Jade Range Co JSFF Installation Manual

Jade Range, LLC

.

A MIDDLEBY COMPANY

FOR YOUR SAFETY

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

WARNING

RETAIN THIS MANUAL FOR FUTURE REFERE

NCE

2650 ORBITER STREET

BREA, CA 92821-6265

PHONE 800.884.5233 714.961.2400

FAX 714.961.2556

JADE DEEP FAT FRYERS

MODELS: JSFF and JTFF Series

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

NOTE: Instructions must be posted in a prominent location which will instruct the

user in the event he detects the smell of gas. This information shall be obtained from

your local gas company.

Do not store or use gasoline or other

flammable vapors or liquids in the

- Open windows

- Do not touch electric switches

- Extinguish any open flame

- Immediately call your gas company

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

Adequate clearances must be provided in front, rear and at sides of appliance for servicing.

The appliance area must be kept free and clear from combustibles. There must be no

material or obstacles obstructing the flow of combustion and ventilation air.

P/N 24-131 REV A 7/00 Page 1

CLEARANCES/INSTALLATIONS – Model JSFF

For installation in noncombustible locations only with zero inch clearances.

For installation with or without six-inch-high adjustable legs or with casters.

CLEARANCES/INSTALLATIONS – Model JTFF

Combustible

Constructions

Left Side

Right Side

Rear

Floor

For installation with six-inch-high adjustable legs or casters on combustible floors.

For installation without legs or casters on noncombustible floors.

1.1.0

Hazard Notices

1.1.1

WARNING! Once the fryer reaches operating temperature, the shortening in the kettle may be hotter

than 375 degrees F. This hot, melted shortening can burn you very badly. Do not let the hot shortening

touch your skin or clothing. Do not try to move the fryer until the shortening has cooled to 135 degrees

F. or less.

1.1.2

WARNING! The fryer may be equipped with a three-prong electrical plug. This three-prong plug is part

of a system that will protect you if something goes wrong with the electrical wiring in the fryer. Be sure

the three-prong plug is plugged into a matching three-prong socket. Do not cut or break off the large

third prong in this plug, or the protective system won’t work.

4 inches 0 inches

4 inches 0 inches

2 inches 0 inches

Combustible (when using six-inch-high legs or casters.

Noncombustible

Construction

1.1.3

WARNING! There is an open gas flame inside this fryer. The fryer can get hot enough to set

nearby materials on fire. Keep all combustible materials away from the fryer.

1.1.4

WARNING! Make sure the fryer can get enough air to keep the flame burning right. Provide

adequate clearance around air openings into the combustion chamber. When the flame is

“starved” for air, it can give off a dangerous gas called “carbon monoxide.” Even though you

cannot see or smell this gas, it can still hurt you.

1.1.5

WARNING! The fryer can also give off carbon monoxide if the flue vent is blocked. See

diagram 1. Blocking the flue vent can also cause the fryer to overheat and cause a fire hazard.

Do not set anything on top of the flue vent, or block it in any way.

P/N 24-131 REV A 7/00 Page 2

Kettle

Fill-to line on kettle

Diagram 1

Do not block the flue vent!

1.2.0

Lighting and Shutdown

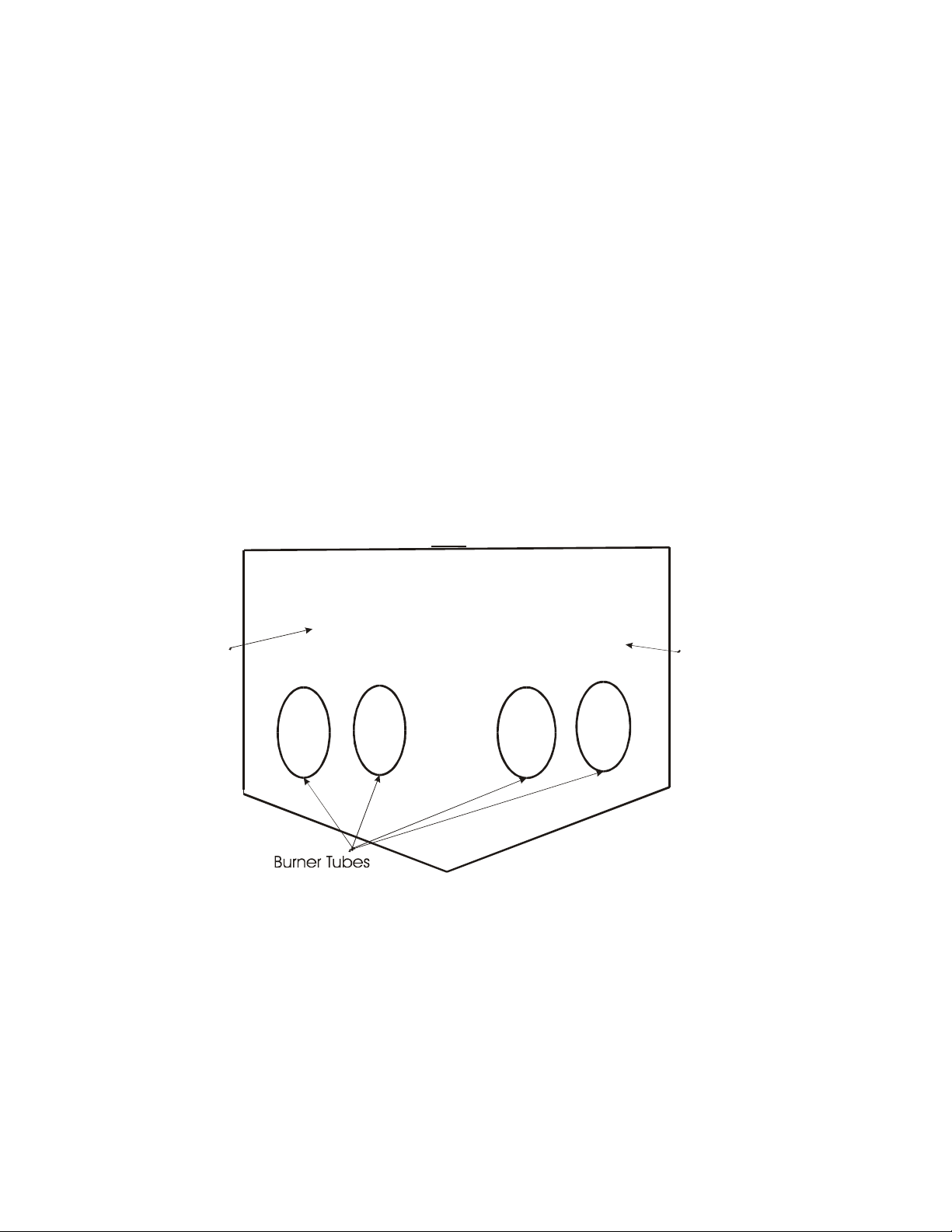

WARNING! Be sure the burner tubes are completely covered with fluid before you try to light

either the pilot or main burners. See diagram 2. If the burners are lit without fluid in the kettle,

the fryer may overheat. This may damage the kettle and void the warranty, and also may create

a fire hazard.

1.2.1

Shortening

Diagram 2

Be sure the burner tubes are

covered before you light the burners!

P/N 24-131 REV A 7/00 Page 3

Lighting the Pilot

a) Open all the gas cocks that supply gas to the fryer. (Some installations may not have these valves.)

b) Turn the thermostat control knob counterclockwise to the lowest setting.

c) Turn the gas valve knob to the “Pilot” position and push it inward. See diagram 3.

d) While you’re holding the knob in, light the pilot burner.

e) Keep pushing the knob in, and let the pilot burn for 30 to 60 seconds.

f) Release the knob. The pilot should keep burning.

g) If the pilot goes out when you release the knob, repeat Steps d), e) and f).

1.2.2

Lighting the Main Burner

a) Be sure the pilot is lit.

b) Turn the gas valve knob to “ON.” See diagram 4.

c) Set the thermostat control knob to the desired temperature. (You may want to check the calibration

of the thermostat control. Section 2.6 of the Operator’s Manual tells you how to do this.)

d) If your fryer is equipped with an electrical power switch, turn this switch “ON” also.

e) The main burners should light and stay on until the shortening in the kettle is heated to the

temperature you set earlier.

Diagram 3 Diagram 4 - Diagram 5

“Pilot” Position “On” Position “Off” Position

P/N 24-131 REV A 7/00 Page 4

1.2.3.1

Complete Shutdown

Shut down the fryer completely whenever you leave it unattended for a long time – especially overnight.

Do not leave the pilot burning.

a) If your fryer is equipped with an electrical power switch, turn this switch to the “OFF” position.

b) Turn the thermostat control knob counterclockwise to the lowest setting.

c) Turn the gas valve knob clockwise to the “Pilot” position. See diagram 3.

d) Push in the knob and turn it clockwise just a bit more.

e) Depress the knob. Continue turning it clockwise to the “Off” position. See diagram 5.

f) Do not relight the fryer for at least 5 minutes. This allows time for extra gas to clear from the fryer.

1.2.3.2

Standby Shutdown

You can leave the fryer on “standby” for a short time. Do not leave the fryer this way overnight.

a) If your fryer is equipped with an electrical power switch, turn this switch to the “OFF” position.

b) Turn the thermostat control knob counterclockwise to the lowest setting.

c) Turn the gas valve knob clockwise to the “Pilot” position. See diagram 3.

1.3.0

Assembly Instructions

1.3.1

Receiving

a) Unpack the fryer from its packing container. Check the fryer and any accessories to be sure they

weren’t damaged during shipment.

b) If you do notice damage, report it to the trucking company that brought the fryer. You should report

any damage within 15 days of the time you receive the fryer.

1.3.2.1

Assembling Legs

The legs may be installed at the factory. If they are not, be sure to install them before you connect the

gas supply line. This will meet sanitation requirements, and will assure an adequate supply of air to the

burners. Section 1.1.4 explained the danger from carbon monoxide when the fryer can’t get enough air.

a) Attach each leg using four ¼-20 x 5/8 hex-head cap screws, with hex nuts and lockwashers. These

parts are supplied with the fryer. Be sure the screws are tight.

b) Mount the screws so the heads are inside the fryer, and the points face outward.

P/N 24-131 REV A 7/00 Page 5

c) It may be easier to attach the legs if you set the fryer on its side or back. If you do this, be sure to

protect the outside of the fryer with cardboard when you lay it down. When you stand the fryer up

again, be careful not to put too much weight on any one leg or pair of legs.

1.3.2.2

Heat Deflector

a) If your fryer requires a heat deflector, you will find a removeable label at the rear top edge of the

fryer. This label will tell you where to put the heat deflector.

b) Attach the heat deflector as shown on the label. Use two #8 x ½ self-tapping screws. These screws

are supplied with the fryer.

c) The angled part of the deflector should extend toward the front of the fryer, over the flue opening. Be

careful not to let anything block the flue opening itself. Section 1.1.5 explained why this is

dangerous.

1.3.2.3

Splash Guard and Flue Pipe

(applies to models 20, 24, 24P, 26, 26P, 34 and 34P.)

a) Remove the two 10-24 x ½ flat head machine screws which are located on each cabinet side just to

the rear of the kettle.

b) Remove the three #10 x 5/8 self-tapping screws located at the top corners and top center of the

cabinet back.

c) Place the splashguard over the top edge of the rear of the kettle, and over the top rear corners of the

fryer cabinet.

d) Align the five holes in the splashguard with the matching holes in the fryer, and replace the screws

you removed in Steps a) and b). Tighten the screws.

e) Fit the flue pipe down inside the opening in the top of the splashguard. The top of the flue pipe fits

over the collar at the top of the flue box, behind the kettle. The top of the flue pipe should sit about ½

inch below the top edge of the splashguard.

1.3.2..4

Installing the Drainboard

a) Lay the drainboard assembly face down on the top of the fryer. The 3/8” holes will attach to the legs.

If you’re going to attach the drainboard to the left side of the fryer, set the drainboard so these holes

are at the left end of the board. To attach the drainboard to the right side of the fryer, set the

drainboard so these holes are on the right side of the board.

b) Slide the hinge rod through the clearance holes in the drainboard, sliding from front to back.

P/N 24-131 REV A 7/00 Page 6

c) The spacer is a hollow tube that is ½ inch in diameter and 2-5/8 inches long. Slide this spacer over

the part of the hinge rod that protrudes from the rear hole in the drainboard. Insert the rear end of the

hinge rod through the matching hole on the splashguard.

d) Your fryer may include a 3/8-16 x ¾ hex-head cap screw on the top front corner of the kettle. If your

fryer includes this screw, remove it.

e) Locate the 3/8-16 x 2-1/2 hex-head screw that is supplied with the fryer. Fit the matching washer

under the head of this screw, then slide the screw through the hole in the hinge rod post, and thread

the end of the screw into the matching hole in the side of the fryer. Tighten the screw securely.

f) Pivot the drainboard to the right (or left, depending on the direction you want the drainboard to extend

from the fryer). Both support legs should drop into position against the cabinet side. The pitch of the

drainboard can be adjusted. To adjust the drainboard, support the weight of the board. Loosen the

thumb screws holding the support legs in place. Slide the support legs toward the cabinet side to

increase the pitch, and away from the cabinet side to decrease the pitch. Once the desired setting

has been obtained, retighten the thumbscrews into the appropriate adjustment hole of the support

legs.

g) When you’re not using the fryer, swing the board back over the kettle as a protective cover.

1.4.0

Utilities

All gas service, electric service, and ventilation must comply with local codes.

1.4.1

Electrical Connections

If local electrical codes do not apply, follow the National Electrical Code as you install the electrical

service. In Canada, follow C.S.A. Standard C22.1 and/or local codes. The wiring diagram(s) will be

located on the inside of the door.

1.4.1.1

Electrical Grounding

a) WARNING! This fryer is equipped with a three-prong (grounding) plug for your protection against

shock hazard. This plug should be plugged directly into a properly grounded three-prong socket. Do

not cut or remove this grounding prong from this plug.

b) Fryers shipped to Canada are not equipped with power supply cords. Be sure the fryer is correctly

grounded.

c) The fryer, when installed, must be electrically grounded in accordance with local codes, or in

absence of local codes, with the National Electric Code, ANSI/NFPA 70-1990.

1.4.2

Fuel Gas Service

If local codes to not apply, install the fuel gas service in accordance with the National Fuel Gas Code,

ANSI Z223.1-1988. In Canada, install the fryer in accordance with CAN1-B149.1 and .2 and/or local

codes.

1.4.2.1

P/N 24-131 REV A 7/00 Page 7

Loading...

Loading...