James Heal Accudry 2 417 Operator's Manual

2

Covering Serial Nos. 417/11/3001 upwards

James H. Heal & Co. Ltd. Publication 290-417-1$D

Halifax, England ©James H Heal & Co Ltd. 2007

1. CONTENTS

Table of contents

1. CONTENTS 2

Table of contents 2

Table of figures 3

List of tables 3

2. INTRODUCTION 4

3. SAFETY 5

Installation 5

Correct use of dryer 5

Stainless steel top 6

Lint 6

Technical safety 6

4. INSTALLATION 7

Packaging 7

Location 7

Levelling 8

Venting 9

Electrical connection 10

5. DESCRIPTION 11

Front view 11

Rear and side view 12

6. OPERATION 14

7. EXHAUST TEMPERATURE 18

Method 1 – Rear exhaust check 19

Method 2 – Front exhaust check 20

8. CLEANING 21

External cleaning 21

Cleaning the door 21

Cleaning the lint filter 22

9. TROUBLE SHOOTING 23

Dryer will not start 23

Load is not dry or takes too long 23

Miscellaneous 23

Healink contacts 24

Spare parts 24

10. TECHNICAL DATA 25

Technical specification 25

11. PERFORMANCE 26

Indicative drying times 26

12. CE COMPLIANCE 27

CE compliance statements 27

Table of figures

Figure 1: Adjust the levelling feet 8

Figure 2: Checking with spirit level 8

Figure 3: Vent ring nut 9

Figure 4: Draining hole 9

Figure 5: UK 13 Amp plug 10

Figure 6: Accudry2 – front view 11

Figure 7: Accudry2 – rear view 12

Figure 8: Accudry2 – facia 13

Figure 9: Accudry2 – controller and description of keys 13

Figure 10: Flat specimen 15

Figure 11: Specimen to be loaded 15

Figure 12: Open door 15

Figure 13: Load specimens 15

Figure 14: Digital thermometer reading 18

Figure 15: Rear exhaust check 18

Figure 16: Locating the calibrated digital thermometer under the drum filter 20

Figure 17: Temperature recording strips 20

Figure 18: Cleaning the door 21

Figure 19: Removing the filter 22

Figure 20: Opening the filter 22

Figure 21: Example serial number label 24

List of tables

Table 1: Technical specification 25

Table 2: Summary of drying times in various environmental conditions 26

Table 3: Summary of drying rates in various environmental conditions 26

James H. Heal & Co. Ltd

Accudry 2 Operator’s Guide

Reference: 290-417-1$D

Page 4 of 27

2. INTRODUCTION

Accudry2 is an air-vented, reverse action, Standardised Tumble Dryer.

Accudry2 is engineered for laboratory stability tests. It is designed to reduce machine

variables and operator error to the absolute minimum.

The user can set the Controller to operate in English, French, German, Italian or Spanish.

The unit is equipped with a digital controller which displays both exhaust air temperature

and times for the heating and cooling periods. All relevant values are displayed

continuously throughout the drying cycle.

Opening the Tumble Dryer door interrupts the cycle and allows the operator to make an

interim examination of the load. Closing the door and pressing the START key allows the

cycle to continue from the same point.

At the end of the pre-set cycle time, an alarm sounds to alert the operator.

HEALINK – the Service and Calibration Division of Heal’s – offers a service and calibration

contract. Calibration covers the drum speed, the exhaust air temperature measurement

and digital timer.

Routine maintenance is confined to cleaning the easy-access lint filter at the front of the

drum.

James H. Heal & Co. Ltd

Accudry 2 Operator’s Guide

Reference: 290-417-1$D

Page 5 of 27

WARNING !

To avoid a fire hazard, including spontaneous combustion, please read this

guide before operating the Accudry2 and observe the following safety

precautions at all times:

3. SAFETY

Installation

This appliance is heavy. Care should be taken when moving it.

It is dangerous to alter the specifications or attempt to modify this product in any way.

Any electrical work required to install this appliance should be carried out by a

suitably qualified person.

Care must be taken to ensure that the appliance does not stand on the electrical

supply cable.

If the machine is situated on a carpeted floor, please adjust the feet in order to allow

air to circulate freely.

This tumble dryer is designed to be vented through to the open air. It should have its

own ventilation system which should not be joined with any other ventilation system

or connected to any other appliance.

Correct use of dryer

Clean the air filter before each use.

Never allow the air inlet at the back of the dryer, the air outlet or vent hose to be

obstructed.

Never direct the vent hose outlet towards the air intake at the back of the machine.

The machine must not recycle exhaust air.

Never use the machine without the filter in position.

Never exceed the maximum 6 kg load capacity of the machine (i.e., do not overload).

Never place dripping wet items in the drum.

Never use the dryer on a carpeted floor where the pile height would prevent air

entering the dryer from the base.

Never tumble dry articles that have NOT been well washed in water and detergent

solution then well rinsed and spun.

Never tumble dry articles contaminated with flammable substances.

Ensure the dryer is installed in accordance with the Installation Instructions given in

this guide.

Never tumble dry: rubber, foam rubber, plastic, plastic foam, nappy pants

or liners, polythene, paper, dry cleaned garments, large or very bulky

items including duvets and sleeping bags. Items not recommended for

tumble drying may be marked with a symbol such as:

James H. Heal & Co. Ltd

Accudry 2 Operator’s Guide

Reference: 290-417-1$D

Page 6 of 27

Stainless steel top

The stainless steel surfaces must not come into contact with liquid cleaning and

disinfecting agents which contain chlorine or sodium hypochlorite. These agents can have

a corrosive effect on stainless steel. Aggressive vapours containing chlorine can also be

corrosive. Do not store containers of these agents on or near the machine.

Lint

Accumulated lint in the dryer can become a fire hazard, it also reduces the efficiency of the

dryer by causing longer drying times and increased power consumption.

Clean the lint filter before every use.

Ensure the area around the dryer is clear of lint.

At regular intervals have the interior of the dryer casing cleaned of any accumulated

lint. For electrical safety, this must be done by a suitably qualified person or an

Healink Engineer.

Technical safety

Before setting up the machine, check it for any externally visible damage. Do not

install or use a damaged machine.

Before connecting the machine, ensure that the connection data on the data plate

(voltage and connected load) match the mains electricity supply. If in any doubt,

consult a qualified electrician.

The electrical safety of this machine can only be guaranteed when continuity is

complete between it and an effective earthing system which complies with local and

national regulations. It is most important that this basic safety requirement is present

and regularly tested, and where there is any doubt, the on-site wiring system should

be inspected by a qualified electrician. The manufacturer cannot be held liable for

the consequences of an inadequate earthing system (e.g., electric shock).

Do not connect the machine to the mains electricity supply by an extension lead.

Extension leads do not guarantee the required safety of the machine (e.g., danger of

overheating).

The machine is built in accordance with current safety requirements. Unauthorised

repairs could result in unforeseen dangers for the user, for which the manufacturer

cannot accept liability. Repairs should only be undertaken by an approved

technician. Ensure electricity is not supplied to the machine until after maintenance

or repair work has been carried out.

In the event of a fault or for cleaning purposes, the machine is only completely

isolated from the electricity supply when it is switched off at the wall socket and the

plug is withdrawn, or it is switched off at the mains, or the mains fuse is withdrawn.

Faulty components must only be replaced by genuine original spare parts. Only

when these parts are fitted can the safety standards of the machine be guaranteed.

In countries where there are areas which may be subject to infestation by vermin,

pay particular attention to keeping the machine and its surroundings in a clean

condition at all times. Any damage which may be caused by vermin will not be

covered by the machine guarantee. Keep the dryer door closed when not use. The

end of the venting hose should be covered with a weather cap and terminal guard or

grille to prevent vermin from entering. Do NOT cover the end of the venting hose

with cloth/fabric of any description which may collect lint and block the exhaust vent.

James H. Heal & Co. Ltd

Accudry 2 Operator’s Guide

Reference: 290-417-1$D

Page 7 of 27

4. INSTALLATION

Packaging

The transport and protective packing has been selected from materials which are

environmentally friendly for disposal and can normally be recycled. Ensure that any plastic

wrappings, bags, etc. are disposed of safely and kept out of the reach of babies and young

children. Danger of suffocation. Rather than just throwing these materials away, please

ensure they are offered for recycling.

Unpack the Accudry2 Standardised Tumble Dryer carefully and check that the following

accessories have been supplied:

Accudry2 Standardised Tumble Dryer

Venting Hose

Operator’s Guide You will find these items inside the drum

Quick Start Guide

Do not dispose of any packaging until the instrument has been found to be in good

condition, correctly installed and operating correctly.

Location

Ensure electrical power is not supplied to the appliance while installation work is being

carried out.

Make sure the dryer door can be opened without hindrance after installation.

When operating the tumble dryer, the room temperature must not exceed 35°C, as it may

affect the performance of the dryer.

When moving the machine, you can hold it by the lid where it protrudes to the rear of the

dryer. To manoeuvre the dryer out of its packaging to its installation site, you will also

need to hold it by the front feet.

A ventilation gap of 10 mm must be maintained between the base of the machine and the

floor. It must not be blocked by deep pile carpets, plinths, etc, which would prevent a

sufficient intake of cool air.

Whilst drying, the tumble dryer will expel a certain amount of warm, very moist air

containing fibre particles, and this should be removed from the room as quickly as possible

to prevent condensation. In general, it is better to carry the dryer's exhaust outside via the

100 mm diameter flexible hose supplied with the dryer; ending permanently at a fixed

weather cap and terminal guard or grille, fitted to an exterior wall. The tumble dryer must

be installed in a clean place, where dirt does not build up. Make sure there are no

obstructing items or material near the air-intake vents provided at the back.

James H. Heal & Co. Ltd

Accudry 2 Operator’s Guide

Reference: 290-417-1$D

Page 8 of 27

Levelling

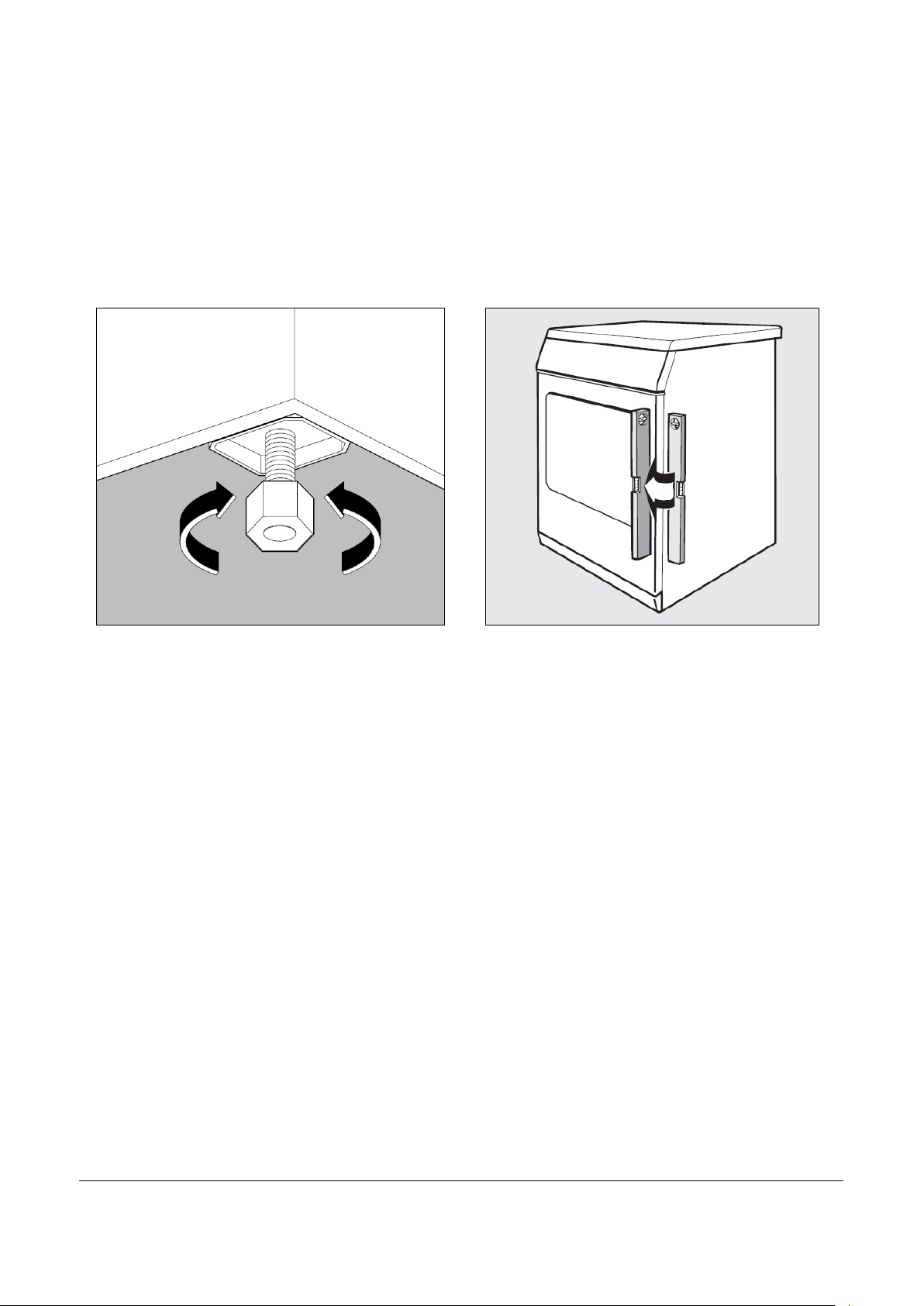

Figure 1: Adjust the levelling feet

Figure 2: Checking with spirit level

To keep vibration and noise to a minimum when the dryer is in use, it should be placed on

a firm, level surface. The machine must be perfectly level to ensure safe and proper

operation.

Once in its permanent operating position, check that the dryer is absolutely level with the

aid of a spirit level. If it is not, raise or lower the two adjustable feet at the front of the

machine until it is.

The feet must never be removed. Do not restrict the floor clearance through deep pile

carpets, strips of wood or similar. This might cause heat build-up which would interfere

with the operation of the appliance.

James H. Heal & Co. Ltd

Accudry 2 Operator’s Guide

Reference: 290-417-1$D

Page 9 of 27

Venting

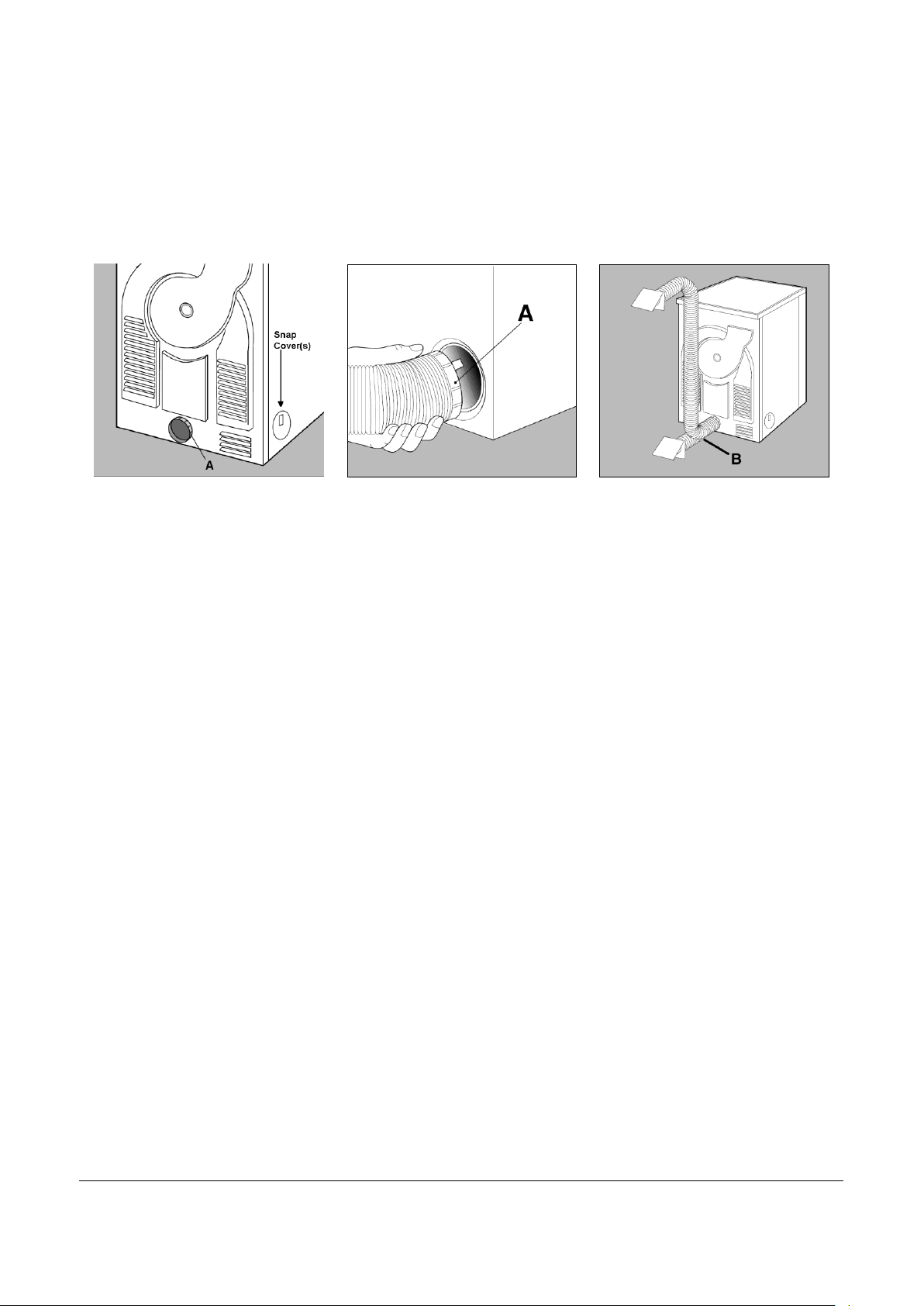

Figure 3: Vent ring nut

Figure 4: Draining hole

To simplify the installation, there is a choice of vent outlets: one at the back, the others in

the left and right-hand side. Connect the hose to whichever is the more convenient by

pulling the ring nut (A) from the vent outlet at the back, screwing it on to the hose and

pushing it firmly back into place. The unused vents should be sealed with the special snap

covers provided.

The exhaust air must not be vented into a chimney or vent flue which is in use, nor should

it be connected to ducting which ventilates rooms with fuel burning appliances.

If the hose is long and the room temperature low, moisture may condense to water inside

the hose. To prevent this water from lying in the hose or flowing back into the tumble

dryer, it is advisable to drill a small hole (approximate diameter 3 mm) in the lowest point

of the hose and to place a small collecting container below it. (See Figure 4, point B).

Once connected to the dryer, run the vent hose to the desired outlet point, ensuring that

the overall length is less than 2 metres, and that it contains no more than two (2) bends.

In order to prevent the tumble dryer from overheating, it is important that the exhaust is

unobstructed. Therefore, in case of a permanent hose fitted to an exterior wall, it must be

ensured an exhaust capacity of at least 150m3/h.

Ensure that the vent hose is not obstructed or compressed. If the hose is partially

obstructed, drying efficiency will be reduced, resulting in longer drying times and higher

energy consumption. If the hose is completely obstructed, the safety cut-outs within the

machine may operate.

Loading...

Loading...