Page 1

R-C-400, R-C-450, R-C-410

Rebarscope®

Operator’s Manual

Original Instructions: Revision July 2018

Page 2

Notice

The Rebarscope® System has been tested in accordance with the EU

regulations governing Electro-Magnetic compliance and it meets required

directives.

Rebarscope® System is a registered trademark of James® Instruments

Inc. and is property of its respective owner.

© 2018 James® Instruments Inc. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic,

photocopying, recording, or otherwise, without prior written permission of

James® Instruments.

No patent liability is assumed with respect to the use of the information

contained herein. Moreover, because James® Instruments is constantly

striving to improve its high-quality products, the information contained in

this manual is subject to change without notice. Every precaution has been

taken in the preparation of this manual. Nevertheless, James® Instruments

assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained

in this publication.

Page 3

ACI 318

Building Code Requirements for Structural

2008

Concrete and Commentary.

We: James® Instruments Inc.

Of: Chicago, IL

In accordance with the following Directive(s):

2006/95/EC

Low Voltage Directive

hereby declare that:

Equipment

Rebarscope® System

Model Number R-C-400, R-C-450, R-C-410

is in conformity with the applicable requirements of the following

documents

Ref. No.

Title

Edition/date

DIN 1045 Concrete, reinforced and prestressed concrete

Structures.

EN 61000-6-3 Electromagnetic compatibility (EMC). Generic

standards. Emission standard for residential,

commercial and light-industrial environments.

EN 61000-6-2 Electromagnetic Compatibility (EMC)

Part 6-2: Generic Standards—Immunity

for Industrial Environments.

BS 1881-204 Testing concrete. Recommendations on the

use of electromagnetic covermeters.

2008

2007

1999

1988

I hereby declare that the equipment named above has been designed to

comply with the relevant sections of the above referenced specifications.

The unit complies with all applicable Essential Requirements of the

Directives.

Signed:

Name: Michael Hoag

Position: President, James® Instruments Inc.

Location: Chicago, IL

On: 7/2/2018

Page 4

Table of Contents

Introduction ....................................................................................... 1

Data Logger Unit .............................................................................. 2

Instrument Contents List .................................................................. 3

Contents List ............................................................................ 4

Control Panel .................................................................................... 5

Control Panel Buttons .............................................................. 6

Menu Layout ..................................................................................... 7

Using the Rebarscope® on Location .............................................. 8

Removing the Lid ..................................................................... 8

Attaching the Shoulder Support Straps ................................... 8

Sensor Probe ................................................................................. 10

Short / Deep Mode ......................................................................... 11

Locating Ferrous and Non-Ferrous Metals .................................... 13

Option 1 – Graphic Bar Display ............................................. 13

Option 2 – Number Display ................................................... 13

Determining Cover ......................................................................... 14

Determining Bar Size ..................................................................... 17

Rebar Sizing Guidelines ........................................................ 23

Pitch & Resolution ................................................................. 24

Utilizing Cover Map Function .........................................................

System Menu ................................................................................. 30

Display Cursor ....................................................................... 30

Language Options ................................................................. 31

Measuring Units ..................................................................... 32

Clock Menu ............................................................................ 32

Erase Memory ....................................................................... 34

Battery Operation .................................................................. 35

Scan Cart (R-C-410 Only) .............................................................. 38

Data Handler Introduction .............................................................. 42

Features ................................................................................. 42

Minimum System Requirements ............................................ 42

Data Handler Overview .................................................................. 45

Software Functions ................................................................ 45

Software Installation ....................................................................... 46

Uploading Cover Map (R-C-450 and R-C-410 only) ...................... 50

25

www.ndtJames.com iii

Page 5

Contents

Uploading Scan Map (R-C-410 only) ............................................. 54

Graphic representation of the Scan Map data................................ 55

Troubleshooting ............................................................................. 58

Maintenance ................................................................................... 61

Safety ............................................................................................. 61

Available Rebarscope® Accessories ............................................ 62

Specifications ................................................................................. 63

Warranty Information ...................................................................... 65

Repair Policy .................................................................................. 70

iv www.ndtJames.com

Page 6

Introduction

Introduction

The James® Instruments Rebarscope® utilizes the latest in eddy

current sensing and micro-processor technology to accurately

locate, determine the depth of, and estimate the size of metal

objects in concrete. The eddy current sensor is specifically

designed to react to the outer surface of the metal object only. It is

uninfluenced by small particles in the concrete, whether the

concrete is fresh or hardened, wet or dry.

The Rebarscope® has built-in test modes for rebar/post tension

cable, conduit and copper pipe. The sensor allows the unit to locate

both ferrous and nonferrous metals in concrete.

With an easy to view display, the Rebarscope® provides the user

with an instantaneous structural analysis. The user is aided by

using a graphic bar in the display, and an audio tone to quickly and

accurately locate metal objects. Large numbers in the display show

the estimate of cover. This information can then be used to display

a map of the cover throughout the structure. Further options allow a

2-dimensional cross-section of the concrete under test.

The Rebarscope® was developed for real world application and

everyday durability in mind. It’s rugged and splash resistant case

allows the user to use the Rebarscope® in the field. It’s small but

sturdy sensing probe can withstand test after test with little wear on

the probe face. Additionally, the Rebarscope® is able to

compensate the sensor signal for a wide temperature range; as

may be seen during in-situ field testing.

The Rebarscope® enables the user to store field test data, and later

upload it to a Personal Computer. Once downloaded, the software

allows the user to analyze the data, while a graphing tool function

allows the creation of a contour map.

www.ndtJames.com

1

Page 7

Data Logger Unit

The data logger unit is a standard with the James® Instruments

Rebarscope®. It is a sophisticated, rugged field proven unit. The

embedded microprocessor technology enables the user to easily

locate, determine the amount of cover, record, and analyze ferrous

and non- ferrous metals.

The large easy to read numbers on the data logger display make

the Rebarscope® user friendly when estimating cover or bar

size.

Plus, with a memory capacity of 8000 data points, the data

logger

allows for a large sum of data to be stored for later

analysis.

The front panel of the data logger unit allows the user to interface

with the sensor probe, scan cart, headphones, charger and a

personal computer via a USB port. The large viewing window

protects the LCD display from possible damages that may occur

during operation. Additionally, large control buttons on the front

panel enable the user to easily scroll through menu options.

www.ndtJames.com

2

Page 8

e

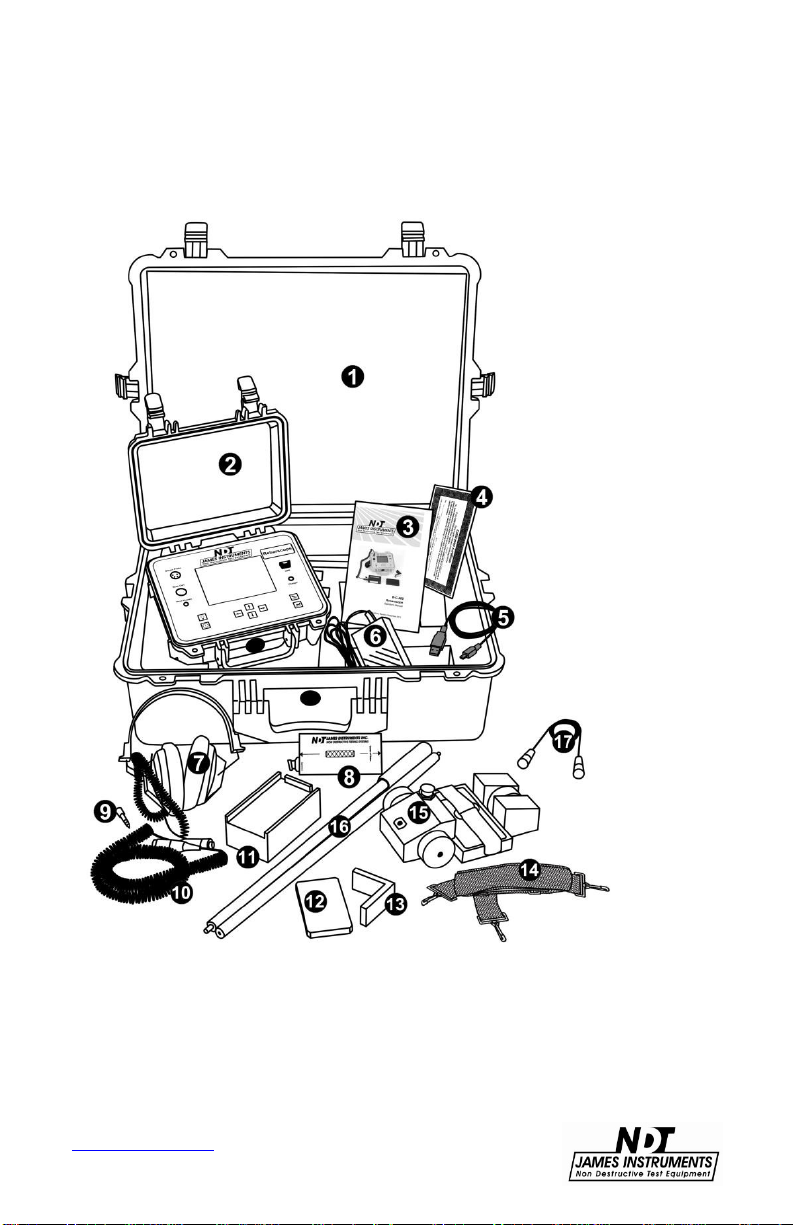

Instrument Contents List

Each Rebarscope® comes with the following items included in the

carrying case.

Figure 1: Rebarscop

®

System Contents

3

www.ndtJames.com

Page 9

Contents List

Item # Description

Case – Used for carrying the Rebarscope®

1

and

Rebarscope® Instrument – Rebar locator encased

2

a durable protective case.

in

accessories.

3

Instruction Manual – Operating instructions for

Rebarscope®.

4

Calibration Certificate – Certificate to confirm that the

instrument has been calibrated to meet or exceed

published specifications.

5

USB Cable – Serial cord used to connect the

Rebarscope® to a PC to upload data.

AC Power Adapter – Used to power the Rebarscope®

6

and recharge the unit.

7 Headphones – Used in noisy environments.

8 Sensor Probe – Shows direction of rebar.

9 Phone Jack – For headset.

10 8’ Coiled Cable – Used with the Sensor Probe.

11 1 5/8” Spacer Block – Used to add space in lower

cover situations.

12 3/8” Spacer Block – Used for sizing feature.

13 Locating Template – Used for sizing feature.

14

Support Strap – Used to secure the Rebarscope®

the user during testing.

to

15 Scan Cart – (opt.) Comes with Complete system only.

16 Scan Cart Extension Poles – (opt.) Used to guide

Scan Cart

17 Scan Cart Cable – (opt.) Yellow cable used to connect

Scan Cart to main unit.

4

www.ndtJames.com

Page 10

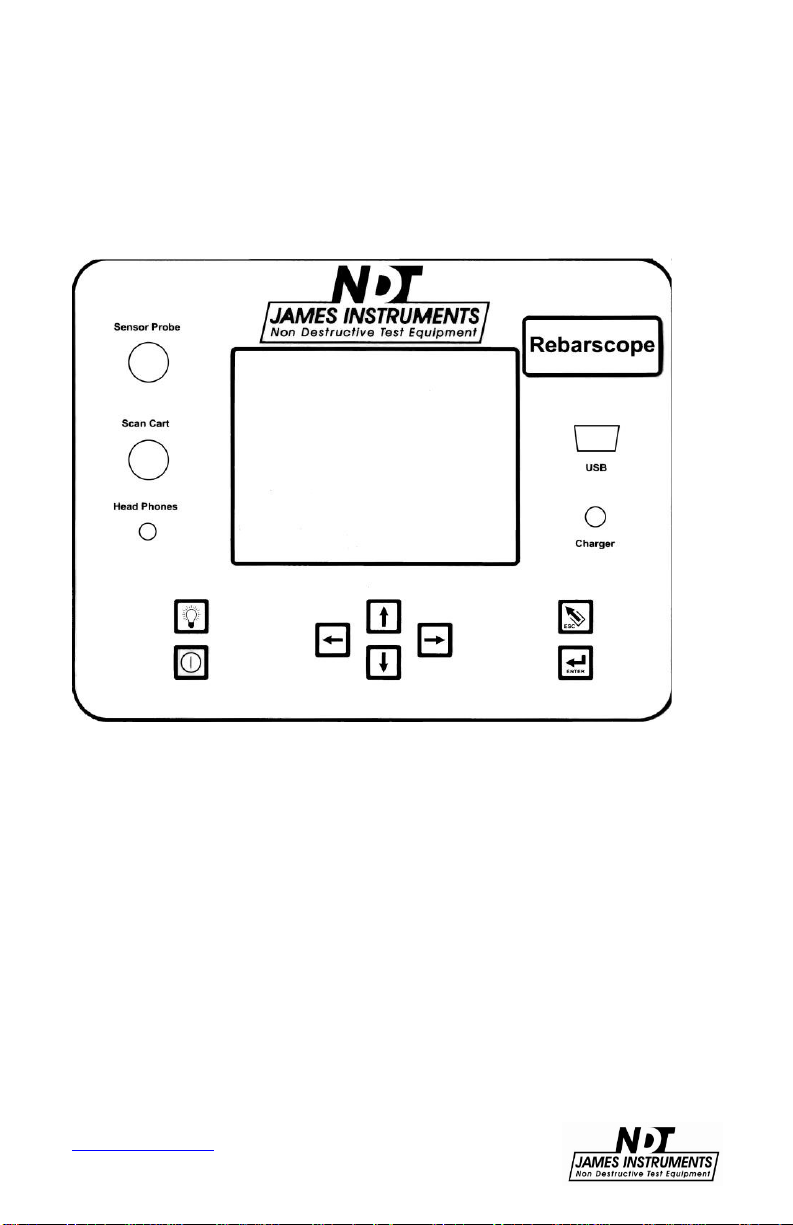

Control Panel

The following buttons appear on the James® Instruments

Rebarscope® System.

www.ndtJames.com

Figure 2: Rebarscope® System Buttons

5

Page 11

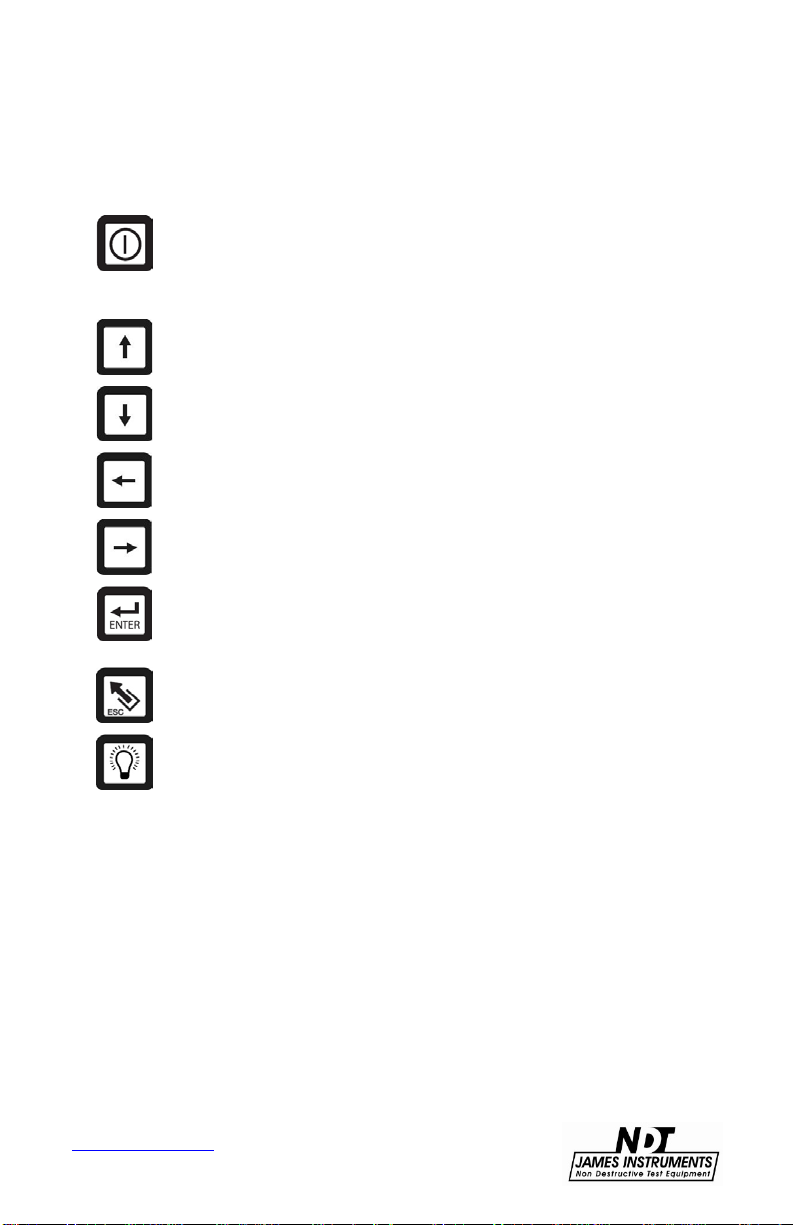

Control Panel Buttons

Key Definition

The power button. Momentarily push this key to turn

“on” the unit. Pressing it again turns off the unit. Upon

power up, the unit will display the locate screen. Press

the escape key to get to the Main Menu.

The up arrow button. This key is used to scroll through

various settings and wave frames.

The down arrow button. This key is used to scroll

through various settings.

The left arrow button. This key allows you to scroll

through various settings.

The right arrow button. This key allows you to scroll

through various settings.

The enter button. Pressing this key allows you to

choose main menu selections. The enter key also

allows you to prepare the Rebarscope® for operation.

The escape button. Pressing this key allows you to

return to the main menu screen from any sub screen.

The back light button. Depressing this key the backlight

of the display comes on. Depressing the key again

turns the backlight off.

www.ndtJames.com

6

Page 12

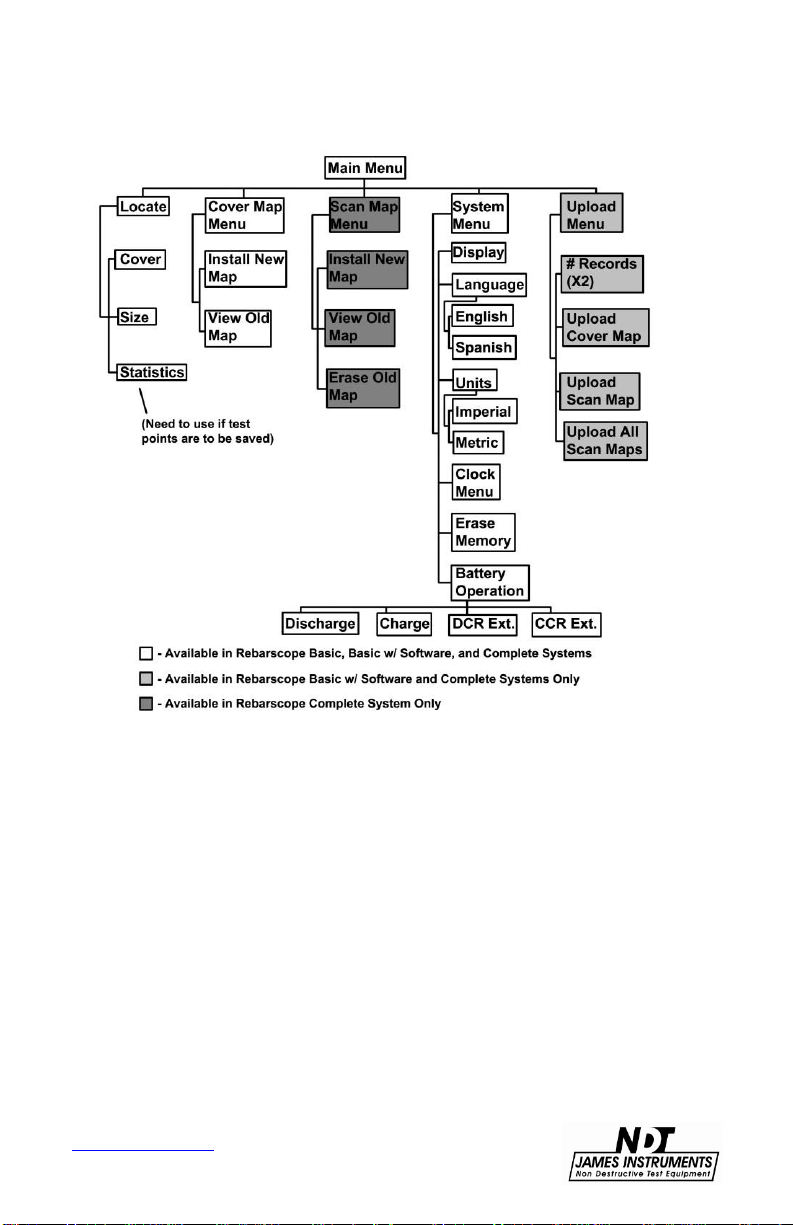

Menu Layout

www.ndtJames.com

Figure 3: Rebarscope

7

®

Function Flow Chart

Page 13

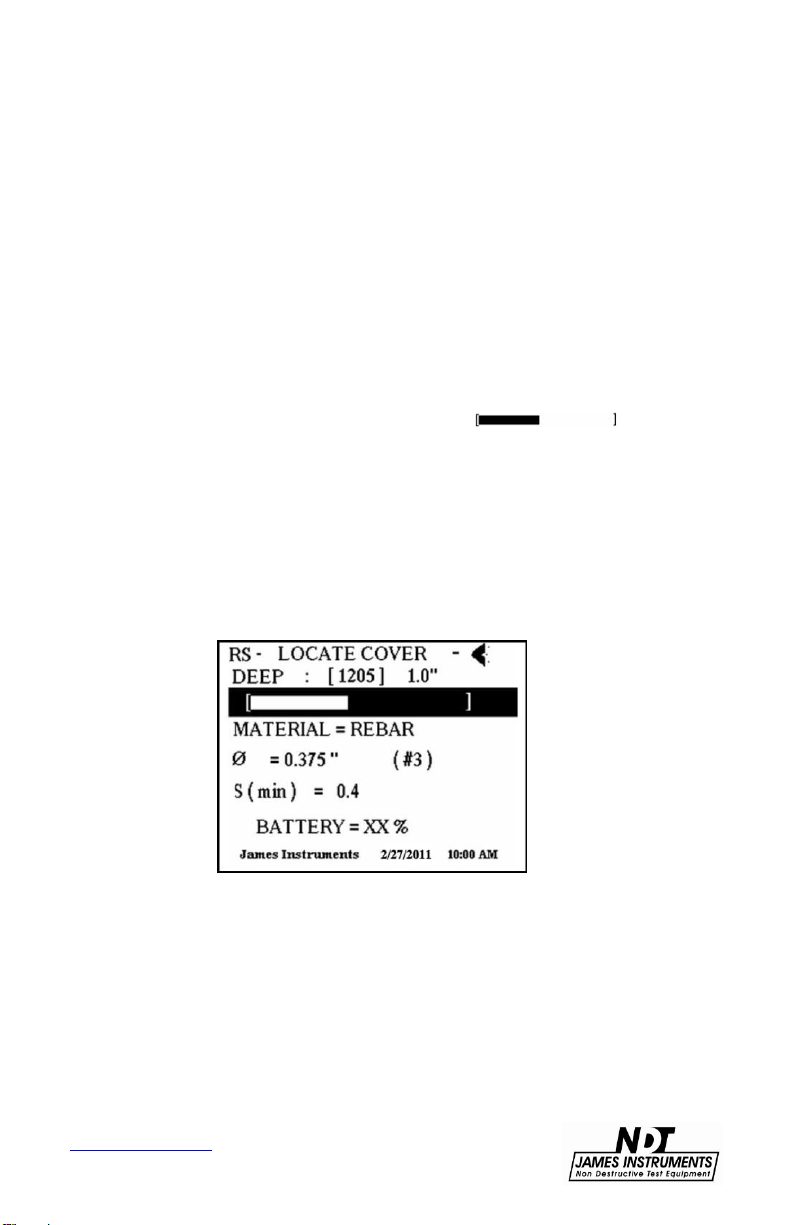

For Quick Reference, in “LOCATE COVER” screen:

1.

For Automatic (RS), Short or Deep mode, go to line

and press the Left arrow button to change

between settings.

2.

For Audio Feature – go to and press the

Right arrow button once for beeps, twice for continuous

tone, and three times for audio off.

3.

Material Options – Rebar (Post Tension Cable) / Conduit /

Copper.

System Menu

Using the Rebarscope® on Location

Removing the Lid

For ease of use in the field, the Rebarscope® lid can be

removed

the lid and

and the shoulder straps installed. To do so, fully open

the cover can be carefully pushed off of the case

hinge pins.

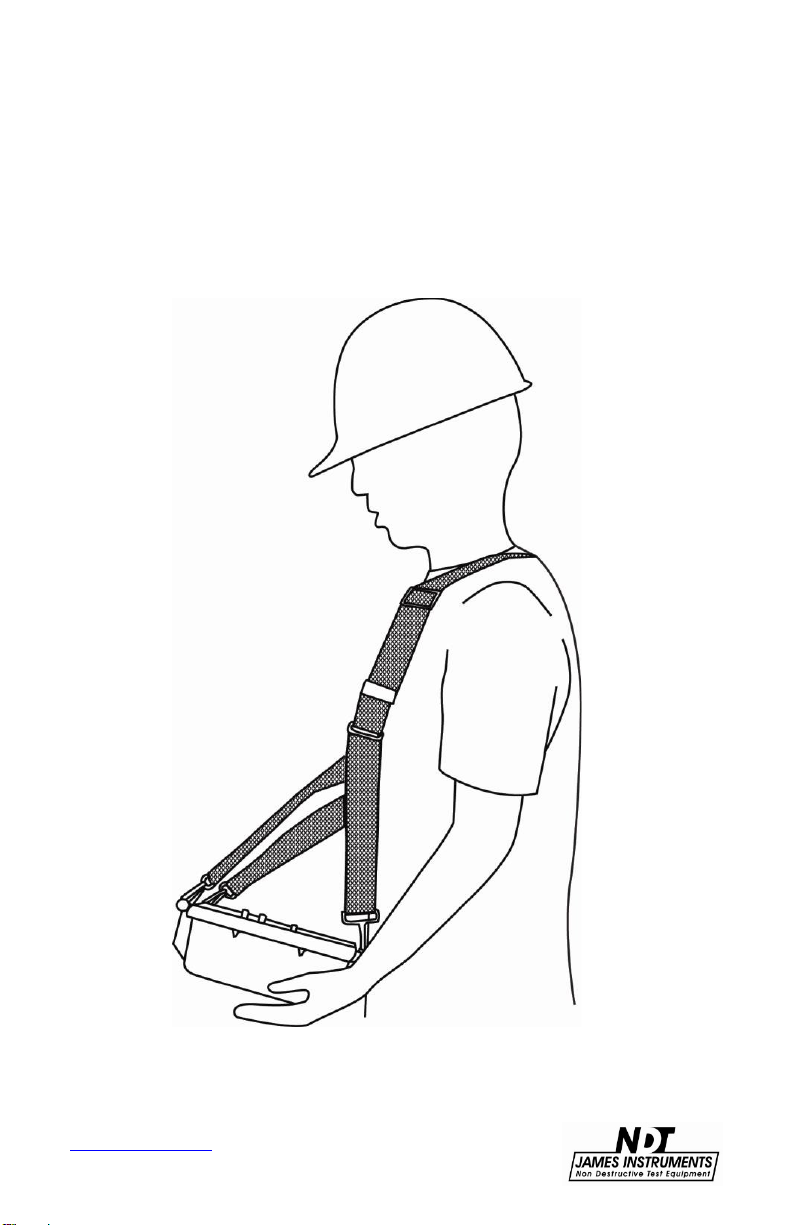

Attaching the Shoulder Support Straps

The Rebarscope® support straps can be used to hold the

Rebarscope® once the Rebarscope® lid has been removed.

When

using the Rebarscope® support straps, make sure that an

eyelet

hook is connected to each corner of the Rebarscope® .

Two of the

around the hinge

hooks clip to the O-rings, while the other two clip

pins.

Follow the step below:

1.

Attach the straight portion of the support strap to the

front metal O-rings of the Rebarscope®.

two

2.

Attach the other two straps (which are stitched to the

straight portion of the harness) to the new exposed

hinges

3.

Pull the supplied support strap over your head so that

rubber guard is resting on the back of the user’s

the

neck.

www.ndtJames.com

of the case.

8

Page 14

4.

Now adjust the strap accordingly so that the

Rebarscope® is within easy reach and readable. (see

Figure 4)

Figure 4: Rebarscope® Support Strap

www.ndtJames.com

9

Page 15

Sensor Probe

The James® Instruments Rebarscope® utilizes the latest in eddy

current sensing technology. The heart of this technology can be

found in the sensor probe which has been specifically designed to

react to the outer surface of metal objects. With this ability, the unit

is able to accurately locate, determine the depth of, and estimate

the size of metal objects within reinforced concrete structures. This

makes the Rebarscope® sensor probe far superior to other

commercially available rebar location systems.

The Rebarscope® sensing probe is compact, weighing only 1 lb

dimensioned at 5”x 2.4”x1.6” and still very tough and durable

and

field application. The sensing probe has been calibrated in our

for

facility for operation with only the data logger unit it was purchased

with. If a new sensor probe is needed it is recommended to send

the complete unit in for proper calibration. Not calibrating the

sensor

unacceptable

information

office.

probe and the data logger unit together can cause

location, cover and bar size readings. For further

regarding repair and calibration please contact our

www.ndtJames.com

10

Page 16

Short / Deep Mode

The Rebarscope® facilitates the analysis of rebar location, cover

and bar sizing; allowing the user to do measurements in short mode

or deep mode. The Rebarscope® also provides the user the ability

to automatically switch between deep and/or short mode.

Note: The single sensing probe operates efficiently in both modes.

When the system is initially turned “on”, the Automatic (RS) mode is

the default setting. To change this, go to the Locate Cover screen.

•

Once in the Locate Cover screen, use the up or down arrow keys

on the front panel to highlight the graphic bar .

•

When the highlight is on the bar, press the left arrow key to

change between modes. (Note: The letters RS in the upper left

hand corner of the screen indicate auto ranging is “on”.)

•

Follow the procedure above to turn off Auto ranging, and to

manually switch between Deep and Short modes as seen on line 1

of this screen.

www.ndtJames.com

Figure 5: Locate Cover Screen

11

Page 17

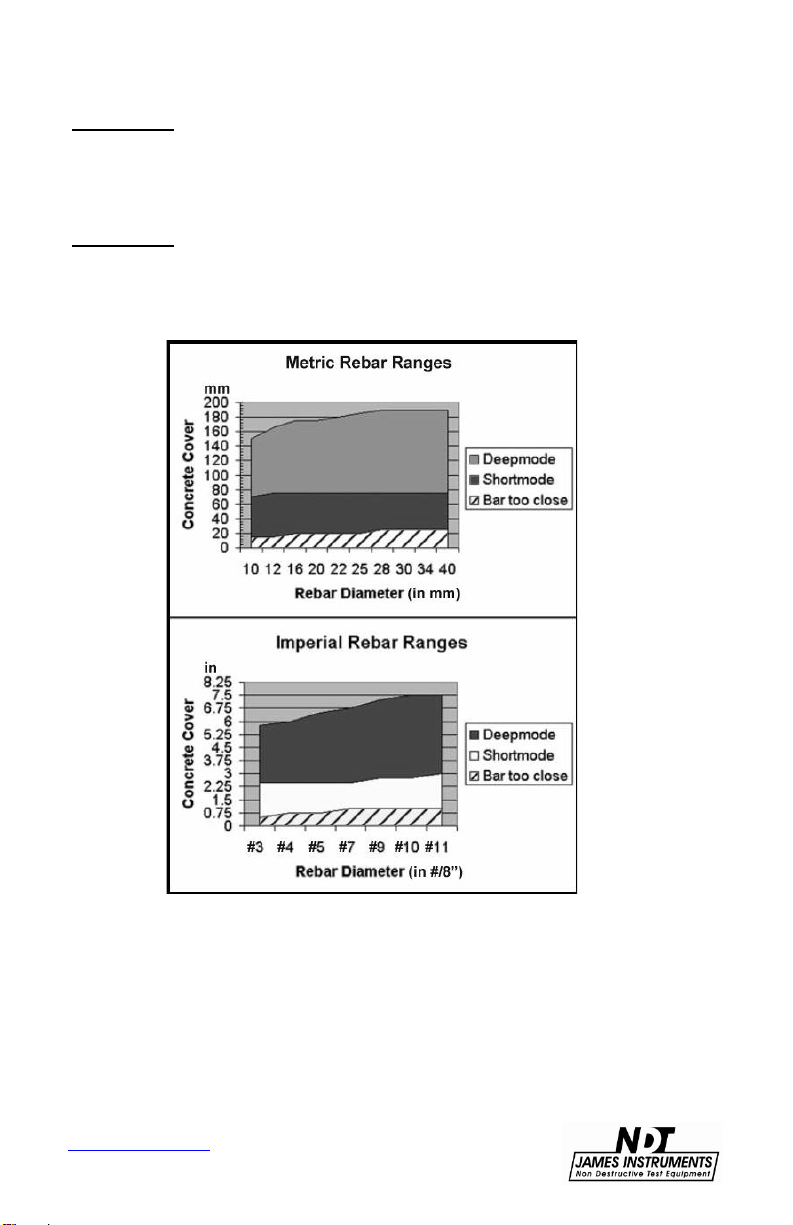

Short mode: Ideal when reinforcement cover ranges from .5” to

3.0”. Locating, determining cover and bar size can all be measured

while in this mode. An error of ± .125” must be accounted for during

measurement of metal bar or pipe location.

Deep mode: Ideal when reinforcement cover ranges from 2.75” to

8”. Locating, determining cover and bar size can all be measured

while in this mode. An error of ± .125” must be accounted for during

measurement of metal bar or pipe location.

Figure 6: Metric and Imperial Graphs for Rebar Ranges

www.ndtJames.com

12

Page 18

Locating Ferrous and Non-Ferrous Metals

The Rebarscope® uses eddy current sensing and micro-processing

technology, and is ideal for locating ferrous and non-ferrous metals.

Metals located with ease are the following:

•

Imperial and Metric reinforcement bars

•

Standard copper pipe

•

Standard conduit pipe

•

Post tension cable (use Rebar mode)

The Rebarscope® allows the user to locate metals by using two

options on the LCD display.

Option 1 – Graphic Bar Display

The action bar displayed on the second line of the location screen

enables the user to determine when the center of the metal bar/pipe

has been detected. When the sensor probe is directly over the

center of the metal bar/pipe, this bar display will have reached its

highest point. When the sensor probe has passed the center of the

metal bar/pipe, the bar display will decrease in size.

Option 2 – Number Display

This option consists of a numerical output value in brackets

displayed on line 1 of the locate cover screen. The range of this

number is 0 to 4095. As the probe moves toward the rebar/pipe the

number will increase. Then when the probe is over the center of the

rebar/pipe you will see the largest number displayed. As you move

the probe away from the center of the rebar/pipe the number will

begin to decrease.

This technique can also be useful in determining whether short or

deep mode is necessary for proper location, cover, and sizing

analysis.

www.ndtJames.com

13

Page 19

Determining Cover

The Rebarscope® allows the operator to easily determine the

concrete cover of rebar. Since the Rebarscope® utilizes eddy

current technology, cover is determined with even more accuracy

than its predecessor. With this, only the bar/pipe is located and no

small particles of metals (such as fly ash) in the concrete can

influence the measurement. The following steps allow for proper

cover measurements:

Step 1: Choose either Imperial or Metric units on the system menu

screen.

Step 2: Decide whether short or deep mode is necessary for your

testing. If needing to adjust this setting, go to the Locate Cover

screen and follow the steps.

Figure 7: Locate Cover Screen

www.ndtJames.com

14

Page 20

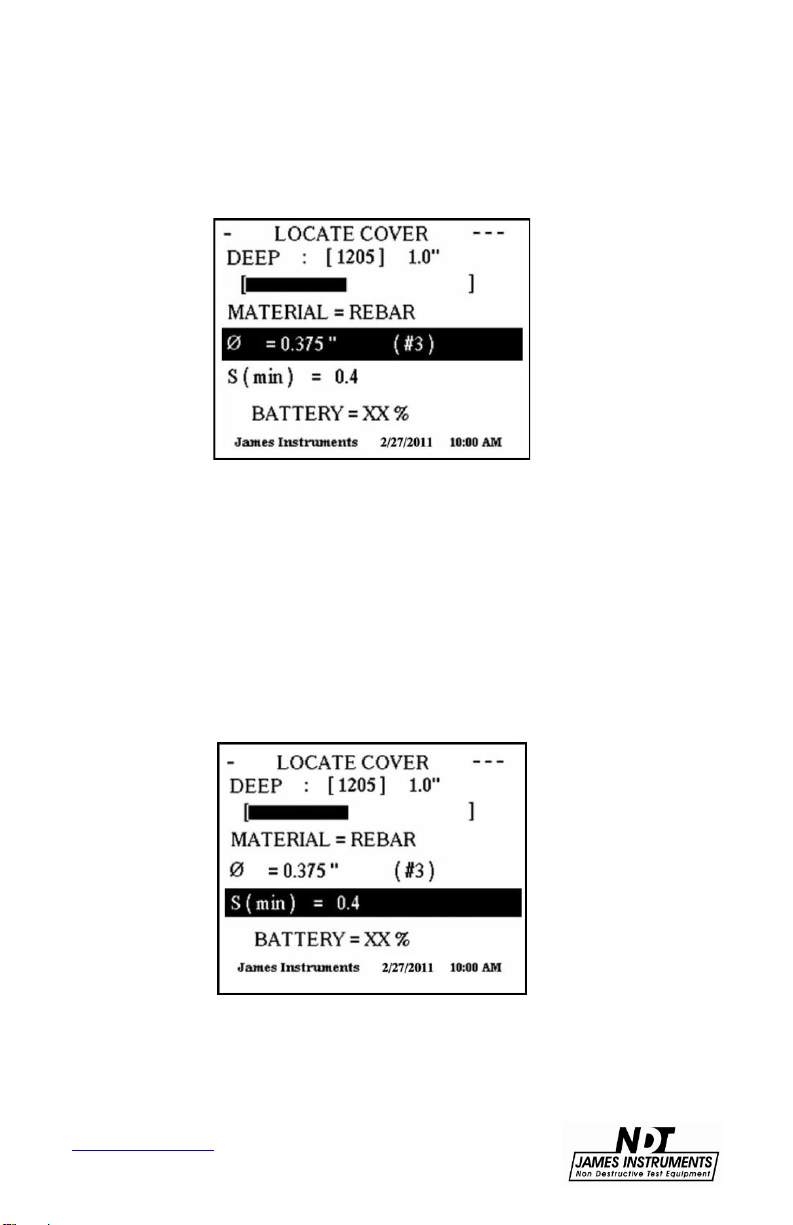

Step 3: Using the down arrow key, scroll the highlighted section

down to the bar diameter category. Once this line is highlighted,

use the right or left arrow keys to choose the proper bar diameter.

Figure 8: Choosing Bar Diameter

Step 4: Now, pass the sensing probe on the surface of the test

structure until the smallest cover is displayed on the right hand

corner of the screen.

Step 5: The Rebarscope® allows the user to choose the minimum

cover to analyze with. This feature is referred to as the S min. Using

the up or down arrow key, scroll the highlighter down to the S min

category and use the left or right arrow keys to choose an S min that

ranges from 0.4 - 5.0.

www.ndtJames.com

Figure 9: Setting Minimum Cover

15

Page 21

Step 6: Now pass the sensing probe on the surface of the test

structure until the smallest cover is displayed on the right hand

corner of the screen. The audio/ headphone feature also allows

user to precisely locate the center of the rebar using the audio

the

signal. This audio feature helps give even more cover precision.

The steps below show how to properly choose the audio signal for

your application.

Figure 10: Dynamic Bar Display

Step 6A: In the Locate Cover screen, use the up / down arrow

to scroll the cursor down to the action bar in the display.

keys

Step 6B: Use the right arrow key to choose either a beeping type

audio signal, or a continuous tone audio signal. A small speaker

icon will appear on the upper right hand corner of the display when

the audio feature has been enabled. Headphones have also been

supplied with the Rebarscope® to help the user hear a clearer

audio

signal in noisy environments.

Step 6C: Pressing the right arrow key one more time after the

continuous tone will turn off the audio feature, and the speaker

on the upper right hand corner will no longer appear on the

icon

display

screen.

16

www.ndtJames.com

Page 22

Determining Bar Size

The bar diameter can be easily determined with the Rebarscope®

without the prior knowledge of cover. This is possible by taking two

readings, one at surface of the structure and another at the same

location but 3/8 inches away. A 3/8 inch spacer block is provided

with the system along with a locating template. This L shaped

template helps keep the exact location of the first reading when

taking the second reading with the 3/8 inch spacer block (see

pictures below).

(Note: Bar sizing is done in Deep mode only, and at a maximum

depth of approximately 4.5 inches.)

www.ndtJames.com

Figure 11: Locating Rebar

17

Page 23

Figure 12: 3/8” Spacer with L Shaped Template

Figure 13: Locating Rebar with Spacer

www.ndtJames.com

18

Page 24

www.ndtJames.com

Figure 14: Analyzing Data

19

Page 25

If the unit shows out of range in the BAR SIZE screen, and the

display reading is 3000 or larger, this means the rebar is too close

to the surface. The first reading should then be taken with the

supplementary 1 5/8” spacer block, and the second with a 3/8”

spacer block. See pictures below. (The supplement spacer block is

used only to add space between the surface and the sensor probe.

It’s size is not critical when performing the sizing function.)

www.ndtJames.com

Figure 15: 1 5/8” Block

Figure 16: 3/8” Block

20

Page 26

The following steps allow for proper bar sizing measurements:

Step 1: Press ESC to exit the Locate Cover screen.

Step 2: In the Main menu screen use the up or down arrow keys to

navigate the highlight to the Locate category.

Figure 17: Bar Size Function

Step 3: Press the right arrow key on the front panel to choose

Locate: Size and press Enter.

Step 4: In the BAR SIZE screen, use the sensor probe to locate the

center of the rebar either by using the bar display or the numerical

output value in brackets [ ].

Figure 18: Bar Size Screen

www.ndtJames.com

21

Page 27

Step 5: Place the sensor on top of the surface where the rebar

diameter is to be measured. If the reading on the first line is larger

than 3000, use the 1 5/8 inches spacer block between the concrete

surface and the sensor. If reading is still above 3000 it may be

necessary to add an additional non-metallic block underneath the 1

5/8 block. (Note: The optimal cover range for sizing is between 1.7”

and 4.2”. Also, the most accurate sizing of rebar occurs when the

first measurement is about 1200.)

Step 6: Once the center has been determined, press Enter for a

few seconds to store the result.

Step 7: The Rebarscope® will now read ADD BLOCK PRESS ENT

on the top line.

Figure 19: Add Block is displayed

At this point the locating template needs to be placed alongside of

the sensor probe; so the exact location of the first reading can be

kept. Note: Taking the second reading at the exact location as the

first is critical for precision. While holding the locating template,

remove the sensor probe and place the 3/8 inch spacer block along

the locating template.

Step 8: Now place the sensing probe over the 3/8 inch spacer block

and press Enter. The Rebarscope® will now display the estimated

diameter of the measured rebar. The Rebarscope® can accurately

determine bar size up to a cover of 4.5" (115mm) in Deep mode.

22

www.ndtJames.com

Page 28

Figure 20: Estimated Diameter is Displayed

Rebar Sizing Guidelines

1. Sizing is done in Deep Mode only, and to a maximum depth of 4.5

inches (~114mm).

2. If the Rebar is too close to the surface (< 2.5 inches), use the 1_5/8”

plastic spacer block (or some wood) to raise the sensor off the surface.

(Rebar Size is best determined when the cover is between 2.5 - 4.5

inches.)

3. Sizing is also best determined when the rebar is isolated - no metal

objects are near the sensor - including the main unit. This may require the

user to move the main unit away from the sensor when testing for rebar

size.

4. Sizing can be done when the rebar “on-center” spacing is equal to, or

greater than 6 inches (~150mm) from any adjacent rebar, conduit pipe,

copper pipe, post tension cable and wire mesh.

5. Sizing accuracy is +/- 1 Bar size for Imperial rebar, and ~ 3mm for

Metric rebar sizes. This variance is due to the physical appearance of

rebar, which has ribs (or ridges) along the length of the reinforcement

bars. It is also due to the program settings of the unit itself. (Imperial

sizes: 3, 4, 5, 6, 7, 9 & 11. Metric sizes: 6, 10, 13, 16, 19, 22, 25, 29, 32,

35, 38, 41 & 51mm.)

6. Due to the high concentration (and/or close proximity) of rebar within a

Column, sizing (and location) is nearly impossible for a Column. It

is not recommended to use the rebar locator for testing Columns.

www.ndtJames.com

23

Page 29

Pitch & Resolution

Measurements can often be influenced by neighboring parallel

bar(s). The graph below shows the minimum spacing to a

corresponding bar.

www.ndtJames.com

Figure 21: Minimum Bar Spacing

24

Page 30

Utilizing Cover Map Function

The James® Instruments Rebarscope® has incorporated a user

friendly cover map to further assist in field analysis. The cover map

mode allows the user to mark the cover and location of a rebar on a

grid. The grid lines are numerically numbered with the Y axis

starting at 1 from left to right. The X axis is also numerically

numbered with number 1 starting at the top of the grid.

The Three symbols below have been selected to allow the user to

distinguish the status of the current reading. A full shaded box

represents that the cover is less than the selected S min. The S min

is the selected minimum cover you have told the Rebarscope® to

detect. A box with 3 thick shaded lines means that the cover is

within range of the selected S min. A box with 3 thin inner lines

means that the Rebarscope® has not detected a bar/tube.

Figure 22: Cover Map Symbols

Please follow this procedure to correctly prepare the Rebarscope®

for Cover Map operations:

25

www.ndtJames.com

Page 31

Step 1: Press the escape key on the front panel to get to the Main

Menu screen.

Figure 23: Cover Function

Step 2: Navigate the highlighted cursor using the up or down arrow

keys to COVER MAP MENU option and press Enter.

Figure 24: Cover Map Menu

www.ndtJames.com

26

Page 32

Step 3: Choose whether you would like to INSTALL NEW MAP or

VIEW OLD MAP by highlighting one and pressing Enter.

Figure 25: Install New Map or View Old Map

Step 4: If View Old Map is chosen please proceed to step 4B, if not

please follow the instruction directly below for installation of a new

map.

Figure 26: Map Display

Step 4A:

1

The Rebarscope® automatically generates a map number.

2

Under the Material category line, choose the material under

investigation. (rebar, conduit, copper)

3.

Choose the diameter of the material under investigation.

4.

Choose the S min (minimum cover)

27

www.ndtJames.com

Page 33

5.

Choose the detection range DEEP or SHORT, that the cover

analysis will be done in.

6.

Press Enter.

7.

The screen now displays the cover map grid.

Step 4B:

1.

After choosing to view old map a REVIEW COVER MAP menu

screen will appear.

2.

The system does not allow adjustment of previous set

Figure 27: Review Cover Map Screen

parameters.

3.

The only function that can be changed is that of which map to

view.

4.

Choose the map number to view and press Enter.

5.

The screen now displays the cover map grid with previously

saved data. New data can be saved into the gridded map along

with the older data.

28

www.ndtJames.com

Page 34

Step 5: Utilizing the Up or Down arrow keys on the front panel

chose the location for your first mark.

Step 6: Pass the sensor probe over the area being investigated; the

blinking cursor will turn into one of the three cover symbols.

Step 7: Pressing the Enter key will save that symbol onto the

screen and store into memory the location information seen on the

bottom of the screen. This information will also appear for this

particular point on the upload screen of the PC software.

www.ndtJames.com

29

Page 35

System Menu

The system setup option on the main menu screen allows you to

make modifications to system configurations. Once in the system

setup sub menu modification can be made to the following

•

Display

•

Language

•

Units

•

Clock menu

•

Erase Memory

•

Battery operation

•

Pressing the escape key takes you back to the main menu screen

Display Cursor

To change the visibility of the display cursor, follow these steps:

•

Press the up or down key until you get to the system setup menu

option. Press Enter. The Setup Menu sub screen should appear.

•

Scroll through the Setup menu using the up or down arrow key.

Select the Display option by pressing Enter. The display should

read the following.

DISPLAY= Black Lines

•

Pressing the left or right arrow keys will give the user the option to

choose Black (highlighted) Lines or White (highlighted) Lines, as

well as the background color.

www.ndtJames.com

30

Page 36

•

Pressing the Escape key will return you to the Main Menu Screen.

Figure 28: Display with Black or White Lines

Language Options

To choose which Language the Rebarscope® will be operating in,

follow these steps:

•

Press the up or down key until you get to the system setup menu

option. Press Enter. The Setup Menu sub screen should appear.

•

Scroll through the Setup menu using the up or down arrow key.

Select the Language menu option by pressing Enter. The display

should read the following.

LANGUAGE=

•

Use the left or right arrow keys to choose English or Spanish as

the language that your Rebarscope® operates in.

Figure 29: Setting the Language

•

Pressing the Escape key will return you to the Main Menu Screen.

31

www.ndtJames.com

Page 37

Measuring Units

English and Metric units are available for the user to choose from.

The following steps allow the user to choose the measuring units

viewed:

Step 1: In the main menu screen use the up or down arrow keys on

the front panel to navigate down to the system set up category.

Step 2: Press Enter.

Step 3: In the system setup screen use the up or down arrow keys

on the front panel to navigate down to the UNITS category.

Step 4: Use the right arrow key to choose either Imperial (English)

or metric measuring units.

Figure 30: Setting the Units

Step 5: Press the ESC key to go back to the main menu screen

and continue measurements.

Clock Menu

To change date and time, please follow these steps:

•

Press the up or down key until you get to the setup menu option.

Press Enter. The Setup Menu sub screen should appear.

32

www.ndtJames.com

Page 38

Figure 31: Clock Menu is Highlighted

•

Scroll through the Setup menu using the up or down arrow keys.

Select the Clock Menu option by pressing Enter. The display should

be similar to the following.

•

Pressing the left or right arrow key will increment the digits on the

Figure 32: Setting the Date and Time

display.

•

Use the up and down key to select each hour and date options.

•

Scroll to the save changes option using the up or down arrow key.

www.ndtJames.com

33

Page 39

•

Pressing the Enter key will store the date and time and return you

Figure 33: Save Changes When Finished

to the Main menu screen.

Erase Memory

To erase stored memory from the Rebarscope®, follow these steps:

•

Press the up or down keys until you get to the system setup menu

option. Press Enter. The Setup Menu sub screen should appear.

SETUP MENU

•

Scroll through the Setup menu using the up or down arrow key.

Select the Erase Memory option by pressing Enter. The display

should read the following.

ERASE MEMORY

•

Press Enter once and a message telling you to press Enter again

to verify this action should appear.

PRESS ENTER AGAIN

•

Pressing Enter a second time will erase ALL stored memory in

the Rebarscope® system. When complete, the phrase “Ø errors”

should be seen on the display screen.

•

Pressing the Escape key will return you to the Main Menu Screen.

www.ndtJames.com

34

Page 40

Battery Operation

The Rebarscope® uses a 14.4V Lithium-Ion battery with a built-in

thermo-sensing circuit. This circuit allows for a suitable charge, and

maintains the voltage to the cells (< 4.1V). Additionally, this circuit

provides the proper charge current to lengthen the battery’s life.

At full charge, the bottom of the display will show BATTERY=100%.

(Note: This value may be inaccurate, if the battery counters were

reset without properly charging the unit.)

-

The battery status can be viewed in the “System Menu”,

under the “Battery Operation” mode. (Fig.34 & 35)

-

When the charger is supplying power to the unit, the battery is

charging, and the charge counter (“Charge CTR”) will increase.

-

When the unit is ON, and the charger is disconnected from the

unit, the discharge counter (“Discharge CTR”) will increase.

-

The battery will continue to charge even after the microcontroller

times out - display and unit turn OFF automatically.

-

When the mode is set to any of the following settings: LocateCover, Size, Statistic, or Cover Map (or Scan Cart for R-C-410)

the charge operation is disabled.

www.ndtJames.com

Figure 34: Battery Operation Menu is Highlighted

35

Page 41

-- BATTERY STATUS-DISCHARGE CTR = xxxx

CHARGE CTR = xxxx

DCR EXT = 0

CCR EXT = 0

Hit ENT to Clear Reg

BATTERY = 100%

Figure 35: Clearing Charger Register

Battery Charge:

1.

Connect the charger to a working outlet, and then to the charger

input on the unit’s front panel. Although, it is recommended for the

unit to be OFF during a charge, the user can monitor the charging

process in the screen above.

2.

If the Charge counter slows to a stop (and does not increase),

this is an indication the charge is complete. The battery now has a

full charge, and needs to be reset. To do this, go to: Main Menu /

System Menu / Battery Operation - press “Enter” to zero the

counters. This action also resets the battery circuit mentioned

above, and will correct any miscounts. (If charging is still an issue,

review the Troubleshooting section on p.57.)

Resetting the battery counters should be done both before and after (at least) a 4hr charge.

When done so, the battery status % on the display will be accurate.

3.

When the Battery percentage reaches ~ 40-50%, be sure to

charge the unit again. (Go to step 1)

4.

A charged battery allows for 4-6 hours of continuous field testing.

5.

To extend the battery’s run time in the field, to turn “OFF” the

background light.

www.ndtJames.com

36

Page 42

Simple Guidelines for Battery Maintenance.

1.

When allowed to discharge and charge regularly, the end user

will experience a better Battery life span (or cycle).

2.

Lithium-ion batteries do not need to be fully charged; as the

charger can aid its performance.

3.

Shallow discharges provide more cycles than deep discharges.

4.

It is recommended to fully charge the unit (4-6hrs) before a

lengthy field test is performed.

5.

As a general rule, it is best to charge the battery both before and

after each use. There is no memory effect, so it is a good practice to

recharge the unit after each use, or at the end of the day - if used

daily.

6.

Charge the battery at a moderate temperature. Do not charge

below 0deg C (or < 32deg F).

7.

Lithium-Ion batteries suffer from stress when exposed to heat.

Therefore, to lengthen the life of the battery, avoid elevated

temperatures > 30deg C (or > 86deg F).

8.

Lithium-Ion batteries may fail when stored for long periods of

time in a discharged state. Thus, before a prolonged storage

period, be sure to apply a charge to the battery. It's recommended

once every 2 months to recharge the battery to keep it fresh. You

should store the Unit (and battery) during this period at room

temperature.

9.

Replacing or repair of the battery should be done by a trained

James® Instruments technician. Please follow the repair

procedure

found on page 68.

www.ndtJames.com

37

Page 43

Scan Cart (R-C-410 Only)

The Rebarscope® Scan cart feature allows the end user to quickly

and easily determine the location and cover of reinforcement in a

concrete structure. The scan cart can be used in a vertical or

horizontal position. The B-Scan diagram generated by the

Rebarscope® facilitates cover readings of a specified rebar.

The following steps allow for proper scan cart application:

Step 1: Insert Rebarscope® probe in scan cart unit with company

logo facing up.

Step 2: Connect scan cart cable (yellow) to front panel of

Rebarscope® unit and scan cart back cover.

Step 3: Turn Rebarscope® and allow unit to initialize.

Step 4: Upon initialization unit defaults to Locate cover screen.

Step 5: Press Esc key.

Step 6: Rebarscope® will now go to the main menu screen. Using

the up or down arrow to highlight the Scan Map Menu.

Step 7: Press Enter

www.ndtJames.com

Figure 36: Highlighted Scan Map Menu

38

Page 44

Step 8: The Scan Map Menu screen will now appear

Figure 37: Scan Map Menu

Step 9: Using the up or down arrow keys navigate the highlighted

line to one of the three sections on the scan map menu screen.

Step 10: Press Enter.

Step 11: The next screen allows you to enter your parameters.

After choosing desired parameters press Enter.

Figure 38: Scan Map Parameters

Step 12: The Rebarscope® now displays the scan cart diagram

screen.

www.ndtJames.com

39

Page 45

Figure 39: Scan Cart Diagram

Step 13: Position scan cart at beginning of area to be analyzed.

Step 14: Press Enter on Rebarscope® Front Panel. The display will

read “Scanner is ON”, and the user is ready to start testing.

now

Step 15: Measuring from the front of the scan cart, begin pushing

the cart at a very slow pace from the starting point; using the

extended handle. (See picture below.)

Step 16: Remain at this same pace until Rebarscope® notifies the

end of scan by producing an end beep noise.

Step 17: The Rebarscope® does not present real time data of a

scan, it is necessary to back the cursor toward the start point to

view data. The results will be displayed in a B-Scan diagram.

www.ndtJames.com

40

Page 46

Figure 40: Scan Map Graph

The scan cart B-Scan diagram can be translated as follows:

•

Cover is represented on the left axis.

•

Distance measured is represented on the top axis.

•

The two dotted lines represent the predetermined setting for Smin.

•

The waveform will start at distance zero and it will be at its lowest

cover reading.

•

As the electro- magnetic decay of the reinforcement bar is

detected by the probe, the built in B-scan analyzer starts to graph

every point of detected cover by its built correlation.

•

Once the scan cart with inserted probe is above the center of a

section of rebar the wave form will be displayed at its top peak.

•

After the scan cart has moved past the center of the rebar a very

noticeable downward decay will begin to display. The wave form

will remain at its lowest possible cover until another rebar’s

electromagnetic decay can be detected by the scan cart.

41

www.ndtJames.com

Page 47

Operating System

Data Handler Introduction

The Data Handler allows you to accept uploaded data from

Rebarscope® to the PC

the

Features

•

Easy to Use

•

Quick

•

Convenient

•

Traceability

•

Data Backup

Minimum System Requirements Rebarscope® Data Handler

Windows Vista or Windows 7

Memory

Processor

Capacity

www.ndtJames.com

1 GB RAM

1 GHz Pentium class processor

1 MB hard drive space

42

Page 48

Upload Data (R-C-450 and R-C-410 only)

•

Connect the unit to the appropriate port of the P.C. using the

supplied serial cable.

•

Press the up or down key to advance to the upload menu option.

Figure 41: Upload Menu is Highlighted

Press Enter. The following upload sub screen should appear.

Figure 42: Upload Sub Screen

Scroll through the upload sub menu using the up or down arrow

key. Select which upload menu function you would like to perform

by pressing Enter. The display should read the following:

UPLOAD SCAN MAP (R-C-410 only) UPLOAD ALL SCAN MAPS (R-C-410 only)

www.ndtJames.com

43

Page 49

•

Pressing the left or right arrow key allows the user to select which

number of test data they want uploaded.

•

Open the Rebarscope® software (“Rebarscope” will appear on the

upper left corner) on the P.C.

•

Press the Lightning Bolt (Upload) icon. The P.C. software will

display “waiting for data”.

•

Go to the Rebarscope® and press the Enter key. Rebarscope®

software waits 50 seconds for the upload information. If no data is

received after 50 seconds a “No data received“ sub screen will

appear.

•

During Test upload the displays reads “Upload In Progress”

•

Once the upload has been completed the display will read

“Upload complete” and data will appear on the screen. Save the

data in a desired folder.

•

Pressing the Escape key will return you to the Main Menu screen.

•

After upload, graphing of data should be done with PC software.

•

Press the graph icon to graph the B-Scan diagram on the PC.

www.ndtJames.com

44

Page 50

Data Handler Overview

The following is an overview of all of the features of the Data

Handler software.

Figure 43: Data Handler Overview

Software Functions

Key Definition

The “Open” command (Ctrl+O) – Opens a previously

uploaded text file.

The “Save” command (Ctrl+S) – Saves uploaded data

to a text file.

The “Upload” command (Ctrl+U) – Uploads data from

the Rebarscope to the Data Handler program.

The “Graph Time” command (Ctrl+T) – Graphs the

stored data.

The “3D” command (Ctrl+D) – Graphs the stored data

as 3D.

www.ndtJames.com

45

Page 51

Software Installation

The PC software that has been developed for the Rebarscope is for

data upload purposes. To install the software on your PC follow

these instructions.

To install the software:

1.

Insert the Rebarscope PC Software CD into the CD-ROM

drive.

2.

If the CD does not load the setup automatically, go to My

Computer, double click on the CD under devices and

double click on setup.exe.

3.

The Install Shield Wizard checks for the operating system

Figure 44: Installation File Location

you are using.

www.ndtJames.com

Figure 45: Install Shield Wizard

46

Page 52

4.

The Install Shield Wizard dialog appears. Click Next to

proceed.

5.

Accept the terms in the license agreement and click Next.

Figure 46: Install Shield Wizard

Figure 47: License Agreement Screen

www.ndtJames.com

47

Page 53

6.

Complete the customer information fields and click Next.

Figure 48: Customer Information Screen

www.ndtJames.com

48

Page 54

7.

The Install Shield Wizard confirms your installation. Click

Install to continue.

8.

The installation progress screen appears.

Figure 49: Install Shield Wizard Confirmation

9.

When the installation has completed the following message

will appear. Click Finish to close the dialog.

www.ndtJames.com

Figure 50: Installation Progress Screen

49

Page 55

Figure 51: Install Shield Wizard Completed

The Data Handler shortcut appears on the desktop as well

10.

as the Start Menu.

www.ndtJames.com

Figure 52: Data Handler Shortcut

50

Page 56

Uploading Cover Map (R-C-450 and R-C-410 only)

Uploading a single Cover Map.

a.

On the Rebarscope® display, go to “Upload Menu”.

i.

Figure 53: Main Menu Screen

On the Data Handler Software press the Upload

ii.

Button.

iii.

iv.

On the Rebarscope® display, choose “Upload

Cover

Map”.

Now save the results into the PC.

www.ndtJames.com

51

Page 57

Fig. 54: Rebarscope Data Handler Screen

The display should show the Cover Map as a text.

Fig.55: Data Handler Screen with Text Data

www.ndtJames.com

52

Page 58

b.

Uploading multiple Cover Maps.

On the Rebarscope® display, go to “Upload Menu”.

i.

Fig. 56: Main Menu Screen

ii. On the Data Handler Software press the Upload

Button.

iii.

On the Rebarscope® display, choose “Upload

Cover

Maps”.

iv.

Now save the results into the PC.

Note: The Data Handler Software doesn’t provide graphical

presentation of the Cover Map, as this only done inside the

Rebarscope® software.

To view the cover map data:

-

From open menu or simply press the open button

or press “Ctrl + O”

Then open the required file in the Data

Handle Software.

-

Also it is possible to open the Cover Map

file as text file

it.

simple by double clicking

Fig. 56

www.ndtJames.com

53

Page 59

Uploading Scan Map (R-C-410 only)

c.

Uploading a single Scan Map.

On the Rebarscope® display, go to “Upload Menu”.

i.

Fig. 58: Main Menu Screen

On the Data Handler Software press the Upload

ii.

Button.

On the Rebarscope® display, choose

iii.

“Upload Scan

Now save the results into the PC.

iv.

d.

Uploading multiple Scan Maps.

On the Rebarscope® display, go to “Upload Menu”.

i.

On the Data Handler Software

ii.

press the Upload

On the Rebarscope® display, choose “Upload Scan

iii.

Maps”.

Now save the results into the PC.

iv.

Note: It is essential to move the scan cart at

a slow rate:

bad readings.

(1 inch/sec maximum) to avoid

Map”.

Button.

www.ndtJames.com

54

Page 60

Graphic representation of the Scan Map data

1.

2D representation:

a.

Open a saved Scan Map data.

b.

Press the Graph Time command symbol.

c.

The software will show a 2D representation of

Cover vs. Distance in inches, and it represents

cross section of the location that was crossed

a

the scan cart.

by

www.ndtJames.com

Fig. 59: Graph Window Screen

As shown in the example above (3 foot map), it

shows the existence of a rebar at a distance of 11”

(1.7”cover), 22.7” (1.7” cover) and 36” (0.9” cover).

55

Page 61

2.

3D representation:

The 3D representation helps to show multiple Scan Maps

one graph, to use this feature; first it requires storing

in

several Scan Maps (minimum two).

As shown in the figure to the

by taking several scan

left,

readings,

Scan Maps to

the 3D option will

these maps to generate a

graph showing the peaks that

represents the existence of a

rebar and valleys that

correspond

rebar, also a color

implemented that shows a

rebar in the dark blue area of

the

are in

and upload all the

the computer,

arrange

3D

to absence of

code is

graph and the empty areas

green or orange color.

Fig.60

www.ndtJames.com

56

Page 62

Using the 3D graph option:

a.

Press the 3D command symbol.

b.

Set the Slice number to 1

c.

Browse for the first Scan Map, select it and click

open,

graph space.

d.

Set the Slice number to 2.

e.

Browse for the second Scan Map (usually all Scan

Maps are save in the same location), select it and

open.

click

f.

The graph starts to form, and by adding more slices

graph will expand in the Z-direction.

the

g.

To export the graph, click “Export”.

h.

Choose s suitable format and click Save.

Fig. 61: Graph Window

at this stage nothing will appear on the

www.ndtJames.com

Fig. 62: Graph Window with Export Dialog Screen

57

Page 63

Troubleshooting

The James® Instruments Rebarscope® built in troubleshooting

diagnostics helps the user identify problems with the system. This is

a beneficial tool for the user which may help to resolve the problem

without the need of sending the system “in” for repair. The

troubleshooting diagnostics are the following: (a) Sensor Cable

Problem, (b) Sensor board Problem, (c) White Display, (d)

Battery Charging problems, (e) Uploading Data issues. Follow

the steps below to properly diagnose the 5 problems listed:

(a)

Sensor Cable Problem

Step 1: Check cable connections between sensor and front panel.

Step 2: Check cable connectors for bent or pushed “in” pins. If yes,

the sensor cable problem will appear.

Step 3: Check sensor and front panel connectors. If a pin(s) has

been bent or pushed “in”, the sensor connector cable problem will

appear.

If steps 1 thru 3 do not correct the problem please contact our office

for assistance and possible repair options.

(b)

Sensor Board Problem

Please Contact our Office for repair options.

(c)

White (or blank) Display

This error condition may occur when using the White Line setting of

the Display mode (under System Menu).

In this condition, the Black background becomes White, along with

the letters; thus making the entire screen White. To correct this

issue, try the following steps… (Note: This is a blind operation; until

the end.)

1.

Press the Escape button (x1)

2.

Press the Down button (x2) for Basic systems, and (x3) for

www.ndtJames.com

58

Page 64

Complete systems.

3.

Press the Enter button (x1)

4.

Press the Right (or Left) Arrow button (x1)

When completed, the display should become visible – with Black

letters and a White background. If this does not reset the display

condition, the user should Power cycle the unit “OFF”, and then

back “ON”.

In the event this White Out condition remains, contact James®

Instruments for further repair instructions. (or see Page 70)

(d)

Battery Charging Problems

This condition can happen when the Charge Counters have not

been reset for some time, or… if there is a problem with the battery

itself. (Note: The main battery usually lasts ~ 3-5 years.)

Before sending the unit to James®, try to Reset (or zero) the

battery

System

Charge and

be reset

properly. Also,

status value to

counters in the Battery Status screen. Go to: Main Menu /

Menu / Battery Operations - press “Enter” to reset the

Discharge counters to zero. These counters need to

periodically for the battery monitoring circuit to work

Zeroing these counters will change the battery

100%. This will happen whether or not the unit was

charged.

Therefore, after resetting the counters, charge the unit for at least

4 hours, and reset the counters again. Doing so will provide the

most accurate % status of the battery.

If this does not correct the charging problem, the system will need

to be evaluated further at James® Instruments. (See Repair

Services

in the Calibration & Repair section.)

(e)

Uploading Data Problems

This condition can happen when first attempting to use the

James®

not being

Instruments software on a PC. It is due to the Comports

set to the same setting within the software.

www.ndtJames.com

59

Page 65

To find the correct Comport to use, follow the steps below…

1.

Go to the PC’s Device Manager… Start button / Control Panel /

Device Manager / Ports.

2.

Connect the USB cable to the unit. Then, while viewing the

‘Ports’ directory, connect the USB cable to one of the PC’s USB

ports. The correct Comport setting will become visible in the ‘Ports”

directory.

3.

When the correct Comport is found, go to the James®

software,

the correct

and click on ‘Tools’ in the task bar (at the top). Select

Comport (1-20) from the drop down list.

4.

Go back to the unit and select the Test Data to upload.

5.

Go back again to the software, and click on the Lightning Bolt

icon in the task bar…

6.

Now press ‘Enter’ on the unit to start the upload process. The PC

should say the computer is “Receiving Data”.

If these steps do not work, it is possible the correct Drivers need to

be installed on the PC. Go to the following website for more help…

http://www.ftdichip.com/Drivers/D2XX.htm

(Note: Although James® does not support Windows XP (any

longer),

the data handler should still work with XP.)

60

www.ndtJames.com

Page 66

Maintenance

• If the Main 14.4V Battery does not hold a charge, the

system should come back to James® Instruments for

battery

before

replacement. (Review Troubleshooting section (d)

sending the unit back to James® Instruments.)

• Calibration is recommended to be done annually, or

when

display readings are suspected to be inaccurate.

• Keep the unit clean. If dust builds up in the unit, clean it

out

with compressed air.

Safety

•

Do not submerge unit in water. This can cause

electrical

•

The sensor generates a magnetic field. Do not point

the

fields.

shock.

sensor on products that are sensitive to magnetic

www.ndtJames.com

61

Page 67

Available Rebarscope Accessories

Part # Description

R-C-3015

R-C-3020

R-C-3030

R-C-3031

R-C-3035

R-C-3040

R-C-3051

R-C-3052

R-C-3056

R-C-475

S-31800

Probe

Scan Cart

Coiled Cable

Scan Cart Cable

Headphones

Locating Template

Basic Software

Scanning Software

USB Cable

Scan Cart Upgrade

Charger

www.ndtJames.com

62

Page 68

Specifications

Rebarscope® System R-C-400, R-C-450, R-C-410

Sensor Dimensions 5”L x 2.4” W x 1.6” H

Sensor Weight 1lb

Instrument Dimensions 10.625” L x 9.68” W x 4.875” H

Instrument Weight 5.4

lbs

Complete System Weight 10 lbs

Basic System Weight 8 lbs

LCD Dimension 3.5”L x 4.65“H

LCD Size 320 x 240 pixels

Operating Temperature -10 - 50 C

Covered Rebar Sizes (#) 3, 4, 5, 6, 7, 9, 11

Standard Copper Pipe Sizes .375, .500, .750, 1.00, .1.250

Standard Conduit Sizes .750, 1.00, 1.250

(mm) 6, 10, 13, 16, 19, 25, 29, 32,

35, 38, 41, 51

Power Source 14.4V, 4hr continuous use

63

www.ndtJames.com

Page 69

Warranty Information

1. Contract

Unless otherwise stated all sales transactions are expressly subject to these

terms and conditions. Modification or additions will be recognized only if

accepted in writing by an authorized Officer of James® Instruments Inc.

(hereinafter referred to as “James®” or the “Company”), or an officially

designated representative. PROVISIONS OF BUYER'S PURCHASE ORDER

OR OTHER DOCUMENTS THAT ADD TO OR DIFFER FROM THESE TERMS

AND CONDITIONS ARE EXPRESSLY REJECTED. NO WAIVER OF THESE

TERMS AND CONDITIONS OR ACCEPTANCE OF OTHERS SHALL BE

CONSTRUED AS FAILURE OF THE COMPANY TO RAISE OBJECTIONS.

2. Warranties

The Company only warrants the equipment manufactured or supplied by the

Company as set forth herein. James® makes no other warranties, either

expressed or implied (including without limitation, warranties as to

merchantability or fitness for a particular purpose). In no event shall James®

be liable for any type of special, consequential, incidental, or penal

damages, whether such damages arise out of or are a result of breach of

contract, warranty, negligence, strict liability or otherwise. Warranty shall not

apply where the equipment manufactured or supplied has been subject to

accident, alteration, misuse, abuse, improper storage, packing, force majeure,

improper operation, installation, or servicing. In addition, the following shall

constitute the sole and exclusive remedies of Buyer for any breach by James®

of its warranty hereunder.

a. New Products

James® warrants the equipment manufactured or supplied by

James® as set forth herein. This limited warranty can only be

exercised by the original purchaser of the equipment from James® or

authorized James® Agent and is not transferable to any subsequent

owner or party. This l imited warranty gives you specific legal rights,

and you may also have other rights which vary from case to case.

i. For James® Equipment

James® warrants that James's equipment will be free

from defects in materials and workmanship for a period of

twenty- four (24) months on the electronic portion and six (6)

months on the mechanical portion from the date of shipment

of equipment from James® to Buyer. Should any defects

be found and reported by the Buyer during the applicable

limited warranty period, the defect will be corrected upon

return of the item to James®. James® will, during the

applicable new equipment warranty period, provide the

necessary replacement parts and labor to correct the defect.

Excluded from the new equipment warranty are all

www.ndtJames.com

64

Page 70

www.ndtJames.com

consumable and wear and tear items suc h as impact bodies,

penetrators, connection cables, etc. These items are subject

to usual wear and tear during usage. Refer to the

Consumable, Wear and Tear Items section of this warranty

document.

Option For Extended Limited Warranty Coverage

The original purchaser of any new equipment of James®

which have been identified or labeled by James® from time

to time in James's sole discretion as being eligible for

extended warranty coverage shall have the option to

purchase certain extensions of the applicable limited

warranty provided hereunder to the electronic portion of

any such items for either a twelve (12), twenty-four (24)

or thirty-six (36) month period (up to a possible maximum

limited warranty coverage period for the electronic

portions of such new James® equipment of sixty (60)

months) by purchasing any such twelve (12), twenty-four

(24) or thirty-six (36) month limited warranty extension

period either all the time of the purchase of any such

item(s) or within ninety (90) days from the date of delivery

of the subject item(s) of the original purchaser of such

item(s). The price for each such extended limited warranty

coverage period shall be as determined by the

Company from time to time and all such purchases of

any extended warranty coverage periods shall only be

effective upon a completed purchase order and payment

directly between James® and the original purchaser of any

such item(s). The extended warranty coverage periods

only valid with respect to the original purchaser of

are

such item(s) from the Company and such extended

warranty coverage is not transferable to subsequent

owners of the subject item(s) or any other parties. Upon

the purchase of any extended limited warranty coverage

period, the Company will issue a certificate to Buyer

evidencing the details of the applicable extended warranty

coverage period purchased by the Buyer.

ii. For Other Manufacturer's Products Supplied by

James®

Products of other manufacturers supplied as such by

James® are warranted by James® only to the extent of

any warranty provided by the original manufacturer, if any.

iii. For Parts and Sub-Assemblies

Parts or sub-assemblies purchased by the Buyer to

perform its own repair work etc. are warranted as provided

hereunder by James® for six (6) months from date of

shipment of material from James® to Buyer.

65

Page 71

iv. For Consumables, Wear and Tear Items

James® supplies consumable items and items subject to

wear and tear during normal usage of James® supplied

products. These items are not covered under warranty.

Buyer is to check for proper fit, form and function of such

items upon receipt of such items. In case of a defect

condition, Buyer can return the item to James® for

evaluation within thirty (30) days of the date of shipment to

the Buyer. James® reserves the exclusive right to issue

full, partial, or no credit to the Buyer based on the

condition of the returned item and circumstances related to

the return. Examples of items in this category: connection

cables, test blocks, impact bodies, penetrators, probes,

extraction liquids, calibration liquids, pins, recording paper,

b. Calibration and Repair

test plugs, etc.

i. For Calibration Services

James® does not warrant the calibration of any

equipment. James® does however warrant the equipment

manufactured by it, in proper working condition, to be

capable of being adjusted to meet James® printed

specifications, if any, for accuracy and performance as to

the particular model type during the period of warranty

applicable as stated above.

ii. For Repair Services

James® warrants repair work performed under the direct

control and supervision of James® personnel for a period

of three (3) months from the date repairs are completed

either at James® or at the customer site. Should the def ect

for which the repair work was performed reoccur within

this period, James® will supply the necessary parts and

labor (repair at James® facility) or parts (repair at Buyer

facility) required to repair the original equipment defect for

which the repair parts and labor were required. Additional

repair charges that may be incurred in conjunction with any

repair service warranty event will be invoiced at the

James® customer s ervice rates and policies in effect at the

time of the event.

Excluded are all consumable and wear and tear items such

as impact bodies, probes, connection cables, etc. These

www.ndtJames.com

66

Page 72

items are subject to usual wear and tear during usage. Refer

to the Consumable Wear and Tear Item section of this

warranty document.

www.ndtJames.com

67

Page 73

c. Warranty Claims

i. For Warranty Claim Processing

James® has established James® organizations in the

Americas, and Europe. Please visit the James® web site

www.ndtJames.com for latest address and contact

3. Regulatory Laws a nd/or Standards

The performance of the parties hereto is subject to the applicable laws of

the United States. The Company takes reasonable steps to keep its

products in conformity with various nationally recognized standards and such

regulations, which may affect its products. However, the Company recognizes

that its products are utilized in many regulated applications and that from

time to time standards and regulations are in conflict with each other. The

Company makes no promise or representation that its product will conform to

any federal, provincial, state or local laws, ordinances, regulations, codes or

standards except as particularly specified and agreed upon for compliance in

writing as a part of the contract between Buyer and the Company. The

Company prices can not i nclude the cost of any related inspections or permits

or inspection fees.

information for the James® organization nearest you.

4. Notices

Notice by either the Company or Buyer will be made only by facsimile or

similar electronic transmission, effective on the first business day after

confirmed receipt, or by letter addressed to the) other party at its address as

provided in this Agreement, effective three (3) business days after deposit

with the U.S. Postal Services, postage prepaid, or one (1) business day after

deposit with a recognized overnight express service.

5. Interpretation

Should any term or provision contained In the contract contravene or be

invalid under applicable law, the contract shall not fail by reason thereof but

shall be construed in the same manner as if such term or provision had not

appeared therein.

6. Assignability

Neither this contract nor any claim arising directly or indirectly out of or in

connection herewith shall be assignable by Buyer or by operation of law,

without the prior written consent of Company. This document shall be binding

upon and inure to the benefit of each party hereto and their respective

permitted successors and assigns.

68

www.ndtJames.com

Page 74

7. Governing Law

This Agreement shall be governed by and construed in accordance with the

internal laws of the State of Illinois, without regard to its conflict of laws

provisions. Buyer and the Company expressly agree to submit to the personal

jurisdiction of the federal and/or stale courts silting in Chicago, Illinois, U.S.A.

and agree that such courts may be utilized if necessary to obtain injunctive or

any other relief. The Hague Convention and the United Nations Convention on

Contracts for the International Sale of Goods shall not apply to the construction

or interpretation of these Standard Terms and Conditions or affect any of its

provisions.

END.

www.ndtJames.com

69

Page 75

Repair Policy

United States | Canada | International

Ship the instrument in a box that meets UPS, Fed Ex, and standard

shipping regulations. Enclose a note describing the problem(s) you

are having. Include the name and phone number of the contact

person in your organization.

The instrument will be evaluated within one week of receipt. The

contact person will be notified with an estimate of the cost of the

repair.

Upon receipt of your authorization of repair and payment terms,

delivery time will be 2 weeks from that day.

If you need the repair back sooner than this, you have the option of

paying an express service fee of 10 percent of the purchase price

of said instrument, plus the repair cost. With this service, you can

receive the instrument back within 3 working days in the USA (5

working days for Europe).

International repair shipments must contain a commercial invoice

listing the instrument being returned and must contain the words:

Country of manufacture: USA

Instrument being returned to manufacturer for repair – no value for

customs, value for carriage only.

Ship the complete system to:

Attn: Repair Department

Attn: Repair Department

James Instruments, Inc. - USA

3727 North Kedzie Avenue

Chicago, IL 60618-4503

USA

Home page: www.ndtJames.com

E-mail: info@ndtJames.com

europe@ndtJames.eu

www.ndtJames.com

James Instruments, Inc.

Windmolen 22

7609 NN Almelo

The Netherlands

70

– Europe

Page 76

James Instruments Inc. 3727 N. Kedzie Ave. Chicago, IL 60618-4503 USA Tel: (773) 463-6565 Fax: (773) 463-0009

James Instruments Inc. - Europe Windmolen 22 7609 NN Almelo The Netherlands Tel: +31 (0)548 659032 Fax: +31 (0)548 659010

Purchase Date: ___________________

Serial Number: ___________________

www.ndtJames.com

71

Loading...

Loading...