Jade JTRH, JMRH, JTRHE Service Manual

Service

Manual

REVIEW COPY 7

Manual number 3000012221

TITAN™

SERIES

SUPER HEAVY DUTY

RANGE LINE

MODEL SERIES JTRH, JMRH & JTRHE

POWERONBLOWER

P.O.

LITEOFF

WARNING

WHEN MAIN GAS TO THE

APPLIANCE IS OFF, POWER

ON SWITCH MUST BE OFF.

THERMOSTAT

0

5

5

500

0

5

4

G

N

I

K

A

B

400

350

WARNING

TURN OFF ELECTRIC & GAS

TO APPLICNCE BEFORE

SERVICING ALL CONTROLS

U

T

E

N

I

M

60

55

50

45

40

25

35

30

AUTO

O

F

F

MANUAL

1

5

0

200

L

O

2

R

5

O

A

0

S

T

300

S

0

5

10

15

20

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Jade Range LLC

A MIDDLEBY COMPANY 2650 Orbiter Street, Brea, CA 92821 • 714-961-2400 • 800-884-5233 • www.jaderange.com

NOTES:

IN LINE WITH ITS POLICY TO CONTINUALLY IMPROVE ITS PRODUCTS, JADE RANGE, INC. RESERVES THE RIGHT TO CHANGE MATERIALS AND SPECIFICATIONS WITHOUT NOTICE.

JADE RANGE EQUIPMENT IS BUILT TO COMPLY WITH APPLICABLE STANDARDS FOR MANUFACTURERS. INCLUDED AMONG THOSE APPROVAL AGENCIES ARE UL, A.G.A., CSA, ETL AND OTHERS.

TitanTM Series Heavy Duty Range

Model Series JTRH, JMRH & JTRHE

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

ELECTRICAL AND GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP

AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR PERFORMING

MAINTENANCE ON THE EQUIPMENT.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED FROM THE

LOCAL GAS SUPPLIER.

WARNING

Failure to follow instructions in this manual can cause property damage, injury or death.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death.

Gas connections should be performed only by a certified professional.

Gas connections must comply with the applicable portions of the National Gas Code and/or all local

gas codes. Failure to comply with this procedure can cause property damage, injury or death.

Before connecting the equipment to the gas supply, verify that the gas connections agree with the

specifications on the data plate. Failure to comply can cause property damage, injury or death.

Before performing any service that involves electrical connection or disconnection and/or exposure

to electrical components, always perform the Electrical LOCKOUT/TAGOUT Procedure. Disconnect

all circuits. Failure to comply with this procedure can cause property damage, injury or death.

Before connecting the gas supply line, it must be purged to remove any contaminates. Failure to

comply can cause property damage.

REVIEW COPY 7

WARNING

WARNING

WARNING

WARNING

All gas joints disturbed during service must be checked for leaks. Do not use an open flame. Use a

hazardous gas tester or a soap and water solution. Bubbles indicate a gas leak. Failure to comply

can cause property damage, injury or death.

SM-2

WARNING

Jade Range LLC – A Middleby Company

TM

Titan

Series Heavy Duty Range

Model Series JTRH, JMRH & JTRHE

WARNING

Do not use an open flame to test for a gas leak. Use a hazardous gas tester or a soap and water

solution. Bubbles indicate a gas leak. Failure to comply can cause property damage, injury or death.

WARNING

If a gas leak is detected, do not operate this or any other equipment until the leak has been properly

repaired and residual gas has dissipated. Failure to comply can cause property damage, injury or death.

WARNING

If a gas odor is detected, shut down the equipment at main shutoff valve and contact the local gas

company or gas supplier for service. Failure to comply can cause property damage, injury or death.

WARNING

Before performing any service that involves gas connection or disconnection and/or exposure to

gas, always follow the Gas LOCKOUT/TAGOUT Procedure. Failure to comply can cause property

damage, injury or death.

WARNING

Do not operate this equipment without properly placing and securing all covers and access panels.

Electrical and grounding connections must comply with the applicable portions of the National

Electric Code and/or all local electric codes.

Equipment equipped with a flexible electric supply cord are provided with a three-prong grounding

plug. It is imperative that this plug be connected into a properly grounded three-prong receptacle.

If the receptacle is not the proper grounding type, contact an electrician. Do not remove the

grounding prong from the plug.

REVIEW COPY 7

WARNING

WARNING

WARNING

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS AT MAIN SHUTOFF VALVE

AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

DO NOT ATTEMPT TO OPERATE THIS DEVICE.

Jade Range LLC – A Middleby Company

FOR YOUR SAFETY

IN THE EVENT OF A POWER FAILURE,

SM-3

TM

Series Heavy Duty Range

Titan

Model Series JTRH, JMRH & JTRHE

TABLE OF CONTENTS

GENERAL ...................................................................................................................................................... 6

INSTALLATION ...................................................................................................................................... 6

OPERATION........................................................................................................................................... 6

CLEANING.............................................................................................................................................. 6

TOOLS .................................................................................................................................................... 6

Standard ........................................................................................................................................... 6

Special .............................................................................................................................................. 6

JTRH GAS / BTU / BURNER SPECIFICATIONS................................................................................ 7

REMOVAL AND REPLACEMENT OF PARTS............................................................................................ 8

COMPONENT LOCATOR, EXTERIOR................................................................................................. 8

COMPONENT LOCATOR, MANIFOLD ................................................................................................ 9

COMPONENT FUNCTION .................................................................................................................... 9

ELECTRICAL LOCKOUT/TAGOUT PROCEDURE........................................................................... 10

GAS LOCKOUT/TAGOUT PROCEDURE.......................................................................................... 10

Gas Leak Test................................................................................................................................10

COVERS AND PANELS....................................................................................................................... 11

Manifold Cover, Top Section......................................................................................................... 11

Convection Oven Control Panel.................................................................................................... 11

Ove n D oo r ...................................................................................................................................... 11

Oven Kick Panel............................................................................................................................. 12

COMP ON EN T R EM OV AL.................................................................................................................... 12

Top Section Open Burner and Orifices ........................................................................................ 12

Top Section Valves: Burner, Oven Shut-off, and Pilot ................................................................ 13

Pilot Valves: Top Section Burners .............................................................................................. 13

Burner Valves: Top Section Burners ........................................................................................... 13

Oven Shut-Off Valves .................................................................................................................... 14

Fan Motor Switches and Indicator Light ....................................................................................... 14

Oven Door Switch .......................................................................................................................... 15

Thermostat and Thermocouple..................................................................................................... 16

Oven Pilot Control Valve with Dropout of 20 - 30+ Seconds........................................................ 16

Ignition Module............................................................................................................................... 17

Oven Pilot Assembly /Thermocouple ............................................................................................ 18

Oven Burner Gas Orifice ............................................................................................................... 18

Oven Burner Assembly.................................................................................................................. 19

Oven Timer..................................................................................................................................... 19

Motor and Blower Assembly.......................................................................................................... 20

REVIEW COPY 7

SM-4

Jade Range LLC – A Middleby Company

TM

Titan

Series Heavy Duty Range

Model Series JTRH, JMRH & JTRHE

SERVICE PROCEDURES AND ADJUSTMENTS .................................................................................... 21

GAS SUPPLY PRESSURE CHECK .................................................................................................... 21

GAS PRESSURE REGULATOR VALVE ADJUSTMENT .................................................................. 22

Check for insufficient gas volume ................................................................................................. 22

TOP BURNER PILOT LIGHT ADJUSTMENT..................................................................................... 22

OVEN PILOT LIGHT ............................................................................................................................ 23

AIR SHUTTER ADJUSTMENT ............................................................................................................ 23

If the flame is soft, lazy, or yellow: ................................................................................................ 23

If the flame is lifting off the burner: ............................................................................................... 23

TOP BURNER ADJUSTMENT ............................................................................................................ 24

OVEN BURNER ADJUSTMENT .......................................................................................................... 24

OVEN THERMOSTAT ADJUSTMENT ................................................................................................ 25

Oven Thermostat Test and Calibration ........................................................................................ 25

GRIDDLE THERMOSTAT TEST AND CALIBRATION ...................................................................... 26

IGNITION MODULE CIRCUIT CHECK ............................................................................................... 27

PILOT IGNITER INSPECTION AND ADJUSTMENT ......................................................................... 28

DOOR SWITCH TEST ......................................................................................................................... 29

CONVECTION OVEN MOTOR TEST ................................................................................................. 29

Motor Not Working ......................................................................................................................... 29

Motor Works – Noisy or Does Not Sound Right .......................................................................... 30

BURNER INSPECTION AND REPAIR ................................................................................................ 30

Nozzle and Orifice Check .............................................................................................................. 30

REVIEW COPY 7

TROUBLESHOOTING ................................................................................................................................31

SEQUENCE OF OPERATION – CONVENTIONAL OVEN ................................................................ 31

SEQUENCE OF OPERATION – CONVECTION OVEN .................................................................... 31

CONVECTION OVEN WIRING DIAGRAM ......................................................................................... 32

TROUBLESHOOTING CHART ............................................................................................................ 33

COMMERCIAL EQUIPMENT LIMITED WARRANTY ............................................................................... 39

Jade Range LLC – A Middleby Company

SM-5

GENERAL

TitanTM Series Heavy Duty Range

Model Series JTRH, JMRH & JTRHE

Jade Titan ranges are produced with the finest

workmanship and materials. Proper installation,

usage and maintenance will result in many years

of reliable service.

Before performing maintenance on the range,

thoroughly read this manual and carefully follow

the instructions in the order given.

This manual is applicable to the Jade Titan ranges

listed on the cover page. Procedures in this manual

apply to all models unless specified otherwise.

Pictures and illustrations apply to all models unless

specified otherwise.

REVIEW COPY 7

INSTALLATION

Refer to the Installation and Operation manual.

OPERATION

Refer to the Installation and Operation manual.

CLEANING

Refer to the Installation and Operation manual.

TOOLS

Standard

Standard set of hand tools

VOM with A.C. current tester (Any quality VOM

with sensitivity of 20,000 Ohms/Volt)

Special

Automotive Drum Brake Spring Installation Tool

(For Spring Replacement and Oven Door

Removal)

Temperature Tester (Thermocouple type)

Gas leak detection equipment

Gas pressure manometer

SM-6

Jade Range LLC – A Middleby Company

TM

Titan

Series Heavy Duty Range

Model Series JTRH, JMRH & JTRHE

JTRH GAS / BTU / BURNER SPECIFICATIONS

FEA TURE Burner Type Burner BTU’s Natural Propane

Orifice Part Orifice Part

Size No. Size No.

.C.W "01 @.C.W "5 @.oN traP

Current

Open Burner front 2-Piece lift off Hex Head 3000010836 35K 39 4620800000 50 4611900000

Open Burner rear 2-Piece lift off Hex Head 3000010835 35K 39 4620800000 50 4611900000

Fire-N-Ice Saute’ Burners Hex Head bolt-on 920 burner 8492300000 20K 46 4622200000 55 4621100000

Step-Up Burner (4 across) Hex Head bolt-on 915 burner 8406200000 15K 51 4624500000 57 4624600000

Step-Up Burner (3 across) 2-Piece lift off Hex Head 3000010836 30K 39 4620800000 50 4611900000

**Open Burners with “S” grates 2-Piece lift off Hex Head n/a 27K 43 4620700000 53 4621700000

Hot Top Tubular U-burner 1317510090 35K 41 4622900000 52 4621400000

Half Hot Top (rear only) 2-Piece lift off Hex Head 3000010836 15K 51 4624500000 57 4624600000

Griddle (manual control) Tubular U-burner 2500010209 30K 39 4620800000 52 4621400000

Griddle (t-stat control) Tubular U-burner 2500010209 25K 43 4620700000 53 4621700000

French Graduated Hot Top 2-Piece lift off Hex Head 3000010836 30K 41 4622900000 52 4621400000

Plancha 2-Piece lift off Hex Head 3000010836 15K 46 4622200000 56 4621200000

Plancha Tubular U-burner 2500045000 20K 46 4622200000 55 4621100000

Char-Broiler Straight tubular burner 1210600000 15K 51 4624500000 57 4624600000

Robata/Satay Infra-Red burner 1212200000 37K 34 3000012091 49 4626800000

Oven (standard) Tubular U-burner 2500010209 35K 37 4624300000 50 4611900000

Oven (convection) Tubular U-burner 2500010209 30K 41 4622900000 52 4621400000

Pilot for standard oven Pilot only (nat) 4616600100 n/a #18 4617900000 #10 4623700000

Pilot for convection oven Pilot w/electrode (nat) 4619600000 n/a #18 4617900000 #10 4623700000

REVIEW COPY 7

Non-current

Pre ’01

Open Burner front Hex head bolt-on 920 burner 8492300000 20K 44 4621500000 55 4621100000

Open Burner rear Hex head bolt-on 920 burner 8492500000 20K 44 4621500000 55 4621100000

’01-’05

Open Burner front Lift off (donut) style 2500128430 35K 37 4624300000 50 4611900000

Open Burner rear Lift off (donut) style 2500128431 35K 37 4624300000 50 4611900000

Pre ’09

French Graduated Hot Top Round (mfg) burner 1322200090 30K 39 4620800000 52 4621400000

Regulators

Specification Model Part No. Capacity

3/4 x 3/4 nat gas RV-48LT 4613500000 250K

3/4 x 3/4 propane RV-48LT 4613400000 250K

1 x 1 nat gas RV-61 4613700000 750K

1 x 1 propane RV-61 4615800000 750K

1 1/4 x 1 1/4 nat gas RV-61 4613200000 1.1M

1 1/4 x 1 1/4 propane RV-61 4614000000 1.1M

1 1/4 x 1 1/4 **hi-capacity nat **RV-81 4629400000 2.5M

Jade Range LLC – A Middleby Company

SM-7

TM

Series Heavy Duty Range

Titan

Model Series JTRH, JMRH & JTRHE

REMOVAL AND REPLACEMENT OF PARTS

COMPONENT LOCATOR, EXTERIOR

POWERONBLOWER

P.O.

AUTO

O

F

F

LITEOFF

MANUAL

WARNING

WHEN MAIN GAS TO THE

APPLIANCE IS OFF, POWER

ON SWITCH MUST BE OFF.

THERMOSTAT

150

550

200

L

500

O

25

R

0

O

A

0

S

45

T

G

N

30

I

K

A

REVIEW COPY 7

B

400

WARNING

TURN OFF ELECTRIC & GAS

TO APPLICNCE BEFORE

SERVICING ALL CONTROLS

N

I

M

60

55

50

45

40

35

0

0

35

U

T

E

S

0

5

10

15

20

25

30

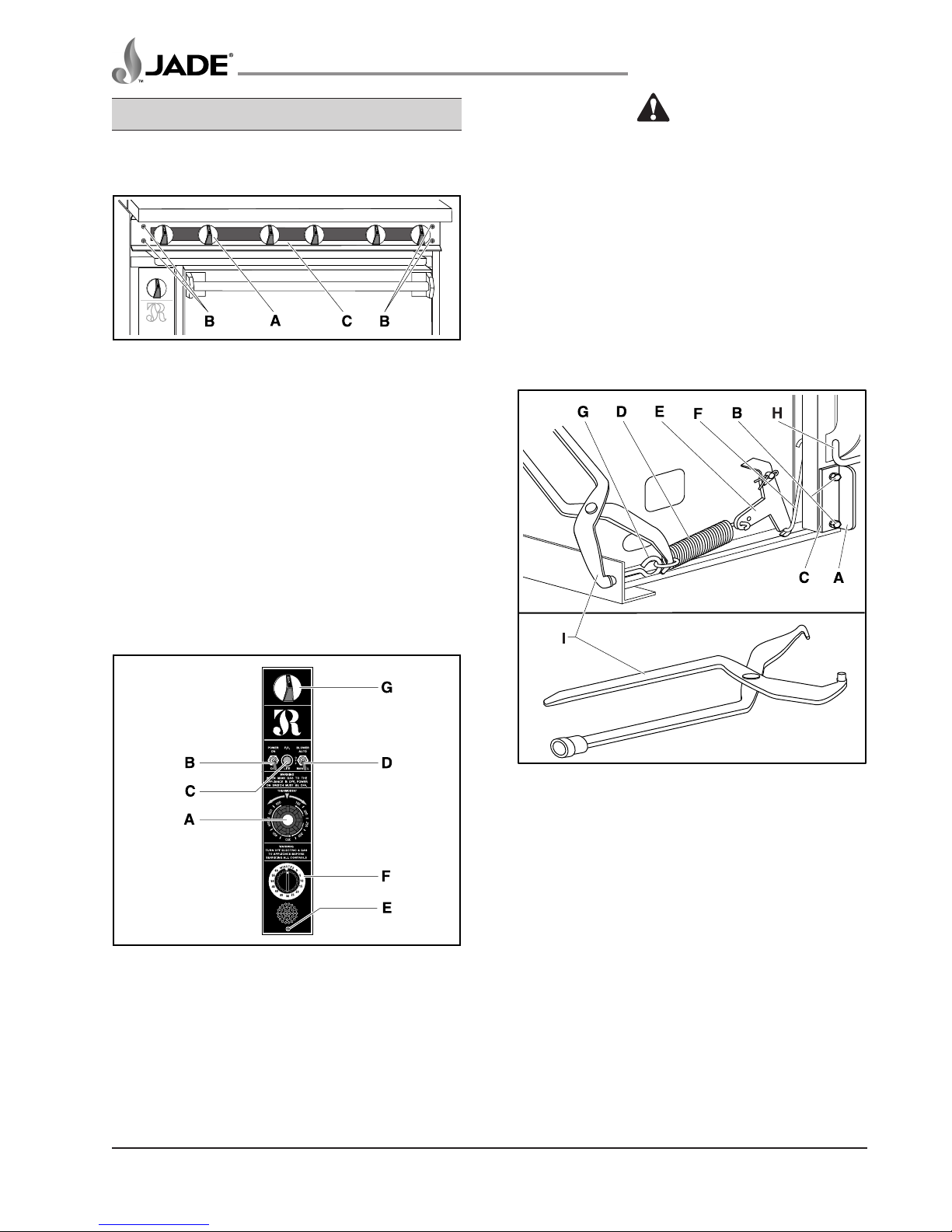

Figure 1: Component Locator, Exterior

A. Burner Grates

B. Burner Control Valves

C. Oven Gas Shut-Off Valve

D. Alternate Oven Shut-Off Valve Location

(Some models)

E. Power ON (P.O.) Light

F. Blower AUTO/MANUAL Switch

G. Power ON/OFF Switch

H. Thermostat Knob

I. Ove n Timer (Optional)

J. Electrical Junction Box

K. Power Cord

L. Fan Power Cord

M. Convection Fan Motor

N. Capacitor Cover (Capacitor located under

cover)

SM-8

Jade Range LLC – A Middleby Company

TM

Titan

Series Heavy Duty Range

Model Series JTRH, JMRH & JTRHE

COMPONENT LOCATOR,

MANIFOLD

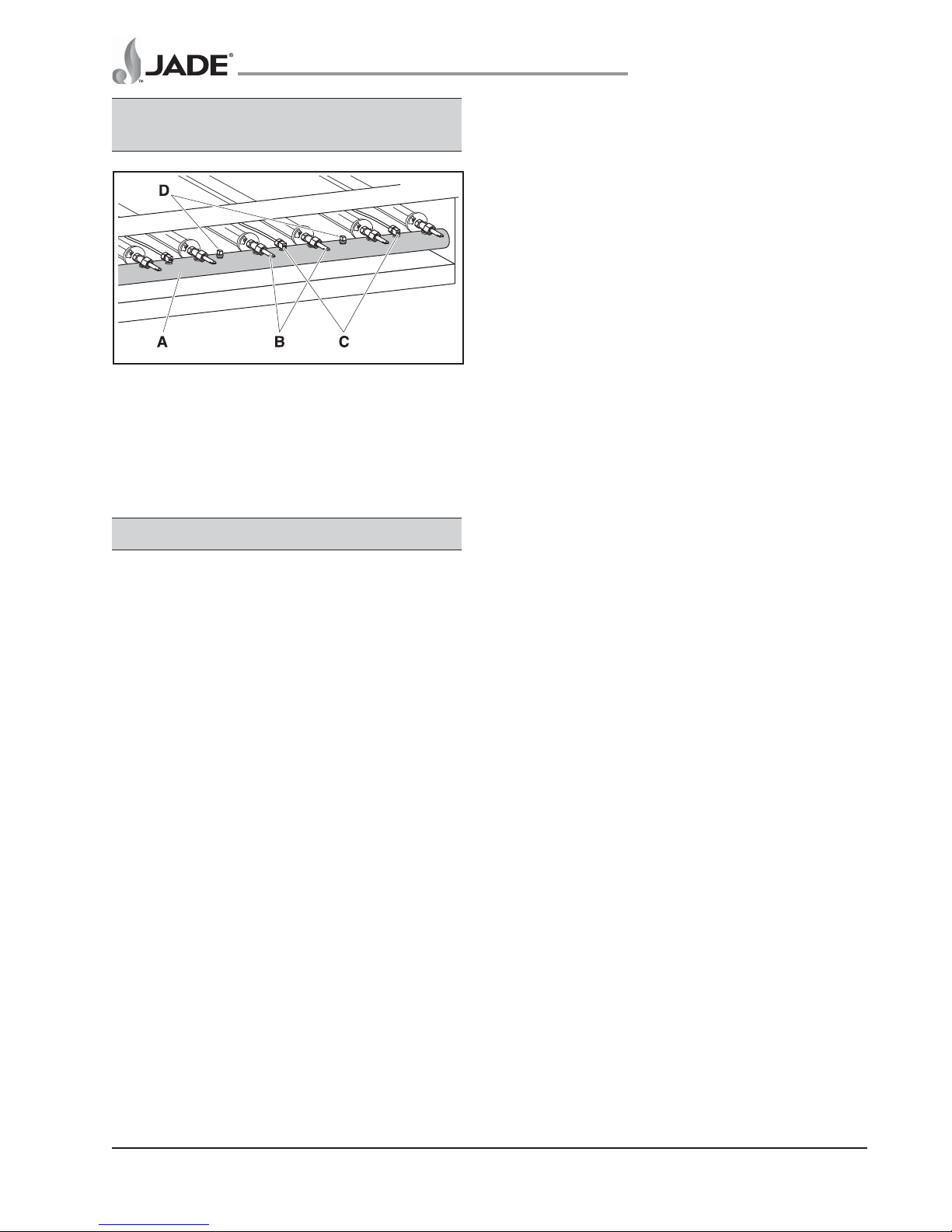

Figure 2: Component Locator, Manifold

A. Manifold

B. Burner Controls (w/Orifices)

C. Pilot Adjustment Valves

D. Pressure Test Plugs

COMPONENT FUNCTION

Control Valves, Top Burners

Brass control valves are used by the operator to

turn on/adjust the gas supply to the burners.

Control Valve, Oven Gas Supply Shut-off

The oven gas shut-off valve turns the gas to the

oven on or off.

Oven Door Switch (Convection models only)

The door switch is located under the oven control panel.

When the oven door opens, the switch opens the circuit

shutting off the fan motor. If door plunger switch has

failed, the AUTO/MANUAL switch will not shut off the fan.

Ignition Module (Convection models only)

The ignition module controls and supplies high

voltage to the oven pilot igniter.

Manifold

The gas supply manifold is located behind the top

section burner knobs. The burner control valves

are attached to the manifold, which is a large pipe

full of gas under pressure.

Motor, Convection Oven

The single-phase convection oven motor circulates

oven heated air. The motor electrical circuit is routed

REVIEW COPY 7

through door switch and through the blower AUTO/

MANUAL switch. The door closes the door switch and

allows voltage to flow from the door switch to the motor.

The motor should operate with the door open when the

blower switch is in the manual position.

Orifice

Each burner is supplied with gas through an

orifice.

Pressure Regulator

The pressure regulator regulates the incoming supply

pressure to keep the pressure of gas in the range at

a constant level (5" WC nat., 10" WC propane).

Oven Pilot and Control Valve Assembly

The safety control valve senses the presence of

the pilot light via the thermocouple and opens the

gas valve to the oven only when the pilot light is lit.

Thermocouple/Safety Control Valve

The thermocouple on the pilot safety valve

prevents gas from being sent to the oven burners

unless the pilot light is on.

Pilot Valve Assembly, Top Burners

Adjustable valves in the gas manifold control

the flow of gas to the individual pilot lights for

the top burners.

Oven Thermostat

The thermostat regulates oven temperature by

regulating the gas flow to the oven as required to

maintain oven temperature.

Oven Timer (Optional)

The oven timer control provides an audible alert

after a specific time interval.

Junction Box (Convection models only)

The junction box is located at the rear of the range

and is the connection point for electrical wires that

control the convection fan motor.

Power Cord (Convection models only)

The power cord connects the range to the power

source. The convection oven will not operate

unless connected to an electrical power supply.

Conventional ovens and top burners do not require

electrical power to operate.

Jade Range LLC – A Middleby Company

SM-9

TitanTM Series Heavy Duty Range

Model Series JTRH, JMRH & JTRHE

ELECTRICAL LOCKOUT/

TAGOUT PROCEDURE

WARNING

BEFORE PERFORMING ANY SERVICE THAT

INVOLVES ELECTRICAL CONNECTION OR

DISCONNECTION AND/OR EXPOSURE TO

ELECTRICAL COMPONENTS, ALWAYS

PERFORM THE ELECTRICAL LOCKOUT/

TAGOUT PROCEDURE. DISCONNECT ALL

CIRCUITS. FAILURE TO COMPLY CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH.

The Electrical LOCKOUT/TAGOUT Procedure is

used to protect personnel working on an electrical

equipment. Before performing any maintenance

or service that requires exposure to electrical

components, follow these steps:

1. In electrical box, place equipment circuit

breaker into OFF position.

2. Place a lock or other equipment on electrical

box cover to prevent someone from placing

circuit breaker ON.

REVIEW COPY 7

The Gas LOCKOUT/TAGOUT Procedure is used to

protect personnel working on a gas equipment.

Before performing any maintenance or service that

requires gas disconnections, follow these steps:

1. Locate the gas shutoff valve or inlet.

2. Place the valve in the OFF position.

3. Place a tag on the valve indicating that service

is being performed on equipment and the gas

must remain off until service is complete.

4. Place a locking device on the gas valve or

inlet, preventing connection until the lock is

removed.

5. On the equipment, make sure all flame sources

are extinguished and/or removed.

6. Bleed residual gas from the equipment inlet

line and allow time for the gas to dissipate

before beginning service on the equipment.

Gas Leak Test

WARNING

3. Place a tag on electrical box cover to indicate

that equipment has been disconnected for

service and power should not be restored until

tag is removed by maintenance personnel.

4. Disconnect equipment power cord from

electrical outlet.

5. Place a tag on the cord to indicate that

equipment has been disconnected for service

and power should not be restored until tag is

removed by maintenance personnel.

GAS LOCKOUT/TAGOUT

PROCEDURE

WARNING

BEFORE PERFORMING ANY SERVICE

THAT INVOLVES GAS CONNECTION OR

DISCONNECTION AND/OR EXPOSURE TO

GAS, ALWAYS FOLLOW THE GAS LOCKOUT/

TAGOUT PROCEDURE. FAILURE TO COMPLY

CAN CAUSE PROPERTY DAMAGE, INJURY

OR DEATH.

ALL GAS JOINTS DISTURBED DURING

SERVICE MUST BE CHECKED FOR LEAKS.

DO NOT USE AN OPEN FLAME. USE A

HAZARDOUS GAS TESTER OR A SOAP AND

WATER SOLUTION. BUBBLES INDICATE A

GAS LEAK. FAILURE TO COMPLY CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH.

WARNING

IF A GAS LEAK IS DETECTED, DO NOT

OPERATE THIS OR ANY OTHER EQUIPMENT

UNTIL THE LEAK HAS BEEN PROPERLY

REPAIRED. FAILURE TO COMPLY CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH.

After completing service on any gas equipment,

all gas joints disturbed during service must be

checked for leaks. DO NOT USE AN OPEN

FLAME. Use a hazardous gas tester or use a soap

and water solution as follows:

1. Apply a soap and water solution to gas joint

and check for bubbles.

2. If bubbles are present, the joint is leaking and

must be repaired before using the equipment.

SM-10

Jade Range LLC – A Middleby Company

TM

Titan

Series Heavy Duty Range

Model Series JTRH, JMRH & JTRHE

COVERS AND PANELS

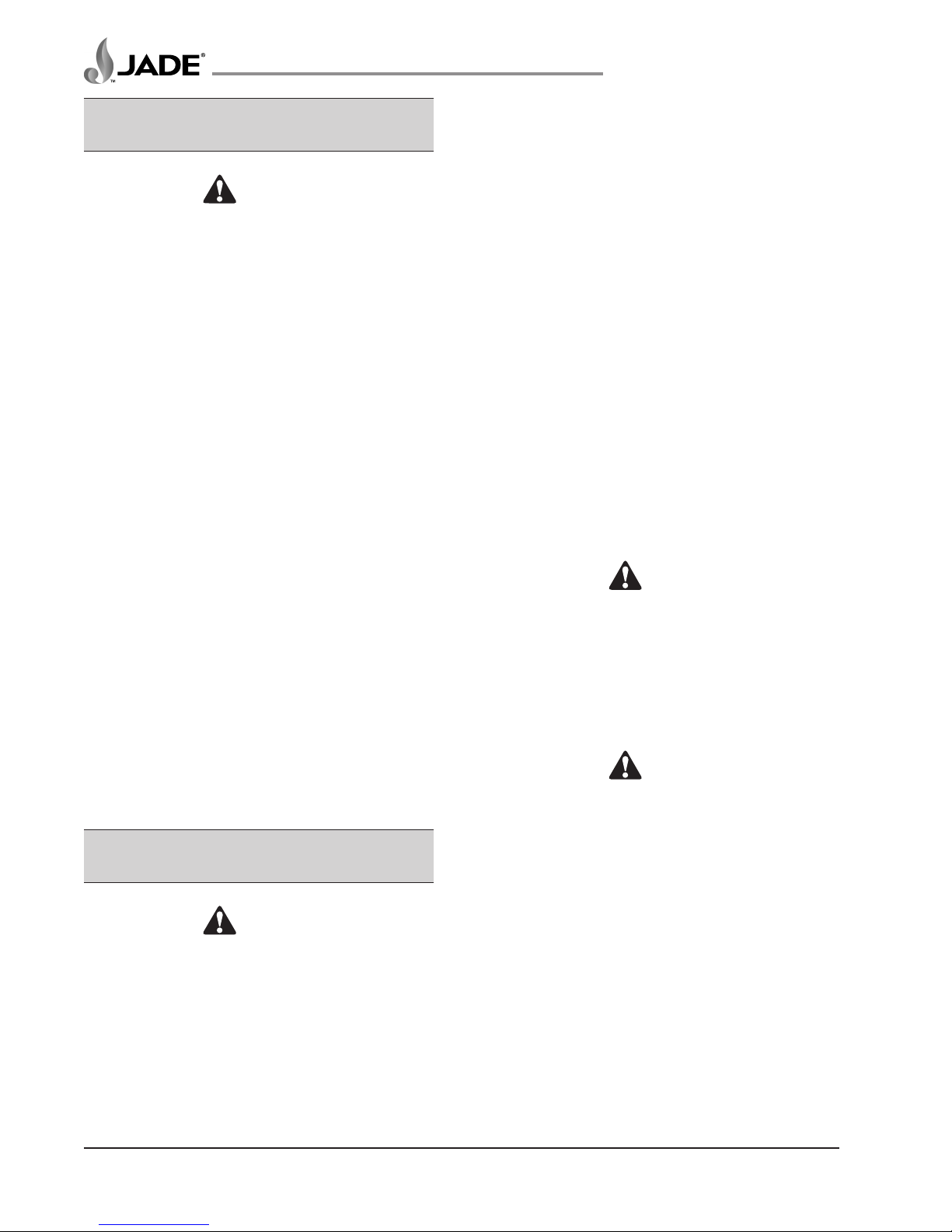

Manifold Cover, Top Section

Figure 3: Manifold Cover, Top Section

A. Gas Valve Knobs

B. Cover Screws

C. Manifold Cover

1. Loosen set screw and remove all knobs

from control valves.

2. Remove four (4) manifold cover screws.

3. Remove manifold cover.

REVIEW COPY 7

WARNING

PERFORM THE ELECTRICAL LOCKOUT/

TAGOUT PROCEDURE.

1. Shut off all electric controls and perform the

Electrical LOCK/TAGOUT procedure.

2. Remove thermostat and gas ON/OFF knobs.

3. Remove cover retaining screw.

4. Pull panel out to clear thermostat shaft.

5. Reverse the procedure to install the panel.

Oven Door

4. Reverse the procedure to install the cover.

Convection Oven Control Panel

Figure 4: Convection Oven Control Panel

A. TEMPERATURE Control Knob

B. Power ON/OFF Switch

C. Power ON Indicator Light

D. Blower AUTO/OFF/MANUAL Switch

E. Retaining Screw

F. Timer

G. Gas ON/OFF Valve for Oven

Figure 5: Oven Door Operating Mechanism

A. Oven Door Hinge

B. Hinge Bolts

C. Door Hinge Shims

D. Door Spring

E. Rocker Arm

F. “S” Hook

G. Eyelet

H. J-Hook to Mount Kick Panel

I. Brake Spring Tool

1. Remove kick plate as described under

COVERS AND PANELS.

Jade Range LLC – A Middleby Company

SM-11

TitanTM Series Heavy Duty Range

Model Series JTRH, JMRH & JTRHE

WARNING

RISK OF BODILY INJURY! OVEN SPRING IS

UNDER CONSIDERABLE TENSION. EXERCISE

GREAT CARE IN REMOVING OR REPLACING

SPRING.

2. Using an automotive brake spring pliers release

spring from eyelet as shown in Figure 5.

3. Remove wire S-Hook to rocker arm from oven

door hinge.

4. Loosen the four bolts that attach oven door hinges.

5. Remove door hinges from behind the door.

6. Using an assistant to support door, remove

four hinge bolts that attach hinges to frame.

7. Reverse the procedure to install the door.

Oven Kick Panel

REVIEW COPY 7

COMPONENT REMOVAL

Top Section Open Burner and Orifices

Figure 7: Top Section Open Burner

and Orifices

A. Manifold

B. Top Burners

C. Burner Control Valve with Orifice

D. Pilot Valve

Figure 6: Oven Kick Panel

A. Oven Kick Panel

B. J-Hook (on Hinge)

1. Lift oven kick panel straight up to release tabs

from retaining slots and pull out to remove.

2. To install the oven kick panel, insert tabs into

hinge J-Hook slots and slide panel towards

bottom of range.

WARNING

PERFORM THE ELECTRICAL LOCKOUT/

TAGOUT PROCEDURE.

1. Shut off all electrical controls and perform the

Electrical LOCKOUT/TAGOUT procedure.

WARNING

PERFORM THE GAS LOCKOUT/TAGOUT

PROCEDURE.

2. Shut off all gas controls and perform the Gas

LOCKOUT/TAGOUT procedure.

3. Remove top grates to expose burners.

4. Remove manifold cover as per COVERS AND

PANELS.

NOTE: It is not necessary to remove pilot tubes in

order to remove burner assemblies.

5. Lift burner assembly at rear of range and

pull away from burner control/orifice to

remove.

SM-12

6. Reverse the procedure to install the burner

assembly.

Jade Range LLC – A Middleby Company

Loading...

Loading...