User Manual

SW-4000Q-10GE

4CMOS Prism Linescan Camera

Document Version: 1.0

SW-4000Q-10GE_Ver.1.0 _Apr.2019

Thank you for purchasing this product.

Be sure to read this manual before use.

This manual includes important safety precautions and instructions on how to operate the unit. Be sure to read

this manual to ensure proper operation.

The contents of this manual are subject to change without notice for the purpose of improvement.

© 2019 JAI

Contents

36

36

37

38

40

40

41

42

42

43

43

44

45

46

46

58

58

59

61

62

64

65

66

67

SW-4000Q-10GE

Notice/Warranty/Certifications

Usage Precautions

Features

Parts Identifications

Preparation

Preparation Process

Step 1:Installing the Software

Step 2:Connecting Devices

Step 3:Verifying Camera Operation

Step 4:Verifying the Connection between

the Camera and PC

Step 5:Changing the Camera Settings

Step 6:Adjusting the Image Quality

Step 7:Saving the Settings

Main Functions

Valid Input / Output Combinations

GPIO(Digital Input/Output Settings)

Pixel Format

ExposureMode

Image Output Timing

Pixel Sensitivity Correction

Gain Control

Lookup Table (LUT)

Gamma Function

ShadingCorrection

Black Level Correction

Variable Line Rate

Electronic Shutter

12

12

12

13

15

15

18

20

21

23

23

24

25

27

27

31

32

33

34

35

35

36

36

3

5

7

8

EEN (Exposure Enable) Function

Test Pattern Function

Color Space Conversion

Counter And Timer Control Function

Chromatic Aberration Correction

Connecting Rotary Encoders

Frame Start Trigger

Binning Function

ROI (Regional Scanning Function)

Chunk Data Function

Delayed Readout

Event Control Function

Action Control Function

Setting List

Feature Properties

Miscellaneous

Troubleshooting

Specifications

Spectral Response

Dimensions

Comparison of the Decibel Display and

Multiplier Display

User’s Record

Index

Revision history

— 2 —

SW-4000Q-10GE

Notice

The material contained in this manual consists of information that is proprietary to JAI Ltd., Japan and may only

be used by the purchasers of the product. JAI Ltd., Japan makes no warranty for the use of its product and

assumes no responsibility for any errors which may appear or for damages resulting from the use of the

information contained herein. JAI Ltd., Japan reserves the right to make changes without notice.

Company and product names mentioned in this manual are trademarks or registered trademarks of their

respective owners.

Warranty

For information about the warranty, please contact your factory representative.

Certifications

CE compliance

As defined by the Directive 2004/108/EC of the European Parliament and of the Council, EMC (Electromagnetic

compatibility), JAI Ltd., Japan declares that SW-4000Q-10GE complies with the following provisions applying to

its standards.

EN 61000-6-3 (Generic emission standard part 1)

EN 61000-6-2 (Generic immunity standard part 1)

FCC

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Warning

Changes or modifications to this unit not expressly approved by the party responsible for FCC compliance could

void the user’s authority to operate the equipment.

KC

— 3 —

SW-4000Q-10GE

Supplement

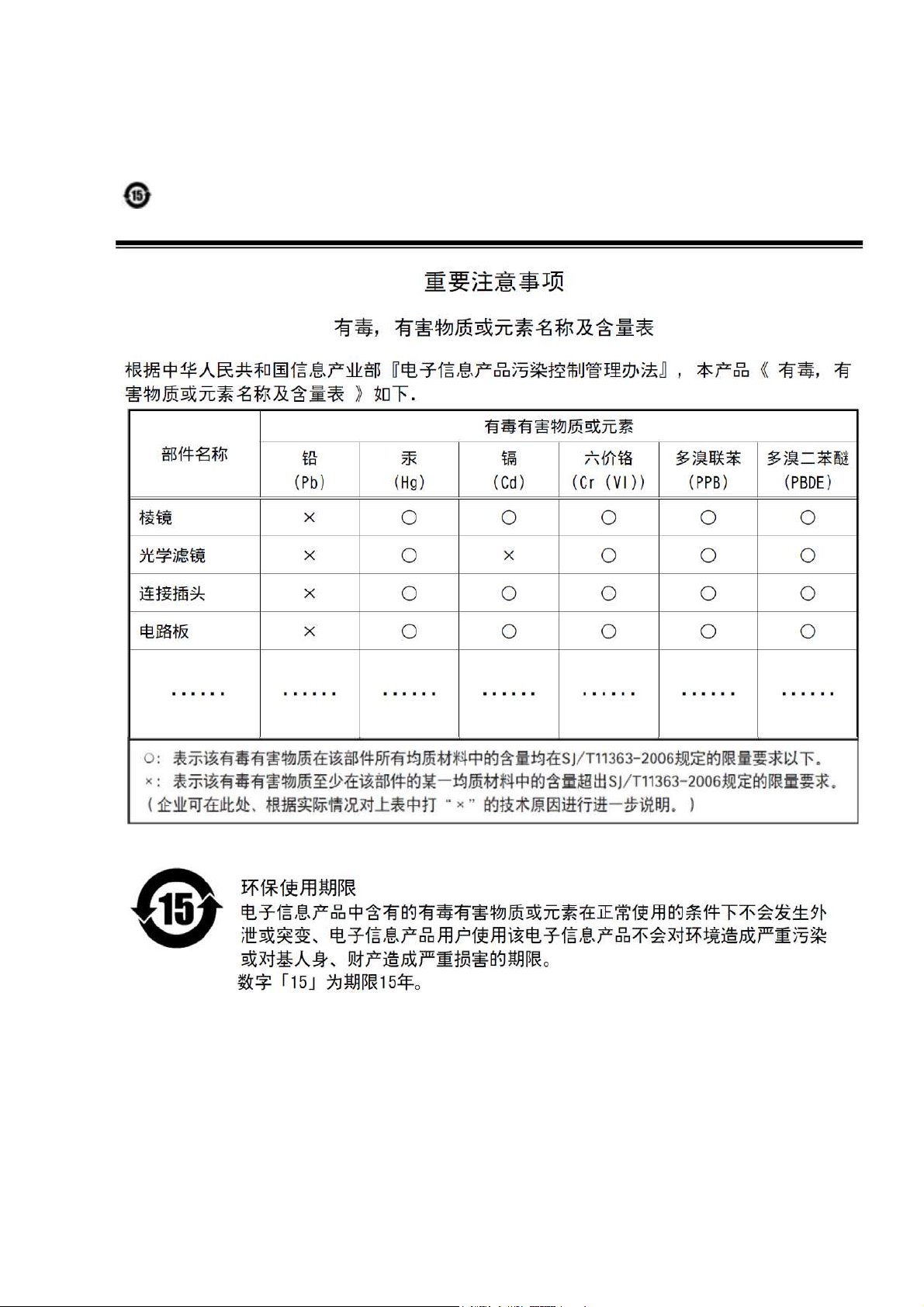

The following statement is related to the regulation on “ Measures for the Administration

of the control of Pollution by Electronic Information Products “ , known as “ China RoHS “.

The table shows contained Hazardous Substances in this camera.

mark shows that the environment-friendly use period of contained Hazardous

Substances is 15 years.

— 4 —

Usage Precautions

Notes on cable configurations

The presence of lighting equipment and television receivers nearby may result in

video noise. In such cases, change the cable configurations or placement.

Notes on LAN cable connection

Secure the locking screws on the connector manually,

and do not use a driver. Do not secure the screws too

tightly. Doing so may wear down the screw threads

on the camera. (Tightening torque: 0.147 Nm or less)

Notes on temperature conditions

The guaranteed operating temperature and humidity of this camera are

-5℃ to +45℃, 20% to 80% (non-condensing).

Please make sure the following temperature condition is met when operating

the unit.

1) The camera's internal temperature sensor detects temperatures of 101 °C

or less during operation.

If the above temperature conditions are exceeded, take measures to dissipate

heat according to your installation environment and conditions.

SW-4000Q-10GE

Secure manually.

Do not secure too tightly.

Notes on attaching the lens

Avoiding dust particles

When attaching the lens to the camera, stray dust and other particles may adhere

to the sensor surface and rear surface of the lens. Be careful of the following

when attaching the lens.

• Work in a clean environment.

• Do not remove the caps from the camera and lens until immediately before

you attach the lens.

• To prevent dust from adhering to surfaces, point the camera and lens

downward and do not allow the lens surface to come into contact with your

hands or other objects.

• Always use a blower brush to remove any dust that adheres.

Never use your hands or cloth, blow with your mouth, or use other methods to

remove dust.

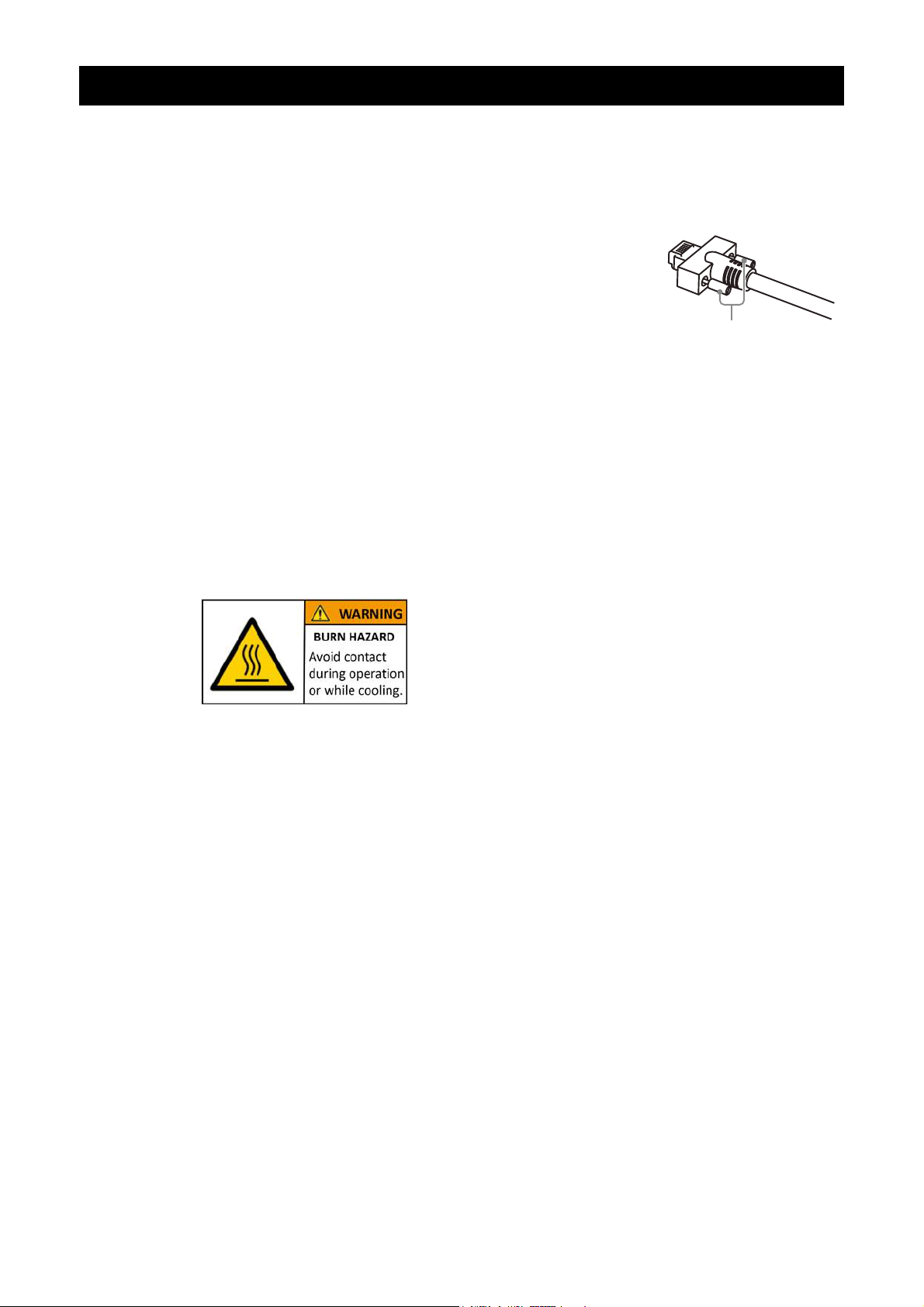

Depending on the operating environment,

the surface of the camera may become very hot

during operation.

Do not touch the camera during operation and

while it is being cooled.

Also, make sure that the cable surface and other

easily deformable items do not contact the surface

of the camera.

— 5 —

Phenomena specific to CMOS image sensors

The following phenomena are known to occur on cameras equipped with CMOS

image sensors. These do not indicate malfunctions.

• Aliasing

When shooting straight lines, stripes, and similar patterns, vertical aliasing

(zigzag distortion) may appear on the monitor.

• Blooming

When strong light enters the camera, some pixels on the CMOS image sensor

may receive much more light than they are designed to hold, causing the

accumulated signal charge to overflow into surrounding pixels.This

“blooming” phenomenon can be seen in the image, but does not affect the

operation of the camera.

• Fixed pattern noise

When shooting dark objects in high-temperature conditions, fixed pattern noise

may occur throughout the entire video monitor screen.

• Defective pixels

Defective pixels (white and black pixels) of the CMOS image sensor are

minimized at the factory according to shipping standards. However, as this

phenomenon can be affected by the ambient temperature, camera settings

(e.g., high sensitivity and long exposure), and other factors, be sure to operate

within the camera’s specified operating environment.

SW-4000Q-10GE

Notes on exportation

When exporting this product, please follow the export regulations of your country

or region.

— 6 —

SW-4000Q-10GE

Features

The SW-4000Q-10GE is a 4CMOS line scan camera using four 4096 pixel line sensors

mounted on a prism, for the R, G, B and NIR channels.

The camera outputs digital data in single-stream or dual-stream via 10 GigE interface.

Features overview

• Prism technology for superior color quality and better color differentiation.

• Pixel size can be switched (

• Supports vertical dual-line binning, 2x horizontal binning, or both.

• It can output both video in visible region and video in the near-infrared region.

Supports Pixel Format RGBa8, which outputs video in the visible region and video

in the near-infrared region as single-stream.

Video in the visible region (RGB8, RGB10V1Packed, RGB10p32, YUV422) and video

in the near-infrared region (Mono8, Mono10Packed) can be output as dual-stream.

• High-speed scanning (Maximum line rate)

Pixel Format RGBa8(8bit) : 73 kHz

Pixel Format YUV422(8bit) + Mono8(8bit) : 74 kHz

Pixel Format RGB8(8bit) + Mono8(8bit) : 72 kHz

• HSI, sRGB, Adobe RGB and XYZ color space conversion.

• Support for connection of rotary encoders.

• Excellent shock and vibration resistance.

• GenICam compliant.

7.5 µm x 7.5 µm, 7.5 µm x 10.5 µm)

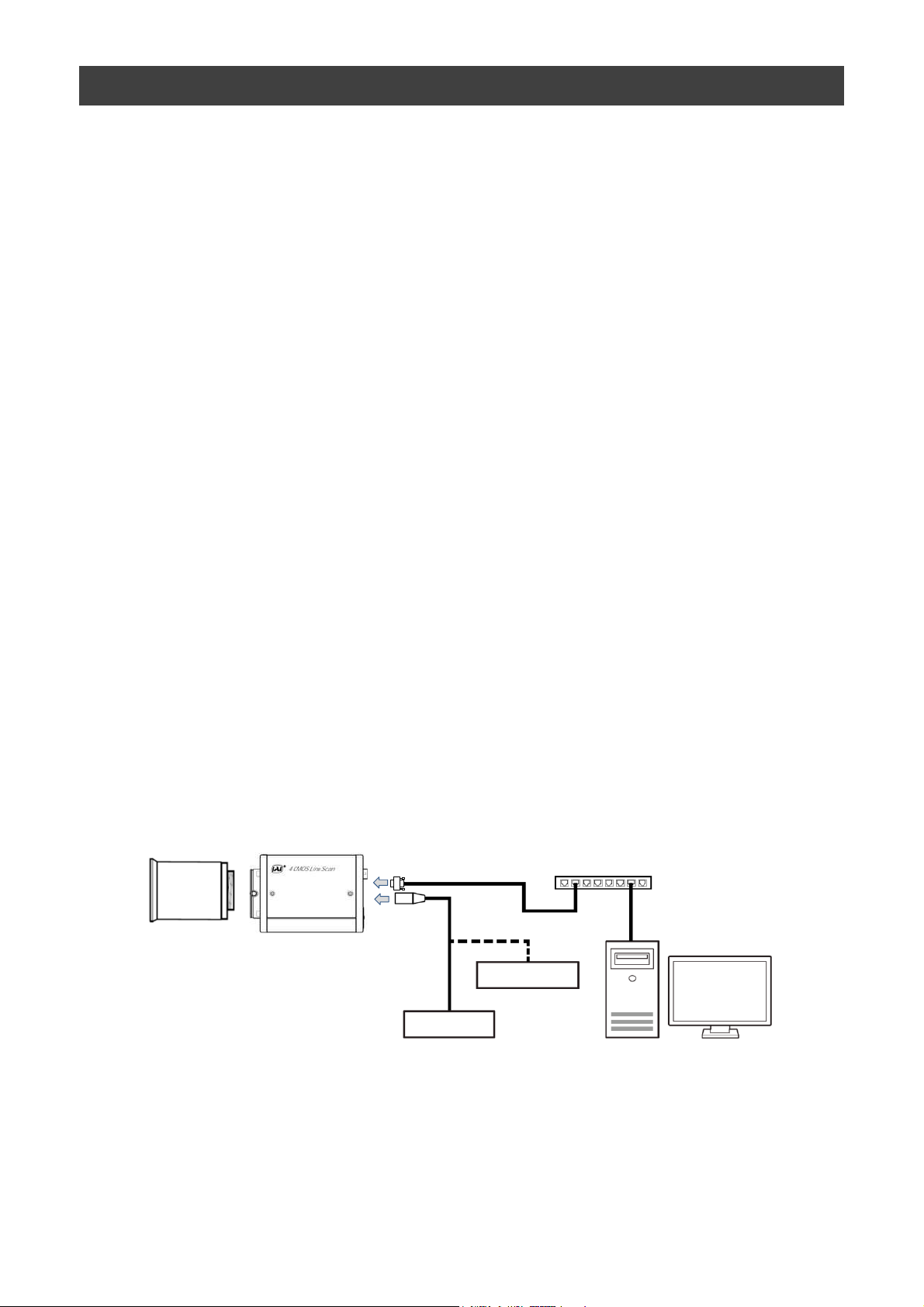

Connection example:

Lens

Camera

Switching hub

AC adapter

External Trigger

PC

— 7 —

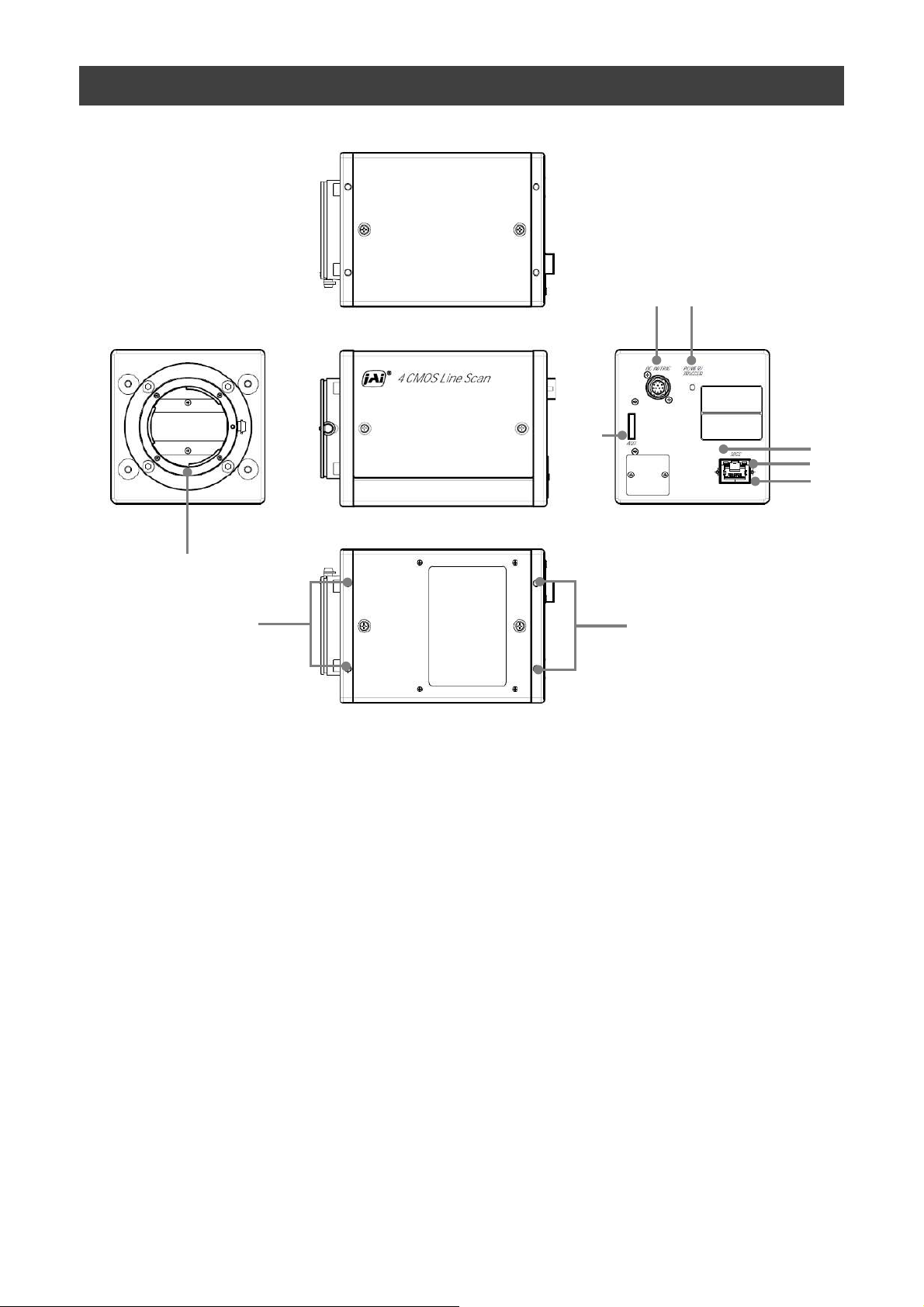

Parts Identification

⑥

SW-4000Q-10GE

②

⑦

①

⑧

⑧

① Lens mount (M52-mount /F-mount)

Mount a M52-mount lens, F-mount lens, etc. here.

❖ Before mounting a lens, be sure to refer to “Step 2:Connecting Devices” and confirm

the precautions for attaching a lens and the supported lens types.

⑤

④

③

— 8 —

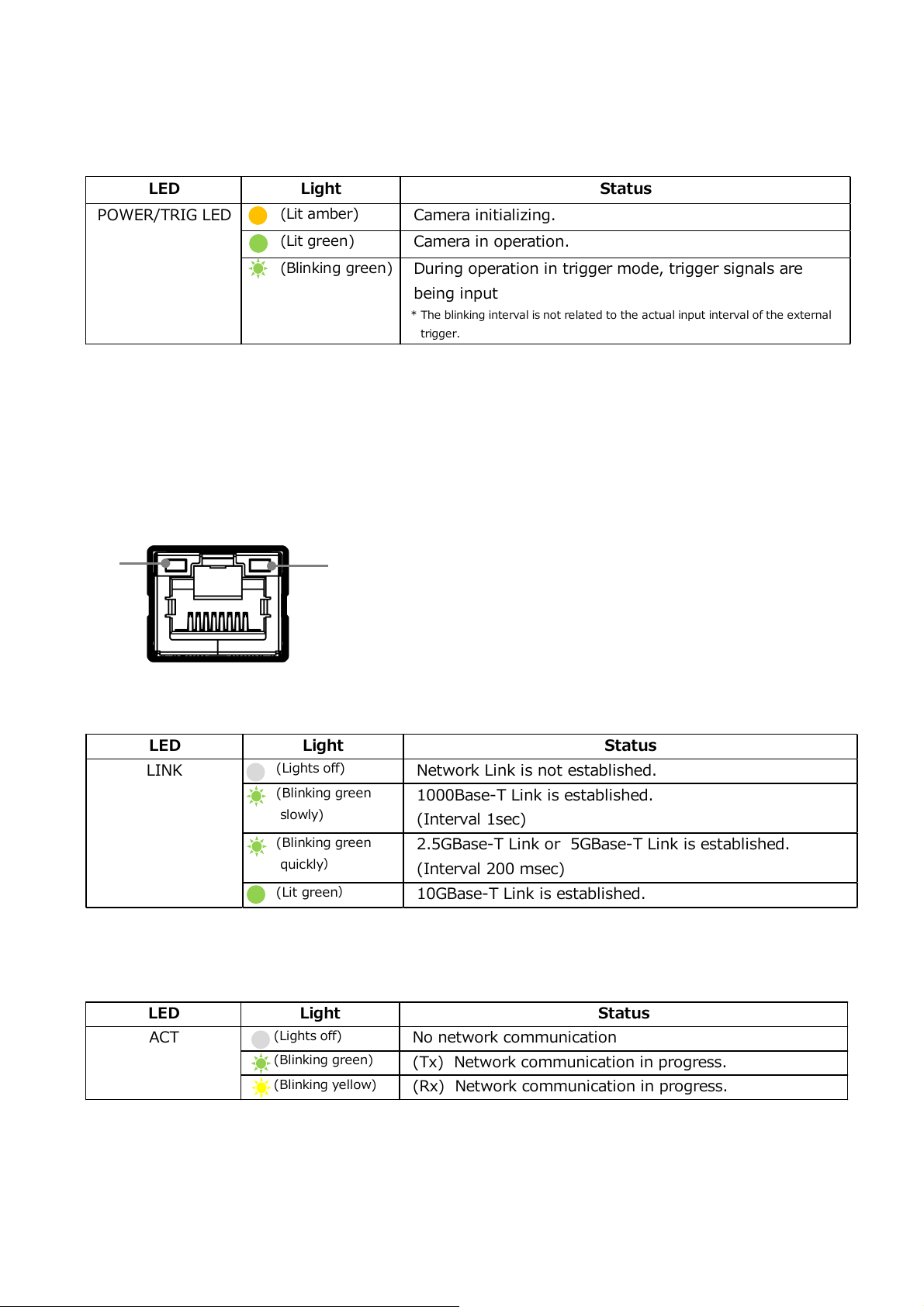

LED Light Status

(Lights off)

No network communication

(Blinking green)

(Tx) Network communication in progress.

(Blinking yellow)

(Rx) Network communication in progress.

ACT

LED Light Status

(Lights off)

Network Link is not established.

(Blinking green

slowly)

1000Base-T Link is established.

(Interval 1sec)

(Blinking green

quickly)

2.5GBase-T Link or 5GBase-T Link is established.

(Interval 200 msec)

(Lit green)

10GBase-T Link is established.

LINK

LED Light

Status

(Lit amber)

Camera initializing.

(Lit green)

Camera in operation.

(Blinking green)

During operation in trigger mode, trigger signals are

being input

* The blinking interval is not related to the actual input interval of the external

trigger.

POWER/TRIG LED

SW-4000Q-10GE

② POWER/TRIG LED

Indicates the power and trigger input status.

LED status and camera status

③ RJ-45 connector

The camera supports the following Ethernet standards.

(1000Base-T, 2.5GBase-T, 5GBase-T, 10GBase-T)

Depending on the Ethernet standard to be used, the cable type and the maximum cable

length are limited.

For details, refer to "Step 2 Connecting Devices".

⑤

④

④ LINK LED

Indicates the link status of the network.

⑤ ACT LED

Indicates the network communication status.

— 9 —

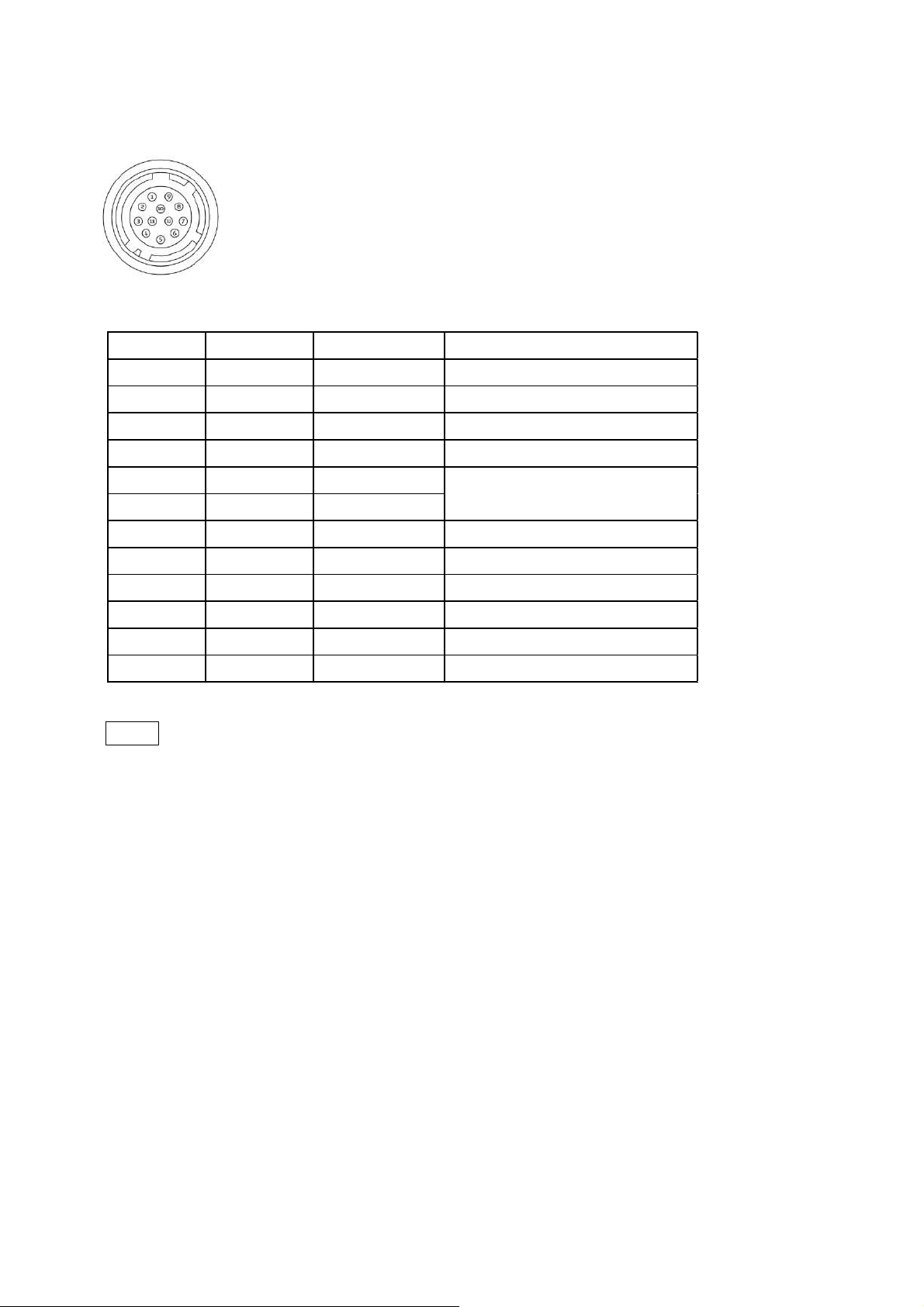

Pin No.

Input/Output

Signal Description

1 GND

2 Power In DC In DC 10 V ~ 25 V

3 GND

4 RESERVED

5 In Opto In 1 -

6 In Opto In 1 +

7 Out TTL Out 4 Line 12

8 NC

9 Out TTL Out 1 Line 1

10 In TTL In 1 Line 4

11 Power In DC In DC 10 V ~ 25 V

12 GND

Line 5

⑥ DC IN/TRIG connector(12-pin round)

Connect the cable for a power supply (optional) or for DC IN / trigger IN here.

HR10A-10R-12PB(71)(Hirose Electric or equivalent )

SW-4000Q-10GE

Note

In order to operate at the maximum line rate, 10-25V DC power must be connected to

both Pin1/Pin2 and Pin 11/Pin12. If you supply power to only one pin pair, the camera

may operate at less than the maximum line rate or may not operate at all.

IMPORTANT! You must supply the same voltage to each pin pair. If you supply different

voltages to each pin pair, the power unit of the camera will be damaged.

TTL signal specification

TTL out signal specification (Typ.)

Output voltage: Low 0.0V

Input/Output current: +/-32mA

TTL in signal specification (Typ.)

Input voltage: Low 0.0~0.8V

High 5.0V

High 2.0~5.5V

— 10 —

Pin No.

Input/Output

Signal Description

1 Out TTL_OUT2 Line 8

2 Out TTL_OUT3 Line 9

3 In TTL_IN2 Line 10

4 N.C.

5 GND GND

6 In TTL_IN3 Line 13

7 N.C.

8 N.C.

9 GND GND

10 GND GND

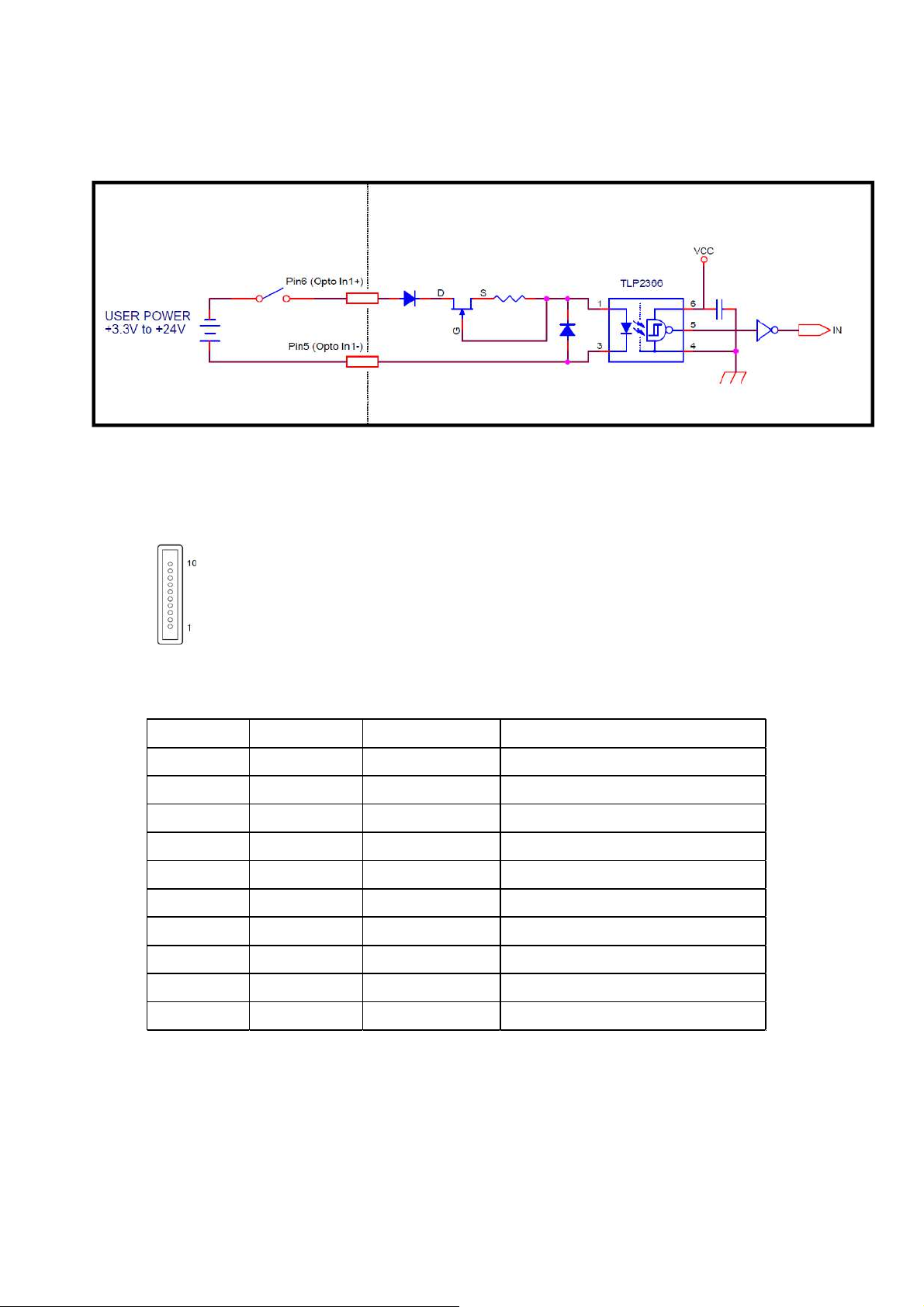

Recommended external input circuit diagram (reference example)

SW-4000Q-10GE

User side

User

side

⑦ AUX connector(10-pin)

JAI Camera side

CAMERA

side

Camera side:3260-10S3(55)(Hirose Electric or equivalent )

Cable side :3240-10P-C(50)(Hirose Electric or equivalent )

⑧ Camera locking screw holes (M4, 6mm depth)

Use these holes when mounting the camera directly to a wall or other structural

system.

— 11 —

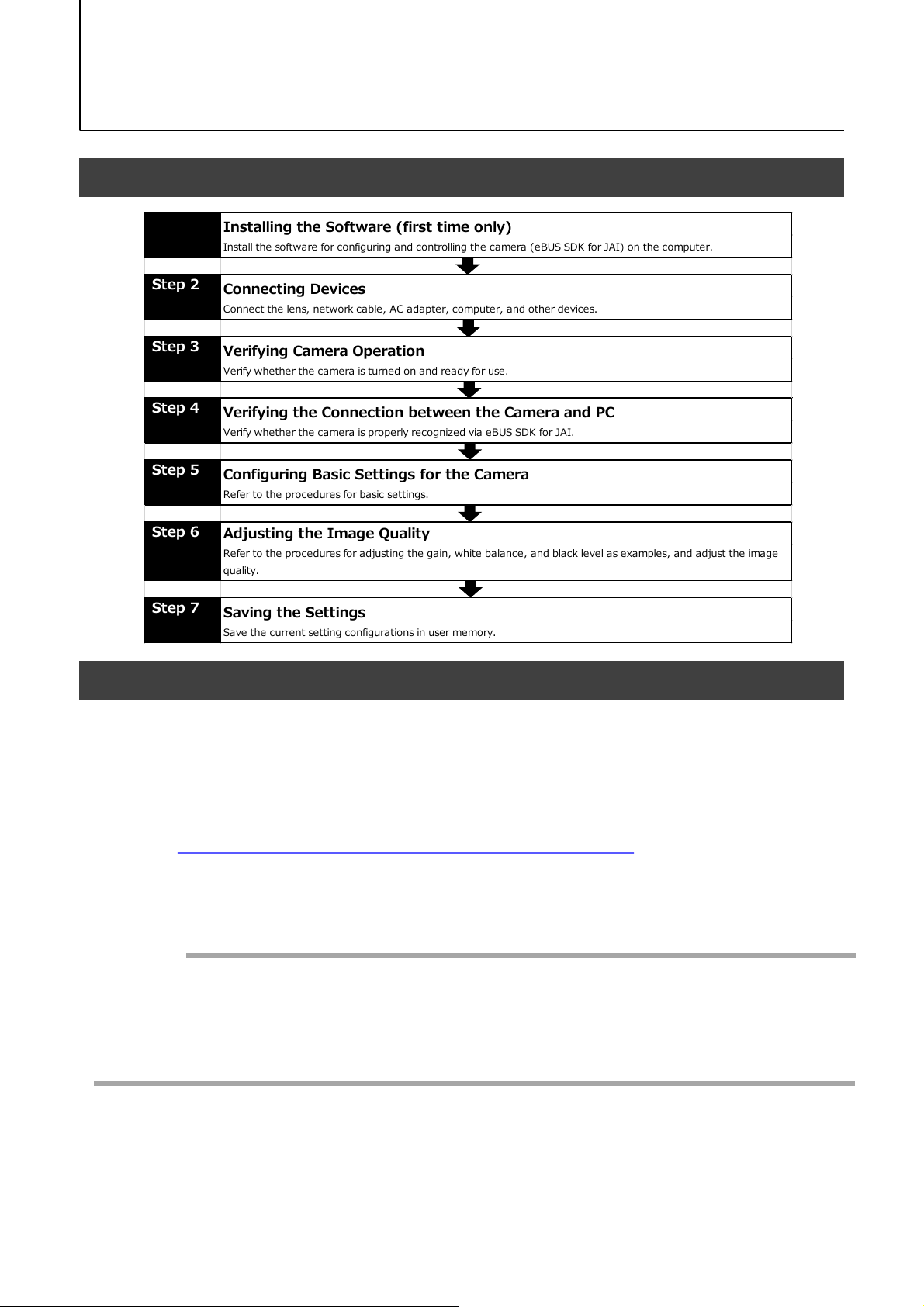

Step 7

Saving the Settings

Save the c urrent setting configurations in user memory.

Step 3

Verifying Camera Operation

Verify whe the r the c ame ra is turne d o n and re ad y for use .

Step 4

Verifying the Connection between the Camera and PC

Verify whe the r the c ame ra is properly re co gnize d via eB US SDK for J AI.

Step 5

Configuring Basic Settings for the Camera

Refer to the pro ce dures fo r basic se ttings.

Installing the Software (first time only)

Install the software for configuring and controlling the camera (eBUS SDK for JAI) on the c omputer.

Step 1

Step 2

Connecting Devices

Connect the lens, network cable, AC adapter, computer, and other devices.

Step 6

Adjusting the Image Quality

Refer to the procedures for adjusting the gain, white balance, and black level as examples, and adjust the image

quality.

Preparation

Preparation Process

SW-4000Q-10GE

Step 1: Installing the Software (first time only)

When using the camera for the first time, install the software for configuring and

controlling the camera (eBUS SDK for JAI) on the computer.

❖ When you install eBUS SDK for JAI, eBUS SDK for JAI player will also be installed.

Download the eBUS SDK for JAI from the JAI website.

1

URL https://www.jai.com/jp/support-software/jai-software

Install eBUS SDK for JAI on the computer.

2

Caution

eBUS SDK for JAI was released in April 2018 and is the latest software for setting and

controlling JAI cameras.

When JAI SDK and eBUS SDK for JAI are installed on the same machine, conflicts can

occur. Therefore, JAI strongly recommends that JAI SDK is uninstalled before installing

eBUS SDK for JAI.

— 12 —

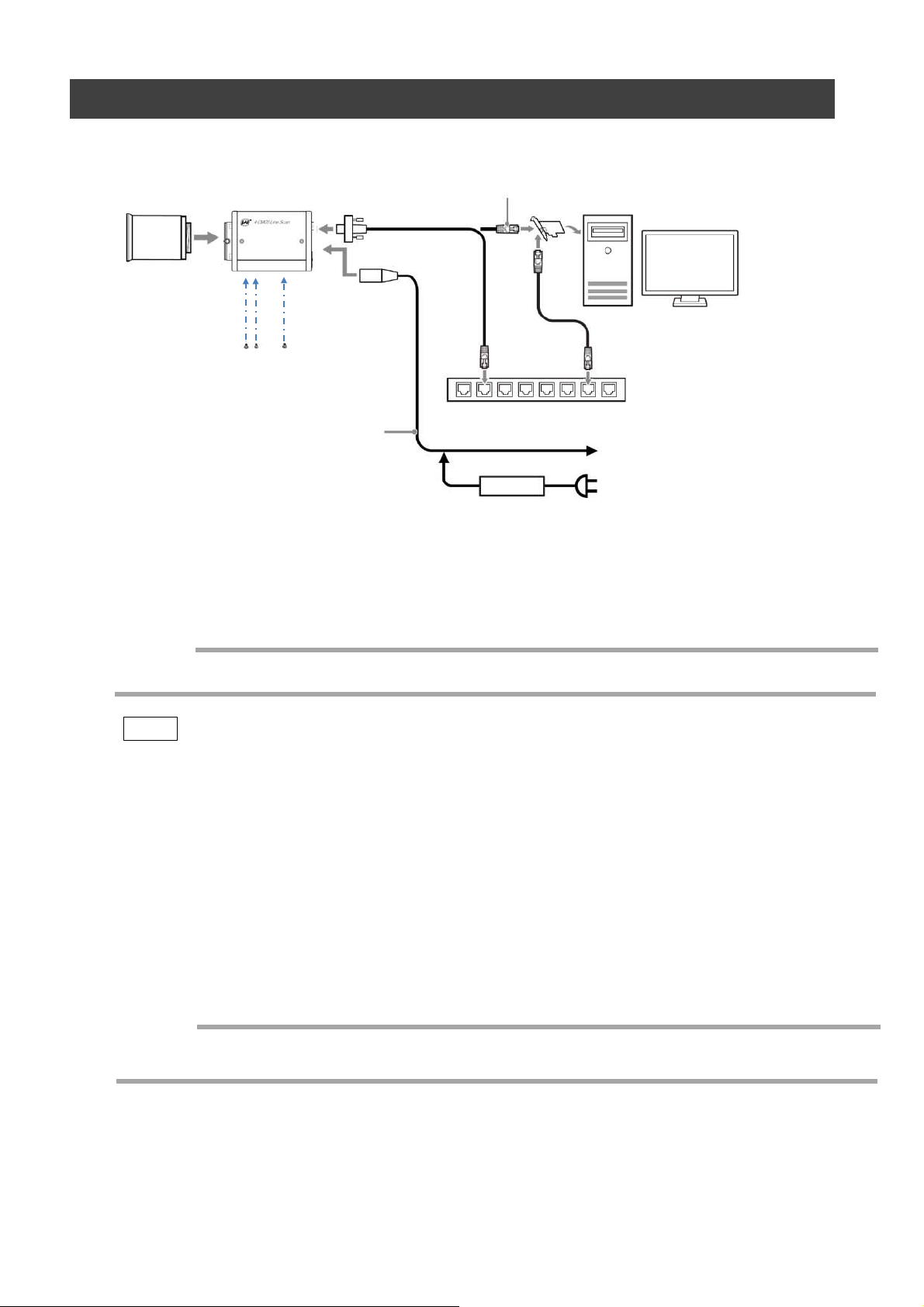

Step 2: Connecting Devices

SW-4000Q-10GE

Camera body

③ LAN cable

①Lens

② Direct connection

⑤ DC IN/trigger IN

connection cable

① Lens

・Attach an M52-mount lens or F-mount lens.

(or direct connection)

④ Network card

Switching hub

or

⑥ AC adapter (not supplied)

Caution

The maximum performance of the camera may not be realized depending on the lens.

Note

The following formula can be used to estimate the focal length.

focal length = WD/(1 + W/w)

WD: Working distance (distance between lens and object)

W : Width of object

w : Width of sensor 30.72 mm on this camera.

② Direct connection

When mounting the camera directly to another device, for example, use screws that match the

camera locking screw holes on the camera. (M4, 6 mm depth)

Caution

For heavy lenses, be sure to support the lens itself. Do not use configurations in which its weight

is supported by the camera.

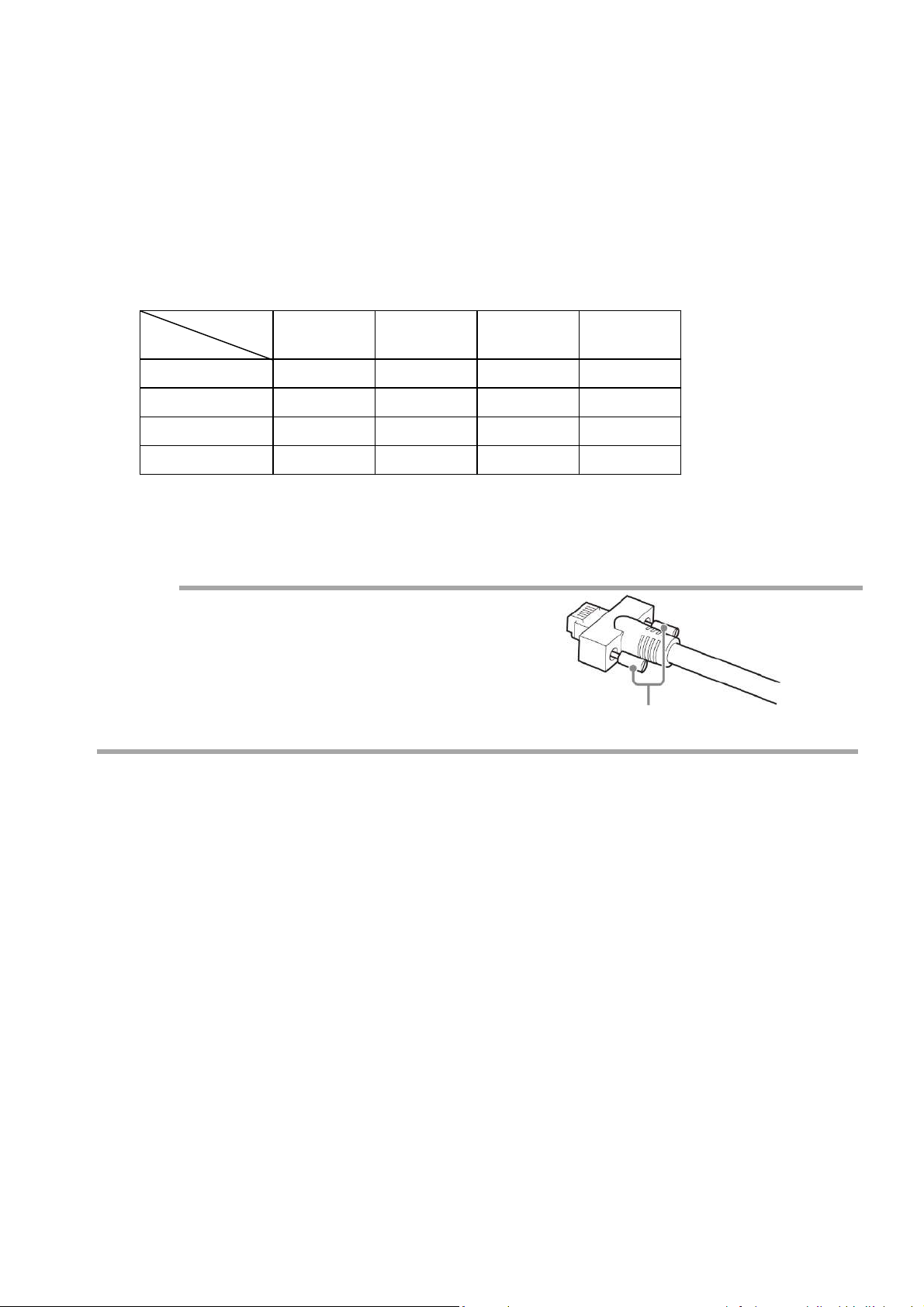

— 13 —

Cat5e Cat6/Cat6e Cat6A Cat7

1000Base-T 100m 100m 100m 100m

2.5GBase-T 100m 100m 100m 100m

5GBase-T 100m 100m 100m

10GBase-T 55m 100m 100m

SW-4000Q-10GE

③ LAN cable

Connect a LAN cable to the RJ-45 connector.

・ The camera supports the following Ethernet standards.

(1000Base-T, 2.5GBase-T, 5GBase-T, 10GBase-T)

・ The longest cable length varies depending on the type of LAN cable and the Ethernet standard.

Below, the table shows the relationship diagram between LAN cable type and Ethernet standard.

Correctly select the LAN cable type according to the Ethernet standard to be used.

■ About the longest cable length

LAN cable type

Ethernet standard

-

-

・ Refer to the specifications of the cable for details on its bend radius.

Caution

Secure the locking screws on the connector

manually, and do not use a driver. Do not secure

the screws too tightly. Doing so may wear down the

screw threads on the camera. (Tightening torque:

0.147 Nm or less)

Secure manually.

Do not secure too tightly.

④ Network card

Install this in the computer that will be used to configure and operate the camera.

Refer to the instruction manual of the network card, and configure settings on the computer as

necessary.

— 14 —

⑤ DC IN / trigger IN connection cable

⑥ AC adapter (power supply) (if necessary)

Connect the AC adapter and the round connector of the connection cable to the DC IN /

trigger IN connector on the camera.

Step 3: Verifying Camera Operation

When power is supplied to the camera while the necessary equipment is connected, the

POWER/TRIG LED at the rear of the camera lights amber, and initialization of the camera

starts. When initialization is complete, the POWER/TRIG LED lights green.

Verify whether power is being supplied to the camera by checking the rear LED.

When properly turned on

Lit green

SW-4000Q-10GE

* For details on how to read the LEDs, see “LED status and camera status” in the “Parts

Identification” section.

Step 4: Verifying the Connection between the Camera and PC

Verify whether the camera is properly recognized via Control Tool.

Connecting the Camera to Control Tool

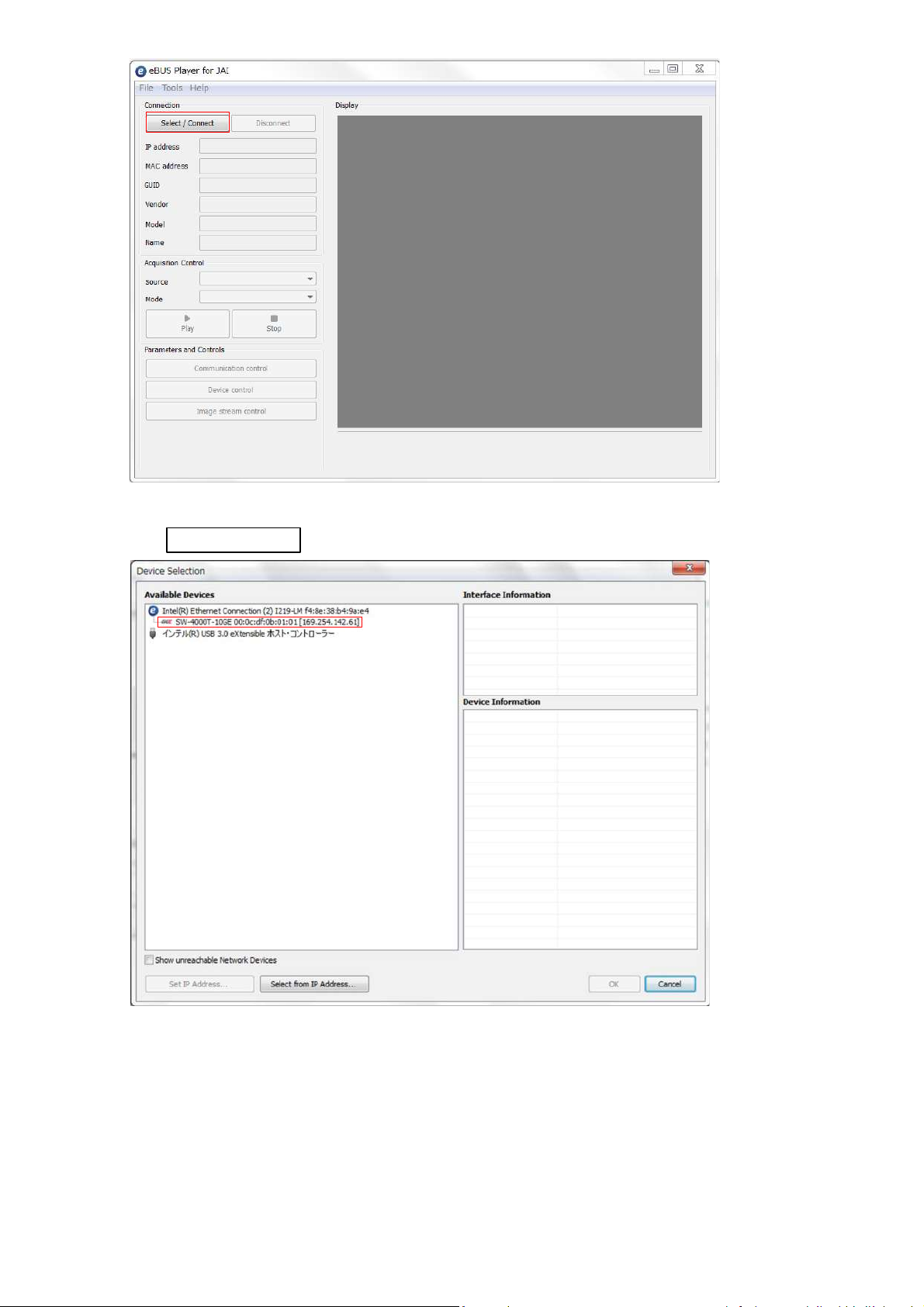

Startup eBUS Player for JAI

1

eBUS Player for JAI startup screen appears.

— 15 —

SW-4000Q-10GE

Select the camera you want to configure.

2

Push Select / Connect button

The connected camera is listed.

Please select one camera.

— 16 —

SW-4000Q-10GE

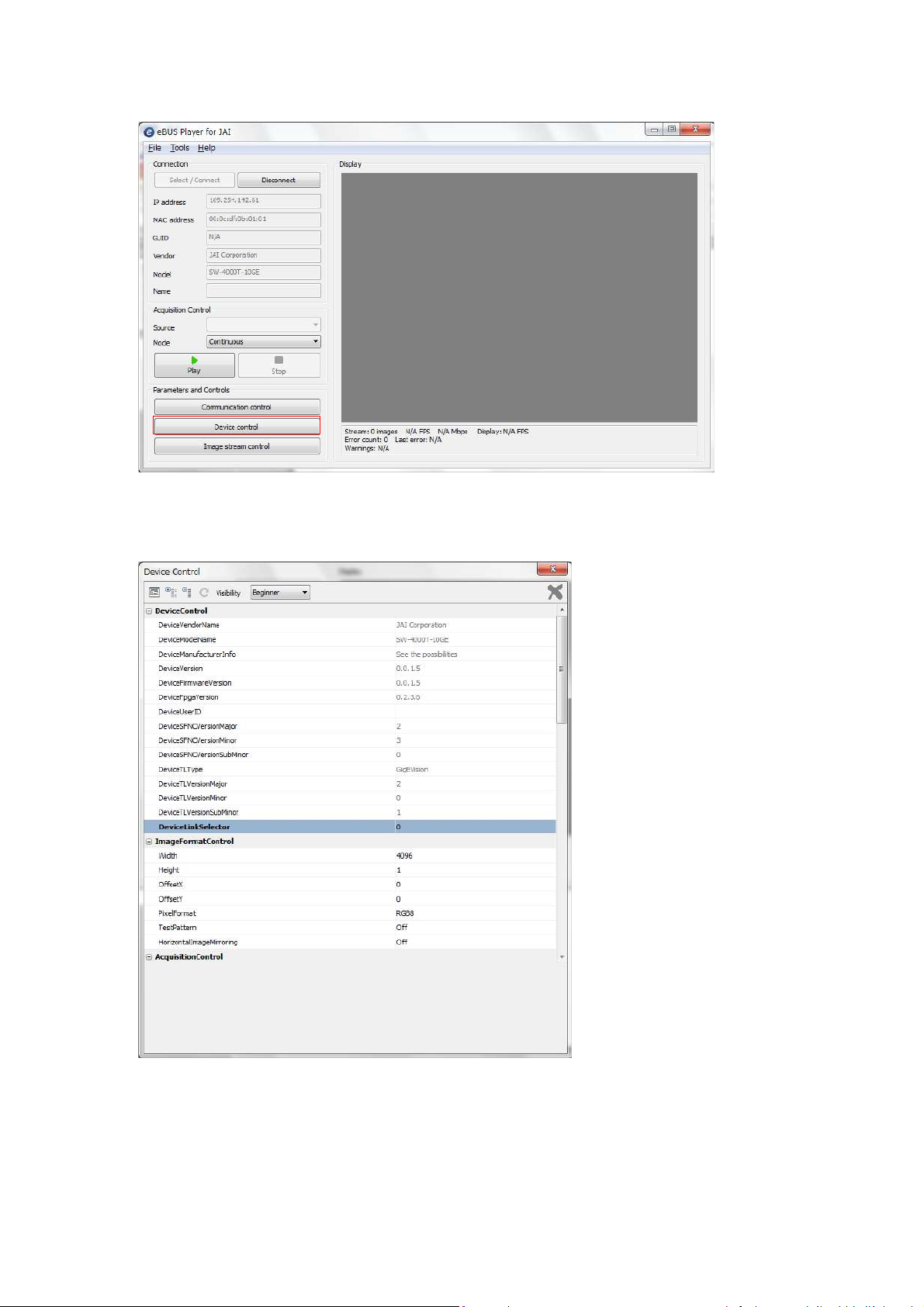

3

Check that the settings of the selected camera are displayed.

Push the Device control button.

The screen shown below will be displayed. In this window you can adjust various

settings of the camera.

This completes the procedure for verifying whether the camera is properly recognized and

whether control and settings configuration are possible.

— 17 —

Item Setting value / selectable range

Trigger Mode On

Trigger Selector Line Start

Trigger Source Any

Trigger Activation

LevelHigh

(high-level duratio n)

,

LevelLow

(low -le vel duratio n)

Exposure Mode TriggerWidth

(co ntro l via trig ger width)

Item Setting value / selectable range

Trigger Mode On

Trigger Selector Line Start

Trigger Source Any

Trigger Activation

Rising Edge

(rising e dge of input signal)

,

Falling Edge

(falling edge of input signal)

Exposure Mode Timed

(control via exposure time)

Exposure Time Varies depending on settings.

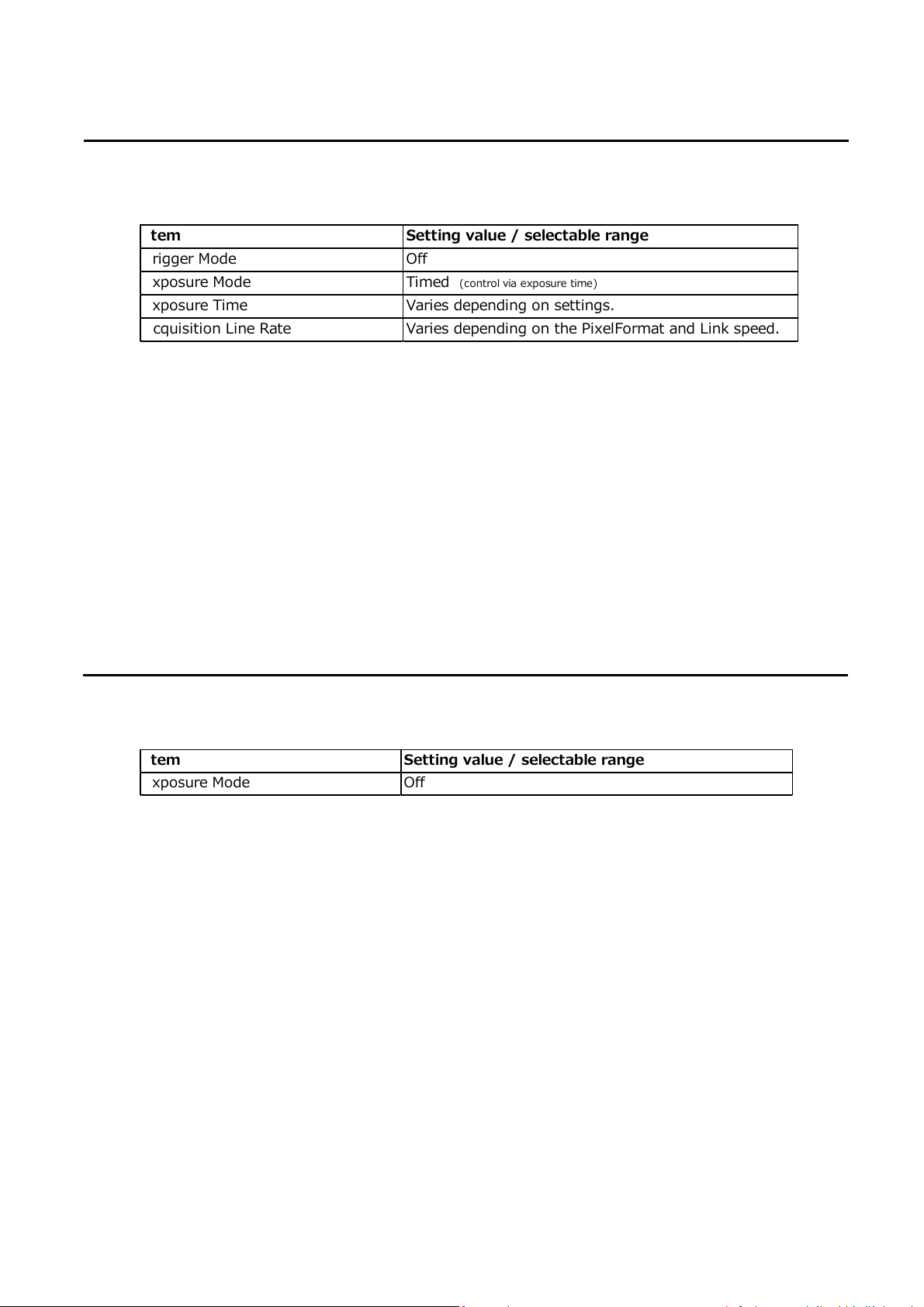

Step 5 Configuring Basic Settings for the Camera

■Control via External Triggers

When Controlling the Exposure Time Using Specified Exposure Times

Configure the settings as follows.

SW-4000Q-10GE

Set [Exposure Mode] to [Timed].

1

Specify the exposure time in [Exposure Time].

2

Set [Trigger Mode] to [On] and set [Trigger Selector] to [Line Start].

3

If necessary, change the [Trigger Source], and [Trigger Activation] settings.

4

When Controlling the Exposure Time Using the Pulse Width of the Trigger

Input Signal

Configure the settings as follows.

Set [Trigger Mode] to [On] .

1

Set [Exposure Mode] to [Trigger Width] .

2

If necessary, change the [Trigger Source] and [Trigger Activation] settings.

3

— 18 —

Item Setting value / selectable range

Exposure Mode Off

Item

Setting value / selectable range

Trigger Mode Off

Exposure Mode Timed

(control via exposure time)

Exposure Time Varies depending on settings.

Acquisition Line Rate Varies depending on the PixelFormat and Link speed.

■Control Without External Triggers

When Controlling the Exposure Time Using Specified Exposure Times

Configure the settings as follows.

Set [Exposure Mode] to [Timed].

1

SW-4000Q-10GE

Set [Trigger Mode] to [Off].

2

Specify a line period slower than the exposure time in [Acquisition Line Rate].

3

Specify the exposure time in [Exposure Time].

4

When Not Controlling the Exposure Time

Configure the settings as follows.

The exposure will be performed with an exposure time equal to 1 / line rate.

* The exposure time specified in [Exposure Time] will be disabled.

— 19 —

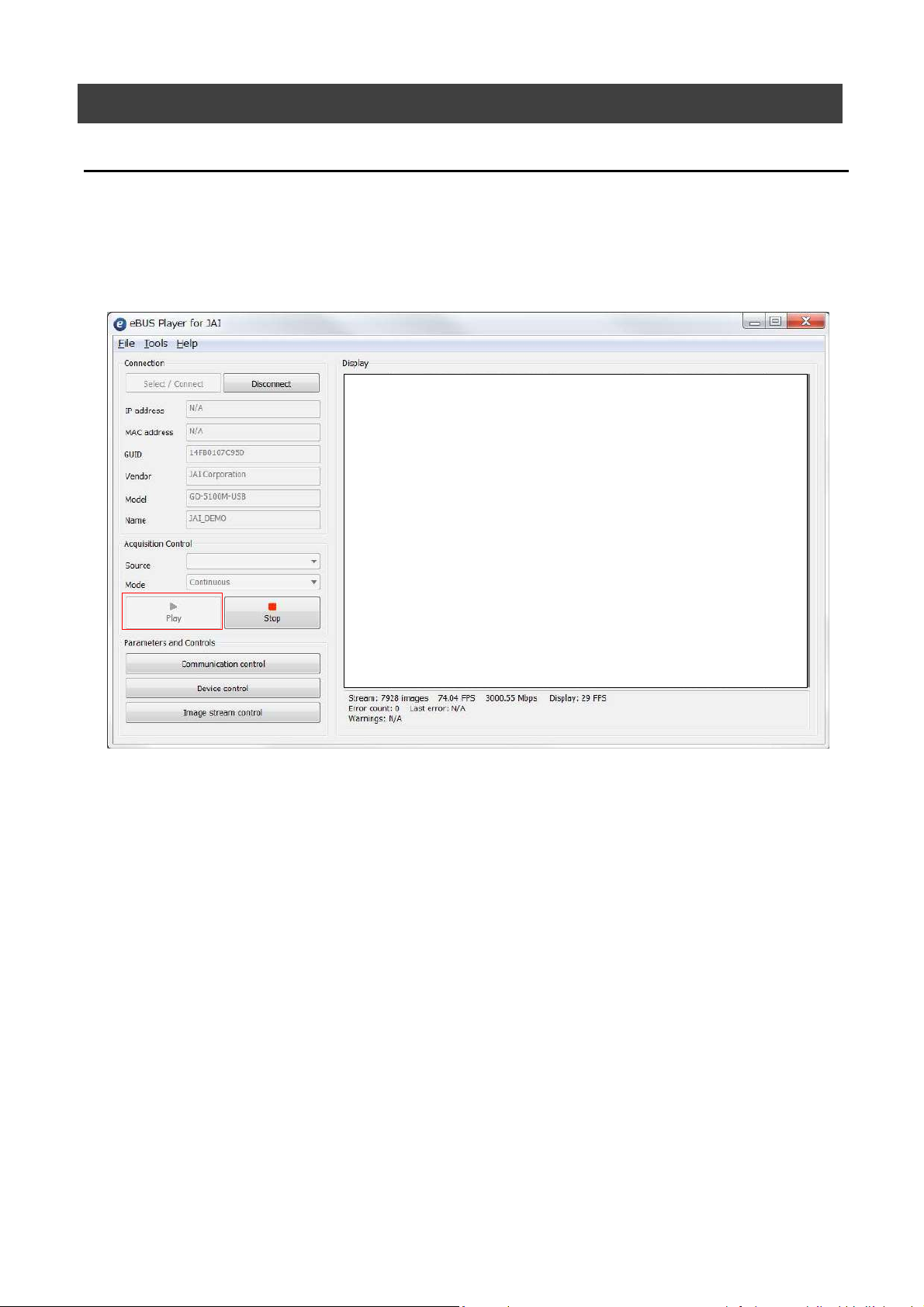

Step 6: Adjusting the Image Quality

Display the camera image and adjust the image quality.

Displaying the Image

Display the image captured by the camera.

When you push [Play] button, the camera image appears in right area.

*) By default settings, the video in the visible region are displayed.

SW-4000Q-10GE

To maximize the performance of the camera, configure its basic function in the following

order.

Configure the line rate.

1

◇ For details on this setting, “Variable Line Rate”.

Configure the exposure time.

2

◇ For details on this setting, “Electronic Shutter” .

Perform DSNU correction.

3

◇ For details on this setting, “Pixel Sensitivity Correction”.

Perform PRNU correction.

4

◇ For details on this setting, “Pixel Sensitivity Correction” .

Adjust the black level.

5

◇ For details on this setting, “Black Level Correction”.

— 20 —

Adjust the white balance.

6

Adjust the white balance using the automatic adjustment function.

① Place a white sheet of paper or similar object under the same lighting conditions as

the intended subject, and zoom in to capture the white.

White objects near the subject, such as a white cloth or wall, can also be used.

Be sure to prevent the high-intensity spot lights from entering the screen.

The white balance is automatically adjusted.

② Select the [Balance White Auto] tab, and select [Once].

The white balance is automatically adjusted.

Step 7: Saving the Settings

The setting values configured in the player (eBUS SDK for JAI) will be deleted when the

camera is turned off. By saving current setting values to user memory, you can load and

recall them whenever necessary. You can save up to three sets of user settings in the

camera. (User Set1 to 3)

SW-4000Q-10GE

Memory(Flash)

DefaultSet

UserSet1

UserSet2

UserSet3

一時メモリ

Memory(RAM)

Working Set

Note

Changes to settings are not saved to the computer (eBUS SDK for JAI).

■ To save user settings

eBUS SDK for

JAI (Player)

Stop image acquisition.

1

Expand [UserSetControl], and select the save destination ([UserSet1] to

2

[UserSet3]) in [UserSetSelector].

Note

The factory default setting values are stored in [Default] and cannot be overwritten.

Caution

Settings can only be saved when image acquisition on the camera is stopped.

— 21 —

Select [UserSetSave], and click [UserSetSave].

3

The current setting values are saved as user settings.

■ To load user settings

Stop image acquisition.

1

User settings can only be loaded when image capture on the camera is stopped.

Select the settings to load (UserSet1 to UserSet3) in [UserSetSelector].

2

Select [UserSetLoad], and click [UserSetLoad].

3

The selected user settings are loaded.

SW-4000Q-10GE

— 22 —

Main Functions

Line4 TTL In 1 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Line5 Opt In 1 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Line10 TTL In 2 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Line13 TTL In 3 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

UserOutput0 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

UserOutput1 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

UserOutput2 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

UserOutput3 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Action0 ○ ○ ○ ○ ○ ー ー ー ー ー ー ー ー ー ー

Action1 ○ ○ ○ ○ ○ ー ー ー ー ー ー ー ー ー ー

Action2 ○ ○ ○ ○ ○ ー ー ー ー ー ー ー ー ー ー

Action3 ○ ○ ○ ○ ○ ー ー ー ー ー ー ー ー ー ー

PulseGenerator0 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ー ー ー ー

PulseGenerator1 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ー ー ー ー

PulseGenerator2 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ー ー ー ー

PulseGenerator3 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ー ー ー ー

Encoder Trigger ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Encoder Direction ー ー ー ー ー ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Logic Block 0 ○ ○ ○ ○ ○ ○ ○ ○ ○ ー ○ ○ ○ ○ ○

Logic Block 1 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ー ○ ○ ○ ○

Acquisition Active ー ー ー ー ー ○ ○ ○ ○ ○ ○ ー ー ー ー

Exposure Active ー ー ー ー ー ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

LVAL ー ー ー ー ー ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Signals to use as output

Output destination

Pulse Generator 0

Pulse Generator 1

Pulse Generator 2

Pulse Generator 3

Logic Block 0

Logic Block 1

Acquisition Start

Acquisi tion End

Frame Start

Frame T ransfer Start

Trigger Selector

Line Selector

Pulse Generator Selector

Trigger Selector

Pulse Generator Selector

Line Selector

Use

Line Start

Line8 TTL Out 2

Line9 TTL Out 3

Line12 TTL Out 4

Line1 TTL Out 1

Valid Input / Output Combinations

The following signals can be used as sources for each output destination (Trigger Selector,

Line Selector, Pulse Generator Selector).

You can also connect two different sources to NAND paths in the GPIO and reuse the signal

generated there as a source for a different selector.

The combinations of source signals and output destinations are indicated in the following.

Selector

(Cross point

switch output)

SW-4000Q-10GE

Source Signal

(Cross point

switch input)

— 23 —

Line1 TTL Out 1

DC IN / TRIG IN connector (12 pin)

Line8 TTL Out 2 AUX connector (10 pin)

Line9 TTL Out 3 AUX connector (10 pin)

Line12 TTL Out 4 DC IN / TRIG IN connector (12 pin)

Line4 TTL In 1 DC IN / TRIG IN connector (12 pin)

Line5 Opt In 1 DC IN / TRIG IN connector (12 pin)

Line10 TTL In 2 AUX connector (10 pin)

Line13 TTL In 3 AUX connector (10 pin)

External

output

External

input

GPIO (Digital Input / Output Settings)

The unit can input/output the following signals to and from external input/output connectors.

These signals can be used as triggers and other necessary signals within the camera or as

signals output from the camera to the system, such as those used for lighting equipment

control.

Signals are selected as follows.

• When using external signals or the signals of each GPIO module as trigger signals:

Select in [Trigger Selector] > [Trigger Source].

• When selecting the signals to use for external outputs:

Select in [Line Selector] > [Line Source].

SW-4000Q-10GE

— 24 —

Pixel format

Stream 0 Stream 1

1 RGB8 Mono8

2 RGB8 Mono10Packed

3 RGB10V1Packed Mono8

4 RGB10V1Packed Mono10Packed

5 RGB10p32 Mono8

6 RGB10p32 Mono10Packed

7 YUV422_8 Mono8

8 YUV422_8 Mono10Packed

9 YUV422_8_UYVY Mono8

10 YUV422_8_UYVY Mono10Packed

This camera can capture the image in the visible region and the near infrared region (NIR)

simultaneously.

There are the following two ways of sending data of the two captured images from the camera.

1. Single-stream output

Stream 0

SW-4000Q-10GE

…

NIR

NIR

R

G

B

B

NIR

R

G

B

NIR

R

G

R

G

B

Support PixelFormat : RGBa8

2. Dual-stream output

Stream 0

Stream 1

…

…

R

R

G

B

NIR

B

R

G

B

NIR

NIR

R

G

B

R

G

B

NIRNIR

Support PixelFormat :

Stream 0 ( RGB8, RGB10V1Packed, RGB10p32, YUV422_8, YUV422_8_UYVY )

Stream 1 ( Mono8, Mono10Packed )

There are ten combinations of PixelFormat that can be set as shown below.

The fastest line rate can be realized by setting 7.YUV422_8, Mono8 or 9.YUV422_8_UYVY, Mono8

With the smallest number of bits per pixel.

By setting 4.RGB10V1Packed, Mono10Packed or 6.RGB10p32, Mono10Packed, which has the largest

number of bits per pixel, the highest image quality can be taken.

— 25 —

SW-4000Q-10GE

ComponentSelector = RGB ComponentSelector = NIR

1 Single-Stream RGBa8 ー

Stream 0 Stream 1

2 RGB8 Mono8

3 RGB8 Mono10Packed

4 RGB10V1Packed Mono8

5 RGB10V1Packed Mono10Packed

6 RGB10p32 Mono8

7 RGB10p32 Mono10Packed

8 YUV422_8 Mono8

9 YUV422_8 Mono10Packed

10 YUV422_8_UYVY Mono8

11 YUV422_8_UYVY Mono10Packed

Dual-Stream

Note

Stream 0, Stream 1 are two UDP streams, each assigned a different port number.

The assigned port number can be confirmed with the following settings.

In [TransportLayerControl] - [GevStreamChannelSelector], select the stream whose port number

you want to check, the port number will be displayed in [GevSCSP].

Setting the pixel format

The pixel format is set with [ComponentSelector] and [PixelFormat].

Single-Stream output

1. Select [RGB] in [ImageFormatControl] – [ComponentSelector].

2. Select [RGBa8] in [PixelFormat].

Dual-Stream output

First stream (Stream 0) setting.

1. Select [RGB] in [ImageFormatControl] – [ComponentSelector].

2. Select [RGB8, RGB10V1Packed, YUV422_8_UYVY or YUV422_8] in [PixelFormat].

Second stream (Stream 1) setting.

1. Select [NIR] in [ImageFormatControl] – [ComponentSelector].

2. Select [Mono8 or Mono10Packed] in [PixelFormat].

There are eleven combinations of PixelFormat that can be set as shown below.

— 26 —

Exposure Mode

Exposure Mode Trigger Mode

OFF

ON

OFF

ON

Trigger Width

ON

Operation mode

OFF

Timed

Imaging of one frame is started by input of external trigger signal.

Start image acquisition in response to the external trigger signal input.

Stop image acquisition in response to the external trigger signal input.

Output acquired images at a specified timing in response to an external

trigger signal input.

* There is a limit to the number of image frames that can be stored

Imaging of one line is started by input of external trigger signal.

The following operation modes are available on the camera.

Image Output Timing

■ Trigger Control

SW-4000Q-10GE

In this camera, the following control is performed by the external trigger signal.

Trigger Selector Description

FrameStart

AcquisitionStart

AcquisitionEnd

FrameTransferStart

internally.

Example : (PixelFormat RGBa8, Width 4096, Height 4096)

It is possible to hold 3 frames of images.

Line Start

— 27 —

■ When [Exposure Mode] is [OFF]

Delay Time from

Exposure Active

Trigger

B1

B2

Exposure Active

Readout

Pixel Format Width

Trigger

Period[A]

(μs)

A

(*)(**)

Trigger to

Exposure

Active[B1]

(μs)

C

Expousre Active

Non Active[B2]

(μs)

Period from

Falling

to Readout

Start[C]

(μs)

SW-4000Q-10GE

D

Readout

Period[D]

(μs)

RGB10V1Pack

RGB10p32

YUV422_8

YUV422_8_UY

*) H Binning = Off

**) GevGVSPExtendedIDMode = Off, GevSCPDPacketSize = 8976

RGB8

RGBa8

ed

VY

4096 14.70 0.4 3.6 37.0 6.56

2048 7.69 0.4 3.6 30.4 3.28

16 5.45 0.4 3.6 23.9 0.03

4096 14.49 0.4 3.6 37.0 6.56

2048 7.37 0.4 3.6 30.4 3.28

16 5.45 0.4 3.6 23.9 0.03

4096 18.27 0.4 3.6 37.0 6.56

2048 9.42 0.4 3.6 30.4 3.28

16 5.45 0.4 3.6 23.9 0.03

4096 18.27 0.4 3.6 37.0 6.56

2048 9.42 0.4 3.6 30.4 3.28

16 5.45 0.4 3.6 23.9 0.03

4096 13.52 0.4 3.6 37.0 6.56

2048 6.76 0.4 3.6 30.4 3.28

16 5.45 0.4 3.6 23.9 0.03

4096 13.53 0.4 3.6 37.0 6.56

2048 6.76 0.4 3.6 30.4 3.28

16 5.45 0.4 3.6 23.9 0.03

— 28 —

■ When [Exposure Mode] is [Timed]

Pixel Format Width

Trigger

Period[A]

(μs)

(*)(**)

Delay Time from

Trigger Rising to

Exposure Active

Rising[B]

(μs)

Period from

Exposure Active

Falling

to Readout

rising[C]

(μs)

Readout

period[D]

(μs)

4096 14.70

0.27 37.0

6.56

2048 7.69

0.27

30.4 3.28

16 5.45 0.27 23.9 0.03

4096 14.49 0.27 37.0 6.56

2048 7.37 0.27 30.4 3.28

16 5.45 0.27 23.9 0.03

4096 18.27 0.27 37.0 6.56

2048 9.42 0.27 30.4 3.28

16 5.45 0.27 23.9 0.03

4096 18.27 0.27 37.0 6.56

2048 9.42 0.27 30.4 3.28

16 5.45 0.27 23.9 0.03

4096 13.52 0.27 37.0 6.56

2048 6.76 0.27 30.4 3.28

16 5.45 0.27 23.9 0.03

4096 13.53

0.27 37.0 6.56

2048 6.76 0.27 30.4

3.28

16

5.45 0.27 23.9 0.03

RGB8

RGBa8

RGB10V1Packed

RGB10p32

YUV422_8

YUV422_8_UYVY

A

Trigger

B

Exposure Active

Readout

SW-4000Q-10GE

C D

*) H Binning = Off

**) GevGVSPExtendedIDMode = Off, GevSCPDPacketSize = 8976

— 29 —

■ When [Exposure Mode] is [Trigger Width]

Pixel Format Width

Trigger

Period[A]

(μs)

(*)(**)

Delay Time from

Trigger Rising to

Exposure Active

Rising[B]

(μs)

Period from

Exposure Active

Falling

to Readout

Start[C]

(μs)

Readout

period[D]

(μs)

Delay Time from

Trigger Falling

to Exposure

Active Falling[E]

(μs)

4096 14.70 0.26 37.0 6.56 0.3

2048 7.69 0.26 30.4 3.28 0.3

16 5.45 0.26 23.9 0.03 0.3

4096 14.49 0.26 37.0 6.56 0.3

2048 7.37 0.26 30.4 3.28 0.3

16 5.45 0.26 23.9 0.03 0.3

4096 18.27 0.26 37.0 6.56 0.3

2048 9.42 0.26 30.4 3.28 0.3

16 5.45 0.26 23.9 0.03 0.3

4096 18.27 0.26 37.0 6.56 0.3

2048 9.42 0.26 30.4 3.28 0.3

16 5.45 0.26 23.9 0.03 0.3

4096 13.52 0.26 37.0 6.56 0.3

2048 6.76 0.26 30.4 3.28 0.3

16 5.45 0.26 23.9 0.03 0.3

4096 13.53 0.26 37.0 6.56 0.3

2048 6.76 0.26 30.4 3.28 0.3

16 5.45 0.26 23.9 0.03 0.3

YUV422_8_UYVY

RGB8

RGBa8

RGB10V1Packed

RGB10p32

YUV422_8

A

Trigger

SW-4000Q-10GE

Exposure Active

Readout

B

E

C

D

*) H Binning = Off

**) GevGVSPExtendedIDMode = Off, GevSCPDPacketSize = 8976

— 30 —

Pixel Sensitivity Correction

Correct variations between the sensor’s pixels.

Calibration must be performed within the camera and correction data must be created

beforehand. DSNU (Pixel Black Correct) / PRNU (Pixel Gain Correct) can be reduced using

that correction data. We recommend performing calibration and creating correction data

whenever the line rate setting is changed significantly.

◇ Correction data is saved for DSNU (Pixel Black Correct) / PRNU (Pixel Gain Correct)

according to the conditions adjusted at the factory. Perform calibration whenever changing

setting, such as the Acquisition Line Rate setting, and use the correction data for DSNU

(Pixel Black Correct) / PRNU (Pixel Gain Correct).

◇ Perform DSNU (Pixel Black Correct) calibration again whenever the exposure time or

analog base gain value is adjusted.

◇ A single correction data entry can be saved on the camera for each user. When calibration

is performed, the correction data is saved to the non-volatile ROM at the same time.

PRNU Correction (Pixel Gain Correct)

PRNU (photo response non-uniformity) is a variation between pixels generated by the sensor

under bright conditions. If the line rate is slowed or a long exposure time is set, the dark

current in the sensor may change and the state of the PRNU may change.

SW-4000Q-10GE

DSNU Correction (Pixel Black Correct)

DSNU (dark signal non-uniformity) is a variation between pixels in the dark areas generated

by the sensor. If the line rate is slowed or a long exposure time is set, the dark current in the

sensor may change and the state of the DSNU may change.

Black level

— 31 —

Gain Control

The following gain functions are available on the camera.

• Analog base gain

• Digital gain

■ Analog base gain

Analog base gain (ABG) is gain that is performed to the analog video signal output from the

sensor. The gain steps can be configured to one of three levels (0 dB, 6 dB, 12 dB).

■ Two digital gain control modes

Two digital gain control modes are available; a mode where you adjust the master gain and

then perform fine adjustment for R, B and NIR (Master Mode), and a mode where R, G, B

and NIR gain are adjusted individually (Individual Mode).

・Master Mode

Set [Individual Gain Mode] to [Off], and adjust the gain by configuring the following four

items.

Digital All x 1 ~ x 8 ( 0dB ~18dB)

Digital Red x 0.67 ~ x 4 (-4dB ~ 12dB)

Digital Blue x 0.67 ~ x 4 (-4dB ~ 12dB)

Digital NIR x 0.67 ~ x 4 (-4dB ~ 12dB)

SW-4000Q-10GE

・Individual Mode

Set [Individual Gain Mode] to [On], and adjust the gain by configuring the following four

items.

Digital Green x 1 ~ x 16 (0dB ~ 24dB)

Digital Red x 1 ~ x 16 (0dB ~ 24dB)

Digital Blue x 1 ~ x 16 (0dB ~ 24dB)

Digital NIR x 1 ~ x 16 (0dB ~ 24dB)

The following two gain values are added together for the total gain value.

Total Gain = Analog Base Gain (dB) + Digital Gain (dB)

— 32 —

Item

Setting value /

selectable range

Description

LUTMode LUT Use LUT.

LUTSelector* Red, Green, Blue Select the LUT channel to control.

LUTIndex 0 ~ 256

Select the LUT index to configure. Indexes represent the

possible pixel values captured on the sensor, from the

lowest value (Index 0) to the highest (Index 256). For

example, Index 0 represents a full black pixel and Index

256 represents a full white pixel.

LUTValue 0 ~ 4095 Set the LUT output value for the selected index.

Lookup Table(LUT)

The LUT function is used to generate a non-linear mapping between signal values captured on

the sensor and those that are output from the camera.

You can specify the output curve using 257 setting points (indexes).

■ To use the LUT function

Configure the settings as follows.

SW-4000Q-10GE

■ LUT Value

LUT values range from 0 at the lowest to 4095 at the highest. Linear interpolation is used to

calculate LUT values between the index points.

4095

LUTValue[256]

Values between points are determined

using the linear interpolation values of

data to the left and right.

LUTValue[2]

LUTValue[1]

LUTValue[0]

0

Index0

Index1 Index2

Index256

— 33 —

Item

Setting value /

selectable range

Description

Gamma

0.45, 0.5, 0.55, 0.6, 0.65,

0.75, 0.8, 0.9, 1.0

Select the gamma correction value.

LUTMode Gamma Use gamma.

Gamma Function

The gamma function corrects the output signals from the camera beforehand (reverse

correction), taking into consideration the light-emitting properties of the monitor display. As

the light-emitting properties of the monitor are not linear, the entire image may be darker or

the gradation in the dark areas may be less noticeable when camera outputs are displayed

without processing. The gamma function can be used to correct the camera signals with an

opposite-direction curve and produce a display that is close to linear.

Y

1.2

1.0

<- Output

0.8

0.6

0.4

0.2

0

Input ->

Example of the light-emitting

properties of the monitor display

X

SW-4000Q-10GE

■ To use the gamma function

Configure the settings as follows.

Note

You can use the LUT function to configure a curve with more detailed points. For details, see

“Lookup Table (LUT)”.

— 34 —

Shading Correction

The shading correction is a function that corrects non-uniformity (i.e., shading) in the amount

of light generated by the lens and lighting equipment.

The following shading correction modes are available on the camera。

■ Flat shading correction

Correct so that the part with the highest luminance level in the screen is taken as the

reference and the other part is adjusted to this luminance level.

SW-4000Q-10GE

◇ Complete correction may not be possible depending on the optical system and light source

you are using.

◇ Data based on corrections performed under factory conditions is stored for this function.

■ Color shading correction

R-channel, B-channel and NIR-channel properties are adjusted by using the G-channel

shading properties as a reference.

Pre-correction Post-correction

■ To perform the shading function

The function is turned ON/OFF via serial communication. This function is not dependent on

the operation mode, but is effective when used during actual use.

◇ You can also save the setting and have it applied whenever the power is subsequently turned

on. For details on saving the setting, see “Step 7: Saving the Settings”

Caution

・For Flat Shading and Color Shading, the maximum correction gain amount is limited to 8 times

the gain amount before correction in all pixels.

・If the highest luminance level in the image is 175 LSB (10 bit image output) or less, it can not

be corrected correctly.

Black Level Correction

Black level correction is a function for adjusting the setup level.

When this function is used, the following is performed for the gain mode setting.

Digital All -133 ~+255 (LSB@12bit)

Digital Red -64 ~ +64 (LSB@12bit)

Digital Blue -64 ~ +64 (LSB@12bit)

Digital NIR -64 ~ +64 (LSB@12bit)

— 35 —

Variable Line Rate

You can set the line rate to 1L or more. This function can be used to match the scanning

speed of the camera to the feeding speed of the object or to lengthen the accumulation time

to increase sensitivity.

• Variable range: RGBa8 66Hz*~ 73kHz

RGB8 + Mono8 66Hz*~ 72kHz

YUV422_8 + Mono8 66Hz*~ 74kHz

*) When taking a trigger signal from the outside, there is no limitation on the minimum value.

• Variable unit: 0.1 Hz

• Supported operation modes: Exposure Mode OFF / Trigger OFF

Exposure Mode Timed / Trigger OFF

◇ You can also save the setting and have it applied whenever the power is subsequently

turned on, but this requires additional operations.

◇ Switching and settings storage for this function is performed via serial communication.

◇ The black level will change depending on the line rate, so be sure to readjust the black

level after changing the line rate or trigger period.

Electronic Shutter

SW-4000Q-10GE

When you use this function, you can set the exposure to a preconfigured accumulation time,

regardless of the line rate.

• Variable range: 3 μs to 15.149 ms

• Variable unit: 0.01 μs (1clk)

• Supported operation modes: When Trigger Mode ON, Exposure Mode Timed

Caution

In “Trigger Mode OFF, Exposure Mode Timed” mode, the line rate configured will be the

maximum value at which the shutter operates. However, in “Trigger Mode ON, Exposure Mode

Timed” mode, the input trigger period will be the maximum value.

◇ You can also save the setting and have it applied whenever the power is subsequently

turned on, but this requires additional operations.

EEN (Exposure Enable) Function

Perform external output for the timing at which video is accumulated to the sensor.

The signal is output to the DC IN / TRIG IN connector (12-pin round) or AUX connector.

Example: Output to DC IN/TRIG IN connector (12-pin round)

Trigger

( Internal / External )

Exposure

EEN

Test Pattern Function

You can display the following types of test patterns (Off, White, GrayPattern1, GrayPattern2,

ColorBar). Video output is not possible while a test pattern is being executed. This function is

not dependent on gain and offset values that have already been configured.

◇ This function cannot be saved as the initial state of the camera.

— 36 —

SW-4000Q-10GE

ColorTransformation ColorTransformationMode ColorTransformationRGBMode

RGB(sRGB) RGB sRGB

RGB(AdobeRGB) RGB AdobeRGB

RGB( UserCustom) RGB UserCustom

XYZ XYZ Off

H S I H S I Off

Default RGB Off

Setting value Description

ColorMatrixValueSelector

ColorMatrixR -R, ColorMatrixR-G, ColorMatrixR-B,

ColorMatrixG-R , ColorMatrixG-G, ColorMatrixG-B,

ColorMatrixB-R , ColorMatrixB-G, ColorMatrixB-B

Select the ColorMatrix setting

component.

ColorMatrixValue -2 to 2 Set th e Color Matrix v alue.

Item

Color Space Conversion (Color Transformation Control)

The SW-4000Q-10GE model allows you to convert the standard color space (RGB) that is

used to produce colors into other color spaces, including XYZ and HSI.

Five color spaces are available: RGB(sRGB), RGB(AdobeRGB), RGB(UserCustom), XYZ, and

HSI. Specify the

Transformation RGB Mode as follows.

*) This function is valid only when PixelFormat is RGBa8, RGB8, RGB10V1Packed, RGB10p32.

Caution

desired color space by configuring Color Transformation Mode and Color

If you set the color space to XYZ or HSI, eBUS Player for JAI will not display the images captured

by the camera properly. To display them properly, XYZ- or HSI-compatible image processing

must be performed on the computer side.

Note

Color space (HSI)

Value of Hue : For 0°-360°, specify as follows.

8bit output: 2°/step 0°(00000000) ~ 360°(10110100)

10bit output: 0.5°/step 0°(0000000000) ~ 360°(1011010000)

Value of Saturation, Intensity: For 0% - 100%, specify as follows.

8bit output: 0%(00000000) ~ 100%(11111111)

10bit output : 0%(00000000) ~ 100%(1111111111)

■ Note on RGB (UserCustom)

This allows you to use user configured 3x3 conversion tables to perform color space conversion.

Source data

R in

ColorMatrixValue[ColorMatrixValueSelector]

RR RG RB

3x3 table :

Destination data

R out

G in

B in

Configuration 3x3 table. Select the item you want to configure in [ColorMatrixValueSelector].

And configure the value in [ColorMatrixValue]. [ColorMatrixValue] can be set to a value from -2

to +2.

GR GG GB

BR BG BB

— 37 —

G out

B out

Counter And Timer Control Function

This camera supports only the counter function.

The counter function counts up change points in the camera’s internal signals using the

camera’s internal counter, and reads that information from the host side. This function is

useful for verifying error conditions via the count value using internal camera operations.

Six counters are available on the camera; Counter0, Counter1, Counter2, Counter3, Counter4

and Counter5.

The functions that can be counted are fixed for each counter.

Counter0: Counts the number of Line Trigger instances.

Counter1: Counts the number of Line Start instances.

Counter2: Counts the number of Exposure Start instances.

Counter3: Counts the number of Frame Trigger instances.

Counter4: Counts the number of Frame Start instances.

Counter5: Counts the number of Frame Transfer End instances.

When a problem occurs in a system that includes this camera, comparing the values from

multiple counters allows you to verify the extent of normal operability and can be useful when

investigating the cause of the problem.

SW-4000Q-10GE

■ Counter occurrence diagram

Line Trigger

Counter0

Exposure Start

Counter2

Event occurrence

Count up

Event occurrence

Count up

Counter2

Request

Counter0

Request

Read count

value

MCU

HOST

Read out

value

Counter reset

Count 0 reset

Counter reset

Counter2 reset

Note

You can reset a specific counter's count value by executing CounterReset[Counter0, Counter1,

Counter2, Counter3, Counter4, Counter5].

— 38 —

Setting value /

selectable range

Description

Counter 0 ~ 5 Select the counter.

CounterEventSource

Counter0

Off, Line Trigger

Counter1

Off, Line Start

Counter2

Off, Exposure Start

Counter3

Off, Frame Trigger

Counter4

Off, Frame Start

Counter5

Off, Frame Transfer End

Select the counter event signal

for which to read the count

value.

When set to Off, the counter

operation will stop (but will not

be reset).

CounterEventActivation

Counter0 Rising Edge

Counter1 Rising Edge

Counter2 Rising Edge

Counter3 Rising Edge

Counter4 Rising Edge

Counter5 Falling Edge

Specify timing at which to count.

(This setting is fixed.)

Item

Counter 0 ~ 5

■ Internal camera blocks

SW-4000Q-10GE

Counter0

Line Trigger

Counter1

Line Start

Counter2

Exposure Start

Counter5

Frame Transfer End

Event detection

Event detection

・

・

・

Event detection

Event detection

Counter reset

Internal MCU of camera

At event oc currence or count up

At event oc currence or count up

Counter

At event oc currence or count up

Counter

At event oc currence or count up

Counter

Counter

Read requested counter value

Send information

to the HOST

■ To use the counter function

Configure the settings as follows.

Six counters are available. Specify a counter (Counter0 to Counter5), and configure the

settings.

— 39 —

Chromatic Aberration Correction

This Function corrects for the chromatic aberration of magnification caused by the lens (i.e.,

when the size of the image differs at the focal point for each color (RGB)). You can save

correction data for three types of lenses. This function assumes that the amount of deviation

between the left and right is identical. If the amount of deviation between the left and right is

not identical, correction will not be performed properly. Specify the number of pixels to delay

or advance the R channel and B channel using the G channel as a reference. The correction

range is –4.0 to +4.0 in steps of 0.1.

■ Adjustment procedure

Enable the chromatic aberration of magnification correction function.

1

Set [Chromatic Aberration Correction Mode] to [On].

Alternatively, select preset Lens1, Lens2, or Lens3.

Correct the R channel.

2

Set [Chromatic Aberration Correction Selector] to [RChannel].

Specify the amount of correction in [Chromatic Aberration Correction Lens1,2,3]

(–4.0 to +4.0 in steps of 0.1).

Similarly, correct the B channel.

3

Set [Chromatic Aberration Correction Selector] to [B Channel].

Specify the amount of correction in [Chromatic Aberration Correction Lens1,2,3]

(–4.0 to +4.0 in steps of 0.1).

SW-4000Q-10GE

Similarly, correct the NIR channel.

4

Set [Chromatic Aberration Correction Selector] to [NIR Channel].

Specify the amount of correction in [Chromatic Aberration Correction Lens1,2,3]

(–8.0 to +8.0 in steps of 0.1).

Connecting Rotary Encoders

This camera can generate trigger signals or detect the scanning direction of the subject in

response to signals output from the rotary encoder.

■ Adjustment procedure

Input the two signals (phase A and phase B) from the rotary encoder.

1

Select which I/O on the camera (Line5:OptIn1, Line4:TTLIn1, Line10:TTLIn2,

Line13:TTLIn3) you want to input each of the two outputs from the rotary encoder

[phase A (Encoder Source A), phase B (Encoder Source B)].

Specify the number of triggers (number of vertical lines) to generate during

2

each rotation of the rotary encoder.

When [Encoder Divider] is set to [N], the rotary encoder generates 65536/N triggers.

When N is an integer multiple of 65536

Camera internal trigger is generated by decimation of output trigger of rotary

encoder.

When N is not an integer multiple of 65536

Using the time interval of the output trigger of the rotary encoder, Camera internal

trigger is generated so that the set division ratio is obtained.

Note

If the time interval of the output of the rotary encoder fluctuates greatly, the output

of the camera internal trigger generated may also fluctuate greatly.

In this case, by setting [EncoderAveragingInterval], it is possible to perform internal

processing with the value obtained by averaging the time intervals of the specified

number of signals.

— 40 —

If necessary, enable the low-pass filter for the signal to prevent unintended

3

operations due to signal noise from the rotary encoder.

Specify the number of cycles from a range of 0 to 15 (0 to 150 ns).

If necessary, specify the strobe length of the generated signal.

4

When [EncoderStrobe] is set to [M], the strobe length will be [M]×10 ns.

Frame Start Trigger

In this camera, Data Leader and Data Trailer are added every frame.

The number of lines of one frame is set by Offset Y, Height of [Image Format Control].

Offset Y’s setting range is 0 to 4095.

Height setting range is 1 to 4096.

SW-4000Q-10GE

■One frame of image data (Offset Y = 0)

Data Trailer

(GigE Vision)

Data Leader

(GigE Vision)

・・・・・

Time passed

■ One frame of image data (Offset Y > 0)

Data Trailer

(GigE Vision)

Image data [ Number of lines (Height - Offset Y) ]

Data Leader

(GigE Vision)

・・・・・

Image data for the number of lines

Image data [ Number of lines (Height - Offset Y) ]

Time passed

When using Frame Start Trigger, after receiving Frame Start Trigger, skip the image data of

the number of lines of Offset Y and send the data of Data Leader, image data, Data Trailer.

(Upon completion of data transmission for one frame, no data will be sent until the next Frame

Start Trigger is received.)

specified by Offset Y will not be sent.

Frame Start

Trigger

One frame of image data

Time passed

One frame of image data

*) Chunk Data (first line of every frame only) is sent after Data Trailer.

— 41 —

Frame Start

Trigger

Binning Function

Offset X (pixels) Offset Y (pixels)

BinningHorizontal Off:

0 to 4080 step 16

BinningHorizontal On:

0 to 2040 step 8

0 to 4095 setp 1

Width (pixels) Height (pixels)

BinningHorizontal Off:

16 to 4096 step 16

BinningHorizontal On:

8 to 2048 step 8

1 to 4096 step 1

The binning function allows you to combine the signal values of clusters of adjacent pixels to

create improved virtual pixels. Using the function results in images with lower pixel resolution

and higher sensitivity.

This camera performs vertical binning via digital addition in the sensor.

This camera performs horizontal binning via digital addition processing.

ROI (Regional Scanning Function)

The ROI (region of interest) function allows you to output images by specifying the areas to

scan.

ROI Settings

Specify the area to scan by specifying width and horizontal offset values under [Image Format

Control].

The setting ranges for the ROI function's readable area based on the Binning setting (Binning

Horizontal) are as follows.

SW-4000Q-10GE

— 42 —

Chunk Data Function

The Chunk Data function adds camera configuration information to the image data that is

output from the camera. Embedding camera configuration information in the image data

allows you to use the serial number of the camera as a search key and find specific image data

from among large volumes of image data. In addition, when images are shot with a single

camera in sequence under multiple setting conditions, you can search for images by their

setting conditions.

■ Configuring Chunk Data

Set [ChunkModeActive] to [True].

1

Select the items of information you want added to image data with

2

[ChunkSelector], and set [ChunkEnable] from [False] to [True].

Note

When [ChunkModeActive] is set to [True], [ChunkImage] is automatically set to [True].

SW-4000Q-10GE

Caution

The Chunk Data function settings cannot be changed during image output. To change the

settings, stop Acquisition.

*) For items that can be added to image data as Chunk Data, refer to [n) ChunkDataControl]

in the setting item list.

Delayed Readout

Delayed readout allows images captured by a [Frame Start] trigger command to be stored

temporarily inside the camera (delayed readout buffer) and read out using a

[FrameTransferStart] trigger after capture.

This function is useful when executing triggers simultaneously on multiple cameras.

Note

This function imposes a heavy processing load on the network bandwidth, as images from

multiple cameras are read out simultaneously.

* About delayed readout buffer size, refer to “Trigger Control”.

— 43 —

Event Control Function

The Event Control Function is a function that outputs a signal change point inside the camera

as information indicative of an event occurrence (event message) by using GVCP (GigE Vision

Control Protocol).

■ Flow from detecting an event to sending an event message

Event signal

SW-4000Q-10GE

Detect an event

Interrupt signal

MCU inside the camera

Keep the event type and

timestamp value when an event

occurs.

Reset event information after an

event message has been sent

Send an event message

■ Events that can use the Event Control Function

Events that can use the Event Control Function are as follows. You can specify whether or not

to send an event message when an event occurs at each event.

Acquisition Start, Acquisition End,

Frame Start, Frame End,

Line Start, Line End,

Exposure Red Start, Exposure Red End,

Exposure Green Start, Exposure Green End,

Exposure Blue Start, Exposure Blue End,

Line1 Rising Edge, Line1 Falling Edge,

Line4 Rising Edge, Line4 Falling Edge,

Line5 Rising Edge, Line5 Falling Edge,

Line8 Rising Edge, Line8 Falling Edge,

Line9 Rising Edge, Line9 Falling Edge,

Line10 Rising Edge, Line10 Falling Edge,

Line12 Rising Edge, Line12 Falling Edge,

Line13 Rising Edge, Line13 Falling Edge,

LVAL Start, LVAL End

ExposureNIRStart, ExposureNIREnd

— 44 —

Action Control Function

The Action Control Function is a function that executes the pre-configured action when the

camera receives action commands. Action commands can send both unicast and broadcast

messages and give instructions for actions to multiple cameras simultaneously by broadcasting

them. A camera that has this function can even give instructions for actions to different types

of multiple cameras. Although this function includes jitter and delays, it is useful for controlling

multiple cameras simultaneously.

Actions are performed when the following three conditions are met.

1. ActionDeviceKey set to the camera and ActionDeviceKey in the action command match

2. ActionGroupKey set to the camera and ActionGroupKey in the action command match

3. ActionGroupMask set to the camera and GroupMask in the action command perform AND

operation, and the result is not 0.

■ About the settings of the camera

1. Specify ActionDeviceKey.

2. Then, specify two actions that can be configured on the camera.

Action1

Select 1 in ActionSelector.

Specify ActionGroupMask [ActionSelector].

Specify ActionGroupKey [ActionSelector].

Action2

Select 2 in ActionSelector.

Specify ActionGroupMask [ActionSelector].

Specify ActionGroupKey [ActionSelector].

3. Set triggers (AcquisitionStart, AcquisitionEnd, FrameStart, AcquisitionTransferStart) to

Action1 and Action2.

SW-4000Q-10GE

■ Setting example

Assume that the following settings have been pre-configured on the camera.

ActionDeviceKey : 0x00001001

ActionGroupMask[1] : 0x00000011

ActionGroupKey[1] : 0x00000001

ActionGroupMask[2] : 0x00000111

ActionGroupKey[2] : 0x00000002

When the camera receives action commands (ActionDeviceKey:0x00001001, ActionGroupMask:0x00000011,

ActionGroupKey: 0x00000002), Action2 is executed.

When the camera receives action commands (ActionDeviceKey:0x00001001, ActionGroupMask:0x00000011,

ActionGroupKey: 0x00000001), ActionDevice and ActionGroupKey[1] match. However, the result of AND operation

performed by ActionGroupMask is 0. Therefore, in this case, neither Action1 nor Action2 is executed.

— 45 —

Setting List

Feature Properties

SW-4000Q-10GE

a) Device Control

Item

Device Vendor Name

Device Model Name

Device Manufacturer Info

Device Version

Device Firmware Version

Device Fpga Version

Device Serial Number

Device User ID

Device SFNC Version Major

Device SFNC Version Minor

Device SFNC Version Sub Minor

Device Manifest Entry Selector

Device TL Type

Device TL Vision Major

Device TL Version Minor

Device TL Version Sub Minor

Device Link Selector

Device Link Speed (Bps)

Device Link Heartbeat Mode

Device Link Heartbeat Timeout (us)

Device Stream Channel Count

Device Event Channel Count

DeviceReset

DeviceTemperatureSelector

DeviceTemperature(C) ー ー Display the internal temperature (°C) of the camera.

Timestamp (ns)

Setting range Default value Description

ー "JAI Corporation" Display the manufacturer name.

ー SW-4000Q-10GE Display the model name.

ー See the possibilities Display the manufacturer information.

ー ー Display the hardware version.

ー ー Display the firmware version.

ー ー Display the FPGA version.

ー ー Display the device ID.

Any ー Set the user ID (16bytes) for the camera.

2 2 Display the SFNC Major version.

3 3 Display the SFNC Minor version.

0 0 Display the SFNC Sub Minor version.

1 1 Display information on valid XML file.

GigE Vsion GigE Vsion Display type of transport layer.

2 2 Display the Major version of transport layer.

0 0 Display the Minor version of transport layer.

1 1 Display the Sub Minor version of transport layer.

0 0 Select I/F for control. (0 fixed)

ー ー Display Link spped.

Off, On On Set the mode of Link heartbeat.

500000 〜 120000000 3000000 Set the time of heartbeat timeout .

ー ー Display the number of stream channels.

ー ー Display the number of event channels.

ー ー Reset the device.

Mainboard Mainboard Select the area of the camera's interior for which to display the temperature

0〜9223372036854775807

(maximum value of unsigned

64-bit)

0

Display/configure information related to the device.

(After the camera receives this command, it returns an ACK response. Then,

execute reset.)

sensor's reading. (fixed Mainboard)

Display the timestamp value. Resets to 0 when the signed maximum 64-bit

value is exceeded.

Timestamp Reset

Timestamp Latch

Timestamp Latch Value (ns)

ー ー Forcibly sets the timestamp's count value to 0.

ーー

0〜9223372036854775807

(maximum value of unsigned

64-bit)

0

Sets the timestamp's count value to TimestampLatchValue.

— 46 —

SW-4000Q-10GE

b) ImageFormatControl

Item

WidthMax

HeightMax

Width

Height

Setting range Default value Description

Configure image format settings.

ー 4096 Display the maximum image width.

ー 4096 Display the maximum image height.

BinningHorizontal 1:

16〜4096 step 16

BinningHorizontal 2:

8〜2048 step 8

1 〜 4096 step 1

4096 Set the image width.

1 Set the image height (number of lines).

Image data with the specified number of lines will be streamed as 1 block.

OffsetX

OffsetY

BinningHorizontal

BinningVertical 1:

0 〜 4080 step 16

BinningVertical 2:

0 〜 2040 step 8

0 Set the horizontal offset.

0 〜 4095 0 Set the vertical offset.

1,2 1 Set the number of pixels in the horizontal direction for which to perform

binning. BinningMode is fixed to Sum.

SensorBinningVertical

1,2 1 Set the number of pixels in the vertical direction for which to perform

binning. BinningMode is fixed to Sum.

ComponentSelector

RGB, NIR RGB Select the component.

PixelFormat ー RGB8 Set the pixel format.

[Setting Range]

[Component Selector = RGB]

RGB8 (Default), RGB10V1Packed, RGB10p32

YUV422_8_UYVY, YUV422_8

RGBA8

[Component Selector = NIR]

Mono8 (Default) , Mono10Packed

*) In Component Selector = RGB, when PixelFormat is set RGBA8,

Pixel Format in ComponentSelector = NIR is invalid.

TestPattern

Horizontal Image Mirroring

Item

c) Acquisition Control

Acquisition Mode

Off,

White,

GrayPattern1(Ramp),

GrayPattern2(Stripe),

ColorBar

Off, On

Off Select the test image.

Off Invert the image left and right.

Setting range Default value Description

Configure image capture settings.

Single Frame,

Countinuous Select the image capture mode.

Multi Frame,

Continuous

Acquisition Start

Acquisition Stop

Acquisition Frame Count

Acquisition Frame Rate(Hz)

Acquisition Line Rate

ー ー Start image capture.

ー ー Stop image capture.

1〜65535 1 In [MultiFrame] mode, set the number of frames to capture.

ー 66 Display the frame rate as a frequency. (unit: Hz)

66 〜 66 Set the AcquisitionLineRate (Hz).

The maximum value varies depending on the PixelFormat and ROI settings.

Trigger Selector

ー

TriggerMode Off, On Off Select the trigger mode.

TriggerSource ー

TriggerActivation

ExposureMode

ExposureTimeMode

ExposureTimeSelector

RisingEdge,

FallingEdge,

Level High,

Level Low

Off, Timed, Trigger Width

Common, Individual Common Select the exposure time mode.

ExposureTimeMode:Common

Common,

ExposureTimeMode:Individual

Red,

Green,

Blue

Acquisition Start

Line4 TTL In 1

Rising Edge

Select the trigger operation.

[Setting range]

Acquisition Start, Acquisition End, Line Start, Frame Start, Frame Transfer Start

Select the trigger signal source.

[Setting range]

PulseGenerator0, PulseGenerator1, PulseGenerator2, PulseGenerator3

UserOutput0, UserOutput1, UserOutput2, UserOutput3

Action 0, Action 1, Action 2, Action 3

Line4 TTL In 1, Line5 Opt In 1, Line10 TTL In 2, Line13 TTL In 3

Logical Block 0, Logical Block 1, Encoder Trigger

Select the polarity of the trigger signal (i.e., location of signal at which

trigger is applied).

[Trigger Selector] = Line Start

ExposureMode is Off or Timed : RisingEdge, Falling Edge

ExposureMode is TriggerWidth : LevelHigh, LevelLow

Timed Select the exposure mode.

Common Select the sensor to set ExposureTime.

To set the common setting values for all three sensors, select Common

ExposureTime 3 〜 15149 Set the exposure time.

RBExposureInterlocked

Off, On Off When set to On, you can change Green while maintaining white balance.

47 —

—

SW-4000Q-10GE

d) Analog Control

Item

IndividualGainMode

Setting range Default value Description

Set whether to enable auto exposure.

Off, On Off In IndividualGainMode, R, G, B, NIR can be configured individually for the

entire gain adjustment range of the sensor.

GainSelector

IndividualGainMode : On

DigitalGreen,

DigitalRed,

DigitalBlue

IndidualGainMode : Off

DigitalAll,

DigitalRed,

DigitalBlue

ー Select the gain to configure.

Gain ー x1.0 Set the gain value for the gain setting selected in [GainSelector].

[Setting Range]

Analog Gain Selector

Analog Red,

IndividualGainMode Off : Digital A ll x 1 〜 x 8 ( 0dB 〜18dB)

IndividualGainMode On: Digital Green x 1 〜 x 16 (0dB 〜 24dB)

Analog Red Select the analog gain to configure.

Digital Red x 0.67 〜 x 4 (-4dB 〜 12dB)

Digital Blue x 0.67 〜 x 4 (-4 dB 〜 12dB)

Digital NIR x 0.67 〜 x 4 (-4d B 〜 12dB)

Digital Red x 1 〜 x 16 (0dB 〜 24 dB)

Digital Blue x 1 〜 x 16 (0dB 〜 2 4dB)

Digital NIR x 1 〜 x 16 (0dB 〜 2 4dB)

Analog Green,

Analog Blue,

Analog NIR

AnalogBaseGain 0dB, 6dB, 12dB 0dB Set the gain value for the analog gain setting selected in [Analog Gain

Selector].

BlackLevelSelector

DigitalAll,

DigitalAll Select the black level to configure.

DigitalRed,

DigitalBlue,

DigitalNIR

BlackLevel

Balance White Auto

Balance White Auto Width

Balance White Auto OffsetX

Balance White Auto Result

Gamma

DigitalAll -133〜255

DigitalRed -64〜 64

DigitalBlue -64〜 64

DigitalNIR -64〜 64

Off,

Once,

Preset5000K,

Preset6500K,

Preset7500K

16〜4096 step 16

0 〜 4080 step 16

ー Idle Display the result for adjusting white balance.

0.45, 0.5, 0.55, 0.6, 0.65,

0.75, 0.8, 0.9, 1.0

DigitalAll 0

DigitalRed 0

DigitalBlue 0

DigitalNIR 0

Set the black level value.

Off Enable/disable auto white balance.

4096 Set the area for adjusting white balance.

0 Set the area for adjusting white balance.

0:Idle

1:Succeeded

2:Error1 - G image was too bright

3:Error2 - G image was too dark

4:Error3 - Timeout

0.45

Set the gamma value.

LUTMode

SensorType

Off, Gamma, LUT Off Select the LUT mode.

TypeA, TypeB TypeA Select the size of pixel.

TypeA : 7.5um x 7.5um

TypeB : 7.5um x 10.5um

e) LUTControl

Item

LUTSelector

LUTIndex

Setting range Default value Description

Configure LUT settings.

Red, Green, Blue, NIR Red Select the LUT channel to control.

0〜256 0 Set the LUT index table number.

LUTValue 0〜4095 Gamma≒1.0 Set the LUT value.

48 —

—

SW-4000Q-10GE

f) Color Transformation Control

Item

Color Transformation Mode

Color Transofrmation RGB Mode

ColorMatrixValueSelector

ColorMatrixValue

Item

g) Digital I/O control

Line Selector

Setting range Default value Description

RGB, XYZ, HSI RGB Set the output image format.

Off, sRGB, AdobeRGB,

Off Set the detailed mode when RGB is selected for the color space.

UserCustom

ー ColorMatrixR-R Select the ColorMatrix setting component.

[Setting range]

ColorMatrixR-R, ColorMatrixR-G, ColorMatrixR-B

ColorMatrixG-R, ColorMatrixG-G, ColorMatrixG-B

ColorMatrixB-R, ColorMatrixB-G, ColorMatrixB-B

-2.0 〜 2.0

ー Set the Color Matrix value.

[Default value]

ColorMatrixValue [ColorMatrixR-R] = 1.0

ColorMatrixValue [ColorMatrixR-G] = 0

ColorMatrixValue [ColorMatrixR-B] = 0

ColorMatrixValue [ColorMatrixG-R] = 0

ColorMatrixValue [ColorMatrixG-G] = 1.0

ColorMatrixValue [ColorMatrixG-B] = 0

ColorMatrixValue [ColorMatrixB-R] = 0

ColorMatrixValue [ColorMatrixB-G] = 0

ColorMatrixValue [ColorMatrixB-B] = 1.0

Setting range Default value Description

Line1 TTL Out 1,

Line4 TTL In 1

Line5 Opt In 1,

Line8 TTL Out 2,

Line9 TTL Out 3,

Line10 TTL In 2,

Line12 TTL Out 4,

Line13 TTL In 3

ー Select the input/output to configure.

Configure settings for digital input/output.

Line Mode Input, Output ー Display the input/output status (whether it is input or output).

Line Inverter True, False False Enable/disable polarity inversion for the selected input signal or output

signal.

Line Status True, False ー Display the status of the input signal or output signal (True: High, False:

Low).

Line Source ー ー Select the line source signal for the item selected in [Line Selector].

[Setting range]

Acquisition Active, Frame Active, Exposure Active,

LVAL,

Pulse Generator 0, Pulse Generator 1, Pulse Generator 2, Pulse Generator 3,

User Output 0, User Output 1, User Output 2, User Output 3,

Line4 TTL In 1, Line5 Opt IN 1,, Line10 TTL In 2,, Line13 TTL In 3,

Logic Block 0, Logic Block 1,

Encoder Trigger, Encoder Direction

Line Format

LineStatusAll

TTL,

OptoCoupled

ー Display the signal format.

ー ー Display the input/output signal status. The state is shown with 16 bits. Bit

assignments are as follows.

bit0:Line1

bit3:Line4

bit4:Line5

bit7:Line8

bit8:Line9

bit9:Line10

bit11:Line12

bit12:Line13

bit1, bit2, bit5, bit6, bit10, bit13 -31 unused (fixed 0)

OptInFilterSelector (ns)

UserOutputSelector

0 〜 1000000 step 100 Off

UserOutput0

UserOutput1

UserOutput2

UserOutput3

UserOutput0

Remove noise from the OptIn input signal of Digital I/O.

Set the UserOutput signal.

UserOutputValue True, False False Set the value for the UserOutput selected in [UserOutputSelector].

49 —

—

SW-4000Q-10GE

h) Counter And Timer Control

Item

Counter Selector

Counter Event Source ー

Setting range Default value Description

Configure counter settings. (This camera only supports counter functions.)

Counter0, Counter1

Counter2, Counter3

Counter4, Counter5

ー Select the counter.

Off