Page 1

VISCAM 1000 System

Vehicle Imaging Subsystem

Document P/N: 10873

Document Version: C

Page 2

Page 3

Disclaimer iii

VISCAM 1000 Systems

Notice

The material contained in this manual consists of information that is proprietary to JAI Inc., and may only

be used by the purchasers of the product. JAI Inc. makes no warranty for the use of its product and

assumes no responsibility for any errors which may appear or for damages resulting from the use of the

information contained herein. JAI Inc. reserves the right to make changes without notice.

Microsoft Windows 8, Windows 7, Windows XP, Windows 2000, Windows 98, Windows NT, and Windows

Explorer are either registered trademarks or trademarks of Microsoft Corporation in the United States

and/or other countries.

Warranty

Each JAI product is warranted to be free from defects in material and workmanship under normal intended

use and service if installed in accordance with this manual. The standard warranty period for the VISCAM

1000 is 1 year (12 months) and begins on the date of shipment from JAI stock.

This warranty shall not apply to repairs or replacements necessitated by any cause beyond the control of

JAI, including but not limited to, 1) improper installation, 2) acts of nature, 3) accidents, 4) misuse, 5)

lack of proper maintenance, 6) unauthorized repairs or modifications.

Be advised, that you need to obtain an RMA number from JAI before returning units for warranty repair.

Page 4

VISCAM 1000 Systems

iv

Disclaimer

Certifications

CE Compliance

The VISCAM 1000 has been certified to conform to the requirements of Council Directive 89/336/EC for

electromagnetic compatibility and to comply with the following European Standards:

Emissions: EN 55022A: 2010/AC:2011

Immunity: EN 61000-4

All JAI products bearing the CE mark have been declared to be in conformance with the applicable EEC

Council Directives. However, certain factory-installed options or customer-requested modifications may

compromise electromagnetic compatibility and affect CE compliance. Please note that the use of

interconnect cables that are not properly grounded and shielded may affect CE compliance.

Contact JAI Applications Engineering Department for further information regarding CE compliance.

FCC

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area may cause harmful interference, in which case the user will be required to correct the

interference at his own expense.

IP66

This equipment has been tested and found to comply with IP66. This proves that the equipment is resistant

to rain and dust in severe outdoor environments.

WARNING

Changes or modifications to this unit not expressly approved by the party responsible for FCC compliance

could void the user’s authority to operate the equipment.

January 30, 2015

Page 5

Tables of Contents v

VISCAM 1000 Systems

Table of Contents

Disclaimer Notice ..................................................................................................... iii

Table of Contents ...................................................................................................... v

1

Introduction ............................................................................................... 1

1.1

Document Overview ..................................................................................... 1

1.2

Product Overview and System Hardware Components ............................................ 1

1.2.1 VISCAM 1000 System ..................................................................................... 2

1.2.2 External Traffic Light Sensor – TLS-301 (optional) ................................................. 2

1.2.3 External Light Sources .................................................................................. 2

1.2.4 Embedded Light Sources (LED-1000 IR, white or blue) ............................................ 2

1.2.5 VJP-300 Junction Panel ................................................................................. 2

1.2.6 Optional 24V DC Power Supply ........................................................................ 2

1.2.7 Optional gigabit Ethernet switch ..................................................................... 2

1.2.8 System interconnection cables ........................................................................ 2

1.3

VISCAM 1000 Product Line .............................................................................. 3

2

Preparing for installation ............................................................................... 4

2.1

Installation Preparation................................................................................. 4

2.2

Overhead Positioning .................................................................................... 4

2.3

Side of Road Installation ................................................................................ 6

3

Installing the VIS - Vehicle Imaging System ......................................................... 7

3.1

VIS Power Requirements ................................................................................ 7

3.1.1 Installing the VISCAM 1000 System.................................................................... 7

3.2

Installing the VJP-300 Junction Panel ................................................................ 9

3.2.1 Connection to VISCAM 1000 (X1 AND X2) ............................................................ 9

3.2.2 X6 Power Input Connector ........................................................................... 11

3.2.3 Trigger Input Connector (X14) ....................................................................... 11

3.3

Installing the TNL-50 .................................................................................. 12

4

System Set-Up .......................................................................................... 14

4.1

Pre-Alignment Checklist .............................................................................. 14

4.2

Select a Suitable Vehicle, License Plate, and Plate Stand for the Setup .................... 14

4.3

Connect the Setup Computer to the Camera ..................................................... 15

4.4

Drive and Park the Setup Vehicle Correctly ....................................................... 15

4.5

Perform Initial Lens Adjustment and Camera Aiming ........................................... 16

4.6

Perform Final Camera Mount and Lens Adjustments ............................................ 19

4.7

TNL-50 Flash Alignment and settings ............................................................... 21

4.7.1 TNL-50 Flash Settings ................................................................................. 22

4.8

LED-1000 Embedded Illuminator Setup ............................................................ 24

4.9

Trigger Mode Selection ............................................................................... 26

4.9.1 Trigger Synchronization Mode Selection ........................................................... 26

4.10

Automatic Triggering and Light Sensing Configuration .......................................... 27

4.10.1 Vehicle Detector Trigger Settings ................................................................... 27

4.10.2 Visualization helper for Vehicle Detector and ALC setup ....................................... 28

4.10.3 ADR settings in ALC mode ............................................................................ 29

4.11

High Dynamic Range Settings ........................................................................ 30

4.12

Time Synchronization Settings ...................................................................... 32

4.13

Solar Position Control for assisting the ALC ....................................................... 33

4.14

Video Streaming and Recording ..................................................................... 34

5

Appendix A: VISCAM 1000 Wiring Diagram ......................................................... 37

6

Appendix B: TLS-301 Light Sensor .................................................................. 38

Page 6

VISCAM 1000 Systems

vi

Table of Contents

6.1

VIS Power Requirements, including TLS-301 ...................................................... 38

6.2

Positioning and installing the TLS-301 ............................................................. 38

6.3

Connection to TLS-301 Traffic Light Sensor (X3 and X7) ........................................ 40

6.4

Moxa MiiNePort Configuration (used for TLS-301) ............................................... 41

7

Appendix C: Installing the TNF-35 .................................................................. 46

8

Appendix D: Ethernet Requirements ............................................................... 49

9

Appendix E: Application Note – Avoiding Conflicts Between ENSetup and Lane Controller

During Debugging ...................................................................................... 50

10

Appendix F: Troubleshooting and Maintenance .................................................. 52

Page 7

Introduction 1

VISCAM 1000 Systems

VISCAM 1000 System Installation Manual

1 Introduction

1.1 Document Overview

This document describes the steps necessary to deploy an installation of the JAI Vehicle Imaging

Subsystem, described as VIS from this point forward. The core of this subsystem is a traffic optimized

series of camera systems. This manual will discuss specifically the VISCAM 1000 system. The system

combines an industry leading vehicle imaging camera with high performance triggering/light sensing and

LED illumination, all in a sleek, weatherproof housing.

This manual also contains information about maintenance and troubleshooting.

JAI strongly recommends that the installer reads this manual thoroughly, in order to obtain sufficient

knowledge about the VIS equipment, before initiating the actual installation.

1.2 Product Overview and System Hardware Components

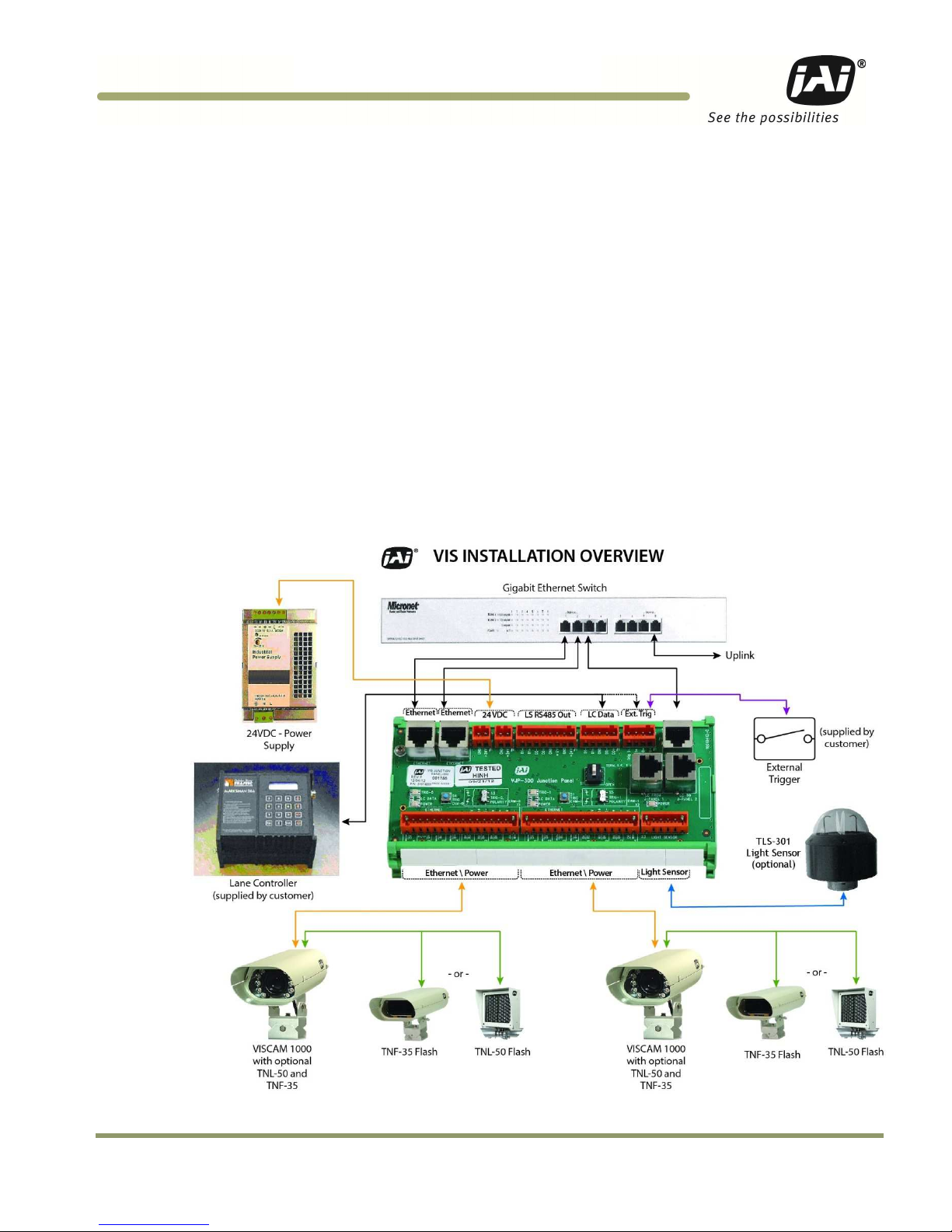

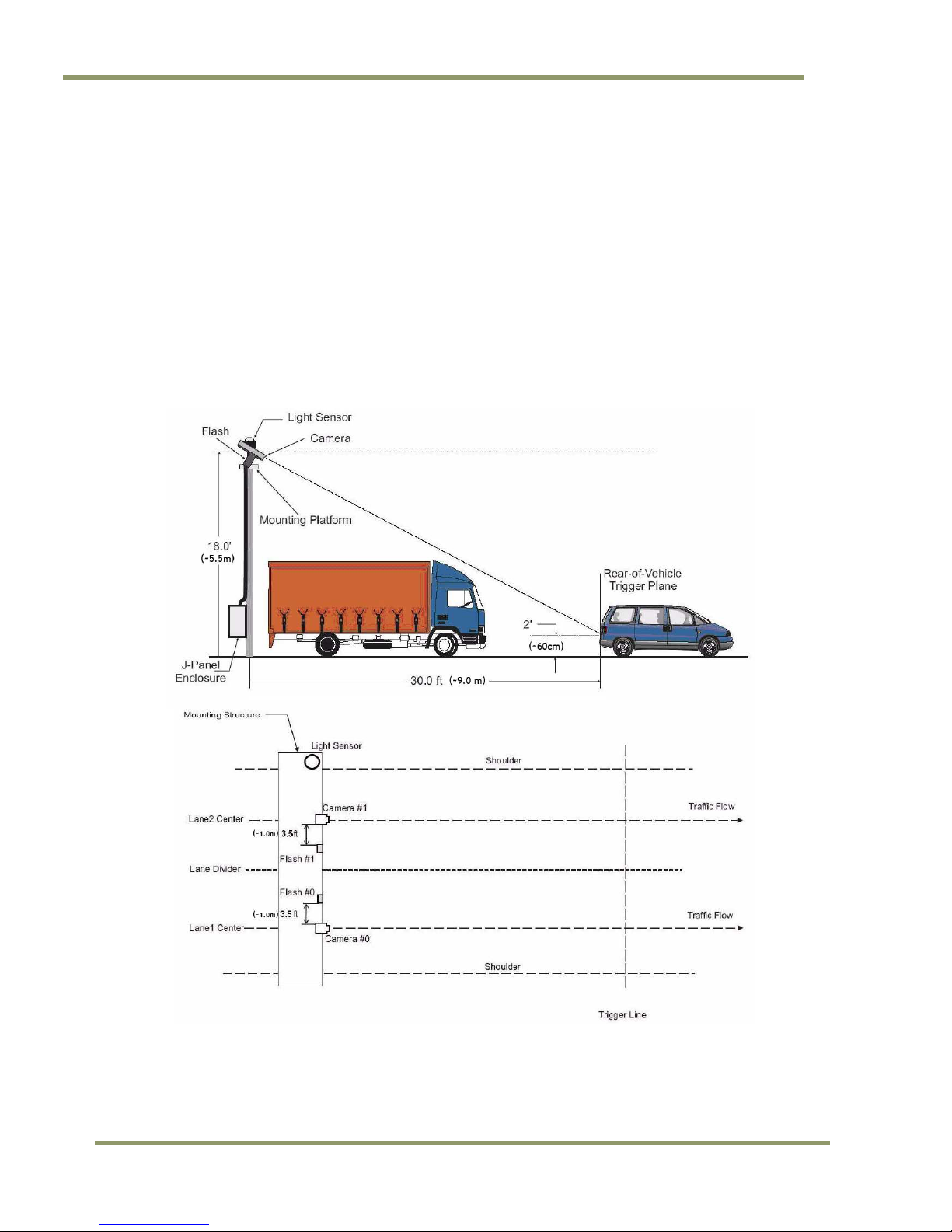

Figure 1. VISCAM 1000 Installation Overview

Page 8

VISCAM 1000 Systems

2

Introduction

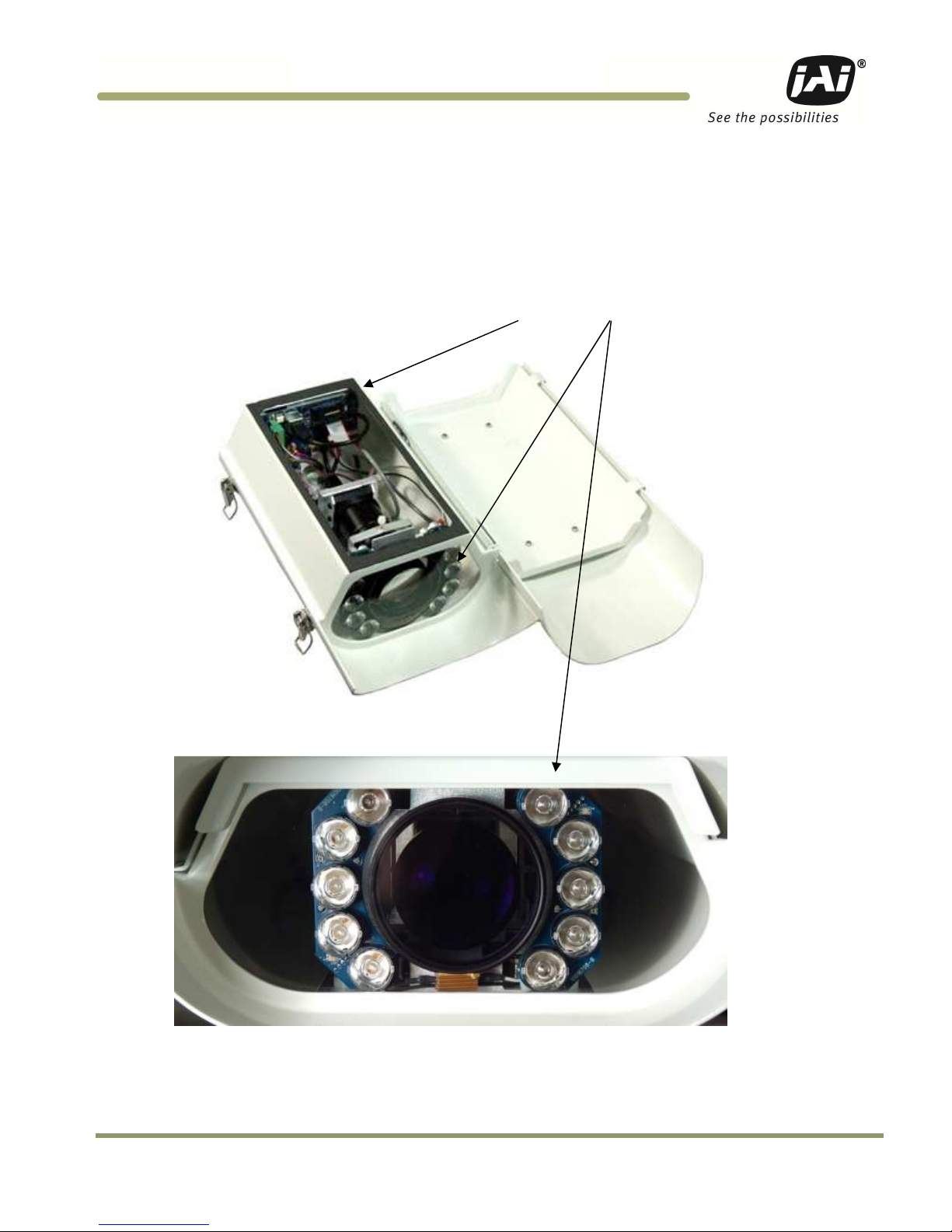

1.2.1 VISCAM 1000 System

The VISCAM 1000 uses a state-of-the-art camera system that freezes the motion of a rapidly moving vehicle

at high resolution, a zoom-lens or fixed focal length lens, and an on-axis illuminator, a weatherproof

housing with sun shield, heater resistors, I/O board, and a pan-tilt-roll mounting bracket. See Figure 2.

The VISCAM 1000 (All-In-One) features an optional embedded JAI trigger/light sensor for image triggering

and image contrast control. It also features an optional embedded LED-1000 illuminator (infrared, white or

blue) for independent 24/7 operation and excellent license plate contrast.

1.2.2 External Traffic Light Sensor – TLS-301 (optional)

The JAI Traffic Light Sensor TLS-301 provides an option to using VISCAM 1000’s built-in light sensing

capabilities described in Section 4.10.3. The TLS-301 estimates vehicles’ license plate lighting conditions

and controls the exposure and gain parameters of each camera to ensure high contrast images of vehicles

traveling through the field of view and their license plates, regardless of vehicle speed, weather or

ambient light conditions. For more information about the TLS-301, see Appendix B at the end of this

document.

1.2.3 External Light Sources

JAI offers a full lineup of lighting solutions optimized for a large number of applications.

The TNF-35 Traffic Night Flash unit is a 17W, long-life flash with an effective life span of up to 4 million

flashes. It comes in various application specific configurations for emission spectrum. With the standard

filter it generates light in wavelengths that are invisible to the human eye, but visible to the camera. For

more information about the TNF-35, see Appendix C at the end of this document.

The TNL-50 is a newer, high-performance LED Flash intended for traffic applications, including automated

number plate reading systems. The TNL-50 is field proven to produce high-contrast images of passing

vehicles and their number plates. With its very high light output, versatility, ease of installation and its

compact size, it makes it easy to see why it is an industry leading illumination solution. It also comes in

three configurations, broadband white, NIR, and blue to support various applications. Additional

information about installing and configuring the TNL-50 can be found in Sections 3.3 and 4.7 of this

document.

Both the TNL-50 and TNF-35 are automatically enabled whenever the camera or the optional TLS-301 Light

Sensor determines that ambient light is insufficient to produce a picture of usable quality.

1.2.4 Embedded Light Sources (LED-1000 IR, white or blue)

Various applications require the use of an embedded illuminator. JAI offers the LED-1000 illuminator with

infrared, white, or blue LEDs. See Figure 2.

1.2.5 VJP-300 Junction Panel

The J-Panel is the central connection point for the VIS components. The J-Panel is a DIN-Rail mounted PCB

(printed circuit board) equipped with various interface terminals for interconnection. Each J-panel can

support up to two VISCAM systems.

1.2.6 Optional 24V DC Power Supply

JAI provides a robust industrial rated power supply.

1.2.7 Optional gigabit Ethernet switch

JAI recommends using a field-proven industrial rated gigabit Ethernet switch.

1.2.8 System interconnection cables

JAI supplies a cabling solution that has proven its reliability on a large number of installation sites.

Page 9

Introduction 3

VISCAM 1000 Systems

1.3 VISCAM 1000 Product Line

The VISCAM 1000 houses a JAI TS(C)-5000EN camera. The EN camera series are Ethernet based with a built

in processor using an embedded Linux O/S for various operations, such as handling communication with

lane controller and back office, frame storage, JPEG compression, and so on. An optional external TLS-301

Traffic Light Sensor is available, as well as optional embedded LED-1000 illuminator.

Figure 2. VIS-CAM 1000 System With EIO 302 I/O board and LED-1000

Page 10

VISCAM 1000 Systems

4

Installing the VIS

2 Preparing for installation

2.1 Installation Preparation

To prepare for installation, consider the fundamental requirements for an effective deployment of the

Vehicle Imaging Subsystem. There are two basic configurations: overhead (over the lane) or side fire

(beside the lane). Figure 3 depicts a typical overhead configuration. Figure 4 depicts a typical side fire

configuration.

2.2 Overhead Positioning

Over lane camera mounting is always employed when the road width being monitored contains three or

more lanes of traffic, when a convenient overhead structure is already in place, or when preventing

vandalism is a paramount concern.

Figure 3. Typical Overhead Site Layout for a single lane

Page 11

Installing the VIS 5

VISCAM 1000 Systems

(a) Single Lane or Dual lane considerations

Figure 3 shows a typical single lane configuration. However, with the VISCAM 1000’s higher 5Mpixel

resolution, it can now cover up to two lanes of traffic.

The VISCAM 1000’s varifocal (zoom) lens is adjusted during installation to create the following conditions:

Standard for US style of plates: 135 pixels across a 1 foot wide license plate placed 2 feet above the ground

level at the nominal trigger position (ground loop, etc.). With typical US lane coverage (14’), the VISCAM

1000 will yield ~180 pixels/plate. If maintaining the 135 pixels per plate, the lane coverage is now 18’.

Standard for European style of plates: 140 pixels across a 50 cm wide license plate placed 60 cm above the

ground level at the nominal trigger position (ground loop, etc.). The coverage is now up to 9 meters, which

can definitely cover two lanes.

(Note: this can differ for other regions or plate styles.) See Section 4 for set up instructions. This resolution

maximizes license plate reader, vehicle matcher, or other image processing techniques performance. The

highest performance from the subsystem is achieved when the variation in plate size is kept to within ±5%,

which typically means that the vehicle trigger accuracy should be within ±1 foot/30 cm (@ trigger plane

defined by client.) at all speeds. Low latency vehicle triggering is very important and should not be

overlooked. Please contact JAI for support on this issue if needed.

(b) Camera tilt considerations

The requirement to freeze the motion of high-speed vehicles limits how steep or shallow the tilt angle of

the camera may be. For example, it is important to prevent the horizon from appearing in the image, and

thereby allowing the sun to blind the camera. For over lane installations, a camera tilt between 20° to 30°

is recommended, with 25° being considered the optimal angle. This angle of tilt is the best compromise

between minimizing visibility blockages caused by closely spaced vehicles and maximizing plate visibility

for plate mounts that are slightly recessed or tilted downwards.

(b) Asynchronous triggering considerations

An embedded vehicle detector is employed to cause the camera to capture an image at the precise

moment the vehicle is in the best position to image both the vehicle and its license plate. If an external

triggering device is used (i.e. ground loop) the delay between the time the vehicle passes the trigger

position on the road and when the trigger signal actually reaches the VISCAM 1000 must be kept to a

minimum to prevent high-speed vehicles from moving out of the area viewed by the camera before the

image is snapped.

(c) Camera height versus trigger distance considerations

It is critically important to select the correct distance between the camera and the location on the road

where the camera is triggered to capture an image. Minimizing the cost of installation is usually also an

important concern. This means that whenever possible, it is best to use existing structures or previously

installed elements. Contact JAI for support on setting/validating site geometry.

Page 12

6

Installing the VIS

2.3 Side of Road Installation

Figure 4. Typical side fire road installation for a single lane

Table 1 below shows the typical distance from VISCAM 1000 to flash/light unit (distance normal from

camera-license plate axis):

Table 1 Typical spacing distance between VISCAM 1000 and flash/light unit

VISCAM

1000

Approx. Distance

in Feet

3.5

Approx. Distance

in Meters

1.0

If the flash is positioned closer to the camera, reflections from retro-reflective license plates will likely

cause overexposure. If it is positioned farther the license plates will be relatively less bright and the image

quality might be deteriorated since more gain will have to be applied by the camera in order to make the

license plates bright enough for ALPR. A solution to this would be to increase the light intensity of the flash

unit.

If the distance from the camera to the trigger line is further than 50 ft then the spacing between flash and

camera will have to be increased to avoid increasing the retro-reflectivity effect, and the flash light

intensity will have to be increased or else the background will not be visible in the image even when retroreflective license plates are close to saturation.

Page 13

Installing the VIS 7

VISCAM 1000 Systems

3 Installing the VIS - Vehicle Imaging System

The individual components of the system are electrically linked together as shown in Figure 1, “VISCAM

1000 Installation Overview”.

3.1 VIS Power Requirements

The maximum power to a VJP-300 J-Panel is:

SYSTEM COMPONENTS

CURRENT

(STEADY STATE)

CURRENT

(INRUSH)

VISCAM 1000 System #0 (with heater on) 2.0A 3.5A

VISCAM 1000 System #1 (with heater on) 2.0A 3.5A

VJP-300 J-Panel 0.2A 1.5A

Total 4.2A 6.5A*

* Since all devices are connected to VJP-300 J-Panel, it limits total inrush current to 6.5A.

3.1.1 Installing the VISCAM 1000 System

The VISCAM 1000 has connections to the J-Panel and an optional Flash Night Light. In general, the

camera(s) should be aimed at the most likely cross-lane position of the vehicle license plates. See

“Installation Preparation” in Section 2 for general site layout guidelines. To install the camera(s):

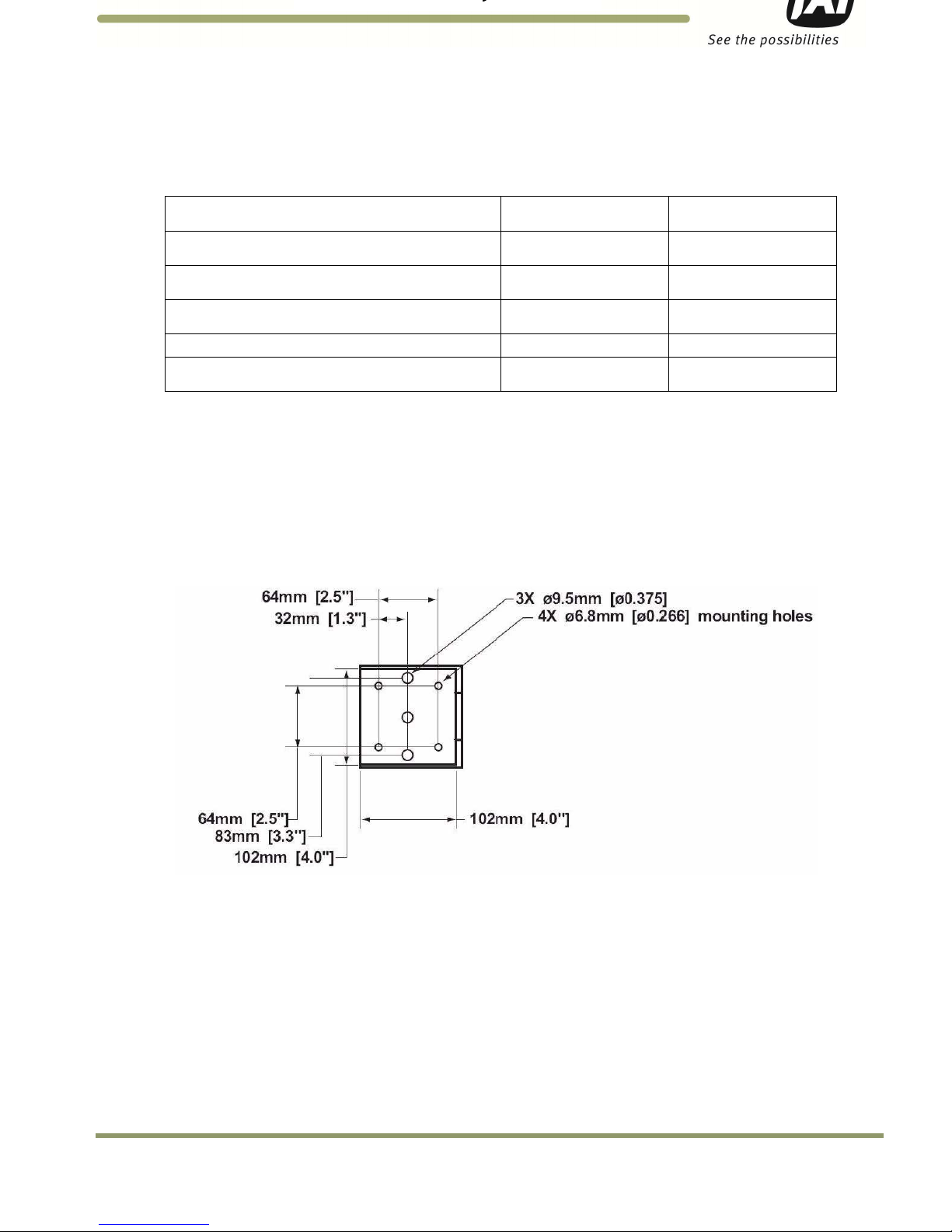

1. Attach VISCAM 1000, with mount, to the mounting structure. The hole pattern is shown in Figure 5 below:

Figure 5. VISCAM 1000 Mount Dimensions.

Page 14

8

Installing the VIS

2. Route the VISCAM 1000 end of the camera cable in accordance with local electrical code requirements.

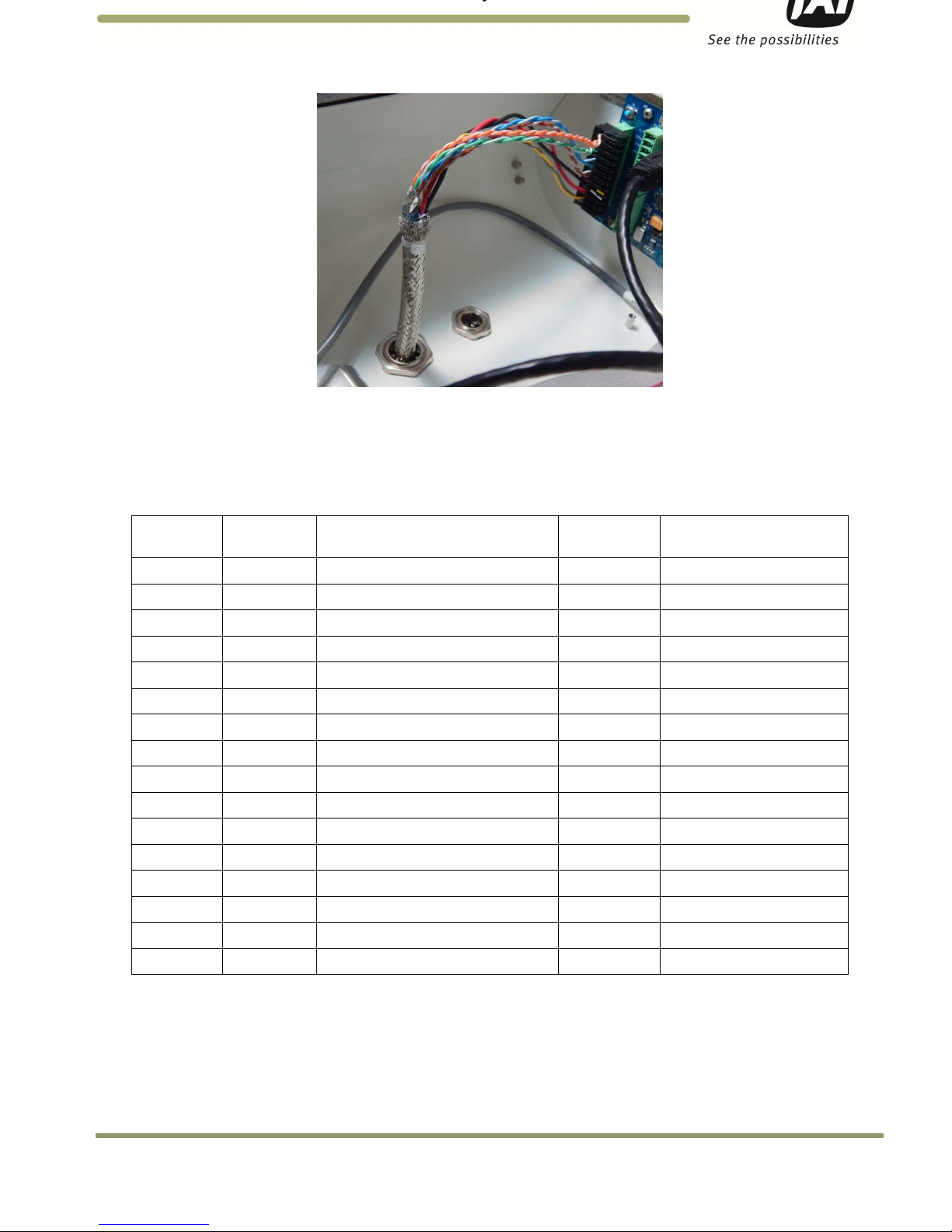

3. The jacket is removed from the cable on the camera end a distance of 7” (~18cm) (1). A thin wire is attached

around the end of the cable to keep the braid in place (1). The cord grip sealing nut is mounted on the cable

(3). See Figure 6.

Figure 6. VISCAM 1000 cabling as it appears after jacket is removed

4. Route cable through enclosure cord grip. Braid/foil shield should be aligned with the cord grip nut inside

enclosure to ensure proper shield connection with EMI cord grip. See Figure 7.

Figure 7. Cable is routed properly to ensure proper shield connection

5. Hand-tighten the sealing nut as far as possible. Hold the body hex stationary with a wrench (24mm). Using a

second wrench (24mm), tighten the sealing nut until the cable is securely held in place. Torque to

approximately 35 in. lbs. (3.9 Nm)

6. Move the thin wire 5 cm away from the cable end and fold the braid back over the thin wire. Use a cable strip

to keep the braid in place. Remove foils and fillers from the cable end. Separate and strip the wires. The 2

pairs of multicore wire can be fitted with bootlace ferrules to keep the cores in place. Connect wires to

terminal block X4 on the VISCAM 1000 I/O Board in accordance with wiring diagram on enclosures inner lid (see

Appendix A). Plug terminal block back to X4 position on VISCAM 1000 I/O Board. Close and secure enclosure lid

with 2 latches. See Figures 8 and 9.

Figure 8. VISCAM 1000 Cabling.

Outer

Braid

Grou

n

ding

Tongues

Grounding

Tongues

Braid is

folded back

Page 15

Installing the VIS 9

VISCAM 1000 Systems

Figure 9. Wires are inserted in VISCAM 1000 I/O board X4 connector

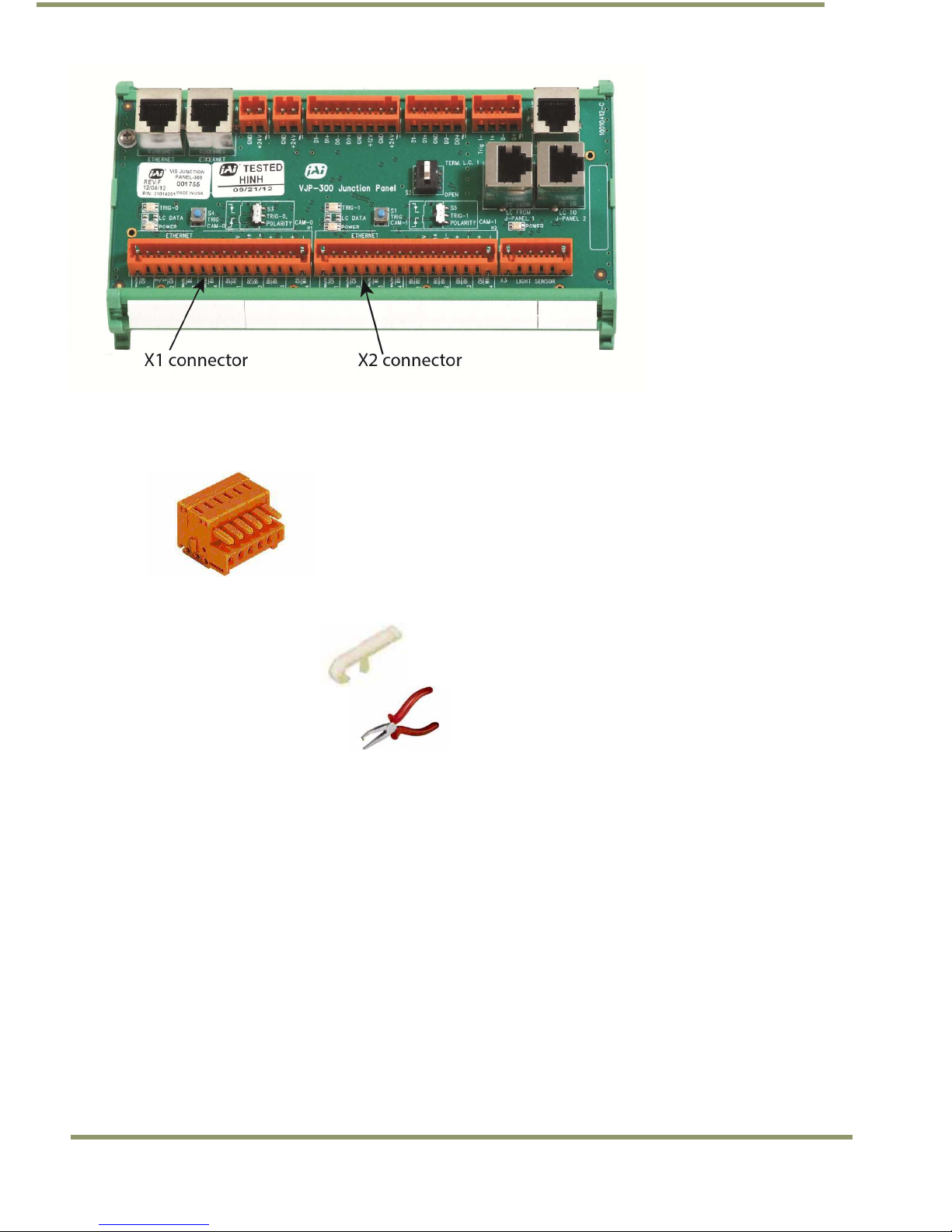

3.2 Installing the VJP-300 Junction Panel

3.2.1 Connection to VISCAM 1000 (X1 AND X2)

The VISCAM 1000 connections to the J-Panel (junction panel) are shown in Table 2 and Figure 10.

Table 2 VISCAM 1000 connections to the J-Panel.

VJP-300

X1, X2 Pin #

VISCAM AIO

X4 Pin #

Wire Color Signal Remarks

1 1 White/orange in Cat5e cable

Ethernet A+

2 2 Orange in Cat5e cable

Ethernet A

-

3 3 White/green in Cat5e cable

Ethernet B+

4 4 Green in Cat5e cable

Ethernet B

-

5 5 White/blue in Cat5e cable

Ethernet C+

6 6 Blue in Cat5e cable

Ethernet C

-

7 7 White/brown in Cat5e cable

Ethernet D+

8 8 Brown in Cat5e cable

Ethernet D

-

9 9 Black wire

Gnd 18 AWG

10 10 Red wire

+24V dc

18 AWG

11 11 Yellow

Vinit+

Trigger

signal, 24 AWG

12 12 Grey Vinit-

Trigger signal, 24 AWG

13 nc

14 nc

15 nc

16 nc

Page 16

10

Installing the VIS

Figure 10. VJP-300 J-Panel X1 and X2 connectors

The connectors on the VJP-300 J-Panel are pluggable terminal blocks with pin spacing of 3.81 mm/ 0.15

inch from WAGO. The contacts are spring loaded. See Figure 11.

Figure 11. Terminal block

When mounting the wire into the connector the wire is stripped 7mm. The connector spring is released by

using one of two tools:

WAGO 734-230

JAI part number 10010134

WAGO 210-250

JAI part number 10014057

The wire is inserted and the spring is activated.

Page 17

Installing the VIS 11

VISCAM 1000 Systems

3.2.2 X6 Power Input Connector

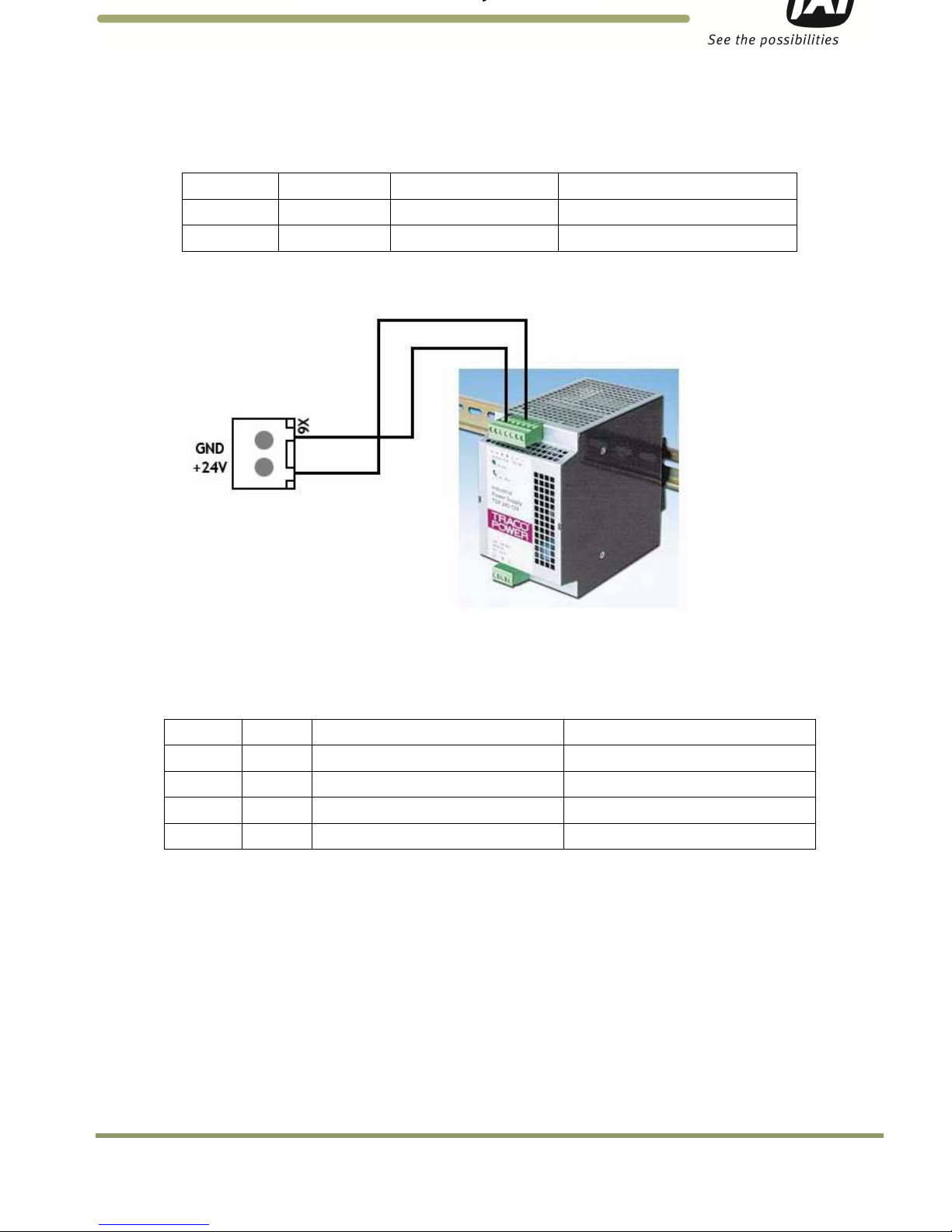

The Power Input connection to the J-Panel is shown in Table 3 and Figure 12. Note: X7 is in parallel to X6.

Table 3 Power input to the J-Panel

X6 Pin #

Signal

Description

Connection to

1 +24V +24V dc

24V DC power supply + output

2 GND +24V return

24V DC power supply return

Figure 12. X-6 Power input connection

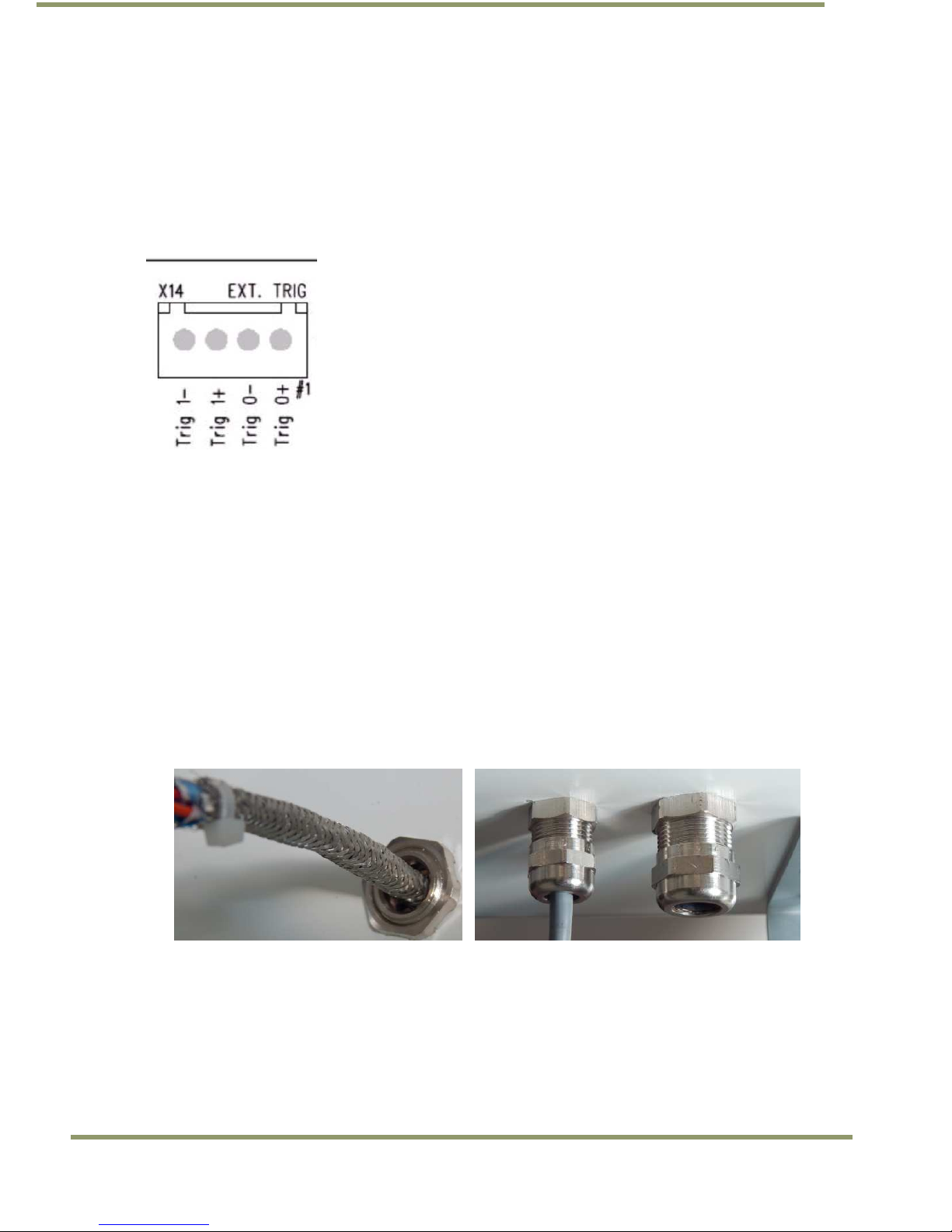

3.2.3 Trigger Input Connector (X14)

The Trigger input connection to the J-Panel is connector X14. The connections are listed in Table 4 and

Figure 13.

Table 4 Trigger input connector.

X14 Pin #

Signal

Description

Connection to

1 Trig0+

Positive Trigger input to

camera 0

Trigger device positive terminal

2 Trig0

- Negative Trigger input to camera 0

Trigger device negative terminal

3 Trig1+

Positive Trigger input to camera 1

Trigger device positive terminal

4 Trig1

- Negative Trigger input to camera 1

Trigger

device negative terminal

3.2.5 (a) Trigger polarity

The switches S3 and S5 set the trigger polarity:

If the trigger signal is normally low (no voltage at trigger input) the switch shall be in position:

Arrow up - positive going

If the trigger signal is normally high (voltage at trigger input) the switch shall be in position:

Arrow down – negative going

As a guideline the two LEDs marked TRIG-0 and TRIG-1 on the VJP-300 J-Panel shall be off when no trigger

pulse is present.

Page 18

12

Installing the VIS

3.2.5 (b) Test Trigger

Activating switches (push buttons) S1 and S4 generates a trigger pulse for test purposes. Only one trigger

pulse is generated each time the switch is activated (only works in arrow up position).

The duration of the trigger pulse is approximately 4 ms.

The trigger indicator LEDs flash when the test trigger switch is activated.

Figure 13. X14 Wiring

3.3 Installing the TNL-50

Securely install night light/flash unit on mounting structure. Roughly aim flash at trigger line (precision

aiming will occur when the system is up and running). See night light datasheet for mounting hole pattern

dimensions.

1. Disconnect wires from interconnection cable’s end connector in order to run cable through VISCAM

1000 enclosure’s cordgrip.

2. Route cable through enclosure cord grip. Braid/foil shield should be aligned with the cord grip nut

inside enclosure to ensure proper shield connection with EMI cord grip. See Figure 14 (left).

3. Hand-tighten the cord grip sealing nut as far as possible. Hold the body hex stationary with a wrench.

Using a second wrench, tighten the sealing nut until the cable is securely held in place. Torque to

approximately 35 in-lbs. (3.9 Nm). See Figure 14 (right).

Figure 14. Insert cable in enclosure and secure cordgrip

4. Connect wires to terminal blocks X5 & X12 on the VISCAM 1000 I/O Board in accordance with wiring diagram

on enclosure’s inner lid (see appendix A). Make sure settings are set per I/O Board Settings Diagram:

a. For TNL-50 Refer to Figure 15 and Table 5.

Page 19

Installing the VIS 13

VISCAM 1000 Systems

Figure 15. Connect TNL-50 wires to terminal blocks X5 and X12 on I/O Board

Table 5 TNL-50 flash unit connection in VISCAM AIO.

Pin X5

Signal

Wire Color

Description

Connection to

1 I/O Gnd

Black

I/O Board

Gnd Pin 2 (see Figure

15)

2 Gnd Black Flash Gnd

Flash ground (negative power terminal)

(GROUND)

3 Out White

Strobe out

Strobe input on flash unit (STROBE OUT)

4 Stat Blue Strobe status

Status output from flash unit (STROBE

STATUS)

5 FPWR Red Flash power

Power from

I/O Board

to output circuit on

I/O Board (pin 6)

6 24V Red

IO board 24V (Fused

0.5A)

Pin 5 (see Figure 15)

Pin X12

Signal

Wire Color

Description

Connection to

7 RS-485+ Green

RS-

485+ For controlling TNL

-

50 Parameters

8 RS-485-

Orange

RS-

485-

For controlling TNL

-

50 Parameters

Page 20

VISCAM 1000 Systems

14

System Set-Up

4 System Set-Up

This section provides a generic procedure for aligning one or more VISCAM 1000 system and associated

equipment at a site.

The example installation process described in this section assumes that:

• The cameras are being mounted on an overhead structure directly over the lane(s) being observed. The process

for aligning a camera mounted at the side of a lane is essentially the same as aligning a single camera mounted

directly overhead.

• The unit employs vehicle detection that will automatically trigger the camera. To determine where the vehicle

will trigger, the ENSetup program displays a trigger area region. This region shows the area where the camera

will detect a moving vehicle. This will give the approximate trigger line. Since the unit is using motion

detection technology, the trigger line will vary a little depending on the speed of the vehicle.

• If the installation utilizes other modes for triggering, the unit can also accept a discrete TTL or Ethernet signal

to the VISCAM 1000 system whenever the back (or front) of a vehicle crosses a fixed line across the road. This

line is referred to as the “trigger line” in this document.

• The installer should be familiar with using the ENSetup program supplied by JAI. Make sure you are using the

latest version by checking at www.jai.com. Please refer to the ENSetup Program User’s Guide if you are

unfamiliar with this software. JAI offers engineering support and software tools to help select the optimum

camera and trigger locations to meet your specific project needs.

• System settings are set to factory default value. This can be done by pressing the Load Factory Defaults button

on the tool bar in the Properties window.

4.1 Pre-Alignment Checklist

• Validate targeted lane coverage and lane overlap (if any)

• Make sure you have an appropriate laptop computer with the JAI ENSetup program installed.

• The setup computer needs to have an Ethernet network adapter installed (preferably 1 Gigabit Ethernet

Adapter) and the TCP/IP network configured with the correct IP-address, subnet-mask and default-gateway.

• The setup computer and the cameras need to be on the same subnet. The cameras are shipped with the

standard IP-address “10.0.0.65” and subnet-address “255.255.255.0”, and the setup computer needs to be

assigned an IP-address “10.0.0.xx” in order to automatically discover the cameras using the ENSetup program

(NB! “xx” must not be “65”).

• All cameras have to be given unique IP-addresses before the alignment begins. This is done using the ENSetup

application.

• Confirm all VIS components and cables are properly connected.

• Ensure network meets minimal system requirements (see Appendix D)

4.2 Select a Suitable Vehicle, License Plate, and Plate Stand for the Setup

To accurately set up the Vehicle Imaging Subsystem, the system installers need access to:

1. A vehicle that can be temporarily parked on the road

2. A plate that is:

a. typical in size and color for the site

b. clean, flat and in “like new” condition

Page 21

System Set-Up 15

VISCAM 1000 Systems

4.3 Connect the Setup Computer to the Camera

• Position the setup computer next to the camera being aligned. Make sure that no portion of the computer or

cables interfere with the camera’s view of the road.

• Connect the setup computer’s network adapter to the camera network. If the installation does not involve a

TLS-301 external light sensor, a direct connection between the setup computer and the camera can be used.

For installations that include a TLS-301, it is preferable to use a local Ethernet switch instead of a local direct

connection to the I/O board. (A direct connection between the setup computer and the camera will disconnect

the camera from the site LAN and thereby disconnect the light sensor as well.) See Figure 16 and follow the

instructions below if you are using a local Ethernet switch.

Disconnect camera’s Ethernet patch cord from the VISCAM 1000 I/O board and connect it to the

switch.

Then connect a new Ethernet patch cord from switch to VISCAM 1000 I/O board’s Ethernet port.

The Setup computer is then also connected to one of the free ports on the switch.

Note: If the switch is running on 24V dc, the I/O board is capable of supplying up to 0.5A on

connector X15 located next to X1 and X3. The pin marked with #1 on X15 is +24V dc.

Figure 16. Example of a network connection using a local switch

4.4 Drive and Park the Setup Vehicle Correctly

• Park the vehicle on the trigger line. Make sure that the vehicle is parked aimed in the same direction as the

average driver would point their car if they were driving through this section of roadway.

Page 22

VISCAM 1000 Systems

16

System Set-Up

4.5 Perform Initial Lens Adjustment and Camera Aiming

1. Back away all of the thumbscrews on the lens holder until they do not touch the knurled adjustment rings on

the lens.

2. Loosen the roll, pan, and tilt bolts on the JAI camera mounting head until each axis can be easily adjusted by

hand but any particular setting will stay in place after you let go.

3. Power on the setup computer and then start the ENSetup program. Press the “Video Window” button to open

the Video Window and then select the camera for adjustment from the tree-view on the left side of the

window. Press the “Live” button in the toolbar to start the video streaming. Press the “Tilt Line” button to

show the alignment guidelines.

The “Tilt Line” can be moved using the mouse, or if the “Tilt Line” is selected, using the arrow-keys. Keep in mind

the image in the video window by default is the center of the camera field of view. You may have to scroll the

image up or down to place the Tilt Line tool where you want the vehicle plate to be in the image.

4. Open EN Setup Video Window Settings. Configure Plate Width to the targeted number of pixels per plate. A

typical value is 135 – 150 pixels which provides high ALPR performance.

5. Interactively adjust the roll, pan, and tilt of the camera mount and the lens zoom and focus rings:

5.1 Adjust the lens focus ring (and camera pan and tilt as necessary) to obtain a focused image of the plate.

5.2 Adjust the lens zoom ring to obtain a plate width approximately equal to the distance between the short

vertical sizing marks that appear above the tilt line. Scroll the image horizontally to check edge to edge

coverage of the field of view as desired.

6. Repeat step 5 iteratively until no further adjustments are needed between each steps.

Note: For viewing full image right click in Video Window and select Preview Image. The adjustments still have

to be done from Video Window but the Preview shows how the full image looks.

Page 23

System Set-Up 17

VISCAM 1000 Systems

Figure 17. Initial Camera Alignment Display example

7. Turn on the “Roll Bar” display on the Setup computer and then roll the camera mount until the

horizontal bumper and trunk seams on the vehicle appear perfectly level with the horizontal line of the

display. Secure mount roll bolts. See Figure 18 for an example.

Figure 18. Roll Bar Display example

Page 24

VISCAM 1000 Systems

18

System Set-Up

Pan the camera mount until the plate is centered under the default position of the vertical line in the middle

of the “Roll Bar” display. The vertical line in the Roll Bar is in the center of the camera field of view. You can

use this feature to ensure the camera is properly aimed at the center of the lane. Securely tighten the pan

adjustment bolt.

Switch back to the “Tilt Line” display. Tilt the camera mount until the plate is positioned just above the tilt

line. Re-adjust the zoom and focus as necessary until the plate just fits in between the vertical markers on the

“Tilt Line”. Changing zoom usually requires that the tilt adjustment be modified also. Do not tighten the Tilt

bolts until after the final lens adjustment. See Figure 19.

Figure 19. Readjustment of camera tilt and zoom display

The camera mount and lens are now ready for final adjustment.

Page 25

System Set-Up 19

VISCAM 1000 Systems

4.6 Perform Final Camera Mount and Lens Adjustments

The final focus adjustment is facilitated using the “Focus Bar” display on the Video Window. Press the “Focus

Bar” button on the toolbar. This displays a “Focus Bar” marker on the Video Window that will open a separate

“Focus Bar” window where the pixel-values taken from the focus bar marker are displayed. The “Focus Bar”

marker can be moved with the mouse pointer, or if the “Focus Bar” marker is selected, using the arrow-keys.

1. Position the “Focus Bar” marker directly over the license plate. See Figure 20.

Figure 20. Focus Bar marker display

2. Adjust the lens zoom ring until the plate width just barely fits in between the short vertical markers on the tilt

line in the display.

3. Carefully adjust the lens focus ring until the focus bar waveform display is maximized in amplitude spread. The

“Focus percentage” display shown on the left side of the “Focus Bar Waveform” window should then be

maximized when the picture has got the best focus. If necessary, readjust the zoom and focus until the width

of the plate is just inside the vertical markers and the waveform spread of the bars is maximized. See Figure

21.

Page 26

VISCAM 1000 Systems

20

System Set-Up

Figure 21. Focus Bar Waveform display

4. Gently snug the zoom and focus lens holder thumbscrews against the lens without changing any of the lens

settings.

5. Use the mouse to move the red waveform cursors to the top and bottom of the waveform amplitude variation.

The “Black Cursor” is located at the bottom of the waveform display, and the “White Cursor” is located on the

top of the waveform display. See Figure 22.

6. Verify that the waveform amplitude variation (for characters in both direct light and shadow, if possible) is at

least 25 and that no portion of the waveform fully saturates either black or white.

Page 27

System Set-Up 21

VISCAM 1000 Systems

Figure 22. Focus Bar Waveform Display with waveform cursors

7. Use one hand to carefully hold the focus ring of the lens in place while you rotate the polarizer filter ring on

the very front of the lens with your other hand. Turn the filter ring until the white mark on the ring is oriented

straight up (or down). Secure the filter ring in place using the thumbscrew or with a small dab of RTV glue.

8. Print out the image of the screen using the “File -> Print…” menus on both the “Video Window” and the “Focus

Bar Waveform” windows to document the settings. If no printers are connected, the “PDFCreator” printer

driver can be used to save the windows as .pdf files.

9. Park the vehicle at the location where it is in a “crossover” position (i.e. between lanes) to check horizontal

coverage between adjacent cameras. Make adjustments as necessary to ensure adjacent cameras both have the

full plate in their respective fields of view.

10. If “Live” mode was used in EN Setup Video window make sure you click on “Freeze” before going to another

camera. “Live” mode stops images from being sent out over TCP and FTP.

4.7 TNL-50 Flash Alignment and settings

The following section provides a general procedure to align the TNL-50 flash head. Be sure to follow any

specific alignment procedure provided with your system.

Align the flash head at night and after aligning the cameras. Park a light colored vehicle at the trigger line

before proceeding with the alignment and flash intensity adjustments.

• Press the “Repetitive Trigger” button on the ENSetup toolbar. This will trigger the camera every second. Make

sure that the “Ethernet” trigger is enabled in the “Camera Properties” section “2 – Trigger”, property “External

Trigger Source”.

• Adjust the flash head tilt and pan control until the entire back of the vehicle is well and evenly illuminated. If

necessary, adjust the flash-head pan control to center the flash beam over the vehicle.

Page 28

VISCAM 1000 Systems

22

System Set-Up

• If the license plates are over-exposed by the TNL-50 Flash then there are multiple possible solutions to correct

this problem. Some of these solutions involve changing some of the VISCAM 1000 system parameters to reduce

sensitivity to nighttime illumination. Other solutions involve changing the brightness of the TNL-50 Flash by

adjusting some of the internal Flash unit settings. Please see next chapter for a detailed description of the

possible solutions.

• Repeat pressing the “Repetitive Trigger” button on the ENSetup toolbar to stop flash firing. Repeat the above

steps for each camera/flash.

4.7.1 TNL-50 Flash Settings

TNL-50 Flash unit come in three different versions: a white light, blue light and NIR light version. All of these

versions primarily work as flash (strobe) unit that illuminate vehicles and license plates when the cameras are

being triggered during low-light conditions.

Both the white and the blue light versions are visible to the human eye so they have an additional “Traffic

Safety Mode” feature built-in which provides a constant light output from the flash units between the bright

strobe flashes. This will make the bright strobe flashes seem less disturbing to the passing vehicles.

The strobe brightness and the Traffic Safety Mode brightness settings are adjusted individually depending on

the customer requirements.

It is possible to adjust the TNL-50 Flash settings directly from ENSetup.

The TNL-50 Continuous Light and Flash Light intensities are set up directly from the EN Setup Properties

window (Category “4 – Light”) by adjusting the “Flash Intensity”, “Flash Traffic Safety Night Intensity” and

“Flash Traffic Safety Day Intensity” settings seen below.

Figure 23. TNL-50 Flash Intensity settings in ENSetup

The light intensities are all specified in percent of maximum intensity output.

Furthermore a dedicated “TNL-50 Light Settings” dialog can be opened using the context menu for the selected

TS(C)-5000EN camera by selecting the “->Advanced Settings->Configure TNL-50 Light Settings”.

Note: as of firmware version later than Jan 2015 the Flash Intensity and Traffic Safety Intensity settings will

override TNL-50 settings. If you send commands directly to the TNL-50 to change intensity the camera will

change it back when it needs to adjust lighting.

Page 29

System Set-Up 23

VISCAM 1000 Systems

Note: Older version of EN Setup has incorrect Alarm Status options for TNL-50. The correct setting should be

“Normally High, Low -> Alarm …” Also the Flash Status Type setting of IO Board needs to be set to TNF DC;

please see Appendix A.

Figure 24. TNL-50 Flash settings context menu in ENSetup

This opens the settings dialog shown below:

Figure 25. TNL-50 Flash settings dialog

Page 30

VISCAM 1000 Systems

24

System Set-Up

Continuous Light Intensity (Traffic Safety Mode): Continuous light setting is only applicable for the white and

blue light versions of the TNL-50. The purpose of this light is to make the flash pulse less disturbing for

oncoming traffic. It has no influence on the image illumination.

Flash Intensity: These settings control the brightness of the TNL-50 when the camera is triggered. This is

typically only used during night when the ambient light level gets below a certain threshold. It makes it

possible to identify the vehicles at night as well as make the license plates readable.

The TNL-50 Flash intensity is very high compared to older flash units so the license plates can easily be

overexposed at night if the Flash Intensity is set too high. Both the distance between the TNL-50 and the

optical axis of the camera - as well as the overall distance from the flash unit to the vehicle will strongly

influence the brightness of the license plate at night. If the license plate gets completely washed out

(completely saturated so the letters and numbers become unreadable) then there are two basic options to

solve this via the flash unit itself: either lower the intensity of the TNL-50 or to move the TNL-50 further away

from the camera (this however only applies if the license plates are retro-reflective!)

Another option is to change the exposure settings inside the camera and thereby lower the cameras gain so the

license plates are less bright in the image. This will also improve the overall image quality since the noise level

in the images will be reduced when the gain is lowered. But typically this also makes the overall brightness of

the images darker so the vehicles become less visible in the images at night.

4.8 LED-1000 Embedded Illuminator Setup

The LED-1000 Embedded Illuminator is primarily used by the VISCAM 1000 to provide sufficient light for the

built-in Vehicle Detector trigger system, so the camera will be able to trigger during night time when the

ambient light is insufficient to light up the vehicles. The LED-1000 is also utilized during the daytime to make

the retro-reflective license plates stand out when they are in shadow condition. The brighter license plates

will enhance the contrast and the readability leading to higher ALPR performance.

The LED-1000 illuminator has two usage models similar to the TNL-50 flash unit: Traffic Safety (Continuous

Light) and Triggered Flash Mode.

Traffic Safety (Continuous Light):

The flash is constantly on at a specified brightness configurable in the LED-300/1000 Light Settings window.

Right click on the camera symbol and select Advanced Settings –> Configure LED-1000 Light Settings.

A dialog box will open and the settings for the LED-1000 light can be controlled from here:

Figure 26. LED-1000 Light Settings dialog box

When selecting light intensity settings, those settings are automatically saved in the I/O Board and become the

default settings next time the system is powered on. When selecting a “custom” setting, the SET button must

be selected for the value to take effect.

Page 31

System Set-Up 25

VISCAM 1000 Systems

Triggered Flash:

When the camera captures an image, the Internal Flash can flash at a different light level. The Internal Flash

Mode and Internal Flash Intensity settings affect this usage.

Internal Flash Mode:

There are three options available as of EN APP firmware version January 2015 (see Figure 27):

Figure 27. LED-1000 Mode selections in ENSetup

- Off: the internal LED light (LED-1000) is always off

- On Always: internal LED light is always flashed when triggered. The light is needed for Vehicle Detector to

work properly therefore this is the recommended setting.

- Auto Light Level: light level can be controlled automatically with the help of ALC or ADR. The “Internal Flash

Auto Intensity …” settings let you fine tune the light level (see Figure 28).

Figure 28. LED-1000 Flash Mode and Intensity settings in ENSetup

When Auto Light Level is selected the following settings take effect:

Page 32

VISCAM 1000 Systems

26

System Set-Up

- Internal Flash Auto Intensity Minimum: the lowest light level the ALC/ADR will set the Internal Flash

Intensity.

- Internal Flash Auto Intensity Maximum: the highest light level the ALC/ADR will set the Internal Flash

Intensity.

- Internal Flash Auto Intensity Knee Point 1 and Knee Point 2: have units in Light Sensor (LS A-Side from ALC

or ADR). Intensity is equal to

o If LS value < Knee Point 1 then intensity equals Intensity Minimum

o If LS value > Knee Point 2 then intensity equals Intensity Maximum

o Otherwise intensity equals

()(

)

+

4.9 Trigger Mode Selection

The VISCAM 1000 system offers several trigger sources. They can all work independently, but can all be

selected in parallel:

• TTL Trigger

• Serial Trigger (NOT USED – CANNOT BE SELECTED)

• Ethernet Trigger

• Vehicle Detector

The selection is in the Trigger control panel in the Properties window for the camera:

4.9.1 Trigger Synchronization Mode Selection

In addition to the selection of External Trigger Source, there is also the selection of Trigger Sync Mode where

the capture rate (frames per second) of the sensor can be controlled. The maximum allowed shutter time

varies, depending on the rate selected as shown in the list below:

1. Internal 50 fps – 3 ms maximum shutter length

2. Internal 60 fps – 3.5 ms maximum shutter length

3. Internal 72 fps (default selection) – 1 ms maximum shutter length

4. External 50 fps – 3 ms maximum shutter length

5. External 60 fps – 3.5 ms maximum shutter length

6. External 72 fps – 3 ms maximum shutter length

As seen in the above list, the camera’s continuous frame rate can either be set to 50, 60 or 72 frames per

second and the camera will actually be capturing images continuously in order for the built-in Vehicle

Detector, as well as the ALC (Automatic Level Control) to work – even if no vehicles are present and no triggers

are sent to the camera.

Page 33

System Set-Up 27

VISCAM 1000 Systems

This is different from the older generations of EN-cameras where the image sensors were using “asynchronous

triggers”. This meant that the imaging sensor was waiting for the next vehicle to pass before an image would

be taken!

The selection of External allows the camera to be externally synchronized with a 50, 60, or 72Hz Sync input.

This feature is necessary if one or more cameras needs to be synchronized to an external synchronization

source – for instance to the A/C power frequency in red-light systems, where the traffic light signals use LED’s

which are “pulsed” from the A/C power source. The 50 Hz and 60 Hz should in this case be selected based on

the A/C frequency where the cameras are installed.

4.10 Automatic Triggering and Light Sensing Configuration

This section describes the parameters to configure when setting up for automatic triggering (Vehicle Detector

Trigger) and light sensing (ALC).

4.10.1 Vehicle Detector Trigger Settings

Select “Vehicle Detector” within “External Trigger Source” to enable Vehicle Detector Trigger. The system will

automatically detect moving vehicles in up to two separate lanes. Note that the traffic in both lanes must be

moving in the same direction.

The Vehicle Detector uses a 200-line high detection area that covers the full width of the image. This detection

area is internally split into 9 horizontal detection grids. Each grid can be individually enabled or disabled. When

used in single lane mode, all 9 are used. When in dual lane mode, four grids are used per lane and the center

grid is normally disabled.

The Vehicle Detector properties are located in the Properties window of the camera in section 12: Vehicle

Detector

Figure 29. Vehicle Detector settings

Below is a short description of the Vehicle Detector parameters:

Shadow Suppression Mode – Disable/Enable shadow suppression. Enabling this feature helps reduce false

triggers caused by shadow. During certain times of day when the shadow is sufficiently dark compared to the

road surface, it could be mistaken as a vehicle by the VD. The shadow can be from a car in the adjacent lane,

or a long shadow cast in front of or behind the vehicle.

Sensitivity - This determines Trigger sensitivity of the system. The range is from .5000 to .9999 – or “Auto”. In

Auto mode the camera automatically adjusts the Vehicle Detector sensitivity based on the current exposure

settings.

The higher the value, the more sensitive the trigger will be. The selection of the setting should be determined

during the initial setup. Default setting is “Auto” and this is the recommended setting for the system, unless

the user application will actively control the sensitivity (no fixed sensitivity value will work correctly for all

light conditions – so active control will be necessary!)

Trigger Line - This determines the location of a “virtual trigger line” which in fact is the center line of a 200

lines high “Vehicle Detection Area” inside the image. It is specified as the line number of the center line

measured from the top of the image and down to the center line of the “Vehicle Detection Area”. The range is

from 350 to 1702 (default).

Page 34

VISCAM 1000 Systems

28

System Set-Up

Retrigger Delay - This setting determines the minimum number of frames between two consecutive triggers.

The actual time can be calculated as the number of frames multiplied by the frame-rate selected in the Trigger

Sync mode setting. If multiple triggers occur within this time then only the first trigger will be accepted. The

purpose for this setting is to minimize the number of “multi triggers” where the same vehicle generates

multiple triggers but only a single image is needed to identify the vehicle.

Lane Empty – This setting is essential to the “Rear Shot” Lane Direction mode (explained below). This specifies

the maximum number of “empty” frames the triggering system is allowed to wait in order to make sure that

the vehicle has left the detection area. If this value is too low then a lot of multi-triggers will be generated. If

it is too high then it limits the ability to detect tail-gating vehicles (in case the tail-gating vehicle is closer to

the vehicle in front than the number of frames specified). Default value is 11 and it is recommended to keep

this maximum value whenever possible.

Lane Configuration - This selection has the choice of Single Lane and Dual Lane. In Single Lane, the Vehicle

Detector algorithm uses the whole Vehicle Detection Area to detect a vehicle. In Dual lane, the image is

divided in half and each half is used to detect vehicles. Thus, if a vehicle happens to be crossing between

lanes, there may be an instance, where the same vehicle may be triggered in both lanes.

Lane Direction – This selects the way the Vehicle Detector triggers are generated. In “Rear Shot” mode the

vehicles will be travelling away from the camera and the triggers are generated when the vehicle leaves the

detection area. In “Front Shot” mode the vehicles will be travelling towards the camera and the triggers are

then generated when vehicles enter the detection area.

Detection Grid – It is possible to enable/disable the Vehicle Detection in each of the 9 grids of the detection

area. It is recommended to disable the middle (Grid 5) in dual-lane configuration. This will minimize the

number of multi-triggers that might occur if the passing vehicles get too close to the middle detection zone

(which is shared between both left and right lane).

4.10.2 Visualization helper for Vehicle Detector and ALC setup

The camera can superimpose the Vehicle Detection Area and ALC Area onto the image to help during trigger

line setup. To enable visualization enable them in “Debug Output Mask”:

1. On Image Graphics (Vehicle Detector): to show Vehicle Detection Area

2. On Image ALC Area: to show ALC Area.

Figure 30. VD and ALC visualization settings

*Be sure to disable the graphics when finished. They appear in the final image!

Figure 31. The visualization as displayed in image

Vehicle Detection Area (green boxes):

1. Each box represents 1 detection grid. There are 2 groups: left lane and right lane.

Page 35

System Set-Up 29

VISCAM 1000 Systems

2. Trigger Line: when in “Live” view mode, aim the camera so that the plates for each lane are at this Trigger

Line and in their respective side.

3. A trigger happens as a vehicle drives past the Trigger Line and comes out of the detection area.

3. The middle blue vertical line should be on top of and line up with the lane divider.

ALC Area (red & purple box):

The ALC area should be configured as close to the license plate area as possible to ensure accurate reading of

the current lighting conditions. Shadows cast onto the plate may not be cast on different parts of the field of

view making plate seems darker in the resulting image.

4.10.3 ADR settings in ALC mode

The VISCAM-1000 supports light sensing using an external (TLS-301) light sensor or using the internal ALC light

sensing functionality for exposure control of the camera. All light sensing settings are set up using ENSetup in

section 5 – ADR Control and the ones that are used by the ALC mode will be explained below.

Some of the settings are used in both external and internal light sensing mode - for example, ADR Shutter Max

specifies the longest (slowest) allowable shutter speed for auto exposure purposes, with values ranging from 0

(30 µs) to 855 (1000 µs).

Other settings are specific to the ALC mode of operation and these settings are marked in the figure below.

Figure 32. ADR Settings specific to ALC

1) Camera ADR Control – The ADR mode has to be set to ALC in order to enable the internal light sensing.

2) ALC Target Value – This is the “set-point” for the closed-loop control of the camera exposure. This value

represents the target average value for the ALC Region Of Interest (ROI). It is a 10-bit value which is then

four times higher than the average value measured in the output images from the VISCAM-1000 (which are

all in 8-bit resolution). So if the Target Value is set to 200 for instance, then the average intensity of the

ALC ROI in the output images will be around (200/4)=50. This value should be kept between 150 - 250 in

order to insure a proper brightness and contrast of the resulting images from the camera. By keeping the

value low there will be a larger “margin” so that over-exposed license plates can be avoided.

3) ALC Damping Factor – This setting controls the speed of the closed-loop control of the camera exposure. It

represents the percentage of change allowed by the control loop for each individual frame. A low value

(10-25) makes the ALC more stable and will give less fluctuation in the exposure. A high value (75-90) will

make the ALC very responsive but at the same time the brightness of the output images will vary a lot

depending on the brightness of the passing vehicles. It is recommended to keep the ALC Damping Factor as

low as 25% or even lower in order to prioritize stability over responsiveness of the ALC.

Page 36

VISCAM 1000 Systems

30

System Set-Up

4) ALC ADR Index Minimum/Maximum – These settings limit the exposure control range utilized by the ALC.

The minimum index will set the lowest ambient light level where the ADR will select the longest exposure

time and highest gain in the camera. By increasing this value the maximum gain will indirectly be limited

for the camera and hence result in images with less noise. This, however, also limits the total exposure of

the system and the resulting images will be darker in general. The maximum index sets the maximum

ambient light level where the ADR will select the shortest exposure time. When the maximum is set to

1500 then the minimum exposure time of the sensor will be used (approx. 30µs). It is recommended to

keep the maximum index at the default value (1500) and to set the minimum index to as low a value as

possible – but where the noise level is still acceptable and the license plates at night are not over-exposed!

A typical minimum index would be around 10-15 which yields a good balance between system sensitivity

and noise level.

5) ALC ROI top/bottom/left/right – these four settings specify the area from which the ALC calculates the

average measurements for the control loop. This area should be selected so it covers the background

(asphalt or concrete road tarmac) area where the vehicles will be located when the images are captured.

This will in most cases be close to the Vehicle Detection area. If the Vehicle Detector is in Rear Shot mode

then the ALC area should be put a bit higher than the detection area (since the vehicles are captured when

they are leaving the detection area). If the VD trigger line is being moved up or down then the ALC ROI

should be moved the same amount in the same direction.

4.11 High Dynamic Range Settings

The imaging sensor used in the VISCAM-1000 supports multi-slope integration. This makes it possible to increase

the dynamic range of the sensor, and helps avoid over-exposed license plates in challenging light scenarios

where the ALC control is unable to correctly assess the brightness of the license plate and the vehicles when

the images are captured. The challenging light scenarios are often caused by shadows being cast onto the scene

in a way where the ALC measures the average of the road surface in shadow – but where the vehicle will be in

the direct sun and thereby inadvertently cause the vehicle to become over-exposed!

The HDR settings are adjusted directly in ENSetup using section “10 – High Dynamic Range Control”.

Figure 33. HDR settings in ENSetup

1) HDR Enable: Selects if the multi-slope integration is enabled or disabled

2) HDR Slope 1/2 Reset percentage: Select the multi-slope reset time for the second and third slope of the

multi-slope integration of the sensor. The reset time is set as a percentage of the total exposure time so it

will automatically be adjusted when the exposure time is changed by the ADR. The higher the value – the

later the reset which in turn increase the dynamic range.

The multi-slope integration will change the sensors response to the light like shown in the example below:

Page 37

System Set-Up 31

VISCAM 1000 Systems

Figure 34. Example of different multi-slope integration settings

If the HDR functionality is switched off then the sensor will have a linear response to the light. If HDR is

enabled then the slope of the response curve will get a “knee-point”. When the light level gets above this level

then the sensor gets less sensitive to the light, (less steep curve) and will be able to image what would

otherwise result in an over saturated/clipped image.

Multi-slope integration will also result in a “compression” of response of the sensor above the knee-point, and

the “contrast” of the bright part of the image will be lower when the HDR level is increased. Another sideeffect is also that the images will get a “pinkish tint”, so that the color fidelity of the brighter areas of the

image will be lower.

The figure above shows two settings:

- Reset time at 70%/85% of the exposure time: This settings makes the sensor capable of coping with

approximately twice the amount of light compared to the linear response (HDR OFF)

- Reset time at 80%/90% of the exposure time: This settings makes the sensor capable of coping with

approximately four times the amount of light compared to the linear response (HDR OFF)

0 200 400 600 800 1000 1200 1400 1600 1800

0

50

100

150

200

250

300

Light level (fL)

Mean

OFF

ON, Level 6, Reset 70%/85%

ON, Level 6, Reset 80%/90%

0 200 400 600 800 1000 1200 1400 1600 1800

0

50

100

150

200

250

300

Light level (fL)

Mean

OFF

ON, Level 6, Reset 70%/85%

ON, Level 6, Reset 80%/90%

Page 38

VISCAM 1000 Systems

32

System Set-Up

It is recommended to use as little HDR as possible so that the compression and lower contrast in the images is

minimized.

4.12 Time Synchronization Settings

Most ITS systems require that all cameras are time synchronized – both with the back-office as well as with

each other. The VISCAM-1000 supports time synchronization using the standard Network Time Protocol (NTP)

where one or more designated NTP Servers provide the time for the whole system.

The NTP Time Synchronization is configured directly using ENSetup in section “14 – Time Synchronization”.

Figure 35. Time Synchronization settings in ENSetup

Before enabling the NTP Client all configuration parameters have to be set up, or else it will require a restart

of the NTP Client in order to make the parameters effective.

The following parameters need to be configured:

1) NTP Client Control – Enable or Disable the NTP client in the camera.

2) NTP-Server 1/2/3 IP-address: these parameters specify which NTP Server(s) on the network that the NTP-

Client will use for the time synchronization. The first IP-address in the list will be considered the preferred

server.

3) NTP Max estimated Error: Specifies the maximum estimated error allowed (in microseconds) before a

ERROR_NTP_TIME error telegram will be generated when an image is captured. This is typically used in

systems where there is a strict requirement to the synchronization accuracy of all cameras (like for

instance Section Control systems).

4) NTP Mode: This controls the NTP-Client mode of operation. Three modes are available: a) “Default”, b)

“Burst” and c) “Burst + Min/Max Poll intervals”. “Default” mode will use default configuration parameters

when the NTP Client daemon is started. “Burst” mode will speed up the initial communication to/from the

NTP Server and thereby help the NTP Client start/restart faster. “Burst + Min/Max Poll intervals” mode will

both speed up initial communication as well as set the minimum and maximum poll interval for

communication between the NTP Server and the NTP Client. This typically means that the minimum and

maximum poll intervals are changed to a lower value than that of the “Default” mode, thereby making the

NTP Client more responsive and more accurate – especially in cases where the NTP Server is not a high-end

dedicated time server, but instead is a service running on a standard PC on the network.

5) NTP Minimum/Maximum Poll interval: These two settings specify the poll interval range used by the NTP

Client. The values are defined in seconds as a power of two so a minimum value of 4 translates to 24

seconds = 16 seconds. A value of 6 translates into 26 seconds = 64 seconds. The minimum value is the poll

interval being used whenever the NTP Client starts up. It will then gradually increase the poll interval to

the maximum value and this maximum value will be used when the time synchronization is in a steady

state.

It is recommended to use the “Burst + Min/Max Poll Interval” mode when a standard PC is being utilized as the

NTP Server on the network.

Page 39

System Set-Up 33

VISCAM 1000 Systems

4.13 Solar Position Control for assisting the ALC

The ALC mode works well for in-image auto determination of gain and exposure time. There are situations

though in which the sun’s position makes it difficult to adjust the image properly.

Examples:

- The Sun is in front of the vehicle so that the plate is in the vehicle’s shadow but the road is bright. The

exposure and gain setting will make the plate dark.

- The Sun is directly behind the vehicle, and the plate’s retro-reflectivity will make it extremely bright.

The camera will be able to compensate for this if it can calculate the sun’s position. You can enable and

configure these controls in the Solar Position Control section.

For more details please see the Solar Position Control Application Note.

Solar Position Control: Enable or disable the Solar Position Control assistance for the ALC.

Camera Location Latitude and Longitude: The camera location is specified as a combination of the Latitude and

Longitude. The Latitude value is in “decimal degrees” where a positive value is degrees above equator (north)

and a negative value is degrees below equator (south). The Longitude is also specified in decimal degrees

where a positive number is degrees east of the “Prime Meridian - Greenwich” and a negative number is degrees

west of Greenwich. A good source for the location coordinates could be either from a GPS – or from reading the

location from various map sources.

1. Camera and vehicle directions:

a. Cameras Direction (Azimuth) is specified as the compass direction that the camera is facing,

where 0 degrees is “true north” and 180 degrees is when the camera is facing directly south.

b. Camera Tilt is the angle the camera is “tilted” down from the horizon. This angle is typically

between 25 degrees to 30 degrees.

c. Vehicle direction (or road direction) is the direction that vehicles will be travelling away from

the camera. This value is typically the same value as the camera azimuth (in gantry mounted

Page 40

VISCAM 1000 Systems

34

System Set-Up

camera systems where the cameras are mounted straight above the road). If on the other

hand the cameras are mounted on the side of the road then the vehicle direction and the

camera direction values will be different! It is however important to note that this angle is

always in the same “general direction” as the cameras – no matter if the vehicles are moving

towards the camera or away from the camera! The direction will always need to be specified

as the angle away from the camera.

2. Shadow Boost Factor settings:

The Shadow Boost Factor is the maximum multiplication factor applied to the ALC set-point value when the

back of the vehicle is in “self-shadow” and the license plates are in shadow as well. The Shadow Boost Factor

Angle specifies the range of sun azimuth angles where the Shadow Boost Factor will gradually be increasingly

applied. It starts out with no boost factor when the sun angle is perpendicular to the vehicle direction, then

gradually increases to the maximum boost factor within the Boost Factor Angle degrees.

3. Road Reflection Boost Factor settings:

The Road Reflection Boost Factor is the maximum multiplication factor applied to the ALC set-point value. This

happens when the sun is right in front of the camera and the sunlight bounces off the road surface. The Road

Reflection Boost Factor Angle specifies the range of sun azimuth and elevation angles where the Road

Reflection Boost Factor will gradually be increasingly applied. It starts out with no boost factor when the sun

angle is less than or equal to this angle from the camera direction and elevation - and is then gradually

increased to the maximum boost factor when the sun is straight in front of the camera and the sun elevation is

the same as the camera tilt angle.

It is important to note that the Shadow Boost Factor and the Road Reflection Boost Factor can be applied at

the same time! This means that when the Road Reflection Factor is at its maximum, then the Shadow Boost

Factor will also be at its maximum – hence applying the combined boost factor to the ALC set-point!

4. Direct Sun Reduction Factor settings:

The Direct Sun Reduction factor is the maximum reduction in the ALC set-point value when the sun is right

behind the camera. The Direct Sun Reduction Factor Angle specifies the range of sun azimuth and elevation

angles where the Direct Sun Reduction Factor will be increasingly applied. It starts out with no reduction factor

when the sun angle is less than or equal to this angle from the camera direction and elevation. It is then

gradually increased to the maximum reduction factor when the sun is straight behind the camera and the sun

elevation is the same as the camera tilt angle.

5. Min/Max Shadow Suppression Elevation settings:

The sun position can also be used for automatically enabling the “Shadow Suppression” in the VISCAM-1000

Vehicle Detector. The camera automatically calculates the sun elevation. If this value is within the Min and

Max Shadow Suppression Elevation then Shadow Suppression is turned on when the Vehicle Detector trigger is

enabled.

4.14 Video Streaming and Recording

In addition to capturing triggered “still” images of passing vehicles and plates, the VISCAM 1000 system offers

two types of video capture functions: live streaming and video clip recording. Live streaming outputs a

continuous compressed video stream for real-time remote viewing. Video clip recording captures a short, user

configured sequence of video frames (AVI) covering the period immediately before and after each triggered

image.

Please refer to the Streaming and AVI video application note for more details.

Page 41

System Set-Up 35

VISCAM 1000 Systems

1. AVI and Streaming Video Format: select output format between 720p or 1080p. You must then “Save

to Flash” and reboot the camera before this setting takes effect.

2. Video OSD Date Format: specify how the date will be displayed in the upper left corner of the AVI clip

or video stream. There are several options:

a. None: the date will not be displayed.

b. YYYY/MM/DD: date will be displayed as “Year/Month/Day”

c. MM/DD/YYYY: date will be displayed as “Month/Day/ Year”

d. DD/MM/YYYY: date will be displayed as “Day/Month/Year”

3. Video OSD Time Format: specify how the current frame time will be displayed in the upper left corner

of the AVI clip or video stream; right below the date. There are several options:

a. None: time is not displayed.

b. 12-hour: time is displayed as “Hour:Minute:Second[AM/PM]”. Hour is from 01 to 12.

c. 24-hour: time is displayed as “Hour:Minute:Second”. Hour is from 00 to 23.

d. 12-hour (ms): time is displayed as “Hour:Minute:Second.Miliseconds[AM/PM]”.

e. 24-hour (ms): time is displayed as “Hour:Minute:Second.Miliseconds”.

4. Streaming Enable: enable/disable streaming. Streaming is required when AVI output is selected and

will automatically be enabled. To enable streaming only, unselect AVI in “Image Acquisition Image 1”

first, then set “Streaming Enable” to “Enable”.

a. NOTE: use this link in VLC or other software to see the video streaming:

i. rtsp://[Camera IP]:8557/PSIA/Streaming/channels/0?videoCodecType=H.264

5. Target FPS: specify the target frames per second for AVI and streaming output. The camera will try its

best to produce video close to this target. If the camera is busy then the frame rate may dip. Range

is from 1 to 20.

6. Target Bit-rate: specify the data rate for the AVI and stream video in term of bits. Higher values

increase final AVI size and bandwidth needed to stream data, but results in better video quality.

Example values:

a. 2000000: 2Mbps.

b. 1800000: 1.8Mbps.

7. Inter-frame Interval: specifies the number of P-frames between I-frames. I-frames (key frames)

contain complete video data. P-frames (predicted frames) are generated by the previous I-frame and

Page 42

VISCAM 1000 Systems

36