Page 1

CM-030GE

User's Manual

CB-030GE

CM-030GE-RA

CB-030GE-RA

Digital Monochrome / Color

Progressive Scan GigE Vision Camera

Document Version: 2.3

CMB-030GE_Ver.2.3_Aug2018

Page 2

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

Notice

The material contained in this manual consists of information that is proprietary to JAI Ltd.,

Japan and may only be used by the purchasers of the product. JAI Ltd., Japan makes no

warranty for the use of its product and assumes no responsibility for any errors which may

appear or for damages resulting from the use of the information contained herein. JAI Ltd.,

Japan reserves the right to make changes without notice.

Company and product names mentioned in this manual are trademarks or registered

trademarks of their respective owners.

Warranty

For information about the warranty, please contact your factory representative.

Certifications

CE compliance

As defined by the Directive 2004/108/EC of the European Parliament and of the Council, EMC

(Electromagnetic compatibility), JAI Ltd., Japan declares that CM-030GE, CB-030GE, CM030GE-RA and CB-030GE-RA comply with the following provisions applying to its standards.

EN 61000-6-3 (Generic emission standard part 1)

EN 61000-6-2 (Generic immunity standard part 1)

FCC

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Warning

Changes or modifications to this unit not expressly approved by the party

responsible for FCC compliance could void the user’s authority to operate the

equipment.

KC

- 2 -

Page 3

CM-030GE / CM-030GE-RA

Supplement

The following statement is related to the regulation on “ Measures for the Administration

of the control of Pollution by Electronic Information Products “ , known as “ China RoHS “.

The table shows contained Hazardous Substances in this camera.

mark shows that the environment-friendly use period of contained Hazardous

Substances is 15 years.

嶷勣廣吭並㍻

嗤蕎嗤墾麗嵎賜圷殆兆各式根楚燕

功象嶄鯖繁酎慌才忽佚連恢匍何〆窮徨佚連恢瞳麟半陣崙砿尖一隈〇云恢瞳ゞ 嗤蕎嗤

墾麗嵎賜圷殆兆各式根楚燕 〃泌和

桟隠聞喘豚㍉

窮徨佚連恢瞳嶄根嗤議嗤蕎嗤墾麗嵎賜圷殆壓屎械聞喘議訳周和音氏窟伏翌

亶賜融延、窮徨佚連恢瞳喘薩聞喘乎窮徨佚連恢瞳音氏斤桟廠夛撹冢嶷麟半

賜斤児繁附、夏恢夛撹冢嶷鱒墾議豚㍉。

方忖仝15々葎豚㍉15定。

Page 4

CB-030GE / CB-030GE-RA

Supplement

The following statement is related to the regulation on “ Measures for the Administration

of the control of Pollution by Electronic Information Products “ , known as “ China RoHS “.

The table shows contained Hazardous Substances in this camera.

mark shows that the environment-friendly use period of contained Hazardous

Substances is 15 years.

嶷勣廣吭並㍻

嗤蕎嗤墾麗嵎賜圷殆兆各式根楚燕

功象嶄鯖繁酎慌才忽佚連恢匍何〆窮徨佚連恢瞳麟半陣崙砿尖一隈〇云恢瞳ゞ 嗤蕎嗤

墾麗嵎賜圷殆兆各式根楚燕 〃泌和

桟隠聞喘豚㍉

窮徨佚連恢瞳嶄根嗤議嗤蕎嗤墾麗嵎賜圷殆壓屎械聞喘議訳周和音氏窟伏翌

亶賜融延、窮徨佚連恢瞳喘薩聞喘乎窮徨佚連恢瞳音氏斤桟廠夛撹冢嶷麟半

賜斤児繁附、夏恢夛撹冢嶷鱒墾議豚㍉。

方忖仝15々葎豚㍉15定。

Page 5

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

Table of Contents

JAI GigE® Vision Camera operation manuals ........................................................ - 5 -

Introduction ............................................................................................. - 5 -

Before using GigE Vision cameras ..................................................................... - 5 -

Software installation ................................................................................... - 5 -

Camera operation ...................................................................................... - 6 -

1. General .............................................................................................. - 6 -

2. Camera nomenclature ............................................................................. - 6 -

3. Main Features ...................................................................................... - 7 -

4. Locations and Functions .......................................................................... - 8 -

4.1. CM-030GE and CB-030GE ................................................................................. - 8 -

4.2. CM-030GE-RA and CB-030GE-RA......................................................................... - 9 -

4.3. Rear panel indicator .................................................................................... - 10 -

5. Pin Assignment .................................................................................... - 11 -

5.1. 12-pin Multi-connector (DC-in/GPIO/Iris Video) ................................................... - 11 -

5.2. Digital Output Connector for Gigabit Ethernet ..................................................... - 11 -

6. Input and output interface ...................................................................... - 12 -

6.1. GPIO interface ........................................................................................... - 12 -

6.1.1 LUT (Look Up Table) .............................................................................. - 12 -

6.1.2 12-bit Counter ..................................................................................... - 13 -

6.1.3. Pulse Generators ................................................................................. - 13 -

6.2. Opto-isolated Inputs/Outputs ......................................................................... - 14 -

6.2.1 Recommended External Input circuit diagram for customer .............................. - 15 -

6.2.2 Recommended External Output circuit diagram for customer ............................ - 15 -

6.2.3 Optical Interface Specifications ................................................................ - 16 -

6.3. Inputs and outputs table ............................................................................... - 16 -

6.4. Configuring the GPIO module .......................................................................... - 17 -

6.4.1 Input/Output Signal Selector .................................................................... - 17 -

6.5. Examples of the pulse generator configuration ................................................... - 17 -

6.5.1 Setting screen of the pulse generator ......................................................... - 17 -

6.5.2 GPIO in combination with Pulse Width trigger mode ...................................... - 18 -

6.5.3 Internal Trigger Generator ...................................................................... - 19 -

7. Image output signal............................................................................... - 20 -

7.1. Output image ............................................................................................. - 20 -

7.2. Vertical Binning (CM-030GE/CM-030GE-RA only)................................................... - 20 -

7.3. Digital Video Output (Bit Allocation) ................................................................. - 21 -

7.3.1 Bit Allocation (Pixel Format / Pixel Type) – CM-030GE/CM-030GE-RA ................... - 21 -

7.3.2 Bit Allocation (Pixel Format / Pixel Type) – CB-030GE/CB-030GE-RA.................... - 22 -

7.4. CB-030GE/CB-030GE-RA. Bayer filter ......................................................... - 23 -

7.5. Image timing ............................................................................................. - 24 -

7.5.1 Horizontal timing .................................................................................. - 24 -

7.5.2 Vertical timing ..................................................................................... - 24 -

7.5.3 Partial Scanning ................................................................................... - 25 -

7.5.4 Vertical binning .................................................................................... - 26 -

7.5.5 Auto Iris Lens video output (12-pin Hirose connector) ..................................... - 27 -

8. Network configuration ........................................................................... - 28 -

8.1. GigE Vision Standard Interface ........................................................................ - 28 -

8.2. Equipment to configure the network system ....................................................... - 28 -

8.2.1 PC .................................................................................................... - 28 -

8.2.2 Cables ............................................................................................... - 28 -

8.2.3 Network card (NIC) ................................................................................ - 28 -

8.2.4 Hub ................................................................................................... - 29 -

8.3. Recommended Network Configurations ............................................................. - 29 -

8.3.1 Guideline for network settings ................................................................. - 29 -

8.3.2 Video data rate (network bandwidth) ......................................................... - 30 -

- 3 -

Page 6

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

8.3.3 Note for setting packet size ..................................................................... - 30 -

8.3.4 Calculation of Data Transfer Rate .............................................................. - 30 -

8.3.5 Simplified calculation (Approximate value) .................................................. - 31 -

8.3.6 Note for 100BASE-TX connection ............................................................... - 31 -

8.4. GigE camera connecting examples ................................................................... - 32 -

8.4.1 Using a switching hub for 1 port ................................................................ - 32 -

8.4.2 Connecting a camera to each port of a multi-port NIC ..................................... - 32 -

8.4.3 The data transfer for multiple cameras ....................................................... - 33 -

9. Functions and operations ........................................................................ - 35 -

9.1. Basic functions ........................................................................................... - 35 -

9.2. Electronic Shutter ....................................................................................... - 35 -

9.3. Auto-detect LVAL-sync / a-sync. accumulation .................................................... - 36 -

10. Operation Modes ................................................................................. - 37 -

10.1. The functions related to GenICam SFNC 1.3 ...................................................... - 37 -

10.2. Operation Mode ........................................................................................ - 40 -

10.2.1 Continuous operation ........................................................................... - 40 -

10.2.2 Edge Pre-select Trigger Mode .................................................................. - 41 -

10.2.3 Pulse Width Control trigger mode ............................................................ - 43 -

10.2.4 Reset Continuous (RCT) trigger mode ........................................................ - 45 -

10.2.5 Sequential Trigger Mode (Pre-Select trigger) ............................................... - 46 -

10.2.6 Delayed Readout Mode (Pre-Select, Pulse width control) ................................ - 48 -

10.2.7 Optical Black transfer mode ................................................................... - 49 -

10.2.8 Operation Mode and Functions matrix ....................................................... - 50 -

11. JAI control tool .................................................................................. - 51 -

11.1. About GenICamTMSFNC1.3 ............................................................................ - 51 -

11.2. JAI SDK Ver.1.3 ......................................................................................... - 51 -

11.3. Examples of camera operation ...................................................................... - 52 -

11.3.1 Generic cautions for operation ................................................................ - 52 -

11.3.2 Connection of camera(s) ....................................................................... - 52 -

11.3.3 Camera setting level ............................................................................ - 52 -

11.4. Input and Output settings ............................................................................ - 52 -

11.4.1 Interfacing with external devices ............................................................. - 52 -

11.4.2 Setting of input and output .................................................................... - 53 -

11.4.3 Setting the image size .......................................................................... - 54 -

11.4.4 Acquisition of the image ........................................................................ - 54 -

11.4.5 How to look at XML file ......................................................................... - 55 -

11.4.6 Feature Tree Information ...................................................................... - 55 -

11.4.7 Feature Properties (Guru) ..................................................................... - 55 -

12. External Appearance and Dimensions ........................................................ - 59 -

12.1. CM-030GE and CB-030GE .............................................................................. - 59 -

12.2. CM-030GE-RA and CB-030GE-RA ..................................................................... - 60 -

13. Specifications .................................................................................... - 61 -

13.1. Spectral response ..................................................................................... - 61 -

13.2. Specification table ..................................................................................... - 62 -

14. Appendix .......................................................................................... - 64 -

14.1. Precautions .............................................................................................. - 64 -

14.2. Typical Sensor Characteristics ....................................................................... - 64 -

14.3. Caution when mounting a lens on the camera .................................................... - 64 -

14.4. Caution when mounting the camera ................................................................ - 65 -

14.5. Exportation .............................................................................................. - 65 -

14.6. References .............................................................................................. - 65 -

Change History ......................................................................................... - 66 -

User's Record ........................................................................................... - 67 -

- 4 -

Page 7

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

JAI GigE® Vision Camera operation manuals

To understand and operate this JAI GigE® Vision camera properly, JAI provides the following

manuals.

User’s manual (this booklet) Describes functions and operation of the hardware

JAI SDK & Control Tool User Guide Describes functions and operation of the Control Tool

JAI SDK Getting Started Guide Describes the network interface

User’s manual is available at www.jai.com

JAI SDK & Control Tool User Guide and JAI SDK Getting Started Guide are provided with the

JAI SDK which is available at www.jai.com.

Introduction

GigE Vision is a standard interface which uses Gigabit Ethernet for machine vision applications.

It was developed primarily by AIA (Automated Imaging Association) members. GigE Vision is

capable of transmitting large amounts of uncompressed image data through an inexpensive

general purpose LAN cable over long distances.

GigE Vision also supports the GenICamTM standard which is maintained by the EMVA (European

Machine Vision Association). The purpose of the GenICam standard is to provide a common

program interface for various machine vision cameras. By using GenICam, cameras from

different manufactures can seamlessly connect in one platform.

For details about the GigE Vision standard, please visit the AIA web site,

www.machinevisiononline.org and for GenICam, the EMVA web site, www.genicam.org.

JAI GigE Vision cameras comply with both the GigE Vision standard and the GenICam standard.

Before using GigE Vision cameras

All software products described in this manual pertain to the proper use of JAI GigE Vision

cameras. Product names mentioned in this manual are used only for the explanation of

operation. Registered trademarks or trademarks belong to their manufacturers.

To use the JAI SDK, it is necessary to accept the “Software license agreement” first.

This manual describes necessary equipment and the details of camera functions.

Software installation

The JAI GigE Vision SDK & Control Tool can be downloaded from the JAI web site at

www.jai.com. The JAI SDK is available for Windows XP and Vista, 32-bit and 64-bit.

For the details of software installation, please refer to the “Getting Started Guide” supplied

on the JAI SDK download page.

- 5 -

Page 8

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

Camera operation

1. General

This manual covers the digital monochrome progressive scan camera CM-030GE/CM030GE-RA and color progressive scan camera CB-030GE/CB-030GE-RA

The CM-030GE/CM-030GE-RA/CB-030GE/CB-030GE-RA are a new additions to JAI GigE Vision

compliant camera series. Both the monochrome version CM-030GE/CM-030GE-RA and the

color version CB-030GE/CB-030GE-RA provide a frame rate of 90.5 frames/second at full

resolution. Using vertical binning (CM-030GE/CM-030GE-RA only) and partial scan provides

higher frame rates.

The 1/3" CCD with square pixels offers a superb image quality. The high-speed shutter

function and asynchronous random trigger mode allow the camera to capture high quality

images of fast moving objects.

The color version CB-030GE/CB-030GE-RA, based on CCD sensor with primary RGB Bayer

mosaic filter, outputs raw Bayer images. Host-based color interpolation is required to display

or save color images.

The CM-030GE/CM-030GE-RA/CB-030GE/CB-030GE-RA also comply with the GenICam standard

and contains an internal XML-file that is used to describe the functions/features of the

camera. For further information about GigE®Vision standard, please go to

www.machinevisiononline.org and about GenICamTM, please go to www.emva.org.

As an application programming interface, JAI provides an SDK (Software Development Kit).

This SDK includes GigEVision Filter Driver,JAI control tool, software documentation and code

examples.

The JAI SDK can be downloaded from www.jai.com.

The latest version of this manual can be downloaded from www.jai.com

For camera revision history, please contact your local JAI distributor.

2. Camera nomenclature

The standard camera composition consists of the camera main body and C-mount protection

cap.

The camera is available in the following versions:

CM-030GE/CM-030GE-RA

Where C stands for "Compact" family, M stands for "Monochrome", 030 represents the

resolution "300 thousand pixel", GE stands for "GigE Vision" interface and RA stands for Right

Angle type

CB-030GE/CB-030GE-RA

Where C stands for "Compact" family, B stands for "Bayer mosaic color", 030 represents the

resolution "300 thousand pixel" , GE stands for "GigE Vision" interface and RA stands for Right

Angle type.

- 6 -

Page 9

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

3. Main Features

Member of Compact series, covering VGA to UXGA resolution

656 (h) x 494 (v) 7.4 µm square pixels

1/3” progressive scan – monochrome and Bayer mosaic color versions

High frame rate of 90.5 frames/second with full resolution in continuous operation

90 frames/second with external trigger and full resolution

+24dB Gain and noise reduction circuit built-in

Increased frame rate with vertical binning (CM-030GE/CM-030GE-RA only) and

partial scan

Exposure time from 43.2 μs to 2 sec. using Pulse Width Control trigger mode

Programmable exposure from 43.2μs to 11.037 ms in Full Frame scan

Sequencer trigger mode for on-the –fly change of gain, exposure and ROI

Edge Pre-select and Pulse width trigger mode

LVAL-synchronous/-asynchronous operation (auto-detect)

Auto iris lens video output allows a wider range of light

GigE Vision Interface with 10 or 8-bit output

Programmable GPIO with opto-isolated inputs and outputs

Can be connected with 100BASE-TX

Right Angle type is available as CM-030GE-RA and CB-030GE-RA

Comprehensive software tools and SDK for Windows XP/Vista

Note: CM/CB-030GE and CM/CB-030GE-RA can be connected with 100BASE-TX.

However, due to the limited bandwidth (100Mbps), the described

specifications such as frame rate, minimum trigger interval and so on cannot

be satisfied for 100BASE-TX connection.

- 7 -

Page 10

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

4. Locations and Functions

4.1. CM-030GE and CB-030GE

Lens mount C-mount (Note *1)

CCD sensor 1/3 inch CCD sensor

12-pin connector DC +12V to 24V power and GPIO interface

RJ-45 Gigabit Ethernet connector with threaded holes for

thumbscrews

LED Indication for power and trigger input

LED GigE Network condition: LINK

LED GigE Network condition: ACT

Holes for RJ-45 thumbscrews When an RJ-45 connector with thumbscrews is used,

remove the two screws located above and below the

Ethernet connector (Note*2)

Mounting holes M3 depth 3.5mm for tripod mount plate (Note * 3)

*1) Note: Rear protrusion on C-mount lens must be less than 10.0mm.

*2) Note: When a RJ-45 cable with thumbscrews is connected to the camera, please do not

excessively tighten screws by using a screw driver. The RJ-45 receptacle on the

camera might get damaged. For security, the strength to tighten screws should be

less than 0.147 Newton meter (Nm). Tightening by hand is sufficient in order to

achieve this.

*3) Note: The depth of holes is 3.5mm. When the tripod adapter plate MP-40 or MP-41 is

used, use the attached screws. If installing the camera directly, please do not use

screws longer than 3.5mm.

Fig. 1. Locations

- 8 -

Page 11

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

4.2. CM-030GE-RA and CB-030GE-RA

Lens mount C-mount (Note *1)

CCD sensor 1/3 inch CCD sensor

12-pin connector DC +12V to 24V power and GPIO interface

RJ-45 Gigabit Ethernet connector with threaded holes for

thumbscrews

LED Indication for power and trigger input

LED GigE Network condition: LINK

LED GigE Network condition: ACT

Holes for RJ-45 thumbscrews When an RJ-45 connector with thumbscrews is used,

remove the two screws located above and below the

Ethernet connector (Note*2)

Mounting holes M3 depth 3.5mm for tripod mount plate (Note*3)

*1) Note: Rear protrusion on C-mount lens must be less than 10.0mm.

*2) Note: When a RJ-45 cable with thumbscrews is connected to the camera, please do not

excessively tighten screws by using a screw driver. The RJ-45 receptacle on the

camera might get damaged. For security, the strength to tighten screws is less than

0.147 Newton meter (Nm). Tightening by hand is sufficient in order to achieve this.

*3) Note: The depth of holes is 3.5mm. When the tripod adapter plate MP-40 or MP-41 is used,

use the attached screws. If installing the camera directly, please do not use screws

longer than 3.5mm.

Fig.2 Locations (CM-030GE-RA / CB-030GE-RA)

- 9 -

Page 12

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

4.3. Rear panel indicator

The rear panel mounted LED provides the following information:

Amber: Power connected - initiating

Steady green : Camera is operating in Continuous mode

Flashing green : The camera is receiving external trigger

Ethernet connector indicates,

Steady green : 1000 Base-T has been connected

Flashing green : 100 Base-TX has been connected (Note)

Flashing amber : Network active in communication

Note: When 10BASE-T is connected, the green is also flashing.

However, the video is not streamed through Ethernet.

Fig.13. Rear Panel

- 10 -

Page 13

Pin No

In/Out

Name

1

In/Out

MX1+ (DA+)

2

In/Out

MX1- (DA-)

3

In/Out

MX2+ (DB+)

4

In/Out

MX3+ (DC+)

5

In/Out

MX3- (DC-)

6

In/Out

MX2- (DB-)

7

In/Out

MX4+ (DD+)

8

In/Out

MX4- (DD-)

Pin no.

Signal

Remarks

1

GND

2

DC input

+12V to +24V

3

Opt IN 2 (-) / GND (*1)

GPIO IN / OUT

4

Opt IN 2 (+)/Iris Video out (*1)

5

Opt IN 1 ( - )

6

Opt IN 1 ( + )

7

Opt Out 1 ( - )

8

Opt Out 1 ( + )

9

Opt Out 2 ( - )

10

Opt Out 2 ( + )

11

DC input

+12V to +24V

12

GND

*1: Iris Video output function can be set by the internal DIP

switch.

3

4

5

6

7

8

9

10

11

12

1

2

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

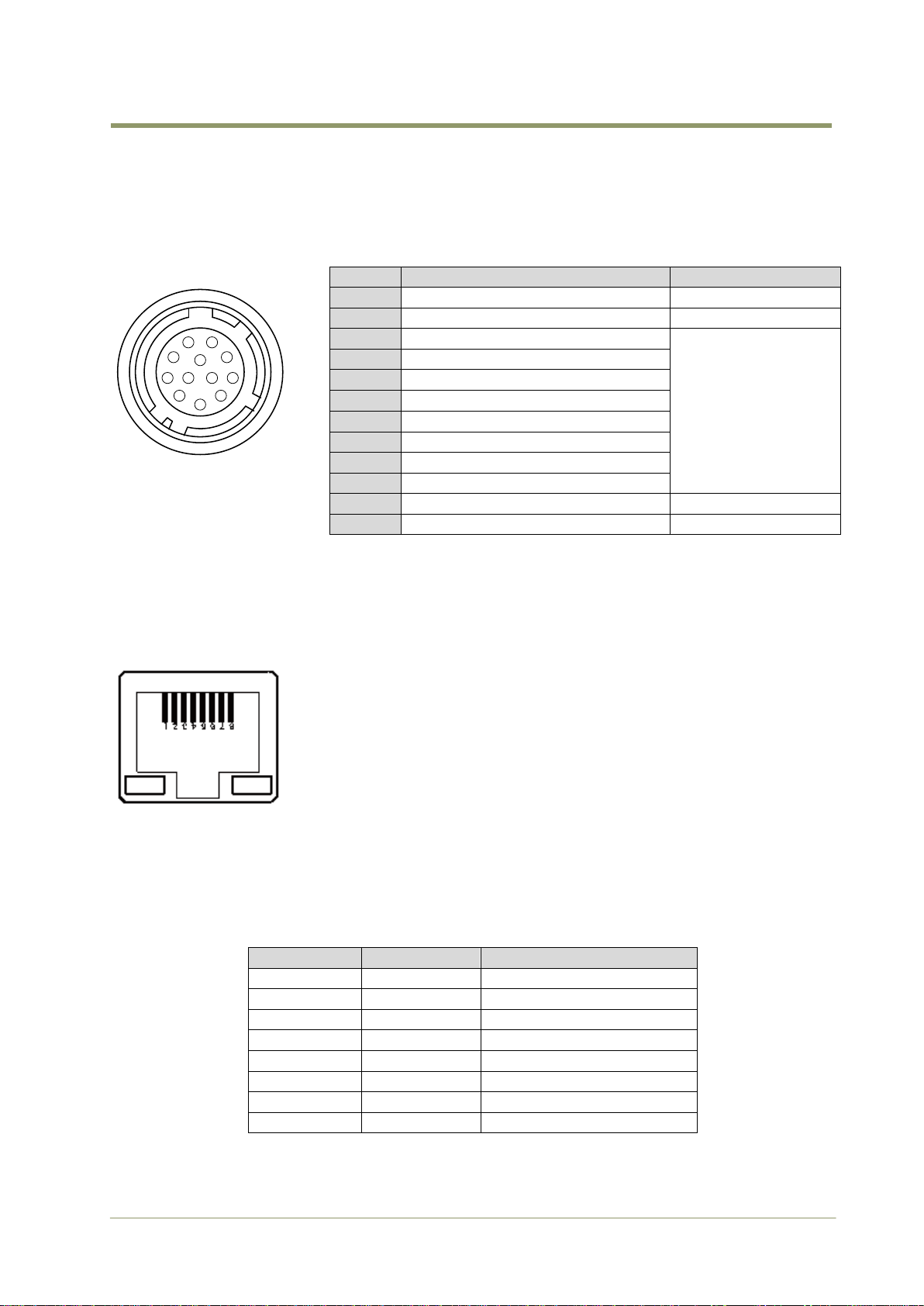

5. Pin Assignment

5.1. 12-pin Multi-connector (DC-in/GPIO/Iris Video)

Type: HR10A-10R-12PB (Hirose) male.

(Seen from rear of camera)

Fig. 4. 12-pin connector.

5.2. Digital Output Connector for Gigabit Ethernet

Type: RJ-45

HFJ11-1G02E-L21RL or equivalent

The CM-030GE/CM-030GE-RA and CB-030GE/CB-030GE-RA cameras

also accept industrial RJ-45 connectors with thumbscrews. This

assures that the connector does not come undone in tough industrial

environments.

Please contact the nearest JAI distributor for details on

recommended industrial RJ-45 connectors.

Fig. 5. Gigabit Ethernet connector

The digital output signals follow the Gigabit Ethernet interface using RJ-45 conforming

connector. The following is pin assignment for Gigabit Ethernet connector.

- 11 -

Page 14

LUT

( Cross Point Switch )

Pulse Generator 1

(20 bit Counter )

Pulse Generator 0

(20 bit Counter )

12 bit

Counter

TRIGGER 0

TRIGGER 1

PORT 1 1

PORT 2

Time Stamp Reset

LVAL IN

DVAL IN

FVAL IN

EEN IN

OPT IN 1

OPT IN 2

Soft Trigger 0

Soft Trigger 1

Soft Trigger 2

Soft Trigger 3

INOUT

Pulse Generator 0

Pulse Generator 1

Pulse Generator 0

Pulse Generator 1

Digital I/O(GPIO) setting

0

1

2

3

4

5

12

13

14

15

16

17

Digital I/O(GPIO) setting

0

1

4

5

16

12

13

Setting for

Line Source

Setting for

Line Selector

25 MHz

Pixel Clock

Counter Clock Source

0

1

Counter Divide by value

1/2 to 1/4096

Bypass0

1 - 4095

Pulse Generator Setting 0

Start Point Counter 0 ( 1)

Length counter 0

Start Point Counter 0 (2) for repeat

End point counter 0

Counter 0 clear

Pulse Generator Setting 1

Pulse Generator 1

Pulse Generator 1

18

19

Pulse Generator 2

Pulse Generator 3

14

15

Pulse Generator Setting 2

Pulse Generator Setting 3

Pulse Generator 2

(20 bit Counter )

Pulse Generator 3

(20 bit Counter )

Line

Signal

Connector

Line 3

Optical Out 1

Hirose 12P pin # 7/8

Line 4

Optical Out 2

Hirose 12P pin # 9/10

Line 5

Optical In 1

Hirose 12P pin # 5/6

Line 6

Optical In 2

Hirose 12P pin # 3/4

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

6. Input and output interface

6.1. GPIO interface

All input and output signals pass through the GPIO (General Purpose Input and Output) module.

The GPIO module consists of a Look-Up Table (LUT – Cross-Point Switch), 4 Pulse Generators

and a 12-bit counter. In the LUT, the relationship between inputs, counters and outputs is

governed by internal register set-up.

The input and output settings for the CM-030GE and CB-030GE series have been fixed as

follows.

6.1.1 LUT (Look Up Table)

The LUT works as a cross-point switch, which allows connecting inputs and outputs freely.

The signals LVAL_IN, DVAL_IN, FVAL_IN and EEN_IN all originate from the camera timing

circuit.

Trigger 0 is connected to the camera's timing circuit and is used for initiating triggered

exposure. Trigger 1 is used for Delayed Readout mode. The Time Stamp Reset signal is used

reset the camera's time stamp function, also making it possible to reset and synchronize the

time stamp of multiple cameras.

Fig.6 GPIO block

- 12 -

Page 15

Start Point

End Point

Length

Start Point

End Point

Length

Pulse Generator 0 IN

(FVAL )

0 1 2 3

1

99 100 101 102 103

2 1

Start Point = 0 End Point = 99

Length = 102

Clock IN

Clock Source=Pixel Clock ( 60MHz)

Clock Pre-scaler = 2399 ⇒ 25KHz

1/25KHz = 40µs

Pulse Generator Clear = 4: Rising Edge

Pulse Generator 0 OUT

(GPIO Port 1 )

Repeat counter: 0 to 255

=0: Continuously repeated

Pulse Generator Setting Example

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

6.1.2 12-bit Counter

A 25 MHz clock or the camera pixel clock (40 MHz) can be used as a source. The counter has a

“Divide by N”, where N has the range 1 through 4096, allowing a wide range of clock

frequencies to be programmed. Setting Value 0 is bypass, setting value 1 is 1/2 dividing and

setting value 4095 is 1/4096 dividing.

6.1.3. Pulse Generators (0 to 3)

Each pulse generator consists of a 20-bit counter. The behavior of these signals is defined by

their pulse width, start point, end point and number of repetitions.

The pulse generator signals can be set in either triggered or periodic mode.

In triggered mode, the pulse is triggered by the rising edge/falling edge/high level or low

level of the input signal.

In periodic mode, the trigger continuously generates a signal that is based on the configured

pulse width, starting point and end point.

Fig.7 Generated pulse

Setting example:

The following example shows the FVAL input to pulse generator. The pulse generator creates

the pulse using FVAL and the pulse is output through GPIO PORT 1. The pixel clock is 60MHz.

The created pulse rises up at the start point and falls down at the end point as shown above.

Accordingly, the High duration is (End point – Start point) clocks x (1/ Pulse gen. frequency).

In the above example, the original oscillation uses pixel clock (60 MHz) and the pixel clock is

divided by 2400. A pulse frequency of the generator is 25 KHz ( 60000000/2400). As the start

point is 0 and the end point is 99, the pulse having 100 x 1/25000 = 4ms width is created.

Fig 8. Pulse generator setting example

- 13 -

Page 16

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

If the HIGH duration needs to be delayed against incoming trigger, the start point should be

set at “N“. The delay value is N x (1/ 25000).

In the above example, N is “0” which is no delay.

The length, in this case, is 102 clocks.

These settings can be achieved by JAI Control tool which is the part of JAI SDK.

6.2. Opto-isolated Inputs/Outputs

The control interface of the C3 GigE Vision camera series has opto-isolated inputs and outputs,

providing galvanic separation between the camera's inputs/outputs and peripheral equipment.

In addition to galvanic separation, the opto-isolated inputs and outputs can cope with a wide

range of voltages; the voltage range for inputs is +3.3V to +24V DC whereas outputs will

handle +5V to +24V DC.

The below figure shows the functional principle (opto-coupler) of the opto-isolated

inputs/outputs.

Fig.9. Opto-coupler

- 14 -

Page 17

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

6.2.1 Recommended External Input circuit diagram for customer

Fig.10 External Input Circuit, OPT IN 1 and 2

6.2.2 Recommended External Output circuit diagram for customer

Fig.11. External Output Circuit, OPT OUT 1 and 2

- 15 -

Page 18

Conditions for Input

Input Line Voltage Range

+3.3v ~ +24V

Input Current

6mA ~ 30mA

Minimum Input Pulse Width to Turn ON

0.5us

Output Specifications

Output Load(Maximum Current)

100mA

Minimum Output Pulse Width

20us

Time Delay Rise TDR

0.5us ~ 0.7us

Rise Time RT

1.2us ~ 3.0us

Time Delay Fall TDF

1.5us ~ 3.0us

Fall Time FT

4.0us ~ 7.0us

Output Port

Trigger 0

Trigger 1

OPT

OUT1

OPT

OUT2

Time

Stamp

Reset

Pulse

Gen. 0

Pulse

Gen. 1

Pulse

Gen. 2

Pulse

Gen. 3

Input Port

LVAL IN

× × × × × ○ ○ ○ ○

DVAL IN

× × × × × ○ ○ ○ ○

FVAL IN

× × × × × ○ ○ ○ ○

EEN IN

× × ○ ○ × ○ ○ ○ ○

OPT IN 1

○ ○ ○ ○ ○ ○ ○ ○ ○

OPT IN 2

○ ○ ○ ○ ○ ○ ○ ○ ○

Soft Trigger 0

○ ○ ○ ○ ○ ○ ○ ○ ○

Soft Trigger 1

○ ○ ○ ○ ○ ○ ○ ○ ○

Soft Trigger 2

○ ○ ○ ○ ○ ○ ○ ○ ○

Soft Trigger 3

○ ○ ○ ○ ○ ○ ○ ○ ○

Pulse Gen. 0

○ ○ ○ ○ ○ × ○ ○ ○

Pulse Gen. 1

○ ○ ○ ○ ○ ○ × ○ ○

Pulse Gen. 2

○ ○ ○ ○ ○ ○ ○ × ○

Pulse Gen. 3

○ ○ ○ ○ ○ ○ ○ ○ ×

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

6.2.3 Optical Interface Specifications

The relation of the Input signal and the output signal through optical interface is as follows.

Fig.12. Optical Interface Performance

6.3. Inputs and outputs table

LEGEND: 0 = valid combination / x = Not valid (do not use this combination)

- 16 -

Page 19

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

6.4. Configuring the GPIO module

6.4.1 Input/Output Signal Selector

Line selector

This sets the input and output to the external equipment. Line 3 through line 6 are already

allocated as below.

Line source

This sets which signal can be fed through selected output, external or internal.

6.5. Examples of the pulse generator configuration

6.5.1 Setting screen of the pulse generator

- 17 -

Page 20

Feature

Value

c)Acquisition and

Trigger controls

Trigger

selector

Trigger Mode

ON

JAI Acquisition and

Trigger Control

JAI Exposure

Mode

Pulse width control

Pulse Generators

Pulse

Generator

selector

Pulse Generator 0 Selector

Line 5 =OPT IN 1

Clock Choice

1 = Pixel Clock

(40MHz)

Counter Dividing Value

0 = Pass through

Length Counter 0

1000 Clocks

Start point Counter 0

100 Clocks

Repeat Count 0

1

End point Counter 0

500 Clocks

Counter Clear 0

Rising Edge

Trigger source

pulse generator 0

LUT

Cross

point switch)

12bit

Counte

Pulse Generator 2

(20bit Counter)

Pulse Generator 1

(20bit Counter)

Pulse Generator 0

(20bit Counter)

LUT

Pulse Generator 3

(20bit Counter)

LVAL IN

DVAL IN

FVAL IN

EEN IN

OPT IN 1

OPT IN 2

Soft Trigger 0

Soft Trigger 1

Soft Trigger 2

Soft Trigger 3

( Cross Point Switch )

Trigger 0

Trigger 1

OPT OUT 1

OPT OUT 2

Time Stamp Reset

Counter

25 MHz

Pixel Clock

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

6.5.2 GPIO in combination with Pulse Width trigger mode

Example: 10µs unit pulse width exposure control (PWC).

Pixel clock is 40MHz. 400 clocks (500-100) equals 10µs.

Fig.13. Pulse Generator Timing Example 1

- 18 -

Page 21

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

Pulse Generator 0

100 Line

500 Line

1000 Line

output

Pulse Generator 0

100 Line

500 Line

1000 Line

output

Feature

Value

c)Acquisition and

Trigger controls

Trigger

selector

Trigger Mode

ON

Pulse Generators

Pulse

Generator

selector

Pulse Generator 0 Selector

Clock Choice

1 = Pixel Clock

(40MHz)

Counter Dividing Value

864(line rate)

Length Counter 0

1000 Clocks

Start point Counter 0

100 Clocks

Repeat Count 0

0

End point Counter 0

500 Clocks

Clear activation

Off

Trigger source

pulse generator 0

LUT

Cross

point switch)

12bit

Counte

Pulse Generator 2

(20bit Counter)

Pulse Generator 1

(20bit Counter)

Pulse Generator 0

(20bit Counter)

LUT

Pulse Generator 3

(20bit Counter)

LVAL IN

DVAL IN

FVAL IN

EEN IN

OPT IN 1

OPT IN 2

Soft Trigger 0

Soft Trigger 1

Soft Trigger 2

Soft Trigger 3

( Cross Point Switch )

Trigger 0

Trigger 1

OPT OUT 1

OPT OUT 2

Time Stamp Reset

Counter

25 MHz

Pixel Clock(40MHz)

Line Rate 46.296 KHz

6.5.3 Internal Trigger Generator

Create a trigger signal and trigger the camera

Fig.14. Pulse Generator 0 timing Example 2

- 19 -

Page 22

Setting

Value for Register address 0xA084

Resolution

Frame rate

Off (no binning)

0x01

656(h) x 494(v) pixels

90.5 fps

2:1 binning

0x02

656(h) x 247(v) pixels

166.2 fps

8

Read Out ( Horizontal)

Read Out

( Vertical)

2 656 1615

494

2

504

OB(31)

2

OB

692

Effective Video Output

656 x 494

OB

OB

Optical Black

Pixel ( 1,1)

7

511

172

864 clock

OB, 6 lines for

vertical and 16 pixels

for horizontal can be

transferred on OB

Transfer Mode.

2

6

6

1

H

Xsg1

Video out

No V binning

V binning

H

Xsg1

Video out

No V binning

V binning

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

7. Image output signal

7.1. Output image

The CCD sensor layout with respect to pixels and lines used in the timing and video full frame

read out is shown below.

Important Note: By using the Optical Black (OB) transfer mode, the user can select whether

to include optical black pixels in the image stream.

7.2. Vertical Binning (CM-030GE/CM-030GE-RA only)

The binning functions can be used to achieve higher frame rate or higher sensitivity. The

drawback is lower resolution.

Vertical binning is done by adding the charge from

pixels in adjacent lines in the horizontal CCD register.

Fig. 13 shows the binning principle. Resolution and

frame rate for all combinations are shown in the below

table.

Fig.13. CM-030GE/CM-030GE-RA binning

The CM-030GE/CM-030GE-RA has ON or OFF function for Vertical Binning:

Fig. 15. CCD sensor layout

- 20 -

Page 23

Analog Signal [mV]

Black Level

1023

890

32

0

25

700

Digital Out [LSB]

White Clip Level

100% Level

800

CCD out

Analog Signal *

Digital Out(10-bit)

Black

Setup 3.6%, 25mV

32LSB

200mV

700mV

890LSB

230mV

800mV

1023LSB

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7

Y0Y1Y2

0 1 2 3 4 5 6 7 8 9 X X X X X X 0 1 2 3 4 5 6 7 8 9 X X X X X X

Y0Y0Y1

Y1

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

7.3. Digital Video Output (Bit Allocation)

Although the CM-030GE/CM-030GE-RA and CB-030GE/CB-030GE-RA are digital cameras, the

image is generated by an analog component, the CCD sensor.

The table and diagram below show the relationship between the analog CCD output level and

the digital output.

The standard setting for 10-bit video level is 890 LSB. 200 mV CCD output level equals 100%

video output.

Fig. 17. Digital Output

7.3.1 Bit Allocation (Pixel Format / Pixel Type) – CM-030GE/CM-030GE-RA

In the GigE Vision Interface, GVSP (GigE Vision Streaming Protocol) is used for an application

layer protocol relying on the UDP transport layer protocol. It allows an application to receive

image data, image information and other information from a device.

In the monochrome camera, CM-030GE/CM-030GE-RA, the following pixel types supported by

GVSP are available.

With regard to the details of GVSP, please refer to GigE Vision Specification available from

AIA (www.machinevisiononline.org).

7.3.1.1 GVSP_PIX_MONO8 (8bit)

1Byte 2Byte 3Byte

7.3.1.2 GVSP_PIX_MONO10 (10bit)

1Byte 2Byte 3Byte 4Byte

- 21 -

Page 24

Address

Internal Name

Access

Size

Value

0xA410

Pixel Format type

R/W

4

0x01080001:Mono8

0x01100003:Mono10

0x010C0004:Mono10 Packed

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7

R0G1R2

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7

G0B1G2

0 1 2 3 4 5 6 7 8 9 X X X X X X 0 1 2 3 4 5 6 7 8 9 X X X X X X

R0R0G1

G1

0 1 2 3 4 5 6 7 8 9 X X X X X X 0 1 2 3 4 5 6 7 8 9 X X X X X X

G0G0B1

B1

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7

G0B1G2

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7

R0G1R2

0 1 2 3 4 5 6 7 8 9 X X X X X X 0 1 2 3 4 5 6 7 8 9 X X X X X X

G0G0B1

B1

0 1 2 3 4 5 6 7 8 9 X X X X X X 0 1 2 3 4 5 6 7 8 9 X X X X X X

R0R0G1

G1

2 3 4 5 6 7 8 9 0 1 X X 0 1 X X 2 3 4 5 6 7 8 9 2 3 4 5 6 7 8 9 0 1 X X 0 1 X X 2 3 4 5 6 7 8 9

Y3Y1Y0

Y2

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

7.3.1.3 GVSP_PIX_MONO10_PACKED (10 bit)

7.3.2 Bit Allocation (Pixel Format / Pixel Type) – CB-030GE/CB-030GE-RA

In the GigE Vision Interface, GVSP (GigE Vision Streaming Protocol) is used for an application

layer protocol relying on the UDP transport layer protocol.

With regard to the details of the GVSP, please refer GigE Vision Specification available from

AIA (www.machinevisiononline.org).

7.3.2.1 GVSP_PIX_BAYRG8 “BayreRG8 “

Odd Line

1 Byte 2 Byte 3 Byte

Even Line

7.3.2.2 GVSP_PIX_BAYRG10 “Bayer RG10”

Odd Line

1 Byte 2 Byte 3 Byte 4 Byte

Even Line

7.3.2.3 GVSP_PIX_BAYGB8 “BayerGB8”

Odd Line

Even Line

7.3.2.4 GVSP_PIX_BAYGB10 “BayerGB10”

Odd Line

1 Byte 2 Byte 3 Byte 4 Byte

Even Line

- 22 -

Page 25

Address

Internal Name

Access

Size

Value

0xA410

Pixel Format type

R/W

4

0x01080009:BAYRG8

0x0108000A: BAYGB8

0x0110000D:BAYRG10

0x0110000E:BAYGB10

FVAL Timing

LVAL

DVAL

1

20

27

31

15

9

Full

2/3 Partial

1/2 Partial

1/4 Partial

1/8 Partial

1

Line # from FVAL raising edge

G BRG

R

G B

R GGR

G B

R GGR

Actual V Line #

1

85

125

187

217

G B

R GGR

G B

R GGR

G B

R GGR

2ck

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

Note: CB-030GE/CB-030GE-RA has the same Bayer sequence for Full and any of partial

scanning as RG. Therefore, comparing full scanning and partial scanning, the center

might be shifted.

As the Pixel Format type, CB-030GE/CB-030GE-RA supports BAYER GB 8 and BAYER

GB 10. When these types are selected, the output starts from 2nd line for all

scanning.

7.4. CB-030GE/CB-030GE-RA. Bayer filter

CB-030GE/CB-030GE-RA is a color camera based on

a CCD sensor with a Bayer RGB color mosaic. The

color image reconstruction is done in the host PC.

The Color sequence in the video signal is the same

for all scanning formats.

The line readout follows LVAL.

The first valid pixel is the same timing as DVAL.

The Bayer color sequence starts with:

RGR for odd numbers.

GBG for even line numbers.

Figure 14 shows the timing sequence for the Bayer

mosaic read-out for the available partial scan

modes.

Fig.18. Bayer layout for each scanning

- 23 -

Page 26

FULL FRAME READ OUT / PATIAL READ OUT

1LVAL 864ck = 21.6us 1ck= 25ns

LVAL

DATA OUT

659ck

31 ck

690ck

174ck

DVAL

656ck

2ck 16ck

OBValid Data

FVAL

DVAL

DATA

EEN

1 2 3

492

493

494

7L

2L 6L

494L

2L

OB

Valid Data

OB

1L

OB

CCD Exposure

LVAL

Valid Data

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

7.5. Image timing

7.5.1 Horizontal timing

The LVAL period is shown for normal continuous mode.

Fig. 19. Horizontal timing

7.5.2 Vertical timing

The FVAL period for normal continuous mode full scan is shown.

Fig. 20. Vertical timing for full scan

- 24 -

Page 27

LVAL

FVAL

DVAL

DATA

EEN

Valid Data

CCD Exposure

A

B

C

7L

1L

AREA

FVAL

Low (L)

A

(L)

B (L)

C

(L)

Total

line

frame

rate

Start line

End line

1/2

7

19

246

18L

290L

159.64

125

370

1/4

7

26

122

26L

181L

255.75

187

308

1/8

7

30

62

29L

128L

361.68

217

278

2/3

7

14

326

13L

360L

128.6

85

410

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

7.5.3 Partial Scanning

The FVAL period is shown for 1/2 partial scan in normal continuous mode.

7.5.3.1 Vertical Timing

The below diagram and table provide vertical timing information for the fixed partial scan

settings 1/2, 1/4, 1/3 and 2/3

Values for vertical timing in partial scan continuous mode.

Fig. 21. Vertical timing for partial scanning

- 25 -

Page 28

FULL FRAME READ OUT / PATIAL READ OUT

1LVAL 864ck = 21.6us 1ck= 25ns

LVAL

DATA OUT

659ck

31 ck

690ck

174ck

DVAL

656ck

2ck 16ck

OBValid Data

V binning

1LVAL 936ck = 23.4us 1ck= 25ns

LVAL

DATA OUT Valid data OB

659ck

31ck

690ck 246ck

DVAL

656ck

2ck

16ck

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

7.5.3.2 Horizontal Timing

The horizontal timing is the same the full scanning.

Fig.22. Horizontal Timing for Partial Scanning

7.5.4 Vertical binning

Vertical binning combines charge from two adjacent lines, reducing the vertical resolution to

half and at the same time increasing frame rate and sensitivity. By activating this function,

the frame rate is increased to 166.2 fps.

This function is available only for CM-030GE/CM-030GE-RA.

Important Note

Vertical Binning cannot be used together with the Partial Scanning.

7.5.4.1 Horizontal Timing

Fig.23. Horizontal Timing for Vertical Binning

- 26 -

Page 29

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

V binning FRAME RATE 257L 166.2fps

LVAL

FVAL

1+2

3+4

491

+

492

493

+

494

DAVL

5L 4L

247L 1L

OB

DATA

OB Valid data OB

1L

CCD Exposure

EEN

DAC

1μ1K

2K2

0.1μ

+5V

IRIS Video Out

7.5.4.2 Vertical timing

7.5.5 Auto Iris Lens video output (12-pin Hirose connector)

This analogue signal is not routed through the GPIO.

This signal is available at pin 4 of 12-pin Hirose

connector. It can be used for lens iris control

in Continuous and RCT modes only.

The signal is taken from the CCD sensor and is output

after the gain circuit. The video output is

without sync. The signal is 0.7 Vpp from <400 AC coupled.

To use this signal, the internal DIP switch must be set

as follows.

The auto-iris lens video output is enabled by setting switch

SW600 to ON (Two Switches to the left). The internal DIP

switch is set to OFF (Two Switches to the right) as factory

default. Fig. 26. Iris video output.

Fig.24. Vertical Timing for Vertical Binning

Fig.25. Iris circuit

- 27 -

Page 30

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

8. Network configuration

For details of the network settings, please refer to the “Getting Started

Guide” supplied with the JAI SDK.

8.1. GigE Vision Standard Interface

The CM-030GE/CM-030GE-RA and CB-030GE/CB-030GE-RA are designed in accordance with the

GigE Vision standard. It transmits digital images over Cat5e or Cat6 Ethernet cables. All

camera functions are also controlled via the GigE Vision interface.

The camera can operate in continuous mode, providing an endless stream of images. For

capturing individual images, related to a specific event, the camera can also be trigged. For

precise triggering, it is recommended to use a hardware trigger applied to the Hirose 12-pin

connector. It is also possible to initiate a software trigger through the GigE Vision interface.

However, when using software trigger, certain latency inherent to the GigE interface must be

anticipated. This latency, that manifests itself as jitter, greatly depends on the general

conditions and traffic on the GigE connection. The frame rate described in this manual is for

the ideal case and may deteriorate depending on conditions.

When using multiple cameras (going through a switch and/or a single path) or when operating

in a system with limited transmission bandwidth the Delayed Readout Mode and Inter-Packet

Delay functions can be useful.

8.2. Equipment to configure the network system

8.2.1 PC

The PC used should have the following performance or better

1) Recommended CPU : Core2 Duo 2.4GHz or better,

Better than Core2 Extreme

2) Recommended memory : 2Gbyte or more

3) Video card : Better than PCI Express Bus Ver.1.0 x16

VRAM should be better than 256MByte, DDR2

4) Other : The resident software should not be used

8.2.2 Cables

GigEVision configures the system by using 1000BASE-T. (100BASE-T can be used with

some restriction. Refer to chapter 8.3.6). In the market, CAT5e (125MHz), CAT6

(250MHz) and CAT7 (600MHz) cables are available for 1000BASE-T. There are

crossover cables and straight through cables available. Currently, as most equipment

complies with Auto MDI/MDI-X, please use straight through cables. (Among crossover

cables, a half crossover type exists, which the Ethernet will recognize as 100BASE-T).

8.2.3 Network card (NIC)

The network card should comply with 1000BASE-T and also have the capability of

JUMBO FRAMES. When the jumbo frame size is set at a larger number, the load on the

CPU will be decreased. Additionally, as the overhead of the packet is decreased, the

transmission will have more redundancy.

- 28 -

Page 31

NIC

Manufacture

Type

PCI-X Bus

PCI-Express

Bus

Intel

PRO/1000MT

Server Adapter

32bit or 64bit

33/66/100/133 MHz

Intel

PRO/1000MT Dual Port

Server Adapter

32bit or 64bit

33/66/100/133 MHz

Intel

PRO/1000GT Quad

Port

Server Adapter

32bit or 64bit

66/100/133 MHz

Intel

PRO/1000PT

Server Adapter

―

( x1 )

2.5Gbps uni-directional

5Gbps bi-directional

Intel

Pro/1000 CT

Desktop adaptor

―

( x1 )

2.5Gbps uni-directional

5Gbps bi-directional

Intel

Gigabit ET2 Quad port

Server Adapter

―

( x4 )

10Gbps uni-directional

20Gbps bi-directional

Intel

Gigabit ET Dual port

Server Adapter

―

( x4 )

10Gbps uni-directional

20Gbps bi-directional

Intel

Gigabit EF Dual port

Server Adapter

―

( x4 )

10Gbps uni-directional

20Gbps bi-directional

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

JAI confirms the following network cards.

8.2.4 Hub

It is recommended to use the metal chassis type due to the shielding performance.

As the hub has a delay in transmission, please note the latency of the unit.

8.3. Recommended Network Configurations

Although the CM-030GE and CB-030GE series conform to Gigabit Ethernet (IEEE 802.3)

not all combinations of network interface cards (NICs) and switches/routers are

suitable for use with the GigE Vision compliant camera.

JAI will endeavor to continuously verify these combinations, in order to give users the

widest choice of GigE components for their system design.

For details of the network settings, please refer to the “Getting Started

Guide” supplied with the JAI SDK.

8.3.1 Guideline for network settings

To ensure the integrity of packets transmitted from the camera, it is recommended to

follow these simple guidelines:

1. Whenever possible use a peer-to-peer network.

2. When connecting several cameras going through a network switch, make sure it is

capable of handling jumbo packets and that it has sufficient memory capacity.

3. Configure inter-packet delay to avoid congestion in network switches.

4. Disable screen saver and power save functions on computers.

5. Use high performance computers with multi-CPU, hyper-thread and 64-bit CPU,

etc.

6. Only use Gigabit Ethernet equipment and components together with the camera.

7. Use at least Cat5e and preferably Cat6 Ethernet cables.

8. Whenever possible, limit the camera output to 8-bit.

- 29 -

Page 32

Item

Unit

Symbol

Image Width

[pixels]

A

Image Height

[pixels]

B

Bits per Pixel

[bits]

C

Frame Rate

[fps]

D

Packet Size

[Bytes]

E

Number of Packets (including Data Leader & Trailer

Packet)

[packets]

G

Data Transfer Rate

[Mbit/s]

J

Item

Unit

value

Data Leader Packet Size

[Bytes]

90

Data Trailer Packet Size

[Bytes]

64

Model

Pixel Type

Packet data volume

(In case the Packet size is 1500)

CM-030GE/CM030GE-RA

MONO8

243Mbit/s

MONO10_PACKED

364Mbit/s

MONO10

485Mbit/s

CB-030GE/CB030GE-RA

BAYRG8,BAYGB8

243Mbit/s

BAYRG10,BAYBG10

485Mbit/s

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

8.3.2 Video data rate (network bandwidth)

The video bit rate for CM-030GE/CM-030GE-RA and CB-030GE/CB-030GE-RA is:

In case of using Jumbo Frame, the packet data will be improved by 2 %.

For CM-030GE/CM-030GE-RA and CB-030GE/CB-030GE-RA, the jumbo frame can be set at

maximum 4040 Bytes (Factory setting is 1440 Bytes). To set Jumbo Frame, refer to chapter 8.2.4.

8.3.3 Note for setting packet size

The packet size is set to 1428 as the factory default. Users may enter any value for the

packet size and the value will be internally adjusted to an appropriate, legal value that

complies with the GenICam standard. The packet size can be modified in the GigE

Vision Transport Layer Control section of the camera control tool.

Regarding data transfer rate, a larger packet size produces a slightly lower data

transfer rate. The CM-030GE and CB-030GE sereis can support a maximum of 4040 byte

packets provided the NIC being used has a Jumbo Frames function with a setting of a

4040 bytes or larger.

Caution: Do not set the packet size larger than the maximum setting available in

the NIC or switch to which the camera is connected . Doing so will cause

output to be blocked.

8.3.4 Calculation of Data Transfer Rate

In order to calculate the data transfer rate, the following parameters and formula are

required.

Setting parameter

Fixed value

- 30 -

Page 33

J={90+64+(E+18)*(G-2)}*8*D/1000000

Where, G=ROUNDUP{A*B*C/8/(E-36)}+2

Pixel format

Bit

Mono8,BAYGR8

8

Mono10_Packed/Mono12_Packed

12

Mono10,Mono12,BayGR10,BAYGR12

16

Item

Unit

Symbol

Setting

Image Width

[pixels]

A

656

Image Height

[pixels]

B

494

Bits per Pixel

[bits] C 8

Frame Rate

[fps] D 90

Packet Size

[Bytes]

E

1500

Number of Packets (including Data Leader & Trailer

Packet)

[packets]

G

Data Transfer Rate

[Mbit/s]

J

Pixel Type

Frame rate at Full Frame[fps]

MONO8, BAYRG8, BAYGB8

36.6 ~ 36.8

MONO10_PACKED

24.4

MONO10, BAYRG10, BAYGB10

18.2 ~ 18.4

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

Formula to calculate Data Transfer Rate

The following table shows Bits per Pixel (Item C) which depends on the pixel format.

Calculation example: CM-140GE Pixel type RGB8

G=ROUNDUP{(656x494x8/8/(1500-36))+2=222+2=224

J={90+64+(1500+18)x(224-2)}x8x90/1000000=243 Mbit/s

8.3.5 Simplified calculation (Approximate value)

A simple way to calculate the approximate data transfer rate is the following.

Transfer data = Image width (pixel) x Image Height (pixel) x depth per pixel(depending

on the pixel format) x frame rate / 1,000,000 (convert to mega bit)

In the case of the CM-030GE with the full image and MONO8 pixel format;

The data transfer rate = 656 x 494 x 8 x 90 / 1000000 = 233 Mbit/s

8.3.6 Note for 100BASE-TX connection

In case of connecting on 100BASE-TX, the maximum packet size should be 1500 byte.

In case of connecting on 100BASE-TX, the specifications such as frame rate, trigger

interval etc. described in this manual cannot be satisfied.

100BASE-T works in FULL DUPLEX. It does not work in HALF DUPLEX.

- 31 -

Page 34

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

8.4. GigE camera connecting examples

8.4.1 Using a switching hub for 1 port

All cameras and NIC belong to the same subnet

The accumulated transfer rate for all cameras should be within 800Mbps

The packet size and the packet delay should be set appropriately in order

for the data not to overflow in the switching hub.

8.4.2 Connecting a camera to each port of a multi-port NIC

This is the example for using a 4-port NIC

The pair of the connecting camera and the NIC constructs one subnet. As for

the IP configuration, it is appropriate to use the persistent IP.

In this case, each camera can use the maximum 800Mbps bandwidth.

However, the load for the internal bus, CPU and the application software

will be heavy, so a powerful PC will most likely be required.

- 32 -

Page 35

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

8.4.3 The data transfer for multiple cameras

8.4.3.1 If delayed readout is not used in continuous mode

The packet delay should be set larger. The data traffic is controlled by the

buffer of the hub. It is necessary to check the buffer value of the unit.

8.4.3.2 If delayed readout is not used in trigger mode

The packet delay should be set larger. The data traffic is controlled by the

buffer of the hub. It is necessary to check the buffer value of the unit.

- 33 -

Page 36

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

8.4.3.3 If delayed readout is used

The packet delay should be set smaller, and the packet delay trigger

controls the data traffic. If the camera has a pulse generator, it can control

the data traffic.

- 34 -

Page 37

Minimum Shutter Time 2L

Maximum Shutter Time

Normal

21.6 µs(1L) * 2L = 43.2 µs

21.6 µs * 511L≈ 11.037 ms

V Binning

23.4 µs * 2L = 46.8 µs

23.4 µs * 257L ≈ 6.0138 ms

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

9. Functions and operations

9.1. Basic functions

The CM-030GE/CM-030GE-RA and CB-030GE/CB-030GE-RA cameras are progressive scan

cameras with 10 or 8-bit video output in Gigabit Ethernet. An analogue iris video signal (DIP

switch select) can be used for controlling auto-iris lenses.

The camera has 2/3, 1/2, 1/4 or 1/8 partial scanning for faster frame rates. Vertical binning

is also available.

The camera can operate in continuous mode as well as in 5 triggered modes:

- Edge Pre-select (EPS)

- Pulse width Control (PWC)

- Reset continuous (RCT)

- Sequential trigger (EPS)

- Delayed readout (EPS, PWC)

Depending on the timing of the trigger input in relationship to FVAL (camera internal Frame

Valid clock), the start of exposure can be immediate (no-delay, LVAL asynchronous) or

delayed until next LVAL (LVAL synchronous).

In the following section the functions are described in detail.

9.2. Electronic Shutter

In the GenICam SFNC interface, the electronic shutter is set by Exposure time (microseconds).

The traditional JAI method for shutter setting can also be used including JAI Shutter Mode, JAI

Preset Shutter, JAI Exposure Time Raw and JAI Exposure Time (us). If setting is done using the

SFNC method, these settings are automatically reflected in the traditional JAI settings area.

Preset Shutter

10 preset shutter steps are available: OFF (1/90); 1/100, 1/120; 1/250; 1/500; 1/1,000;

1/2,000; 1/4,000; 1/8,000; 1/10,000 sec.

Programmable Shutter

It is possible to set the shutter speed in the range of 2L to 511L by 1L unit, in case of Full

Frame operation. When 511L is set, it is the equivalent of “OFF (1/90)“ or 11.037ms.

Pulse Width Control

With this mode selected the exposure time is controlled by the width of the trigger pulse. The

minimum trigger pulse width is equal to 1L (21.6 µs)

- 35 -

Page 38

Minimum value

Maximum Value

Normal Scan

43 us

11,038 us 511L

2/3 Partial Scan

43 us

7,733 us 358L

1/2 Partial Scan

43 us

6,221 us 288L

1/4 Partial Scan

43 us

3,867 us 179L

1/8 Partial Scan

43 us

2,722 us 126L

V-Binning Scan

46 us

6,013 us 257L

Ext. trigger

FVAL

(1)

(3)

(1) In this period camera executes trigger at next LVAL (prevents feed-through noise)

(2) Avoid trigger at FVAL transition (+/- 1 LVAL period), as the function may randomly switch

between "next LVAL" and "immediate".

(3) In this period camera executes trigger immediately (no delay)

(2)

Fig. 27. Auto-detect LVAL sync /a-sync accumulation

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

Exposure Time Abs (GenICam Standard)

This is a function specified in the GenICam standard.

The shutter speed can be entered as an absolute exposure time in microseconds (μs) in

register address 0xA018. The entered absolute time (Time Abs) is then converted to

programmable exposure (PE) value inside the camera.

The below equations show the relationship between the PE value used by the camera for the

different readout modes and the "Exposure Time Abs" value entered in register 0xA018.

As the calculation is based on rounding down to the closest integer, precise values may not

always occur.

The relation between PE value and Time Abs:

Normal readout PE= 2 + INT

V Binning readout PE= 2 + INT (Exposure time -46) µs / (936/40000000)

Note: (1) INT means integer (rounded down). (2) Pixel clocks/line. (3) Pixel clock

The following table shows minimum value and maximum value for each readout mode.

(1)

(Exposure time -43) µs / (864

(2)

/40000000

(3)

)

GPIO in combination with Pulse Width Trigger

More precise exposure time can be obtained by using GPIO in combination with Pulse Width

Trigger mode. The clock generator and counter can be programmed in very fine increments.

As for the setting example, refer to chapter 6.5.1.

9.3. Auto-detect LVAL-sync / a-sync. accumulation

This function replaces the manual setting found in older JAI cameras. Whether accumulation

is synchronous or a-synchronous in relationship to LVAL depends on the timing of the trigger

input.

When trigger is received while FVAL is high (during readout), the camera works in LVALsynchronous mode, preventing reset feed trough in the video signal. There is a maximum

jitter of one LVAL period from issuing a trigger and accumulation start.

If trigger is received when FVAL is low, the cameras works in LVAL-asynchronous mode (no

delay) mode. This applies to both pre-select (PS) trigger mode and pulse width trigger (PW)

mode.

- 36 -

Page 39

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

10. Operation Modes

The CM-030GE and CB-030GE series comply with GenICam SFNC (Standard Features Naming

Convention) version 1.3 and the acquisition of the image, the trigger functions, the exposure

settings and so on are different from those used in early versions of these cameras.

Note: In this section, the GUI shown is from the CB-200GE.

10.1. The functions related to GenICam SFNC 1.3

The following functions are the most affected by SFNC 1.3.

Features – Acquisition and Trigger Control

Acquisition mode

The image can be captured in two ways, continuous or single fame.

Continuous

By executing AcquisitionStart command, the image can be output until AcqusitionStop

Trigger is input.

Single Frame

By executing AcquisitionStart command, one frame of the image can be output and then

the acquisition is stopped.

Trigger Selector

This can be selected from FrameStart or TransferStart.

FrameStart

The trigger pulse can take one frame capture.

TransferStart

The trigger pulse can read out the image stored in the frame memory. This is used for the

delayed Readout

TriggerMode

This selects either trigger mode (ON) or continuous mode (OFF).

TriggerSoftware

This is one of the trigger sources which enables trigger commands to be created using

software. In order to use TriggerSoftware, TriggerSource should be set at Software.

TriggerSource

The trigger source can be selected from the following signals.

- 37 -

Page 40

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

TriggerActivation

This can set how the trigger is activated.

RisingEdge: The trigger is effective at the rising edge of the pulse.

FallingEdge: The trigger is effective at the falling edge of the pulse.

ExposureMode

This can select the exposure mode.

Timed: The exposure is set in units of μ seconds or lines.

TriggerWidth: The exposure is the same as the trigger width.

The CM-030GE and CB-030GE series have a JAI Acquisition and Trigger Control function which

is the same as used for previous models and includes 7 types of exposure modes.

Acquisition and Trigger Control and JAI Acquisition and Trigger Control are linked to each

other and if the one is set, the setting parameters are reflected in the other.

The following is an example: when JAI Acquisition and Trigger Control is set at EPS,

TriggerMode is automatically set ON and ExposureMode is set to Timed.

- 38 -

Page 41

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

The exposure time can be set in the JAI Shutter Mode by selecting either lines or

microseconds and the setting values are reflected in the same items of Acquisition and

Trigger Control.

Other parameters such as trigger signal should be set in Acquisition and Trigger Control.

The following description uses JAI Acquisition and Trigger Control and the operation mode can

be selected in JAI Exposure Mode.

- 39 -

Page 42

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

10.2. Operation Mode

This camera can operate in 6 primary modes.

1. Continuous Mode Pre-selected exposure

2. Pre-select trigger mode Pre-selected exposure

3. Pulse Width Control trigger mode Pulse width controlled exposure

4. Reset Continuous trigger mode Pre-selected exposure

5. Sequential Trigger Pre-selected exposure

6. Delayed Readout Trigger Pre-selected exposure,PWC

10.2.1 Continuous operation

For applications not requiring asynchronous external trigger, but where a continuous stream

of images is required, this mode should be used.

In this mode it is possible to use a lens with video controlled iris.

For timing details, refer to fig. 19. through fig. 24.

To use this mode:

- 40 -

Page 43

Full scan

513 L

2/3 partial

363 L

1/2 Partial

293 L

1/4 Partial

184 L

1/8 Partial

131 L

1/2 V Binning

260 L

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

10.2.2 Edge Pre-select Trigger Mode

An external trigger pulse initiates the capture, and the exposure time (accumulation time) is

the fixed shutter speed set by registers. The accumulation can be LVAL synchronous or LVAL

a-synchronous.

The resulting video signal will start to be read out after the selected shutter time.

For timing details, refer to fig. 19. through fig.24 and figures 28 and 29.

To use this mode:

Important notes on using this mode

Trigger pulse >2 LVAL to <1 FVAL)

The following table shows minimum trigger interval in synchronous accumulation mode

1) In case of a-synchronous mode, the exposure time should be added to the above

table.

2) In order to keep the minimum trigger interval in partial scan mode, a exposure time

should be set within a number of normal read out line(511L). If it is exceeded, the

minimum trigger interval is longer by (exposure time – 511L).

- 41 -

Page 44

LAVL ASYNC

3μ s± 1μ s

TRIG

2 L(min)

CCD Exposure

EEN

Exposure time

FAVL

FULL: 6L~7.1L(131us~152.6us)

V binning: 4L~5.2L(98.4 us~121.2us)

When a trigger pulse is input during FVAL

LOW period, LVAL a-sync mode functions.

LAVL SYNC

TRIG

2

L(min)

LVAL

1L(max)

CCD Exposure

EEN

Exposure time

FAVL

FULL:6 L (131us)

When a trigger pulse is input during FVAL

HIGH period, LVAL sync mode functions.

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

10.2.2.1 LVAL_sync timing

Fig. 28 Edge Pre-select LVAL sync Timing

10.2.2.2 LVAL_async timing

Fig.29. Edge Pre-select LVAL async Timing

- 42 -

Page 45

Full scan

513 L

2/3 Partial

363 L

1/2 Partial

293 L

1/4 Partial

184 L

1/8 Partial

131 L

V Binning

260 L

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

10.2.3 Pulse Width Control trigger mode

In this mode the accumulation time is equal the trigger pulse width. Here it is possible to

have long time exposure. The maximum recommended time is <2 seconds.

The accumulation can be LVAL synchronous or LVAL a-synchronous.

The resulting video signal will start to be read out after the trigger rising edge.

For timing details, refer to fig. 19. through fig. 24 and fig. 30 through 31.

To use this mode:

Important notes on using this mode

Trigger pulse width >2 LVAL to <2 seconds

The following table shows minimum trigger interval in synchronous accumulation mode

1)In case of a-synchronous mode, the exposure time should be added to the above

table.

2) In order to keep the minimum trigger interval in partial scan mode, a exposure time

should be set within a number of normal read out line(511L). If it is exceeded, the

minimum trigger interval is longer by (exposure time – 511L).

- 43 -

Page 46

LAVL ASYNC

3μs±1μs

TRIG

2 L(min) 1L

CCD Exposure

EEN

Exposure time

FAVL

FULL: 6L~7.1 L( 131us~152.6us)

V binning:4L ~5.2L(98.4us ~121.2us)

When a trigger pulse is input during FVAL

LOW period, LVAL a-sync mode functions.

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

10.2.3.1 LVAL_sync timing

Fig. 30 Pulse width control. LVAL sync

10.2.3.2 LVAL_async timing

Fig.31. Pulse Width control LVAL async

- 44 -

Page 47

Full scan

579 L

2/3 Partial

426 L

1/2 Partial

356 L

1/4 Partial

247 L

1/8 Partial

194 L

1/2 V Binning

326 L

CM-030GE/CM-030GE-RA / CB-030GE/CB-030GE-RA

10.2.4 Reset Continuous (RCT) trigger mode

The RCT mode operates like EPS (edge preselect) mode with smearless function. An

external trigger pulse will immediately stop the video read out, reset and restart the

exposure, then operate as normal mode until the next trigger. After the trigger pulse is

input, a fast dump read out is performed. In the CM-030GE/ CB-030GE, this period is

1.3608ms which is 63L. The exposure time is determined by the pre-set shutter speed. If

no further trigger pulses are applied, the camera will continue in normal mode and the

video signal is not output. The fast dump read out has the same effect as “smearless read

out”. Smear over highlight areas is reduced for the trigger frame. The reset continuous

trigger mode makes it possible to use triggering in conjunction with a lens with video

controlled iris.

To use this mode:

Important notes on using this mode

Trigger pulse >2 LVAL to <1 FVAL)

The following table shows minimum trigger interval in asynchronous accumulation mode

- 45 -

Page 48

Trigger

Sequence

operation

Sequence 1 Sequence 2 Sequence 3 Sequence 4

Trigger

CCD Exposure

1.3608ms(63L)

Full:6L

~ 7.1L(131us ~ 152.6us)

V Binning:4L ~ 5.2L(98.4us ~ 121.2L)

EEN

FVAL

DVAL

ID

ROI

Shutter

Gain

Width