Page 1

)3

Page 2

Contents ii

Revision 01 – 3 June 1999 FP12 DIMMER USER MANUAL

EMC COMPLIANCE

This product is approved for use in Europe and Australia/New Zealand and conforms to the following

standards:

European Norms Australian / New Zealand

Standards

EN 55014-1 AS/NZS 1044

EN 55014-2 AS/NZS 4251.1

EN 60335-1 AS/NZS 3350.1

To ensure continued compliance with EMC Directive 89/336 and the Australian

Radiocommunications Act 1992, use only high quality data cables with continuous shield, and

connectors wit h cond u ctive backshell s. Exa mples of such cables are:

DMX: Belden 8102 100% Aluminium foil screen, 65% Copper bra i d.

JANDS ELECTRONICS PTY LTD 1999

All rights reserved

DISCLAIMER

Information contained in this manual is subject to change without notice and does not

repre sent a c ommitment on the par t of th e vend or. JAND S EL EC TR ON IC S PTY LTD

shall not be liable for any loss or damage whatsoever arising from the use of

information or any error contained in this manual.

It is recommended that all service and repairs on this product be carried out by JANDS

ELECTRONICS PT Y LT D or its author ised service agents.

JANDS ELECTRONICS PTY LT D cannot accept any liability w ha ts oe v e r for a ny los s

or damage caused by service, maintenance or repair by unauthorised personnel, or by

use other t han that intended by the manufacturer.

JAN DS FP Ser ies dimme rs mus t o nly be u sed for the p ur pos e t hey we re int end ed b y

the manufacturer and in conjunction with this operating manual.

Disconnect mains power when not in use.

Manufactured in Australia by:

JANDS ELECTRONICS PTY LTD ACN 001 187 837

40 Kent Rd

Locked Bag 15

Mascot NSW 2020

Australia

PHONE: +61-2-9582-0909

FAX: +61-2-9582-0999

INTERNET: www.jands.com.au

Page 3

Contents ii

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

Table of Contents

1.0 Introduction

2.0 Equipment Description

2.1 Front panel layout ...............................................................................................2-1

3.0 Getting Started

3.1 Connecting power............................................................................................... 3-1

3.2 Setting the mains frequency................................................................................. 3-1

3.3 Powering up........................................................................................................3-2

3.4 Connecting loads.................................................................................................3-2

3.5 Connecting DMX-512 input................................................................................ 3-2

3.6 DMX Termination...............................................................................................3-2

3.7 Power-up sequence.............................................................................................3-2

4.0 Dimmer Operation

4.1 Operating modes................................................................................................. 4-1

4.1.1 DMX mode...........................................................................................4-1

4.1.2 Test mode............................................................................................. 4-1

4.2 Status LED......................................................................................................... 4-3

5.0 Fault Diagnosis

5.1 Output protection................................................................................................5-1

5.2 DMX faults ......................................................................................................... 5-1

5.3 Phase fault indication...........................................................................................5-2

5.4 Thermal protection.............................................................................................. 5-2

5.5 Over-voltage...................................................................................................... 5-2

5.6 Fault finding guide.............................................................................................. 5-3

6.0 Installation

6.1 Dimmer Vent ilation............................................................................................. 6-1

Page 4

Contents iii

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

7.0 Maintenance

8.0 Technical Data and Specifications

8.1 DMX connector pin-outs .................................................................................... 8-2

8.2 DMX bank allocations.........................................................................................8-2

8.3 Mains wiring colour codes...................................................................................8-3

8.4 Internal Mains Wiring..........................................................................................8-3

8.4.1 Normal Three Phase plus Neutral Operation..........................................8-3

8.4.2 Single Phase Operation ......................................................................... 8-3

8.4.3 Delta Supply Operation......................................................................... 8-3

Page 5

Introduction 1-1

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

1.0 Introduction

The JANDS FP12 is a high quality, rugged, 12 channel, 2.4kVA per channel (10A/240V)

dimmer ra ck specifically de signed fo r demand ing tou ring and thea tre ap plications.

The FP12 can be powered from three-phase or single-phase mains supplies. The FP12

features opto-controlled Triacs and medium risetime chokes protected by

thermal/magnetic circuit breakers. The FP12 uses microprocessor-based digital control

for accurate dimming a nd in -built tes t funct ion s. Dig ital control is v ia stand ard DMX-51 2

protocol.

The FP12 features toroidal output chokes. These chokes provide excellent high

frequency noise suppression and, together with the temperature-controlled fan, low

acoustic noise.

Co n tr ol s ig n a l to the dimme r is v ia a s ta nd ar d D M X -512 socket at t he front panel, while

t h e d immed outlets an d three phase power entry are located on th e r ea r panel.

Feat u re s

• 12 x 2.4 KW dimming channels

• DMX-512 digital control protocol

• DMX terminating swit ch

• Su itable for both tourin g a nd permanen t in stallatio n s

• Soft turn o n characteristic

• Low acoustic/electrical noise

• Toroidal output chok es

• Circuit breaker protection of output devices

• Three mains phase indicator LEDs

• Built in test facilities

• Dimmer c urve set for linear r elationship between the con trol input and output power

• Compensates for fluctuations in the mains supply voltage, and filters superimposed

mains con trol tone s, ens uring a c on stan t light ou tpu t and inc re ased lamp life

• Rack mounted (3 rack units)

• Microprocesso r control

• Temperature-controlled cooling fan

• Temperature monitor and thermal cut-ou t

• Dimmer will hold last DMX value sh ould control data b e inte rrupted

• 50/60Hz operation

• CE and C-Tick approved

Page 6

Equipment Description 2-1

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

2.0 Equipment Description

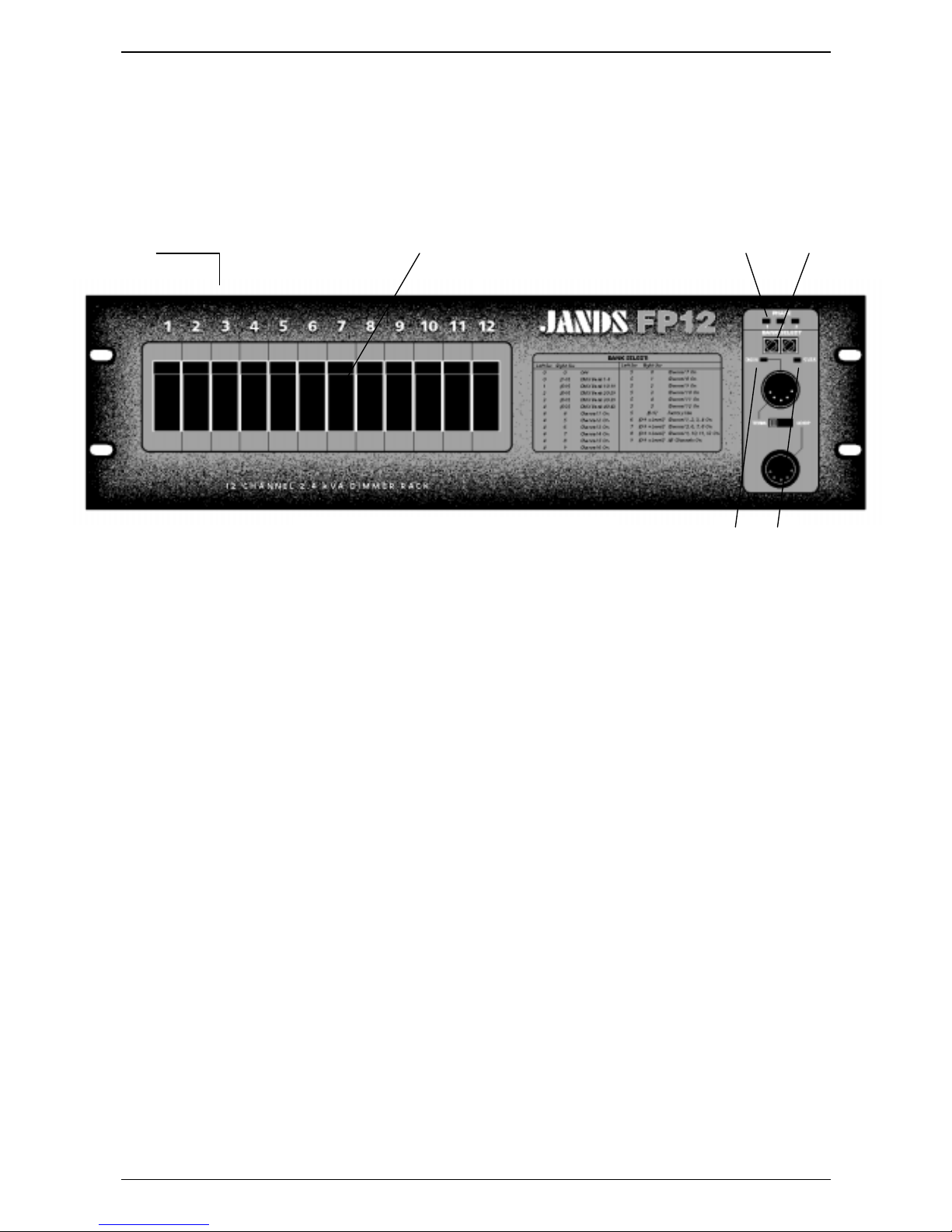

2.1 Front panel layout

Refer to Fig 2.1 (below) for a description of the front panel controls.

1. Channel output sockets (rear panel): The twelve output sockets are each rat ed at

10 amps.

2. Channel circuit breakers: If a breaker trips during use ensure the fault has been

cleared before resetting.

3. Bank select switches: These switches select the DMX start bank and the Test

functions.

4. DMX IN LED: A red LED indicates the presence of DMX signals. If there is no

DM X s ig na l, t he LE D w ill fla sh a t a r a t e of a p p r o xima t e ly 2 s e co n d s o n - 2 s ec o nd s

off.

5. STATUS LED: A red LED flashes in the presence of a fault. In normal operation

this L ED shou ld be o ff.

6. PHASE LEDs: Three blue LEDs (one for each phase) indicate that t he three phase

mains supply is available.

➀ ➁ ➂

➃ ➄

➅

Figure 2.1FP12 front panel layout

Page 7

Getting Started 3-1

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

3.0 Getting Started

The FP12 would normally be rack mounted before any wiring is terminated. Refer to

se ction 6 .0 Installatio n fo r installat ion de tails.

3.1 Connecting power

Th e FP 1 2 d immer is s up plie d w ith a fle xible cab le fit t ed wit h a mu lt ipin po w er plu g fo r

the connection of incoming mains power. The FP12 is ideally powered from a three

phase star (four wire plus earth) supply. If the dimmer pow e r ca b le is d ama g e d it mu s t b e

replaced with another cable available from JANDS or its service agents.

The upstream supply must be protect ed by fuses or circuit breakers at not more than the

rated max imum.

The power plug should be connected to an appropriately rated socket o utlet. The plug’s

retaining lock ring (if pres ent) must be screwe d home .

WARNING

DAMAGE TO THE PLUG MAY OCCUR IF THE RETAINING LOCK RING IS

NOT PROPERLY SECURED.

Ensure adequate mains plug access once the dimmer is insta lled .

3.2 Setting the mains frequency

The FP12 can be configured to run from either 50Hz or 60Hz mains power. As supplied

from the facto ry the dimmer is con figu re d for 50 Hz.

Th e dimmer o perat ing frequ ency may be c h anged as follo ws:

• Disconnect the mains supply to the dimmer

• Remov e the lid

• Change the three jumpers on the main circuit card as shown in Figure 3.4

• Replace the lid and reconnect power

Figure 3.4: 60Hz jumper locations

60

50

50

60

50

60

Page 8

Getting Started 3-2

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

3.3 Powering up

Turn on the power and check that the three PHASE indicator LEDs are on before

connecting any loads. If any of the PHASE LEDs are dim or off, power down and

remedy the fault before trying again. Refer to section 5.3 Phase fault indication.

If all is well, po we r do wn and connec t loads.

3.4 Connecting loads

The standard output connector s are twelve Clipsal 415P 10 amp sockets (export models

may differ from these configurations). Ensure any plugs are pushed firmly into their

sockets.

The FP12 will drive most incandescent loads as well as pinspot s, fans, and dimmable

fluorescent tub es. The load shou ld be within t he s pe cified limits.

3.5 Connecting DMX-512 input

The input signal to the dimmer should conform to the USITT DMX-512 1990

specification. The DMX input connects t o the frontpanel socket labelled “DMX IN”. T he

DMX signal may be daisy-chained to the next dimmer via the connector labelled

“LOOP”.

The red DMX IN LED indicates the presence of DMX signals.

The DMX receiver input is protected against extreme over-voltages across any input pins

and from any input to chassis. The “terminating” resistor is not pro tected against o vervoltages.

3.6 DMX Termination

In any DMX-512 system the signal should be terminated at the last d imme r or receiver in

the chain, and the FP12 can provide this function. To terminate the DMX signal, set the

frontpanel slide switch from “Loop” t o t he “Term” position. Not e that in this position no

signal is present at the “Loop” connecto r.

3.7 Power-up sequence

When powering up lighting systems, the following sequence should be used:

1. First the control desk;

2. Then any softpatches and/or DMX r eceivers;

3. Finally th e dimmers, prefera b ly on e a t a time starting fro m the first dimmer rack in th e

DMX loop.

This pro ced ure min imises t he ris k of la mps and fixt ures re spondin g to any fals e DMX

da ta p ro du c e d b y c ontrol d e s k s or a n c illa ry e qu ip me n t a t tu r n -o n ( p rod u c in g the lig h ting

equivalent of an audio “thump”) and prevents damage to lamps, dimmers, and other

contro lled devices.

Use the reverse procedure when powering down.

Disconnect mains power when not in use.

Page 9

Dimmer Operation 4-1

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

4.0 Dimmer Operation

Th is s e c tion a s s u mes th e d imme r ha s b e e n c or re c tly co n nec te d to thre e p h a s e po we r a n d

a source of DMX-512 control signal.

4.1 Operating modes

The FP12 has two operat ing modes:

1. DMX mode: the dimmer is controlled from an external DMX-512 control

console,

2. Test mode: the d immer is con trolle d by the intern al mic rop roc essor.

4.1.1 DMX mode

In this mode, the DMX Bank Select switches are used to select which bank of 12

channels from the 43 possible DMX-512 banks will con trol the FP12 .

See Table 4.1 (below) for a list of banks and their corresponding Channels.

Decide which bank of channels is required, and rotate the selector switches to the

desired setting. For example, if DMX Channels 25 to 36 are desired (ie. bank 3), set

selectors to “03”. FP12 Channel #1 is now DMX Channel #25. A FP12 with this

setting ignores DMX Channels 1 to 24 and 37 to 512, and only decodes Channels 25 to

36 as it ’s dimmer information.

Set tin g the Selectors to “ 00 ” p uts the d immer in a st andby state, w ith all channels o ff.

Bank Channels Bank Channels Bank Channels Bank Channels

00

Outputs Off

11 121 - 132 22 253 - 264 33 385 – 396

01 1 - 12 12 133 - 144 23 265 - 276 34 397 – 408

02 13 - 24 13 145 - 156 24 277 - 288 35 409 – 420

03 25 - 36 14 157 - 168 25 289 - 300 36 421 – 432

04 37 - 48 15 169 - 180 26 301 - 312 37 433 – 444

05 49 - 60 16 181 - 192 27 313 - 324 38 445 – 456

06 61 - 72 17 193 - 204 28 325 - 336 39 457 – 468

07 73 - 84 18 205 - 216 29 337 - 348 40 469 – 480

08 85 - 96 19 217 - 228 30 349 - 360 41 481 – 492

09 97 - 108 20 229 - 240 31 361 - 372 42 493 – 504

10 109 – 120 21 241 - 252 32 373 - 384 43 505 – 512

Table 4 .1 DMX ba nk / Cha nne l allocat ion

4.1.2 Test mode

In th is mo de , th e F P1 2’ s int e rna l co n tr o ller is u se d t o d riv e t he dimme r ch ann els . I t is

accessed by setting the Selector switches to banks between “44” and “99”. No DMX

contro l is necessary, but a control signal may be left connected if desired.

Page 10

Dimmer Operation 4-2

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

Th is mod e is s p lit into tw o s e c tions wit h in d ividu a l C h a nn e l te s ting fro m b a nks “ 4 4 ” to

“59” and group channel testing from banks “60” to “99”. The first section is not level

contro llable and each channel is driven to full.

Refer to Table 4.2.

Selector Channel Output

Switches Under Test Level

44 Channel 1 Full

45 Channel 2 Full

46 Channel 3 Full

47 Channel 4 Full

48 Channel 5 Full

49 Channel 6 Full

50 Channel 7 Full

51 Channel 8 Full

52 Channel 9 Full

53 Channel 10 Full

54 Channel 11 Full

55 Channel 12 Full

56 - 59 12 Step Chase Full

Table 4.2 TEST MODE – I ndividual Channel Select i on

The se cond section is level cont rollable, t he level being set by the right hand S elector

switch. The left-hand Selector switch changes the grouping. Refer to T able 4.3.

Selector Switches Channel Channel Left

Right Grouping Level

6 0-9 Channels 1-4 ON (Phase A) 0-9

7 0-9 Channels 5-8 ON (Phase B) 0- 9

8 0-9 Channels 9-12 ON (Phase C) 0-9

9 0-9 Channels 1-12 ON 0-9

Table 4.3 TEST MODE – Group Selection

Page 11

Dimmer Operation 4-3

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

4.2 Status LED

The Status LE D is used to indicate fault conditions. In normal operation this LED should

not illumin ate. Wh en activ e this LE D will either be flashing or on c on tinuously.

1. When the LED is flashing an over-temperature o r o ver-voltage condition is present,

and the dimmer outputs will be off until the over-voltage or over-temperature

condition is re moved.

2. When the status LED is on continuously, one or more of the following error

conditions have o ccurred :

• Over-voltage

• Over-temperature

• Serial data errors

• Software failure

Th e d immer outputs ar e a ctive while the Sta tus LED is on continuously.

If the Status LED is on it may be cleared by changing the setting of the bank select

sw itche s or by sw itching the dimmer off momentarily.

Page 12

Fault Diagnosis 5-1

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

5.0 Fault Diagnosis

NOTE

Contact your authorised JANDS Distributor for repairs or servicing.

In Australia refer all repairs to an authorised JANDS service agent or return the

faulty unit in suitable packaging to:

JANDS ELECTRONICS Service Dept,

40 Kent Rd

Mascot NSW 2020

Australia

5.1 Output protection

Each of the twelve output circuits is prot ected by a 10 amp fast-acting thermal/magnetic

circuit breaker. These break er s are de signed to pass the rated cu rren t, but will disconnect

the output circuit for any overload condition (the larger the overload, the quicker the

disconnect ion).

NOTE: 3-pin GPO outlet sockets are rated at 10 amps. Dimmer channels should

not be loaded beyond th e socket capaci t y.

The breakers protect the dimmer’s output devices from short-circuit loads and faulty

wiring lo oms, and save on expen sive dimmer repair s. A tripped cir cu it b reaker indicates a

load fault th at req uir es immediate attention .

If a short-circuit lamp or output cable is plugged into t he dimmer, th e b r e a ke r w ill trip to

dis c onn e c t the fa u lt fro m th e d imme r. In n e a r ly a ll c irc u ms ta nc es, this is q u ick e n ou g h to

prevent damage to the output devices.

In some circumstances however, a triac failure may be experienced, although these

devices are usually quite reliable and robust. If a triac does fail, it will either turn a

channel on to full (triac short-circuit), or turn it off (triac open-circuit). If a triac fault

should occur, that channel may be isolated by tripping that channel’s circuit breaker.

Th ese br eak ers have be en sp ecified for e lect ric al pr ot ect ion, re liabilit y and s afet y. T hey

will allow r e p ea ted t u rn-o n sur g e s to c old la mp s w ith ou t fa ilu re , w h ile s till p rot ectin g th e

triacs . The br eake rs will inte rrupt larg e sho rt-circuit fault cur re nt s with out damage.

5.2 DMX faults

Th e FP 12 dimme r fe at u re s a n “O ut p ut H o ld” fac ility t ha t “r eme mber s” t he last r eceived

DMX message. In the event of a cable being unplugged or severed, the FP12 dimmer

rack will continue to output the “Held” DMX levels until a new DMX message is

provided.

The DMX IN LED will “flash ” slowly if the DMX signal is remov ed .

Note that control consoles, when powered down, may transmit spurious DMX data

which can unint entionally cau se dimmer channels t o tur n on. Disco nnect mains po wer

when not in use.

The DMX receiver input is protected against extreme over-voltages across any input pins

and from any input to chassis. The “terminating” resistor is not pro tected against o vervoltages.

Page 13

Fault Diagnosis 5-2

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

5.3 Phase fault indication

The three blue PHASE LEDs will show when a ll th ree power input phases are present.

WARNING

IF ONE OR MORE PH AS E LEDS IS O FF, IMMEDIATELY DIS CO NNECT

POWER TO THE DIMMER AND CHECK THE M A INS SU PPLIES AND

WIRING BEFORE RE-CONNECTING POWER TO THE DIMMER.

Although t he dimmer will survive most power supply faults, indications of unusual or

po tentially danger ous power c onditions should ne ver be ignored.

5.4 Thermal protection

The FP12 dimmers feature temperature-controlled fan cooling. As the internal

temp er ature of th e d immer increases, the fan speed a lso incre ases.

Th e in t e rn al h e at s ink t e mp er a t u r e is c o ns t a nt ly mo n it o r e d by t he d imme r. I f t he h ea t s ink

temperature rises above the specified maximum, the dimmer will automatically shut

do w n th e o ut p ut dr ive . T he fa n will c o nt inue t o co o l t he h ea ts ink du rin g t he shu t do w n

period.

The electronic shutdown is backed up by a buried cutout , which shuts down power to all

electronics other than the cooling fan should the temperature continue to rise.

Even though the FP12 is a fan-cooled dimmer, it is very important that adequate

ventilation is provided when in use, particularly around the sides of the chassis. If air

circulation to t he air vents is blocked and/or the ambient air temperature is too high, the

dimmer will shut down and the status LED w ill flash un til th e temperat ure is red uced .

Refer to sect ion 6.1 Dimmer Ventilation regarding FP12 ventilation requirements.

5.5 Over-voltage

The FP12 incorporates an over-voltage cutout that constantly monitors the incoming

mains volt age . If t he main s volt ag e rise s abo ve t he s pec ified ma ximum t he dimme r will

shut down and th e status LED will flash until the o ver- vo ltag e con dition is re mov ed .

Page 14

Fault Diagnosis 5-3

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

5.6 Fault finding guide

FAULT SYMPTOM POSSIBLE CAUSE REMEDY

Breaker trips wh en desk channel

flashed to full or near full

Larg e inca ndescent load

Excessive load

Use console preheat facility

Reduce channel loading

Breaker trips after prolonged

operation

Excessive load

Lamp or wiring fault

Reduce channel loading

Check lamps and wiring

Breaker trips immediately when

channel is driven

Output short

Triac short

Check lamps and wiring

Factory service

One channel flickers when dimmed

Same load flickers on another

Channel

DMX source problem

Faulty dimmer channel

Insufficient or very inductive load

Softpatch another console fader

Service console

Factory service

Connect >100W incandescent

lamp in parallel

Radio interference Faulty EMC filtering Factory service

All Channels flicker when dimmed Incorrect DMX protocol / wiring

Untermi nated DMX l i ne

Mains cont rol tones exceed limits

Replace DMX source / wiring

Set Terminate switch on last

DMX receiver to TERM

Contact factory

Signa l LE D fli ckers Faulty DMX wiring/conn ecti ons

Faulty console

Faulty dimmer rack

Repair

Repair

Factory service

Status LED flashing Over-voltage

Over-temperature

Check mains connection/supply

Improve dimmer cooling

Status LED on continuously Recent over-voltage

Recent over - temperatu re

DMX control er rors

Software failure

Check mains connection/supply

Improve dimmer cooling

Check DMX wiri ng, console

Factory service

No signal a t DMX Loop output Termi nate switch set t o TE RM Set Termi nate switch to LOOP

Page 15

Installation 6-1

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

6.0 Installation

The FP12 dimmer is designed for use in 19 inch racks or a 19 inch bar frame, and

oc c u pie s 3 r a ck u nit s ( ex p o r t mo d els ma y diffe r ) . T he dimme r is s upplied with rear rack

mounting support brackets, which provide additional support for to ur ing applications.

The three phase power cable entry is located at the rear right side of the rack when

viewed from the front. Ensure adequate access to the power plug when mounting

dimmers in racks.

6.1 Dimmer Ventilation

Th e FP1 2 d imme r is fa n-c oo le d, w ith the a ir inta k e a t th e r ig h t a nd a ir e x ha ust a t th e left

when viewed from the front. All racks must have adequate ventilation for the side-to - side

airflow of th e dimmers. Fully en closed ra ck s will ca use ove rheating pr ob lems.

Ra c k s mu s t a llow at least 100 square centimetres of air venting per dimmer a t each side

of t h e r a c k , lev e l with the dimmer’ s inta k e a nd exh a u s t s lots. Add itiona l v e ntin g a re a w ill

serve to further reduce internal dimmer temperatures and will enhance the dimmer’s

ope rat ion al reliability.

Dimme rs may be sta cke d in r ack s wit hou t in ter venin g ra ck s paces as long as the racks

are adequately vented.

Ra c k s of d imme rs mu s t be p laced such that o ne rack do es not breat he the hot exhaust o f

the rack to its right. Allow at least 0.5m (18") between racks unless duty cycles are light.

Page 16

Maintenance 7-1

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

7.0 Maintenance

With c ar e, t he F P12 dimmer w ill requir e little or no ma intenance.

Periodic electrical safety checks may be required by law in some applications.

WARNING

DO NOT ALLOW THE ENTRY OF LIQUIDS OF ANY SORT INTO THE

DIMMER CHASSIS.

EXTERNAL CLEANING:

If th e fr on t pan el requires cleaning , w ipe with a mild d eterg ent on a damp soft cloth.

DO NOT spray liquids onto t he front panel.

DO NOT use solvents for cleaning the front panel.

INTERNAL CLEANING:

Th e FP1 2 dimme r w ill req uir e lit tle inte rn al main te nanc e o th er t ha n pe rio dic flush ing o f

dust build to pr event t he fan and air-path becoming clogged with dirt or fluff.

• ISOLATE POWER to the dimmer (by disconnecting the power cable or

locking off the mains supply isolator).

• Remov e the lid.

• Blow clean the fan and internals with compressed air from left to right.

• DO NOT "spin" the fan with compressed air - the blades may break off.

• When the fan and internals are clean, replace the lid and screws, and re-connect

the power cable.

ROUTINE MAINTENANCE:

In stalled dimme rs shou ld be routinely flushe d of d ust at six - to twelve-mon th pe riod s.

Touring dimmers may need a more rigo rou s maint enanc e r outine, which s h ould include:

• Inspection of chassis for evidence of impact damage and physical abuse

• Inspection of outlets for wear and damage

• Inspection of power cable for wear and damage

• Electrical checking of ground integrity from power cable to chassis

• Electrical checking of ground integrity from power cable to ou tlet grounds

• Flushing of dust buildup

• Testing the operation of all frontpanel switches and breakers

Page 17

Technical Data and Specifications 8-1

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

8.0 Technical Data and Specifications

PARAMETER FP12

No. of Channels: 12

Input Power Requirements:

3 phase Star only

415 VAC Phase-Phase @ 40A/phase

protected at 50A/phase

Full size neutral required

Ma ximum Power / C hannel 2.4 kW

Minimum P ower/Chann el 25W

Maximum Dissipation <24 W/channel (<300 W total)

Ma ximum A mb ient Temp 40ºC

Control Signal DMX-512 (1990) Prot ocol

DM X I nput 5 pin AXR male / female

Test Function Level Individual Channels @ 100%

Group Channels @ 10% steps

LED Indicators DMX IN, STATUS,

Phases A, B, and C

Output Protection 12 x 10 Amp thermal/magnetic circuit breakers

Over-temperature cutout Electronic: 83oC rising, 78oC fa llin g

Mechanical: 90oC

Over-voltage cutout Average 290VAC

Ingress protection IP20

Size (mm) 482 (w) x 133 (h) x 250 (d)

Weight 16 kg net

Rack mounting requirements 3 x 19” rack spaces / standard spacing for mounting holes

Ventilation required at sides of rack

No blank spaces required between units

Power inlet at rear right (looking from front of unit)

Rear access required for patching outputs

Page 18

Technical Data and Specifications 8-2

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

8.1 DMX connector pin-outs

PIN

No

CONNECTION

(DMX IN)

CONNECTION

(LOOP)

1 SHIELD SHIELD

2 IN- OUT3 IN+ OUT+

4nc nc

5nc nc

The DMX shield connection is tied to chassis by a 47K resistor and a RF bypass

capacitor.

8.2 DMX bank allocations

BANK CHANNELS BANK CHANNELS

00 Off 22 253 – 264

01 1 – 12 23 265 – 276

02 13 – 24 24 277 – 288

03 25 – 36 25 289 – 300

04 37 – 48 26 301 – 312

05 49 – 60 27 313 – 324

06 61 – 72 28 325 – 336

07 73 – 84 29 337 – 348

08 85 – 96 30 349 – 360

09 97 – 108 31 361 – 372

10 109 – 120 32 373 – 384

11 121 – 132 33 385 – 396

12 133 – 144 34 397 – 408

13 145 – 156 35 409 – 420

14 157 – 168 36 421 – 432

15 169 – 180 37 433 – 444

16 181 – 192 38 445 – 456

17 193 – 204 39 457 – 468

18 205 – 216 40 469 – 480

19 217 – 228 41 481 – 492

20 229 – 240 42 493 – 504

21 241 – 252 43 505 – 512

Page 19

Technical Data and Specifications 8-3

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

8.3 Mains wiring colour codes

FLEXIBLE TAILS I NS T ALLED WIRING

PHASE A BROWN RED

PHASE B WHITE WHITE

PHASE C BLACK BLUE

NEUTRAL BLUE BLACK

EARTH GREEN / YELLOW GREEN / YELLOW

8.4 Internal Mains Wiring

Th e FP1 2 d immer has be en design ed to run from most commonly use d p ower s ystems.

8.4.1 Normal Three Phase plus Neutral Operation

The FP12 is normally supplied with a three-phase power cable and plug att ached, suiting

the vast majority of available mains supplies (ie. three phase and neutral).

The incoming mains supply must be prot ected at not more than the specified maximum.

Mains supplies are generally protect ed at lower currents (32 amps or 40 amps at most

Aus tra lia n ve n u e s ). I t is the r e s p on s ibility o f the u s er to e ns u re that th e d imme r is u s e d in

a manner that do es not exceed the available supply capacity.

The power cable is terminated within t he dimmer at a six-way terminal block and an

earthing stud. The six-way terminal block has three poles for the t hree live mains phases

(labelled A1, A2, A3), and three poles for the mains neutral (N1, N2, N3). The three

neu t r a l po le s ar e brid g e d by a co p p e r lin k , wit h t he inc o min g ma ins ne u t r a l co n ne c t ed t o

t er minal N2.

8.4.2 Single Phase Operation

The dimmer may be configured for single phase operation where three phase mains

supply is unavailable.

The d immer should be supplied with three same-phase actives and three neutrals. The

three active lines must each be protected at no t more than the specified maximum. The

three neutral conducto rs must each be rated at t he same current as t he act ives. The eart h

conductor shou ld be similarly rat ed .

The bridge between the three neutral terminal poles (N1, N2, N3) must be removed

before the three incoming neutral lines are connected.

Although it is possible to supply the dimmer with one large single phase feed, the

dimme r’ s br ea ke rs may n ot be r at ed t o clea r fau lts if t he s upply is protected at cur rents

greater t han the specified maximum.

Th e overv oltage d etection w ill opera te as normal.

8.4.3 Delta Supply Operation

The available venue mains supply in some countries (eg. the Philippin e s ) is in the form o f

three phases (220 volts between phases) with no neutral connection. The dimmer ma y b e

configured for operation from 220V delta supplies.

Page 20

Technical Data and Specifications 8-4

Revision 0.1 – 3 June 1999 FP12 DIMMER USER MANUAL

The bridge between the three neutral terminal poles (N1, N2, N3) must be removed

before the three incoming active lines are connected.

• The first incoming active is connected to terminals A1 and N3.

• The second incoming active is connected to ter minals A2 and N1.

• The third incoming active is connected to t er minals A3 and N2.

WARNING

This connection is ILLEGAL in Australia, Europe and the U.K.

This connection renders the output socket’s neutral pins LIVE.

Note that a dimmer wired in this fashion will be subjected to CONTINUOUS

OVERVOLTAGE if connected to the 415V wye or star three-phase supply of most

countries.

The three active lines must each be prot ected at not more t han the specified maximum.

The earth conductor must be rated t he same as the active lines.

WWXXMANUAL ENDS

WWX

X

Loading...

Loading...