James Heal Elastomer Abrader, Elastabrasion User Manual

OPERATOR’S GUIDE

ElastAbrasion

Elastomer Abrader

Compliant with

PV 3984

ASTM D8115

Covering Serial Numbers

1804/18/1000 & upwards

Publication 290-1804-1$A

©2018

James Heal ©2018

ElastAbrasion Operator’s Guide

Page 2 of 30

Published by:

JAMES HEAL

RICHMOND WORKS

HALIFAX

WEST YORKSHIRE

HX3 6EP

ENGLAND

TELEPHONE +44 (0) 1422 366355

FACSIMILE +44 (0) 1422 352440

E-mail info@james-heal.co.uk

Internet http://www.james-heal.co.uk

© 2018

James Heal ©2018

ElastAbrasion Operator’s Guide

Page 3 of 30

Table of Contents

OPERATOR’S GUIDE .......................................................................................................... 1

JAMES HEAL .......................................................................................................................... 5

Setting the Standard ............................................................................................................. 5

Areas of Expertise ................................................................................................................. 5

ElastAbrasion - Elastomer Abrader ........................................................................................ 6

Features and Benefits ................................................................................................ ........... 6

Air Jets ................................................................................................................................. 7

Specimen Holder ................................................................................................................... 7

Clean Environment ................................................................................................................ 8

Scope of Application ............................................................................................................. 9

Standards .............................................................................................................................. 9

Installation .......................................................................................................................... 10

Safety.................................................................................................................................. 10

Siting & Unpacking .............................................................................................................. 10

Checklist ............................................................................................................................. 11

Standard Accessories .......................................................................................................... 11

Test Materials ..................................................................................................................... 11

Accessories ........................................................................................................................ 11

Connecting to Services ........................................................................................................ 12

Electrical Connection .......................................................................................................... 12

Vacuum Extraction .............................................................................................................. 12

Compressed Air ................................ ................................................................ ................... 13

Airline Layout ..................................................................................................................... 15

Operation ............................................................................................................................ 16

Safety.................................................................................................................................. 16

Emergency Stop .................................................................................................................. 16

Setting up ElastAbrasion ..................................................................................................... 17

The Abradant ...................................................................................................................... 17

The Spindle, Collar & Weight .............................................................................................. 17

The 1 mm Setting Gauge ..................................................................................................... 18

The Shim Kit ....................................................................................................................... 19

Mounting the Specimen ....................................................................................................... 20

Control Panel ...................................................................................................................... 21

Setting the Speed ............................................................................................................... 21

Selecting the Number of Rubs ............................................................................................. 21

Starting ............................................................................................................................... 21

Resetting the Counters ....................................................................................................... 22

James Heal ©2018

ElastAbrasion Operator’s Guide

Page 4 of 30

Summary of a Test Procedure ............................................................................................. 23

Technical Data .................................................................................................................... 25

Instrument Specification ..................................................................................................... 25

Dimensions .......................................................................................................................... 25

Pneumatic Scheme .............................................................................................................. 27

Care and Maintenance ........................................................................................................ 28

User Servicing ..................................................................................................................... 28

CE Conformity ..................................................................................................................... 28

Disposal of ElastAbrasion .................................................................................................... 28

James Heal Service & Calibration ....................................................................................... 29

Revision History .................................................................................................................. 30

James Heal ©2018

ElastAbrasion Operator’s Guide

Page 5 of 30

JAMES HEAL

Chlorinated Water

Perspiration

Dry Cleaning

Phenolic Yellowing

Dry Heat

Print Durability

Hot Pressing

Rubbing

Laundering

Washing

Light

Water

Abrasion

Security of Attachments

Bursting Strength

Seam Slippage

Compression and Puncture

Shrinkage

Crease and Wrinkle Recovery

Snagging

Crimp

Spray Rating

Drape

Stretch and Recovery

Durability

Surface Deterioration

Flammability

Tear Strength

Mass per unit area

Tensile Strength

Pilling and Fuzzing

Washing and Drying

At James Heal, we are dedicated to designing and developing high precision testing

instruments and test materials for physical and colour fastness testing. Our worldwide

Service and Calibration division and expert technical assistance complement our product

range, adding real value to your laboratory testing activities.

Setting the Standard

We are committed to forming close relationships and have established numerous

partnerships within the textile industry, from trade and standards organizations, to test

houses, customers and distribution partners.

With a heritage spanning more than 140 years, we have evolved and grown through a

culture of continuous improvement, resulting in a thorough understanding of the

applications, operating conditions and requirements of customers worldwide – from

independent testing Laboratories and test houses, to fabric suppliers, manufacturers and

retailers.

Using knowledge and expertise, we consistently set the industry standard through product

innovation and technology, with customer and user needs, present and future, driving our

technological advancements. You can be assured that with James Heal, you will always

receive the highest levels of product quality and customer service. We have Agents and

Distribution partners all over the globe, ensuring locally available product whenever, and

wherever you need it.

Areas of Expertise

Textile: Colour Fastness

Textile: Physical

Non-Textile

Bursting strength of nonwovens, plastics, paper and medical products

Micro-scratching of laminates, wooden, painted, automotive and high gloss surfaces

Physical and colour fastness testing of leather

Rubbing fastness of laminates and wooden surfaces

Tear strength of paper and plastics

James Heal ©2018

ElastAbrasion Operator’s Guide

Page 6 of 30

ELASTABRASION - ELASTOMER ABRADER

Our ElastAbrasion has been designed with the James Heal unique product signature and

has been produced completely with the user in mind. We have combined the James Heal

technical and performance expertise, with intuitive design and operation to produce the

most cost effective, ergonomic and user friendly instrument.

Features and Benefits

Air jet cleaning system

Automatic controllers ensure efficient use of compressed air

Specially designed sample holder

Hinged lift up top plate for easy access

Versatile and intuitive key pad user interface

Quick lock clamp rings for easy mounting of abradant

Unique ‘soft lissajous’ pattern

Cabinet to contain debris

Facility to attach a vacuum hose

User safety – Instrument will only function when the cabinet is closed

Variable speed

Changeable number of rubs

Standard 18 months warranty

Test materials - abradant required only

Negates the need for reference rubber

Engineering support

Applications support

Operator training is available through James Heal

Tested and approved by Volkswagen

Multi directional abrasion reflecting real life usage

Reduction in cost compared with the rotary drum abrader

Increased productivity – 4 specimens tested simultaneously

Approximately 50% reduction in variability of results compared with the rotary

drum abrader

James Heal ©2018

ElastAbrasion Operator’s Guide

Page 7 of 30

Air Jets

Each holder is bordered with 3 equidistant air jets supplying a constant 1 bar of

compressed air pressure. Any elastomeric debris is blown away from the abrading table,

removing the potential for interference with any further abrasion of the specimen.

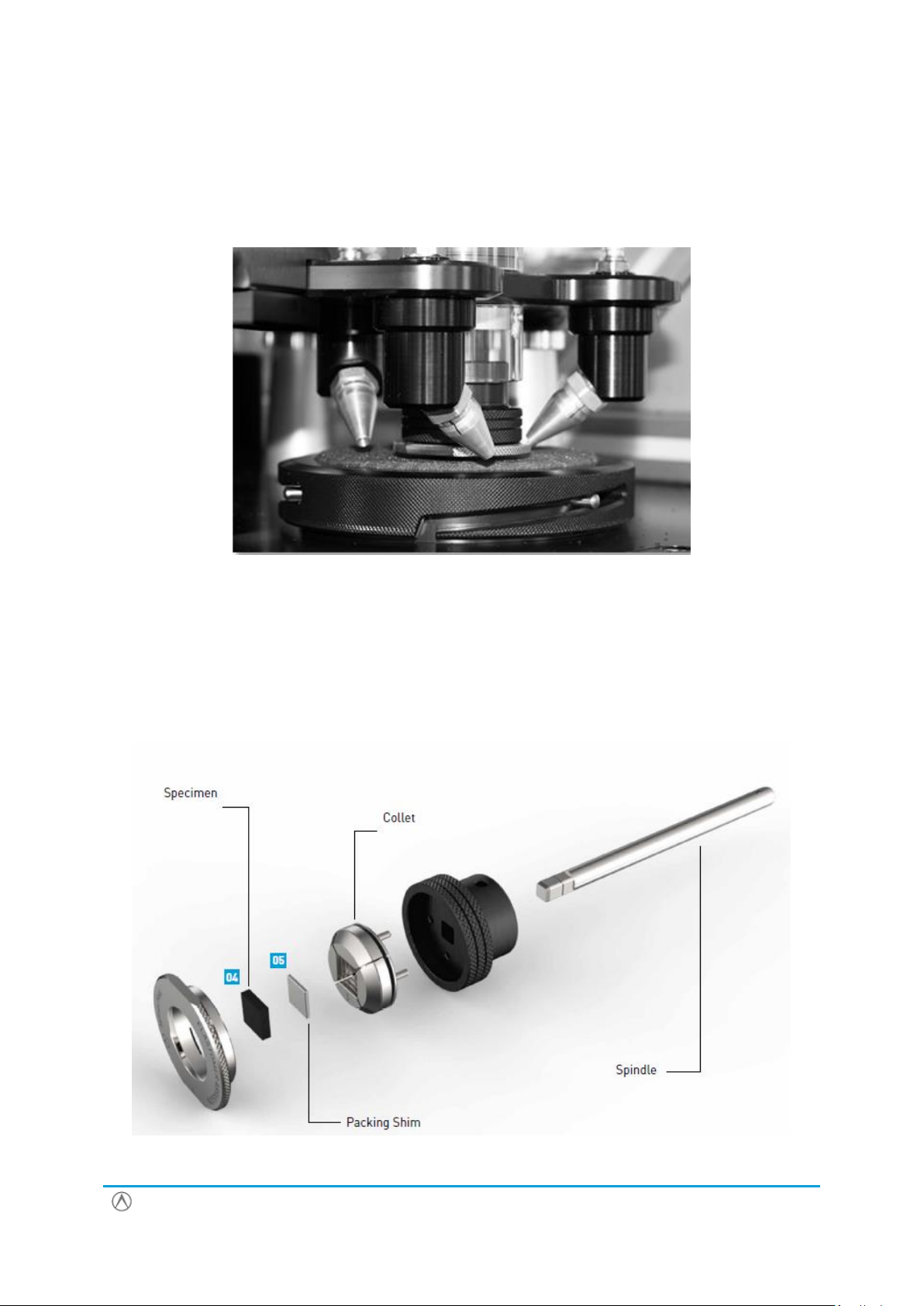

Specimen Holder

The specimen holder is designed to hold an elastomeric specimen 15±0.2mm X 15±0.2mm

with a maximum thickness of 12mm. The packing shims are used to create a protrusion of

2±0.2mm. The collet is held in a fixed position within the holder to avoid movement.

James Heal ©2018

ElastAbrasion Operator’s Guide

Page 8 of 30

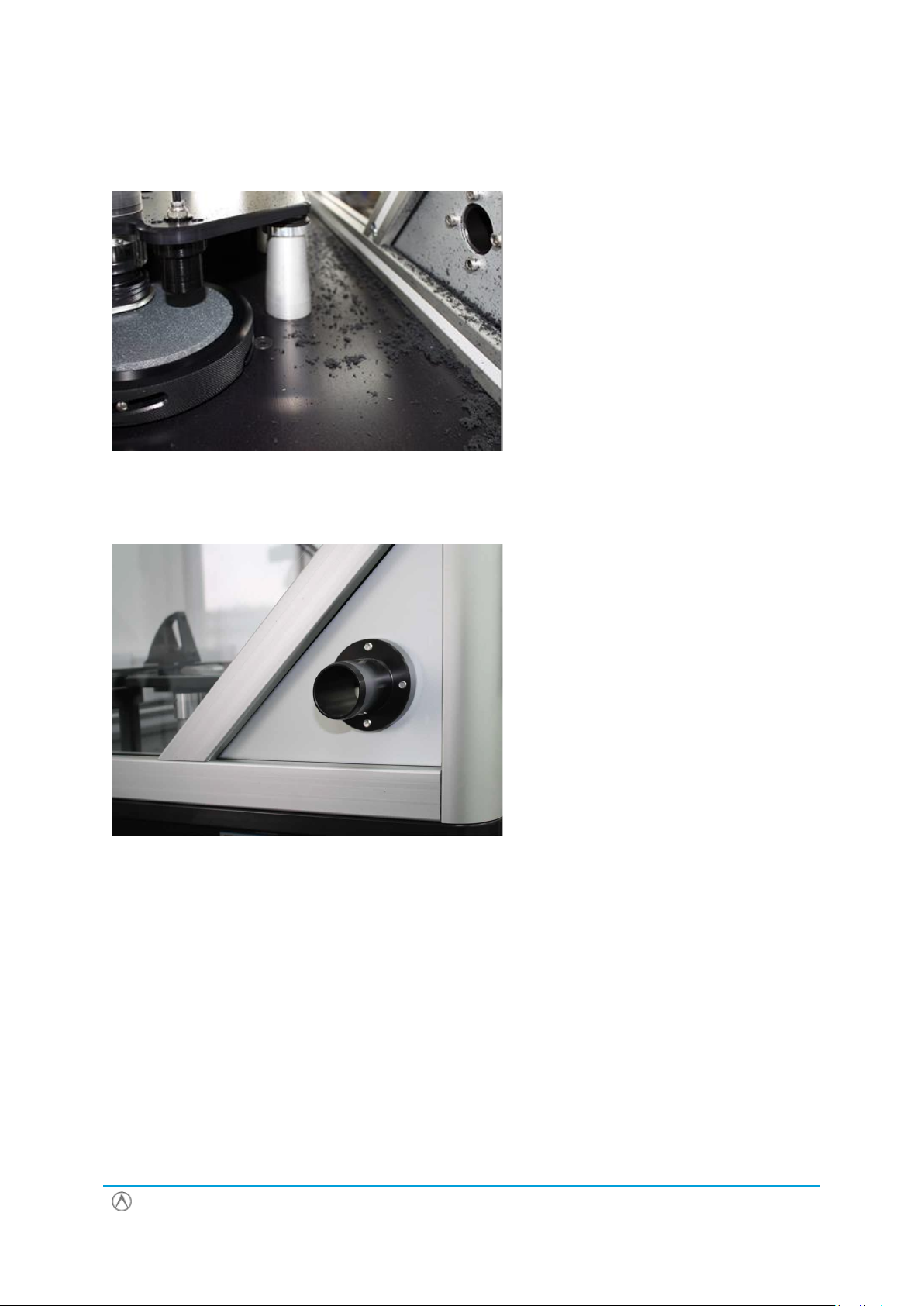

Clean Environment

ElastAbrasion is enclosed in a cabinet;

this ensures that the debris produced

by the abraded specimens is

contained.

Two vacuum attachment points have

been included in the cabinet design.

A vacuum hose can be attached to

either side of the cabinet to extract

any fine airborne debris.

The vacuum can be powered through

the ElastAbrasion by fitting an IEC

connector to the vacuum wiring and

plugging into the instrument; it can

then start and stop automatically

with each test.

James Heal ©2018

ElastAbrasion Operator’s Guide

Page 9 of 30

Scope of Application

ElastAbrasion has been designed for determining of the abrasion resistance of elastomers

and thermoplastic elastomers.

The instrument conforms to PV 3984, a standard used in the motor industry, developed for

engine mounts.

ElastAbrasion allows 4 elastomeric samples to be tested simultaneously.

It eliminates the use the traditional BAM reference rubber to verify the abradant, as each

piece of sandpaper is discarded after one use.

The user does not need to attend the instrument to brush away the debris as the

compressed air continually blows this away.

Users will see approximately 80% reduction in cost and time over traditional methods, and

reduced variability of results.

There is scope to develop test methods appropriate for tyres and shoes, or any other

material that currently requires the use of the rotary drum abrader, or other similar

methods.

Our innovation team welcome any other requests for further development of this

instrument and accessories.

Standards

PV 3984

Elastomers and Thermoplastic Elastomers — Determination of Abrasion

ASTM D8115-17

Rubber Property — Abrasion Resistance (Multi-Directional Platform Abrader)

Loading...

Loading...