Page 1

TM/RM-1327GE Series

Digital Monochrome/Color

Progressive Scan, Interline-Transfer Gigabit Ethernet Camera

Document Version: E

Document P/N: 10164

Page 2

Page 3

TM/ RM -1327GE Series

Notice

The material contained in this manual consists of information that is proprietary to JAI, Inc., and

may only be used by the purchasers of the product. JAI, Inc. makes no warranty for the use of its

product and assumes no responsibility for any errors which may appear or for damages resulting

from the use of the information contained herein. JAI, Inc. reserves the right to make changes

without notice.

Microsoft, Windows XP, Windows 2000, Windows 98, Windows NT, and Windows Explorer are either

registered trademarks or trademarks of Microsoft Corporation in the United States and/or other

countries.

Warranty

For information about the warranty, please contact your factory representative.

Certifications

CE Compliance

The TM-1327GE series of cameras have been certified to conform to the requirements of Council

Directive 89/336/EC for electromagnetic compatibility and to comply with the following European

Standards:

Emissions: EN 55022A: 1998 + A1: 2000 + A2: 2003

Immunity: EN55024: 1998 + A1: 2001 + A2: 2003

All JAI products bearing the CE mark have been declared to be in conformance with the applicable

EEC Council Directives. However, certain factory-installed options or customer-requested

modifications may compromise electromagnetic compatibility and affect CE compliance. Please

note that the use of interconnect cables that are not properly grounded and shielded may affect CE

compliance.

Contact JAI Applications Engineering Department for further information regarding CE compliance.

FCC

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area may cause harmful interference, in which case the

user will be required to correct the interference at his own expense.

Notice iii

Page 4

TM/ RM-1327GE Series

WARNING

Changes or modifications to this unit not expressly approved by the party responsible for FCC

compliance could void the user’s authority to operate the equipment.

TM-1327GE Series Operation Manual

JAI, Inc.

625 River Oaks Parkway

San Jose, CA 95134

Tel:(408) 383-0300

Tel:(800) 445-5444 (toll-free)

Fax:(408) 383-0301

E-mail: camerasales.americas@jai.com

www.jai.com

iv Notice

Page 5

TM/ RM -1327GE Series

February 12, 2008

Notice v

Page 6

TM/ RM-1327GE Series

Table of Contents

Disclaimer Notice....................................................................................................iii

Table of Contents ....................................................................................................v

List of Figures ....................................................................................................... vii

List of Tables.........................................................................................................ix

vi Table of Contents

Page 7

TM/ RM -1327GE Series

List of Figures

List of Figures vii

Page 8

TM/ RM-1327GE Series

viii List of Figures

Page 9

TM/ RM -1327GE Series

List of Tables

List of Tables ix

Page 10

TM/ RM-1327GE Series

x List of Tables

Page 11

TM/ RM -1327GE Series

1.TM-1327GE Software

1 Software Introduction

1.1 Scope of the Document

This manual describes how to access and use features specific to JAI's Gigabit Ethernet camera, the

TM-1327GE. The camera’s different operation modes are described in the hardware section of this

manual, which begins on page 29.

The TM-1327GE series consists of the TM-1327GE (monochrome) and the TMC-1327GE (color). Unless

otherwise noted, all information contained in this manual is relevant to both models.

1.2 Related Documents

The appendix contains descriptions of the TM-1327GE camera’s internal frame grabber and how to

connect the camera. The appendix complements, and should be used in conjunction with the three

following documents:

Operation Manual

• Cam2Net User’s Manual

• Cam2Net IP Device Drivers

• Cam2Net C++ SDK Reference Manual

These documents are part of the GigE software package and are added to your system when the

software is installed.

1.3 Gigabit Ethernet Camera Interface

The GigE interface provides an easily connectable, high-bandwidth imaging solution, where video

data is sent as IP packets over an industry-standard GigE network.

Point-to-point (unswitched) transmission is up to 100 meters. With Gigabit Ethernet switches, the

transmission distance is virtually unlimited.

Note: Refer to the section on time-outs and packets in the Cam2Net User’s Manual for more

information on packet sizes for point-to-point and networked applications.

Communication with a GigE camera is completely user transparent, so if you usually work with

Camera Link® or the JAI Cam2Net adapter, you will find it very easy to migrate.

The TM-1327GE camera has internal frame memory, which sends only the actual image data using

the Gigabit Ethernet interface.

At the PC, the Cam2Net Software Development Kit (SDK) provides a communications interface that

maps the RS-232 command channel through the IP link. All commands sent to and received from the

camera are transparently routed to/from the host PC using the GigE link.

Software Operation 11

Page 12

Refer to the Cam2Net User’s Manual for details about network requirements, compatibility, and so

on.

1.4 Software Installation

The following instructions explain how to install the JAI GigE camera-control software on a PC.

1.4.1 Before Installing the GigE Series Camera-Control Software

Before installing the JAI GigE camera-control software, please note the following requirements.

• Your computer must have a Pentium processor running at least 1.4GHZ, and its operating

system must be either Microsoft Windows XP Pro or Windows 2000.

• Installation of the software requires approximately 75 MB of free space in your PC hard disk.

1.4.2 Installing the Software

To install the JAI GigE camera-control software, read and follow the directions included in the

document download card. If your computer does not have Internet access, call JAI at 1 800 445 5444

to request that the software be sent to you on a CD-ROM.

Install the software using the following steps:

1. Open the folder “JAI” and run the IPEngineSDK.exe file to install the Camera Interface

Application.

2. Open the folder “GigE_Software” and run the setup.bat file. This installs the GigE camera

software as part of the Camera Interface Application. It copies the file cycampulnix.dll to the

folder C:\Program Files\JAI\Cam2Net\Binaries.

TM/ RM-1327GE Series

3. The program initiates a driver scan. Allow the network card driver installation at this time. (If

you cancel the installation for some reason this dialog box can be accessed at a later time; go

to “Start” --> “Programs” --> “JAI AS” --> “Launch Driver Installation Tool” to launch the driver

install).

4. A driver installation tool dialog box displays. Read the message about canceling found new

devices and then click “OK”.

Figure 1. Scanning for Drivers

[screen shot]

5. The Driver Installation Tool dialog box appears with a listing of all NIC cards on the system.

6. Right click on the net driver desired for the camera. If the driver is an Intel Pro a high

performance option is available for install.

Figure 2. Intel Pro Install Choices

[screen shot]

7. Right click on the net driver desired for the camera.

8. Select the desired driver install “Install High Performance IP Device Driver” or “Install Intel

Network Driver”. The network installation options vary, based on the NIC card installed on the

system. A dialog box asks for verification of the selected install. Click “Yes”. Follow the

instructions on any additional dialog boxes.

12 Software Operation

Page 13

TM/ RM -1327GE Series

9. For information on other network card installs click “Start”-->”JAI A.S”-->”Cam2Net”--

>”Documentation”-->” Cam2Net IP Device Drivers”. An Acrobat file has instruction to help

guide you through the proper install.

10. Go to “Start” --> “Programs” --> “JAI AS” --> “Cam2Net” --> “Launch Coyote application”

to launch the camera control tool.

1.4.3 Uninstalling the Software

To uninstall the JAI GigE camera-control software from the control panel, use the following steps:

1. Open “Add or Remove Programs” in the control panel.

2. Select “JAI Cam2Net” from the lists of the installed software.

3. Click the “Change or Remove” button as shown in Figure 3.

Figure 3. Change and Remove Buttons

[screen shot]

1.4.4 Quick-Start

Use the following quick-start process when the Camera Interface Application is installed on your PC.

1. Connect the camera. The Hirose pin layout is shown in Table 1 on page 6. Both the Hirose and

the network cable (RJ-45) are illustrated in Figure 6.

2. Run the Camera Interface Application.

3. Click “Detect.” Assign a suitable IP address to the camera. The window shown in Figure 4

appears.

Figure 4. Network Device Finder Window

[screen shot]

4. Select the appropriate camera from the list, similar to the window shown in Figure 5 and click

OK.

Figure 5. Select Camera Window

[screen shot]

5. Go to the “Acquisition” tab and click Start. An image stream should appear.

6. Click Configure and open the “GigE Camera Software” dialog box. This is your integrated

control software.

Note: the color version (TMC-1327GE) requires color interpolation to be performed in the frame

grabber or by using the host computer’s CPU. In default mode, the camera supports 2 x 2 color

interpolation. For better color performance, the user can select 3 x 3 interpolation in the

Camera Interface Application. Go to the “Acquisition” tab and click Configure. In the

Software Operation 13

Page 14

TM/ RM-1327GE Series

Advanced Configuration Window, select the “Pixel Type” tab. Make sure the camera is set to

the proper color space and pixel depth, then click the check-box labeled “Use 3 x 3 Bayer

Interpolation” in the “Conversion Options” panel. More information on color interpolation and

the color filter array (CFA) can be found in Section 8.2 beginning on page 38 of this manual.

14 Software Operation

Page 15

TM/ RM -1327GE Series

2 Connectors

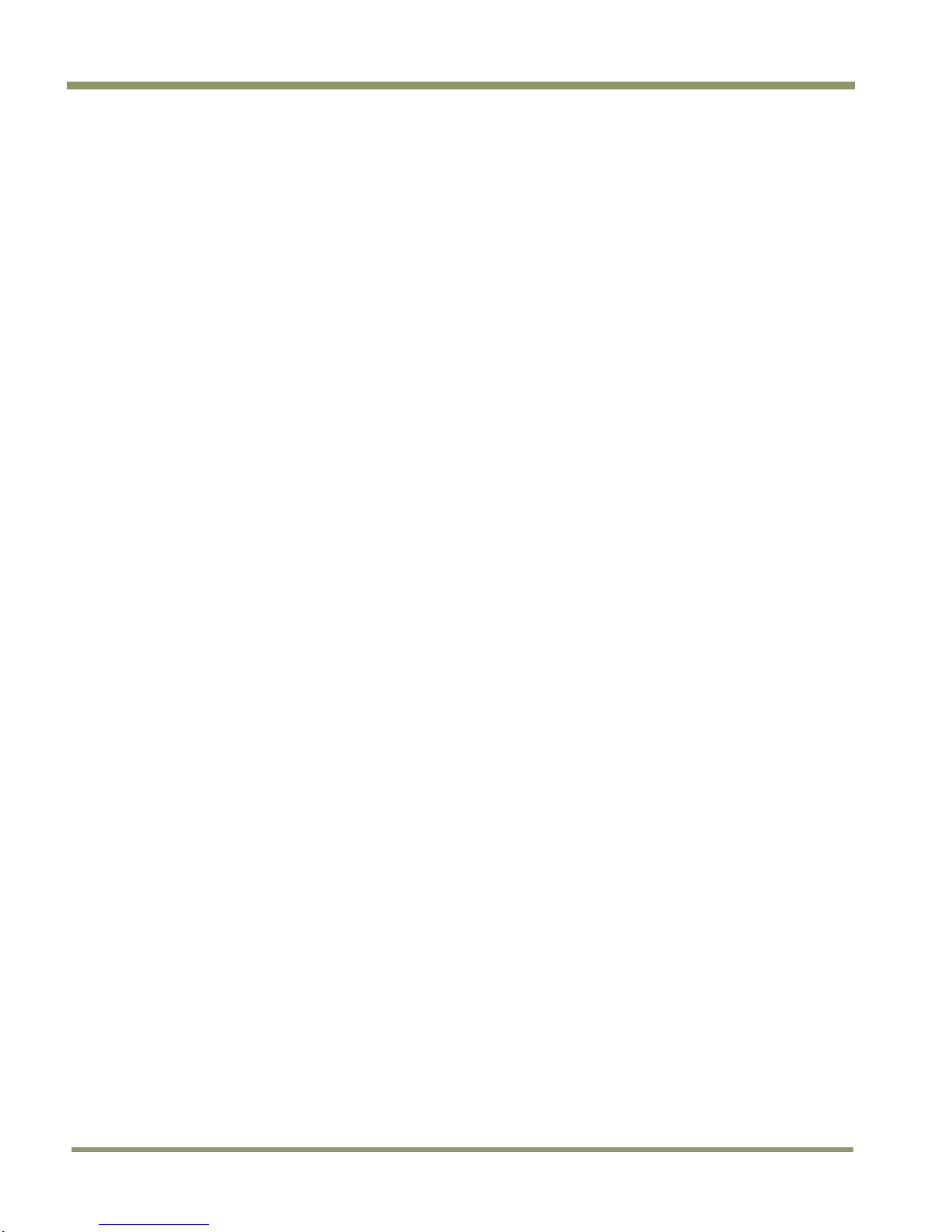

The camera has two sockets, as shown in Figure 6 below:

• 12-pin Hirose for power, trigger, RS-232 communication and TTL I/O.

• RJ-45 for Gigabit Ethernet.

Figure 6. TM-1327GE Back Panel Connectors

These connectors are described in Section 2.1 and Section 2.2 below.

2.1 Power and Signals Connector

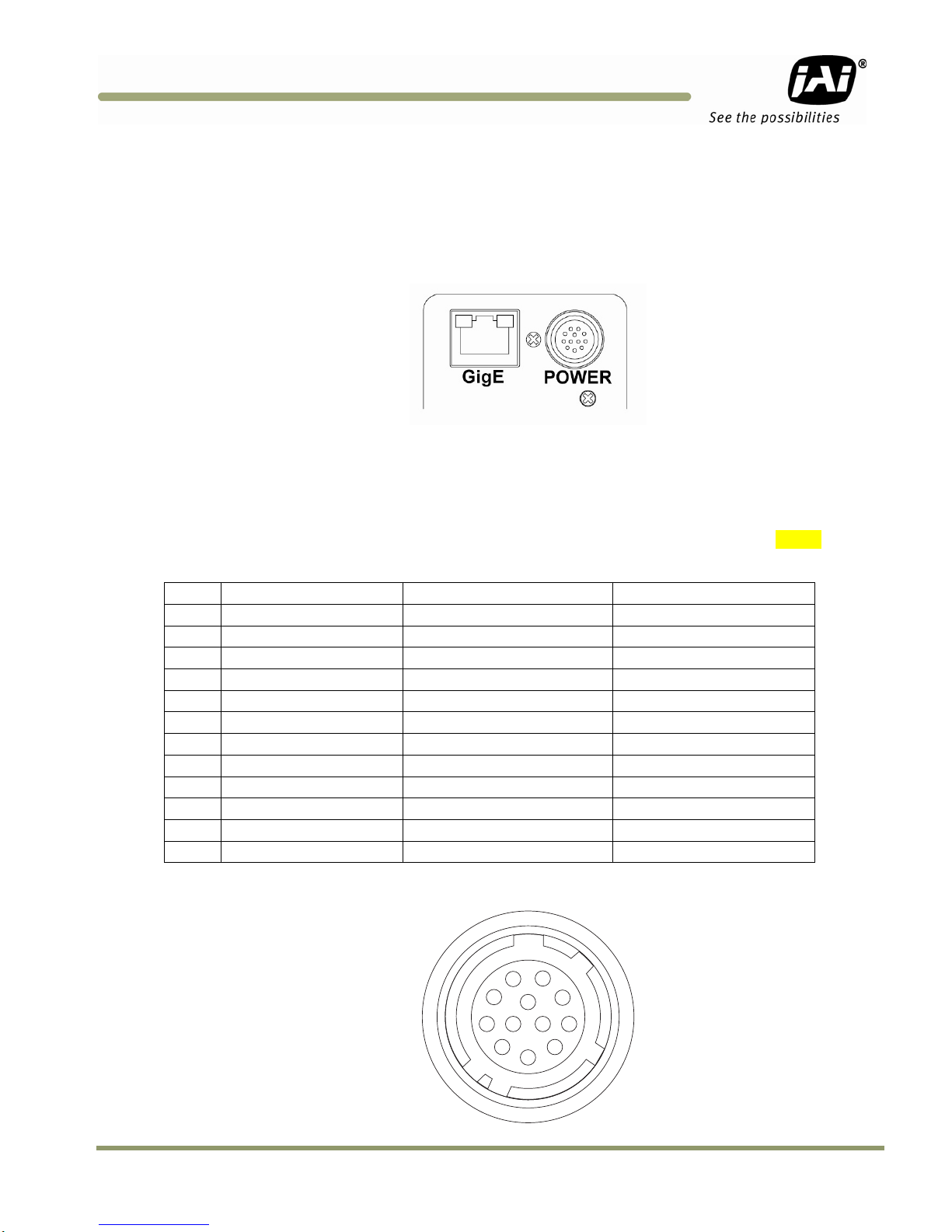

The GE camera receives power and signal through a 12-pin Hirose connector. Table 1 below lists the

pin layout and describes the function of each pin. The table lists the GPIO assignments for the

relevant pins. A magnified illustration of each pin’s assignment follows in Figure 7 on page 7.

Table 1 Hirose Connector, Pin Assignment

Pin # Definition Description GPIO Assignment

1 GND Power ground

2 +12V Power supply in

3 AGND Analog ground (video)

4 VIDEO Video out

5 GND Ground (TTL) - Digital

6 TTL IN (EXT_TRIG) VINIT in (CC1 equivalent) I0

7 TTL IN (EXT_VD) HD in (CC4 equivalent) I1 (can bypass GPIO LUT)

8 TTL OUT (STROBE) Strobe output Q0

9 TTL IN (EXT_HD) VD in (CC3 equivalent) I2 (can bypass GPIO LUT)

10 RESV Reserved

11 TTL IN (INTG_CON) Reserved I3

12 RESV Reserved

Figure 7. HR10A-10R-12P

9

1

2

11

3

4

10

5

8

12 7

6

Connectors 15

Page 16

2.2 Ethernet

TM/ RM-1327GE Series

The GigE socket, marked on the camera’s back panel as “GigE,” is a standard RJ-45 Ethernet socket.

Use at least cat5e UTP cables (Cat6 cables are preferred). If you wish to connect the camera

directly to a PC, you must use a cross-over cable. Refer to the Cam2Net User's Manual for details.

Figure 8. Ethernet GigE Socket

1

GigE

1

JAI recommends the use of shielded cables to reduce emissions and for CE/FCC compliance. Double-shielded cables will

further reduce emissions.

16 Connectors

Page 17

TM/ RM -1327GE Series

3 Configuring the TM-1327GE Camera

The configuration of your GigE camera consists of two parts:

• The imager configuration (CCD and control circuits)

• The internal frame grabber configuration

The imager can be configured for partial scan, binning, etc., just like a Camera Link camera. The

internal frame grabber is automatically configured for the pixel type, windowing, image size and I/O

and so on, by the GigE camera software.

3.1 Setup

If you have a peer-to-peer connection between the TM-1327GE camera and your PC without network

switches, your packet size can be the default value (8128 bytes) as shown in Figure 9. However, if

you are connecting the TM-1327GE to your PC through a network switch, then you need to know

maximum packet size that your network switch supports. Typically, if your switch supports jumbo

packets, then you should keep the packet size to 8128 bytes. If your switch does not support jumbo

packets, then you may need to change the packet size to 1440 bytes.

Figure 9. Camera Interface Application Dialog Box

[screen shot]

To use the integrated GigE camera software, use the following steps:

1. Start the Camera Interface Application. The dialog box shown in Figure 9 appears.

2. Click the Detect to detect the device and driver in the “Device Actions” panel.

3. Click Select Camera and select TM-1327GE or TMC-1327GE (color) from the camera list.

4. Select the “Acquisition” tab and click Configure. The camera configuration dialog box appears.

5. Select the “GigE Camera Software” tab. This is the Integrated GigE Camera Software shown in

Figure 11 on next page.

The TM-1327GE camera can operate in either 8-bit or 10-bit digital output mode. The 8-bit/10-bit

selection is possible through the GigE integrated software. To select the mode, open the Configure

page and select the Pixel Type tab as shown in Figure 10. Under Pixel Type, select either Grayscale

8, or Grayscale 10. Note that when Grayscale 10, 2 taps is selected, the LUT (Look-Up Table) is not

available in this mode.

Figure 10. Advanced Configuration Window

[screen shot]

3.2 Configuring the Imager

To configure the TM-1327GE’s imager, use the integrated GigE camera software that is part of the

Cam2Net camera interface application. You can also use the AccuPiXEL GigE control tool, but that

will not update any internal grabber settings. “Hardware Introduction” on page 29 of this manual

contains a description of the different image settings of the camera.

Configuring the Camera 17

Page 18

TM/ RM-1327GE Series

Figure 11. Integrated GigE Camera Software

3.2.1 GUI Features

You can control the following camera functions using the integrated camera software:

• Shutter Speed and Mode

• Scan Mode

• Gain Control

• Offset Level

• Memory Pages

• LUT (Look-Up Table) Control

3.3 Configuring the Internal Frame Grabber

The integrated camera software updates the internal frame grabber settings automatically. In

addition, because the internal frame grabber configuration is independent of the imager

configuration, you can set up (that is, “window”) the internal frame grabber separately, for

example, the Image Settings tab in the integrated camera software. This has the added benefit of

reducing unnecessary traffic on the GigE network, therefore freeing bandwidth for other cameras.

[screen shot]

3.4 Modes

This section includes several examples of setup actions available through the camera configuration

dialog box. Note that items 3.4.2 through 3.4.8 are all found under the GigE Camera Software tab of

the configuration dialog, as previously shown in Figure 11.

3.4.1 Check the Current Camera Setting

You can manually send camera commands from the “Port Communication” tabbed dialog shown in

Figure 12. Use the serial port and click the “CR” check box. Enter :RPST and click Send to get the

current camera setting. For detailed information about the current camera setting, refer to Table 4

on page 24.

Figure 12. Advanced Configuration - Port Communication

[screen shot]

3.4.2 Exposure Control

In Exposure Control, under the GigE Camera software tab, shown in Figure 13, you can specify the

shutter mode and set the shutter speed and direct shutter values.

Figure 13. Exposure Control

Mode

Use the pull-down menu shown in Figure 14 to select from Manual or Async mode.

18 Configuring the Camera

[screen shot]

Page 19

TM/ RM -1327GE Series

Figure 14. Mode Control Pull-down

[screen shot]

Shutter Speed

The shutter speed setting, shown in Figure 15, allows you to select the specific shutter speed for

Manual shutter and Async shutter. Manual shutter speed 0 is No Shutter mode; Async shutter speed 0

is Async - No Shutter mode; Async shutter speed 9 is Async - No Delay shutter mode (pulse width

control). Direct Shutter allows you to select shutter speed for direct shutter count by the video line.

External trigger polarity is set to active low in the Async mode.

Figure 15. Shutter Speed

[screen shot]

3.4.3 Scan Mode

The TM-1327GE camera has full and partial scan modes as shown in Figure 16. The partial scan area

allows you to select the different scan lines. When the scan area starts from an odd line, for a color

camera, an offset of 1 is added in the vertical direction.

Figure 16. Scan Mode

[screen shot]

3.4.4 Gain Settings

The Gain Settings control box, shown in Figure 17, allows you to change the Gain value from -3dB to

12dB. To change the value, move the slider or enter the value directly into the text box.

Figure 17. Gain Settings

[screen shot]

3.4.5 Offset (Black Level) Level Control

The offset level setting, shown in Figure 18, allows you to change offset voltage. To change the

value, move the slider or enter the value directly into the box.

Offset value determines the digital gain. Setting Vbottom above the zero level helps cut out some of

the infrared clutter and other noise on the lower end of the spectrum. Changing the Vbottom

setting adjusts the black level. Increasing the setting to a higher number causes the auto black level

control to darken the image, lowering the number lightens the image. A 0 setting is the lightest, and

255 is the darkest. The graph below shows how a new Vbottom effectively creates a new sensitivity

base point. Adjusting the Vtop can also lighten or darken the image.

Configuring the Camera 19

Page 20

TM/ RM-1327GE Series

The built-in auto black level control adds tiny positive or negative voltages to both Vtop and

Vbottom to compensate black level changes due to temperature. Auto black level does not change

the overall system gain.

Figure 18. Offset Level

[screen shot]

3.4.6 Look-Up Table

The look-up table (LUT) control, shown in Figure 19, allows you to change two knee point values.

Figure 19. Look-Up Table

[screen shot]

Enter X1, Y1, X2, Y2 values directly to adjust the knee curve. In the integrated camera software,

the look-up table cannot be controlled interactively. The Table Selection pull-down menu allows

you to select the Linear or Gamma 45 option. This control also allows you to check the positive or

negative image option.

3.4.7 Memory Pages

All the camera parameters such as shutter mode, shutter speed, gain, offset level, scan mode, and

LUT can be saved into seven (7) available memory pages on the EEPROM in the camera. The pages

are numbered 0-6. The Load Page button loads the corresponding camera settings from the EEPROM

while the write page button writes the current camera settings to the corresponding memory page

in the EEPROM.

Page 1, shown in Figure 20, is the power-up default page. Page 0 is the factory default. To save your

current camera settings for power up default, write the settings to memory page 1.

Figure 20. Memory Pages

20 Configuring the Camera

[screen shot]

Page 21

TM/ RM -1327GE Series

To reset memory page 1 to the factory default settings, load memory page 0 and save those settings

to memory page 1. Page 0 is password-protected and you cannot write to it. If you find that you do

need to write to page 0, contact JAI for password access.

Note: Configurations such as grabber settings, pulse generator, GPIO, and image setting must be

saved into the XML file. Refer to Section 3.4.1, “Check the Current Camera Setting,” on page

11 for more information.

3.4.8 Free-Running Mode

The camera must be in “Manual Shutter” or “Direct Shutter” mode. In the example below, there is

no partial scan.

1. Connect to the camera.

2. Under the “Device Features” tab, set the GPIO look-up table to Q5=1.

3. Under the “GigE Software” tab, change the manual shutter or direct shutter values.

4. Click Start.

You should now see a free-running video stream.

3.4.9 Externally Triggered

The external trigger is sent through pin 6 of the 12-pin Hirose connector. To use the software to

enable the external trigger, use the following steps:

1. Change the GigE camera software shutter mode to Async. Shutter.

2. Set the GPIO look-up table to Q4 = I0 and Q5 = 1.

3.4.10 Internally Triggered

The camera-control software includes pulse generators that you can use to trigger the camera

internally. To do this, use the following steps:

1. Select “Pulse Generator 0” under the “Device Features” tab. Set the pulse width and delay and

check the “Periodic” option if needed.

2. Set the GPIO look-up table to Q5=1 and Q4=I7.

3. Set the shutter mode in the GigE camera software page to async shutter. For more information,

refer to Section , “Mode,” on page 13.

3.4.11 Save/Restore Settings to Your Hard Disk

To save your current settings into the XML file, go to the main menu, select “File” and click Save As.

The XML file saves all your configurations, such as grabber settings, pulse generator, GPIO and

language settings.

The XML file will not, however, save camera parameters such as shutter mode, shutter speed, gain

settings, offset level, scan mode, and LUT. For more information about saving these camera

parameters, refer to Section 3.4.7, “Memory Pages,” on page 15.

3.4.12 White Balance Control (Color Versions Only)

To determine white balance, use the following steps:

1. Select full scan mode in the GigE Camera Software tabbed dialog. shown in Figure 11 on page

10.

2. Start the live video by clicking Start in the Acquisition tab of the Camera Interface Application

dialog box.

Configuring the Camera 21

Page 22

TM/ RM-1327GE Series

3. Click “Configure” and select the RGB filter tab from the Advanced Configuration window. Show

the camera a piece of white paper to make sure that the image is not saturated.

4. Click Analyze to automatically calculate the white balance.

5. Once white balance has been calculated, click Apply Results to apply white balance. You can

also assign custom gain and offset values to the R, G, and B channels. If you choose to assign

custom values, click Apply Results.

Figure 21. White Balance Control Settings

[screen shot]

3.4.13 Main Menu: Option

The Grabber Settings tabbed dialog box has a check box to enable the test pattern that is internally

generated by the integrated camera software.

3.4.14 Version

You can view the version number of the Cam2Net camera interface application by clicking Help-->

About. The version number of the integrated GigE camera software appears in a text box control

called “Version” in the GigE Camera tabbed dialog box.

3.4.15 Exit

From the main menu, select “File,” and click “Exit” to exit the software.

22 Configuring the Camera

Page 23

4 Signal Handling

This section describes the signal handling of the GE cameras in the following section:

• “Camera Inputs” on page 18

• “GPIO Control Block” on page 19

• “GPIO Label Tables” on page 21

• “Pulse Generators” on page 23

Refer to the Cam2Net User’s Manual for additional details.

4.1 Camera Inputs

For information on the polarity and type of the signals required to support specific camera

functions, refer to “Asynchronous Reset” on page 42

The TM-1327GE has three externally controllable standard signals:

• Trigger (VINIT or EXT_TRIG) (CC1 equivalent)

• VD in (EXT_VD) (CC3 equivalent)

• HD in (EXT_HD) (CC4 equivalent)

The labels for these signals in the GPIO Control Block programming language are:

• I0, for VINIT (must be configured as EXT_TRIG)

• I1, for VD in (must be configured as EXT_VD)

• I2, for HD in (must be configured as EXT_HD)

TM/ RM -1327GE Series

4.2 GPIO Control Block

Figure 22 below shows the GPIO Control Block signals for the GE Cameras.

Figure 22. GE Camera GPIO Control Block

Signal Handling 23

Page 24

TM/ RM-1327GE Series

Inputs I0 through I7 can be either external or internal inputs to the look-up table. The outputs are

used by the imager part of the GE camera.

The HD and VD signals can be passed through, bypassing the GPIO lookup table. Figure 24 on page 20

shows a screen dump of the GPIO configuration page, where HD/VD bypass selection can be made.

The default value 0 (zero) is through the lookup table. Value 1 (one) is bypassing the lookup table.

The SDK and the Cam2Net Camera Interface Application both supply methods to select GPIO bypass

of the external VD and HD (I1 and I2).

You can select which signal source to lead to the GPIO inputs. This is done in the GPIO look-up table

page as shown in Figure 23.

Figure 23. GPIO Look-Up Table

[screen shot]

Figure 24. The GPIO Configuration

[screen shot]

4.3 GPIO Label Tables

Table 2 shows which GPIO inputs carry the different signals. The top line for each label contains the

default signal.

Table 2 GPIO Look-Up Table Input Labels

Input Label Signal Description

I0 TTL_IN(EXT_TRIG) TTL-input 0. Used for external trigger.

FDV Internal signal. Frame Data Valid.

I1 TTL_IN(EXT_VD) TTL-input 1. Used for external vertical drive.

LDV Internal signal. Line Data Valid.

I2 CTRL2 Internal control signal.

TTL_IN(EXT_HD) TTL-input 2. Used for external horizontal drive.

I3 CTRL1 Internal control signal.

TTL_IN(INT) TTL-input 3. Used for external integration control.

I4 CAM_STROBE Internal signal. Strobe Input.

PULSE_GEN3 Pulse Generator 3 signals go here.

I5 CTRL0 Internal control signal.

PULSE_GEN2 Pulse Generator 2 signals go here.

I6 PULSE_GEN1 Pulse Generator 1 signals go here.

N/A

I7 PULSE_GEN0 Pulse Generator 0 signals go here.

N/A

24 Serial Commands

Page 25

TM/ RM -1327GE Series

Table 3 shows which output labels carry the output signals.

Table 3 GPIO Look-Up Table Output Labels

Output label Signal Description

Q0 TTL-OUT(STROBE) Strobe output

Q1 N/A

Q2 N/A

Q3 N/A

Q4 EVINIT Trigger

Q5 N/A

Q6 EXT_VD Vertical Drive

Q7 EXT_HD Horizontal Drive

Q8 pulse_trig1 Pulse Generator 1 gets its trigger here

Q9 pulse_trig0 Pulse Generator 0 gets its trigger here

Q10 pulse_trig3 Pulse Generator 3 gets its trigger here

Q11 pulse_trig2 Pulse Generator 2 gets its trigger here

Q12 N/A

Q13 N/A

Q14 TRIG Trigger for camera’s internal frame grabber

Q15 RESV Reserved

4.4 Pulse Generators

The TM-1327GE camera has four independently programmable pulse generators. These generators

can run as either periodic or triggered. To run the pulse generators as triggered, they can be

triggered on either levels or signal edges. These generators can be tied to the camera inputs

(camera-control lines). For example, you can set pulse generator 0 in the Device Features tabbed

dialog box to the following values:

• Delay = 600

• Width = 14,000

• Granularity = 1

Now check the Periodic option and change the camera settings to Async 9. This triggers the camera,

based on the pulse width set in the Pulse Generator page.

Be careful with the pulse generator’s GPIO input and output polarity. If the delay and pulse-width

duration are switched around, the output polarity must be negated in the GPIO lookup table.

The pulse generators are configured in the “Pulse Generator” section of the “Device Features” tab

of the “Advanced Configuration” window as shown in Figure 25.

Figure 25. Pulse Generator Page

[screen shot]

Signal Handling 25

Page 26

TM/ RM-1327GE Series

5 GigE Series Camera Serial Commands

You can control the GigE series cameras by serial command either using RS-232 or Camera Link. The

Start character is always “:” and the End character is always <CR> (return). For example, to set

Asynchronous Pulse Width Mode, send the command :ASH=9<CR> to the camera. Table 4 lists serial

commands you can use to control the camera.

Table 4 TM-1327GE Command List

Command Parameters

:MGA= XXX <cr> :o<cr> Set CDS gain (XXX = 047 - 0E7)

:VTP= XXX <cr> :o<cr> Set VTOP (XXX = 000 - 0FF)

:VBT= XXX <cr> :o<cr> Set VBOTTOM (XXX = 000 - 0FF)

:MSH= X <cr> :o<cr> Set Manual Shutter (X = 0 manual, no shutter)

:ASH= X <cr> :o<cr> Set Async Shutter (X=0 async no shutter, X=9 PWC)

:DSH= X <cr> :o<cr> Set Manual Direct Shutter (1-1052)

:ADS= XXX <cr> :0<cr> Set Async Direct Shutter (DDD=000- 81F)

:DDP= N <cr> :o<cr> Set output data depth (N = 0 : 8 bit, N = 1 : 10 bit)

:LINR <cr> :o<cr> Set linear table

:GM45 <cr> :o<cr> Set gamma .45 table

:KNEE= X1Y1X2Y2 <cr> :o<cr> Set knees (X1, Y1, X2, Y2 = 00 - FF)

:NLUT X <cr> :o<cr>

:WRPG X <cr> :o<cr>

:LDPG X <cr> :o<cr> Load Page (X = 0 - 6)

:RDPG X <cr> :o[settings]<cr> Read Page (X = 0 - 6)

:RPST <cr> :o[settings]<cr> Report current settings Scan Mode

:SMDA <cr> :o<cr> Set Full Scan Mode

:SMDU= XXXXYYYY <cr> :o<cr>

:TAH= X <cr> :o<cr>

:TPTN X <cr> :o<cr>

:CAM? <cr> :o[model]<cr> Enquire Camera Model

:VER? <cr> :o[version]<cr> Enquire MPU firmware version

End of

Command

Ack Response Description

Gain, Vtop, and Vbottom

Shutter Mode and Shutter Speed

Data Output Control

Lookup Table

EEPROM

Miscellaneous

Set positive knee or negative knee (X=0 positive,

X=1 negative)

Write Page X = 0 - 6; (Page 0 is factory setting, Page

1 is power up default setting)

Set User Scan Area (XXXXX=0000 - 040F,

YYYY=0001 - 0410

External Trigger Polarity (X=1 Active High, X=0

Active Low)

Enable/Disable Test Pattern (X = 1Enable, X = 0

Disable)

Note: If a command is not accepted for any reason, the camera returns a N ack response “:e”<cr>

Report Command: RPST<cr>

TS Return : O RR + “24 bytes” + <cr>

26 Serial Commands

Page 27

TM/ RM -1327GE Series

Table 5 18 Bytes Status Report

Byte 1, 2 MGA Gain Control (H’0000 - H’00FF)

Byte 3, 4 VTOP VTOP (H’0080 - H’00C0)

Byte 5, 6 VBTM VBOTTOM (H’0078 - H’00FF)

Byte 7,8 Reserved

Byte 9 Function Flag 0

Bit 7 output pixel order 1 “00”=<-- “10”=<-- “01”=<--

Bit 6 output pixel order 0

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Byte 10 Function Flag 1

Bit 7 ShutterMode2

Bit 6 ShutterMode1

Bit 5 ShutterMode0

Bit 4 Output Data Depth 0=8 bit 0=8bit; 1=10bit

Bit 3

Bit 2

Bit 1

Bit 0

Byte 11 Function Flag 2

Bit 7 LUTSIGN 0=Positive LUT; 1=Negative LUT

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2 LUTTABLE2 “000”=Linear LUT

Bit 1 LUTTABLE1 “001”=Gamma.45 LUT

Bit 0 LUTTABLE0 “010”=Two Knee Table

Byte 12 Function Flag 3

Bit 7 TESTPATTERN 0=Disable TP; 1=Enable TP

Bit 6 Reserved System Flag

Bit 5

Bit 4 Reserved System Flag

Bit 3

Bit 2

Bit 1

Bit 0 Reserved System Flag

Byte 13 X1

Byte 14 Y1

Byte 15 X2 (X2, Y2) Coordinate for Knee 1

Scan Mode Full/Partial Scan

“000”=Manual Shutter

“001”=Async Shutter

“010”=Async Direct Shutter

“011”=Direct Shutter

(X1, Y1) Coordinate for Knee 1

(X1, Y1 = H’00 - H’FF)

Serial Commands 27

Page 28

TM/ RM-1327GE Series

Byte 16 Y2 (X2, Y2 = H’00 - H’FF)

Byte 17 User Scan Start Point of User Scan Area

Byte 18

Byte 19 Direct Shutter H’000 - H’40F

Byte 20 Byte 21, 22

Byte 23, 24 Reserved Total line number H’040 - H’1F3

Active Line of

Scan

Active Line of User Scan Area

28 Serial Commands

Page 29

TM/ RM -1327GE Series

2.TM-1327GE Hardware

6 Hardware Introduction

This chapter contains the following sections:

• “Product Description” on page 29

• “Features” on page 30

6.1 Product Description

The JAI TM-1327GE is a high-speed progressive scan CCD camera. The interline-type CCD permits full

vertical and horizontal resolution of very high speed shutter images and applications. The electronic

shutter, which has speeds to 1/16,000 second, can be reset asynchronously by external pulse

control. The frame rate for a full image is 30 fps, with partial scan mode of up to 1 line. A 2:1 ratio

imager format with uniform square pixels provides superior image definition in any orientation.

Operation Manual

The TM-1327GE has a full dynamic range control function, which can be set at externally selectable

look-up table (LUT) knee slopes to convert 10-bit input to 8-bit output, thereby optimizing the

CCD’s full dynamic range in the normal output signal range.

Applications for the TM-1327GE include machine vision, medical imaging, intelligent transportation

systems, high-definition graphics, on-line inspection, gauging, character reading, archiving, and high

security surveillance.

The TM-1327GE series consists of the TM-1327GE (monochrome) and the TMC-1327GE (color). Unless

otherwise noted, all information contained in thIs manual is relevant to both models.

6.2 Features

The TM-1327GE has the following features:

• Miniature size and light weight

The printed circuit boards in the TM-1327GE have been arranged to create modular electronics,

giving the camera flexibility. In addition, the use of miniature solid-state components results in a

compact, lightweight camera that is 50.8mm x 50.8mm x 83.5mm in dimensions, and weighs only

140 grams.

• Imager

The TM-1327GE uses a progressive scan interline transfer CCD that has the following features:

− Resolution of 1392 x 1040 active pixels for excellent image quality.

− 6.45 x 6.45 μm square pixels for precise dimensional measurement.

− High-speed electronic shutter capability for high dynamic resolution of moving objects

that eliminates the need for a mechanical shutter.

− Progressive scan CCD eliminates interlace deterioration of image and increases ease of

computer interface.

Hardware Introduction 29

Page 30

TM/ RM-1327GE Series

− High sensitivity and low noise at fast scanning. The CCD has an excellent S/N ratio at the

default setting greater than 51dB.

• Electronic shutter

The TM-1327GE has a substrate drain-type shutter mechanism which provides superb pictures at

various speeds without smearing. For more information, refer to Section 8.3, “Electronic Shutter,”

on page 41.

• Asynchronous reset

The TM-1327GE captures asynchronous reset images and provides single-shot video output with

single FDV. This makes it simpler for an ordinary frame grabber to capture the asynchronous reset

images. The TM-1327GE’s asynchronous reset is flexible and accepts external horizontal drive (HD)

for phase locking. When the VINIT (5V) pulse is applied to CC1, it resets the camera's scanning and

purging of the CCD.

The TM-1327GE has three modes to control the asynchronous reset and shutter speed:

− Async, no shutter. The video signal and FDV are reset by external VINIT.

− Async direct shutter. The shutter speed control depends on the number of horizontal lines

controlled through the serial commands.

− External VINIT with pulse width. The duration between pulse edges controls the shutter

speed externally.

• Output

The TM-1327GE has a 10-bit/8-bit Gigabit Ethernet output. The analog output is 714 mV p-p

composite video (75 ohms) on all models.

• Warranty

Contact your factory representative for details about the warranty.

30 Hardware Introduction

Page 31

7 Installation

The following instructions will help you to set up your camera quickly and easily. JAI suggests that

you read through these instructions first, before you unpack and set up your camera system.

7.1 Getting Started

7.1.1 Unpacking Instructions

JAI recommends that you save the original packing cartons for the cameras and accessories in case

you need to return or exchange an item.

We also recommend that you bench-test any equipment being sent to another location for field

installation to assure that everything is fully operational as a system.

7.1.2 Components

When you receive your TM-1327GE camera from JAI, the contents of the shipping box should include

the camera and a document download card. If either of these items are missing, contact your JAI

representative immediately. The document download card includes instructions and web locations

for downloading the datasheet, manual, and camera-control software. If you do not have Internet

access, contact JAI to receive this material on a CD-ROM.

7.1.3 Accessories and Options

The following additional accessories and options may be required for your application:

TM/ RM -1327GE Series

• PD-12U series power supply

• 12P-02S power cable

• Cat5e or cat6 shielded Ethernet cable (not supplied by JAI)

Check with your JAI representative before you install your camera to determine what you might

need.

7.2 Camera Setup

7.2.1 Heat Dissipation

The TM-1327GE is a compact camera. Since all the electronics have been packed in a compact

package, the outer case of the camera can become hot because of heat dissipation. For optimal

performance, JAI recommends using a cooling fan to set up a positive air flow around the camera

and following the precautions below.

• Mount the camera on a large heat sink (camera bracket) made out of a heat-conductive

material like aluminum.

• Make sure the flow of heat from the camera case to the bracket is not blocked by a non-

conductive material like plastic.

• Make sure the camera has enough open space around it to facilitate the free flow of air.

Contact JAI at (800) 445-5444 or send an E-mail to camerasales.americas@jai.com

questions.

7.2.2 Connector Pin Configurations

The TM-1327GE has a 12-pin Hirose connector for power input and signal integration as shown in

Figure 24.

if you have any

Hardware Installation 31

Page 32

TM/ RM-1327GE Series

Figure 26. 12-Pin Connector Pinouts

Pin #1 is Ground and pin #2 is +12V DC. Table 6 shows the pin-out table.

Table 6 12-Pin Connector

Pin Description Pin Description

1 GND 7 VD in

2 +12V DC 8 Strobe

3 GND (analog) 9 HD in

4 Video out 10 Reserved

5 GND (digital) 11 Reserved

6 VINIT in 12 Reserved

The GigE socket, marked on the camera’s back panel as “GigE,” is a standard

RJ-45 Ethernet socket as shown in Figure 25.

Figure 27. GigE Ethernet Connector

Use at least cat5e UTP cables (cat6 cables are preferred). Refer to the Cam2Net User’s Manual for

details. JAI recommends the use of shielded cables to reduce emissions and for CE/FCC compliance.

Double-shielded cables further reduce emissions.

7.2.3 Power Supplies and Power Cable Setup

Power Supplies

The TM-1327GE camera requires 12V DC power obtained through the 12-pin connector located on

the rear panel of the camera. JAI recommends the following power supplies:

PD-12UU 100-240V AC/12V DC 1.2A universal voltage power supply,

US Plug

PD-12UUP PD-12UU with12-pin connector US plug

PD-12UE PD-12UU European plug

PD-12UEP PD-12UU with 12-pin connector European plug

32 Hardware Installation

Page 33

TM/ RM -1327GE Series

If you are providing power through the 12-pin connector, the PD-12P, PD-12UEP and PD-12UUP

power supplies are available with the 12-pin mating connector already attached to the leads from

the power supply. You can connect the PD-12UU and PD-12UE power supplies to the JAI power cable

using a terminal strip or directly.

When wiring the PD-12UU and PD-12UE power supplies directly, note the following:

• Twist the lead ends together and tin-solder for strength and electrical continuity.

• Use shrink tubing or a similar insulator to prevent exposed leads from touching and shorting.

• The +12V lead is marked with a red stripe or white lettering; be sure not to reverse the leads.

• Make sure all connections are properly insulated to prevent shorting.

JAI Power Cables

If you are using JAI power cables, such as the 12P-02S, refer to the Figure 26 which shows the cable

pin-out diagram and pinouts. The color-coded leads use Gray for Ground and Yellow for +12V.

Figure 28. 12P-02S Interface Cable (optional)

12P-02S Interface Cable

Pin# Lead Color Function Pin# Lead Color Function

1 Gray GND 7 Black coax TTL IN (EXT_VD)

2 Yellow +12V DC 8 White coax shield TTL OUT (STROBE)

3 Red coax shield AGND 9 White coax TTL IN (EXT_HD)

4 Red coax VIDEO 10 Brown RESV

5 Orange coax shield GND 11 Blue RESV

6 Orange coax TTL IN (EXT_TRIG) 12 Black coax shield RESV

Note: Make sure that the unused leads are not touching and that there is no possibility that exposed

wires could cause the leads to short.

Building Your Own Power Cable

Refer to the 12-pin connector pin-out in Figure 26 on page 34. Connect the Ground lead to pin #1,

and the +12V DC lead to pin #2 of the 12-pin connector. Power must be DC-regulated, and of

sufficient current to properly power the camera.

Attaching the Power Cable to the Connector

The 12-pin connector is keyed and will only fit in one orientation. To properly attach the power

cable to the camera connector, use the following steps:

1. Rotate the connector while applying slight pressure until the keyways line up.

2. Press the connector into place until firmly seated.

3. Plug the power cord into the 100V AC socket. This powers up the camera.

Hardware Installation 33

Page 34

TM/ RM-1327GE Series

7.2.4 Attaching the Camera Lens

The TM-1327GE camera accepts 2/3” or larger format size C-mount lenses. To attach the C-mount

2

to the camera, carefully engage the threads and rotate the lens clockwise until it firmly seats

lens1

on the mounting ring. Do not force the lens if it does not seat properly.

Note: Some lenses with extremely long flangebacks may exceed the mounting depth of the camera.

7.2.5 Adjustable Back-Focus

Before cameras are shipped, back focus is carefully set using a collimator, oscilloscope and other

specialized equipment. While the factory-set focus serves well in most cases, an adjustable back

focus makes it possible to improve image sharpness when using lower-cost zoom lenses, custom

optics, or in unusual parameters.

There should be an obvious need to refocus the lens before attempting to change the back focus.

This is a very exacting task. Some cameras have been returned to the factory to reset the back

focus after failed attempts to change the focus by customers. It might be wise to label cameras

whose back focus was adjusted

1. The camera must be connected to a monitor before attempting to adjust the back focus.

2. To back focus the camera, first attach a C-mount lens in the mount. Be certain that the lens is

properly seated.

3. Next set the lens focus to infinity (if the lens is a manual iris, set the iris to a high f number

while still retaining a well illuminated image).

4. Loosen the three miniature hex set-screws (use a 0.9 mm hex wrench) that lock the focus ring

in place (two screws for a CS-mount). Slowly turn the lens and focus ring assembly back and

forth until you obtain the best image of the desired object. This sets the back focus. Once the

best image is obtained, tighten the focus ring set-screws until they are snug. Do not overtighten the screws.

Note: Mini-bayonet cameras adapted to C-mount do not have the back focus feature.

Figure 29. Back-Focus Set-Screw Locations

2

C-mount to F-mount and C-mount to K-mount adapters are available for larger format lenses (35mm). Check with local

photography dealers for these lens adapters.

34 Hardware Installation

Page 35

8 Operation

This chapter contains information about performing operational procedures. It contains the

following sections:

• “Progressive Scanning” on page 37

• “Electronic Shutter” on page 41

• “External Sync” on page 42

• “Asynchronous Reset” on page 42

• “Programmable Look-Up Table (LUT) and Knee Control” on page 45

• “Camera Timing Charts” on page 46

• “Video Output” on page 48

• “External HD Locking and External VD Reset” on page 49

• “Asynchronous Reset” on page 49

8.1 Progressive Scanning

Standard TV-system scanning is 525 lines interlace scanning as specified in the RS-170 protocol.

Every other horizontal line (odd lines and even lines) is scanned at a 60Hz rate per field, and the

scanning is completed with two fields (one frame) at 30Hz rate. Because of the interlace scanning,

the vertical resolution of CCD cameras is limited at 350 TV lines, regardless of the horizontal

resolution. When electronic shutter is applied, the CCD can hold only one field of charge at each

exposure. This means that the vertical resolution of the electronic shutter camera is only 244 TV

lines. The situation is the same for an HDTV-format camera, since it has interlaced scanning and the

vertical resolution of the shuttered image is 500 lines.

TM/ RM -1327GE Series

The TM-1327GE uses a state-of-the-art progressive scanning interline transfer CCD which scans all

lines sequentially from top to bottom at one frame rate. Like a non-interlace computer screen, it

generates a stable, crisp image without alternating lines and provides full vertical TV resolution of

1040 lines.

The interline transfer architecture is also important to generate simultaneous shuttering. This is

different from full frame transfer architecture, which requires a mechanical shutter or strobe light

in order to freeze the object motion.

The TM-1327GE outputs the progressive scanned image with an electronic shutter in two different

formats.

• Progressive scanning digital - The CCD signal goes through A/D converters 10-bit in, 10-bit/8-bit

out. The digital output is available using the Gigabit Ethernet connector.

• Analog output - The analog output is the same as 75 ohms, 714mV format available from BNC

and 12-pin connector.

8.2 Bayer Color Filter (Color Versions)

JAI AccuPiXEL series color cameras are high-resolution, high-speed progressive scan CCD cameras.

The interline transfer, progressive scan CCD permits full vertical and horizontal resolution of images

acquired at very high shutter speeds. The electronic shutter, which has speeds to 1/16,000 sec., can

be reset asynchronously by external pulse control. Uniform square pixels provide superior image

definition in any orientation. On-chip micro lenses mean increased sensitivity.

8.2.1 Color Filter Array

JAI AccuPiXEL cameras use Bayer CFA (color filter array) as their standard primary color filter. This

filter provides the most popular color interpolation supported by numerous software suppliers.

Hardware Operation 35

Page 36

TM/ RM-1327GE Series

The digital format allows the camera to output accurate pixel data, including the color information.

When the data is stored in the frame buffer of a frame grabber or computer, the color information

is easily manipulated to restore the original color images. Because the color filter array contains

only a single R, G or B color in each pixel, the restored image has to fill in colors in the missing pixel

locations. The software uses neighboring pixel information to “guess” the missing colors to make

smooth, clear images. This is called “color interpolation.” Today’s high-speed computers allow such

color interpolation to be done almost in real time. Because these cameras do not contain internal

color processing circuitry, they are smaller and less expensive than full-function color cameras.

8.2.2 Bayer Color Filter Array (CFA)

The Bayer CFA is an R, G, B primary color filter array. This is the most widely accepted CFA for the

single-chip CCD progressive scan format. This type of array layout has a specific order for each

color’s pixels. Since the human eye’s resolution and color recognition are highest at green, the CFA

contains two greens per each red and blue.

It is critical for the frame grabber and color interpolation to know where the individual color pixels

exist relative to sync (LDV and FDV) timing.

This requirement makes digital output the preferred choice, because the timing relationships are

very accurate.

8.2.3 Starting Pixel Configuration

All manufacturers produce identical Bayer CFAs, but there are slight differences between the CCDs

produced by different manufacturers. The first line is generally R and G. The camera timing can be

adjusted to start with either G or R by skipping the very first pixels at each line. The majority of

color interpolation software can select between a variety of pixel relations, such as R/G start or

G/R start, as well as G/B start and B/G start. Once the correct scanning is configured, the rest of

the interpolation will be exactly the same. Please contact JAI for further information regarding CCD

manufacturers.

36 Hardware Operation

Page 37

TM/ RM -1327GE Series

Figure 30. Example of Color CCD CFA Pattern

8.2.4 Sync and Data

The individual color data is exactly the same as the pixel data. This means that the timing

relationships of the color cameras are also the same as of the B/W cameras.

For a detailed timing chart, please refer to each B/W camera’s data sheet and manual.

The following diagram is an example of the TMC-1327GE default mode. FDV and LDV are used

internally for the GigE interface.

Hardware Operation 37

Page 38

TM/ RM-1327GE Series

Figure 31. Example of TMC-1327GE in Default Mode

8.2.5 Camera Functions

AccuPiXEL color cameras perform all functions the same way as B/W cameras. However, because of

color characteristics, the LUT (Look-up Table) is different. The LUT is a powerful tool to adjust the

dynamic range as well as color dynamic range. Since human color perception is non-linear, LUT

selection can help optimize color contrast by selecting the LUT value. Gamma 0.45 is logarithmic

and is closed to human perception.

When LUT is selected, black-level adjustment must be more accurate than for B/W cameras.

For a detailed timing chart, please refer to the standard AccuPiXEL camera data sheet, or contact

JAI.

8.2.6 Interpolation Software

The color interpolation can be performed in the frame grabber or by using the host computer’s CPU.

Most major frame grabbers with processing capability provide tools for color interpolation. Software

vision packages also provide color interpolation capability, but speed and performance may be

determined by the PC’s resources and by the complexity of the interpolation routine. 8.2.7 Color

Interpolation The Bayer pattern color filter array (CFA) consists of R, G, and B primary colors. Each

pixel represents one of three colors. In order to display or print color images, the signal has to be

converted to RGB output, which has three independent channels (outputs) and sync signals.

Color interpolation software or firmware performs the color preprocessing by

filling the missing color pixels with neighboring pixels. It then separates the

stream of data, (8-bit or 10-bit) into 3 (RGB) data (8-bit x 3) and adds the color

matrix to adjust and balance each of the R,G, and B channels (white balance or

color balance).

38 Hardware Operation

Page 39

TM/ RM -1327GE Series

The image quality depends on the camera’s own pixel data (including pixel data independency from

neighboring pixels, noise and color filter), and interpolation of the software algorithm such as 3 x 3

interpolation, 2 x 2 interpolation, color matrix, white balance capability, etc.

All AccuPiXEL color cameras are carefully designed for maximum color performance. JAI strongly

suggests that you use digital output for the best performance.

Some software is used on board (FPGA or DSP) to perform the interpolation. Other software simply

uses the host computer’s memory and CPU. The process speed may vary depending on the

architecture and speed of the computer.

8.3 Electronic Shutter

The TM-1327GE has a substrate drain-type shutter mechanism which provides a superb picture at

various speeds without smearing. A built-in flexible shutter speed control selects the electronic

shutter rate from 1/30 to 1/21,000.

With VINIT high (CC1), the CCD keeps discharging. With an active low pulse to VINIT, the camera

resets and purges the charge momentarily. Then it starts integrating for the period of shutter

control set by either an external pulse width or internal shutter control. Progressive scanning

permits a full 1040 lines of vertical resolution, as compared to a conventional CCD camera which

captures only half the vertical lines per shutter.

8.4 External Sync

The TM-1327GE accepts an external synchronization of standard HD and VD on CC3 and CC4 of the

Gigabit Ethernet connector for general locking to an external source. The tolerance is ±2%

horizontal frequency.

8.5 Asynchronous Reset

The TM-1327GE camera includes the following modes to control the asynchronous reset and shutter

speed:

• Async No Shutter (recommended for strobe applications)

• Async Direct Shutter

• External VINIT with Pulse Width (No-Delay Shutter)

8.5.1 Async No Shutter

Async No Shutter allows for strobe and back-to-back strobing (strobing both before the transfer gate

and right after) applications as shown in Figure 30.

Figure 32. Async No Shutter

Hardware Operation 39

Page 40

TM/ RM-1327GE Series

8.5.2 Internal Direct Shutter Speed Control

Figure 33. Internal Direct Shutter Speed Control

The video signal starts with internal VINIT. When the external VINIT pulse is applied, internal VINIT

is latched to HD and the internal VINIT is delayed to set up the shutter speed period. The shutter

speed is controlled by communication software. Video output timing starts right after the internal

VINIT and single shots, FDV is output at the internal VINIT timing.

8.5.3 External VINIT With Pulse Width (No-Delay Shutter)

For multiple-camera applications such as 2D or 3D measurement and multi-angle inspection,

simultaneous image capturing at an exact shutter timing for all cameras is a critical requirement.

The TM-1327’s asynchronous pulse-width control mode provides no-delay shutter (Figure 32) as

standard. Regardless of the internal pulse timing, the camera discharges at the VINIT leading edge

and transfers charges at the trailing edge of the pulse. Even though each camera runs with slightly

different H and data clock timing, the image capturing is exactly simultaneous.

40 Hardware Operation

Page 41

TM/ RM -1327GE Series

Figure 34. No-Delay Shutter

8.5.4 Async Direct Shutter

Async Direct Shutter exposure is determined by a direct shutter value entered from 1 to 1040. The

shutter value equals 1.5H (horizontal line time) or 47.6 μsec. for each increment. The Async Direct

Shutter exposure timing functions exactly the same as the internal shutter speed control. Async

Direct Shutter is controlled by GigE camera acquisition software and sent serially through an

Ethernet cable to the camera. The GUI interface that controls Async Direct Shutter exposure is

illustrated in Figure 33 below.

Figure 35. Async Direct Shutter

[screen shot]

8.6 Programmable Look-Up Table (LUT) and Knee Control

The TM-1327GE has a built-in LUT (look-up table) for dynamic range control. At a specific gain

setting, the offset (minimum level.... dark point) and A/D reference top voltage (maximum level...

saturation point) are set to 10-bit A/D input so that the full dynamic range of the CCD is utilized at

10-bit references as the input and the LUT output is converted into 8-bit to adjust the gamma

correction. Notice that the LUT (look-up table) is not available in the 10-bit grayscale mode.

The look-up table has two knee points (variable gamma selection) that allow the 10-bit input to be

segmented into three regions. The look-up table selection can be made by knee curve direct input.

Hardware Operation 41

Page 42

8.7 Camera Timing Charts

TM/ RM-1327GE Series

42 Hardware Operation

Page 43

TM/ RM -1327GE Series

Hardware Operation 43

Page 44

8.8 Video Output

Table 7 Video Output (Horizontal Timing)

Table 8 Video Output (Vertical Timing)

Vertical Timing

M

Q

TM/ RM-1327GE Series

Horizontal Timing

Number of pixels 30fps (μs)

A 1741 31.65

B 349 6.35

C 1392 25.31

D 0 0

E 0 0

F 61 1.11

G 61 1.11

H 364 4.44

Full Scan Area User Scan Area (SP:x, TL:y)

Number of lines 30fps (μs) Number of lines 30fps (μs)

J

1053 33332.24 (nfp+8)+nrp+y ((nfp+8)+nrp+y)*31.65

K

13 411.17 (nfp+11)+nrp ((nfp+8)+nrp)*31.65

L

1040 32920.73 y y*31.65

0 0 0 0

N

0 0 0 0

P

3 94.96 nrp+3 (nrp+3)*32.65

3 94.96 3 94.96

R

7 221.58 nfp+2 (nfp+2)*32.65

Where

8.9 External HD Locking and External VD Reset

Table 9 External HD Locking and External VD Reset (Horizontal Timing)

Horizontal Timing

Number of pixels 30fps (μs)

eA <1 <0.02

eB 160 2.91

eC 1448 28.75

eD 15 0.27

44 Hardware Operation

Page 45

TM/ RM -1327GE Series

Table 10 External HD Locking and External VD Reset (Vertical Timing)

Vertical Timing

Full Scan Area User Scan Area (SP:x, TL:y)

Number of lines 30fps (μs) Number of lines 30fps (μs)

eE <1 <31.65 <1 <31.65

eF 9 284.89 9 284.89

eG 1044 33047.34 (nfp+2)+nrp+y ((nfp+2)+nrp+y)*31.65

eH 0 0 0 0

8.10 Asynchronous Reset

Table 11 Asynchronous Reset

aA <1L <31.65

aB 9L + 960P 302.34

aC 160P 2.91

aD 9L 284.89

(L: lines)

(P: pixels)

30 fps

(μs)

Table 12 Asynchronous Direct Shutter and Pulse-Width Control

aE <1L <31.65 <10P <0.18

aF 53P 0.96 53P 0.96

aG (n+1)L+960P (n+1)*31.65+17.45 z+960P z+17.45

aH K-1 (K-1)*31.65 K-1 to K (K-1 to K)*31.65

Asynchronous Direct Shutter

(ADS=n)

(L: lines)

(P: pixels)

30 fps (μs) (L: lines) 30 fps (μs)

Pulse-Width Control (Pulse

Width=z)

Hardware Operation 45

Page 46

9 Troubleshooting

9.1 Problems and Solutions

This section contains troubleshooting tips for common problems. Generally, problems can easily be

solved by following these instructions. If the following remedies fail to offer a solution to your

problems, contact a JAI representative.

9.1.1 Symptom: No Video

Remedies: Check that the following are properly connected and operational.

• Power supplies

• Power cables

• Main power source

• Shutter control

• Async mode

• Lens

• Digital output cable

• Analog video cable

9.1.2 Symptom: Dark Video

Remedies: Check that the following are properly connected and operational.

TM/ RM-1327GE Series

• Shutter selection

• Iris opening on the lens

9.1.3 Symptom: Non-Synchronized Video

Remedies: Check that the following are properly connected and operational.

• Proper mode output

• Frame grabber software camera selection

9.2 Information and Support Resources

For further information and support:

Phone: (408) 383-0300

(800) 445 -5444

Fax:(408) 383-0301

E-mail: camerasales.americas@jai.com

Mail: JAI, Inc. Sales Department

625 River Oaks Parkway

San Jose, CA 95134

ATTN: Video Applications

Web Site: www.jai.com

46 Troubleshooting

Page 47

10 Appendix

10.1 Specifications

Table 13 TM-1327GE Camera Specifications Table

Feature TM-1327GE

Imager 2/3” progressive scan interline transfer CCD

Active Area 8.98mm x 6.71mm

Active Pixels 1392 (H) x 1040 (V)

Cell Size 6.45?m x 6.45?m

Display Mode

(Active Pixels)

Sync

Data Clock Output 55.00 MHz

Resolution Digital: 1392 (H) x 1040 (V)

S/N Ratio 52dB min.

Min. Illumination

Video Output

Gamma Programmable LUT (1.0 std.)

Lens Mount C-mount (use >2/3” format lenses or larger)

Power Requirement 12V DC ±10%, 430mA (typical at 25°C)

Operating Temp. -10°C to 50°C*

Vibration 7 Grms (10 Hz to 2000 Hz) Random

Shock 70G, 11 ms half sine

Size (W x H x L) 50.8mm x 50.8mm x 84.8mm

Weight 211.7 grams (7.5 oz.) without tripod

Optional Functions

Optional Accessories

Power Cable

Power Supply

TM/ RM -1327GE Series

1392 (H) x 1040 (V) @ 30 Hz

Internal/External auto switch

VD=30.00 Hz±5%, non-interlace

HD=31.59kHz±5%

Monochrome = 0.02 lux; Color = 0.6 lux

f = 1.4 (no shutter) @ 30 fps

Analog: 714 mV, 75 ohms, (750 mV white clip)

Digital output: Gigabit Ethernet (8- or 10-bit selectable)

OP 3-1, internal IR filter;

OP 3-2, optical filter removal;

12P-02S

PD-12UUP series (includes power connector)

*. Refer to Section 7.2.1 on page 32 for information on camera heat dissipation. Image quality

degrades with increasing temperature.

Specifications 47

Page 48

TM/ RM-1327GE Series

10.1.1 TM-1327GE Physical Dimensions

Figure 36. Physical Dimensions

48 Specifications

Page 49

TM/ RM -1327GE Series

10.1.2 Spectral Response

Figure 37. Spectral Response

Specifications 49

Page 50

Page 51

TM/ RM -1327GE Series

Page 52

Europe, Middle East & Africa

Phone +45 4457 8888

Fax +45 4491 8880

Asia Pacific

Phone +81 45 440 0154

Fax +81 45 440 0166

Americas

Phone (Toll-Free) 1 800 445-5444

Phone +1 408 383-0301

www.jai.com

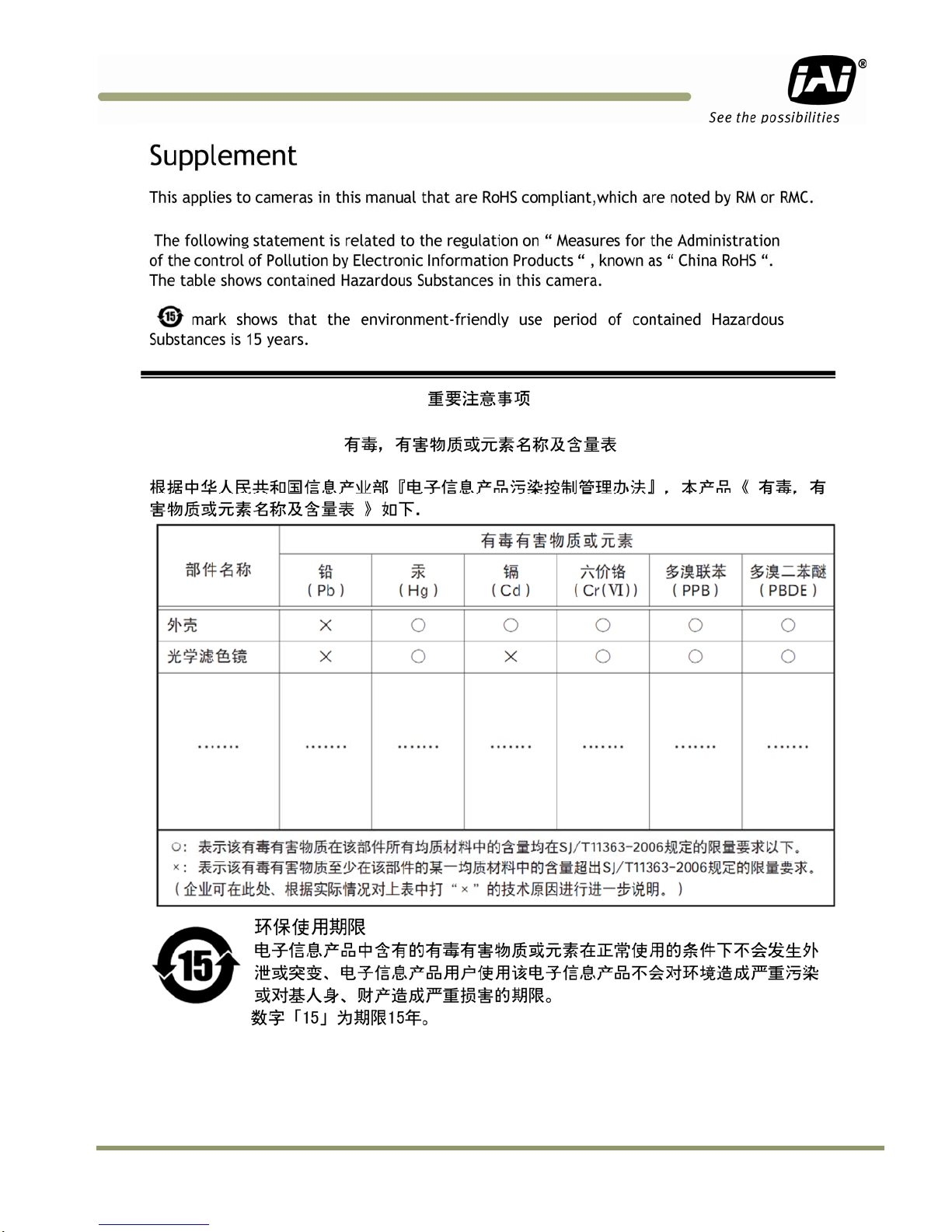

Loading...

Loading...