JAI Vehicle Imaging Subsystem 300, Vehicle ImagingSubsystem 400, VIS CAM 300, VIS CAM 400 Installation Manual

JAI Intelligent Transportation Systems

Vehicle Imaging

Subsystem 300/400

Installation Manual

10436

Rev. B

Page ii

Vehicle Imaging Subsystem 300/400

Page iii

A

S

S

O

C

I

A

T

I

O

N

Notice

The material contained in this manual consists of information that is proprietary to JAI Inc., and may only be used by the purchasers of the product. JAI Inc. makes no warranty for the use of its product and assumes no responsibility for any errors

which may appear or for damages resulting from the use of the information contained herein. JAI Inc. reserves the right to

make changes without notice.

Microsoft, Windows XP, Windows 2000, Windows 98, Windows NT, and Windows Explorer are either registered trademarks

or trademarks of Microsoft Corporation in the United States and/or other countries.

Warranty

Each JAI product is warranted to be free from defects in material and workmanship under normal intended use and service if

installed in accordance with this manual. The warranty period is 2-years and begins on the date of shipment from JAI stock.

This warranty shall not apply to repairs or replacements necessitated by any cause beyond the control of JAI, including but not

limited to, 1) improper installation, 2) acts of nature, 3) accidents, 4) misuse, 5) lack of proper maintenance, 6) unauthorized

repairs or modifications.

Be advised, that you need to obtain an RMA number from JAI before returning units for warranty repair.

Certifications

CE Compliance

The TS-2030EN and TS-9720EN series of cameras have been certified to conform to the requirements of Council Directive

89/336/EC for electromagnetic compatibility and to comply with the following European Standards:

Emissions: EN 55022A: 1998 + A1: 2000 + A2: 2003

Immunity: EN55024: 1998 + A1: 2001 + A2: 2003

All JAI products bearing the CE mark have been declared to be in conformance with the applicable EEC Council Directives.

However, certain factory-installed options or customer-requested modifications may compromise electromagnetic compatibility and affect CE compliance. Please note that the use of interconnect cables that are not properly grounded and shielded may

affect CE compliance.

Contact JAI Applications Engineering Department for further information regarding CE compliance.

FCC

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area may cause harmful interference, in which case the user will be required to correct

the interference at his own expense.

M

O

T

U

A

MEMBE

D

E

T

A

I

M

A

G

I

N

G

R

FILE #

A3942

R

E

U

G

L

®

I

S

T

D

E

E

R

JAI PULNiX, INC.

F

M

R

I

ISO-9001

Page iv

WARNING

Changes or modifications to this unit not expressly approved by the party responsible for FCC compliance could void the

user’s authority to operate the equipment.

Vehicle Imaging Subsystem 300/400 Installation Manual

JAI Inc.

625 River Oaks Parkway

San Jose, CA 95134

Tel:(408) 383-0300

Tel:(800) 445-5444

Fax:(408) 383-0301

E-mail: imaging@jai.com

www.jai.com

Page v

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Document Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 System Components description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.3.1 Traffic Light Sensor – TLS300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.2 VISCAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.3 Illumination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.4 VJP-300 Junction Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.3.5 RS485 Device Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.3.6 ENSetup Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4 Operational Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.1 Trigger Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Installation Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.1 Over Lane Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1.2 Side of Road Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Installing the Vehicle Imaging System . . . . . . . . . . . . . . . . . . 15

3.1 Installing the TNF-300 Traffic Light Sensor. . . . . . . . . . . . . . . . . . . . 15

3.1.1 To install the Traffic Light Sensor: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.1.2 Optional Side Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.2 Installing the Camera(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Installing the J-Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.3.1 X1 and X2 VIS CAM 300/400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.3.2 X3, X7 Traffic Light Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.3 X6 Power Input Connector 24

3.3.4 X8 LS RS485 Out Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.3.5 X14 Trigger Input Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.6 X15 Lane Controller Connector (X4 and X5) . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4 Illumination Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4.1 Installing the TNF-31 Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5 Trigger Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.5.1 Installing The Laser Vehicle Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4 System Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 Preparation for Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.1 Pre-Alignment Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.2 Select a Suitable Vehicle, License Plate, and Plate Stand for the Setup . . . . . . 32

4.1.3 Select the Camera to Align . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1.4 Validate the Installation Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1.5 Edit the alignment settings on the Setup Computer . . . . . . . . . . . . . . . . . . . . .33

4.1.6 Connect the Setup Computer to the Camera . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1.7 Drive and Park the Setup Vehicle Correctly . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.1.8 Properly Position the License Plate Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1.9 Perform Initial Lens Adjustment and Camera Aiming . . . . . . . . . . . . . . . . . . .35

4.1.10 Finalize Lens Adjustments and Camera Aiming . . . . . . . . . . . . . . . . . . . . . . .38

4.1.11 Flash Head Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table of Contents

Page vi

5 Appendix A: Camera Functional and Connector Description 43

5.1 I/O Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2 X4: I/O Board Connection to J-panel . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.4 Electrical interface on the I/O board: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.5 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2.6 Typical wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3 I/O Board Flash Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.3.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.3.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.3.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.3.5 Typical Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.3.6 X6: I/O Board Night Light/2nd Flash Connection . . . . . . . . . . . . . . . . . . . . . . 53

5.3.7 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.3.8 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.9 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.10 Typical Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.4 Night Light TNC 100 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.5 X7:I/O Board Laser Vehicle Detector Connection . . . . . . . . . . . . . . . . 58

5.5.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.5.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.5.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.5.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.6 X1, X3: I/O Board Ethernet Test Connectors . . . . . . . . . . . . . . . . . . . 61

5.6.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.6.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.6.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.6.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.6.5 Test setup 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.6.6 Test setup 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.7 X15: I/O Board Auxiliary power connector . . . . . . . . . . . . . . . . . . . . 65

5.7.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.7.2 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.8 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.8.1 Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.8.2 Recommended Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.8.3 Mounting the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6 Appendix B: J-Panel Functional and Connector Description 67

6.1 J-Panel Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.2 X1: J-panel connection to Camera 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.2.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.2.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.2.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.2.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.2.5 Typical Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.2.6 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table of Contents

Page vii

6.2.7 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.3 X2: J-panel connection to Camera 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.3.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

6.3.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.3.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.3.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

6.3.5 Typical Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.3.6 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

6.3.7 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.4 X3: Light Sensor Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.4.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

6.4.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.4.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.4.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

6.4.5 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

6.5 X4: Lane Controller Signal to J-Panel #2 . . . . . . . . . . . . . . . . . . . . . . 78

6.5.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

6.5.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.5.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.5.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

6.6 X5: Lane Controller Signal from J-Panel #1 . . . . . . . . . . . . . . . . . . . . 79

6.6.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

6.6.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.6.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.6.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

6.7 X6, X7: 24V DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.7.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

6.7.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.7.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.7.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

6.8 X8: RS485 signal to Ethernet interface . . . . . . . . . . . . . . . . . . . . . . . 82

6.8.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

6.8.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

6.8.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

6.8.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

6.9 X11: Ethernet Interface from Camera 0 . . . . . . . . . . . . . . . . . . . . . . . 83

6.9.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

6.9.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.9.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.9.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

6.10 X12: Ethernet Interface from Camera 1 . . . . . . . . . . . . . . . . . . . . . . . 84

6.10.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

6.10.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

6.10.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

6.10.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

6.11 X14: External Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.11.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

6.11.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

6.11.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

6.11.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Table of Contents

Page viii

6.12 X15: Lane Controller interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.12.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.12.2 Connector specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.12.3 Connector signal specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.12.4 Connector physical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.12.5 Connecting Lane Controller RS485 signal between J-Panels 89

7 Appendix C: Two Cameras, One Flash Configuration . . . . . 90

8 Appendix D: Pluggable Terminal Blocks . . . . . . . . . . . . . . . 92

9 Appendix E: Moxa N-Port 5232 Configuration . . . . . . . . . . . 93

10 Appendix F: Multiple Moxa N-port Configuration Diagram 99

11 Appendix G: Ethernet Requirements. . . . . . . . . . . . . . . . 100

12 Appendix H: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 101

Table of Contents

Page ix

List of Figures

FIGURE 1. VIS elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FIGURE 2. Back shot VIS installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

FIGURE 3. Typical Over Lane Site Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FIGURE 4. Typical Over Lane Site Layout Plan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

FIGURE 5. VIS 300 U.S. Camera options chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

FIGURE 6. VIS 300 European Camera options chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

FIGURE 7. A typical side of road installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FIGURE 8. A typical side of road installation plan view with no canopy/overhead structue. 13

FIGURE 9. Flash and camera distances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

FIGURE 10. Install the traffic light sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

FIGURE 11. TLS-300 signal and power cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

FIGURE 12. Installing the TLS-300 through the mounting pipe and flange. . . . . . . . . . . . . . . 16

FIGURE 13. Pipe clamps should be about 6-inches apart on a vertical surface. . . . . . . . . . . 17

FIGURE 14. Camera Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

FIGURE 15. Camera mount template. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

FIGURE 16. Camera cabling as it appears before electrical installation. . . . . . . . . . . . . . . . . . 18

FIGURE 17. Cable final wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

FIGURE 18. Properly wired X-4 connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

FIGURE 19. Back of the video camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

FIGURE 20. VIS CAM connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

FIGURE 21. TLS 300 to J-Panel wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

FIGURE 22. X-6 Power input connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

FIGURE 23. Wiring for the X8 to converter connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

FIGURE 24. Test trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

FIGURE 25. Two lane controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

FIGURE 26. TNF-31 flash unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

FIGURE 27. S3 switch setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

FIGURE 28. Connecting an AC flash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

FIGURE 29. Connection for LVD to VIS CAM 400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

FIGURE 30. Example of a network connection using a local switch. . . . . . . . . . . . . . . . . . . . 34

FIGURE 31. Initial Camera Alignment Display example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

FIGURE 32. Roll Bar Display example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

FIGURE 33. Readjustment of camera tilt and zoom display. . . . . . . . . . . . . . . . . . . . . . . . . . . 38

FIGURE 34. Focus Bar marker display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

FIGURE 35. Focus Bar Waveform display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

FIGURE 36. Focus Bar Waveform Display with waveform cursors. . . . . . . . . . . . . . . . . . . . . 41

FIGURE 37. Connection requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

FIGURE 38. Component layout of the EN board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

FIGURE 39. Board connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

FIGURE 40. Interface drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

FIGURE 41. Electrical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

FIGURE 42. Physical interface table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

FIGURE 43. Category 5 or 6 wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

FIGURE 44. Flash connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

FIGURE 45. I/O board electrical interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

FIGURE 46. Switch location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

FIGURE 47. Connecting DC Flash to a board powered from the Flash power supply. . . . . . . 52

FIGURE 48. Connection DC Flash to an internally powered board. . . . . . . . . . . . . . . . . . . . . 52

FIGURE 49. AC flash unit connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

List of Figures

Page x

FIGURE 50. Second flash connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

FIGURE 51. IO board electrical interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

FIGURE 52. Wiring a second DC flash from the flash power supply. . . . . . . . . . . . . . . . . . . . 55

FIGURE 53. Connecting to a 2nd DC Flash unit with the I/O Board electronics internally

powered.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

FIGURE 54. Connecting the second AC flash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

FIGURE 55. Connecting to the night light (TNC 100) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

FIGURE 56. Detection board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

FIGURE 57. LVD Trigger Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

FIGURE 58. Electrical interface on the I/O board: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

FIGURE 59. Ethernet test connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

FIGURE 60. EN network test configuration setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

FIGURE 61. Test setup 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

FIGURE 62. Auxiliary power connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

FIGURE 63. EN-CAM component layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

FIGURE 64. Connecting from J-Panel to camera zero. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

FIGURE 65. J-Panel electrical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

FIGURE 66. Ethernet wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

FIGURE 67. Board and camera J-panel connection to camera 1. . . . . . . . . . . . . . . . . . . . . . . 72

FIGURE 68. J-panel electrical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

FIGURE 69. Category 5 or 6 ethernet wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

FIGURE 70. Light sensor indicator on the board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

FIGURE 71. Light sensor connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

FIGURE 72. Signal to J-panel #2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

FIGURE 73. Signal from J-panel #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

FIGURE 74. Signal from J-panel #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

FIGURE 75. Principle in the power distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

FIGURE 76. RS485 to Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

FIGURE 77. Interface from Camera 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

FIGURE 78. Interface from Camera 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

FIGURE 79. External Trigger connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

FIGURE 80. Trigger polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

FIGURE 81. Trigger 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

FIGURE 82. Trigger 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

FIGURE 83. Lane controller setup diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

FIGURE 84. Lane controller setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

FIGURE 85. Two camera, one flash, configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

FIGURE 86. Terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

FIGURE 87. Standard configuration of Basic Settings: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

FIGURE 88. Standard configuration of Network Settings: . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

FIGURE 89. Standard configuration of Serial settings for port 1: . . . . . . . . . . . . . . . . . . . . . . 95

FIGURE 90. Standard configuration of Serial settings for port 2: . . . . . . . . . . . . . . . . . . . . . . 96

FIGURE 91. Configuration overview of serial port 1 and 2. . . . . . . . . . . . . . . . . . . . . . . . . . . 96

FIGURE 92. Operation configuration of Serial port 1: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

FIGURE 93. Operation configuration of Serial port 2: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

FIGURE 94. Configuration overview of operating settings for serial port 1 and 2. . . . . . . . . . 98

FIGURE 95. Moxa configuration example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

FIGURE 96. Network cabling example: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

List of Figures

Page xi

List of Tables

TABLE 1. Light Sensor Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TABLE 2. Electrical wiring for the VIS CAM installation. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

TABLE 3. VIS CAM connections to the J-Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

TABLE 4. TLS 300 to J-Panel connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

TABLE 5. Power input to the J-Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

TABLE 6. X8 to converter connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

TABLE 7. Trigger input connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

TABLE 8. X15 Lane Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

TABLE 9. Flash unit connection in VIS CAM 400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

TABLE 10. Wiring for LVD to VIS CAM 400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

TABLE 11. Typical minimum plate heights and nominal plate heights: . . . . . . . . . . . . . . . . .32

TABLE 12. Wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

TABLE 13. Physical interface pinouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

TABLE 14. Connector table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

TABLE 15. Ethernet test connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

TABLE 16. Signal parameters and conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

TABLE 17. Physical interface table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

TABLE 18. LED indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

TABLE 19. Switch labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

TABLE 20. Signal table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

TABLE 21. Ethernet physical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

TABLE 22. LED indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

TABLE 23. Connector switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

TABLE 24. Physical interface connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

TABLE 25. LED physical indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

TABLE 26. Physical connector table for J-panel 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

TABLE 27. Physical pin connections J-panel #1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

TABLE 28. Physical connection for pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

TABLE 29. RS485 physical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TABLE 30. Physical connector description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

TABLE 31. Pin connections for Ethernet from Camera 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

TABLE 32. Connector table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

TABLE 33. WAGO physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

TABLE 34. Master to slave connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

TABLE 35. Essential specifications for the pluggable terminal block. . . . . . . . . . . . . . . . . . . 92

TABLE 36. Troubleshooting table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

TABLE 37. Fault symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

TABLE 38. Check/Possible reason . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

List of Tables

Page xii

List of Tables

May 16, 2007

VIS CAM 300/400 Installation Manual

1 Introduction

1.1 Document Overview

This document describes the steps necessary to deploy an installation of the JAI Vehicle Imaging

Subsystem, described as VIS from this point forward.

This manual also contains information about maintenance, troubleshooting and RMA (Return Material

Authorization) procedures.

JAI strongly recommends that the installer read this manual thoroughly, in order to obtain sufficient

knowledge about the VIS equipment, before initiating the actual installation.

1.2 Product overview

The JAI VIS consists of the following components:

• TLS-300 Traffic light sensor.

• The VIS Camera 300 unit, comprised of a TS-9720EN-5001 Ethernet camera with zoom-lens and

• TNF-31 Flash unit or optional TNC-60 permanent illumination.

• VJP-300 EN-Junction panel with terminal blocks and RJ-45 connectors and embedded diagnostics

• RS485-to-Ethernet Converter

• System interconnection cables

anti-glare filter, a weatherproof housing with sun shield, heater resistors, interconnection PCB, and

a pan-tilt-roll mounting bracket. Or the VIS Camera 400 unit, comprised of a TS-2030 EN ethernet

camera with fixed focal lens (standard) or zoom-lens (optional) and anti-glare filter, a weatherproof

housing with sun shield, heater resistors, interconnection PCB, and a pan-tilt-roll mounting

bracket.

features

VIS CAM 300/400 Installation Manual

Page 2

VIS CAM 300/400 Installation Manual

• Optional gigabit Ethernet switch

• Optional 24V DC Power Supply

• Optional Laser Vehicle Trigger

• ENSetup Program

• Installation Documentation

FIGURE 1. VIS elements

1.3 System Components description

1.3.1 Traffic Light Sensor – TLS300

The JAI traffic light sensor is the driver of the VIS control network. It controls video signal parameters

of each camera to ensure high contrast images of passing vehicles and their license plates, regardless of

vehicle speed, weather or ambient light conditions.

Under the clear plastic dome of the traffic light sensor are mounted, in opposing directions, two vertical

plates and corresponding light collection staffs that protrude above a flat black base plate. The sensor

Introduction

Page 3

VIS CAM 300/400 Installation Manual

measures the ambient light reflecting off the face of both vertical plates. The design is such that when

the face of one plate is in direct sun, the other one is in shadow. These two measurements identify the

range of light levels that the camera is required to image without saturation when a vehicle and its

license plate are in the camera’s field of view (FOV). To ensure correct functionality of the TLS-300, it

is very important to ensure during installation, that the sensor’s base plate is levelled with the road

surface, and that the orientation of the sensor is rotated so that the direction from the vertical plate A to

vertical plate B is the same as the direction of the traffic flow being observed by the traffic camera (see

Figure 2).

FIGURE 2. Back shot VIS installation.

The TLS-300 light sensor is an essential component that ensures the VIS cameras will be ready to

capture high quality images of any vehicle and its license plate in virtually all weather and light

conditions.

It is very important to ensure that sensor positioning closely resembles real road conditions where the

vehicle image is most likely to be captured.

The light sensor is connected by means of the J-Panel VJP-300 and an RS485-to-Ethernet converter to

the Ethernet switch.

1.3.2 VISCAM

The VISCAM uses a state-of-the-art progressive interline transfer CCD that captures all of the vertical

resolution at once, thereby eliminating field-to-field imaging delays. The use of progressive scanning

allows the camera to freeze the motion of a rapidly moving vehicle at high resolution.

The VISCAM 300 houses a JAI TS-9720EN, while the VISCAM 400 houses the TS-2030EN Ethernet

camera with a built in IBM Power PC using an embedded Linux O/S and 64Mb memory for various

Introduction

Page 4

VIS CAM 300/400 Installation Manual

operations, such as frame store, JPEG compression, vehicle fingerprint extraction, license plate find,

running applications, and so on.

When the TLS-300 Traffic Light Sensor is used to control the VISCAM exposure settings, no moving

parts (such as an auto-iris lens) are included in the VIS system. This helps ensure high reliability for the

system.

A 12.5 mm to 75 mm manual zoom lens is provided as a standard with the VISCAM 300. This allows

the VISCAM to be mounted in a wide range of positions while ensuring sufficient resolution on the

vehicle license plates. A 35 mm fixed focal length lens is provided standard with the VISCAM 400. A

zoom lens is also available as an option. An anti-glare polarizing filter is mounted in front of the lens to

reduce smear in the picture caused by sun glints.

1.3.3 Illumination

1.3.3 (a) TNF-31 Flash

The TNF-31 Flash generates light in wavelengths that are invisible to the human eye, but visible to the

camera. This makes the flash suitable for illuminating both oncoming and receding views of traffic.

Unlike near-infrared illuminators, the TNF-31 yields high contrast images of license plates even if they

have red characters on white or yellow backgrounds.

The TNF-31 Flash is automatically enabled whenever the TLS-300 Light Sensor determines that

ambient light is insufficient to produce a picture of usable quality. When the TNF-31 is enabled, it fires

every time the vehicle detector triggers the camera.

1.3.3 (b) White light LED.

JAI offers White LEDs mounted inside the camera enclosure. This option is usually employed when

certain rare color combinations on license plates do not yield sufficient contrast with the TNF-31 Flash

option alone.

1.3.4 VJP-300 Junction Panel.

The VIS J-Panel is the central connection point for the VIS components. The J-Panel is a DIN-Rail

mounted PCB equipped with various interface terminals for interconnection of the VIS components;

this can be Ethernet connection, serial connection, TTL trigger feed and power supply. It offers the

possibility of manually selecting trigger polarity to the camera. Furthermore the J-Panel is equipped

with status LED’s and trigger switches for diagnostics and troubleshooting purposes.

1.3.5 RS485 Device Server.

The MOXA RS485 Device Server enables connection of RS485 serial devices to the Ethernet. The

purpose for the MOXA RS485 Device Server in the VIS system is to convert Ethernet to RS485

communication for the TLS-300 Light Sensor.

Introduction

1.3.6 ENSetup Program.

The ENSetup Program is an Ethernet based software tool specifically designed to assist the installer

with VIS installation, and EN-Camera configuration and diagnostics. The program runs on a standard

PC / Laptop with Windows XP installed. Refer to Section 4 on page 31 of this manual and the VISCAM

300/400 EN Setup Manual for details.

1.4 Operational Overview.

During installation, the VISCAM and the optional light source are aimed at the area of the road where

vehicles and their license plates are most likely to pass through. The Traffic Light Sensor continually

registers the ambient light. The camera uses this information to set up exposure variables to ensure an

optimal image of the vehicle and license plate. During transition from day to night the camera enables

the optional TNF-31 Flash and/or white light LED’s to secure adequate image quality during low

ambient light conditions.

1.4.1 Trigger Mode

Page 5

VIS CAM 300/400 Installation Manual

A vehicle passes by a vehicle detector, sending a trigger to the VIS.

•

• The VIS employs a trigger to snap a video image of the vehicle and license plate when they are

optimally positioned in the camera field of view.

• The optional flash, if used, fires simultaneously with the camera to ensure correct exposure for the

image if the ambient lightning is too low.

Introduction

Page 6

VIS CAM 300/400 Installation Manual

2 Preparing for installation

2.1 Installation Preparation

To prepare for installation, consider the fundamental requirements for an effective deployment of the

Vehicle Imaging Subsystem. There are two basic ways to position the camera: over the lane or beside

the lane. Figure 3 and Figure 4 depict a typical over-lane installation. Figure 7 and Figure 8 on page 13

depict a typical beside-lane camera installation.

2.1.1 Over Lane Positioning

Over lane camera mounting is always employed when the road width being monitored contains more

than two lanes of traffic, when a convenient overhead structure is already in place, or when preventing

vandalism is a paramount concern.

FIGURE 3. Typical Over Lane Site Layout

Preparing for installation

FIGURE 4. Typical Over Lane Site Layout Plan.

Page 7

VIS CAM 300/400 Installation Manual

2.1.1 (a) Camera tilt considerations

The requirement to freeze the motion of high-speed vehicles limits how steep or shallow the tilt angle of

the camera may be. For example, it is important to prevent the horizon from appearing in the image,

and thereby allowing the sun to blind the camera. For over lane installations, a camera tilt between 20°

to 30° is recommended–with 25° being considered the optimal angle. This angle of tilt is the best

compromise between minimizing visibility blockages caused by closely spaced vehicles and

maximizing plate visibility for plate mounts that are slightly recessed or tilted downwards.

2.1.1 (b) Asynchronous triggering considerations

When the VIS is operated in trigger mode, a vehicle detector is employed to cause the camera to capture

an image at the precise moment the vehicle is in the best position to image both the vehicle and its

license plate. The delay between the time the vehicle passes the trigger position on the road and when

the trigger signal actually reaches the VIS must be kept to a minimum to prevent high-speed vehicles

from moving out of the area viewed by the camera before the image is snapped.

2.1.1 (c) Continuous operation considerations

2.1.1 (d) Camera height versus trigger distance considerations

It is critically important, to select the correct distance between the camera and the location on the road

where the camera is triggered to capture an image. Minimizing the cost of installation is usually also an

important concern. This means, that whenever possible, it is best to use existing structures or previously

Preparing for installation

Page 8

VIS CAM 300/400 Installation Manual

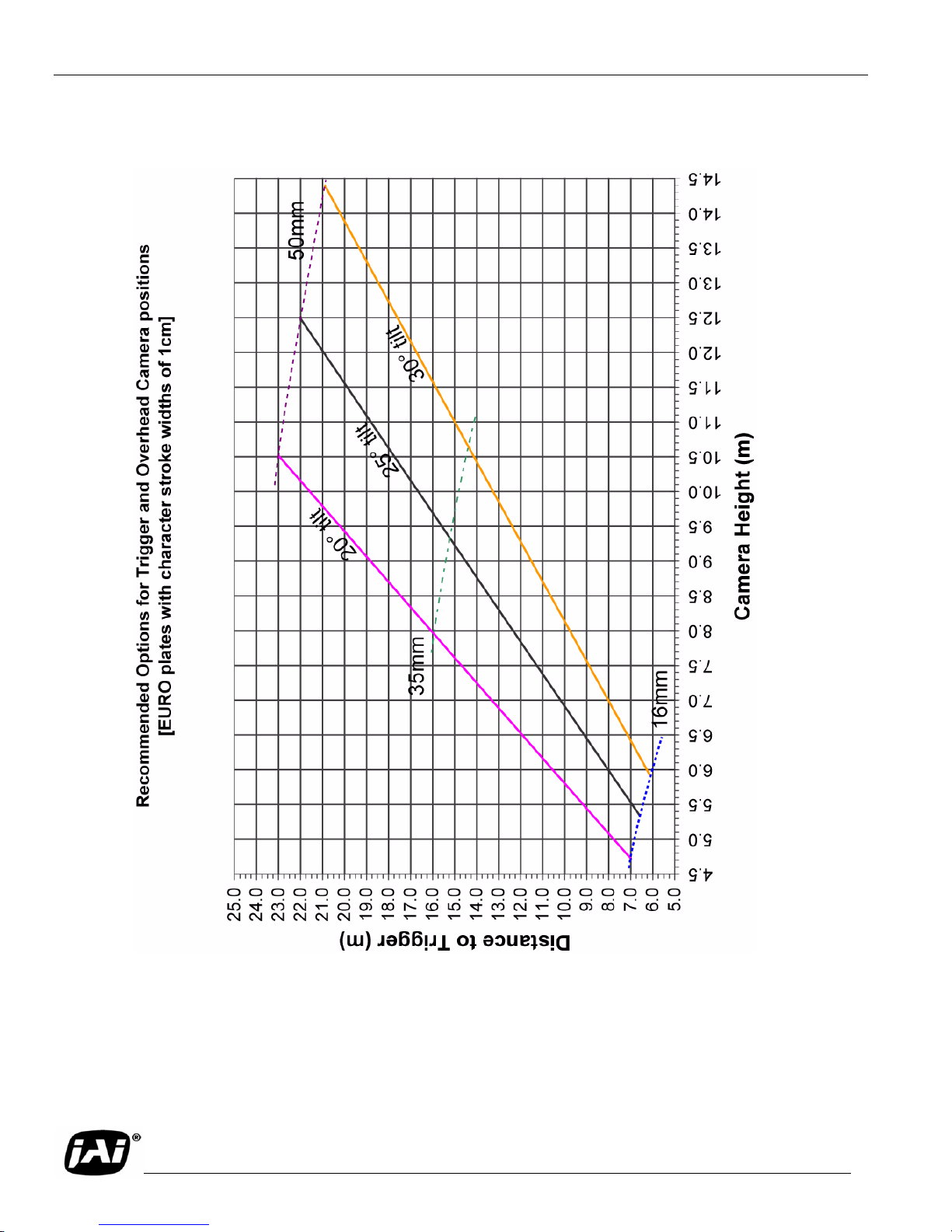

installed elements. The following charts (Figure 5 and Figure 6) provide a wide range of trade-offs

between camera height and trigger distance to enable the installer to select convenient camera and light

sensor locations relative to existing mounting structures and vehicle trigger locations. Adhering to the

installation options provided in the installation charts, yields camera images that are generally suitable

for automatic license plate readers (ALPR).

To use the charts correctly, please follow the steps below.

1. First measure the height above the road to convenient camera mounting locations.

2. Measure the distance along the road from directly beneath each candidate camera position to conve-

nient trigger locations.

3. Select the appropriate installation chart for either USA or European style license plates. To obtain

charts for license plates from other countries, please contact the JAI ITS division directly at (+1)

408 7470 300 – 102.

4. Plot the candidate camera-height / trigger-distance pairs on the chart and determine if the selected

location lies within the wedge of recommended values.

5. If several locations are suitable, choose the one that yields the greatest overall slant range between

camera and trigger location.

The standard VISCAM 300 unit is equipped with a 25 – 75 mm zoom lens. This lens provides the full

range of camera height and trigger distance listed in the installation charts.

Preparing for installation

FIGURE 5. VIS 300 U.S. Camera options chart.

Page 9

VIS CAM 300/400 Installation Manual

Preparing for installation

Page 10

VIS CAM 300/400 Installation Manual

VIS 400 U.S. Camera options chart

Preparing for installation

FIGURE 6. VIS 300 European Camera options chart.

Page 11

VIS CAM 300/400 Installation Manual

Preparing for installation

Page 12

VIS CAM 300/400 Installation Manual

VIS 300 European Camera options chart

Preparing for installation

VIS CAM 300/400 Installation Manual

2.1.2 Side of Road Installation

FIGURE 7. A typical side of road installation.

FIGURE 8. A typical side of road installation plan view with no canopy/overhead

structue.

Page 13

Generally the flash head must be separated from the camera by a radial distance of at least three and a

half feet (1.2 meters).

If the flash is positioned closer to the camera, reflections from the license plate will cause overexposure.

If possible, position the flash head in level with the reference plane shown in Figure 9. This plane is in

level with the top surface of the camera enclosure, but slices through the center of the lens.

Camera to Flash Location Distance

Preparing for installation

Page 14

VIS CAM 300/400 Installation Manual

FIGURE 9. Flash and camera distances.

Preparing for installation

3 Installing the Vehicle Imaging System

The individual components of the system is electrically linked together as shown in Figure 1, “VIS

elements,” on page 2. The VIS CAM 300/400 camera has connections to the J-Panel and an optional

Flash, Night Light and Laser Vehicle Detector. The J-Panel has connection to two VIS CAM 300/400

cameras, one Traffic Light Sensor, a 24V Power Supply, a Lane Controller, a RS485-to-ethernet

converter for the light sensor signals, Trigger input, an optionally second J-Panel and finally a gigabit

Ethernet switch.

3.1 Installing the TNF-300 Traffic Light Sensor.

When installing the Traffic Light Sensor ensure the unit is positioned higher than either the camera or

the flash unit so the A-side is in direct sun whenever the targeted vehicles license plates are. See

Section 2.1 on page 6 for general site layout guidelines.

It is extremely important the light sensor be properly positioned at the site. The light sensor must be

placed so that no shadows from surrounding structures are cast on side A when the license plates being

imaged by the VISCAM are in direct sunlight.

Page 15

VIS CAM 300/400 Installation Manual

Because sun angles at any given site can change according to time of day and time of year, it is

important to verify that the proposed setup will function on the actual spot.

3.1.1 To install the Traffic Light Sensor:

1. Disconnect Power

2. Loosen the four hex screws and remove the flange from the mounting base. See Figure 10.

FIGURE 10. Install the traffic light sensor.

Installing the Vehicle Imaging System

Page 16

VIS CAM 300/400 Installation Manual

FIGURE 11. TLS-300 signal and power cable.

3. Route the Traffic Light Sensor end of the TLS-300 signal and power cable through the mounting

pipe and the flange (see Figure 12)

4. Screw the flange onto the pipe, finger-tight, to allow

subsequent minor adjustment

5. Attach the cable connector to the Traffic Light Sensor

6. Attach the Traffic Light Sensor body to the flange and

secure it with the four Allen screws

7. Orient the Traffic Light Sensor such that the white

reflectors are parallel to the trigger plane with side B

facing (visible from) the trigger plane

8. Route the free end of the cable to the VIS J-Panel in

accordance with the local code requirements

9. Connect the color-coded wires to J-Panel connector X3

as described in “X3, X7 Traffic Light Sensor ” on

page 22. Make sure that no power is applied when performing any wiring operation.

FIGURE 12.Installing the TLS-300 through the mounting pipe and flange.

TABLE 1. Light Sensor Cables

PIN# Wire color Signal

1 White/green Heater gnd

2 Green Heater gnd

3 Red/blue Heater +24V dc

4 Blue/red Heater +24V dc

5- nc

6Yellow +24V dc

7- nc

8- nc

9- nc

10 White Gnd

11 - nc

12 - nc

13 Brown D114 White/brown D1+

15 Orange D016 White/orange D0+

- Black Shlds

Installing the Vehicle Imaging System

VIS CAM 300/400 Installation Manual

3.1.2 Optional Side Mount

1. Attach the pipe clamps approximately 6-inches apart on a vertical

mounting surface as shown in Figure 13.

2. Loosen the four Allen screws and remove the flange from the

mounting base. Figure 10, “Install the traffic light sensor.,” on

page 15.

3. Route the Traffic Light Sensor end of the TLS-300 signal and the

power cable through the pipe and flange.

4. Screw the flange onto the pipe somewhat tightly to allow subse-

quent minor adjustment

5. Place the pipe in the pipe clamps and tighten them to secure the

pipe to the vertical mounting surface.

6. Attach the Traffic Light Sensor body to the flange and secure it

with the four Allen screws.

7. Orient the Traffic Light Sensor such that the white reflectors are

parallel to the trigger plane with side B facing (visible from) the

trigger plane

8. Route the free end of the cable to the VIS J-Panel in accordance

with local code requirements

9. Connect the color-coded wires to the J-Panel connector X3 as

described in Section 3.3 on page 21. Make sure that no power is

applied when performing any wiring operation.

Page 17

3.2 Installing the Camera(s)

In general, the camera(s) should be aimed at the most likely cross-lane position of the vehicle license

plates. See “Installation Preparation” on page 6 for general site layout guidelines. To install the

camera(s):

1. Attach the camera mount to the camera enclosure using the included mounting bolts and washers.

Refer to Figure 14.

FIGURE 14. Camera Installation

FIGURE 13. Pipe clamps should be about

6-inches apart on a vertical surface.

Approximate weight 6.6 kg

Measurements include the extended sun shield

Installing the Vehicle Imaging System

Page 18

VIS CAM 300/400 Installation Manual

2. Align the camera enclosure mounting surface with the hole pattern of the camera mount and secure

it to the camera mount with the five provided ¼-20 hex bolts.

3. Attach the camera, with mount, to the mounting structure. The hole pattern is shown in Figure 15

below

FIGURE 15. Camera mount template.

4. Route the camera end of the camera cable according to the camera IAW local electrical code

requirements

5. The jacket is removed from the cable in the camera end and the wires are stripped as shown in the

Figure 16 below. There are two sets of four twisted pairs. Four of the pairs are for ethernet signals.

These pairs are individually foil shielded and have a common braid shield. The other four pairs are

individually foil shielded without the common braid shield. The shield on the Ethernet pairs must

be run as close to the connector as possible. All wires must be stripped for insulation app. 7mm.

FIGURE 16. Camera cabling as it appears before electrical installation.

6. The cable is separated into the Ethernet part (with the braid shield) and the power and control part

(the rest). Each part is fastened with cable ties to the respective cable relief’s on the terminal block

X4 on the VIS-CAM I/O Board.

Installing the Vehicle Imaging System

FIGURE 17. Cable final wiring.

Page 19

VIS CAM 300/400 Installation Manual

7. The wires are inserted into X4 as shown in Table 2 and Figure 18. A mounting tool for releasing

the spring enabling insertion of the wire is enclosed together with the connectors. (Mounting the

wires can be eased by separating the terminal block in the middle – just “break” it into two blocks

of eight terminals – and then re-join it when the wires are mounted)

TABLE 2. Electrical wiring for the VIS CAM installation.

X4 Pin # Wire Color Signal Remarks

1 White/orange in Cat5e/6 cable Ethernet A+

2 Orange in Cat5e/6 cable Ethernet A3 White/green in Cat5e/6 cable Ethernet B+

4 Green in Cat5e/6 cable Ethernet B5 White/blue in Cat5e/6 cable Ethernet C+ not used with

VIS CAM

6 Blue in Cat5e/6 cable Ethernet C- not used with

VIS CAM

7 White/brown in Cat5e/6 cable Ethernet D+ not used with

VIS CAM

8 Brown in Cat5e/6 cable Ethernet D- not used with

VIS CAM

9 Black Gnd

10 Red +24V dc

11 Black Vinit+ Trigger signal

12 Pink Vinit- Trigger signal

13 Black RS485D+ Lane Controller

14 Brown RS485D- Lane Controller

15 Black RS485D+ Lane Controller

16 Orange RS485D- Lane Controller

Installing the Vehicle Imaging System

Page 20

VIS CAM 300/400 Installation Manual

FIGURE 18. Properly wired X-4 connector.

8. The cable is mounted in the cable entry on the back side of the camera as shown in the Figure 19

below. The rubber bushing is mounted around the jacket and the metal brace is mounted around the

shield securing proper electrical connection from the shield to the metal housing (se figure

Figure 19).

FIGURE 19. Back of the video camera.

For a detailed description of the VIS CAM 300/400 interface please refer to See “ Appendix A: Camera

Functional and Connector Description” on page 43 in this manual:.

Installing the Vehicle Imaging System

VIS CAM 300/400 Installation Manual

3.3 Installing the J-Panel

The J-panel layout is shown in Appendix A, See “Connection requirements.” on page 43. This

Appendix has a detailed description of the J-Panel function and connectors.

3.3.1 X1 and X2 VIS CAM 300/400

The VIS CAM connections to the J-Panel are shown in Table 3 and Figure 20

TABLE 3. VIS CAM connections to the J-Panel.

X1, X2 Pin # Wire Color Signal Remarks

1 White/orange in Cat5e/6 cable Ethernet A+

2 Orange in Cat5e/6 cable Ethernet A3 White/green in Cat5e/6 cable Ethernet B+

4 Green in Cat5e/6 cable Ethernet B5 White/blue in Cat5e/6 cable Ethernet C+

6 Blue in Cat5e/6 cable Ethernet C7 White/brown in Cat5e/6 cable Ethernet D+

8 Brown in Cat5e/6 cable Ethernet D-

9 Black wire in Red/Black pair Gnd

10 Red wire in Red/Black pair +24V dc

11

12

White wire in Brown/White

pair

Brown wire in Brown/White

pair

Vinit+ Trigger signal

Vinit- Trigger signal

13 White wire in Red/White pair RS485D+ Lane Controller

14 Red wire in Red/White pair RS485D- Lane Controller

15

16

White wire in Orange/White

pair

Orange wire in Orange/White

pair

RS485D+ Lane Controller

RS485D- Lane Controller

not used with VIS CAM

not used with VIS CAM

not used with VIS CAM

not used with VIS CAM

Page 21

Installing the Vehicle Imaging System

Page 22

VIS CAM 300/400 Installation Manual

FIGURE 20. VIS CAM connections.

3.3.2 X3, X7 Traffic Light Sensor

The Traffic Light Sensor TLS-300 connection to the J-Panel is shown in Table 4 and Figure 21.

TABLE 4. TLS 300 to J-Panel connections.

X3 Pin X Signal Description Connection to Light Sensor Cable wire color

1 +24V dc Power output Yellow

2 Gnd Power return White

3 D0+ RS485 databus D0+ White/orange

4 D0- RS485 databus D0- Orange

5 D1+ RS485 databus D1+ White/brown

6 D1- RS485 databus D1- Brown

X7 Pin X

1 Heater +24V dc Power output Red/blue and Blue/red

2 Heater gnd Power return White/green and Green

Installing the Vehicle Imaging System

FIGURE 21. TLS 300 to J-Panel wiring.

Page 23

VIS CAM 300/400 Installation Manual

Installing the Vehicle Imaging System

Page 24

VIS CAM 300/400 Installation Manual

3.3.3 X6 Power Input Connector

The Power Input connection to the J-Panel is shown in Table 5 and Figure 22

The maximum power to a J-Panel is

Camera #0 2.0A

Camera #1 2.0A

Traffic Light Sensor 2.0A

RS485-to-Ethernet conv

0.3A

Tot al 6.3A

TABLE 5. Power input to the J-Panel

X6 Pin # Signal Description Connection to

1 +24V +24V dc 24V DC power supply + output

2 GND +24V return 24V DC power supply return

FIGURE 22. X-6 Power input connection.

Installing the Vehicle Imaging System

VIS CAM 300/400 Installation Manual

3.3.4 X8 LS RS485 Out Connector

The RS485 output from the Light Sensor to the RS485-to-Ethernet converter connector is X8. The

connections from X8 to the converter are shown in Table 6 and Figure 23

TABLE 6. X8 to converter connector

X8 Pin # Signal Description Connection to RS485-to-Ethernet converter

1

+24V

dc

2 Gnd Power return V- power input

3

+12V

dc

4Gnd

5 D0+ RS485 databus D0+ D+ Port 2

6 D0- RS485 databus D0- D- Port 2

7 D1+ RS485 databus D1+ D+ Port 1

8 D1- RS485 databus D1- D- Port 1

24V Power output

12V Power output

Power return

V+ power input

Page 25

FIGURE 23. Wiring for the X8 to converter connector.

Up to four cameras can be connected to one Light Sensor using one Moxa Nport 5232 Device Server. If

more than four cameras need to be connected to the same Light Sensor please refer to “Appendix E:

Moxa N-Port 5232 Configuration” on page 93 in this Manual.

Installing the Vehicle Imaging System

Page 26

VIS CAM 300/400 Installation Manual

3.3.5 X14 Trigger Input Connector

The Trigger input connection to the J-Panel is connector X14. The connections are listed in Table 7

TABLE 7. Trigger input connector.

X14 Pin # Signal Description Connection to

1 Trig0+ Positive Trigger input to camera 0 Trigger device positive terminal

2 Trig0- Negative Trigger input to camera 0 Trigger device negative terminal

3 Trig1+ Positive Trigger input to camera 1 Trigger device positive terminal

4 Trig1- Negative Trigger input to camera 1 Trigger device negative terminal

3.3.5 (a) Trigger polarity

The switches S3 and S5 sets the trigger polarity:

If the trigger signal is normally low

(no voltage at trigger input) the switch shall be in position

Arrow up - positive going

If the trigger signal is normally high

(voltage at trigger input) the switch shall be in position

Arrow down – negative going

As a guideline the two LEDs marked TRIG-0 and TRIG-1 shall be off when no trigger pulse is present.

3.3.5 (b) Test Trigger

Activating switches S1 and S4 generates a trigger pulse for test purposes. Only one trigger pulse is

generated each time the switch is activated.

The duration of the trigger pulse is approximately 4 ms.

The trigger indicator LEDs flash when the test trigger switch is activated.

FIGURE 24. Te s t tri g g e r

Installing the Vehicle Imaging System

Page 27

VIS CAM 300/400 Installation Manual

3.3.6 X15 Lane Controller Connector (X4 and X5)

The Lane Controller connection to the J-Panel is connector X15. The connections are listed in Table 8 .

TABLE 8. X15 Lane Controller

X15 Pin # Signal Description Connection to

1 D0+ RS485 databus D0+ Lane Controller databus 0+

2 D0- RS485 databus D0- Lane Controller databus 0-

3 Gnd gnd gnd

4 D1+ RS485 databus D1+ Lane Controller databus 1+

5 D1- RS485 databus D1- Lane Controller databus 1-

It is possible to have one Lane Controller connected to several cameras or one Lane Controller to each

camera:

One Lane Controller for two or more cameras

1. The Lane Controller is connected to the X15 pin 1 and 2 (no connections to pin 4 and 5)

2. Switch S2 position “OPEN”

3. The Lane Controller can be connected to more J-Panels by connecting RJ45 patch cables between

connector X4 and connector X5 on the next J-Panel (and from X4 on the next J-Panel to X5 on the

third J-Panel). Switch S2 on the other J-Panels must also be in the “OPEN” position.

Two Lane Controller to two cameras

1. The Lane Controller for camera 0 is connected to X15 pin 1 and 2

2. The Lane Controller for camera 1 is connected to X15 pin 4 and 5

3. Switch S2 position “TERM”

4. Do not connect any cables to X4 and X5

FIGURE 25. Two lane controller.

Installing the Vehicle Imaging System

Page 28

VIS CAM 300/400 Installation Manual

3.4 Illumination Options

3.4.1 Installing the TNF-31 Flash

The connection to the Flash unit in the VIS CAM 300 is shown in Table 9 and Figure 26.

FIGURE 26. TNF-31 flash unit

TABLE 9. Flash unit connection in VIS CAM 400.

Pin Signal Description Connection to

1 I/O Gnd IO Board Gnd Pin 2 when no power is available from the flash

2 Gnd Flash Gnd Flash ground (negative power terminal)

3 Out Strobe out Strobe input on flash unit

4 Stat Strobe status Status output from flash unit

5 FPWR Flash power Power from flash to output circuit on I/O Board

624V

IO board 24V (Fused

0.5A)

1 2 3 4 5 6

Pin 5 when no power is available from the flash

The cable from the flash unit is connected to the VIS CAM 300 I/O Board as shown in figure 3.17 and

3.18. There are two examples shown: one where the output circuit on the I/O Board is powered from the

flash unit and one where the output circuit is powered from the I/O Board.

It is recommended that I/O Board output circuit be powered from the flash unit in order to obtain

galvanic isolation between the to units. In cases where this is not possible (such as when using mains

supplied flash units) power is taken from the I/O Board.

The cable must be shielded and the shield connected to the metal at the cable entry in the camera house.

The switch labelled S3 on the VIS CAM 300 I/O Board must be in position “NIGHT L” (away from

connector X5 as shown below).

FIGURE 27. S3 switch setting

Installing the Vehicle Imaging System

Page 29

VIS CAM 300/400 Installation Manual

Figure 28 shows how to connect to an AC powered Flash unit with the I/O Board interface electronics

internally powered by the I/O Board. The Flash AC power connection is not shown.

FIGURE 28. Connecting an AC flash.

Other Flash connection examples are found in “ Appendix A: Camera Functional and Connector

Description” on page 43.

The VIS CAM 300 has an interface for two flashes. When this option is selected (S3 position “FLASH

2”) and the other flash is connected to connector X6, the two flashes fire alternately. Please refer to “

Appendix B: J-Panel Functional and Connector Description” on page 67 for details.

Installing the Vehicle Imaging System

Page 30

VIS CAM 300/400 Installation Manual

3.5 Trigger Options

3.5.1 Installing The Laser Vehicle Detector

The connection from the Laser Vehicle Detector to the VIS CAM 300 is shown in Figure 29 and

Table 1 0

FIGURE 29. Connection for LVD to VIS CAM 400.

1 2 3 4 5 6 7 8

TABLE 10. Wiring for LVD to VIS CAM 400.

X7 Pin # Signal Description Connection to

1 24V (Fused 0.5A) Power to laser Laser power input

2 Gnd Power gnd Laser ground

3 Trigger Trigger from laser Trigger out on laser

4 RS485- Transmit to laser Receive input on laser

5 RS485+ Receive from laser Transmit output on laser

6 Gnd Communication gnd Communication gnd on laser

7 nc No connection 8 nc No connection -

The cable must be shielded and the shield connected to the metal at the cable entry in the camera house.

The switch S3 and/or S5 on the J-panel must be in position “positive going” (pushed towards X1/X2) to

enable the laser trigger input on the IO Board.

Installing the Vehicle Imaging System

4 System Set-Up

This section provides a generic procedure for aligning one or more VIS CAM 300/400 cameras and

their associated equipment at a site. If you received a specific installation manual from JAI for your

project then follow those instructions instead of the procedure described here.

The example installation process described in this section assumes that:

• The cameras are being mounted on an overhead structure directly over the lane(s) being observed.

The process for aligning a camera mounted at the side of a lane is essentially the same as aligning a

single camera mounted directly over the lane.

• The site employs an accurate vehicle detection device that outputs a discrete TTL signal to the VIS

system whenever the back (or front) of a vehicle crosses a fixed line across the road. This line is

referred to as the “trigger line” in this document. Examples of such triggering devices are: Peak’s

trafficLoop, STI’s Vehicle Detector light curtain, and JAI’s Laser Vehicle Detector.

• License plate reading or vehicle matching is performed on the images produced by the VIS system.

In these cases, precise location and alignment of the cameras is critical to project success. If the

VIS images are only for human interpretation, then achieving the exact camera alignment is much

less critical.

• The installer is familiar with using the ENSetup program supplied by JAI. Please refer to the

ENSetup Program User’s Guide if you are unfamiliar with this software. JAI offers engineering

support and software tools to help select the optimum camera and trigger locations to meet your

specific project needs. Contact ITS Engineering Support at (408) 383-0300 for further information

about obtaining JAI assistance.

Page 31

VIS CAM 300/400 Installation Manual

4.1 Preparation for Alignment

4.1.1 Pre-Alignment Checklist

Make sure you have a JAI supplied setup computer with the ENSetup program installed.

•

• The Setup computer needs to have an Ethernet network adapter installed (preferably 1 Gigabit

Ethernet Adapter) and the TCP/IP network configured with the correct IP-address, subnet-mask

and default-gateway.

• The Setup computer and the cameras need to be on the same subnet. The cameras are shipped with

the standard IP-address “10.0.0.65” and subnet-address “255.255.255.0”, and the Setup computer

needs to be assigned an IP-address “10.0.0.xx” in order to automatically discover the cameras

using the ENSetup program (NB! “xx” must not be “65”).

• All cameras have to be given unique IP-addresses before the alignment begins. This is done using

the ENSetup application.

• Confirm all VIS CAM components and cables are properly connected.

System Set-Up

Page 32

VIS CAM 300/400 Installation Manual

4.1.2 Select a Suitable Vehicle, License Plate, and Plate Stand for the Setup

To accurately set up the Vehicle Imaging Subsystem, the system installers need access to:

1. A vehicle that can be temporarily parked on the road

2. A plate that is:

a. typical in size and color for the site

b. clean, flat and in “like new” condition

3. An adjustable plate stand that allows the plate to be mounted in a vertical plane, at various heights

above the road, and at variable roll angles. The stand must allow the plate to be placed at both the

nominal plate height and the minimum expected plate height. The stand must also allow the plate to

be rolled at least + or – 10 degrees from horizontal but held firmly in place once a specific roll angle

is selected. The stand should be heavy enough so that the wind will not blow it over or move it.

TABLE 11. Typical minimum plate heights and nominal plate heights:

Plate Height Front of Vehicle Back of Vehicle

minimum (bottom edge) 8in or 20cm 15in or 38cm

nominal (middle) 16in or 40cm 24in or 60cm

4.1.3 Select the Camera to Align

If the site employs a single camera per lane, then you can choose any lane to start the alignment

•

procedure.

• If the site employs multiple cameras regularly spaced across a roadway to provide continuous field-

of-view coverage from edge to edge, select one of the cameras at either edge of the roadway to be

the first camera to align.

• Align all remaining cameras in order from the first camera aligned to the last camera at the other

side of the roadway. The next camera aligned is always the one adjacent to the camera most

recently aligned.

4.1.4 Validate the Installation Geometry

The VIS cameras and vehicle trigger line should have been installed at the locations agreed to by you

and JAI. Typically JAI utilizes a specially developed Excel worksheet to confirm the suitability of the

equipment placement at the site from an image processing perspective. See Figure for an example

worksheet. However, equipment is often not located where the worksheet specifies. It is therefore

imperative that the actual equipment layout at any given site be measured to verify that the cameras and

trigger are located at the desired locations relative to each other. If necessary, move the camera/trigger

positions until the distances required in the worksheet are met. If it is not possible to move the

equipment to the required locations, then the impact of any changes to the subsequent image processing

must be assessed. Enter the actual camera locations into the Input section of the JAI worksheet and then

note the changes in the Results section. If there are any questions about the suitability of a specific

camera/trigger layout, contact your JAI representative for advice.

System Set-Up

Page 33

VIS CAM 300/400 Installation Manual

4.1.5 Edit the alignment settings on the Setup Computer

In order to carry out the alignment properly, the ENSetup program has to be configured with two values

from the worksheet. See the ENSetup Program User’s Guide (Video Window Setup section) for details

on changing Video Window properties.

Using the ENSetup program, make sure the “tilt line” and “plate num cols” items on your Portable

Setup computer are exactly the same as the measurements, including the proper plate size parameters

measured in Section 4.1.4, “Validate the Installation Geometry,” on page 32. All other camera settings