Page 1

Event 4 Technical Manual

Revision 1 19/07/99

Page 2

Contents ii

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

EMC COMPLIANCE

This product is approved for use in Europe and Australia/New Zealand and conforms to the following standards: AS/NZS 4251.1

(EN 55103-1), AS/NZS 4252.1 (EN 55103-2), AS/NZS 3260 (EN 60950).

To ensure continued compliance with EMC Directive 89/336 and the Australian Radio communications Act 1992, use only high

quality data cables with continuous shield, and connectors with conductive back shells. Examples of such cables are:

DMX, MIDI, Keyboard cables: Belden 8102 100% Aluminium foil screen, 65% Copper braid.

Video: Amtron FR2651 Flat round cable, woven shield.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses an d can radiate radi o frequency energy and, if not p roperly installed and used in accord ance with

the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equi pment off and on, the user is enco uraged to try to correct the int erference by one or more of the

following measures:

- reorient or relocate the receiving antenna;

- increase the separation b et ween t he equipment and receiver;

- connect the equipment into an outlet on a different circuit from that to which the receiver is connected;

- consult the dealer o r an experienced radio/tel evi sion technician for hel p.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du

JANDS ELECTRONICS PTY LTD 1999

All rights reserved

DISCLAIMER

Information contained in this manual is subject to change without notice and does not represent a commitment on

the part of the vendor. JANDS ELECTRONICS P/L shall not be liable for any loss or da mage whatsoever arising

from the use of information or any error contained in this manual.

It is recommended that all service and repairs on this product be carried out by JANDS ELECTRONICS P/L or it’s

authorised service agents. JANDS ELECTRONICS P/L cannot accept any liability whatsoever for any loss or

damage caused by service, maintenance or repair by unauthorised personnel, or by use other than that intended by

the manufacturer. JANDS lighting consoles must only be used for the purpose they were intended by the

manufacturer and in conj unction with the operating manual.

Manufactured in Australia by JANDS Electronics Pty Ltd (ACN 001 187 837)

40 Kent Rd (Locked Bag 15)

MASCOT NSW 2020

Sydney Australia

PHONE:+61-2-9582-0909 FAX:+61-2-9582-0999 INTERNET:http://www.jands.com.au

Page 3

Contents iii

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

Table of Contents

Table of Contents .......................................................................iii

1. Introduction.............................................................................1-1

2. Equipment Description ..........................................................2-1

2.1 Tools...........................................................................................................................2-1

2.2 Disassembly...............................................................................................................2-1

2.3 Reassembly ................................................................................................................ 2-2

2.4 Precautions and Installation Notes.............................................................................2-2

3. Circuit Notes...........................................................................3-1

3.1 Processor Card ...........................................................................................................3-1

3.1.1 Boot ROM, FLASH, and RAM..................................................................3-1

3.1.2 Trim procedure............................................................................................ 3-1

3.1.3 Battery.........................................................................................................3-2

3.1.4 Logic ........................................................................................................... 3-2

3.1.5 Desk Lamp Dimmer....................................................................................3-2

3.1.6 DMX Outputs..............................................................................................3-2

3.1.7 Keyboard.....................................................................................................3-2

3.1.8 Expansion Bus.............................................................................................3-3

3.2 Front Panel Cards.......................................................................................................3-3

3.2.1 Card Select Jumpers....................................................................................3-3

3.2.2 LCDs...........................................................................................................3-3

4. DIP Switch Settings................................................................4-1

5. Boot ROM inbuilt menu, self tests, setups, etc....................5-1

5.1 Entering the Boot Menu.............................................................................................5-1

5.2 Menu Usage ...............................................................................................................5-1

5.3 Boot Menu..................................................................................................................5-1

5.3.1 Continue...................................................................................................... 5-1

5.3.2 Reload Software..........................................................................................5-1

5.3.3 Test..............................................................................................................5-2

CPU......................................................................................................................5-2

Page 4

Contents iv

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

Bus .......................................................................................................................5-2

RAM.....................................................................................................................5-4

FLASH................................................................................................................. 5-4

VGA..................................................................................................................... 5-4

Ports .....................................................................................................................5-4

VGA..................................................................................................................... 5-4

DMX 1 ................................................................................................................. 5-4

DMX 2 ................................................................................................................. 5-4

MIDI.....................................................................................................................5-5

Cards .................................................................................................................... 5-5

Scan......................................................................................................................5-5

Activate................................................................................................................5-5

Misc......................................................................................................................5-6

DMX In................................................................................................................ 5-6

Vers......................................................................................................................5-6

Trash RAM ..........................................................................................................5-6

Boot......................................................................................................................5-6

6. Fault Finding Table .................................................................6-1

7. Maintenance............................................................................7-1

8. Technical Data and Specifications........................................8-1

Event 4 Specifications 8-1

9. Glossary of Terms...............................................................9-1

Appendix A: History of Modifications .......................................9-1

Appendix B: Connector Pinouts................................................9-1

Appendix C: Spare Parts............................................................9-1

Appendix D: DMX to MIDI adaptor.............................................9-1

Appendix E: 2 x DMX, MIDI signal combiner............................9-1

Appendix F: Circuit diagrams....................................................9-1

Page 5

Contents v

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

EV4CPU1 Circuit diagrams........................................................9-2

EV4MAST3 Circuit diagrams......................................................9-3

EV4ASN3 Circuit diagrams........................................................9-4

EV4PRE3 Circuit diagrams........................................................9-5

EV4PAL3 Circuit diagrams.........................................................9-6

BKLTSML0 Circuit diagrams .....................................................9-7

Page 6

Introduction

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

1 - 1

1. Introduction

The Event 4 lighting control console is designed for stage, theatre, corporate, and live

music applications. It has been designed to control all equipment with a DMX-512

input. New fixture types can be added by modifying the fixture library disk if they are

not available on the existing release library.

The console has been designed with the capability for users to upgrade the software

without removing the base. This is achieved by inserting a diskette with the new

operating system, and selecting the appropriate options in the “boot menu”. The boot

menu also provides other functions, including console self tests.

Note that static sensitive devices are used throughout the console, and normal handling

precautions should be applied during service. Note also that connections should never

be made with the power switched on.

Metric fasteners are used almost exclusively throughout the console.

The Event 4 Operating Manual should be consulted for a description of desk

operation.

Jands recommends that all service procedures be performed by a Factory Authorised

Service Centre or the Jands Electronics Service Department.

Page 7

Circuit Notes 3 - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

2. Equipment Description

The Event 4 is constructed using a folded steel chassis, covered with a reverse

screened lexan. The decorative wooden ends are made from plantation growth native

Australian timber mounted on an aluminium former, which provides structural

rigidity. The timber also protects the fascia of the floppy disk drive. An additional pair

of front to back struts reduce flex and ensure front to back spacing is consistent with

the base.

A separate assembly is used to hold the power supply (PSU) and central processor

(CPU) cards. This bracket is removable as a complete pre-wired unit. A backpanel

vent next to the CPU card is removable from the inside and can be used to fit options.

2.1 Tools

With the exception of the base screws and D connector mounting nuts, metric

hardware is used throughout the console. The following tools are recommended:

• 7mm nut driver

• 5mm nut driver

• #1 Posidrive screwdriver

• #2 Posidrive screwdriver

2.2 Disassembly

Access to the console is through the base. To remove the base place the console face

down onto soft padding. Using the #2 posidrive screwdriver remove all (and only) the

silver screws, leaving the four black screws. The base can then be lifted away.

To remove the PSU/CPU assembly, disconnect all cables to the CPU and PSU, and

use the 7mm nut driver to undo:

• three nuts next to the power inlet socket,

• two nuts between the PSU and CPU,

• three nuts between the CPU card and the vent/option panel

Use the posidrive screwdriver to undo:

• two screws that hold the CPU tray to the chassis.

The assembly can then be removed by sliding it toward the front until it is clear of the

studs, then lifting it out of the chassis.

Note that the CPU card can be removed from the console without removing the

complete assembly. To remove the CPU card from the assembly:

• Remove all connections to the card

• Undo the D connector nuts

• Undo the nine PCB mounting screws

• Slide the CPU card away from the back panel until the D connectors are clear of

the assembly, and lift the CPU away.

Page 8

Circuit Notes 3 - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

The remaining PCBs may be removed by undoing the relevant screws, however

attention should be made to the following points:

• Faders should be pushed to their mid position before their knob is removed.

Failure to do so may result in damaged faders.

• The position of the address jumpers on the Palette and Assign cards should be

noted when they are removed so they can be correctly set during reassembly

2.3 Reassembly

Attention should be paid to the following during reassembly:

• LCDs and their windows should be wiped clean with a lint-free cloth before

assembly.

• Ensure the address jumper on Palette and Assign cards are set correctly. Note all

cards should only ever have one (1) address jumper installed. Refer to section 3.2.1

for further information on the card select jumper settings.

• When fitting the CPU ensure all connectors are properly installed, including the

DMX output connector. Also check that the DMX connector wiring is located

within the cutout section of the CPU card.

• The CPU trim procedure should be followed if either the CPU or power supply

have been changed, or if the trim has been inadvertently adjusted. Refer to section

3.1.2.

• Test the console fully before installing the base. This includes the disk drive, desk

lamps, back lights, and DMX outputs.

• Double check all flatcable latch connectors are closed before the base is installed.

• Do not overtighten the base screws.

2.4 Precautions and Installation Notes

The Event 4 should be installed in a position which allows sufficient ventilation

around the back panel vents – there should be at least 100mm clear space around the

back panel.

The Event 4 has been manufactured to comply with all CE/C-Tick regulations, and

uses plated panels to ensure minimal radiation emanates from the chassis. In order to

maintain compliance all panels and covers should attached using all screws. All

connections should be made using the recommended cable type. All back shells should

be connected to the cable shield.

Page 9

Circuit Notes 3 - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

3. Circuit Notes

The Event 4 uses a main CPU to provide all processing functions. The CPU

communicates with the front panel PCBs via the front panel card bus.

3.1 Processor Card

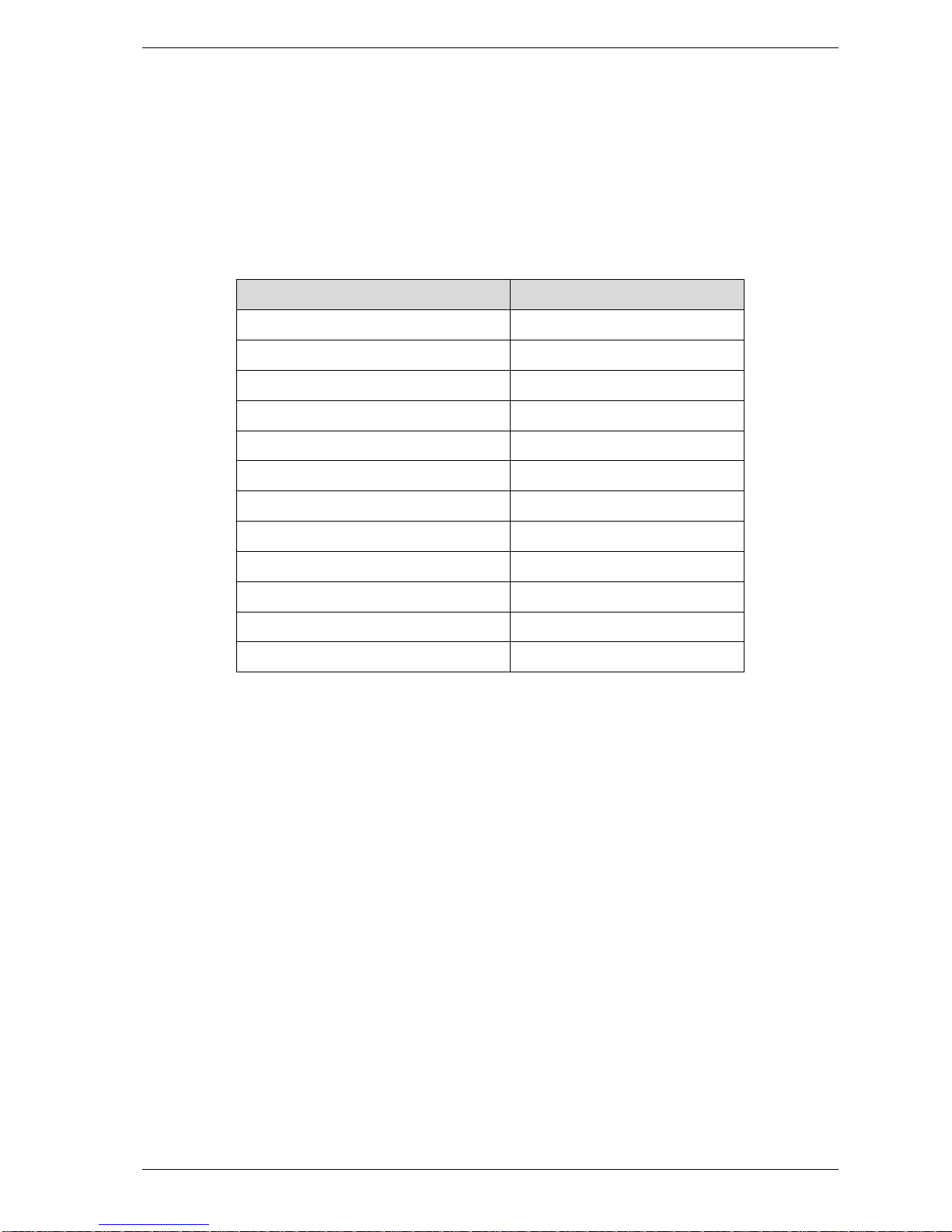

The major functional blocks are as follows:

Function IC Number

Core CPU IC1-8, IC33, IC30, OSC1

Boot EPROM IC25

FLASH ROM IC11-14

RAM Bank 1 IC16-19

Floppy Disk Drive Controller IC48

DMX output IC53, IC38, IC39, IC50, IC51

MIDI IC48, IC35, IC52

VGA output IC6, IC57-60, IC66

Reset/power fail/RAM power IC15

Real time clock IC31

Front Panel Card bus IC9, IC10

Expansion bus IC24, IC26-29

3.1.1 Boot ROM, FLASH, and RAM

The CPU memory consists of a Boot EPROM (IC25), four FLASH ROMs (IC11,

IC12, IC13, IC14), and four static RAMs (IC16-19).

The CPU card has the capacity to be fitted with a maximum of 2MBytes program

memory (four x 29F040 devices) and 2MBytes show memory (four x 512Kbyte

devices).

Only AMD brand 29F040 FLASH devices should be used with boot software versions

up to 0.5.

3.1.2 Trim procedure

The adjustment trim on the CPU card adjusts the point where the CPU is informed that

power is failing. If a console is dropping its memory, trimpot T1 may be out of

adjustment and should be adjusted as follows:

1. Save any necessary console information to diskette

2. Turn T1 fully anticlockwise

3. Place a shunt across J1

4. Switch console on and wait until it has completely started up

5. Slowly adjust T1 until LED L3 lights

Page 10

Circuit Notes 3 - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

6. Switch off console.

7. Remove shunt across J1

This procedure should be performed whenever either a new CPU or PSU is installed.

3.1.3 Battery

The lithium battery should last approximately 5 years from the date the battery was

made - note that a 4 year life from date of product sale would not be unex pected when

delivery and manufacturing times are allowed for. The battery should be considered

flat if its terminal voltage measures below 2.9 volts. Backup any required show data to

diskette before the battery is replaced.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the battery manufacturer. Dispose of

used batteries according to the battery manufacturer’s

instructions.

3.1.4 Logic

The logic requirements for the board are contained in two logic devices, IC33 and

IC53. These are in circuit programmable, and are programmed by connecting an

appropriate header to CONN3. If it is necessary to reprogram these devices in the

field, follow the instructions supplied with the kit.

3.1.5 Desk Lamp Dimmer

The desk lamp dimmer circuit consists of a PWM switching circuit protected by a

PTC polyswitch. The polyswitch will trip under overload conditions – when it does

LED L6 will extinguish. Due to the nature of the polyswitch it is necessary to either

disconnect all desk lamps or switch the console off for approximately one minute in

order for it to reset.

3.1.6 DMX Outputs

The DMX outputs are not opto-isolated, however a protection network decouples the

driver ICs from high voltages which may be applied during external mains faults.

After a fault has been removed these devices take approximately one minute to reset,

and during this time the output cables should be disconnected or the console switched

off.

3.1.7 Keyboard

The console is protected against excessive load current through the keyboard

connector by a polyswitch. After a fault has been removed this device takes

approximately one minute to reset, and during this time the keyboard should be

disconnected or the console switched off.

Page 11

Circuit Notes 3 - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

3.1.8 Expansion Bus

The expansion bus is provided to allow for options to be added in the future. The

expansion bus is a buffered extension of the system CPU bus. It is not compatible

with Jandshog, Event, or ESP2 type expansion bus option panels, and they should not

ever be installed.

3.2 Front Panel Cards

All front panel cards follow a design similar to that of other Jands consoles. A

multiplexed 8 bit data/address bus is used to exchange bytes of information between

the CPU and the front panel cards. The pin connections however are not compatible

and under no circumstances should Event, ESP2, and Jandshog type front panel circuit

boards ever be connected to an Event 4 CPU card. Damage will result.

3.2.1 Card Select Jumpers

A jumper on each Preset and Assign card selects the address of the card in the system.

When installing new cards ensure that the replacement card has its jumper in the same

position as the card it is replacing.

The correct jumper position for a Preset or Assign card is equal to its position from the

left eg. the left most Preset and Assign cards have their jumpers set to 0, the next have

it set to 1, etc. Master and Palette cards have no address jumper.

3.2.2 LCDs

The character LCD modules use a single backlight driver circuit to deliver the high

voltage required for all of the electroluminescent (EL) backlights. This is the function

of the EL driver board, mounted near the power supply. This board receives its power

and an analogue control from the CPU card.

Note that intensity of the character LCD backlights reduces with age. This is normal

and to minimise the reduction the backlights are deactivated if the console hasn’t been

used for a preset time. The backlights are immediately reactivated when any front

panel button is pressed.

Page 12

DIP Switch Settings 3 - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

4. DIP Switch Settings

NOTE: At the time of printing all DIP sw itches should be off for n ormal console

operation.

Dip SW1 - no function

Dip SW2 - no function

Dip SW3 - no function

Dip SW4 - no function

Dip SW5 - no function

Dip SW6 - Enable main code diagnostics

Dip SW7 - Execute software from RAM – use for development only

Dip SW8 - Reserved

Page 13

Boot ROM inbuilt Menu, sel f tests, setups , etc 5 - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

5. Boot ROM inbuilt menu, self tests,

setups, etc

The Boot ROM contains software that can be used to test, setup, and configure the

console. Note that the software is subject to change depending on the boot software

version.

5.1 Entering the Boot Menu

The boot menu is accessed by holding down the “RECORD” button on the keypad

while turning power on. Release the Record button when the opening menu is

displayed in the programmer LCD.

5.2 Menu Usage

Each menu offers a number of options available. The options are selected by pressing

one of the five buttons above the programmer LCD, or press EXIT to return to the

previous menu.

5.3 Boot Menu

The following menu options are available in the opening menu

1. Continue

2. Load FLASH

3. Test

5.3.1 Continue

Use this option to exit the boot menu and continue normal execution into the main

operating software. Use this option if the boot menu has been entered by mistake.

5.3.2 Reload Software

Selecting the Load FLASH option initiates the software reload sequence from diskette.

Ensure you have an Event 4 software diskette with the file “EVENT4.BIN in the drive

and follow the instructions on the LCD. Note that this facility should be used with

caution and it is not recommended that software be reloaded at a critical time, eg. just

before the start of a show.

Page 14

Boot ROM inbuilt Menu, sel f tests, setups , etc 5 - 2

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

5.3.3 Test

The following menu options are available in the Test menu:

1. CPU

2. Ports

3. Cards

4. Misc

5. Boot

Tests may be run continuously or once as required.

CPU

Use this option to test parts of the CPU card. When selected the following options are

displayed:

1. Bus

2. RAM

3. FLASH

4. VGA

Bus

The Bus exercise is not a test as such, but is used to debug CPU cards that have

fundamental faults, such as factory testing of newly manufactured CPU cards.

The CPU has been programmed to output sequences of events that can be seen on a

CRO, synchronised to the edge of L5 and L4. The data can be used to verify the

correct operation of the CPU control signals.

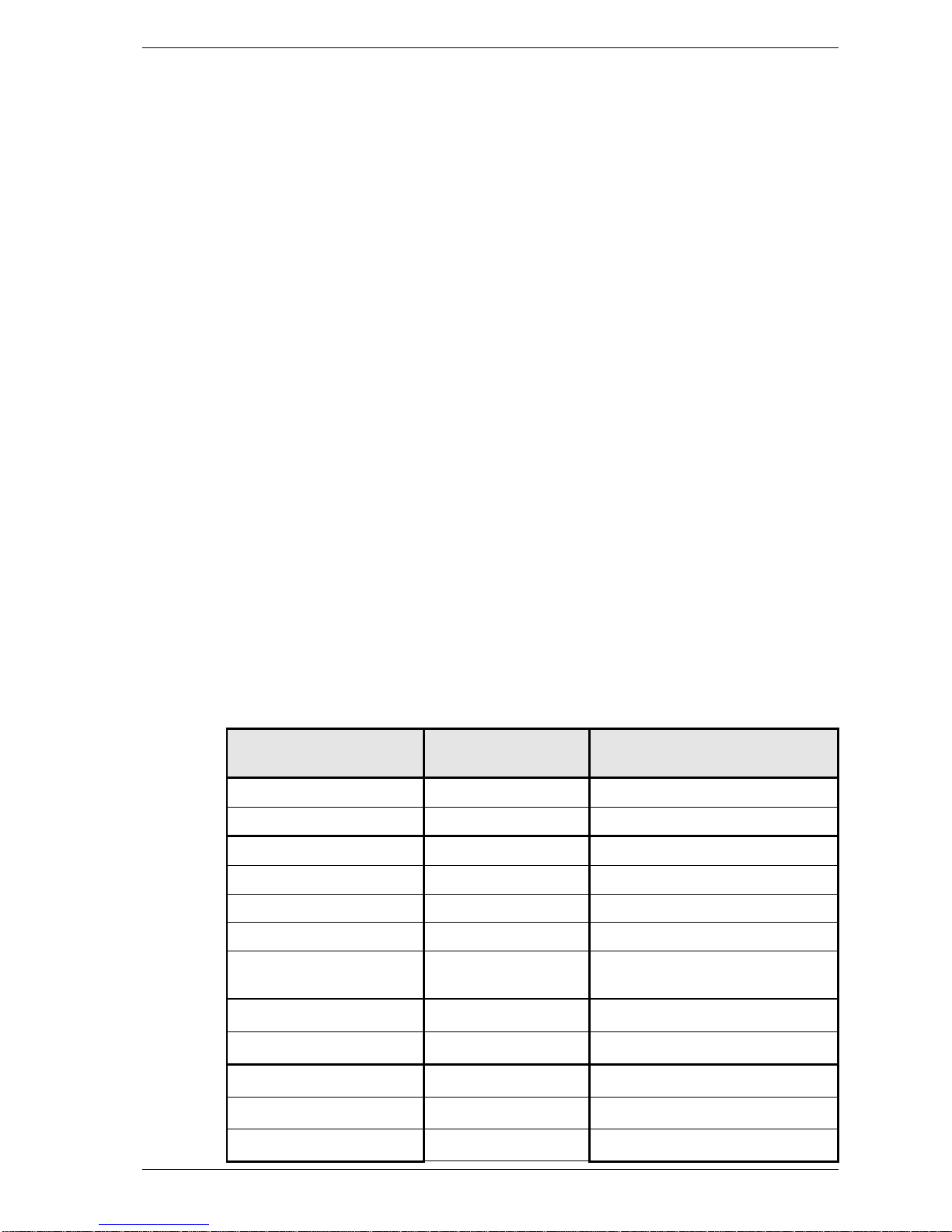

The sequence of operations performed during this routine are shown in table 3.

Event Signals of

interest

Comment

Set Green LED L5 on L5 CRO Synchronisation

Set Green LED L5 off L5 CRO Synchronisation

Move 01 to 40010004 IC16 pin 29 Write to RAM bank 0 byte 0

Move 02 to 40010005 IC17 pin 29 Write to RAM bank 0 byte 1

Move 04 to 40010006 IC18 pin 29 Write to RAM bank 0 byte 2

Move 08 to 40010007 IC19 pin 29 Write to RAM bank 0 byte 3

Move 40010004 to

CPU

IC16-19 pin 24 Read from RAM bank 0

Set Red LED L4 on L4 CRO Synchronisation

Set Red LED L4 off L4 CRO Synchronisation

Move 10 to 20000000 IC13 pin 29 Write to FLASH byte 0

Move 20 to 20000001 IC14 pin 29 Write to FLASH byte 1

Move 40 to 20000002 IC12 pin 29 Write to FLASH byte 2

Page 15

Boot ROM inbuilt Menu, sel f tests, setups , etc 5 - 3

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

Move 80 to 20000003 IC11 pin 29 Write to FLASH byte 3

Move 20000004 to

CPU

IC11-14 pin 24 Read from FLASH

Move AA to 606A0000 IC65 pin 13 PC Memory Write

Move 606A0000 to

CPU

IC65 pin 14 PC Memory Read

Move 55 to 60000000 IC65 pin 50 PC IO Write

Move 60000000 to

CPU

IC65 pin 49 PC IO Read

Table 3: Bus exercise event summary

Figure 1 shows the relationship between L5, IC16 WR, and the CPU DACK signals as

measured while running this test.

Figure 1: Sample waveform during Bus Exercise

Trace #1: L5

Trace #2: IC16 Pin 29 (WR)

Trace #3: IC1 pin 44 (DACK1)

Trace #4: IC1 pin 43 (DACK0)

Page 16

Boot ROM inbuilt Menu, sel f tests, setups , etc 5 - 4

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

RAM

The system RAM is checked for correct operation. This test requires approximately 2

minutes to execute.

FLASH

The system FLASH is checked for correct operation. This test requires approximately

50 seconds to execute. Note that due to the limited number of write cycles available in

FLASH devices, it is not recommended that this test be run continuously.

VGA

The VGA controller is initialised and a memory test is performed on its RAM. This

test takes approximately 17 seconds to execute and during execution a VGA monitor

will show the memory test patterns.

Ports

Use this option to test the ports of the CPU card. When selected the following options

are displayed:

1. VGA

2. DMX1

3. DMX2

4. MIDI

VGA

Test bars are displayed on the VGA and LCD screens for the purpose of checking

colour (VGA) and grey scaling (LCD). Press enter to return to the normal menu when

the screen results have been viewed.

DMX 1

The DMX1 output is connected to the MIDI input via the adaptor cable shown in

Appendix D, or the combiner circuit shown in Appendix E. When the test is run the

DMX1 output is exercised and the results read back into the MIDI input. The test takes

about 3 seconds to complete.

DMX 2

The DMX2 output is connected to the MIDI input via the adaptor cable shown in

Appendix D, or the combiner circuit shown in Appendix E. When the test is run the

DMX2 output is exercised and the results read back into the MIDI input. The test takes

about 3 seconds to complete.

Page 17

Boot ROM inbuilt Menu, sel f tests, setups , etc 5 - 5

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

MIDI

The MIDI output is connected to the MIDI input via a standard MIDI link cable. When

the test is run the MIDI output is exercised and the results read back into the MIDI

input. The test takes about 3 seconds to complete.

Cards

Use this option to test the front panel cards of the console. When selected the

following options are displayed:

1. Scan

2. Activate

Scan

This test scans the front panel card bus and displays on the VDU the cards found.

When run continuously this test will activate the front panel card bus and the signals

can be used to troubleshoot faulty PCBs.

Activate

When run this test activates the front panel card bus as shown in Table 4, and can be

used to verify correct operation of the majority of the front panel controls. In general a

pressed switch is indicated by its associated LED (or the LCD if no LED available),

and fader values are displayed on the associated LCD or channel LED. The Channel

master levels and preset faders operate in familiar two preset mode, with the levels

appearing at both DMX outputs.

This test is terminated by pressing Exit.

Card Control Type Indication

Palette Palette select Associated LED

Assign Flash button Associated LED changes from

green to red

Assign Fader levels Associated LCD

Assign LCD contrast Controlled by Assign Fader #1

Master Buttons with red LED Associated LED

Master Buttons with Bicolour LED Associated LED turns from

green to red

Master Buttons with no LED LCD

Master Wheels LCD

Master Faders LCD

Preset Faders Associated Mimic LEDs

Preset Flash Buttons Associated Mimic LEDs

Table z: Front panel activation responses

Page 18

Boot ROM inbuilt Menu, sel f tests, setups , etc 5 - 6

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

Misc

Use this option to run miscellaneous tests on the console. When selected the following

options are displayed:

1. DMX In

2. Vers

3. Trash RAM

DMX In

DMX signal from an external source is connected to the MIDI input using the adaptor

cable detailed in Appendix D. The DMX signal present is displayed on the VDU. Note

that both DMX outputs transmit a test data pattern that can be used to feed into the

input, however only one should be plugged into the MIDI input. Note also that the data

pattern changes each time the test is run.

Press Exit to terminate the test.

Vers

The software version of the test routines is output to L4 and L5 in flashes. The green

LED (L5) flashes once at the start of the test. The version is then displayed in red LED

(L4) flashes. The version is also displayed on the master LCD at startup, and for this

reason this test is mainly for use when no Master card is available.

Trash RAM

The system memory is completely cleared.

Boot

The console is restarted. This is generally used when use of the self tests has been

completed and it is desired to start the main operating software. Holding the Enter

button down immediately after activating this option allows re-entry to the self tests

and setups.

Page 19

Fault finding table 6 - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

6. Fault Finding Table

Symptom Possible Cause Remedy

Console won’t run

Show memory corrupt Deep Clear

Program memory corrupt Reload program

Mains fuse blown Replace fuse in power inlet

Front panel config error on start up

Flat cable disconnected Check that all flat cable connectors

are locked closed

Faulty flatcable Replace flatcable

Circuit board not working Replace card

Console crash with message

“Address error exception” etc

Software Bug Write down message and forward

to Jands, then try reboot or

program reload

Console drops its memory

Flat battery Replace battery

Power fail circuit out of adjustment Re-trim T1 as per section 3.1.2

Console always shows error

Software bug Write down message and forward

to Jands, then RAM trash as

described in section 5.3.3.4.3

Console won’t write or read diskette

Disk not DOS format Format on a PC compatible

computer (DOS 3.0 and above)

Diskette damaged Replace diskette

Poor quality diskette Use quality diskette

Diskette drive damaged Replace diskette drive

Fixture not available for patching

Fixture library in console not up to

date or corrupt

Load latest library from library

diskette.

No DMX output

Incorrect patch Check patch

Incorrect receiver address Check receiver

Faulty DMX cable Repair / replace cable

No line termination Terminate DMX line

Blown DMX driver Replace driver

Patch to other DMX output

Desk Lamp off

Short circuit lamp Remove short circuit then switch

console off for 1 minute

Level turned down Adjust level

Blown bulb Replace bulb

Radio Interference

Unearthed power cable Use earthed cable/outlet

Poor quality cables Use quality shielded cables

No intensity control from console

Grand Master down Adjust Grand Master

DMX

DBO button active Press DBO button

VGA monitor not working

Monitor not turned on Check power connection

Check power switch

Monitor not plugged into console Check VGA connection to console

Page 20

Maintenance 7 - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

7. Maintenance

If a console should start to misbehave or operate erratically, the problems encountered

can usually be attributed to one of two causes:

• normal wear and tear, eg. switches failing and becoming intermittent.

• physical abuse, eg. transit damage, spilt drinks, shorted cables.

Parts most likely to wear out in time with normal use include the following:

• switches

• faders

• LCD backlights

• digital encoders

These are generally easy to spot and there is little that can prevent such wear from

occurring, however careful use will maximise their life. Almost all parts of the console

can be damaged by physical abuse, however there are a number of things that can be

done to prevent this kind of damage:

• Cover the console when not in use, eg. before, after and between sets.

• ALWAYS insert a diskette into the floppy disk drive when the console is to be

transported. This prevents damage to the drive mechanism.

• Do not use spare audio lines for DMX cable. If so, there is a danger that the

connector will get plugged in to the wrong signal.

• Do not smoke over the console.

• Do not obstruct the rear ventilation holes.

• When cleaning, do not use solvents and never allow the entry of liquids into the

console. Use only a damp soft cloth for cleaning.

The console operating software is extremely complex. It is recommended that the

console be deep cleared at the start of each new tour.

Page 21

Technical Data and Specifications 8-1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

8. Technical Data and Specifications

Event 4 Specifications

Mains Supply: 90-265VAC, 47-63Hz, 60 watts max.

Mains Fuse: 2A, M205 delay type

Temperature: 40°C maximum ambient

Outputs: DMX Out 1 & 2, MIDI Thru, MIDI Out, Two Desk Lamps, VGA

Inputs: Keyboard (AT type), MIDI In

Control channels: 36 preset fader – 360, 24 preset fader - 240

Data Protocol: USITT DMX-512/1990, electrically conforms to RS485A.

Memory capacity: 2Mbytes

Disk Drive: IBM format DOS 3.0 and above, 1.44MB high density

Desk Lamps: 12 volt 5 watt x 2, maximum output 10W total

Construction: All steel chassis with lexan/polycarbonate covered control surface

Dimensions: L: 945mm W: 530mm H: 110mm

Weight: 19 kg net / 24.5 kg shipping

Ingress protection: IP20

Page 22

Glossary of Terms 9 - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

9. Glossary of Terms

Abbreviation Term Explanation

ADC Analogue to Digital

Converter

A device for converting real world (analog)

signals into digital information a micro-processor

can manipulate

BOOT BOOT System startup

CE Chip enable A select pin provided on a device to enable it to

be used in conjunction with a CS line

CE Compliance mark Equipment marked as such complies with the

European safety/EMC regulations

C-Tick Compliance mark Equipment marked as such complies with the

Australian EMC regulations

CPU Central Processing

Unit

The heart of a microprocessor or computer

CS Chip Select A connection that is asserted under certain

circumstances to select a particular device

DAC Digital to Analogue A device for generating an analogue

representation of a digital control signal

Converter

DIP Dual In-line

Package

A device package format with 2 parallel rows of

pins

EL Electroluminescent A type of backlight that uses high voltage

EPROM Erasable

Programmable

Read Only

Memory

A type of memory that is not intended to be reprogrammed in circuit

FLASH Flash RAM A type of memory very much like EPROM but

which is designed to be re-programmed insystem enabling program updates

GAL Generic Array

Logic

A logic device that can be programmed to

perform many logic functions

$ Hexadecimal

number

The number $A is 10

(decimal)

and $F is 15

(decimal)

IRQ Interrupt Request A connection that is asserted when a device has

information ready to be accessed by the CPU

Jumper Shunt, Link A jumper is used to configure a system by

shorting a pair of pins together

LED Light Emitting

Diode

A diode that is optimised to radiate light

LCD Liquid Crystal

Display

A type of display that uses a liquid to prevent the

transmission of light

NMI Non-Maskable

Interrupt

An IRQ that cannot be ignored

Page 23

Glossary of Terms 9 - 2

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

PSU Power Supply Unit The power supply converts incoming mains to

voltages usable by the electronics

PWM Pulse Width

Modulation

A cyclic technique of digital power control where

a load is switched fully on for a period of time

dependant upon the required output power

RAM Random Access

Memory

Memory in which the data contained within can

be accessed in any order. The term RAM

generally refers to memory that can be read and

written to by the system

ROM Read Only

Memory

Memory that cannot be changed by the system

SMD Surface Mount

Device

A miniaturised leadless component mounted on

the upper or lower surface of a circuit board

SRAM Static RAM A form of RAM that uses static memory cells to

store information.

Page 24

Appendix A – History of M odi fications A - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

Appendix A: History of Modifications

Serial Number Modification

Page 25

Appendix B - Connector Pinouts B - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

Appendix B: Connector Pinouts

Front Panel Card Bus Connector (View from component side)

Palette, Assign, Master Cards

FDD Power Connector Main Power Connector (CONN8)

D0

GND

D3

D4

GND

D7

R/W

+5

MUX

+12

+5V

GND

GND

NC

GND

D1

D2

GND

D5

D6

+5

ALE

DS

-12

+5V

GND

-12V

GND

+5V

+12V

GND

DIM

Page 26

Appendix B - Connector Pinouts B - 2

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

FDD Connector (CONN6) Expansion bus Connector (CONN2)

DMX CONNECTOR (Conn19)

DSKCHG

HDSEL

RDATA

WRTPRT

TRK0

WGATE

WDATA

STEP

DIR

MTR1

DS0

DS1

MTR0

INDEX

DRATE1

NC

DENSEL

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

DMX1+

DMX1-

GND

DMX2-

DMX2+

GND

ACK

+12v

A2

A3

GND

A6

A7

GND

A10

A11

+5

A14

A15

GND

A18

IO

GND

R/W

D7

GND

D4

D3

GND

D0

INT

A0

A1

-12V

A4

A5

GND

A8

A9

GND

A12

A13

+5

A16

A17

GND

NC

RESET

GND

D6

D5

GND

D2

D1

GND

Page 27

Appendix B - Connector Pinouts B - 3

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

DESK LAMP CONNECTIONS

PIN No. FUNCTION

1NC

2GND

3V+

DESK LAMP CONNECTOR

MIDI CONNECTIONS

PIN FUNCTION

No.

IN OUT THRU

1NCNCNC

2 NC SHIELD SHIELD

3NCNCNC

4 IN+ OUT+ OUT+

5 IN- OUT- OUT-

MIDI CONNECTOR

KEYBOARD CONNECTIONS

PIN No. FUNCTION

1KCLK

2KDATA

3NC

4GND

5+5V

KEYBOARD CONNECTOR

1

3

3

3

2

2

5

5

2

4

1

4

1

Page 28

Appendix B - Connector Pinouts B - 4

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

DMX CONNECTIONS

PIN No. FUNCTION

1SHIELD

2SIGNAL-

3SIGNAL+

4NC

5NC

DMX CONNECTOR

VGA CONNECTIONS

PIN No. FUNCTION

1RED

2 GREEN

3BLUE

4NC

5NC

6 RED RETURN

7 GREEN RETURN

8 BLUE RETURN

9 NC

10 GND

11 NC

12 NC

13 HSYNC

14 VSYNC

15 NC

VGA CONNECTOR

5

3

4

1

11

6

2

1

Page 29

Appendix C - Spare Parts C - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

Appendix C: Spare Parts

The following spare parts for Event 4 consoles are available from the JANDS Service

Department:

ITEM PART No.

Switching power supply NFS40-7608 ZSX0200

Fuse M205 2 amp fast blow (mains) ZEF2150

3.5” Disk drive ZZA1440

Desklamp socket AXR-3-31PB ZPG0380

DMX out socket AXR-5-21PB ZPG2100

Fader 10K 60mm (Alps) ZRS0200

Fader knob black/white line ZZK0400

Fader knob black/blue line ZZK0450

Fader knob black/green line ZZK0460

Fader knob black/red line ZZK0470

Fader knob black/grey line ZZK0480

Encoder HRPG ZRP0450

Encoder knob ZZK1210

Switch (Schadow) SERU ZSW0450

Switchcap SRKL (Schadow) ZSC0050

Switch (Cherry) MX1A-A1NW ZSW1500

Switchcap (Cherry) no LED window ZSC0500

Switchcap (Cherry) with LED window ZSC0550

Lithium Battery 6126 CR (CPU) ZDC0100

75176 / DS3695 (DMX driver) ZIC1010

IC H11N1 ZIC0170

Small back light driver card complete YPC177

Preset Card complete YPC173

Palette card complete YPC172

Page 30

Appendix C - Spare Parts C - 2

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

Assign card complete YPC175

Master card complete YPC176

CPU card complete YPC174

Page 31

Circuit Diagrams and Overlays D - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

R9

270R

IC2

75176

OPTO1

H11N1

8

5

7

6

2

1

5

4

6

IC1

75176

8

5

9

10

11

8

IC3C

74HC10

3

4

5

6

IC3B

74HC10

1

2

13

12

IC3A

74HC10

VCC

VCC

VCC

D1

1N914

R1

220R

VCC

VCC

VCC

R2

10K

R3

10K

R4

10K

R5

10K

VCC

1

2

3

From DM X1 output

1

2

3

From DM X2 output

4

5

From M IDI output

R6

220R

R7

220R

VCC

5

4

T o MID I I nput

VCC

5

4

From Keyboar d Input

C1

100nF

Appendix D: DMX to MIDI adaptor

A DMX to MIDI adaptor cable is required to run some of the Auxiliary tests contained in the Boot

ROM. The adaptor should be wired as shown:

DMX pin MIDI pin Detail

3 5 connect with 220R 0.25W 5% resistor

2 4 direct connection

1 2 direct connection

Appendix E: 2 x DMX, MIDI signal combiner

A DMX /MIDI combiner circuit is required to run some of the Auxiliary tests contained in the

Boot ROM.

Page 32

Circuit Diagrams and Overlays F - 1

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

Appendix F: Circuit diagrams

Page 33

Circuit Diagrams and Overlays F - 2

Revision 1 - 07 July

1999 Event 4 TECHNICAL MANUAL

EV4CPU1 Circuit diagrams

Page 34

1 2 3 4 5 6 7 8

A

B

C

D

8

7654321

D

C

B

A

1

Jands Electronics P/L

40 Kent Rd

Mascot NSW 2020

Australia

Ph (02) 9582-0909

3

0

9-Jul-1999 16:34:10

H:\LAB\EVENT4\CIRCUIT\Ev4cpu1.sc1

Title

Size: Number:

Date:File:

Revision:

Sheet of

Time:

A2

Event4 CPU card

Ev4CPU1.SC1

Drawn By:

1. Set VR2 fully CCW

2. Short J1

3. Start Console

4. Adjust VR2 until L3 lights

5. Remove J1 short

R1

1K

C1

100nF

VCC

A/D81A/D92A/D103A/D114A/D125A/D138A/D149A/D1510A/D1611A/D1714A/D1815A/D1916A/D2017A/D2120A/D2221A/D2322A/D2423A/D2526A/D2627A/D2728A/D2829A/D2930A/D3033A/D31

34

TT035TT1

36

R/W

39

TS

40

SIZ0

41

SIZ1

42

DA0

43

DA1

44

DTIP

47

AA

48

BD49BR50BG

51

TBI

54

TEA

55

PST056PST157PST258PST3

59

AVEC

62

ATM

63

IPL064IPL165IPL2

66

RST

67

TRST/D

70

TDO/DSO

71

TDI/DSI

72

TMS/BKMT

73

TCK

74

HIZ

75

MTMOD076MTMOD177MTMOD2

78

DDATA081DDATA182DDATA283DDATA3

84

TIE LOW

85

CLK

87

A/D089A/D190A/D291A/D392A/D495A/D596A/D697A/D7

98

IC1

MCF5202

VCC

L1

LED GREEN

R2

1K

A02A13A24A35A46A57A68A7

9

B018B117B216B315B414B513B612B7

11

E

19

DIR

1

IC2

74HC245

A02A13A24A35A46A57A68A7

9

B018B117B216B315B414B513B612B7

11

E

19

DIR

1

IC3

74HC245

A02A13A24A35A46A57A68A7

9

B018B117B216B315B414B513B612B7

11

E

19

DIR

1

IC4

74HC245

A02A13A24A35A46A57A68A7

9

B018B117B216B315B414B513B612B7

11

E

19

DIR

1

IC5

74HC245

R3

1K

VCC

R4

1K

OC

1

CLK

11

1D22D33D44D55D66D77D88D

9

1Q192Q183Q174Q165Q156Q147Q138Q

12

IC6

74HC574

OC

1

CLK

11

1D22D33D44D55D66D77D88D

9

1Q192Q183Q174Q165Q156Q147Q138Q

12

IC7

74HC574

OC

1

CLK

11

1D22D33D44D55D66D77D88D

9

1Q192Q183Q174Q165Q156Q147Q138Q

12

IC8

74HC574

A02A13A24A35A46A57A68A7

9

B018B117B216B315B414B513B612B7

11

E

19

DIR

1

IC9

74HC245

A02A13A24A35A46A57A68A7

9

B018B117B216B315B414B513B612B7

11

E

19

DIR

1

IC10

74HC245

R27

10R

A012A111A210A39A48A57A66A75A827A9

26

A1023A1125A124A1328A1429A153A162A17

30

Vpp

1

D013D114D215D317D418D519D620D721CE22OE24WE

31

IC11

28020

A012A111A210A39A48A57A66A75A827A9

26

A1023A1125A124A1328A1429A153A162A17

30

Vpp

1

D013D114D215D317D418D519D620D721CE22OE24WE

31

IC12

28020

VR2

1K TRIM

C19

10uF

R5

1K

VCC

R28

10K

R29

4K7

VCC

R13

10K

L2

LED RED

Q2

BCX17

CEO12CEI13VOUT

2

VCC

3

VBATT

1

RES16WDI

11

GND

4

OSC17OSC2

8

LOW

6

PFI

9

PFO

10

BAT-ON

5

/RES

15

WDO

14

IC15

MAX693

VCC

BAT1

3V

VCC

C6

100nF

VCC

1234567

8

16151413121110

9

SW1

SW-DIP8

A012A111A210A39A48A57A66A75A827A9

26

A1023A1125A124A1328A143A1531A162A1730A18

1

D013D114D215D317D418D519D620D7

21

CE22OE24WE

29

GND

16

VSS

32

IC16

62040

A012A111A210A39A48A57A66A75A827A9

26

A1023A1125A124A1328A143A1531A162A1730A18

1

D013D114D215D317D418D519D620D7

21

CE22OE24WE

29

GND

16

VSS

32

IC17

62040

A012A111A210A39A48A57A66A75A827A9

26

A1023A1125A124A1328A143A1531A162A1730A18

1

D013D114D215D317D418D519D620D7

21

CE22OE24WE

29

GND

16

VSS

32

IC18

62040

A012A111A210A39A48A57A66A75A827A9

26

A1023A1125A124A1328A143A1531A162A1730A18

1

D013D114D215D317D418D519D620D7

21

CE22OE24WE

29

GND

16

VSS

32

IC19

62040

A02A13A24A35A46A57A68A7

9

B018B117B216B315B414B513B612B7

11

E

19

DIR

1

IC24

74HC245

A012A111A210A39A48A57A66A75A827A9

26

A1023A1125A124A1328A1429A153A162A17

30

Vpp

1

D013D114D215D317D418D519D620D721CE22OE24WE

31

IC13

28020

A012A111A210A39A48A57A66A75A827A9

26

A1023A1125A124A1328A1429A153A162A17

30

Vpp

1

D013D114D215D317D418D519D620D721CE22OE24WE

31

IC14

28020

A012A111A210A39A48A57A66A75A827A9

26

A1023A1125A124A13

28

CE/PGM

22

VCC

32

OE

24

GND

16

O013O114O215O317O418O519O620O7

21

VPP

1

A1429A153A162A1730A18

31

IC25

27020

A02A13A24A35A46A57A68A7

9

B018B117B216B315B414B513B612B7

11

E

19

DIR

1

IC26

74HC245

A02A13A24A35A46A57A68A7

9

B018B117B216B315B414B513B612B7

11

E

19

DIR

1

IC27

74HC245

A02A13A24A35A46A57A68A7

9

B018B117B216B315B414B513B612B7

11

E

19

DIR

1

IC28

74HC245

A02A13A24A35A46A57A68A7

9

B018B117B216B315B414B513B612B7

11

E

19

DIR

1

IC29

74HC245

R14

10K

R30

47K

L3

LED RED

R7

1K

VCC

OC

1

CLK

11

1D22D33D44D55D66D77D88D

9

1Q192Q183Q174Q165Q156Q147Q138Q

12

IC30

74HC574

VCC

R31

10R

R32

4M7

VCC

X1

32.768KHz

R34

470K

R8

1K

C25

10nF

R33

4M7

C26

22pF

D05D16D27D38D49D510D612D7

14

GND

15

CS16AS17DS21STBY20R/W19RESET

22

MOT

2

SQW

27

PS

26

CLKOUT

25

CLKFS

24

OSC13OSC2

4

IRQ

23

Vdd

28

NC

1

NC

11

NC

13

NC

18

IC31

MC146818A

VCC

R10

1K

R11

1K

VCC

ISP port

GND

INT

GND

Interface

BDM

DS

ALEH

ALEL

D6D2D1

D0

-12+5+5

+12

D5

D4D3D7

RW

GND

GND

GND

GND

GND

GND

GND

GND

GND

A4

A5

A6A7A10

A12

A14

A15A16

A18RWD7D3D4

D5

+12

+5

+5

-12

ACK

D0

D1D2D6

REsetIOA17

A13

A11

A9

A8A0A1

A2

A3

Card Bus

Expansion

Bus

GND

A0A1A2A3A4A5A6A7A8A9A10

A11

A12

A13

A14

A15

A16

A17

D24

D25

D26

D27

D28

D29

D30

D31

D24

D25

D26

D27

D28

D29

D30

D31

A2A3A4A5A6A7A8A9A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A2A3A4A5A6A7A8A9A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

D24

D25

D26

D27

D28

D29

D30

D31

D16

D17

D18

D19

D20

D21

D22

D23

A2A3A4A5A6A7A8A9A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A2A3A4A5A6A7A8A9A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

D16

D17

D18

D19

D20

D21

D22

D23

D8D9D10

D11

D12

D13

D14

D15

D8D9D10

D11

D12

D13

D14

D15

A2A3A4A5A6A7A8A9A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A2A3A4A5A6A7A8A9A10

A11

A12

A13

A14

A15

A16

A17

A18

A20A2A3A4A5A6A7A8A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A20

A2A3A4A5A6A7A8A9A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

D0D1D2D3D4D5D6

D7

D0D1D2D3D4D5D6

D7

A24

A25

A26

A27

A28

A29

A30

A31

A0A1A2A3A4A5A6

A7

A8A9A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

D0D1D2D3D4D5D6

D7

D8D9D10

D11

D12

D13

D14

D15

D16

D17

D18

D19

D20

D21

D22

D23

D24

D25

D26

D27

D28

D29

D30

D31

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

AD8

AD9

AD10

AD11

AD12

AD13

AD14

AD15

AD16

AD17

AD18

AD19

AD20

AD21

AD24

AD25

AD26

AD27

AD28

AD29

AD30

AD31

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

AD8

AD9

AD10

AD11

AD12

AD13

AD14

AD15

AD16

AD17

AD18

AD19

AD20

AD21

AD24

AD25

AD26

AD27

AD28

AD29

AD30

AD31

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

AD8

AD9

AD10

AD11

AD12

AD13

AD14

AD15

AD16

AD17

AD18

AD19

AD20

AD21

AD24

AD25

AD26

AD27

AD28

AD29

AD30

AD31

D24

D25

D26

D27

D28

D29

D30

D31

D24

D25

D26

D27

D28

D29

D30

D31

D24

D25

D26

D27

D28

D29

D30

D31

D24

D25

D26

D27

D28

D29

D30

D31

SRAMPOWR

C9

100nF

RESET

CLK24M

EXPINTIN

1

GND

2

Vcc

4

OUT

3

IC32

24MHz

R19

10K

R20

10K

R21

10K

R22

10K

R23

10K

R24

10K

R25

10K

R26

10K

EXPINTOUT

INTEN

KEYINT

DMXINT

MIDIINT

RS232INT

SRAMPOWR

A1

66

INTEN

9

A3

53

IPL0

2

DIPSW

4

SPAREOUT

5

D27

6

CARDDS

10

D2511D24

12

S1

13

MEMCLK

15

LA19

21

RS232INT

22

SIZ1

23

RAM1SIZ

24

BOOTROM

25

INT1

26

A20

27

A30

29

EXPACK

30

DA0

31

FLASHW3

34

FLASHRD

35

RAM2SIZ

36

MEM_WR

38

S2

39

A29

40

A9

41

EXPSEL

42

MEM_RD

43

VA9

44

LA9

45

INT5

52

SPAREIN

54

A31

55

S4

56

IO_WR

58

IO_RD

59

RAM1W0

60

FLASHW0

61

RAM1W2

62

FLASHW2

63

RAM2W367RAM2W268RAM2W1

69

ACLK

70

A0

71

RAM2W0

74

DA1

75

CPUCLK

83

MIDIINT

85

INT6

86

CARDBUF

87

RW

88

DMX2WR

89

IOCHRDY

90

A22

91

AA

92

IOSEL

94

A21

95

DMX1WR

96

DTIP

98

RAM1W3

99

RAM1W1

100

FLASHW1

101

A2

102

RAM1RD

103

CARDAL

104

RTCADD

105

RAM2RD

106

CARDMUX

107

TS

108

RTCDATA

117

S3

118

A4

119

D26

122

SIZ0

123

INT7

124

EXPINT

125

IPL2

126

IPL1

127

ALE

128

RESET

19

SDI20MODE

46

SDO50SCLK

78

ISPEN

18

MiscIO

121

CARDRW

3

IC33

2096

D24

D25

D26

SCLK

MODE

ISPEN

SDO

SDI

IOSEL

DMX1WR

DMX2WR

IORD

IOWR

MEMRD

MEMWR

ALE

IOCHRDY

SPAREOUT

SPAREIN

GND

GND

GND

GND

GND

SPARE

A0A1A2

A3A4A5A6A7A8A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

GND

1

D02D13D25D36D48D59D611D712VCC

13

RW14ALE

15

VCC

16

DS17MUX18-1219+12

20

GND4GND7GND

10

CONN1

20WAYIDC

D02D13D25D36D48D59D611D7

12

A047A145A2

44

A342A441A539A638A736A835A933A10

32

A1130A1229A1327A1426A1524A1623A1721A18

20

INT49ACK

48

IO18SPARE17RESET15RW

14

CONN2

50WAYIDC

J1

LINK

REBOOT

LINK

CONN3

8X.1

JH2MAIN

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

CONN13

IDC26

A18

VCC

D(0..31)

A(0..31) R/W

A(0..31)

R78

2K2

R80

22K

R81

22K

R82

1K

VCC

R83

C108

R84

C109

R85

C110

R86

C111

R87

C112

R88

C113

R89

C114

R90

C115

R91

C116

R92

C117

R93

C118

R94

C119

-12

+12

VCC

R116

10K

VCC

VA9

C135

100nF

C136

100nF

R124

10K

R125

10K

R127

10K

VCC

C107

100nF

OC1CLK111D22D33D44D55D66D77D88D

9

1Q192Q183Q174Q165Q156Q147Q138Q

12

IC68

74HC574

L4

LED REDL5LED GREEN

R35

1K

R36

1K

D5

BAV103

R129

10K

R130

4K7

Backlite

R131

10K

VCC

D9

BAV103

D24

D25

D26

D27

D28

D29

D30

D31

A0

A1

A2

A3

A4

A9

A20

A21

A22

A29

A30

A31

Sys_Reset

NMI

AD22

AD23

AD22

AD23

AD22

AD23

C155

100nF

D6

BAV103

VCC

C12

10pF

VCC164882113

GND

1173349658197

112

VCC

7131925323846536069808894

100

GND

6121824313745526168798693

99

tp3

R18

1M

TP1

SHUNT

A20

Twelve x 220R Twelve x 10nF

A19

A19

Page 35

1 2 3 4 5 6 7 8

A

B

C

D

8

7654321

D

C

B

A

2

Jands Electronics P/L

40 Kent Rd

Mascot NSW 2020

Australia

Ph (02) 9582-0909

3

0

9-Jul-1999 16:35:55

H:\LAB\EVENT4\CIRCUIT\Ev4cpu1.sc2

Title

Size: Number:

Date:File:

Revision:

Sheet of

Time:

A2

Event4 CPU Card

Ev4CPU1.SC2

Drawn By:

1011

IC35E

74HC14

8 9

IC35D

74HC14

56

IC35C

74HC14

VCC

R39

0.47R 5W

L6

LED GREEN

R110

1K

+12

Q7

TIP42

R40

220R

Q5

BCX19

R43

10K

R51

47R

P1

RUE090

D3

BAV103D4BAV103

C10

100nF

C20

10uF

VCC

R521KR531KR541KR551KR56

1K

1

W2D7

3D34D25D16D07

XI8FF

9

Q010Q111Q213Q314Q8

15

R

18

Q419Q520Q621Q7

22

HF

23

EF

24

RS

25

FL

26

D628D529D430D3

31

12

17

27

IC38

7202

1

W2D7

3D34D25D16D07

XI8FF

9

Q010Q111Q213Q314Q8

15

R

18

Q419Q520Q621Q7

22

HF

23

EF

24

RS

25

FL

26

D628D529D430D3

31

12

17

27

IC39

7202

3 4

IC35B

74HC14

VCC VCC

R37

1K

R38

1K

VCC

R111

1K

VCC

DENSEL

1

MTR0

2

DS1

3

DS0

4

MTR1

5

Vss

6

DIR

7

STEP

8

WDATA

9

WGATE

10

HDSEL

11

INDEX

12

TRK0

13

WRTPRT

14

RDATA

16

DSKCHG

17

DRATE1

18

DRATE2

19

X1

20

Vcc

15

X2

21

IDED7

22

IDEENL

23

IDEENH

24

HDCS0

25

HDCS1

26

IOCS16

27

A0

28

A1

29

A2

30

A331A432A533A6

34

TC

35

DACK

36

SSPIRQ37PSPIRQ

38

PINTR39FINTR

40

A741A842A9

43

IOR

44

IOW45AEN

46

Vss

47

D048D149D2

50

D3

51

FDRQ

52

D4

53

D5

54

D6

55

D7

56

RESET

57

GAMECS

58

SLCT

59

PE

60

BUSY

61

ACK

62

PD7

63

PD6

64

PD5

65

PD4

66

Vss

67

PD3

68

PD2

69

PD1

70

PD0

71

Vcc

72

SLCTIN

73

INIT

74

ERROR

75

AUTOFD

76

STROBE

77

RXD1

78

TXD1

79

DSR1

80

RTS181CTS182DTR183RI184DCD185RI286DCD287RXD288TXD289DSR290RTS291CTS292DTR293DRV294Vss95MTR296DS397VIO98MTR399IOCHRD

100

IC48

37C665IR

VCC

1 2

IC35A

74HC14

123

4

5

6

7

8

IC50

75176

123

4

5

6

7

8

IC51

75176

VCC

VCC

VCC

VCC

R41

220R

R42

220R

R112

220R

R113

220R

VCC

D2

BAV103

VCC

R114

220R

R115

220R

R57

47R

R60

10R

R44

10K

R45

10K

C28

1uF

C29

1uF

B1

Bead

B2

Bead

B4

Bead

B3

Bead

VCC

VCC

PolySwitch

FDD

MIDI

KEYBOARD

DMX1

DMX2

In Thru Out

D24

D25

D26

D27

D28

D29

D30

D31

A0

A1

A2

A3A4A5

A6

A7A8A9

D(0..31)

A(0..31)

RESET

R/W

RSTDRV

D24

D25

D26

D27

D28

D29

D30

D31

D24

D25

D26

D27

D28

D29

D30

D31

A0

DMX1WR

DMX2WR

1

GND

2

Vcc

4

OUT

3

OSC1

24MHz

MIDIINT

RS232INT

IOWR

IORDCLK24M

IOCHRDY

1

2

3 4

5

6

IC52

H11N1

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

CONN6

34WAYIDC

A1

2

INTEN

3

A3

4

F12

10

F26

11

F2012F24

13

KEYB_CLK

15

SPAREOUT

21

F22

23

D2524D3125D27

26

F25

27

DMX1O

28

KEYB_DATA

29

RW

35

D26

36

VPP

38

DMXFULL

39

F28

40

SPAREIN

41

EXPINTIN

43

GLED

44

DMX2EMPTY

45

IO

53

PINTR

55

RLED

57

D28

59

F1660F17

61

DMX2RD

62

DMX1RD

63

F10

68

DMX2O

69

RES

70

MEMCLK

80

LAMPCLK

83

D3085D29

86

F11

87

F27

88

INT1

89

F23

90

DMX1FULL

91

A093A2

95

DMX1EMPTY

98

D24

99

LAMP

102

DMX1RESET

103

BACKLITE

105

DMX2RESET

106

EXPINTOUT

107

F21

108

KEYINT

117

F14

119

F15

121

F13

126

F18

127

SCLK

78

MODE46ISPEN

18

SDI

20

SDO

50

RESET

19

EnaVEE

123

VEE

125

Sys_Reset

6

LCDON

66

DISPOFF

8

NMI

54

DMX_Reset

128

IC53

2096

SPAREIN

SPAREOUT

SCLK

MODE

ISPEN

SDI

SDO

INTEN

KEYINT

DMXINT

EXPINTOUT

EXPINTIN

IOSEL

LAMPCLK

12345

CONN15

5PINDIN

1234567

8

CONN8

8X.156

VCC

VCC

+12

-12

12345

CONN16

5PINDIN

12345

CONN17

5PINDIN

12345

CONN18

5PINDIN

B6

Bead

B5

Bead

12345

CONN19

5X2MM

R48

1K

VCC

A0A1A2

A3

D24

D25

D26

D27

D28

D29

D30

D31

R108

1K

TH1

C870

TH2

C870

TH3

C870

TH4

C870

MOV2

SA12CA

MOV3

SA12CA

123

CONN7

3X.156

+12

B7

Bead

B8

Bead

B10

Bead

B9

Bead

B11

Bead

B12

Bead

Backlite

P2

KU3H

PolySwitch

Sys_Reset

NMI

123

4

CONN9

4X.156

+12

-12

VCC

AUX POWER

GND1173349658197112

VCC164882113

P3

RUE090

C165

100nF

MOV1

SA12CA

MOV4

SA12CA

Page 36

1 2 3 4 5 6 7 8

A

B

C

D

8

7654321

D

C

B

A

3

Jands Electronics P/L

40 Kent Rd

Mascot NSW 2020

Australia

Ph (02) 9582-0909

3

0

9-Jul-1999 16:37:12

H:\LAB\EVENT4\CIRCUIT\Ev4cpu1.sc3

Title

Size: Number:

Date:File:

Revision:

Sheet of

Time:

A2

Event4 CPU Card

Ev4CPU1.SC3

Drawn By:

1213

IC35F

74HC14

R62

10R

C13

100nF

R63

150R

R64

150R

C31

1uF

C14

100nF

C22

10uF

R58

47R

VCC

R70

150R

D8

BAV103

32

1

IC56

LM334

C34

220pF 1206

C35

220pF 1206

R71

47R

R72

47R

R59

47R

C23

10uF

C15

100nF

VCC

R73

1R

R74

1R

C32

1uF

R65

150R

R66

150R

C16

100nF

VCC

D01D1

2

WE

3

RAS

4

5

A06A17A28A39A411A512A613A714A8

15

OE

16

CAS

17

D218D3

19

IC57

414256

D01D1

2

WE

3

RAS

4

5

A06A17A28A39A411A512A613A714A8

15

OE

16

CAS

17

D218D3

19

IC58

414256

D01D1

2

WE

3

RAS

4

5

A06A17A28A39A411A512A613A714A8

15

OE

16

CAS

17

D218D3

19

IC59

414256

D01D1

2

WE

3

RAS

4

5

A06A17A28A39A411A512A613A714A8

15

OE

16

CAS

17

D218D3

19

IC60

414256

VDD1

1

EROM

2

SD15

3

SD14

4

SD13

5

SD12

6

VSS1

7

SD11

8

SD10

9

SD9

10

SD8

11

VSS2

12

MEMW

13

MEMR

14

LA17

15

LA18

16

LA19

17

LA20

18

LA21

19

LA22

20

LA23

21

IOCS16

22

MCS16

23

SHBE

24

BALE

25

VDD2

26

SA0

27

SA1

28

SA2

29

SA3

30

SA4

31

SA5

32

SA6

33

SA7

34

SA8

35

SA9

36

SA10

37

SA11

38

SA12

39

VSS3

40

RESET41SA1342SA1443SA1544SA1645AEN46IOCHRD47REFRESH48IOR49IOW500WS51IRQ52VSS453SD054SD155SD256SD357VDD358SD459SD560VSS561SD662SD763AVSS164VFILTR65AVDD166TWR67VSYNC68HSYNC69AVSS270OVRW71AVDD272EED173EECS74BLUE75GREEN76RED77IREF78P079VSS4

80

VDD4

81

P1

82

P2

83

P3

84

AVDD3

85

P4

86

P5

87

P6

88

P7

89

AVSSS3

90

VSS7

91

DCLK

92

BLANK

93

EVIDEO

94

ESYNC

95

EDCLK

96

MD31

97

MD30

98

MD29

99

MD28

100

VSS8

101

MD27

102

MD26

103

MD25

104

MD24

105

WE3

106

MD23

108

MD22

109

MD21

110

MD20

111

MD19

112

MD18

113

MD17

114

MD16

115

WE2

116

MD15

117

MD14

118

MD13

119

VSS9

120

VDD6

121

MD12

122

MD11

123

MD10

124

MD9

125

MD8

126

WE1

127

VSS10

128

MD7

129

MD6

130

MD5

131

MD4

132

MD3

133

MD2

134

MD1

135

MD0

136

VSS11

137

WE0

138

CAS

139

VDD7

140

OE

141

RAS

142

MA9

143

VSS12

144

MA8

145

MA7

146

MA6

147

MA5

148

MA4

149

MA3

150

MA2

151

MA1

152

MA0

153

AVDD4

154

MFILTR

155

AVSS4

156

MCLK

157

XTAL

158

OSC

159

VSS13

160

VDD5

107

IC65

GD5429

C36

10pF

R67

150R

R68

150R

R69

150R

C37

10pF

C38

10pF

C17

100nF

C24

10uF

C33

1uF

C18

100nF

R75

10R

R76

10R

Video

1

GND

2

Vcc

4

OUT

3

IC66

14.31818MHz

MD16

MD17

MD18

MD19

MD20

MD21

MD22

MD23

MD24

MD25

MD26

MD27

MD28

MD29

MD30

MD31

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MD16

MD17

MD18

MD19

MD20

MD21

MD22

MD23

MD24

MD25

MD26

MD27

MD28

MD29

MD30

MD31

D24

D25

D26

D27

D28

D29

D30

D31

A0

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A(0..31)

D(0..31)

ALE

MEMWR

MEMRD

RSTDRV

IOCHRDY

IOWR

IORD

123456789

1011121314

15

CONN11

VGACONN

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

C40

100nF

VCC

C41

100nF

VCC

C42

100nF

VCC

C43

100nF

VCC

C44

100nF

VCC

C46

100nF

VCC

C56

100nF

VCC

C57

100nF

VCC

C58

100nF

VCC

C59

100nF