (per second)

Chc

3.PH

Display the number of connected phases. Note

that 2.PH is displayed when 1 or 2 phase power is

connected.

Chc

50.H

Display the mains frequency

Scn

SC1

Press MENU/ to play Scene 1. Press and hold

MENU/ to record Scene 1.

Scn

SC2

Press MENU/ to play Scene 2. Press and hold

MENU/ to record Scene 2.

CHS

SP1-SP9

Activate the chase and set the rate

ALL

0-FL

Drive all channels in 10% increments

Table 2: Menu Function Reference

Page 12

Dimmer Operation 11

Revision 2.0c – 30 August 2013 HPC User Manual

5.1.2 Cap Function

The Cap function is used to scale the output voltage of all channels from the maximum

of 240V. This may be used to extend lamp life or allows other voltage loads to be run,

such as 230V or 120V lamps.

Note that the Cap level may be individually set for a channel by selecting that channels

“Mode” button when in the cap menu. If this is the case when the menu is entered the

display will show “---“.

5.1.3 Preheat Function

The Preheat function is used to inject a small amount of power into the lamps when

the control level is set to zero. This provides a small amount of energy to heat the lamp

filament and so minimise thermal shock if they are flashed to full. This may extend

lamp life and reduce the surge on the mains supply at the expense of an increase in

system power consumption.

Adjust the level until the lamps start to glow, then slowly reduce it until the lamps just

go dark.

Note that the Preheat level may be individually set for a channel by selecting that

channels “Mode” button when in the Preheat menu. If this is the case when the menu

is entered the display will show “---“.

This function is ignored for channels set On or to Switch.

5.1.4 DMX Termination

Any long DMX-512 data line must be terminated at the end for correct operation, and

the HPC provides this function. Selecting the “End” option toggles the terminate

function. The TERM LED on the front panel indicates when the DMX-512 is terminated.

Note that no signal is present on the DMX OUT socket when the terminate function is

active.

5.1.5 DMX Data Loss

The HPC can be configured to hold the current output or dim to Scene 1 when DMX-

512 data is interrupted. To set the dimmer to fade to Scene 1, select “SC.1” in the

“no.S” menu. To set the dimmer to hold the current output, select “HLD” in the “No.S

menu.

Note that in both cases the HPC will turn all DMX controlled outputs off if data is not

restored within 10 minutes.

5.1.6 DMX Source

When the Ethernet module is fitted, the source of DMX and RDM can be assigned

between the existing 5 pin DMX connector and the optional Ethernet connector. It is

possible to select between the 4 possible combinations - refer to the following table.

The left digit indicates the source of level information while the right digit indicates the

source of RDM information.

Page 13

Dimmer Operation 12

Revision 2.0c – 30 August 2013 HPC User Manual

Display Setting DMX Channel

Level Data is

received on:

RDM Control Data is received on:

d d

Front panel DMX connector Front panel DMX connector

d E

Front panel DMX connector Ethernet Option connector

E d

Ethernet Option connector Front panel DMX connector

E E

Ethernet Option connector Ethernet Option connector

5.1.7 Automatic Relay Control – Bypass Relay

Each channel of the HPC includes relay that when activated bypasses the dimmer

circuit. The HPC includes a automatic bypass mode that activates the Bypass relay if

the channel is dimmed to full for more than about 60 seconds. The bypass relay is

immediately deactivated should the level drop below full. This mode can be globally

activated/deactivated via the “rLC” -> “byp” option in the menu.

Note that the Automatic Bypass function may be individually enabled for each channel

by selecting that channels “Mode” button when in the Bypass menu. If this is the case

when the menu is entered the display will show “---“.

The Bypass relay does not activate for channels where the Cap value does not equal

240.

5.1.8 Automatic Relay Control – Isolate Relay

Each channel of the HPC includes relay that is used to Isolate the dimmer circuit. The

HPC includes an isolate activation mode that automatically activates the Isolate relay if

the channel is dimmed to zero for more than about 60 seconds. This mode can be

activated/deactivated for all channels via the “rLC” -> “iso” option in the menu.

Note that the Automatic Isolate function may be individually enabled for each channel

by selecting that channels “Mode” button when in the Isolate menu. If this is the case

when the menu is entered the display will show “---“.

The Isolate relay does not activate for channels where the preheat is set to anything

other than 0.

5.2 Deep Clear

The HPC includes a deep clear facility to enable the internal processor to be reset to

the factory default settings. In general this should not be required however if

necessary the following procedure should be followed:

1 Turn HPC power off

2 Press and hold the “+” and “-“ buttons

3 Turn the HPC power on

4 Release the buttons held in step 2

5 Press the MENU/ button

Page 14

Dimmer Operation 13

Revision 2.0c – 30 August 2013 HPC User Manual

5.3 RDM Facility

RDM is a specification for a protocol that enables a RDM “controller” to set and alter

parameters within a RDM “device” via the DMX-512 connection. An RDM system

consists of one RDM controller and at least one RDM device. The HPC is an RDM

device.

The HPC includes RDM commands that enable most of the parameters in its menu to

be altered and to change the function of each channel between On, Off, Dim, and

Switch. Refer to Section 9.2 for further information regarding the RDM commands

implemented by the HPC.

In general a RDM controller should automatically “discover” the HPC (and any other

connected/powered devices) when it’s turned on. If not, ensure RDM Discovery is

enabled in the controller, power up the HPC, and re-initiate Discovery on the

controller. Refer to the operation manual for the controller regarding how to use it to

read/alter HPC parameters.

When using the DMX connection, all RDM commands are received on pins 2 and 3 of

the DMX cable.

Page 15

Fault Diagnosis 14

Revision 2.0c – 30 August 2013 HPC User Manual

6.0 Fault Diagnosis

NOTE

Contact your authorised JANDS Distributor for repairs or servicing.

In Australia refer all repairs to an authorised JANDS service agent or

return the faulty unit in suitable packaging to:

JANDS PTY LTD Service Dept,

2-26 Kent Rd

Mascot NSW 2020

Australia

6.1 Output protection

Each of the output circuits is protected by a fast-acting thermal/magnetic circuit

breaker. These breakers are designed to pass the rated current, but will disconnect the

output circuit for any overload condition (the larger the overload, the quicker the

disconnection). If a circuit breaker trips there’s either a fault which should be rectified

or the channel is overloaded.

6.2 Thermal Protection

The HPC dimmers feature temperature-controlled fan cooling. As the internal

temperature of the dimmer increases, the fan speed increases. The inlet and exhaust

areas of the chassis must be kept clear while the HPC is on.

The HPC continuously monitors the internal heatsink temperature. As the temperature

approaches the rated maximum the internal processor attempts to reduce the heat

build up by reducing the output levels. If the temperature continues to rise the dimmer

will shut down the output drive, however this should only be necessary if there is

inadequate ventilation or if the ambient temperature is above the rated maximum.

Refer to Section 7.1 Ventilation regarding HPC ventilation requirements.

6.3 Neutral-Ea rth Detection

The HPC includes a fault detector that monitors the Neutral-Earth (N-E) voltage – in

normal operation there should be little of no voltage difference between the Neutral

and Earth. If the voltage exceeds a predetermined amount the outputs are turned off.

The N-E fault detector may be disabled in the menu.

Page 16

Fault Diagnosis 15

Revision 2.0c – 30 August 2013 HPC User Manual

6.4 Fault Finding Guide

FAULT SYMPTOM POSSIBLE CAUSE REMEDY

Breaker trips

Excessive load Reduce channel loading

Lamp or wiring fault Check lamps and wiring

Poor ventilation Increase air flow to HPC side vents

Faulty HPC Service HPC

One channel flickers when dimmed

DMX source problem

Softpatch another console fader

Service console

Faulty HPC channel Service HPC

Same load flickers on other channel

Insufficient or very inductive load Connect >100W incandescent lamp

in parallel

NE Error on display

Poor Earth or Neutral connection Check supply wiring. Disable N-E

detector in menu (6.3)

All Channels flicker when dimmed

Incorrect DMX protocol / wiring Replace DMX source / wiring

Un-terminated DMX line Activate Terminate facility on the

last HPC (5.1.4)

Mains control tones exceed limits Contact factory

Signal LED flickers

Faulty DMX wiring/connections Repair

Faulty console Repair

Faulty HPC Service HPC

RDM doesn’t work at all

Controller has RDM disabled or not

configured correctly

Reconfigure controller

Controller does not conform to the

published RDM standard

Check specification for the

controller version of RDM

HPC RDM source not correctly set Change source setting (5.1.5)

Intermediate equipment (eg DMX splitter)

not RDM compatible

Check specs of all other equipment

RDM operation erratic

DMX line un-terminated

Terminate the DMX line

Poor DMX wiring

Replace DMX wiring

Specific RDM feature doesn’t work

Feature not supported by either HPC or

Controller

Check specs for supported

commands (9.2)

Channel/s don’t respond to DMX

Channels set to On or Off Change channel mode (4.3.1)

Level source incorrectly set Change source setting (5.1.5)

Error LED flashing

Over-temperature Improve HPC ventilation

Error LED on continuously

Recent over-temperature Improve HPC ventilation

DMX control errors Check DMX wiring, console

HPC memory corrupt Deep Clear HPC

Software failure Service HPC

No signal at DMX Loop output

Terminate facility active De-activate Terminate facility

Channels wont drive to full

CAP function enabled Change CAP Setting in menu

HPC very hot Increase air flow to HPC vents

All channels glow

Preheat set too high Reduce preheat level

HPC shuts down

HPC very hot Increase air flow to HPC vents

Page 17

Installation 16

Revision 2.0c – 30 August 2013 HPC User Manual

7.0 Installation

The HPC is designed for use in 19 inch racks or a 19 inch bar frame, and occupies 3 or 4

rack units. The HPC is supplied with rear rack mounting support brackets, which

provide additional support for touring applications.

The mains supply power cable entry is located at the rear right side of the rack when

viewed from the front. Ensure adequate access to the power plug when mounting

HPC’s in racks.

7.1 Ventilation

The HPC dimmer is fan-cooled, with the air intake at the right and air exhaust at the

left when viewed from the front. Equipment racks must have adequate ventilation for

the side-to-side airflow. Fully enclosed racks will cause overheating problems.

Racks must allow at least 100 square centimetres of air venting per HPC at each side

of the rack, level with the intake and exhaust slots. Additional venting area will serve to

further reduce internal temperatures and will enhance the HPC’s operational

reliability.

HPC’s may be stacked in racks without intervening rack spaces as long as the racks are

adequately vented at the sides. Racks of HPC’s must be placed such that one rack does

not breathe the hot exhaust of the rack next to it. Allow at least 300mm (12") between

racks unless duty cycles are light.

The inlet air temperature must not exceed the specified maximum ambient air

temperature.

7.2 Supply Wiring

The HPC has been designed to run from commonly found star power systems, ie.

where a neutral is available. The incoming mains supply must be protected at not more

than the specified maximum.

The HPC must have its labelled terminals connected to the supply phases as indicated

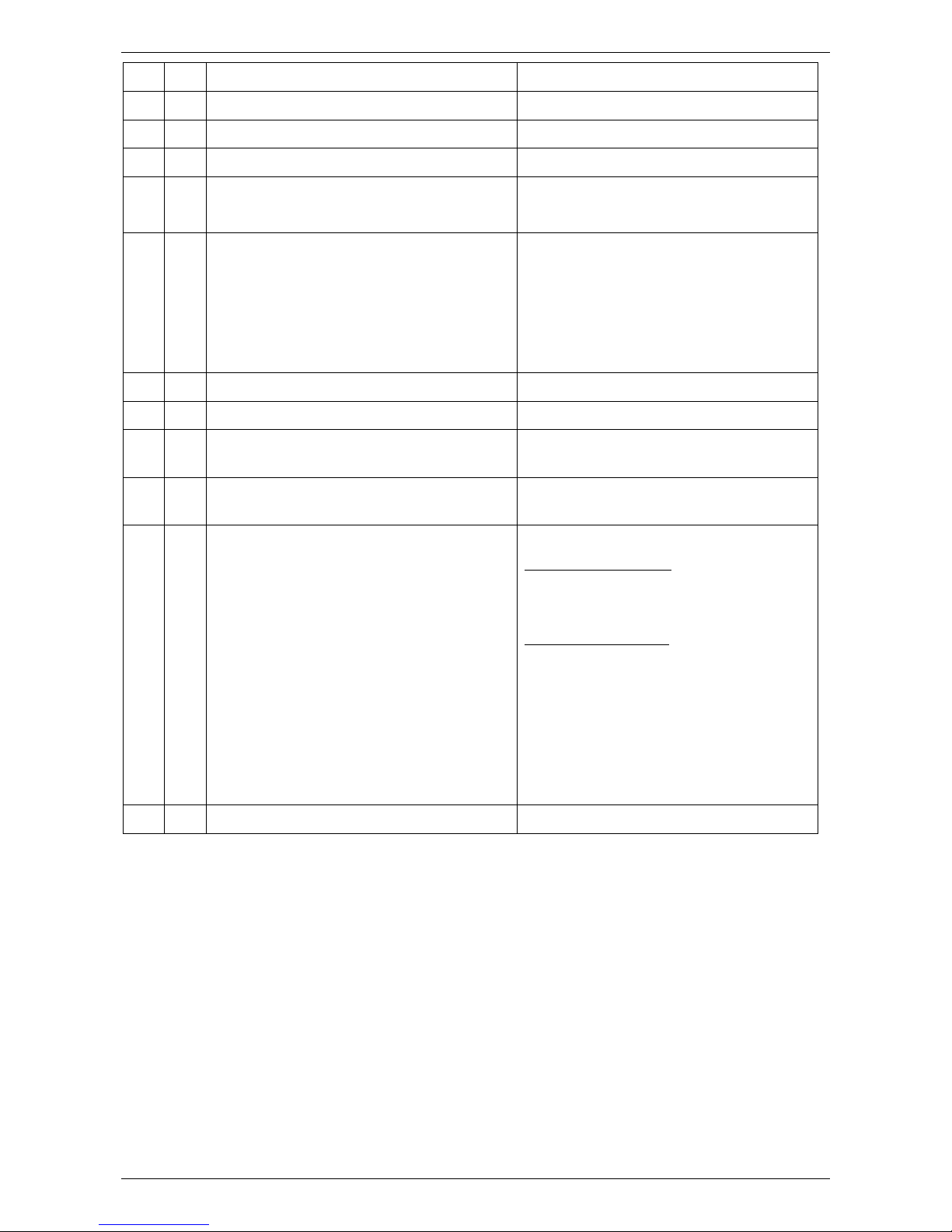

in Table 3.

HPC Power Terminal

Supply Type A B1 B2 C N E Notes

Two wire

(A + N)

A A A A N E

Link terminals A, B1, B2,

and C

Three Wire

(2A + N)

A A B B N E Remove link between

B1 and B2

Four Wire

(3A+N)

A B B C N E Insert link between B1

and B2

Table 3: HPC Power Supply Connections

Page 18

Maintenance 17

Revision 2.0c – 30 August 2013 HPC User Manual

8.0 Maintenance

With care, the HPC will require little or no maintenance. However periodic electrical

safety checks may be required by law in some countries.

8.1 External Cleaning

If the front panel requires cleaning, wipe with a mild detergent on a damp soft cloth.

DO NOT allow liquids into the chassis.

DO NOT spray liquids onto the front panel.

DO NOT use solvents for cleaning the front panel.

8.2 Internal Cleani ng

The HPC will require little internal maintenance other than periodic flushing to prevent

the fan and air-path becoming clogged with dirt or fluff.

1. ISOLATE POWER to the dimmer (by disconnecting the power cable or locking

off the mains supply isolator).

2. Remove the lid.

3. Blow clean the fan and internals with compressed air from left to right. DO

NOT "spin" the fan with compressed air - the blades may break off.

4. When the fan and internals are clean, replace the lid and screws, and re-

connect the power cable.

8.3 Routine Maintenance

Installed HPC’s should be routinely flushed of dust at six- to twelve-month periods.

Touring HPC’s may need a more rigorous maintenance routine, which should include:

• Inspection of chassis for evidence of impact damage and physical abuse

• Inspection of outlets for wear and damage

• Inspection of power cable for wear and damage

• Electrical checking of ground integrity from power cable to chassis

• Electrical checking of ground integrity from power cable to outlet grounds

• Flushing of dust build-up

• Testing the operation of all front panel switches and breakers

A Neutral-Earth test may show a low reading. This is normal and is a consequence of

the N-E voltage detector detailed in Section 6.4.

Page 19

Technical Data and Specifications 18

Revision 2.0c – 30 August 2013 HPC User Manual

9.0 Technical Data and Specifications

PARAMETER SPECIFICATION

Active-Neutral Supply Voltage

100-230VAC ±10% Full size neutral required

Supply Frequency 40-66Hz

Supply Protection 10K Amps

Rated Insulation Voltage 430VAC Phase to Phase, 250VAC Phase to Neutral

Rated Output Current 10 Amps per channel

Minimum Power/Channel 25W

Maximum Dissipation <24 W/channel

Electric Shock protection SELV

System Earth Type MEN

Output Protection Thermal/magnetic circuit breakers

Maximum Ambient Temperature 40ºC

Maximum Altitude 2000m

Over-temperature cutout Soft limit starts at 92°C, Full cutout at 100°C

Control Signal

ANSI E1.11:2004 DMX-512-A

ANSI E1.20:2006 RDM

DMX Input 5 pin AXR male / female

Snapshot Scenes 2

Test Function Level Individual Channels @ 100%

All Channels @ 10% steps

LED Indicators SIGNAL, ERROR, TERM, IC

Phases A, B, and C

Ingress protection IP20

Internal Separation Form 1

Environment B

Size 478mm (w) x 133mm (h) x 355mm (d)

Weight 19.5kg with 220us risetime

Rack mounting requirements Three x 19” rack spaces / standard spacing for mounting holes.

Inlet air ventilation on right side, exhaust air on left side (when

looking from front of unit). Rack must include suitable ventilation.

Power inlet at rear right.

Page 20

Technical Data and Specifications 19

Revision 2.0c – 30 August 2013 HPC User Manual

9.1 DMX Connector Pinouts

PIN

No

CONNECTION

(DMX IN)

CONNECTION

(LOOP)

1 SHIELD SHIELD

2 IN- OUT-

3 IN+ OUT+

4 DMX Loop pin 4 DMX In pin 4

5 DMX Loop pin 5 DMX In pin 5

9.2 RDM Implementation

9.2.1 Root Device PIDs

Get Set PID Notes

- - DISC_UNIQUE_BRANCH

DISC_MUTE

DISC_UN_MUTE

DEVICE_LABEL

STATUS_MESSAGES Supported:

STS_OVERTEMP

STS_PHASE_ERROR

STS_DIM_PANIC

STS_JANDS_NEUTRAL_EARTH_FAULT (0x8000)

STATUS_ID_DESCRIPTION For:

STD_JANDS_NEUTRAL_EARTH_FAULT (0x8000)

QUEUED_MESSAGE

SUPPORTED_PARAMETERS

PARAMETER_DESCRIPTION

DEVICE_LABEL

DEVICE_INFO

DEVICE_MODEL_DESCRIPTION

MANUFACTURER_LABEL

FACTORY_DEFAULTS Will always report 0 on Get

SOFTWARE_VERSION_LABEL

DMX_START_ADDRESS

SLOT_INFO 1 per channel: ST_PRIMARY, SD_INTENSITY

SLOT_DESCRIPTION “Chn-xx”

Page 21

Technical Data and Specifications 20

Revision 2.0c – 30 August 2013 HPC User Manual

SENSOR_DEFINITION 4: Temperature, Frequency, DMX rate, Phases

SENSOR_VALUE

IDENTIFY_DEVICE Animates display. Will time out

RESET_DEVICE 0x01 & 0xFF – Result in warm reset

CAPTURE_PRESET Scenes 1,2

Preset 0x0001, 0x0002

PRESET_PLAYBACK Scene 1,2

Preset 0x0000 = Off

0x0001 = Scene 1

0x0002 = Scene 2

Level 0x00 - 0xFF supported

JANDS_HPC_NE_FAULT_DETECT_MODE Pid=0x8080, Pdl=1, 0x00=Off, 0x01=On

JANDS_HPC_DMX_PROTECT_MODE Pid=0x8082, Pdl=1, 0x00=Off, 0x01=On

JANDS_HPC_DMX_LOSS_MODE Pid=0x8084, Pdl=1, 0x00=Hold, 0x01=Fade to

Scene1

JANDS_HPC_PREHEAT_LEVEL Pid=0x8086, Pdl=1, 0x00=Off, 0x01 - 0x32 =

Level

JANDS_HPC_OUTPUT_CAP_VALUE Pid=0x8088, PDL=0x1,

Up to firmware rev 2.00:

0x0=100%, (no output cap limit) 0x1-0xC = -5%

/ Step

From firmware rev 2.10:

0x00 = Full = 240V

0x1--0xE = -10V/ Step down to 100V

Global output cap limit for all channels (will

override any separate channel values)

Get will return 0xff if levels differ between

channels. (Also see sub-device PIDs)

JANDS_HPC_DMX_TERM_MODE Pid=0x808A, Pdl=1, 0x00=Off, 0x01=On

Page 22

Technical Data and Specifications 21

Revision 2.0c – 30 August 2013 HPC User Manual

9.2.2 Sub Device PIDs

One sub device per HPC channel (12 total)

Get Set PID Notes

SUPPORTED_PARAMETERS

DEVICE_MODEL_DESCRIPTION Up to firmware rev 2.12:

Channel dependant

From firmware rev 2.13:

Same for all sub-devices

MANUFACTURER_LABEL Same as root

DEVICE_LABEL Up to firmware rev 2.12:

Not supported

From firmware rev 2.13:

Same as root and channel offset info

DEVICE_INFO

SOFTWARE_VERSION_LABEL Same as root

DMX_PERSONALITY 7 personalities to controls dimmer channel

mode (see user manual for details):

1 = Off

2 = On

3 = Dmx Switch

4 = Dimmer: Relay Control FULL

5 = Dimmer: Relay Control BYPASS

6 = Dimmer: Relay Control ISOLATE

7 = Dimmer: Relay Control NONE

DMX_PERSONALITY_DESCRIPTION Off, On, Dimmer, Switch

JANDS_HPC_PREHEAT_LEVEL Pid=0x8086, Pdl=0x1,

0x0=Off,

0x1=0x32 = Level for sub-device./ channel

JANDS_HPC_OUTPUT_CAP_VALUE Pid=0x8088, PDL=0x1,

Up to firmware rev 2.00:

0x0=100%, (no output cap limit) 0x1-0xC = -5%

/ Step

From firmware rev 2.10:

0x00 = Full = 240V

0x1--0xE = -10V/ Step down to 100V

Global output cap limit for all channels (will

override any separate channel values)

Get will return 0xff if levels differ between

channels. (Also see sub-device PIDs)

Loading...

Loading...