Page 1

User Manual

AT-140GE

Digital 3CCD Progressive Scan

RGB Color Camera

Document Version:Ver.1.0

AT-140GE_Ver.1.0_Dec09

1013E-0912

Page 2

AT-140GE

Notice

The material contained in this manual consists of information that is proprietary to JAI Ltd.,

Japan and may only be used by the purchasers of the product. JAI Ltd., Japan makes no

warranty for the use of its product and assumes no responsibility for any errors which may

appear or for damages resulting from the use of the information contained herein. JAI Ltd.,

Japan reserves the right to make changes without notice.

Company and product names mentioned in this manual are trademarks or registered

trademarks of their respective owners.

Warranty

For information about the warranty, please contact your factory representative.

Certifications

CE compliance

As defined by the Directive 2004/108/EC of the European Parliament and of the Council, EMC

(Electromagnetic compatibility), JAI Ltd., Japan declares that AT-140GE complies with the

following provisions applying to its standards.

EN 61000-6-3 (Generic emission standard part 1)

EN 61000-6-2 (immunity)

FCC

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Warning

Changes or modifications to this unit not expressly approved by the party responsible for FCC

compliance could void the user’s authority to operate the equipment.

- 1 -

Page 3

AT-140GE

Supplement

The following statement is related to the regulation on “ Measures for the Administration

of the control of Pollution by Electronic Information Products “ , known as “ China RoHS “.

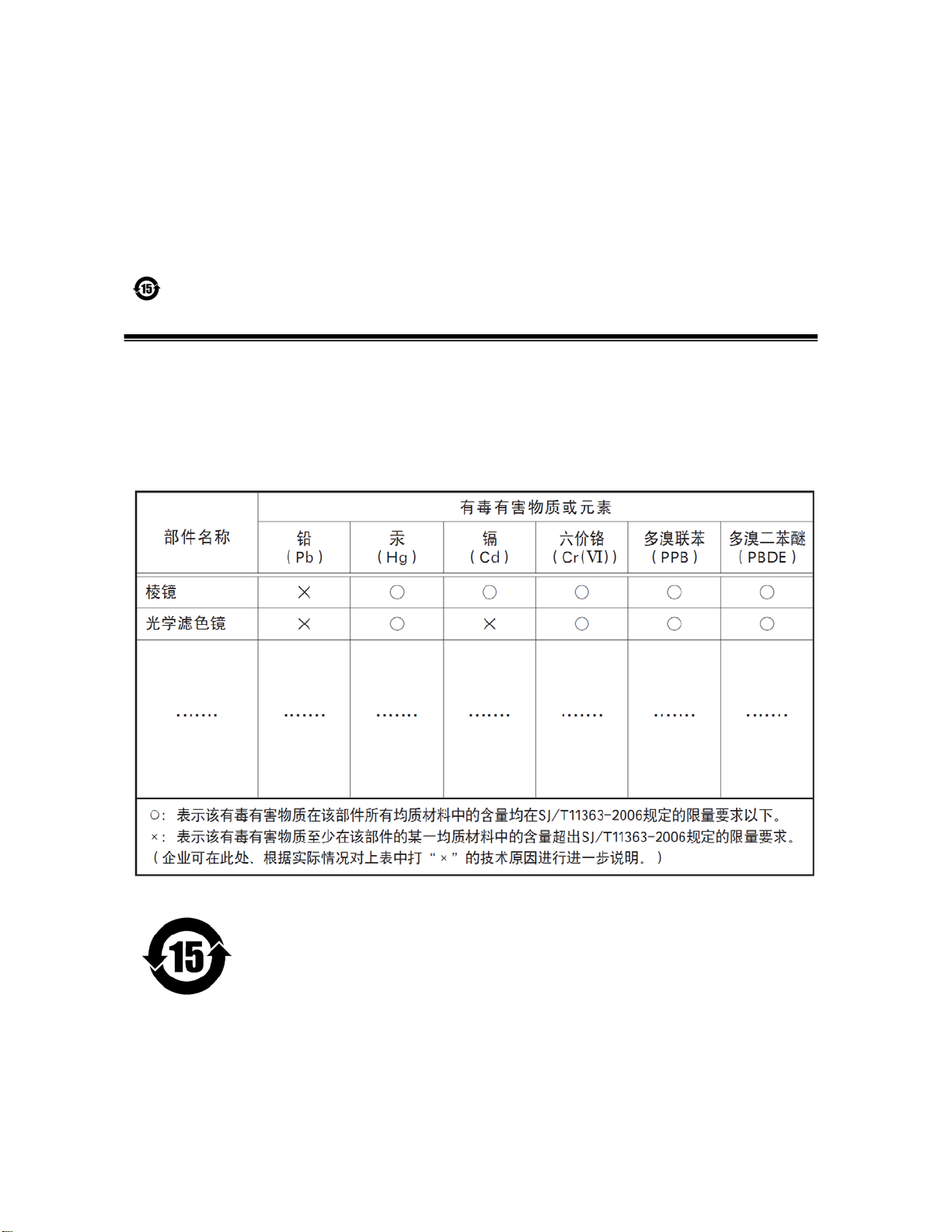

The table shows contained Hazardous Substances in this camera.

mark shows that the environment-friendly use period of contained Hazardous

Substances is 15 years.

嶷勣廣吭並㍻

嗤蕎嗤墾麗嵎賜圷殆兆各式根楚燕

功象嶄鯖繁酎慌才忽佚連恢匍何〆窮徨佚連恢瞳麟半陣崙砿尖一隈〇云恢瞳ゞ 嗤蕎嗤

墾麗嵎賜圷殆兆各式根楚燕 〃泌和

桟隠聞喘豚㍉

窮徨佚連恢瞳嶄根嗤議嗤蕎嗤墾麗嵎賜圷殆壓屎械聞喘議訳周和音氏窟伏翌

亶賜融延、窮徨佚連恢瞳喘薩聞喘乎窮徨佚連恢瞳音氏斤桟廠夛撹冢嶷麟半

賜斤児繁附、夏恢夛撹冢嶷鱒墾議豚㍉。

方忖仝15々葎豚㍉15定。

Page 4

AT-140GE

Table of Contents

JAI GigE Vision® Camera operation manuals ............................................ - 4 -

Introduction ................................................................................... - 4 -

Before using GigE Vision camera .......................................................... - 5 -

Software installation ......................................................................... - 6 -

Camera Operation ............................................................................ - 6 -

1. General ..................................................................................... - 6 -

2. Camera nomenclature ................................................................... - 6 -

3. Main Features .............................................................................. - 7 -

4. Locations and Functions ................................................................. - 8 -

4.1. Locations and functions .................................................................................. - 8 -

4.2. Rear panel indicator ...................................................................................... - 9 -

5. Pin Assignment ........................................................................... - 10 -

5.1. 12-pin Multi-connector (DC-IN/Trigger) ............................................................... - 10 -

5.2. Digital Output Connector for Gigabit Ethernet..................................................... - 10 -

5.3. D-Sub 9pin connector (For GPIO) ................................................................... - 11 -

5.4. DIP switch ................................................................................................. - 11 -

5.4.1 SW-600 .............................................................................................. - 11 -

5.4.2 SW-100 .............................................................................................. - 12 -

6. Input and output circuits ............................................................. - 13 -

6.1. Iris video output ......................................................................................... - 13 -

6.2. Trigger input ............................................................................................. - 13 -

6.3. XEEN output .............................................................................................. - 13 -

6.4. Auto iris video output level ............................................................................ - 14 -

7. GPIO (General purpose inputs and outputs) ....................................... - 15 -

7.1. Overview .................................................................................................. - 15 -

7.1.1 LUT (Look Up Table) .............................................................................. - 15 -

7.1.2 12-bit Counter ..................................................................................... - 16 -

7.1.3 Pulse Generators (0 to 1) ........................................................................ - 16 -

7.2. Opto-isolated Inputs/Outputs ......................................................................... - 16 -

7.2.1 Recommended External Input circuit diagram for customer .............................. - 16 -

7.2.2 Recommended External Output circuit diagram for customer ............................ - 17 -

7.2.3 Optical Interface Specifications ................................................................ - 17 -

7.3. Inputs and outputs table ............................................................................... - 18 -

7.4. Configuring the GPIO module (register settings) .................................................. - 19 -

7.4.1 Input /Output Signal Selector ................................................................... - 19 -

7.4.2 12-bit counter ...................................................................................... - 19 -

7.4.3 Pulse generators (20-bit x 2) .................................................................... - 20 -

7.5. GPIO programming examples .......................................................................... - 21 -

7.5.1 GPIO Plus PWC shutter ........................................................................... - 21 -

7.5.2 Internal Trigger Generator ...................................................................... - 22 -

8. GigE Vision Streaming Protocol (GVSP) ............................................. - 23 -

8.1. Digital Video Output (Bit Allocation) ................................................................. - 23 -

8.2. Bit Allocation (Pixel Format / Pixel Type) .......................................................... - 23 -

8.2.1 GVSP_PIX_RGB8_PACKED (RGB 24bit output) ................................................ - 23 -

8.2.2 GVSP_PIX_RGB10V1_PACKED (RGB 32bit output) ............................................ - 24 -

8.2.3 GVSP_PIX_RGB10V2_PACKED (RGB 32bit output) ............................................ - 24 -

9. Functions and Operations .............................................................. - 24 -

9.1. GigE Vision Standard Interface ........................................................................ - 24 -

9.2. Recommended Network Configurations ............................................................. - 24 -

9.2.1 Guideline for network settings ................................................................. - 25 -

9.2.2 Video data rate (network bandwidth) ......................................................... - 25 -

9.2.3 Note for setting packet size ..................................................................... - 25 -

- 2 -

Page 5

AT-140GE

9.2.4 Calculation of Data Transfer Rate .............................................................. - 26 -

9.2.5 Note for 100BASE-TX connection ............................................................... - 27 -

9.3. Basic Functions ........................................................................................... - 27 -

9.3.1 Basic construction ................................................................................. - 27 -

9.3.2 Modes of operation ................................................................................ - 28 -

9.3.3 Partial scan (Fast Dump ON) .................................................................... - 28 -

9.3.4 Vertical Binning (VB) .............................................................................. - 30 -

9.3.5 Electronic shutter (SM) ........................................................................... - 30 -

9.3.6 Auto-detect LVAL-sync / async accumulation ................................................ - 31 -

9.4. Pre-processing functions ............................................................................... - 32 -

9.4.1 Shading compensation ............................................................................ - 32 -

9.4.2 White balance ...................................................................................... - 33 -

9.4.3 Linear matrix ....................................................................................... - 33 -

9.4.4 Blemish compensation ............................................................................ - 34 -

9.4.5 Gamma setting (Look Up Table) ................................................................ - 34 -

9.4.6 Knee compensation ............................................................................... - 34 -

9.5. Other functions .......................................................................................... - 35 -

9.5.1 Test pattern generator (Address 0xA13C) ..................................................... - 35 -

9.5.2 Center marker ..................................................................................... - 35 -

9.6. Sensor Layout and timing .............................................................................. - 36 -

9.6.1 CCD Sensor Layout ................................................................................ - 36 -

9.6.2. Horizontal timing (Normal continuous mode) ............................................... - 37 -

9.6.3 Vertical timing (Normal continuous mode) ................................................... - 37 -

9.6.4 Horizontal timing (Partial scan mode) ......................................................... - 38 -

9.6.5 Vertical timing (Partial scan mode) ............................................................ - 38 -

9.6.6 Horizontal timing (Vertical binning mode) .................................................... - 39 -

9.6.7 Vertical timing (vertical binning mode) ....................................................... - 40 -

9.7. Operation Modes - Timing .............................................................................. - 40 -

9.7.1 Continuous operation ............................................................................. - 40 -

9.7.2 Edge Pre-select Trigger Mode (EPS) ............................................................ - 41 -

9.7.3 Pulse Width Control Trigger Mode .............................................................. - 43 -

9.7.4 Reset Continuous Trigger (RCT) ................................................................. - 45 -

9.7.5 Sequential Trigger Mode (EPS) .................................................................. - 46 -

9.7.6 Delayed Readout EPS and PWC Modes (EPS and PWC) ...................................... - 47 -

9.7.7 Smearless mode ................................................................................... - 48 -

9.7.8 Optical Black transfer mode ..................................................................... - 49 -

9.7.9 Multi ROI mode (Multi Region of Interest) .................................................... - 50 -

9.8. Mode and functions matrix ............................................................................ - 50 -

10. External Appearance and Dimensions ............................................ - 51 -

11. Specification table ..................................................................... - 52 -

Register Map ................................................................................. - 55 -

Appendix ...................................................................................... - 66 -

1. Precautions .................................................................................................. - 66 -

2. Typical Sensor Characteristics ........................................................................... - 66 -

3. Caution when mounting a lens on the camera ........................................................ - 66 -

4. Caution when mounting the camera .................................................................... - 67 -

5. Exportation .................................................................................................. - 67 -

6. References .................................................................................................. - 67 -

Change history ............................................................................... - 68 -

User's Record ................................................................................ - 69 -

- 3 -

Page 6

AT-140GE

JAI GigE Vision® Camera operation manuals

To understand and operate this JAI GigE Vision® camera properly, JAI provides the following

manuals.

User’s manual (this booklet) Describes functions and operation of the hardware

JAI SDK & Control Tool User Guide Describes functions and operation of the Control Tool

JAI SDK Getting Started Guide Describes the network interface

User’s manual is available at www.jai.com

JAI SDK & Control Tool User Guide and JAI SDK Getting Started Guide are provided with the

JAI SDK which is available at www.jai.com.

Introduction

GigE Vision is the new standard interface using Gigabit Ethernet for machine vision

applications and it was mainly set up by AIA (Automated Imaging Association) members. GigE

Vision is capable of transmitting large amounts of uncompressed image data through an

inexpensive general purpose LAN cable for a long distance.

GigE Vision also supports the GenICamTM standard which is mainly set up by the EMVA

(European Machine Vision Association). The purpose of the GenICam standard is to provide a

common program interface for various machine vision cameras. By using GenICam, cameras

from different manufactures can seamlessly connect in one platform.

For details about the GigE Vision standard, please visit the AIA web site,

www.machinevisiononline.org and for GenICam, the EMVA web site, www.genicam.org.

JAI GigE Vision cameras comply with both the GigE Vision standard and the GenICam standard.

- 4 -

Page 7

AT-140GE

NIC

manufacturer

Model

PCI Bus

PCI-X Bus

PCI-Express Bus

Intel

PRO/1000MT

(PWLA8490MT)

(33MHz)

(100MHz)

Intel

PRO/1000GT

(PWLA8391GT)

(33MHz)

(33MHz)

Intel

PRO/1000PT

(EXPI9300PT)

( x1 )

Intel

Gigabit CT

Desktop adaptor

(EXPI9301CT)

( x1 )

Intel

PRO/1000PT Quad

port

(EXPI9404PT)

( x4 )

Intel

PRO/1000PT Dual

port

(EXPI9402PT)

( x4 )

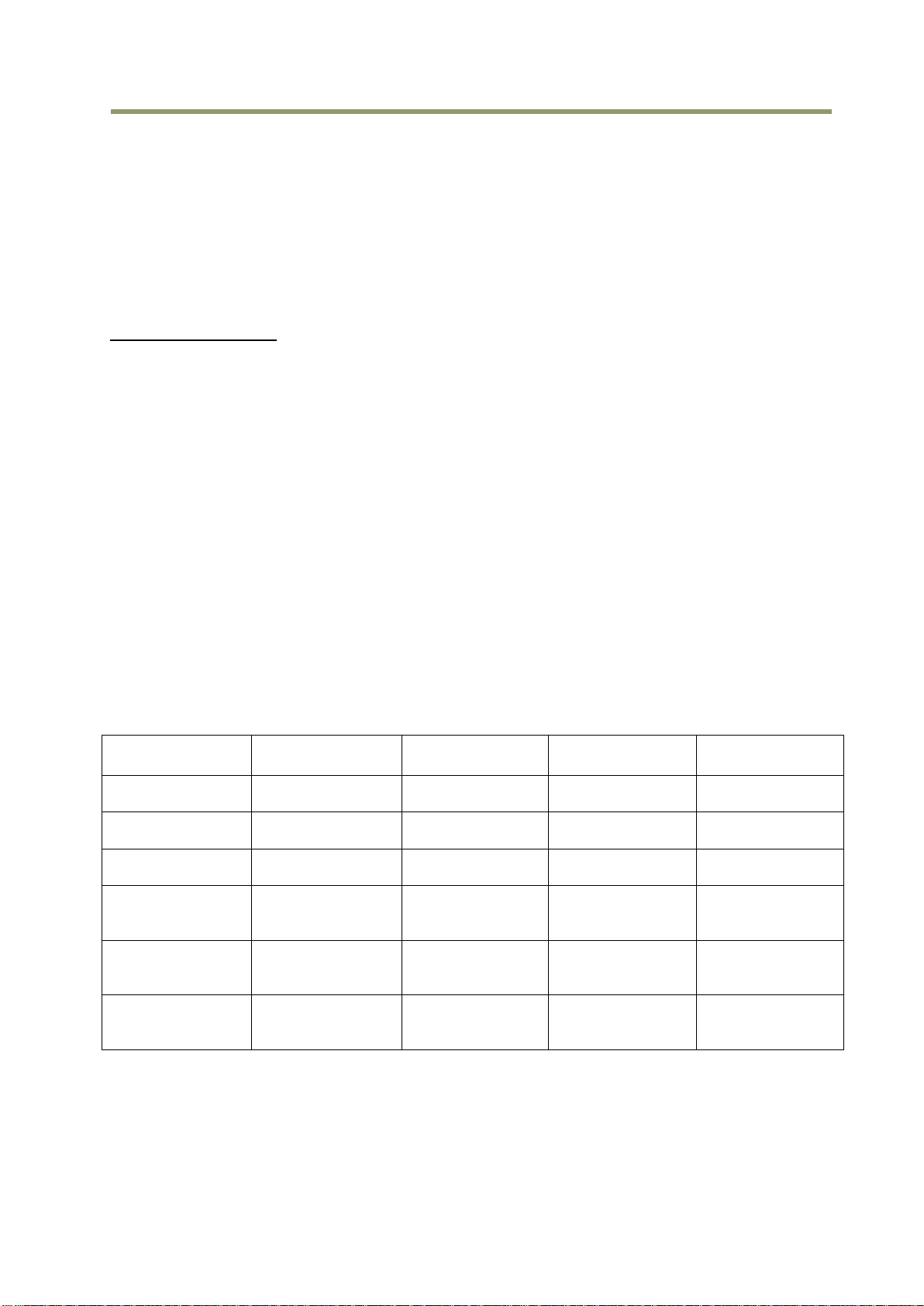

Before using GigE Vision camera

All software products described in this manual pertain to the proper use of JAI GigE Vision

cameras. Product names mentioned in this manual are used only for the explanation of

operation. Registered trademarks or trademarks belong to their manufacturers.

To use the JAI SDK, it is necessary to accept the “Software license agreement” first.

This manual describes necessary equipment and the details of camera functions.

Equipment to be used

In order to set up the GigE Vision system, use the following equipment or equivalent.

It is necessary to use a PC and peripherals which comply with Gigabit Ethernet requirements.

1. Camera(s) which comply with GigE Vison and GenICam

2. Power supply for camera

3. Network cable (CAT5e or CAT6)

4. Computer CPU: Intel Core Duo 2 2.4GHz or more

Memory: 2GB (recommended)

Video card: PCI Express Bus x 16 connection

VRAM : DDR2 with 256MB or more

DVI : capable of display 2560 x 1600 pixels

5. Network adapter (note 1)

6. Network HUB (if needed)

7. Trigger switch (If needed)

8. JAI SDK (Software Development kit)

Note:

Pentium 4 type PC is not recommended due to dependency on chip set bus performance.

Note1: At the time of publishing this document these combinations have been verified:

The above NICs are verified under the following conditions.

CPU:Intel Core 2 Duo, 2.4GHz

2 GB memory

Windows XP, SP2(32 bit)

Driver: Filter driver supplied with JAI SDK

- 5 -

Page 8

AT-140GE

Software installation

The JAI GigE Vision SDK & Control Tool can be downloaded from the JAI web site at

www.jai.com. The JAI SDK is available for Windows XP and Vista, 32-bit and 64-bit.

For the details of software installation, please refer to the “Getting Started Guide” supplied

on the JAI SDK download page.

Camera Operation

1. General

The AT-140GE is a digital 3CCD progressive scan RGB color camera. It employs three 1/2-inch

1392 (h) x 1040 (v), 1.45 Megapixel CCDs and runs at 20 frames per second in full resolution

mode. The AT-140GE has a GigE Vision interface and its output can be either 24-bit or 32-bit

RGB. JAI developed a new 1/2-inch compact F4.0 prism optical system and in combination

with a linear color matrix, the AT-140GE provides a higher fidelity of color reproduction. The

AT-140GE also incorporates a dynamic shading circuit, gamma correction circuit and knee

correction circuit to provide high picture quality. Functions like partial scanning and vertical

binning allow higher frame rates.

The latest version of this manual can be downloaded from: www.jai.com

The latest version of the JAI GigE Vision SDK & Control Tool for the AT-140GE can be

downloaded from: www.jai.com

For camera revision history, please contact your local JAI distributor.

2. Camera nomenclature

The standard camera composition consists of the camera main body and C-mount protection

cap.

The camera is available in the following versions:

AT-140GE

Where A stands for "Advanced" family, T stands for "3 CCD", 140 represents the resolution "1.4

million pixels" , and GE stands for "GigE Vision " interface.

- 6 -

Page 9

AT-140GE

3. Main Features

3 x 1/2" CCD progressive scan RGB color camera for vision applications

3 x 1392(h) x 1040 (v) 4.65m effective square pixels

Compact RGB prism for C-mount lenses

Shading reduction permits wider choice of lenses

20.77 frames per second with 1392 (h) x 1040 (v) pixels

59.45 fps with 1392 (h) x 131 (v) pixels in 1/8 partial scan mode

Variable partial scan is available for faster frame rate

Vertical binning for higher sensitivity and frame rate of 32.92 fps

24-bit RGB output or 32-bit RGB output (RGB 8, RGB 10V1 or RGB 10V2 pixel format)

Gamma is selectable for 0.45, 0.6 or LUT (Look Up Table)

Linear matrix circuit with sRGB or Adobe RGB pre-setting

Knee function available for knee point and knee slope settings.

Shading compensation circuit built in

Blemish compensation ON/OFF

Noise reduction circuit (ON/OFF, level settings)

Smearless mode available in EPS and PWC

Edge Pre-select, Pulse Width Control and Reset Continuous Trigger modes

Sequence trigger mode for on-the –fly change of gain, exposure and ROI

Delayed readout mode for smooth transmission of multi-camera applications

Common or individual programmable exposure for RGB

Auto exposure capability

AGC (Automatic Gain Control) from -3dB to 12dB

Manual, continuous, one push or pre-set white balance

Analog iris video output for lens iris control

LVAL synchronous/asynchronous operation (auto-detect)

Comprehensive software tools and SDK for Windows XP/Vista (32 bit “x86” and 64

bit “x64” JAI SDK Ver. 1.2.1 and after )

- 7 -

Page 10

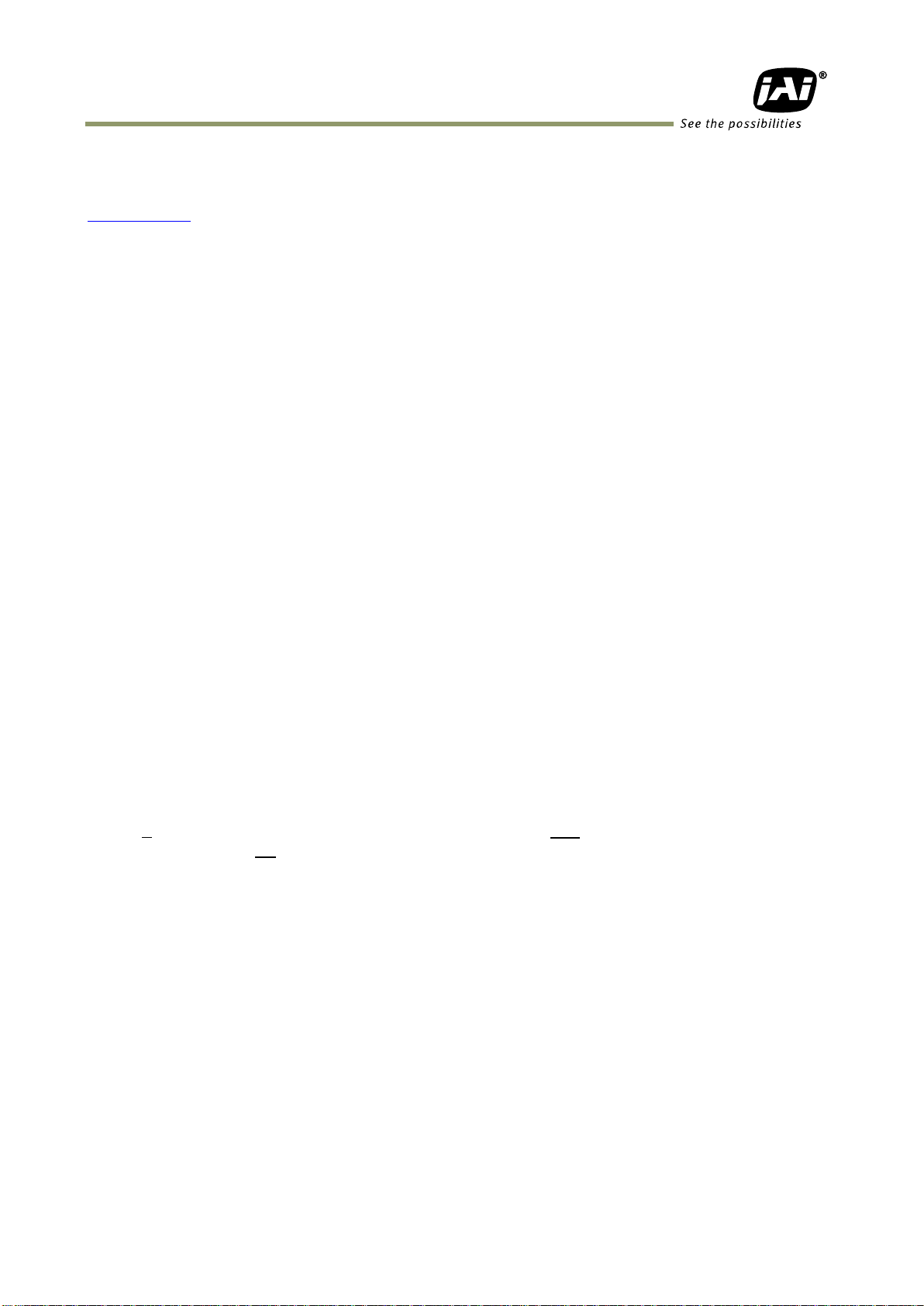

4. Locations and Functions

4.1. Locations and functions

AT-140GE

1. Lens mount Lens mount of C-mount type. *1)

2. CCD sensor 1/2 inch CCD

3. RJ-45 connector GigE Vision interface with thumb screws

4. 12-pin connector DC+12V, Trigger IN and EEN out

5. D-sub 9-pin connector LVDS IN and TTL IN and OUT

6. LED Power and trigger indications

7. LINK Indication for Network connection

8. ACT Indication for GigE communication

9.Holes for RJ-45 thumbscrews Vertical type and horizontal type (*2)

10.Mounting holes M3, max length 5mm (*3)

*1) Note: Applicable C-mount lens should be designed for 3-CCD cameras. Rear protrusion on

C-mount lens must be less than 4mm.

Be advised: when using a lens with the iris diaphragm fully open, vignetting on corners

may occur.

*2) Note: When an RJ-45 cable with thumb screws is connected to the camera, please do not

excessively tighten screws by using a driver. The RJ-45 receptacle on the camera might

be damaged. For security, the strength to tighten screws is less than 0.147 Newton

meter (Nm). Tightening by hand is sufficient in order to achieve this.

*3) Note: The tripod adapter plate MP-41 can be used.

Fig. 1. Locations

- 8 -

Page 11

AT-140GE

4.2. Rear panel indicator

The rear panel mounted LED provides the following information:

Amber : Power connected - initiating

Steady green : Camera is operating in Continuous mode

Flashing green : The camera is receiving external trigger

Ethernet connector indicates,

Steady green : 1000 Base-T has been connected

Flashing green : 100 Base-TX has been connected (Note)

Flashing amber : Network active in communication

Note: When 10BASE-T is connected, the green is also flashing.

However, the video is not streamed through Ethernet.

Fig.2 Rear Panel

- 9 -

Page 12

AT-140GE

Pin No

In/Out

Name

1

In/Out

MX1+ (DA+)

2

In/Out

MX1- (DA-)

3

In/Out

MX2+ (DB+)

4

In/Out

MX3+ (DC+)

5

In/Out

MX3- (DC-)

6

In/Out

MX2- (DB-)

7

In/Out

MX4+ (DD+)

8

In/Out

MX4- (DD-)

Pin no.

Signal

Remarks

1

GND

2

+12 V DC input

3

GND

4

Iris video

Continuous and RCT modes only

5

GND

6

-

7

-

8

GND

9

XEEN out

Negative logic

10

Trigger in

*1)

11

-

12

GND

3

4

5

6

7

8

9

10

11

12

1

2

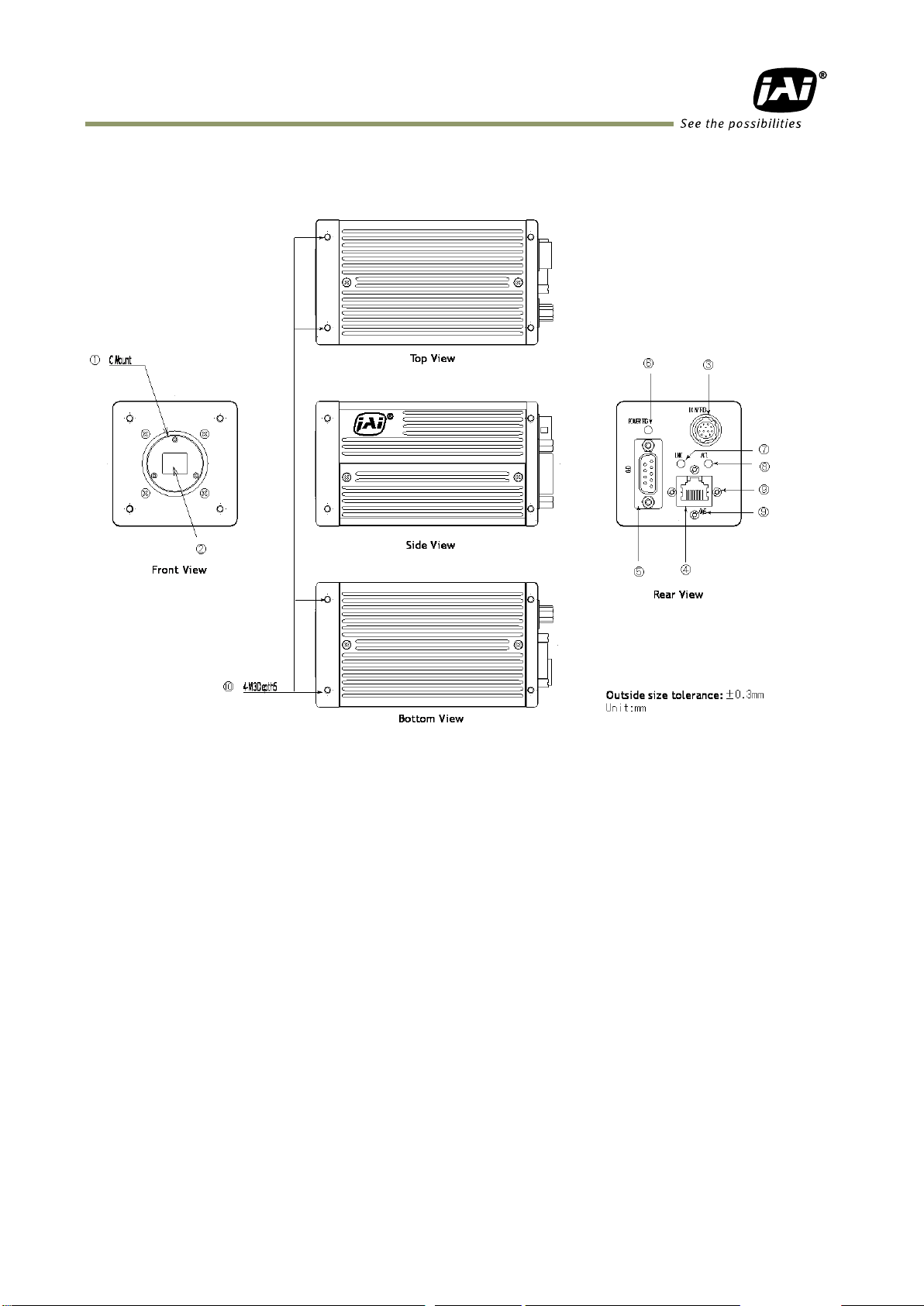

5. Pin Assignment

5.1. 12-pin Multi-connector (DC-IN/Trigger)

Type: HR10A-10R-12PB-01

(Hirose) male.

(Seen from rear of

camera.)

Fig. 3. 12-pin connector. *1) 75 ohm termination can be selected by DIP SW600.

5.2. Digital Output Connector for Gigabit Ethernet

Type: RJ-45

HFJ11-1G02E-L21RL or equivalent

The AT-140GE cameras also accept industrial RJ-45 connectors with

thumbscrews. This assures that the connector does not come undone

in tough industrial environments.

Please contact the nearest JAI distributor for details on

recommended industrial RJ-45 connectors.

Fig. 4. Gigabit Ethernet connector

The digital output signals follow the Gigabit Ethernet interface using RJ-45 conforming

connector. The following is the pin assignment for the Gigabit Ethernet connector.

- 10 -

Page 13

AT-140GE

No

I/O

Name

Note

1 I LVDS In 1-

2 I LVDS In 1+

3 I TTL IN 1

75ohm Terminator (Note 1)

4 O TTL Out 1

5 GND

6 NC 7 NC

8 O TTL OUT 2

9 GND

No

Functions

Setting

ON

OFF

1

Trigger input termination

75Ω

TTL

ON

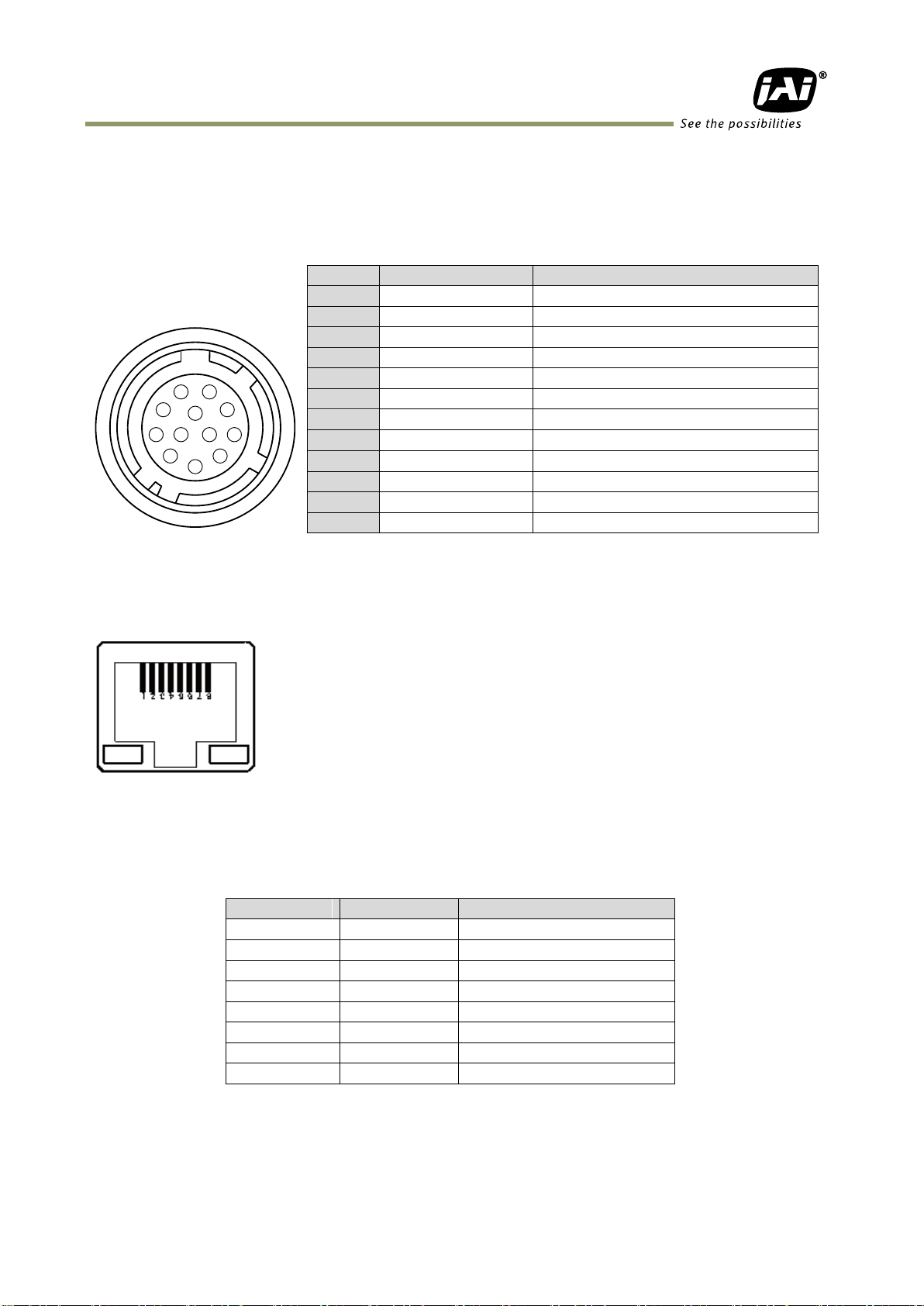

5.3. D-Sub 9pin connector (For GPIO)

Type : DD-09SSG

Fig. 5.D Sub 9pin connector

Note1) Can be changed by DIP switch (SW600).

5.4. DIP switch

DIP switches are located on circuit boards. When the top cover is removed, please pay careful

attention so that circuit boards may not be damaged.

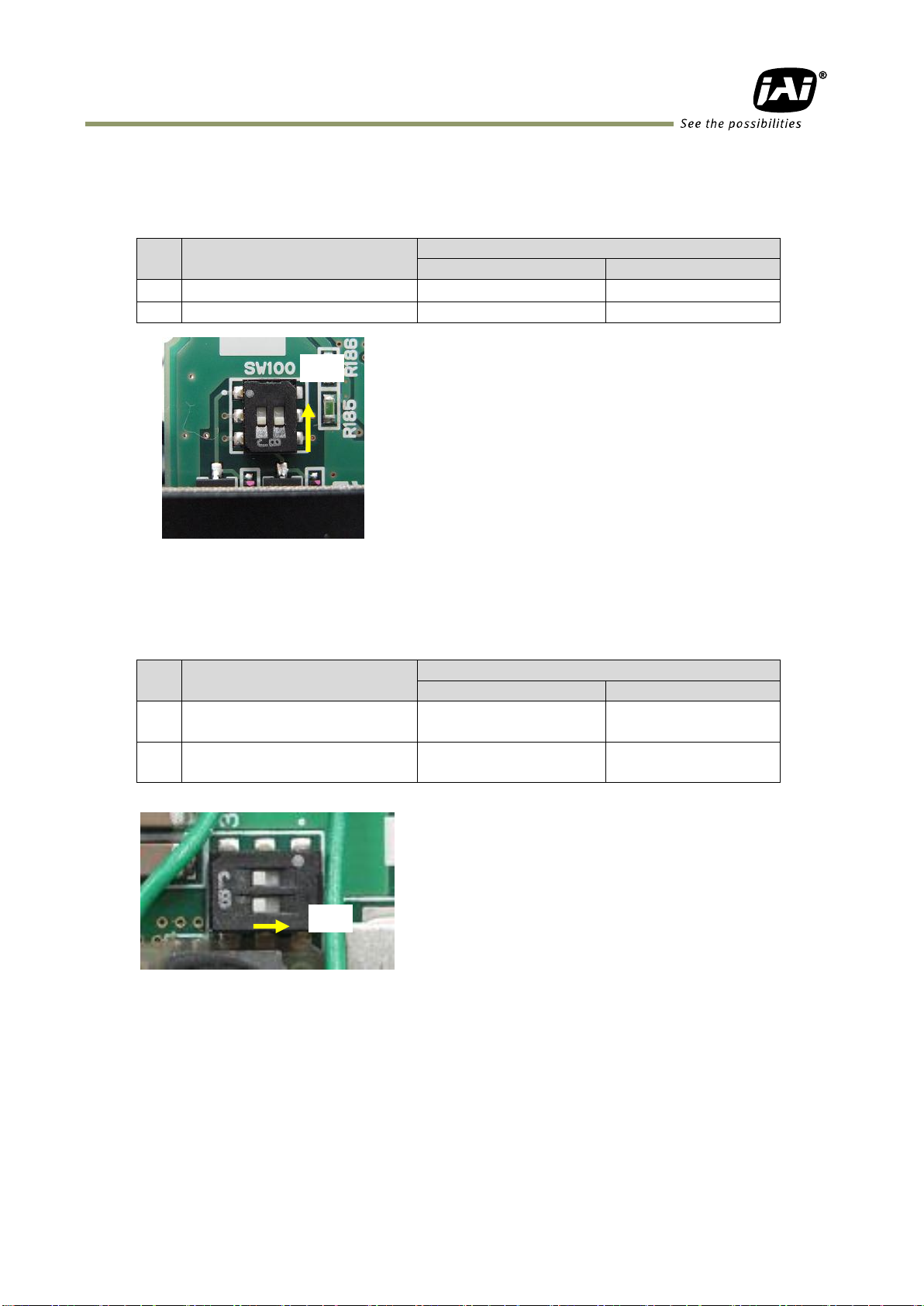

5.4.1 SW-600

This switch sets the 75 ohm trigger input termination to ON or OFF.

The factory default setting is OFF which is TTL level.

Fig.6. SW600 (On rear panel)

- 11 -

Page 14

AT-140GE

No

Functions

Setting

ON

OFF

1

EEN output select

Open collector (EEN)

TTL(XEEN)

2

NC - -

No

Functions

Setting

ON

OFF

1

OPT IN(+) / Iris video OUT

select

Iris video

OPT IN (+)

2

OPT IN(-) / Iris video OUT

select

GND for iris video

OPT IN (-)

ON

ON

5.4.2 SW-100

This switch can select the type of the signal which is output through 12-pin #10. The factory

default is TTL (XEEN) and it can be changed to Open collector (EEN).

Fig.7. SW100 (Right board looking from the front)

5.4.3 SW-700

This DIP switch can select OPT IN or Iris video output through pin#3 and #4 of the

HIROSE 12 pin connector.

Fig.8 SW700 (On the top board)

- 12 -

Page 15

AT-140GE

DAC

Iris Video

2K2

1K

1μ

0.1μ

+5V

+5V

●

●

●

●

●

SW600

TTL

1K

100K

0.001μ

0.1μ

1K2

15K

39K

75

HIROSE 12P

#10

+5V

1K

0.1

10K

10

10

220

EEN

HIROSE

#9

120

150

Open

Collector

Push

Pull

10K

1K

180

SW100

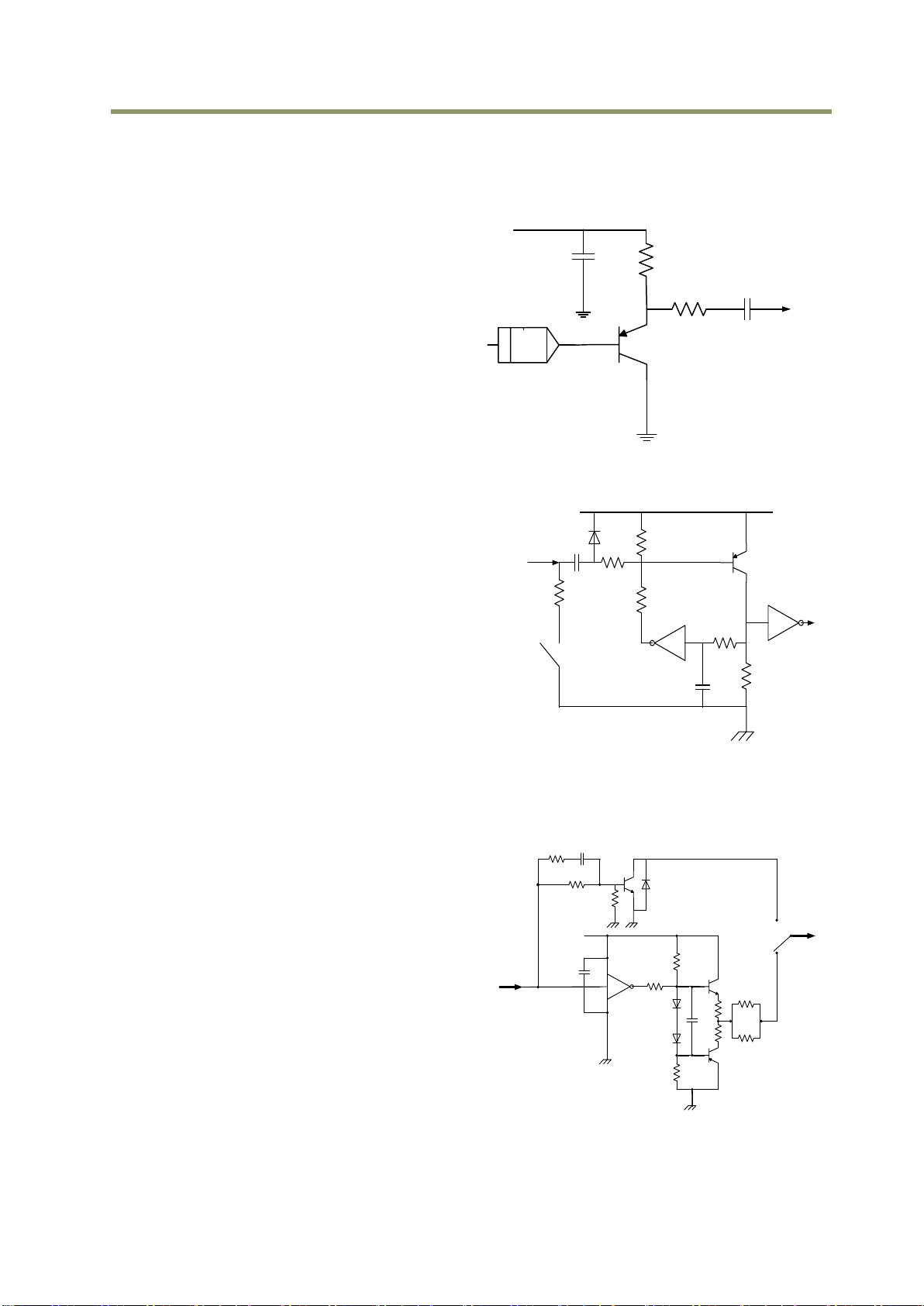

6. Input and output circuits

This chapter introduces the basic diagram and bit allocation of digital output.

6.1. Iris video output

This signal can be used for lens iris control In

Continuous and RCT modes. The signal is NUM

luminance signal and passes through the gain

circuit. However, due to reversed

compensation applied, the gain settings do

not influence this signal. The iris video output

is 0.7 V p-p from 75 and without sync.

Fig. 9 Iris video output.

6.2. Trigger input

The trigger input is on pin #10 on the 12-pin

connector or pin#3 on the D-sub 9-pin

connector. The input is AC coupled. To allow

a long pulse width, the input circuit is a flipflop, which is toggled by the negative or

positive differentiated spikes caused by the

falling or rising trigger edges.

The trigger polarity can be changed.

Trigger input level is 4 V 2 V. It can be

terminated by SW600: ON for 75. OFF for

TTL(Factory default).

Fig.10 Trigger input.

6.3. XEEN output

XEEN is found on pin #4 or #8 on D-sub 9-pin

connector.

The output circuit is 75 complementary

emitter followers. Output level 3 V from 75.

(No termination).

When the open collector is used, the maximum

current is 120mA. However, if a current of more

than 50mA is flowed, it is necessary to use

bigger diameter wires for connecting pin#8 and

9. In case of narrower wires, due to its

resistance, it may not work properly.

This output can be changed to Open collector

signal by SW100.

EEN is found in OPT out in 12-pin connector.

Fig.11 EEN output

- 13 -

Page 16

CCD out

Analog Out

200mV

700mV

230mV↑

800mV

0

100% Level700

200

Analog Out [mV]

CCD Out [mV]

265

930

AT-140GE

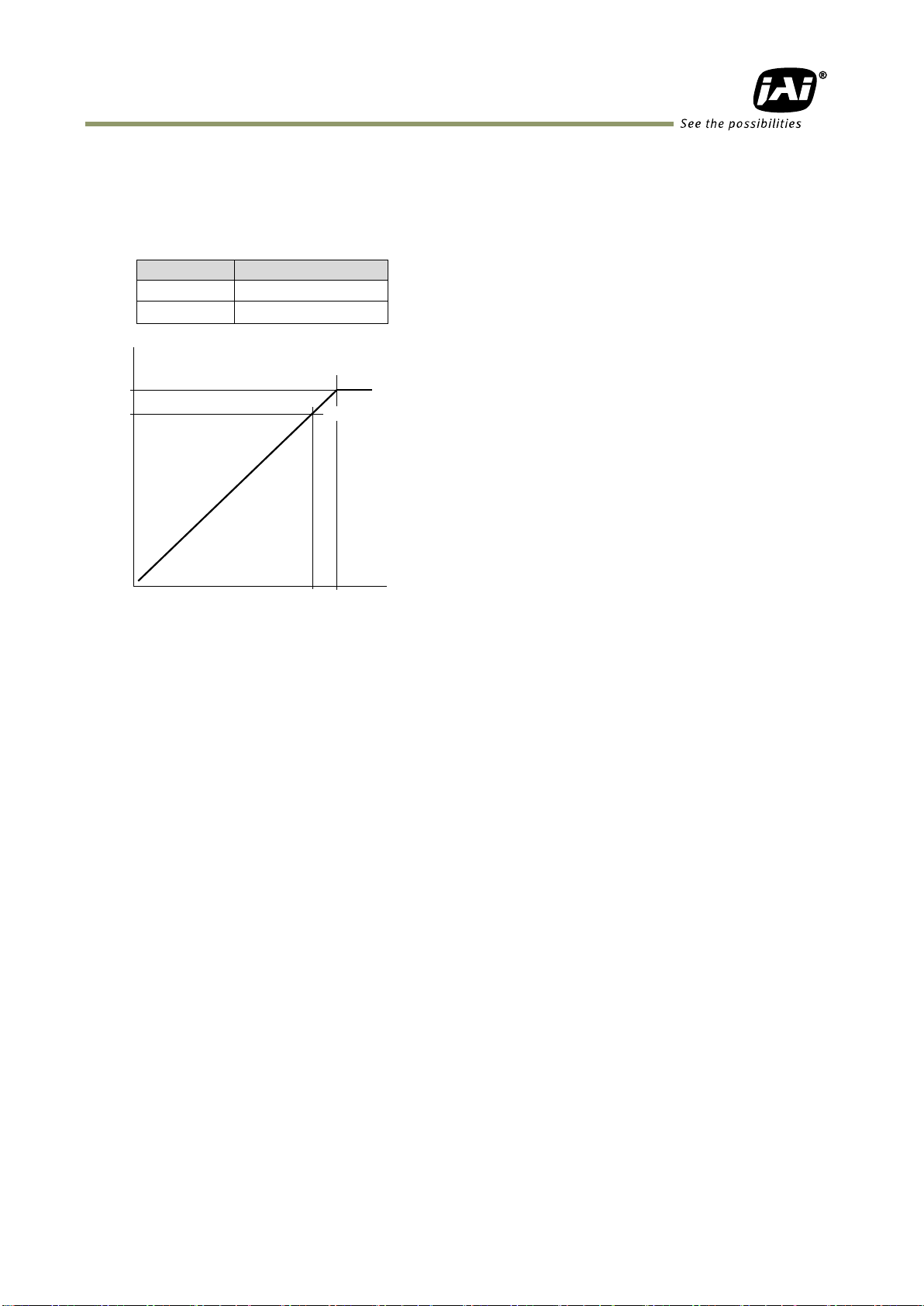

6.4. Auto iris video output level

This video output signal is NUM luminance signal and does not have SYNC. It is available only

in Continuous mode and RCT mode. It is also not available in partial scan mode.

This signal is not affected by the gain control.

Fig.12 Iris video output

- 14 -

Page 17

AT-140GE

LUT

( Cross Point Switch )

Pulse Generator 1

(20 bit Counter )

Pulse Generator 0

(20 bit Counter )

12 bit

Counter

TRIGGER 1

TRIGGER 2

TTL OUT 2

OPT OUT 1

OPT OUT 2

Time Stamp Reset

Sequence Reset

LVAL IN

DVAL IN

FVAL IN

EEN IN

OPT IN 1

OPT IN 2

LVDS IN 1

Soft Trigger 0

Soft Trigger 1

Soft Trigger 2

Soft Trigger 3

Pulse trigger IN

Pulse OUT

Pulse Generator 0

Pulse Generator 1

Digital I/O(GPIO) setting

Digital I/O(GPIO) setting

Setting for

Line Source

Setting for

Line Selector

Pixel Clock

Counter Clock Source

1

Counter Divide by value

Bypass0

1 - 4095

Pulse Generator Setting 0

Start Point Counter 0

Length counter 0

Repeat Counter 0

End point counter 0

Counter 0 clear

Pulse Generator Setting 1

Pulse Generator 1

Pulse Generator 0

TTL IN 1

TTL OUT 1

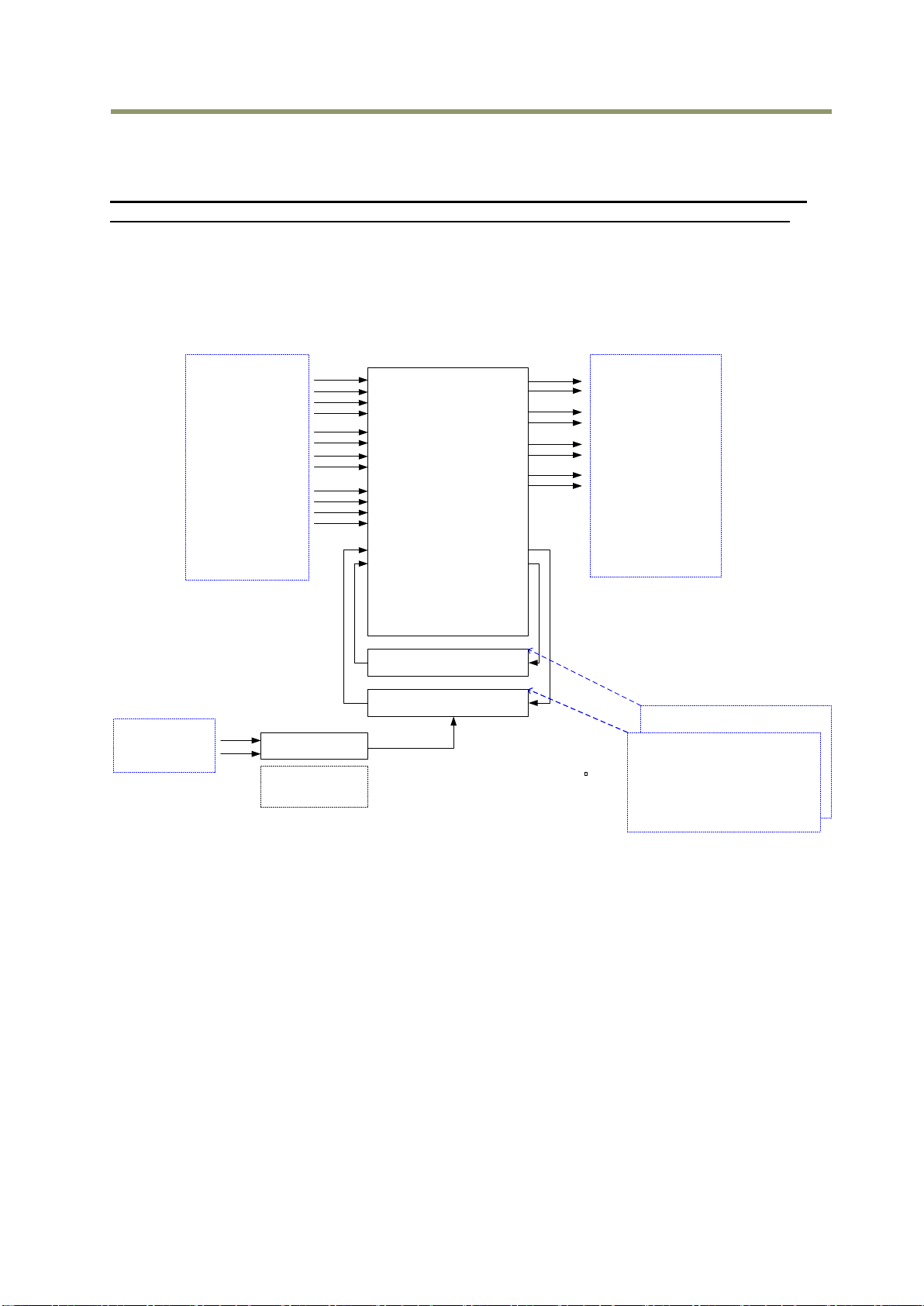

7. GPIO (General purpose inputs and outputs)

In chapter 7, there are some examples of settings. the values shown in these examples

may need to be adjusted to fit the pixel clock specifications of this particular model.

7.1. Overview

All input and output signals pass through the GPIO (General Purpose Input and Output) module.

The GPIO module consists of a Look-Up Table (LUT – Cross-Point Switch), 2 Pulse Generators

and a 12-bit counter. In the LUT, the relationship between inputs, counters and outputs is

governed by internal register set-up.

On the above block diagram, Trigger 0 is used for Exposure and Trigger 1 is used for Delayed

Readout. The Time Stamp Reset can reset the time stamp in compliance with the GigE Vision

standard. This is used for having the same time stamp in case of using multiple cameras.

The blocks shown in the above diagram have the following functionality:

7.1.1 LUT (Look Up Table)

The LUT works as a cross-point switch, which allows connecting inputs and outputs freely.

The signals LVAL_IN, DVAL_IN, FVAL_IN and EEN_IN all originate from the camera timing

circuit. Trigger 0 is connected to the camera's timing circuit and is used for initiating

triggered exposure. Trigger 1 is used for Delayed Readout mode. The Time Stamp Reset

signal is used to reset the camera's time stamp function, also making it possible to reset and

synchronize the time stamp of multiple cameras.

- 15 -

Page 18

AT-140GE

7.1.2 12-bit Counter

The camera pixel clock (42.954 MHz) can be used as a source. The counter has a “Divide by

N”, where N has the range 1 through 4096, allowing a wide range of clock frequencies to be

programmed. Setting value 0 is bypass, setting value 1 is 1/2 dividing and setting value 4095

is 1/4096 dividing.

7.1.3 Pulse Generators (0 to 1)

Each pulse generator consists of a 20-bit counter. The behavior of these signals is defined by

their pulse width, start point, end point and number of repetitions.

The pulse generator signals can be set in either triggered or periodic mode.

In triggered mode, the pulse is triggered by the rising edge/falling edge/high level or low

level of the input signal.

In periodic mode, the trigger continuously generates a signal that is based on the configured

pulse width, starting point and end point.

7.2. Opto-isolated Inputs/Outputs

The control interface of the C3 GigE Vision camera series has opto-isolated inputs and outputs,

providing galvanic separation between the camera's inputs/outputs and peripheral equipment.

In addition to galvanic separation, the opto-isolated inputs and outputs can cope with a wide

range of voltages; the voltage range for inputs is +3.3V to +24V DC whereas outputs will

handle +5V to +24V DC.

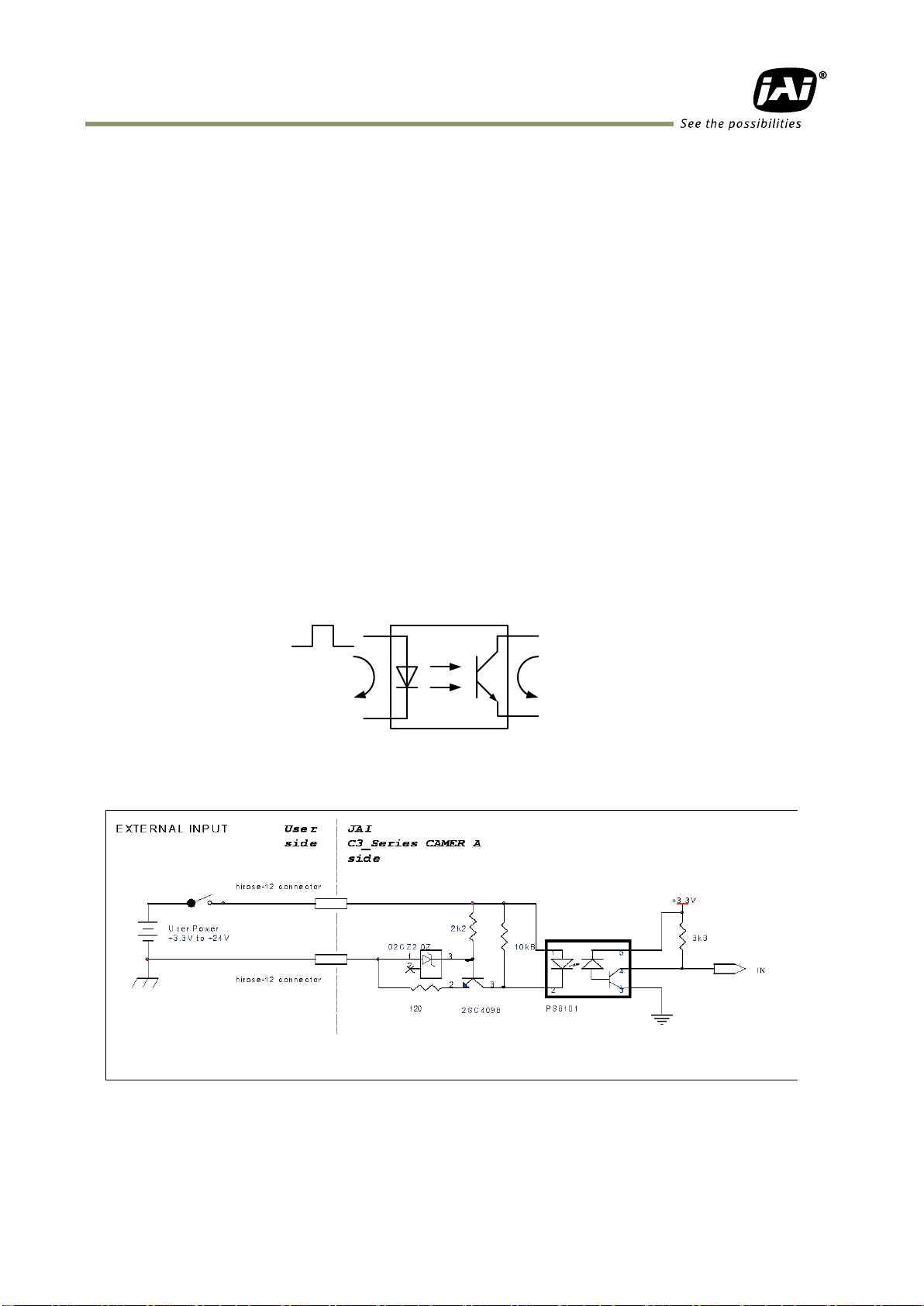

The figure below shows the functional principle (opto-coupler) of the opto-isolated

inputs/outputs.

Fig.13 Opto-coupler

7.2.1 Recommended External Input circuit diagram for customer

Fig.14 External Input Circuit, OPT IN 1 and 2

- 16 -

Page 19

AT-140GE

User Power (VCC)

3.3V

5V

12V

24V

Time Delay Rising TDR(µs)

0.54

0.54

0.62

0.68

Rising Time RT(µs)

1.2

1.2

2.0

3.0

Falling Delay Time FDR(µs)

1.5

1.5

2.4

2.1

Falling Time FT(µs)

3.6

3.4

4.5

6.8

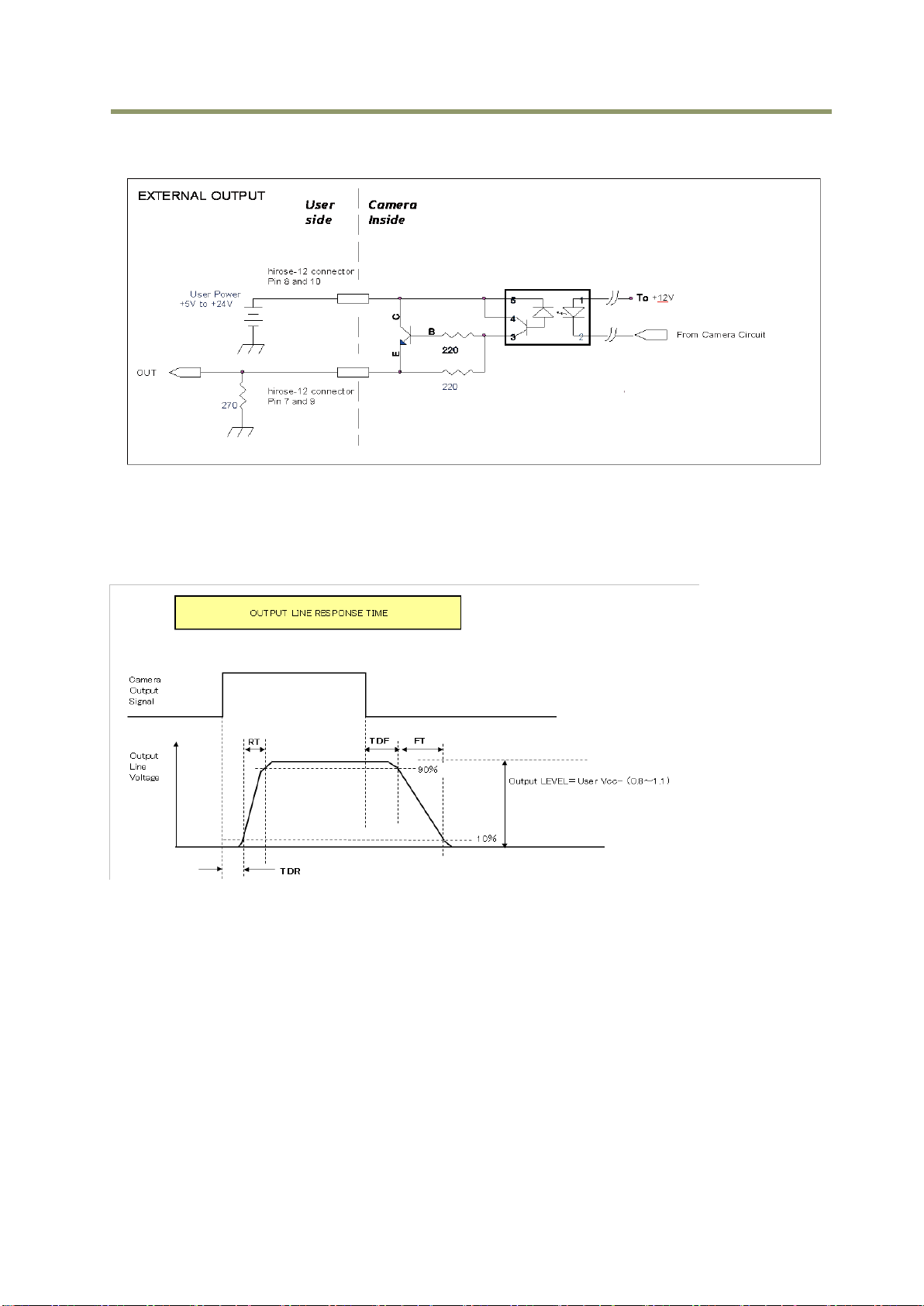

7.2.2 Recommended External Output circuit diagram for customer

Fig.15. External Output Circuit, OPT OUT 1 and 2

7.2.3 Optical Interface Specifications

The relation of the input signal and the output signal through the optical interface is as

follows.

Fig.16 Optical Interface Performance

- 17 -

Page 20

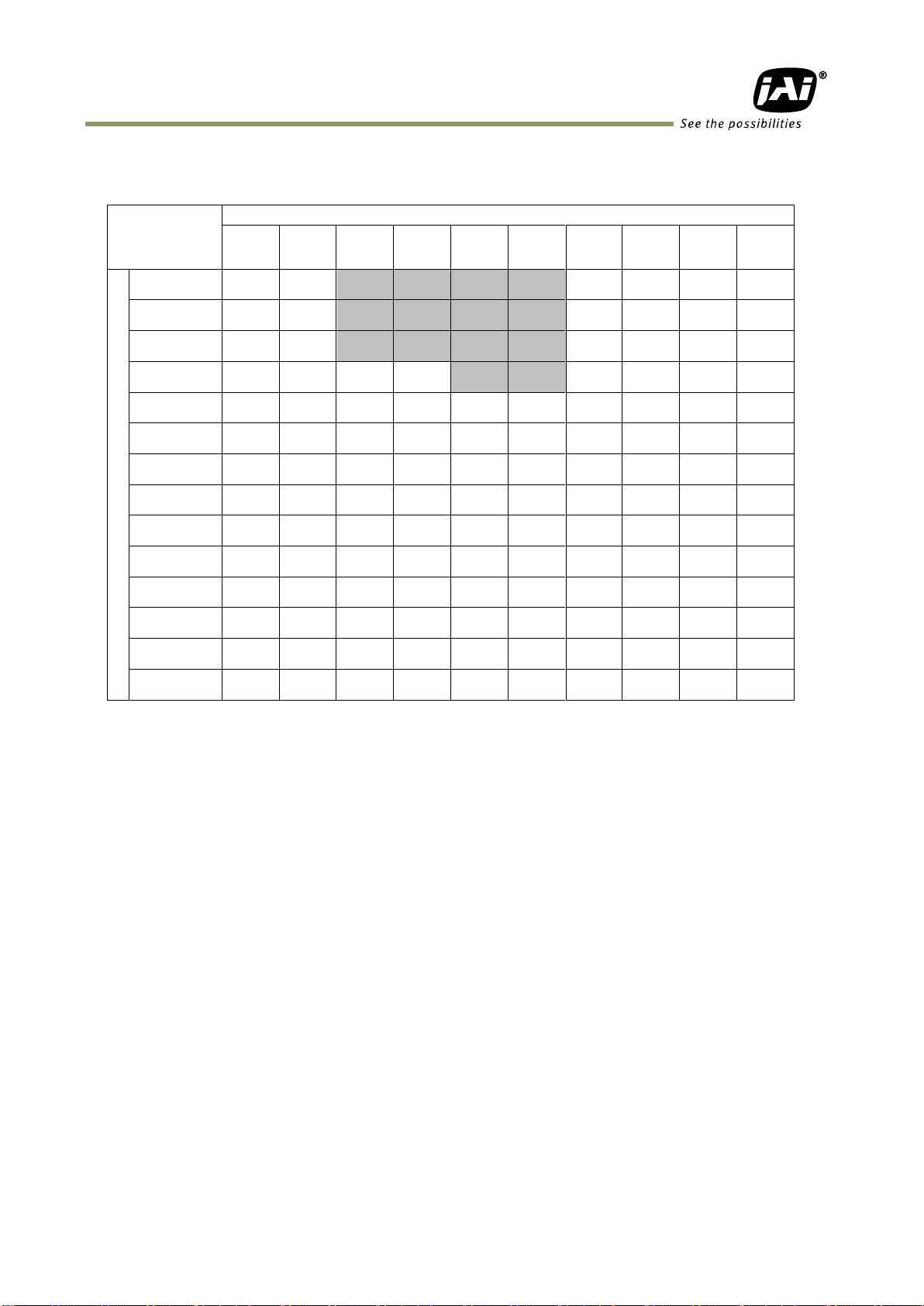

7.3. Inputs and outputs table

Output Port

Trigger

0

Trigger

1

OPT

OUT1

OPT

OUT2

TTL

OUT 1

TTL

OUT 2

Time

Stamp

Reset

Seq.

Reset

Pulse

Gen. 0

Pulse

Gen. 1

Input Port

LVAL IN

× × ×

×

○

○

× ○

○

DVAL IN

× × ×

×

○

○

× ○

○

FVAL IN

× × ×

×

○

○

× ○

○

EEN IN

× × ○

○

○

○

× ○

○

OPT IN 1

○ ○ ○

○

○

○

○ ○ ○

○

OPT IN 2

○ ○ ○

○

○

○

○ ○ ○

○

TTL IN

○ ○ ○

○

○

○

○ ○ ○

○

LVDS IN

○ ○ ○

○

○

○

○ ○ ○

○

Soft Trigger 0

○ ○ ○

○

○

○

○ ○ ○

○

Soft Trigger 1

○ ○ ○

○

○

○

○ ○ ○

○

Soft Trigger 2

○ ○ ○

○

○

○

○ ○ ○

○

Soft Trigger 3

○ ○ ○

○

○

○

○ ○ ○

○

Pulse Gen. 0

○ ○ ○

○

○

○

○ ○ ×

○

Pulse Gen. 1

○ ○ ○

○

○

○

○ ○ ○

×

AT-140GE

LEGEND: 0 = valid combination / x = Not valid (do not use this combination)

- 18 -

Page 21

AT-140GE

Address

Internal Name

GenIcam Name

Access

Size

Value (Range)

0xB004

Counter Dividing Value

ClockPreScaler

R/W

4

0x000: Bypass

0x001: 1/2 Dividing

0x002: 1/3 Dividing

|

0xFFF: 1/4096 Dividing

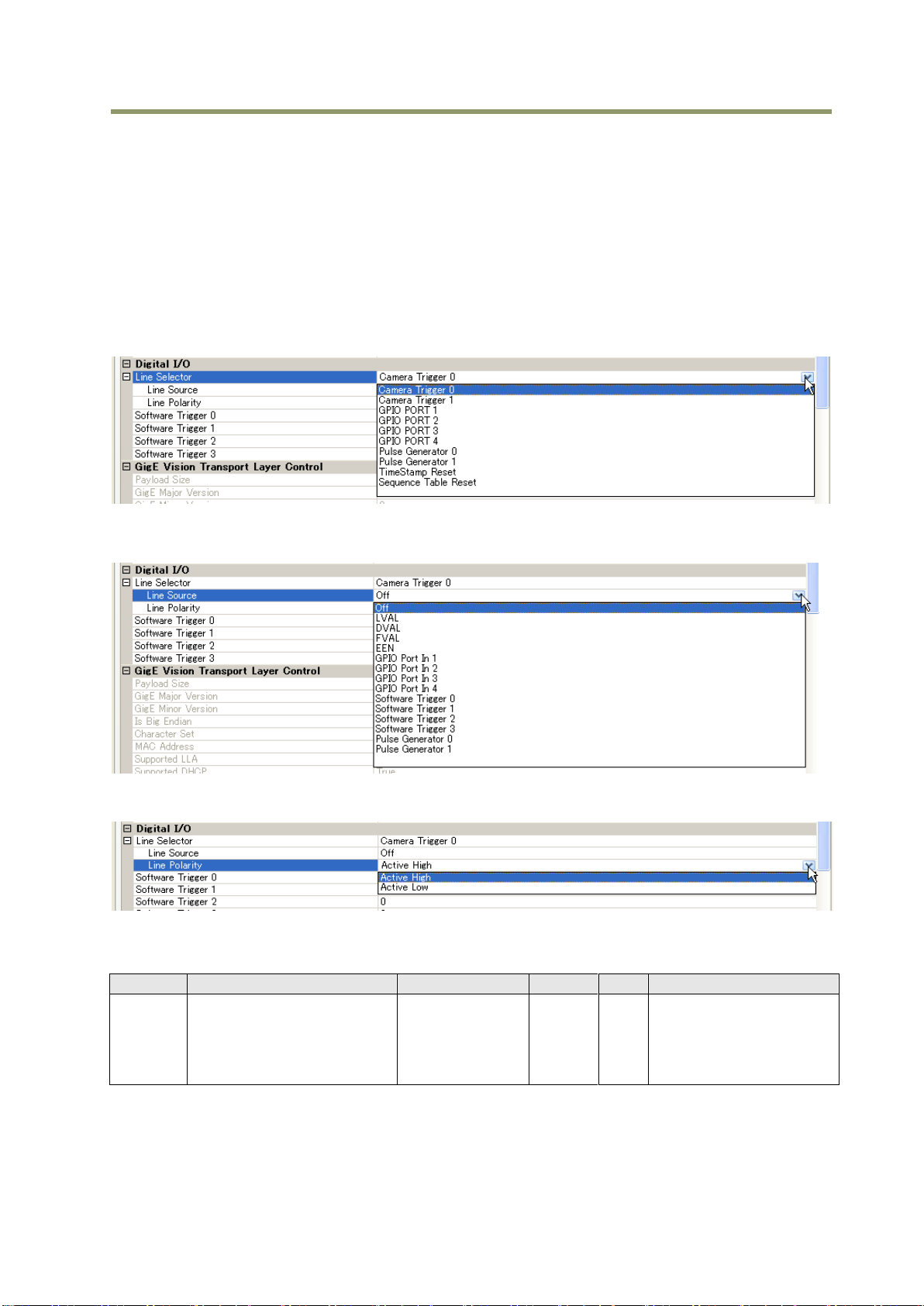

7.4. Configuring the GPIO module (register settings)

7.4.1 Input /Output Signal Selector

GPIO is used to determine which signal is assigned which terminal. For the details, please

refer to Register Map, Digital I/O, Acquisition and Trigger Control and Pulse Generator.

Line Selector

Line Source

Line Polarity

7.4.2 12-bit counter

- 19 -

Page 22

AT-140GE

Start Point

End Point

Length

Start Point

End Point

Length

Pulse Generator 0 IN

(FVAL )

0 1 2 3

1

99 100 101 102 103

2 1

Start Point = 0 End Point = 99

Length = 102

Clock IN

Clock Source=Pixel Clock ( 60MHz)

Clock Pre-scaler = 2399 ⇒ 25KHz

1/25KHz = 40µs

Pulse Generator Clear = 4: Rising Edge

Pulse Generator 0 OUT

(GPIO Port 1 )

Repeat counter: 0 to 255

=0: Continuously repeated

Pulse Generator Setting Example

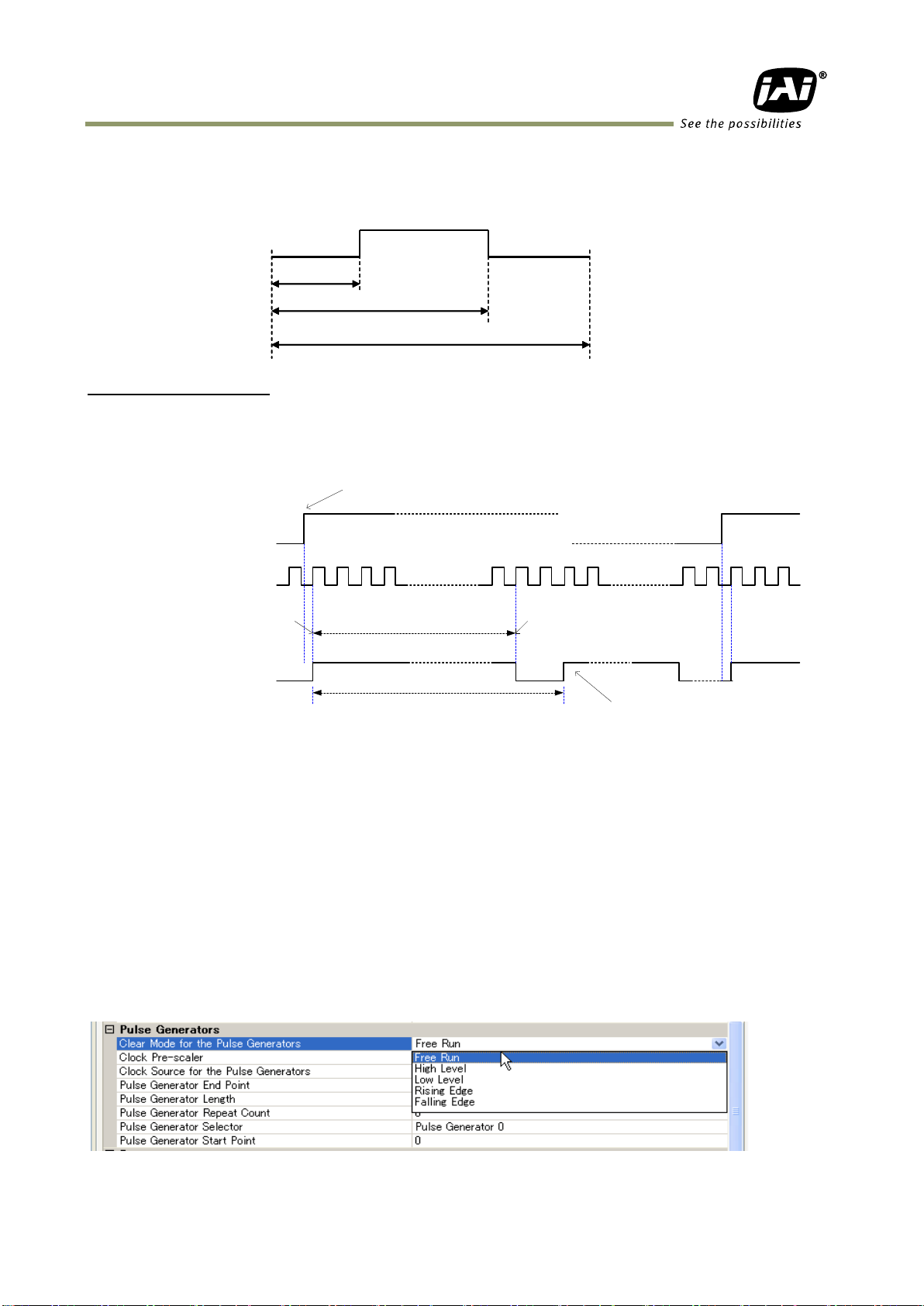

7.4.3 Pulse generators (20-bit x 2)

There are 2 pulse generators (designated 0 through 1) that can be used to create various

timing scenarios by programming start point, endpoint, length and repeats.

An example of settings

The following example shows the FVAL input to a pulse generator. The pulse generator

creates the pulse using FVAL and the pulse is output through GPIO PORT 1.

The created pulse rises up at the start point and falls down at the end point, as shown above.

Accordingly, the High duration is (End point – Start point) clocks x (1/Pulse gen. frequency).

In the above example, the original oscillation uses pixel clock (60 MHz) and the pixel clock is

divided by 2400. A pulse frequency of the generator is 25 KHz (60000000/2400). As the start

point is 0 and the end point is 99, a pulse having a width of 100 x 1/25000 = 4ms is created.

If the High duration needs to be delayed against an incoming trigger, the start point should be

set at “N”. The delay value is N x (1/ 25000). In the above example, the N is “0” which is no

delay. The length, in this case, is 102 clocks.

These settings can be achieved by using the JAI Control Tool which is part of the JAI SDK.

Fig.17 Pulse generator setting example

- 20 -

Page 23

7.5. GPIO programming examples

Address

Register

Value

0xA040

Trigger Mode

2 = PWC ( Pulse Width Control)

①

0xB090

Pulse Generator 0 Selector

4 =OPT IN 1

②

0xB000

Clock Choice

1 = Pixel Clock (43MHz)

0xB004

Counter Dividing Value

0 = Pass through

0xB008

Length Counter 0

1000 Clocks

0xB00C

Start point Counter 0

100 Clocks

0xB010

Repeat Count 0

1

0xB014

End point Counter 0

530 Clocks

0xB018

Counter Clear 0

4 = Rising Edge Clear

③

0xB060

CAMERA TRIGGER Selector

16 = pulse generator 0

LUT

( Cross Point Switch )

Pulse Generator 1

(20 bit Counter )

Pulse Generator 0

(20 bit Counter )

12 bit

Counter

TRIGGER 1

TRIGGER 2

TTL OUT 2

OPT OUT 1

OPT OUT 2

Time Stamp Reset

Sequence Reset

LVAL IN

DVAL IN

FVAL IN

EEN IN

OPT IN 1

OPT IN 2

LVDS IN

Soft Trigger 0

Soft Trigger 1

Soft Trigger 2

Soft Trigger 3

Pulse trigger IN

Pulse OUT

Pulse Generator 0

Pulse Generator 1

Digital I/O(GPIO) setting

Digital I/O(GPIO) setting

Setting for

Line Source

Setting for

Line Selector

Pixel Clock

Counter Clock Source

1

Counter Divide by value

Bypass0

1 - 4095

Pulse Generator Setting 0

Start Point Counter 0

Length counter 0

Repeat Count 0

End point counter 0

Counter 0 clear

Pulse Generator Setting 3

Pulse Generator 1

Pulse Generator 0

TTL IN

①

②

⇒

⇒

⇒

⇒

⇒

1000clk

100clk

1

530clk

4 Rising Edge

③

TTL OUT 1

OPT IN

PULSE Generator 0

OUT

100

530

1000

7.5.1 GPIO Plus PWC shutter

Example: 10µs unit pulse width exposure control (PWC).

Pixel clock is ~43MHz. 430 clocks (530-100) equals 10µs.

AT-140GE

Fig.18 Pulse Generator Timing Example 1

- 21 -

Page 24

Pulse Generator 0

100 Line

500 Line

1000 Line

output

Pulse Generator 0

100 Line

500 Line

1000 Line

output

7.5.2 Internal Trigger Generator

Address

Register

Value

0xA040

Trigger Mode

1 = EPS

①

0xB000

Clock Choice

1 = Pixel Clock

0xB004

Counter Dividing Value

1829= 1/1830 dev(Line Rate)

0xB008

Length Counter 0

1000 Clocks

0xB00C

Start point Counter 0

100 Clocks

0xB010

Repeat Count 0

0 = Free Run

0xB014

End point Counter 0

500 Clocks

0xB018

Counter Clear 0

0 = No Clear

②

0xB060

CAMERA TRIGGER Selector

11 = pulse generator 0

LUT

( Cross Point Switch )

Pulse Generator 1

(20 bit Counter )

Pulse Generator 0

(20 bit Counter )

12 bit

Counter

TRIGGER 1

TRIGGER 2

TTL OUT 2

OPT OUT 1

OPT OUT 2

Time Stamp Reset

Sequence Reset

LVAL IN

DVAL IN

FVAL IN

EEN IN

OPT IN 1

OPT IN 2

LVDS IN 1

Soft Trigger 0

Soft Trigger 1

Soft Trigger 2

Soft Trigger 3

Pulse trigger IN

Pulse OUT

Pulse Generator 0

Pulse Generator 1

Digital I/O(GPIO) setting

Digital I/O(GPIO) setting

Setting for

Line Source

Setting for

Line Selector

Pixel Clock

Counter Clock Source

1

Counter Divide by value

Bypass0

1 - 4095

Pulse Generator Setting 0

Start Point Counter 0

Length counter 0

Repeat Count 0

End point counter 0

Counter 0 clear

Pulse Generator Setting 3

Pulse Generator 1

Pulse Generator 0

TTL IN 1

①

②

⇒

⇒

⇒

⇒

⇒

1000clk

100clk

0

500clk

0 Free run

TTL OUT 1

Create a trigger signal and trigger the camera

AT-140GE

Fig.19 Pulse Generator 0 timing Example 2

- 22 -

Page 25

AT-140GE

Analog Signal [mV]

Black Level

1023

890

32

0

25

700

Digital Out [LSB]

White Clip Level

100% Level

800

CCD out

Analog Signal *

Digital Out(24-bit)

Digital Out(32-bit)

Black

Setup 3.6%, 25mV

8LSB

32LSB

200mV

700mV

222LSB

890LSB

230mV

800mV

255LSB

1023LSB

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7

R0G0B0

8. GigE Vision Streaming Protocol (GVSP)

8.1. Digital Video Output (Bit Allocation)

Although the AT-140GE is a digital camera, the image is generated by an analog component,

the CCD sensor.

The table and diagram below show the relationship between the analog CCD output level and

the digital output.

The standard setting for 10-bit video level is 890 LSB. 200 mV CCD output level equals 100%

video output.

Fig.20 Digital output (10-bit output)

8.2. Bit Allocation (Pixel Format / Pixel Type)

In the GigE Vision Interface, GVSP (GigE Vision Streaming Protocol) is used for an application

layer protocol relying on the UDP transport layer protocol. It allows an application to receive

image data, image information and other information from a device.

As for the sensors in the AT-140GE, the following pixel types supported by GVSP are available.

With regard to the details of GVSP, please refer to the GigE Vision Specification available

from the AIA (www.machinevisiononline.org).

8.2.1 GVSP_PIX_RGB8_PACKED (RGB 24bit output)

1 Byte 2 Byte 3 Byte 4 Byte

- 23 -

Page 26

AT-140GE

0 1 0 1 0 1 X X 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7

B0

B0G0R0

R0

G0

0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9 X X

R0

B0

G0

Address

Internal Name

Access

Size

Value

0xA410

Pixel Format type

R/W

4

0x02180014:RGB8Packed

0x0220001C:RGB10V1Packed

0x0220001D:RGB10V2Packed

8.2.2 GVSP_PIX_RGB10V1_PACKED (RGB 32bit output)

1 Byte 2 Byte 3 Byte 4 Byte

8.2.3 GVSP_PIX_RGB10V2_PACKED (RGB 32bit output)

1 Byte 2 Byte 3 Byte 4 Byte

9. Functions and Operations

9.1. GigE Vision Standard Interface

The AT-140GE is designed in accordance with the GigE Vision standard. Digital images are

transmitted over Cat5e or Cat6 Ethernet cables. All camera functions are also controlled via

the GigE Vision interface.

The camera can operate in Continuous mode, providing an endless stream of images. For

capturing individual images related to a specific event, the camera can also be triggered. For

precise triggering, it is recommended to use a hardware trigger applied to the Hirose 12-pin

connector. It is also possible to initiate a software trigger through the GigE Vision interface.

However, when using a software trigger, certain latency inherent to the GigE interface must

be expected. This latency, which manifests itself as jitter, greatly depends on the general

conditions and traffic on the GigE connection. The frame rate described in this manual is for

the ideal case and may deteriorate depending on conditions.

When using multiple cameras (going through a switch and/or a single path) or when operating

in a system with limited transmission bandwidth the Delayed Readout Mode and Inter-Packet

Delay functions can be useful.

9.2. Recommended Network Configurations

Although the AT-140GE conforms to Gigabit Ethernet (IEEE 802.3) not all combinations of

network interface cards (NICs) and switches/routers are suitable for use with the GigE Vision

compliant camera.

JAI will endeavor to continuously verify these combinations, in order to give users the widest

choice of GigE components for their system design.

- 24 -

Page 27

AT-140GE

Model

Pixel Type

Frame Rate

Packet data volume

(assumes the packet size is 4036)

AT-140GE

RGB8Packed

20.77 fps

732 Mbit/s

RGB10V1Packed

RGB10V2Packed

20.77 fps

(Note 1)

972 Mbit/s

9.2.1 Guideline for network settings

To ensure the integrity of packets transmitted from the camera, it is recommended to follow

these simple guidelines:

1. Whenever possible use a peer-to-peer network.

2. When connecting several cameras going through a network switch, make sure it is

capable of handling jumbo packets and that it has sufficient memory capacity.

3. Configure inter-packet delay to avoid congestion in network switches.

4. Disable screen saver and power save functions on computers.

5. Use high performance computers with multi-CPU, hyper-thread and 64-bit CPU, etc.

6. Only use Gigabit Ethernet equipment and components together with the camera.

7. Use at least Cat5e and preferably Cat6 Ethernet cables.

8. Whenever possible, limit the camera output to 8-bit.

☞ For more details regarding network settings, please refer to the “Getting Started Guide” which

is a separate document.

9.2.2 Video data rate (network bandwidth)

The video bit rate for the AT-140GE in Continuous mode is:

Note1: depending on the packet size, the frame rate of 20.77 fps may not be achieved. It

may be reduced to 18 to 19 frames per seconds. This figure will depend of the system

configuration used (RESEND not possible)

If Jumbo Frames (Max.16020) are not used, the packet data will be bigger by 2%.

If Jumbo frames are used, the packet size may be automatically optimized to a smaller size.

For details of setting Jumbo Frames, please refer to the “Getting Started Guide”.

9.2.3 Note for setting packet size

The packet size is set to 1476 as the factory default. Users may enter any value for the

packet size and the value will be internally adjusted to an appropriate, legal value that

complies with the GenICam standard. The packet size can be modified in the GigE Vision

Transport Layer Control section of the camera control tool.

Regarding data transfer rate, a larger packet size produces a slightly lower data transfer

rate. The AT-140GE can support a maximum of 16020 byte packets provided the NIC being

used has a Jumbo Frames function with a setting of a 16020 bytes or larger.

Caution: do not set the packet size larger than the maximum setting available in the

NIC or switch to which the camera is connected . Doing so will cause output

to be blocked.

- 25 -

Page 28

AT-140GE

Item

Unit

Symbol

Image Width

[pixels]

A

Image Height

[pixels]

B

Bits per Pixel

[bits]

C

Frame Rate

[fps]

D

Packet Size

[Bytes]

E

Number of Packets (including Data Leader & Trailer

Packet)

[packets]

G

Data Transfer Rate

[Mbit/s]

J

Item

Unit

value

Data Leader Packet Size

[Bytes]

90

Data Trailer Packet Size

[Bytes]

62

J={90+62+(E+18)*(G-2)}*8*D/1000000

Where, G=ROUNDUP{A*B*C/8/(E-36)}+2

Pixel format

Bit

RGB8

24

RGB10V1Packed

32

RGB10V2Packed

32

Item

Unit

Symbol

Setting

Image Width

[pixels]

A

1392

Image Height

[pixels]

B

1040

Bits per Pixel

[bits] C 24

Frame Rate

[fps]

D

20.77

Packet Size

[Bytes]

E

4036

Number of Packets (including Data Leader & Trailer

Packet)

[packets]

G

Transfer Data Rate

[Mbit/s]

J

9.2.4 Calculation of Data Transfer Rate

In order to calculate the data transfer rate, the following parameters and formula are

required.

Setting parameter

Fixed value

Formula to calculate Data Transfer Rate

The following table shows Bits per Pixel (Item C) which depends on the pixel format.

Calculation example: AT-140GE Pixel type RGB8

G=ROUNDUP {(1392 x 1024 x 24/ 8 / (4036-36)) + 2 = 1086 + 2 = 1088

J={90+62+(4036+18)x(1088-2)} x 8 x 20.77 / 1000000 = 732 Mbit/s

- 26 -

Page 29

AT-140GE

Pixel Type

Frame rate at Full Frame scan[fps]

RGB8_Packed

Approx. 2

RGB10V1_Packed,RGB10V2_Packed

Approx.1.5

750 nm700650600550

50

0

450

4

0

0

Light

CCD

CCD

CCD

B ch

A/D & process circuit

Blemish compensation

Shading compensation

Color matrix

LUT/Gamma/Knee

GigE Interface

G ch

A/D & process circuit

Blemish compensation

Shading compensation

Color matrix

LUT/Gamma/Knee

R ch

A/D & process circuit

Blemish compensation

Shading compensation

Color matrix

LUT/Gamma/Knee

750 nm700650600550

50

0

450

4

0

0

750 nm700650600550

50

0

450

4

0

0

9.2.5 Note for 100BASE-TX connection

In order to use 100Mbps network, 100BASE-TX and Full Duplex are available. Half

Duplex cannot be used.

In the case of connecting on 100BASE-TX, the maximum packet size should be 1500

bytes.

In the case the of connecting on 100BASE-TX, the specifications such as frame rate,

trigger interval and so on described in this manual cannot be satisfied.

Note: The above frame rates are based on approx. 70Mbps of total frame transfer data.

9.3. Basic Functions

9.3.1 Basic construction

The AT-140GE is a 3CCD camera equipped with F4, 1/2 inch prism optics. Red, green and blue

color signals are taken from each 1.45 mega CCD which are filtered to the red, green and

blue spectral wavelengths. A 32-bit microprocessor controls all functions in the AT-140GE

camera. The CCD sensor output is normalized in CDS and preamplifiers. The signals are then

digitized to 16 bits. Digital gain control, color matrix, look-up tables and setup can do signal

processing in 16 bits before the signal is converted to a 32- or 24-bit RGB pixel format via

GigE Vision interface.

Fig.21 Principle diagram for signal processing

- 27 -

Page 30

AT-140GE

Fast-dump period

Fast-dump period

Normal scan period

9.3.2 Modes of operation

The AT-140GE has multiple operating modes including a normal continuous mode, triggered

modes and others. In the normal continuous mode, the camera runs at 20.77 frames per

second continuously. This is used for operation when a trigger signal is not required. There

are 5 triggered modes and the trigger signal is supplied via HIROSE 12-pin or D-Sub 9-pin

connectors. In the triggered modes, the frame rate is 20 fps.

Normal continuous mode

Edge pre-select trigger mode (EPS)

Pulse width control trigger mode (PWC)

Reset continuous trigger mode (RCT)

EPS Sequential trigger mode

Frame delay readout trigger mode (EPS and PWC)

Smearless mode

OB transfer mode

Multi ROI mode

9.3.3 Partial scan (Fast Dump ON)

The partial scanning function uses the middle of the image vertically to achieve faster frame

rates. This is very useful when capturing and inspecting an image which does not require the

full height.

Full scan Partial Scan

Fig.22 Partial scan conceptual drawing

The partial scan mode for the AT-140GE is variable. The first line and the last line to be read

out can be set.

The variable scan readout is connected with the ROI settings.

1. If ROI is set, these settings are applied to the partial scan settings.

2. If the multi ROI feature is used, the smallest line number and the largest line number of

the multi ROI areas define the partial scan area.

3. When the sequence trigger is used, the situation is the same as for multi ROI. The smallest

line and the largest line define the partial scan.

In order to execute partial scanning, the fast dump setting should be ON.

The first line can be set anywhere from the 1st line to 1033rd line and the end line can be set

from the 8th line to 1040th line. This means the minimum height of the partial scan is 8 lines.

- 28 -

Page 31

AT-140GE

Image Height

Image start line

/ end line

Minimum: 8 line Maximum: 1040 lines

Image starts at 1st line

Image starts at 1033rd line

This is in case image height is 8 line

1/8

1033

/1040

8 line

1040 lines

Fig.23 Variable Partial scan

How to calculate total line number and frame rate in variable partial scan mode

Frame rate (fps) = Horizontal frequency(21.938KHz) / Total lines

Total lines = ①OB period + ②Fast Dump period in the upper part of the frame (L) +

③Effective image period (L) + ④Fast dump period in the lower part of frame

(L) + ⑤Blank period (L)

Where,

OB period = 4L (Fixed)

Blank period = 6L (Fixed)

Fast dump period for the upper part = Round up

Fast dump period for the lower part = Roud up

4+Start line 1

1040End line +2

4

4

Calculation example

Readout: 1/2 partial scan at the center (520L), Start line (261), End line (780)

OB period = 4L

Blank period =6L

Fast dump period for the upper part = (4+261-1) ÷4 +1= 66 + 1=67 67

Fast dump period for the lower part = (1040-780+2) ÷ 4 =65.5 66

Total lines = 4+67+520+66 +6 = 663

Frame rate = 21.938/ 663 =33.08 fps

+ 1

- 29 -

Page 32

AT-140GE

Setting

Effective/total

Horizontal

Frequency

Frame rate

Off (No V Binning))

1040 /1056

21.938 KHz

20.77 frames/sec.

2:1 V Binning

520 / 530

17.447 KHz

32.92 frames /sec.

Mode

Read Out

Minimum shutter speed

Maximum

shutter speed

Continuous

Edge Pre-select

Full

Partial

22.8 µs at PE=0(1/43,000s)

45.58µs x

1056L=1 Frame

(48.13 ms)

V binning

28.7 μs at PE=0(1/35,000s)

Pulse Width

Full

Partial

45.58 µs x 2L+22.9 µs( 0.5L)=

114 µs (≒1/10,000s)(Note)

42 Frames

( 2 seconds )

V Binning

57.32 µs x 2L + 28.7 µs(0.5L)=

143.3µs (≒1/8.000s)(Note)

Note: In Pulse Width mode, the minimum trigger pulse width requires more than 2LVAL.

Horizontal Direction

Vertical Direction

Full

Full

1/2

Binning

Frame rate 25.21 fps

Frame rate 40.98 fps

Normal full scanning

2 line Vertical Binning

H

H

Horizontal CCD Register

S/H

Reset

Video

Out

Xsg1

Vertical CCD Register

Pixel

9.3.4 Vertical Binning (VB)

Vertical Binning mode is a function where the signal charges from 2 adjacent (vertical) pixels

are added together and read out as one pixel. Binning results in half vertical resolution but

higher frame rate and sensitivity. The charge accumulated in 2 adjacent lines is added

together in the horizontal CCD register. This is done by providing two pulses to the vertical

CCD register for each line read out. Vertical binning cannot be used together with partial

scanning.

Fig.24 Vertical Binning

9.3.5 Electronic shutter (SM)

The AT-140GE has the following shutter modes.

Programmable Exposure (PE)

The setting command is PE and the exposure time can be controlled from 0L to 1056L in 1

LVAL units (45.58µs). Calculating actual shutter speed requires adding 0.5L to the

setting value. This is because there is 0.5L overhead.

The resulting range is from 0.5LVAL to 1056LVAL. Setting 1056L is Shutter OFF.

Programmable exposure can be set for R, G and B together or individually in EPS and RCT

modes.

The shutter speed for each operation mode is shown below.

- 30 -

Page 33

AT-140GE

FVAL

(1)

(3)

(1) In this period camera executes trigger at next LVAL (prevents feed-through noise)

(2) Avoid trigger at FVAL transition (+/- LVAL period), as the function may randomly

switch between “ next LVAL ” and “ immediate ”.

(2)

External Trigger

+/- 1 LVAL

(3)

In this period, camera executes trigger immediately ( no delay).

Exposure Time Abs (GenICam

Standard)

This is a function specified in the GenICam standard.

The shutter speed can be entered as an absolute exposure time in microseconds (μs) in

register address 0xA018. The entered absolute time (Time Abs) is then converted to a

programmable exposure (PE) value inside the camera.

The calculating formula below shows the relationship between the PE value used by the

camera for the different readout modes and the value entered in register 0xA018.

Due to rounding (decimals rounded down), some discrepancies may occur.

The relation between PE value and Time Abs

Normal readout PE= INT (Exposure time – 64.13) µs / (1958/42954000)

Vertical Binning PE= INT (Exposure time – 84.13) µs / (2462/42954000)

(Note: INT means round down.)

Note :The minimum value in normal readout is 22.8µs.

GPIO in combination with Pulse Width trigger

More precise exposure time can be obtained by using GPIO in combination with Pulse Width

mode. The clock generator and counter can be programmed in very fine increments.

For an example, refer to 7.5.1 GPIO Plus PWC shutter

Auto shutter

The AT-140GE has an automatic shutter function which sets the video at an appropriate level

depending on illumination.

Auto shutter range : 1/25 sec to 1/250 sec

9.3.6 Auto-detect LVAL-sync / async accumulation

This function replaces the manual setting found in older JAI cameras. Whether accumulation

is synchronous or asynchronous in relation to LVAL depends on the timing of the trigger input.

When a trigger is received while FVAL is high (during readout), the camera works in LVALsynchronous mode, preventing reset feed-through in the video signal. There is a maximum

jitter of one LVAL period from issuing a trigger and accumulation start.

When a trigger is received during FVAL low, the camera works in LVAL-asynchronous mode (no

delay) mode.

This applies to both Edge Pre-select (EPS) trigger mode and Pulse Width Control (PWC) trigger

mode.

Fig.25 Auto-detect LVAL sync/async accumulation

- 31 -

Page 34

AT-140GE

Video Level

Video Level

Video Level

Video Level

Fig.26 Shading compensation

9.4. Pre-processing functions

9.4.1 Shading compensation

The AT-140GE implements a digital shading compensation

circuit for the white shading which could be caused in the

prism or optical system. The whole image is divided

horizontally and vertically and uses the center level as the

reference. The circuit will compensate the difference between

the center and each divided area. The range for compensation

is a maximum of 30%. In the factory, the shading compensation

is done under the following conditions and stored in the

“Factory” area of the memory.

Lens used: Kowa 12mm F1.8 to F16

F value: F5.6

Note: Conditions for lens used with AT-140GE

In order to get an appropriate picture, it is recommended to use 1/2 inch, 3CCD lenses.

Shading is dependent on F value and focal length. Using a wide angle lens or using the

lens fully open, will cause the shading characteristics to deteriorate.

The AT-140GE has two shading compensation circuits.

1. Color shading compensation

In this mode, the shading is compensated using the G channel as the reference.

Adjust R and B channels to match the characteristics of the G channel. Use white balance

to match R, G and B levels.

Fig.27 Conceptual drawing for color shading compensation

2. Flat shading compensation

In this mode, each channel can be adjusted to achieve flat characteristics.

Fig.28 Conceptual drawing for flat shading compensation

- 32 -

Page 35

AT-140GE

Continuous

One push

Manual

Tracking range

4000K to 9,000K

4000K to 9,000K

4000K to 9,000K

Adjustable range

-6dB ~ +6dB

-6dB ~ +6dB

-6dB ~ +6dB

Store the setting value

No

Yes

Yes

8

8

Windousize X :2

Window size Y :2

Window offset X :3

Window offset Y : 3

Setting example

Fig.29 White balance measuring area

9.4.2 White balance

The AT-140GE has 4 white balance modes: manual balance, one push auto white balance,

continuous auto white balance and pre-set white balance.

The pre-set white balance can be set to 4000K, 4600K or 5600K.

The white balance of the AT-140GE is set under 7800K lighting in factory. When the camera is

started up at the first time, it is white balanced to 7800K and R and B gain settings are 0.

For executing the white balance, the entire image is

divided into 64 areas, 8 for horizontal and 8 for vertical.

The following drawing is an example of using a 2 x 2 area in the image center.

Note: In continuous mode, if the white part is not enough to make an adjustment, the white balance

may not achieve a proper white color.

Note: The completion of one push auto white requires a maximum of 5 seconds to complete.

Note: If the master gain is set less than 0dB, R and B gain can not be controlled up to -6dB. For

instance, if the master gain is set at -3dB, the saturation level of R and B gain is deteriorated

under 0dB.

9.4.3 Linear matrix

The AT-140GE incorporates a linear color matrix circuit to improve color reproduction.

As this circuit processes signals in the linear stage, before the gamma correction circuit, the

gamma circuit does not affect color reproduction.

This circuit has:

1. Linear OFF

2. sRGB Standard which HP and Microsoft specify for printers and monitors. This preset

is based on this standard.

3. Adobe RGB Standard which Adobe systems specify. This preset is based on this standard.

4. User User can manipulate R, G and B color relationships based on applications. Set

the gain for R-R, R-G, R-B, G-R, G-G, G-B, B-R, B-G, B-B to adjust.

Important Note:

If sRGB or Adobe RGB is used, please note the following procedure.

1) Achieve the white balance under the condition of D65 (6500K) illumination.

2) Gamma should be set at 0.45 and set the linear matrix at either sRGB or Adobe RGB.

3) Monitor should comply with sRGB or Adobe RGB color reproduction capability.

- 33 -

Page 36

AT-140GE

CCD out

Analog Signal

Digital Out(32bit)

Digital Out(24bit)

Black

Setup 3.6%, 25mV

32LSB

8LSB

200mV

700mV

890LSB

222LSB

230mV↑

800mV

1023LSB

255LSB

Functions

Data length

Setting range

Knee Point

10bit

0LSB ~ 1023LSB

Knee Slope

12bit

0(x0.0005) ~ 4095(x2.0000)

Defective Pixel

Video Input

Video Output

Knee Slope

Knee Point

Analog Signal [mV]

Black Level

1023

890

32

0

25

700

Digital Out [LSB]

100% Level

White Clip Level

835

9.4.4 Blemish compensation

The AT-140GE has a blemish compensation circuit.

Blemish control has 0:OFF, 1:Black, 2:White and 3:Both. When 1, 2 or 3 is selected, the

stored factory data can be loaded.

Fig.30 Conceptual drawing for blemish compensation

9.4.5 Gamma setting (Look Up Table)

The AT-140GE has various gamma settings

including LUT (Look Up Table). Gamma can be

set OFF (1.0), 0.6, 0.45, or to exhibit

characteristics set using LUT.

The following shows the typical characteristics

in the case of gamma 0.6.

Fig.31. Gamma setting

9.4.6 Knee compensation

If the relation of input and output is linear (1:1), the

output signal is saturated at a certain level of the

input signal and details cannot be reproduced in the

saturated area. The knee compensation circuit

maintains linear output up to a knee point and

compresses the level after the knee point. This is set

by a knee slope function. The AT-140GE supports up

to 200% signal compression by knee slope. Factory

default is OFF.

Fig.32 Example of Knee characteristics

- 34 -

Page 37

AT-140GE

Value

Description

0

OFF

4

Horizopntal Ramp Scale

5

Vertical Ramp Scale

6

Moving Ramp Scale

8

Normal Color Bar

9

Vertical Color Bar

10

Moving Color Bar

1 = Vertical 2 = Horizontal 3 = Both

9.5. Other functions

9.5.1 Test pattern generator (Address 0xA13C)

The AT-140GE has an internal test pattern generator. These signals are output as the last

process of the digital signal processing circuit and can be used for adjustment of the related

system. The AT-140GE has a total of 6 test pattern types.

9.5.2 Center marker

The AT-140GE is equipped with a center marker generator. The center marker can be

selected from three types as described below.

Note: The center marker is displayed only in full scan mode.

Fig.33 Center marker

- 35 -

Page 38

9.6. Sensor Layout and timing

blank

Read Out

(Vertical)

1050

Active Pixels

1392(H)x1040(V)

Optical Black Lines

Optical Black

1392

2

4

8

2

blank

1958 Clock

Read Out (Horizontal)

6

524

1434

1040

1056

9.6.1 CCD Sensor Layout

Fig.34 CCD sensor layout

AT-140GE

- 36 -

Page 39

AT-140GE

D A TA O U T

D V AL

C CD Ou t

F VA L

S UB

S G

E E N

L V A L

X E E N

(Hi rose 12pi n)

Du mmy +

Bl a n k

OB

Re s e r v ed

OB

4 0 c k

Re s e r v ed

2

1 3 9 2 ck

1 4 3 4 ck

1392 ck

1958 ck

1434 ck 524 ck

1 ck=42.954 NHz (23.28 ns/ck)

1866 ck

86 ck

92

945 ck

859 ck

86

167

20 ck

524 ck

524 ck

2 ck

FVAL Rising Edge

FVAL Falling Edge

1 LVAL Period

Effective Pixels

Exposure Period

123

4 5

D A T A O U T

D V A L

L V A L

S U B

S G

F V A L

E E N

FVA L

LVA L

1 F V A L p e r i o d

E x p o s u r e

P e r i o d

X E E N

(Hir ose 12pi n)

10 56 L

10 50 L

6L

1L = 2134Cl ock ( 36. 79us)

8L

OB

R

e

s

e

r

v

e

d

E f f e ct i v e L i n es

10 40 L

Re s er ved

B l a nk

OB

1

0

4

0

1

0

3

9

1

0

3

8

1

0

3

7

1

0

3

6

6L

2

0.5L

9.6.2. Horizontal timing (Normal continuous mode)

Fig. 35 Horizontal timing

9.6.3 Vertical timing (Normal continuous mode)

Fig.36 Vertical timing for full scan

- 37 -

Page 40

AT-140GE

D A TA O U T

D V AL

C CD Ou t

F VA L

S UB

S G

E E N

L V A L

X E E N

(Hi rose 12pi n)

Du mmy +

Bl a n k

OB

Re s e r v ed

OB

4 0 c k

Re s e r v ed

2

1 3 9 2 ck

1 4 3 4 ck

1392 ck

1958 ck

1434 ck 524 ck

1 ck=42.954 NHz (23.28 ns/ck)

1866 ck

86 ck

92

945 ck

859 ck

86

167

20 ck

524 ck

524 ck

2 ck

FVAL Rising Edge

FVAL Falling Edge

1 LVAL Period

Effective Pixels

Exposure Period

9.6.4 Horizontal timing (Partial scan mode)

Fig.37 Horizontal timing (Partial scan, the same as normal continuous)

9.6.5 Vertical timing (Partial scan mode)

Fig.38 Vertical timing (Example:1/8 partial scan setting)

- 38 -

Page 41

AT-140GE

Partial scan

examples

Effective lines

Total lines

Horizontal

Frequency

Frame rate

2/3

692

792

21.938 KHz

27.69 fps

1/2

520

663

21.938 KHz

33.08 fps

1/4

260

468

21.938 KHz

46.87 fps

1/8

128

369

21.938 KHz

59.45 fps

D A TA O U T

D V AL

C CD Ou t

F VA L

S UB

S G

E E N

L V A L

X E E N

(Hi rose 12pi n)

Du mmy +

Bl a n k

OB

1 4 3 4

1 3 9 2

1 3 9 2

1 4 3 4

OB

2

9

c k

4

0 c k

2 9 c k

467

2462

1028

1 clock =42.954 MHz (23.28ns/Clock)

86

92

2370

86

1289(30μs)

1375

1028

1028

1 LVAL period

FVAL Rising Edge

FVAL Falling Edge

Effective Pixels

Exposure Period

9.6.6 Horizontal timing (Vertical binning mode)

Fig. 39 Horizontal timing for V binning.

- 39 -

Page 42

AT-140GE

9.6.7 Vertical timing (vertical binning mode)

Fig.40 Vertical timing for V binning.

9.7. Operation Modes - Timing

9.7.1 Continuous operation

For applications not requiring asynchronous external triggering, this mode should be used. In

this mode it possible to use a lens with a video controlled iris.

For timing details, refer to fig.35. through fig.40.

To use this mode:

Set function: Exposure mode Continuous

Pixel format RGB8, 10V1, 10V2

Partial scan Fast dump ON, ROI

Vertical binning Binning vertical ON

Shutter mode Programmable, Exposure Time Abs,

Auto shutter

- 40 -

Page 43

AT-140GE

Mode

Minimum trigger interval

LVAL Sync

1056L + 3L

LVAL Async

Exposure time + 1056L + 3L

Smearless is ON

Smearless time(352L) + Maximum exposure time +1056L + 3L

Note: 1) On the above table, 1056L is FVAL interval on normal continuous mode

2) In the vertical binning mode, 1L is different from the normal scanning. So, the minimum

trigger interval will be different.

9.7.2 Edge Pre-select Trigger Mode (EPS)

An external trigger pulse initiates the capture, and the exposure time (accumulation time) is

the fixed shutter speed set by programmable exposure or Exposure Time Abs. The

accumulation can be automatically set either LVAL synchronous or LVAL asynchronous in

relation to FVAL and trigger timing.

The resulting video signal will start to be read out after the selected shutter time.

For timing details, refer to fig35 . through fig43 .

To use this mode:

Set function: Exposure mode Edge pre-select

Pixel format RGB8, 10V1, 10V2

Partial scan Fast dump ON, ROI

Vertical binning Binning vertical ON

Shutter mode Programmable, Exposure Time Abs

GPIO setting

Important notes on using this mode

Active Trigger pulse >2 LVAL to <1 FVAL

Minimum Trigger interval is shown in the following table.

Fig.41 Edge Pre-select.

- 41 -

Page 44

EPS timing LVAL sync details

1. 5L

DATA out

t1+1L( Max)

FVAL

EEN

LVAL

XEEN

( Hir ose 12pi n)

13. 5L

Ext. Trigger

Exposure Period

Exposure Delay

Data Out Delay

Exposure Period

DATA out

1 to 2L

Ext. Tri g

FVAL

EEN

LVAL

XEEN

( Hir ose 12pi n)

9. 7us

13 to 14L

Exposure

Exposure Period

Exposure delay

Data Out Delay

AT-140GE

Fig.42 Edge Pre-select LVAL SYNC details

EPS timing LVAL async details

Fig.43 Edge Pre-select LVAL ASYNC details

- 42 -

Page 45

AT-140GE

Mode

Minimum trigger interval

LVAL Sync

1.Exposure time < 1056L

1056L + 3L

2.Exposure time ≥ 1056L

Exposure time +2L

LVAL aSync

Exposure time + 1056L + 3L

Smearless is ON

Smearless time (352L) + Exposure time + 1056L + 3L

Note: 1) On the above table, 1252L is FVAL interval in normal continuous mode

2) In the vertical binning mode, 1L is different from the normal scanning. So, the minimum

trigger interval will be different.

9.7.3 Pulse Width Control Trigger Mode

In this mode the accumulation time is equal to the trigger pulse width. Here it is possible to

have a long time exposure. The accumulation can be automatically set either LVAL

synchronous or LVAL asynchronous in relation to FVAL and trigger timing. The maximum

recommended exposure time is <2 seconds.

The resulting video signal will start to be read out after the trigger’s rising edge.

For timing details, refer to fig.35 through fig.40 and fig.44 through fig.46 .

To use this mode:

Set function: Exposure mode Pulse width control

Pixel format RGB8, 10V1, 10V2

Partial scan Fast Dump ON, ROI

Vertical binning Binning vertical ON

GPIO settings

Important notes on using this mode

Trigger pulse width >2 LVAL to <2 seconds.

Minimum trigger interval is shown in the following table.

Fig.44 Pulse Width Control.

- 43 -