SW-2000M-CL-65

1

SW-2000M-CL-65

CMOS High Speed Monochrome

Line Scan Camera

Document Version: 1.1

Date: 28 August 2014

File: Manual_SW-2000M-CL-65_First_Release_1-1.docx

User's Manual

SW-2000M-CL-65

2

Notice

The material contained in this manual consists of information that is proprietary to JAI Oy,

Finland and may only be used by the purchasers of the product. JAI Oy, Finland makes no

warranty for the use of its product and assumes no responsibility for any errors which may

appear or for damages resulting from the use of the information contained herein. JAI Oy,

Finland reserves the right to make changes without notice.

Company and product names mentioned in this manual are trademarks or registered

trademarks of their respective owners.

Warranty

12 months from date of delivery, 4 months for repairs covering the work and parts at the

factory.

Certifications

CE compliance

As defined by the Electromagnetic compatibility requirements of Directive 2004/108/EC of the

European Parliament and of the Council, JAI Oy, Finland, declares that SW-2000M-CL-65

complies with the following provisions:

EN 61000-6-2 (2005), EMC immunity

EN 61000-6-4 (2007), EMC emissions

FCC

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

- Consult the dealer or an experienced radio/TV technician for help.

-

Warning

Changes or modifications to this unit not expressly approved by the party

responsible for FCC compliance could void the user’s authority to operate the

equipment.

SW-2000M-CL-65

3

-

Contents –

1 General ....................................................................................................... 5

1.1 Camera nomenclature ............................................................................... 5

2 Main features ................................................................................................ 5

3 Connectors and mounting .................................................................................. 6

3.1 Main unit ............................................................................................... 6

3.2 Rear panel and indicators ........................................................................... 7

4 Input and output ............................................................................................ 8

4.1 M8 connector for power supply .................................................................... 8

4.2 Camera Link connector .............................................................................. 8

4.3 Camera Link output modes ......................................................................... 9

5 Operation and functions .................................................................................. 10

5.1 Introduction .......................................................................................... 10

5.1.1 Image sensor ...................................................................................... 10

5.1.2 Image processing ................................................................................. 11

5.2 Operating Modes ..................................................................................... 12

5.3 DSNU Corrector ...................................................................................... 12

5.4 Offset and gain stage ............................................................................... 12

5.5 Test Pattern Generator ............................................................................. 12

5.6 Flat Field Corrector, FFC ........................................................................... 12

5.7 Region of interest, ROI ............................................................................. 13

5.8 Binning ................................................................................................ 13

5.9 Reversed readout direction ........................................................................ 13

5.10 Camera Link interface .............................................................................. 14

5.11 Ethernet interface ................................................................................... 14

5.12 Firmware updates ................................................................................... 15

5.12.1 MCU firmware update ........................................................................ 15

5.12.2 FPGA firmware update ....................................................................... 16

6 Command line interface .................................................................................. 17

6.1 Connecting via Telnet .............................................................................. 17

6.2 Connecting via Camera Link Serial Bus .......................................................... 17

6.3 Entering the commands ............................................................................ 17

6.4 Command Format .................................................................................... 18

7 Description of commands ................................................................................. 19

7.1 Group A: General settings .......................................................................... 21

7.1.1 MODE – select camera operating mode ....................................................... 21

7.1.2 NET - network settings .......................................................................... 21

7.1.3 CL SERIAL – sets the baud rate ................................................................. 23

7.1.4 Saving and restoring the capture settings ................................................... 24

7.2 Group B: Commands affecting exposure ......................................................... 26

7.2.1 SENSOR – selects the sensor mode .......................................................... 26

7.2.2 LINE PERIOD and LINE RATE .................................................................... 26

7.2.3 LINE CTRL - Exposure Control .................................................................. 27

7.2.4 LINE IT - integration time ....................................................................... 30

7.2.5 GAIN - signal gain ................................................................................ 30

7.2.6 OFFSET - output offset .......................................................................... 30

7.2.7 FFC – flat field correction ...................................................................... 31

7.3 Group C: Commands affecting image output format .......................................... 32

7.3.1 CL MODE - Camera Link mode .................................................................. 32

7.3.2 CL RATE - Camera Link pixel rate ............................................................. 32

7.3.3 READOUT – pixel readout direction ........................................................... 32

7.3.4 ROI – region of interest ......................................................................... 33

7.3.5 BINNING – paring of pixels ...................................................................... 34

7.4 Group D: Utilities .................................................................................... 35

SW-2000M-CL-65

4

7.4.1 HELP or ‘?’ – list of commands ................................................................. 35

7.4.2 STATUS - camera information and settings .................................................. 35

7.4.3 VER - camera information ...................................................................... 35

7.4.4 TEST - test patterns ............................................................................. 35

7.4.5 REBOOT – restart the camera .................................................................. 37

7.4.6 FIRMWARE UPDATE – initiate the MCU update ............................................... 37

8 Summary of commands .................................................................................... 38

9 Software tools for camera communications ........................................................... 41

9.1 JAI SweepConf ....................................................................................... 41

9.2 JAI Sweep Ethernet Tool ........................................................................... 42

9.3 Internal web server ................................................................................. 44

10 External dimensions ....................................................................................... 45

11 Specifications ............................................................................................... 46

11.1 Operating range...................................................................................... 46

11.2 Common properties ................................................................................. 47

11.3 Performance per selected sensor mode ......................................................... 47

11.4 Spectral sensitivity .................................................................................. 48

12 Change History .............................................................................................. 49

SW-2000M-CL-65

5

1 General

The JAI Sweep Series SW-2000M-CL-65 is a CMOS line scan camera based on a custom-made

2048 pixel imager with large square pixels of 20 µm for high responsivity. It operates at a rate

of up to 80,000 scans per second.

The camera outputs digital data in 8-, 10-, or 12-bit formats, one, two, or three pixel values at

a time via one Camera Link connector. The camera is configured by software through the serial

communication port of the Camera Link interface or via a 10/100 Mbps Ethernet port using an

industry standard RJ-45 connector.

The default lens mount is F-mount. Additional options will be added.

The latest version of this operation manual can be downloaded from www.jai.com

.

For camera revision history, please contact your local JAI distributor.

1.1 Camera nomenclature

The standard camera composition consists of:

SW-2000M-CL-65 camera body with F

-mount x 1

Lens mount/sensor protection cap x 1

In the model number of the camera, SW stands for “Sweep” Series, 2000 represents the

resolution “2000 pixels”, M stands for “monochrome”, CL stands for “Camera Link®” interface,

and 65 stands for “65 kHz” maximum scan rate.

2 Main features

• CMOS line scan camera

• Resolution: 2048 x 1

• Pixel size: 20 µm, square

• Selectable Quantum Well size: 60k or 360k electrons

• Selectable clock rate for sensor and data output

• Maximum scan rate: 65,000 lines per second

• Camera Link Base Configuration data interface

o One connector

o 8, 10, or 12 bits per pixel

o Single, dual, and triple data formats

• DSNU correction as factory default

• Flat field correction (FFC)

• Test pattern generator for set-up and troubleshooting

• Default lens mount: F-mount

• DC input voltage range from +12 V to +24 V

• Ethernet port for

o Control and monitoring

o Firmware updates

o Download of files from camera (internal web server)

• Short ASCII commands for set-up via Camera Link or Ethernet using the Telnet protocol

o Windows user interface

SW-2000M-CL-65

6

3 Connectors and mounting

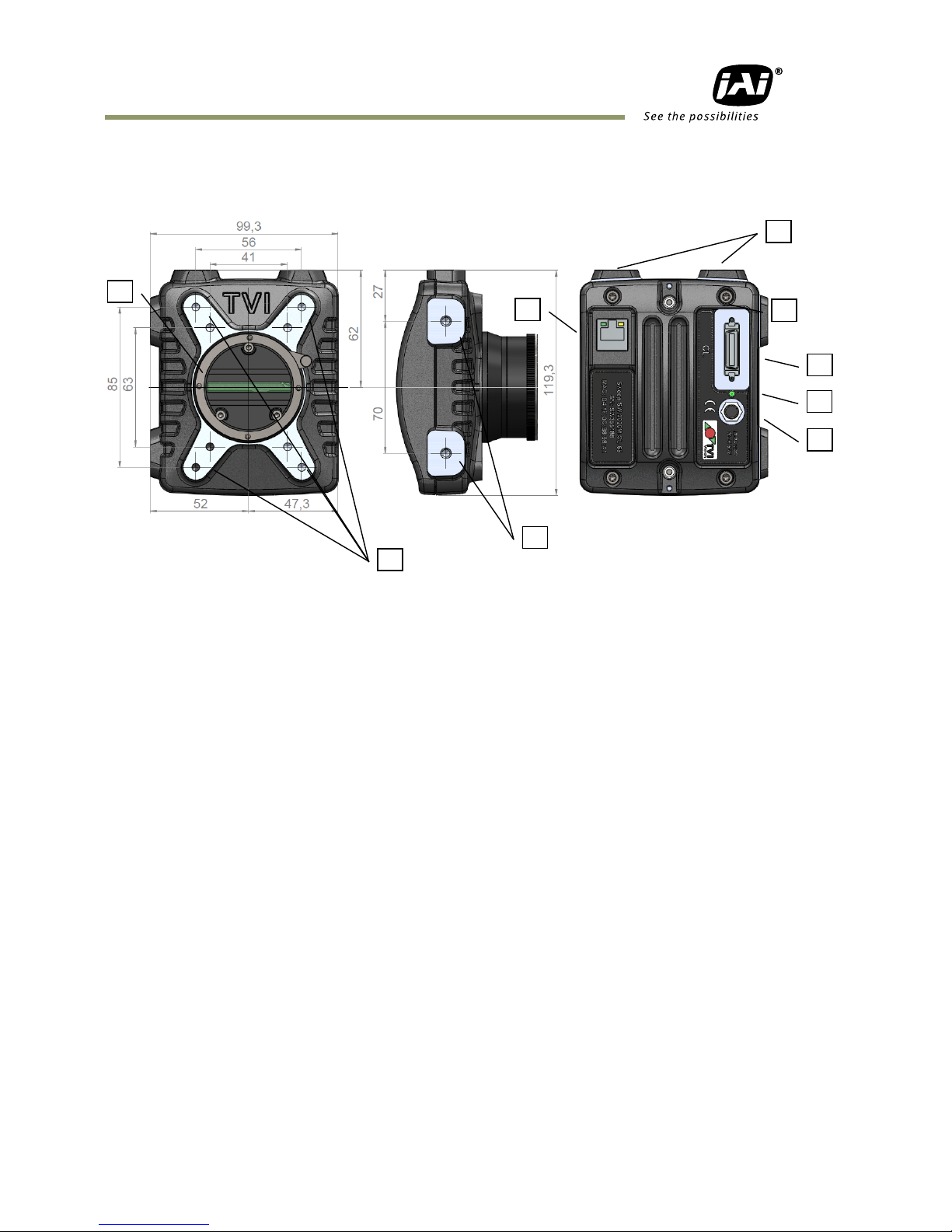

3.1 Main unit

Fig. 1. Location of external features

1 Camera Link Base Configuration connector

(1)

2 LED indicator

3 M8 connector for supply voltage (+12 to +24 V DC)

4 Ethernet connector

5 Lens mount: Nikon F-Mount

6 Mounting holes: all 12 pcs. are M5 with depth of 8 mm

*Note 1:

Please do not excessively tighten the Camera Link connector screws by using tools.

This may damage the receptacle on the camera side. It is sufficient to tighten by hand.

1

2 4 3 5 6 6 6 6 6 6 6 6

1

SW-2000M-CL-65

7

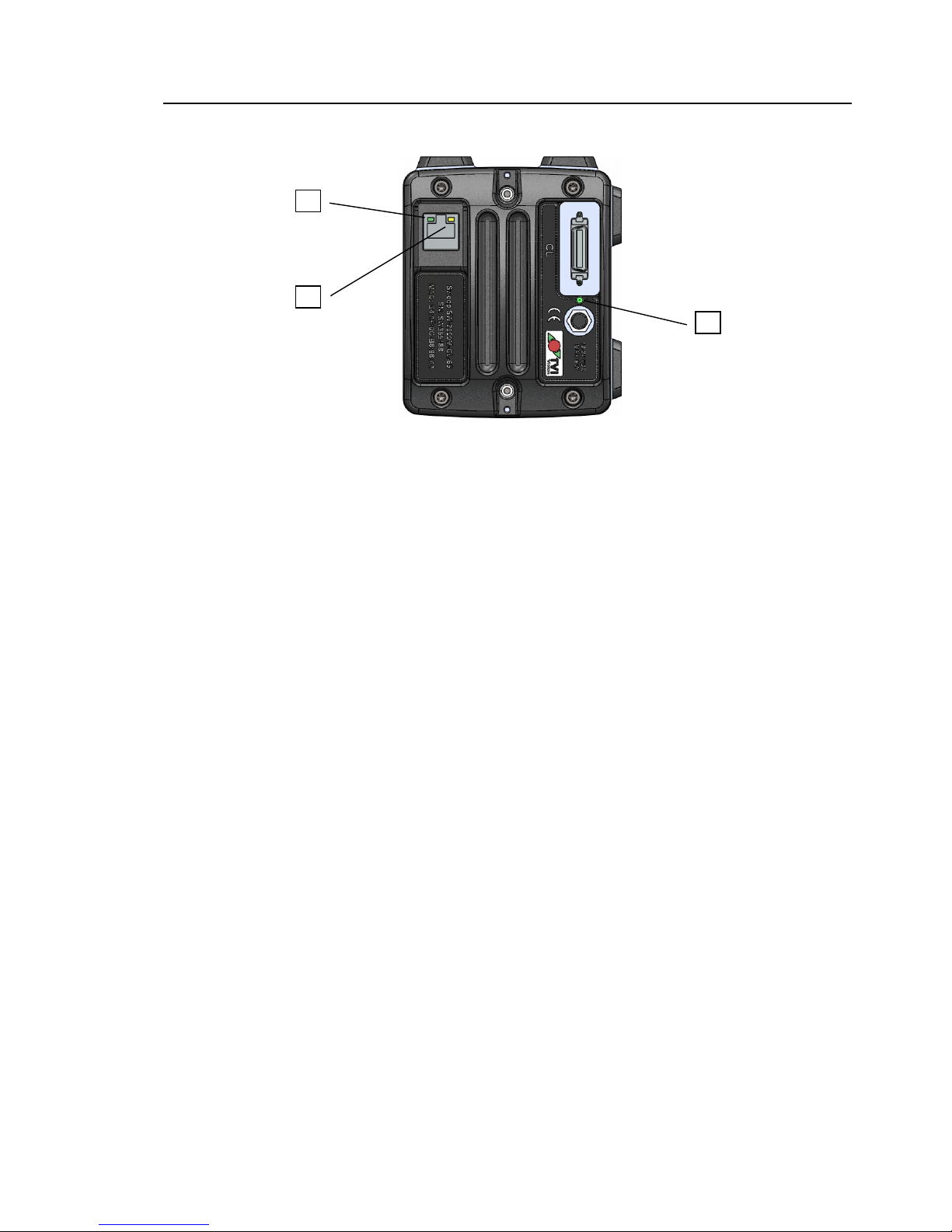

3.2 Rear panel and indicators

Fig.2. Rear panel

Status indicator

A multi-colour LED with the following functions:

Green (steady)

Normal operation

Green (flashing slowly)

Busy, performing a time consuming operation like FFC calibration.

Green (flashing rapidly)

Performing firmware update or waiting for a firmware update to start.

Orange (steady)

Initializing

Orange (flashing rapidly)

Firmware update in progress.

Do not disconnect the Ethernet cable.

Do not switch off the power.

Red

Internal error

Ethernet Link LED

Green (steady)

Connected to an active network device. This indicates the existence of a physical

link only. It does not indicate a valid TCP/IP network configuration.

Ethernet Status LED

Yellow (flashing)

Activity indicator. Blinks shortly during data transfer.

1 2 3

SW-2000M-CL-65

8

4 Input and output

4.1 M8 connector for power supply

Camera side connector is an industry standard 3-pin M8 male connector. Use any compatible

3-pin M8 female connector on the cable side.

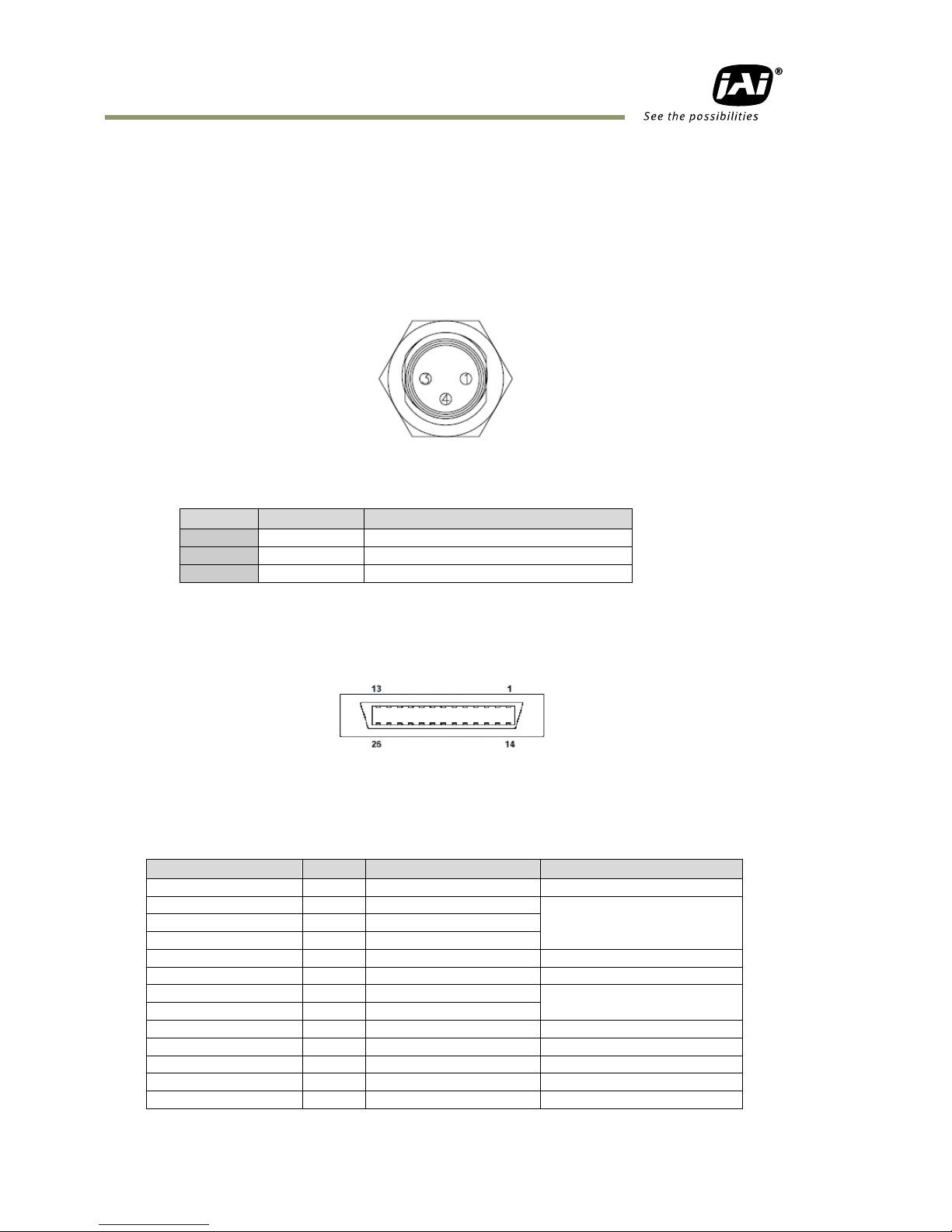

Fig. 3. Power supply connector (viewed looking into the camera)

4.2 Camera Link connector

Fig. 4. Camera Link connector (viewed looking into the camera)

The connector and respective signalling comply with Base Configuration of AIA Camera Link

standard v2.0. Please use only compliant cabling.

Pin No

In/Out

Name

Note

1,14 Shield

GND

2(-),15(+)

O

TxOUT0

Data out

3(-),16(+)

O

TxOUT1

4(-),17(+)

O

TxOUT2

5(-),18(+)

O

TxClk

Clock for CL

6(-),19(+)

O

TxOUT3

Data out

7(+),20(-)

I

SerTC (RxD)

LVDS Serial Control

8(-),21(+)

O

SerTFG (TxD)

9(-),22(+)

I

CC1 (Trigger)

Trigger, line rate

10(+),23(-)

I

CC2 (reserved)

integration control

11,24 N.C.

12,25 N.C.

13,26

Shield

GND

Pin No.

Signal

Remarks

1

DC in

+12 V to +24 V

3

GND

Ground (power supply negative)

4

CHGND

Chassis ground

SW-2000M-CL-65

9

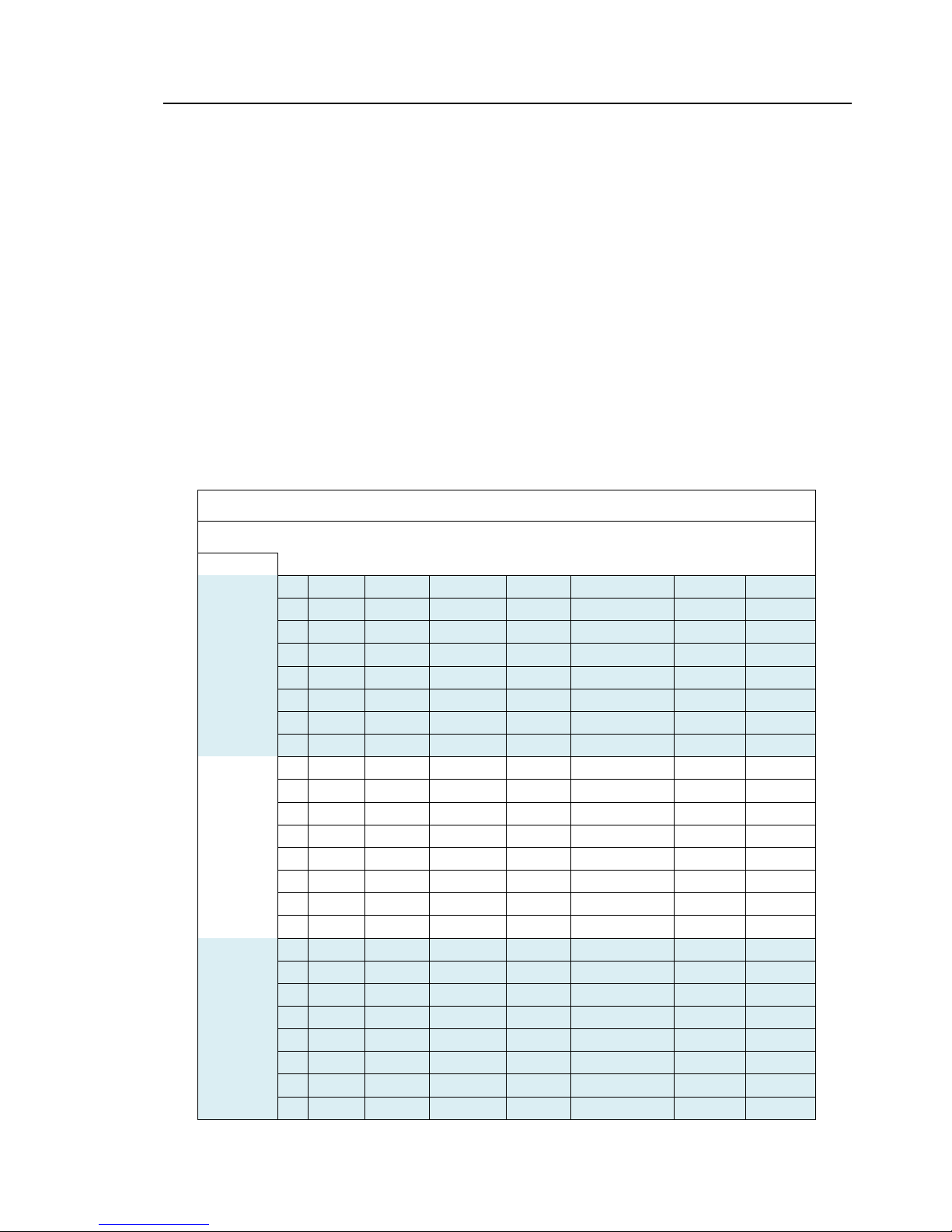

4.3 Camera Link output modes

All these modes are presented in the standard according to the names shown on the first line.

This table shows the use of these configurations to implement various data output modes.

Bit depths of 8, 10, and 12 are supported, where MSB is labeled as M11 and LSB as M0. Camera

operates internally with more than 12 bits. All blanks are electrically zeroes.

Dual and Triple modes send data from multiple pixels in parallel to enable higher scan rates

and/or longer cable lengths. Camera Link is nominally limited to 10 meters and 85 MHz. Data

from two or three consecutive pixels is sent out at once, where the index n-1 refers to the

previous pixel and n-2 respectively to the pixel before that. If the pixels are numbered from 1

to 2048, then the transmission in 8-bit Triple mode starts with a 24-bit package, where port A

shows the 8-bit value for pixel #3, Port B equals pixel #2 and Port C contains data from the first

pixel. Respectively, the Dual modes effectively send the data out as odd and even numbered

pixels, two in parallel.

CL v2.0

specification

8-bit x 1

10-bit x 1

12-bit x 1

8-bit x 2

10-bit x 2

12-bit x 2

8-bit x 3

Mode

Base 8

Base 10

Base 12

Base 8 x2

Base 10 x2

Base 12 x2

Base 8 x3

Port

Bit

8 bit

10 bit

12 bit

8 bit Dual

10 bit Dual

12 bit Dual

8 bit Triple

A 0 M4

M2

M0

M4

M2

M0

M4

1

M5

M3

M1

M5

M3

M1

M5 2 M6

M4

M2

M6

M4

M2

M6 3 M7

M5

M3

M7

M5

M3

M7

4

M8

M6

M4

M8

M6

M4

M8 5 M9

M7

M5

M9

M7

M5

M9 6 M10

M8

M6

M10

M8

M6

M10

7

M11

M9

M7

M11

M9

M7

M11

B 0 M10

M8

M4(n-1)

M10

M8

M4(n-1)

1

M11

M9

M5(n-1)

M11

M9

M5(n-1)

2

M10

M6(n-1)

M10

M6(n-1) 3 M11

M7(n-1)

M11

M7(n-1)

4

M8(n-1)

M10(n-1)

M8(n-1)

M8(n-1)

5

M9(n-1)

M11(n-1)

M9(n-1)

M9(n-1)

6

M10(n-1)

M10(n-1)

M10(n-1)

7

M11(n-1)

M11(n-1)

M11(n-1)

C 0 M2(n-1)

M0(n-1)

M4(n-2) 1 M3(n-1)

M1(n-1)

M5(n-2) 2 M4(n-1)

M2(n-1)

M6(n-2)

3

M5(n-1)

M3(n-1)

M7(n-2) 4 M6(n-1)

M4(n-1)

M8(n-2) 5 M7(n-1)

M5(n-1)

M9(n-2)

6

M8(n-1)

M6(n-1)

M10(n-2) 7 M9(n-1)

M7(n-1)

M11(n-2)

SW-2000M-CL-65

10

5 Operation and functions

5.1 Introduction

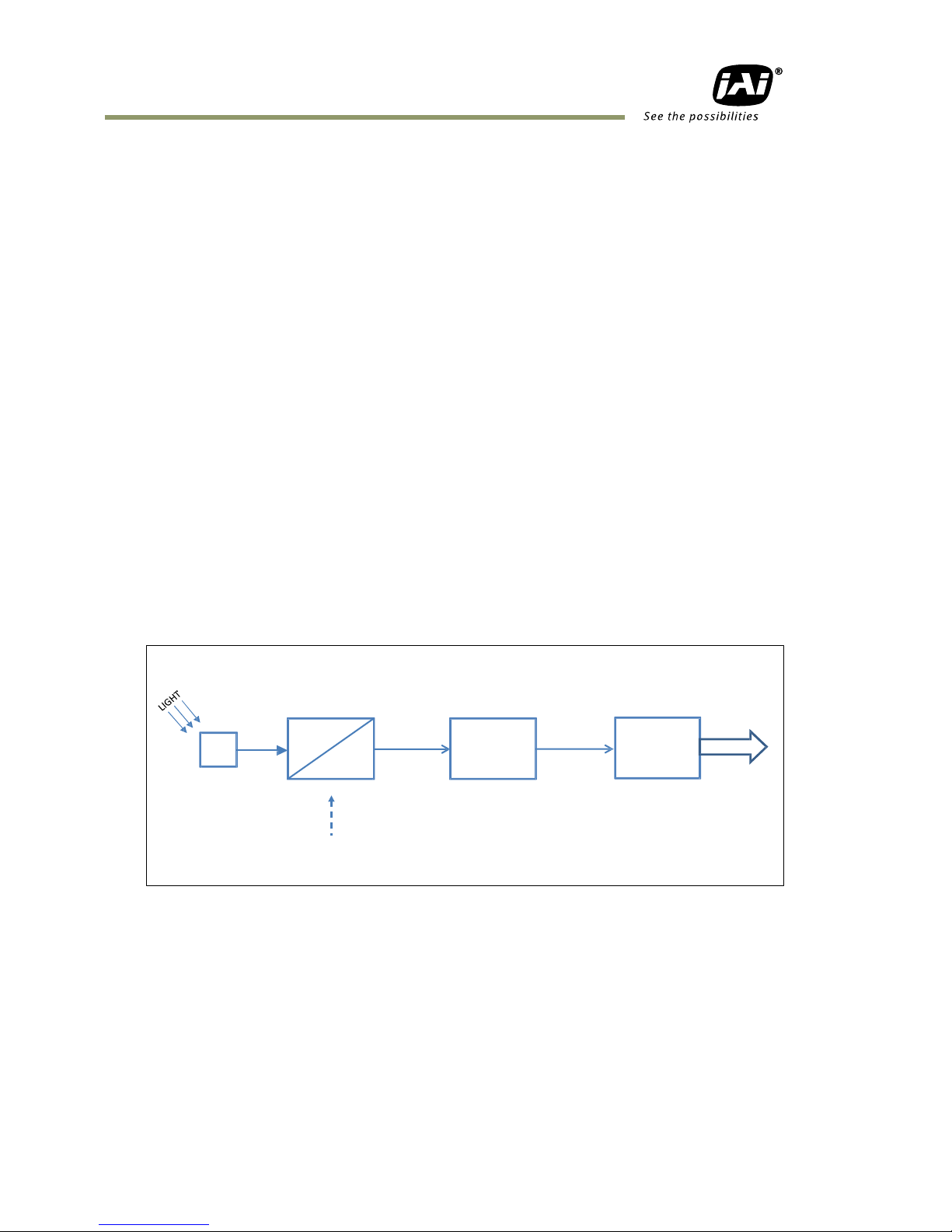

5.1.1 Image sensor

The SW-2000M-CL-65 is built around a high performance CMOS line scan image sensor, which

converts the light collected by each pixel into electrical charge. The amount of charge

generated in each of the individual pixels is basically directly proportional to the amount of

light they receive.

The sensor has two options to store the charge of each pixel. These are called Quantum Wells.

The smaller well can hold about 60,000 electrons (60 ke

-

), while the larger has capacity for 360

ke

-

. The larger well should be used whenever feasible as it provides the best image quality due

to higher dynamic range and better signal-to-noise ratio (SNR).

SNR is limited by the shot noise of the light itself and thus it is beneficial to collect as many

photons (light) as possible. The smaller well can be used to provide about six times higher

response to light, but with the cost of lower SNR and dynamic range.

Correlated Double Sampling (CDS) is used for sampling the charge voltage and the reset level

to find the difference, which is then digitized into more than 12 bits and sent out of the sensor

for processing.

Fig.5. Sensor block diagram

e

-

PIXEL

SMALL

LARGE

VOLTAGE

VOLTAGE

CDS

A/D

12½ BITS

QUANTUM WELL

COMMAND: SENSOR

SW-2000M-CL-65

11

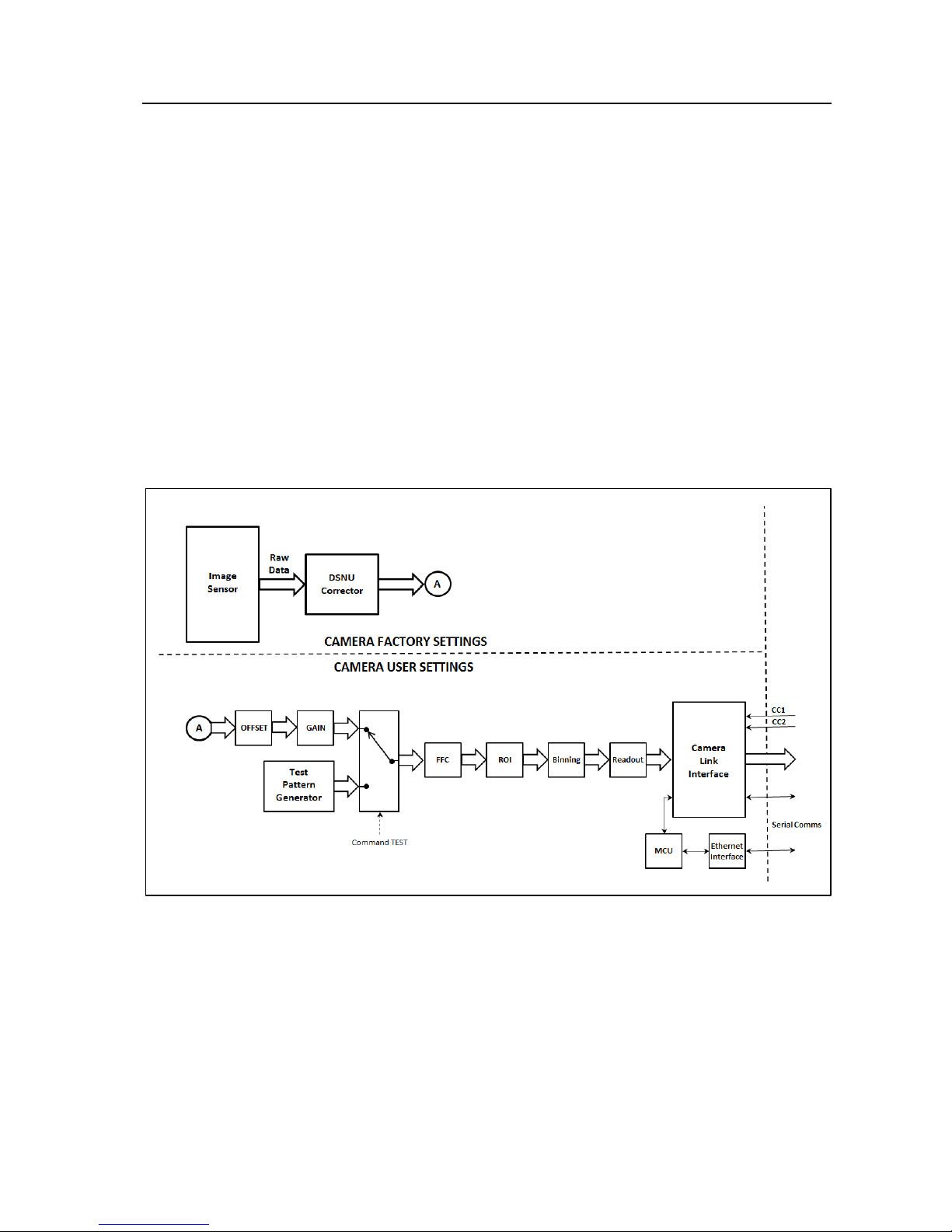

5.1.2 Image processing

The output data from the imager is buffered for further processing to be then finally sent out of

the camera via the Camera Link interface. The processing chain is controlled by user accessible

commands. The DSNU corrector is calibrated individually for each camera at the factory and

always in use with fixed settings.

The scan rate and the integration of light within each line period can be controlled either by

the Camera Link input signals CC1 and CC2, internal timers, or a combination of these.

Serial communication channels are used to control and monitor the camera. Both the standard

Camera Link serial channel as well as the Ethernet connection can be used for the same

purpose and even at the same time. Some functions are only supported via Ethernet.

Fig.6. Image processing block diagram

SW-2000M-CL-65

12

5.2 Operating Modes

The cameras can be configured to offer several operating modes that are fundamentally

different from each other. The operating mode is configured upon start-up and can only be

changed by issuing a new mode selection command and rebooting the camera.

5.3 DSNU Corrector

DSNU (Dark Signal Non-uniformity) describes the pixel specific differences of response in dark,

while PRNU (Photo Response Non-uniformity) respectively describes the pixel specific

differences of response to equal amounts of light falling onto all the pixels. Both are basic

sensor- and pixel-specific imperfections, which can be characterized and minimized. DSNU is

corrected already during production. Users may use the FFC function to further adapt the

camera into existing lighting conditions, if necessary.

5.4 Offset and gain stage

This block first shifts the digital pixel value up or down and then applies a digital gain. The

result is limited to stay between zero and the maximum digital value.

5.5 Test Pattern Generator

The SW-2000M-CL-65 can send out five, defined test patterns instead of the real imaged lines

for purposes like interfacing and problem analysis. The patterns replace the image data and

can thus be used also to test the following blocks. Original, full patterns are available after

switching off the FFC, ROI and binning. Test data is also affected by the readout direction

selection.

5.6 Flat Field Corrector, FFC

Factory calibrated DSNU corrector minimize pixel specific differences in darkness. There is no

use to correct the PRNU as a factory setting as it is less than the noise. Real applications only

rarely can provide equal amounts of light for all pixels. This is caused mainly by effects like

uneven distribution of light (light profile) or properties of lenses like vignetting. Pixels at the

center region tend to get more light, while the intensity decreases towards both ends of the

line image sensor.

The compensation method called Shading Correction results in a flat, equal response to light

under the same conditions in which the calibration routine was run. It is generally thought of as

a coarse correction to regionally scale or gain the pixel responses without paying attention to

any pixel-specific differences. Also, generally, a method called Flat Field Correction (FFC) is

used for operations where a similar correction is done more precisely and for each pixel

SW-2000M-CL-65

13

individually. The correction typically uses a 2-point linear method, where both the dark and

bright level pixel responses are equalized making it possible to have uniform response on all

light levels within the operating range of the camera. This would in fact be a complete, single

routine to perform DSNU, PRNU and Shading Corrections all at the same time, but the

corrections are separated in this implementation. DSNU correction is preset at the factory.

Shading correction is replaced by FFC, which operates assuming a fixed dark reference level

and includes the PRNU correction.

The FFC unit of SW-2000M-CL-65 offers the possibility to scale the pixel values by factors that

are calculated by imaging a calibration target in order to produce a uniform (flat) response

under the same conditions as where the calibration routine was run. A constant value (same as

DSNU target value) is used as the dark reference. Bright references are taken by averaging the

lines that were imaged from the calibration target.

5.7 Region of interest, ROI

This block can be used to select up to four sections of pixels to be used as one combined line of

pixels. The purpose is to reduce the amount of data and to remove unnecessary regions.

5.8 Binning

Neighboring pixels can be digitally added or averaged as pairs. The resulting larger pixels are

then sent out as one. The resolution as well as the number of pixels will be half. The goal is to

have larger pixel area either to increase the response or to reduce noise.

5.9 Reversed readout direction

This function enables reading of the pixel values in correct order in cases, where it is not

practical to install the camera to follow the intended imaging direction.

SW-2000M-CL-65

14

5.10 Camera Link interface

One Camera Link connector is available to connect standard Base Configuration interface

devices (frame grabber boards, etc.) to receive image data, to control the scan rate and

exposure of the camera, as well as to communicate via the Camera Link serial channel.

Output modes include possibilities to transfer two or three pixel values at the same time to

increase throughput or to decrease the pixel clock frequency. The clock rate can be adjusted

between 20 to 85 MHz in steps of 5 MHz. Lower frequencies may allow use of longer cables.

5.11 Ethernet interface

The Ethernet interface is provided as an alternative way to communicate with the camera. The

10/100 Mbps port provides very fast data transfer rates compared to standard Camera Link

speeds, which are all less than 1 Mbps.

Connection to Ethernet offers usual networking possibilities like remote access and connecting

multiple cameras together for control and monitoring. Standard Camera Link serial

communication is allowed to be in use at the same time. This of course requires caution if both

channels are used for changing camera settings.

Firmware updates are loaded only via this interface. Standard web browsers can be used to

establish connections to the internal web server, which includes a few basic functions. Some

documents are available for downloading (example: this document in PDF format).

SW-2000M-CL-65

15

5.12 Firmware updates

It is possible to update or change the camera firmware without opening the housing. New code

is loaded in via the Ethernet port and with help of web browser user interface. There are two

kinds of firmware updates: MCU and FPGA. The MCU (microcontroller unit) updates affect the

user interface and high level features of the camera, while the FPGA (field-programmable gate

array) updates provide enhancements for low level or hardware related functions.

The MCU update is first initiated by the command FIRMWARE UPDATE and then completed with

help of the user interface that opens up by accessing the main page of the camera web server.

The FPGA update is done by directly accessing the respective update page.

Caution: Ensure that the camera receives proper power during the complete firmware

update process. A power break can potentially leave the camera in a state, where it can

not start again.

5.12.1 MCU firmware update

1. Make sure you have the correct file (.hex) for the camera model and the existing

configuration available.

2. Make sure you have a working communication via the Ethernet port.

3. Make sure you have a compatible web browser and can access the main page

(http://10.10.10.10

).

4. Check and make a note of the existing configuration. Telnet command: VER.

5. Save any settings that you want to keep. The camera will reboot during the process.

6. Initiate the camera by telnet command FIRMWARE UPDATE. You may still cancel the

operation after this. Send command CONFIRM when asked, if you want to go ahead.

7. The green LED near the power connector should now start flashing rapidly. This is the

indication that the camera is waiting for the new code.

8. Access http://10.10.10.10

or refresh the page, if you already were there. The user

interface will let you browse for the new file (.hex) and upload it to the camera.

9. You can still cancel the update here, in which case the camera will reboot once

automatically. The LED turns first into steady orange color. Wait until it becomes green

and steady again. You will have to make a new connection to the camera after this.

10. If you instead clicked on the upload button, this LED will continue flashing with multiple

colors during the loading. Do not interrupt the upload.

11. The camera will then automatically reboot. The LED will first go off, then turn orange

and finally green.

12. Close old communication sessions to the camera and establish new ones as needed.

13. Verify by command VER that the MCU version number has changed as intended.

SW-2000M-CL-65

16

5.12.2 FPGA firmware update

1. Make sure you have the correct file (.rbf) for the camera model and the existing

configuration available.

2. Make sure you have a working communication via the Ethernet port.

3. Make sure you have a compatible web browser and can access the main page

(http://10.10.10.10

) already before initiating this update.

4. Check and make a note of the existing configuration. Telnet command: VER.

5. Save any settings that you want to keep. The camera must be rebooted during the

process.

6. Access http://10.10.10.10/FPGAupdate.html

.

7. Browse and open the file (.rbf). You may cancel the operation now by closing the web

page. Click on Upload to proceed. Do not interrupt the upload.

8. The green LED near the power connector should now turn off.

9. Wait for the user interface page to change. Then click on the ‘HOME’ button. The LED

remains off.

10. The camera must next be rebooted. You may power cycle the camera or send the

REBOOT command followed by CONFIRM.

11. Close old communication sessions to the camera and establish new ones as needed.

12. Verify by command VER that the Logic version has changed as intended.

SW-2000M-CL-65

17

6 Command line interface

The command line interface provides an easy, interactive way to control the camera. All

commands can be given either through the Ethernet interface using the Telnet protocol, or

through the Camera Link serial port using plain ASCII communication. The command line usage

instructions are common to both Telnet and serial bus command line interfaces.

6.1 Connecting via Telnet

To connect the camera using Telnet:

• Consult your IT department to check if you can plug the camera to your local area

network with the default IP address 10.10.10.10. You may change the address by using

the NET IP command. Alternatively, you may configure your network card to build a

direct connection to the camera.

• Connect the camera to a local area network using a twisted-pair cable. A shielded cable

of category 5 or higher is recommended.

• Open a Telnet client on the computer. Two options are available from JAI. Please refer

to chapter 9

of this document. Also free or commercial Telnet clients can be

downloaded from various internet sites. The following Telnet clients are examples of

clients tested with the Sweep cameras:

o Foxterm

o PuTTY

• Open a Telnet connection to the IP address of the camera.

6.2 Connecting via Camera Link Serial Bus

To connect the camera using the Camera Link Serial Bus:

• Open a serial port. This may be a COM port of your PC or a terminal supplied by the

frame grabber board.

• Select the port settings: 9600 bps, 8 data bits, no parity, 1 stop bit

• Open a serial connection.

6.3 Entering the commands

The commands are typed in the client console window like in any command line interface. A

carriage return (ENTER) terminates the command line and transmits it to the command

interpreter in the camera for parsing and execution.

If the communication is coded into a software application then each line must have a carriage

return character (ASCII: 0x0D) at the end. Also, a line feed character (0x0A) may be sent after

the carriage return, but it is not needed.

SW-2000M-CL-65

18

6.4 Command Format

The following notation is used for describing the command syntax:

• BOLDFACE indicates the fixed command word that must be typed as it is

• | A vertical line delimits alternative forms of a command

• {braces} are used to group the alternative forms delimited by the vertical line |

• <wedge brackets> are used to delimit the names of values

• [square brackets] indicate an optional part that can be omitted

• All parameters (numbers, options) must be separated by one or more spaces.

• All commands are case insensitive; VER, Ver and ver are all equal

Example: LINE IT {<time>|<value>%}

A command described using this syntax has two alternative forms. The first form takes a time

as its only parameter, while the second form takes the percentage as an optional integration

time. The following commands are valid examples of this:

LINE IT 12 (according to form: LINE IT <time>)

LINE IT 100% (according to form: LINE IT <value>%; the optional <time> is omitted)

When the command parameter is a physical quantity, the unit itself must not be given. For

example, the integration time is set to 12 µs but the microsecond unit is implied by the camera.

It must not be typed by the user.

SW-2000M-CL-65

19

7 Description of commands

The commands can be divided into four groups:

Group A: General settings

MODE for selecting operating mode after boot-up.

NET for network settings for the Ethernet command communication. NET settings are saved

automatically.

CS SAVE, LOAD, SAVE2, LOAD2 and FACTORY RESET for saving, loading or restoring the

settings of group B and C.

Group B: Commands affecting exposure

SENSOR for setting sensor responsivity.

LINE RATE and LINE PERIOD for setting the scan rate.

LINE IT for selecting the actual light integration time.

LINE CTRL for selecting the trigger source.

GAIN for setting the camera gain.

OFFSET for setting the line offset value.

FFC for Flat Field Correction.

Group C: Commands affecting image output format

CL MODE for setting the Camera Link output format.

CL RATE for setting the pixel clock frequency.

READOUT for selecting normal or reverse readout direction.

ROI for selecting Region Of Interest.

BINNING for combining adjacent pixels.

Group D: Utilities

HELP or ‘?’ for list of all commands.

STATUS to display camera information and settings.

VER for displaying firmware versions and camera identifiers.

TEST for selecting test patterns.

REBOOT for restarting the camera.

FIRMWARE UPDATE to change the MCU code.

SW-2000M-CL-65

20

The four groups will be described in detail in the following sections. Most commands display

help on how to use it if a question mark is added after the command, and current status of the

function if the command is entered as such with no parameters.

The general principle with all the group B and C commands is that users may experiment with

the settings without losing the latest, saved and working setup (exception: CS FACTORY RESET).

New settings are in use, but not permanently saved, until the user decides to save them. It is

always possible to return to the latest saved settings either by sending the CS LOAD or REBOOT

command or power cycling the camera.

NOTE: The CS FACTORY RESET command also saves the new values.

SW-2000M-CL-65

21

7.1 Group A: General settings

7.1.1

MODE – select camera operating mode

The command MODE selects the operating mode that will be entered when the camera is

rebooted.

Command

Description

MODE ?

Returns the MODE setting syntax and a list of available modes

to select from.

MODE

Returns the present setting of MODE.

MODE <file name>

Sets a new operating mode. Reboot required.

7.1.2 NET - network settings

The Ethernet control interface settings can be changed using the NET group of commands.

Caution: Setting incorrect network properties can cause the camera to be unreachable

through the network. If this happens, please use the Camera Link interface to reset the

network settings.

Command

Description

NET ?

Returns the NET settings syntax for manual/DHCP, IP address,

Gateway and Subnet Mask.

NET

Returns the present setting of manual/DHCP, IP Address,

Subnet Mask and Gateway to

gether with the settings after the

next reboot of the camera.

7.1.2.1

NET IP - set the IP address

The command NET IP sets the IP address of the camera. Default is 10.10.10.10.

Command

Description

NET IP ?

Returns the NET IP setting syntax.

NET IP

Please use command NET for settings information.

NET IP <xxx.xxx.xxx.xxx>

Sets the camera to use a static IP address xxx.xxx.xxx.xxx.

NET IP AUTO

Sets the camera to obtain a dynamic IP address using DHCP.

Caution: It is recommended to use a static IP address. If a dynamic address is selected,

there is no straightforward way to determine the address assigned by the DHCP server. The

address must be queried through the Camera Link serial interface.

SW-2000M-CL-65

22

7.1.2.2 NET MASK – set the IP subnet mask

This command sets the IP subnet mask of the camera. The command has no effect in case of

using dynamic IP addressing.

Command

Description

NET MASK ?

Returns the syntax for setting NET MASK.

NET MASK

Please use command NET for settings information.

NET MASK <xxx.xxx.xxx.xxx>

Sets the camera to use an IP subnet mask.

7.1.2.3 NET GATEWAY – set the IP default gateway

The command NET GATEWAY sets the IP default gateway (default router) of the camera. The

command has no effect in case of using dynamic IP addressing.

Command

Description

NET GATEWAY ?

Returns the NET GATEWAY syntax.

NET GATEWAY

Please use command NET for settings information.

NET GATEWAY <xxx.xxx.xxx.xxx>

Sets the address of the default gateway.

7.1.2.4 NET FACTORY RESET – resetting the net settings

The command NET FACTORY RESET sets the net to the factory default values.

Command

Description

NET FACTORY RESET

Resets the network settings to factory default values.

7.1.2.5 NET NAME – set a name for the camera for the network

Command

Description

NET NAME ?

Returns the NET NAME syntax.

NET NAME

Please use command NET for settings information.

NET NAME <name>

Sets the name of the camera.

NET NAME DELETE

Removes the name.

7.1.2.6 NET CLOSE – close the current session

This command closes the current session immediately.

Command

Description

NET CLOSE

Ends the current Telnet session.

Alternative commands are NET QUIT and BYE.

SW-2000M-CL-65

23

7.1.3 CL SERIAL – sets the baud rate

The baud rate of the serial communications channel via the Camera Link cable has the default

value of 9600 bps, but can be set for higher speed. Please note that as the new value takes

effect immediately, the response to this command will not be received correctly, if the

command was given via Camera Link. In that case it is recommended to save the settings before

this and to reload them after connecting again with the new speed.

Command

Description

CL SERIAL ?

Returns the CL SERIAL command syntax.

CL SERIAL

Returns the present CL SERIAL settings.

CL SERIAL <rate>

Sets the Camera Link serial communications channel to one of the

accepted baud rates of 9600, 19200, 38400, 57600 and 115200.

Other settings are 8 bits, no parity bit and one stop bit, commonly referred like 9600,8,N,1.

SW-2000M-CL-65

24

7.1.4 Saving and restoring the capture settings

7.1.4.1 CS – show image capture settings

The command CS shows existing settings for this group of commands:

• SENSOR

• LINE RATE, LINE PERIOD

• LINE CTRL

• LINE IT

• GAIN

• OFFSET

• CL MODE

• CL RATE

• READOUT

• ROI

• BINNING

• FFC

7.1.4.2

CS SAVE – save settings (1

st

set)

This command stores all the above-mentioned settings to the first location in non-volatile

memory. The settings are loaded at power-up and during reboot of the camera.

7.1.4.3

CS LOAD – load settings (1

st

set)

This command restores all the above-mentioned settings from the first memory location of the

non-volatile memory.

Command

Description

CS ?

List of available Capture Settings group commands.

CS

Returns the present Capture Settings.

CS SAVE

Saves the present Capture Settings to the first memory

location. Loaded during reboot and power-up.

CS LOAD

Loads the stored Capture Settings from the first memory

location.

CS SAVE2

Saves the present Capture Settings to the second memory

location.

CS LOAD2

Loads the stored Capture Settings from the second memory

location.

CS FACTORY RESET

Restores the Capture Settings to the factory values and

saves them to the first memory location.

SW-2000M-CL-65

25

7.1.4.4 CS SAVE2 – save settings (2

nd

set)

This command stores all the above-mentioned settings to the second location in non-volatile

memory.

7.1.4.5

CS LOAD2 – load settings (2

nd

set)

This command restores all the above-mentioned settings from the second memory location of

the non-volatile memory.

7.1.4.6

CS FACTORY RESET – restore settings to factory default

This command restores the factory values for all the above-mentioned settings from the

camera non-volatile memory and saves them like the command ‘CS SAVE’.

SW-2000M-CL-65

26

7.2 Group B: Commands affecting exposure

7.2.1 SENSOR – selects the sensor mode

The sensor has two possibilities of collecting the light generated charge. The default setting

uses the larger well size for a wider dynamic range and a better signal to noise ratio, which

results in more valid bits. The smaller well is used for higher responsivity, but it brings along

more noise and a smaller dynamic range. The difference of the responsivity between the two

well sizes is approximately a factor of 6. It takes a few seconds to start using the other well

size.

Command

Description

SENSOR ?

Returns the SENSOR setting syntax.

SENSOR

Returns the present setting of SENSOR.

SENSOR DYNAMIC

Sets the sensor into the high dynamic range operating mode.

Larger Quantum Well is in use. This is the default setting.

SENSOR RESPONSIVE

Sets the sensor into the high responsivity operating mode.

Smaller Quantum Well is in use.

7.2.2 LINE PERIOD and LINE RATE

These commands are used to set the scan rate for the internal timing generator, which is

selected by the LINE CTRL INT command. A new setting will be effective even though the

camera is in external timing mode. The LINE RATE is the inverse of the LINE PERIOD and if one

of them is changed then the other will be changed as well.

The LINE PERIOD command specifies the line interval in microseconds. The valid range is from

15.3 to 100000.0. The line period can be changed with the resolution of 0.1 µs. However,

internal rounding can take place. In this case, the resulting rounded line period length is

returned as the response to the command. The response has a resolution of 0.01 µs.

The LINE RATE command is used for specifying the scan rate as lines per second. The valid

range is from 10 to 65,000. The line rate can be specified in steps of 0.1 Hz. However, internal

rounding can take place. In this case, the resulting rounded line rate is returned as the

response to the command.

Command

Description

LINE PERIOD ?

Returns the command syntax.

LINE PERIOD

Returns the present line period .

LINE PERIOD <line period>

Sets the line period as microseconds (µs) in steps of 0.1.

LINE RATE ?

Returns the command syntax.

LINE RATE

Returns the present line rate.

LINE RATE <line_rate>

Sets the line rate as lines per second in steps of 0.1 Hz.

Default: 1000.

SW-2000M-CL-65

27

7.2.3

LINE CTRL - Exposure Control

The camera has three exposure control modes: internal, external and mixed, which is a

combined mode of the first two. The start and length of each line, as well as the time that the

light is collected within each line period, follow the same principles regardless of the selected

mode.

The time when the exposure of one line ends and the exposure of the next line starts (change

of line) initiates a procedure that is common to all the modes. That includes stopping the

integration of light – or actually the collecting of the light generated electrons to the selected

Quantum Wells (one per pixel), sampling the respective charge voltages, and starting the

conversions into digital values to represent the amount of light that each pixel collected.

At the same time, the new line period starts and the camera starts to process the data that in

fact originates from the line period that occurred two periods earlier. There is a constant delay

from the end of each scan to the time where the first pixel value comes out of the camera. The

user always gets exactly one line of data for each request of a new line, but due to the internal

delay, it cannot always be the next line after the request.

It is possible to limit the amount of time that light is effectively collected (integration time)

within each scan period by using an electronic shutter function. The integration time always

ends at the same time as the line. The start of the integration time should thus be selected to

match the intended length.

Only two signals or events are needed for these operations. First one is the new line request

and the second one is the signal to start the integration. The source for these events can either

come directly from the input signals of the camera, or from internal timers, or as a

combination of these two.

Command

Description

LINE CTRL ?

Returns the command syntax.

LINE CTRL

Returns the present line control setting.

LINE CTRL EXT

Line rate and integration time are controlled externally by the

host.

LINE CTRL INT

Line rate and integration time are controlled by the camera.

Default setting.

LINE CTRL MIX

Line rate is controlled by externally by the host.

Integration time is controlled internally by the camera.

7.2.3.1 Internal exposure control (command: LINE CTRL INT)

The scan rate is defined either by the LINE RATE or the LINE PERIOD command, which are

inverse of each other. The LINE IT command (LINE Integration Time) sets the length of the

exposure time during each scan. The Line IT must be shorter than the Line Period. The actual

integration takes place in the first part of the line period. If the Line Integration time is

commanded to be longer than the Line Period then the integration time will stop at the same

SW-2000M-CL-65

28

time as the line period ends.

The Internal exposure mode cannot be synchronized to an external event. If external

synchronization is needed then External or Mixed mode must be selected for Exposure Control.

7.2.3.2

External exposure control (command: LINE CTRL EXT)

The line period and integration time are controlled externally by the CC1 and CC2 input signals

at the Camera Link connector.

1) CC1. Line control. The time between two rising edges of CC1 defines the line period.

2) CC2. Integration control. There are three special cases of CC2:

A) CC2 constantly low: the integration time will always be the minimum possible.

B) CC2 constantly high: the integration time will always be the maximum possible.

C) The integration time is from any rising edge of CC2 to the next rising edge of CC1 in

all the other cases.

CC1

CC2

Line interval

CC1

CC2

Line interval

Integration time

C1)

B)

Always 1

CC2

CC2

A)

Always 0

Integration time

CC1

C2)

Line interval

CC2

Integration time

CC1

Line interval

C3)

CC1

Integration time

Actual integration

*)

*) The delay between CC2 rising edge to start of actual integration and delay between CC1 rising edge to end of integration

depends on the sensor clock frequency.

SW-2000M-CL-65

29

7.2.3.3 Mixed mode exposure control (command: LINE CTRL MIX)

The line period is now the time between two consecutive rising edges of the CC1 input signal at

the Camera Link connector.

The integration time is controlled internally by the command LINE IT. The syntax for LINE IT

gives the ability to set the integration time in microseconds or in percentage of maximum

possible integration time.

This mode is useful in situations, where the integration time needs to stay constant regardless

of variations in the line frequency. Each scan would then be triggered from some external

source, while the actual integration time of light would be programmed in advance as an

absolute value. It is of course important to keep the integration time shorter than the line

period. If the line period is shorter than the commanded integration time then the integration

time will be limited by the line period. The use of percentage values for LINE IT command

avoids this, but then the integration time also varies according to the line trigger input (CC1)

frequency.

The integration time is from A to B as set by user by the LINE IT command in advance. If the

integration time is longer than the Line interval, the line interval is used as the integration

time.

CC1

Line interval

A

Integration time

B

Command

Line period control

Integration time

Related commands

LINE CTRL INT

internal

internal

LINE RATE or LINE PERIOD,

and LINE IT

LINE CTRL EXT

external

external

none

LINE CTRL MIX

external

internal

LINE IT

SW-2000M-CL-65

30

7.2.4 LINE IT - integration time

This command is used to control the integration time (effective exposure time) for each line.

The timing can be specified either as an absolute time in microseconds, or as percentage of the

line period. The integration time given as percentage of the line interval is recalculated

automatically when the line rate changes. The integration time set in absolute units remains

constant, unless the line rate setting forces the camera to shorten it.

Command

Description

LINE IT ?

Returns the command syntax.

LINE IT

Returns the present Line Integration setting.

LINE IT <time>

Sets the integration time to <time> in microseconds, where <time> is a

numerical value between 2.00 – 99998.50 with 0, 1 or 2 decimal places.

LINE IT <time>%

Sets the integration time to <time> per cent of the line interval, where

<time> is a numerical value between 0.10 % to 100.00 % (default) with

0, 1 or 2 decimal places.

7.2.5 GAIN - signal gain

The gain control can be used to scale the camera response up or down. In addition to the gain

control the Sensor responsivity can be selected to be Dynamic or Responsive giving a factor of 6

in responsivity due to the difference in quantum well size.

Please note that it is not practical to repeatedly swap the well. Instead, it is better to select it

first and then use only the GAIN command as far as possible.

Command

Description

GAIN ?

Returns the command syntax.

GAIN

Returns the present Gain setting.

GAIN <value>

Sets the Gain to <value>, where <value> is any number between 0.1

and 32 with up to three decimals. The default setting is 1.000

7.2.6

OFFSET - output offset

The value given by this command is directly added to or subtracted from all the pixel values

prior to applying the GAIN.

Command

Description

OFFSET ?

Returns the command syntax.

OFFSET

Returns the present Offset setting.

OFFSET <offset>

Changes the signal level prior to the GAIN stage.

Offset is always given as a 12-bit number. Offset changes in any 10

bit scale need to be multiplied by a factor of 4 to get the correct

value for this command. Respectively, 8 bit offsets must be

multiplied by 16. Default value is zero.

<offset> is a positive or negative integer within a range of -1023 to 1023. This equals ± 25 % of

SW-2000M-CL-65

31

the full scale. The offset is always entered as a 12-bit number, which means that if you have

set the camera for one of the 8-bit output modes, you should multiply the intended offset shift

by 16 to get the offset for this command.

Please keep in mind that this command changes the digital output signal level just before the

gain factor is applied. A positive number raises the output levels, while negative numbers drop

the levels being though limited to zero.

7.2.7

FFC – flat field correction

The function of the Flat Field Correction (FFC) is to compensate for differences in the optical

input. This can be shading due to lower transmission at the lens sides or similar optical

corrections. The Flat Field Correction must be done when the input light distribution is as

uniform as possible in order not to make the FFC correction add errors to the compensation

when activated.

The procedure is then to establish a scene illumination as uniform as possible and having the

intended optics for the application before saving the FFC line graph for the correction. A

uniform test target is needed. It is recommended to calibrate the correction slightly off focal.

This can be achieved either by changing the viewing distance (recommended option) or by

turning the lens a little off the best focus. The correction must be OFF during calibration.

Command

Description

FFC ?

Returns the FFC command syntax

FFC

Shows whether the correction is ON of OFF.

FFC RUN

When FFC RUN is sent to the camera the actual line image will be

corrected to make the line as horizontal as possible.

FFC ON

Activates the FFC function. If no line graph is saved prior to

activation of the FFC function then no change will be made to the

line image.

FFC OFF

Switches the FFC function OFF. FFC ON command returns the same

correction factors into use, unless a new FFC SAVE command was

given. Default setting.

SW-2000M-CL-65

32

7.3 Group C: Commands affecting image output format

7.3.1

CL MODE - Camera Link mode

This command selects the output mode for the final image data.

Command

Description

CL MODE ?

Returns the command syntax

CL MODE

Returns the present CL MODE setting

CL MODE SINGLE 8

8 bits per pixel. Default setting.

CL MODE SINGLE 10

10 bits per pixel

CL MODE SINGLE 12

12 bits per pixel

CL MODE DUAL 8

8 bits per pixel, 2 pixels in parallel

CL MODE DUAL 10

10 bits per pixel, 2 pixels in parallel

CL MODE DUAL 12

12 bits per pixel, 2 pixels in parallel

CL MODE TRIPLE 8

8 bits per pixel, 3 pixels in parallel

7.3.2

CL RATE - Camera Link pixel rate

Sets the pixel clock frequency within range of 20 to 85 MHz. Parameter MIN finds the slowest

suitable rate in respect to the current line rate. Both are in steps of 5 MHz.

Command

Description

CL RATE ?

Returns the CL RATE command syntax.

CL RATE

Returns the present CL RATE setting.

CL RATE <cl_rate>

Sets the Camera Link clock frequency to <cl_rate> in MHz.

Default value is 50 MHz.

CL RATE MIN

Sets the Camera Link clock frequency to the slowest rate sufficient

for the existing line rate.

7.3.3

READOUT – pixel readout direction

Sets the pixel readout to normal or reverse direction.

Command

Description

READOUT ?

Returns the READOUT command syntax.

READOUT

Returns the present READOUT setting.

READOUT NORMAL

Sets the READOUT direction to normal starting with first pixel. Default

setting.

READOUT REVERSE

Sets the READOUT direction to reverse starting with last pixel.

SW-2000M-CL-65

33

7.3.4

ROI – region of interest

This command can be used to select only specific sections of each line to be sent out. Up to

four regions can be defined. The selected parts of the line will be combined together to make

one, shorter line. There are no empty pixels or spaces in between the regions in the output

data.

Furthermore, both binning and reversed readout order can be applied after this. Please note

that all pixel number indices still and always refer to the real, physical pixel numbers of the

sensor itself. First pixel is labelled as ‘1’ and thus the last pixel is number 2048.

The start pixel index must always be odd and smaller than the respective end pixel index at

each region and the regions must not overlap. All indices must be within range of 1 to 2048.

Minimum width of each ROI is 16 pixels. Each region may have individual widths. Changes to

selections are made by defining the complete set again.

Region #1 Region #2 Region #3 Region #4

□□□□□…□□□□□□ □□□□□□□…□□□□□□□□ □□□…□□□ □□□…□□□

↑ ↑ ↑ ↑ ↑ ↑ ↑ ↑

X0 X1 X2 X3 X4 X5 X6 X7

examples: 23 88 897 1356 1807 2020

Command

Description

ROI ?

Returns the ROI command syntax

ROI

Returns the present ROI setting, e.g. ROI ON, X1-X2, X3-X4, X5-X6

ROI X0-X1

Sets the ROI to start at pixel X0 and stop at pixel X1

ROI X0-X1, X2-X3

Sets region #1 to start at pixel X0 and end at pixel X1

and region #2 to start at pixel X2 and end at pixel X3

ROI X0-X1, X2-X3,

X4-X5

Sets region #1 to start at pixel X0 and end at pixel X1

and region #2 to start at pixel X2 and end at pixel X3

and region #3 to start at pixel X4 and end at pixel X5

ROI X0-X1, X2-X3,

X4-X5, X6-X7

Sets region #1 to start at pixel X0 and end at pixel X1

and region #2 to start at pixel X2 and end at pixel X3

and region #3 to start at pixel X4 and end at pixel X5

and region #4 to start at pixel X6 and end at pixel X7

ROI ON

Activates ROI. If no regions are specified then all 2048 pixels will be

sent out.

ROI OFF

Deactivates ROI. ROI ON command returns the same regions into use,

unless new regions have been defined. Default setting.

SW-2000M-CL-65

34

7.3.5

BINNING – paring of pixels

Binning mode combines adjacent pixels as pairs either to double the response by summing the

two original values or to decrease noise by taking the average of the two values. ROI operation

may be in use prior to this. Binning decreases the number of output values by factor of two.

The two output values are added together in the summing mode and the output is limited to

the maximum digital value of the original pixel values. The averaging mode sums the two

values with no maximum limit and then takes the most significant bits into use to represent the

new, combined pixel (lowest bit is removed).

The number of first pixel of each pair is always odd.

Command

Description

BINNING ?

Returns the BINNING command syntax.

BINNING

Returns the present BINNING setting.

BINNING AVG

Activates BINNING in the averaging mode.

BINNING SUM

Activates BINNING in the summing mode.

BINNING OFF

Deactivates BINNING mode. Default setting.

SW-2000M-CL-65

35

7.4 Group D: Utilities

7.4.1

HELP or ‘?’ – list of commands

7.4.2 STATUS - camera information and settings

This command displays version information of various components of the camera. The

command also returns camera model number, MAC address and serial number.

Command

Description

STATUS

Display version information and settings.

7.4.3 VER - camera information

This command displays version information of various components of the camera. The

command also returns camera model number, MAC address and serial number.

Command

Description

VER

Display version information and identifiers of the camera.

7.4.4

TEST - test patterns

The image data can be replaced by artificially generated, known test patterns to help

interfacing the camera, trouble shooting, and locating faults. Horizontal patterns ramp either

up or up-down within each line with steps that equal the selected camera output bit depth. All

lines are then equal. Vertical patterns perform the same, but in line to line direction. All values

within each line are then equal.

The last pattern, P5, is a combination of these two directions to enable tracking in both

domains with a single test pattern. It starts exactly like the horizontal pattern P1, but when

then advancing to next lines it leaves the darkest pixel values out one by each line. This

effectively also shortens the length of the horizontal sequences causing the position of the

horizontal ramps to move from line to line. The last line of one sequence then finally only

contains the maximum values making it to look like one completely white line.

The lowest value is actually always the same as what the vertically changing pattern P3 would

have, if it had been started at the same time as P5. Thinking of the visual looks of the pattern

P3, the correct looks of this pattern (P5) can be better understood: the base level or the

darkest parts of the pattern vary just like the vertically ramping P3 would vary. And while the

base level gets brighter then also the horizontal pattern gets tighter as the lengths of those

horizontal ramps decrease making the respective image look like a pattern of higher

frequencies.

SW-2000M-CL-65

36

Command

Description

TEST OFF

No test pattern. Image data originates from the sensor (default).

TEST P1

Sawtooth: horizontal rising ramps from 0 to maximum. All lines are

equal. In case of 8 bit output, the line graph includes 8 such periods,

when advancing across the 2K pixels. The respective image should thus

look like this:

TEST P2

Triangles: horizontal ramps from 0 to maximum followed by falling

ramps from maximum to zero. All lines are equal. In case of 8 bit

output, the line graph includes 4 of such periods, when advancing

across the 2K pixels. The respective image should thus look like this:

TEST P3

Vertical sawtooth: rising ramps from 0 to maximum in line to line

direction. Each line has only one value for all the pixels. In case of 8 bit

output, the ramp from black to white takes 256 lines in the respective

image:

TEST P4

Vertical triangles: rising ramps from 0 to maximum followed by falling

ramps from maximum to zero in line to line direction. Each line has

only one value for all the pixels. In case of using an 8 bit output mode,

the cycle repeats itself every 512 lines. The respective image should

look like this:

SW-2000M-CL-65

37

TEST P5

A combination of rising ramps in both directions.

Horizontally the length of the sequence varies at the same phase as the

lowest value of the pattern changes from line to line.

Vertically the lowest value of each line specific pattern varies from line

to line as rising ramps from zero to maximum, similarly to how the

pattern P3 behaves on its own.

The resulting image is shown below (8-bit). The first line is identical to

any line of P1. Then, instead of always starting from zero, the lowest

value will ris

e by one per line thus also making the sequence shorter.

This will continue making the pattern look like having higher

frequencies all the way until finally a completely white line is

produced. The sequence will then start over from the beginning.

TEST

Returns information on the current status of test modes

Note: all ramps increase or decrease by one level per pixel or line, where the step follows the

selected output bit depth of 8, 10 or 12 bits. When the direction of any ramp changes, the last

value of previous ramp is repeated once as the first value of the next ramp to keep the lengths

of the sequences equal, when feasible.

7.4.5

REBOOT – restart the camera

The command REBOOT resets the camera and starts it from the beginning as if the power had

been cycled.

Command

Description

REBOOT

Restart the camera. Same initialisations as with power-up.

Close existing telnet sessions and start new ones as needed.

7.4.6

FIRMWARE UPDATE – initiate the MCU update

This command is needed to start the loading of new firmware for the MCU. Please refer to

‘Operations and functions’ chapter for detailed instructions

. Also the FPGA update process is

described there.

Command

Description

FIRMWARE UPDATE

Initiates the microcontroller firmware update after confirmation.

SW-2000M-CL-65

38

8 Summary of commands

A – General settings.

Command Function Command Format Parameter Remarks

1

Camera operating

mode

MODE <file name>

fundamental settings,

reboot required

2

Network settings

NET

3 set IP address

NET IP <address>

NET IP AUTO

xxx.xxx.xxx.xxx

static, DHCP off

dynamic, DHCP on

4 set subnet mask NET MASK <mask> xxx.xxx.xxx.xxx

only with static

address

5 set default router

NET GATEWAY

<address>

xxx.xxx.xxx.xxx

only with static

address

6 reset net settings NET FACTORY RESET

7

camera name

for

network

NET NAME <name>

new name

8

remove the camera

name for network

NET NAME DELETE

9 close session

NET CLOSE,

NET QUIT or

BYE

10

baud rate for

Camera Link serial

communications

CL SERIAL

9600, 19200, 38400,

57600 or 115200

bps

11

Save capture

settings

CS SAVE

affected commands:

SENSOR

LINE RATE

LINE PERIOD

LINE CTRL

LINE IT

GAIN

OFFSET

CL MODE

CL RATE

READOUT

ROI

BINNING

FFC

12

Load capture

settings

CS LOAD

13

Restore factory

settings for image

capture and save

CS FACTORY RESET

SW-2000M-CL-65

39

B – Commands affecting exposure

Command Function Command Format Parameter Remarks

1

Sensor operating

mode

SENSOR

DYNAMIC

RESPONSIVE

Larger capacity,

lower noise.

Smaller capacity,

higher responsivity.

2 Line interval LINE PERIOD <time>

Line interval in µs, from

15.3 to 100 000

Minimum depends

on CL mode and

rate, ROI and

binning

3 Line rate LINE RATE <rate>

Lines per second, from 10

to 65,000

Maximum depends

on CL mode and

rate, ROI and

binning

4 Timing source LINE CTRL <mode>

INT = internal

EXT = external

MIX = external line timing,

internal integration time

5

Integration

time as

microseconds

LINE IT <time> 2.00 to 99,998.60 µs

Minimum and

maximum depend

on line rate

6

Integration time as

percentage

LINE IT <time>% 0.10 % to 100.00 %

7

Gain

GAIN <gain>

0.100 to 32.000

digital

8

Offset

OFFSET<offset>

-1023 to 1023

entered as 12 bits

9

Calibrate the Flat

Field Correction

FFC RUN define and apply

10

activate correction

FFC ON

11 deactivate FFC OFF

SW-2000M-CL-65

40

C – Commands affecting image output format

Command Function Command Format

Parameter Remarks

1 Camera Link mode CL MODE <mode>

SINGLE 8

SINGLE 10

SINGLE 12

DUAL 8

DUAL 10

DUAL 12

TRIPLE 8

8 bits, 1 pixel/clock

10 bits, 1 pixel/clock

12 bits, 1 pixel/clock

8 bits, 2 pixels/clock

10 bits, 2 pixels/clock

12 bits, 2 pixels/clock

8 bits, 3 pixels/clock

2

Camera Link clock

frequency

CL RATE

<rate>

CL RATE MIN

From 20 to 85 MHz.

MIN is to use the slowest

sufficient rate.

Both in steps of 5 MHz.

3

Readout direction

READOUT

Normal or Reverse

4

Set the regions of

interest

ROI <regions>

Pixel numbers, 1 to 4

regions.

5

Activate ROI

ROI ON

6 Deactivate ROI ROI OFF

7 Pixel binning BINNING <mode> AVG, SUM or OFF

D – Utilities

Command Function Command Format

Parameter Remarks

1

Help

HELP or ‘?’

list of commands

2

Help on any specific

command

add a ‘ ?’

examples:

GAIN ?

LINE RATE ?

3

Query of existing

setting

<command> with no

parameters

examples:

GAIN

LINE RATE

4

Camera information

and settings

STATUS

4

Camera identifiers

and version numbers

VER

Model, SN, MAC.

Versions: MCU, HW,

sensor, logic.

5

Selection of test

patterns

TEST <pattern>

TEST OFF

From P1 to P5

6

Re-booting the

camera

REBOOT close telnet sessions

7 Firmware update FIRMWARE UPDATE http://10.10.10.10

SW-2000M-CL-65

41

9 Software tools for camera communications

The camera can communicate either via its Camera Link port or the Ethernet (10/100) port.

Both communications can be used at the same time. The reply is sent to only the channel,

where the command was received from.

Ethernet port supports multiple telnet sessions at the same time. Standard terminal programs

can be used for control at command level. Default IP address is 10.10.10.10. Telnet Port is

number 23.

JAI provides two control tools as Windows software, as well as web browser access.

9.1 JAI SweepConf

The SweepConf offers a graphical user interface with sliders and pop down menus for the most

common functions as well as a telnet terminal. The same tool works for either Camera Link or

Ethernet.

Fig.7. Front page after initialization.

SW-2000M-CL-65

42

9.2 JAI Sweep Ethernet Tool

The Sweep Ethernet Tool is a telnet terminal program with possibility to run scripts and to

display single line graphs (average of 32 lines).

Fig.8. Front page after initialization and the help command.

SW-2000M-CL-65

43

Fig.9. Line graph display with no frame grabber. Test pattern 2.

SW-2000M-CL-65

44

9.3 Internal web server

The internal Web server can be accessed by standard web browsers at http://10.10.10.10/

.

It offers some documents for download and is used while updating camera firmware.

Fig.10. Home page.

SW-2000M-CL-65

45

10 External dimensions

Fig.11. External dimensions in mm.

SW-2000M-CL-65

46

11 Specifications

11.1 Operating range

Parameter

Min

Typical

Max

Unit

Notes

Number of pixels

2048 - CMOS (custom), line scan

Pixel size 20.0 - 20.0 µm square

Fill factor 100 - 100 %

Length of the imager 40.96 - 40.96 mm

Pixel clock 20 - 85 MHz

adjustable

Line scan period

(external mode)

15.3 - 100k µs max. line rate: 65 kHz

Line scan period

(internal mode)

15.3 - 100k µs line rate: 10 Hz to 65 kHz

Electronic shutter

(internal mode)

2 - 100k µs

Internal A/D conversions 12½ bit

Gain control

0.1 x

-

32 x

-

additionally, effect of

Quantum Well selection adds a

scale factor of 6-to-1 for

small-to-large size,

respectively

Flange back distance 46.5 mm Nikon F-mount

Protective glass BK7 with AR coating

Position of optical axis ±0.1 ±0.2 mm

Supply voltage 11.8 12 - 24 26.0 Vdc

WARNING:

Overvoltage may damage the

camera permanently.

Power consumption 4 - 5 W

Operating temperature +5 - +60

°C

Storage temperature -10 - +60

°C

Humidity, operating 5 - 80 % relative, non-condensing

Humidity, storage 5 - 80 % relative, non-condensing

Vibration 3 G

IEC 60068-2-6

Shock 25 G

IEC 60068-2-27

Dimensions

(with no lens mount)

119.3

99.3

45.3

mm

width

height

depth

Weight 660 g w/o lens mount

SW-2000M-CL-65

47

11.2 Common properties

Property

Notes

Operation modes

External (external trigger, external shutter)

Internal (internal trigger, internal shutter)

Mixed (external trigger, internal shutter)

Data interface

Camera Link Base Configuration

Output modes

8, 10 or 12 bits x1

8, 10 or 12 bits x2

8 bits x3

Communication

interface

Via Camera Link (CL) or 10/100 Mbps Ethernet

CL baud rates: 9600, 19200, 38400, 57600, or 115200 bps

Regulation

EN 61000-6-2 (2005), EMC immunity

EN 61000-6-4 (2007), EMC emissions

FCC Part 15, Subpart B

11.3

Performance per selected sensor mode

Parameter

Symbol

Responsive

Dynamic

Unit

Notes

Quantum efficiency

QE 60 60 %

Quantum well size 60 360 ke-

Conversion factor 6.4 1.1 DN/ke- note: per 1000 e-

Signal-to-noise ratio SNR 240

47.6

580

55.3

dB

EMVA-1288

Dynamic range DR 64 68 dB

Temporal dark noise 2.5 1.6 DN

Responsivity 480 80 DN/nJ/cm

2

Linearity error 0.5 0.7 % 5 % to 95 % of saturation

Notes:

•

all specifications are subject to change without notice

• wavelength of light: 625 nm

• DN as 12 bit

• Gain: 1.0

SW-2000M-CL-65

48

11.4 Spectral sensitivity

Fig. 12. Total spectral response (typical, without lens)

0,0

10,0

20,0

30,0

40,0

50,0

60,0

70,0

80,0

350 400 450 500 550 600 650 700 750 800 850 900 950 10001050 1100

Quantum Efficiency (%)

Wavelength (nm) (visible light is 390 to 750 nm)

SW-2000M-CL-65

49

12 Change History

Date

Revision

Changes

12 June 2014 1.0 First Release (1.0)

28 Aug 2014 1.1 First Release, rev. 1.1

(FCC, input voltage, CS commands, web server)

SW-2000M-CL-65

50

User's Record

Camera type: Sweep SW-2000M-CL-65

Revision: Release A, rev.1.1

Serial No. ……………

Firmware version. MCU: 1.027

Logic: 10.002

Please contact your local JAI distributor for camera revision history.

User's mode settings.

User's modifications.