Jade JMRH Installation Manual

InstallaInstalla

Installa

InstallaInstalla

tion &tion &

tion &

tion &tion &

TITAN™

SERIES

SUPER HEAVY DUTY

RANGE LINE

MODEL SERIES JTRH, JMRH & JTRHE

OperOper

Oper

OperOper

ManualManual

Manual

ManualManual

aa

tiontion

a

tion

aa

tiontion

POWERONBLOWER

P.O.

AUTO

O

F

F

LITEOFF

MANUAL

WARNING

WHEN MAIN GAS TO THE

APPLIANCE IS OFF, POWER

ON SWITCH MUST BE OFF.

THERMOSTAT

150

550

200

L

500

O

250

R

O

A

S

450

T

G

N

300

I

K

A

B

400

350

WARNING

WHEN MAIN GAS TO THE

APPLIANCE IS OFF, POWER

ON SWITCH MUST BE OFF.

TURN OFF ELECTRIC & GAS

TO APPLIANCE BEFORE

SERVICING ALL CONTROLS.

Please read this manual completely before attempting to

install or operate this equipment! Notify carrier of damage.

Inspect all components immediately.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Jade Range LLC

A MIDDLEBY COMPANY 2650 Orbiter Street, Brea, CA 92821 • 714-961-2400 • 800-884-5233 • www.jaderange.com

NOTES:

IN LINE WITH ITS POLICY TO CONTINUALLY IMPROVE ITS PRODUCTS, JADE RANGE, LLC RESERVES THE RIGHT TO CHANGE MATERIALS AND SPECIFICATIONS WITHOUT NOTICE.

JADE RANGE EQUIPMENT IS BUILT TO COMPLY WITH APPLICABLE STANDARDS FOR MANUFACTURERS. INCLUDED AMONG THOSE APPROVAL AGENCIES ARE UL, A.G.A., CSA, ETL AND OTHERS.

Manual number 2413200000 revC Printed in U.S.A.

TitanTM Series Heavy Duty Range

Model Series JTRH & JTRHE

IMPORTANT FOR YOUR SAFETY

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIED

INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR SERVICE BY OTHER THAN

QUALIFIED PERSONNEL MAY RESULT IN DAMAGE TO THE UNIT AND/OR INJURY TO THE OPERATOR.

Qualified installation personnel are individuals, a firm, corporation, or company which either in person or through

a representative are engaged in and are responsible for:

A. The installation or replacement of gas piping or the connection, installation, repair or servicing of equipment, who

is experienced in such work familiar with all precautions required, and have complied with all requirement of state

or local authorities having jurisdiction. Reference: National Fuel Gas Code, ANSI Z223.1, section 1.4, latest

addendum, or National Gas - Propane Installation Code CSA B149.1 as applicable.

B. The installation of electrical wiring from the electric meter, main control box or service outlet to the

electric appliance. Qualified installation personnel must be experienced in such work, be familiar with

all precautions required and have complied with all requirements of state and local authorities having

jurisdiction. Reference: National Electric Code, ANSI/NFPA No. 70, latest addendum.

JADE TITAN SERIES RANGE(S) MUST BE INSTALLED IN ACCORDANCE WITH LOCAL CODES, OR

IN THE ABSENCE OF LOCAL CODES, WITH THE NATIONAL FUEL GAS CODE, ANSI Z223.1 LATEST

ADDENDUM, INCLUDING:

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 psig (14" WC/3.45 kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping system at test pressures equal to or greater than

1/2 psig (14" WC/3.45 kPa).

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

W ARNING

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO OPERATE THIS DEVICE.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS AT MAIN SHUTOFF VALVE

AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

W ARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING,

SERVICING OR OPERATING THIS EQUIPMENT.

IO-2

Jade Range LLC – A Middleby Company

TM

Titan

Series Heavy Duty Range

Model Series JTRH & JTRHE

Contents

INTRODUCTION ...............................................................................................................................................................4

UNPACKING / INITIAL INSPECTION ...................................................................................................................... 4

GENERAL ...................................................................................................................................................................4

DATA PLATE LOCATION .......................................................................................................................................... 4

LOCATION..................................................................................................................................................................4

GAS CONNECTIONS ................................................................................................................................................4

GENERAL RANGE SPECIFICATIONS .................................................................................................................... 5

TITAN OVEN Specifications ...................................................................................................................................... 5

GAS BURNER BTU SPECIFICATIONS ................................................................................................................... 5

INSTALLATION .................................................................................................................................................................6

HOOD AND VENTILATION REQUIREMENTS ........................................................................................................ 6

Combustion Air....................................................................................................................................................6

Ventilation ............................................................................................................................................................6

BATTERY INSTALLATION REQUIREMENTS ........................................................................................................ 6

Waldorf Configuration.........................................................................................................................................6

ADJUSTABLE LEG INSTALLATION ........................................................................................................................ 7

OPTIONAL CASTER INSTALLATION......................................................................................................................7

RESTRAINING DEVICE INSTALLATION ................................................................................................................ 7

HI-SHELF /RISER INSTALLATION .......................................................................................................................... 8

MOUNTING SALAMANDER OR CHEESEMELTER ............................................................................................... 8

INSTALLATION CODES AND STANDARDS ..........................................................................................................8

ELECTRICAL INSTALLATION (CONVECTION MODELS ONLY).........................................................................8

Clearances from Combustible Materials ...........................................................................................................8

LEVELING...................................................................................................................................................................9

GAS LINE AND REGULATOR INSTALLATION ...................................................................................................... 9

Gas Line Pressure Testing.................................................................................................................................9

Gas Leak Check................................................................................................................................................10

BURNER FLAME ADJUSTMENTS.........................................................................................................................10

Flame Characteristics for a Properly Adjusted Burner .................................................................................. 10

Top Burner Pilot Adjustment ............................................................................................................................10

Top Burner Adjustment ..................................................................................................................................... 11

Oven, Griddle and Hot Top Burner Adjustment (Tubular Type Burners) .....................................................11

OPERATION ....................................................................................................................................................................12

TOP BURNER CONTROLS ....................................................................................................................................12

LIGHTING OVEN PILOT LIGHT ............................................................................................................................. 13

Standard Oven ..................................................................................................................................................13

Convection Oven...............................................................................................................................................13

Convection Oven Re-Igniter (Electronic Ignition)........................................................................................... 14

CONVECTION OVEN OPERATION.......................................................................................................................14

Convection Oven Controls ...............................................................................................................................14

Lowering/Changing Oven Temperature ..........................................................................................................15

Use of Oven Without Blower Fan ....................................................................................................................15

STANDARD OVEN OPERATION ........................................................................................................................... 16

CARE AND CLEANING ..................................................................................................................................................17

SERVICE..........................................................................................................................................................................18

LIMITED WARRANTY.....................................................................................................................................................19

CA PROP 65 GAS WARNING........................................................................................................................................20

Jade Range LLC – A Middleby Company

IO-3

INTRODUCTION

TitanTM Series Heavy Duty Range

Model Series JTRH & JTRHE

UNPACKING / INITIAL INSPECTION

This appliance was inspected before leaving the

factory. After unpacking, inspect the unit for any

damage that may have occurred during shipping.

**The transportation company assumes all

responsibility for safe delivery. If the appliance is

found to be damaged, save all packaging materials

and contact the carrier within 7 days of delivery.

Move the appliance as close as possible to

installation location. Remove all boxes and

packaging material from inside of oven. Remove

all shipping banding from pallet and top of range.

Remove all tops and oven components from their

boxes.

GENERAL

Jade Titan ranges are manufactured for use with

natural or propane gas. The gas type for each

range and the BTU rate is listed on the name

plate. Verify the unit is for the correct gas type

before installing it, by reading specifications on

appliance rating plate. Please read the installation

instructions carefully. Proper installation is

essential for safe and trouble free operation of this

appliance.

LOCATION

Locate appliance in an area that will make it easy

to load and unload the oven and will facilitate the

movement of food orders. Read Ventilation

Requirements in the Installation portion of this

manual before locating the appliance.

WARNING

THE EQUIPMENT AREA MUST BE KEPT FREE

AND CLEAR OF ANY COMBUSTIBLE

MATERIALS.

GAS CONNECTIONS

Titan ranges are supplied with a 1-1/4" front manifold

and a 1" rear tailpipe. For rear connection, remove

cap. Ranges are supplied with 3/4" gas pressure

regulator. Operating pressure is 5.0" W.C. for natural

gas or 10.0" W.C. for propane gas.

**Maximum incoming pressure is 14.0" W.C.(1/2 psi

3.45 kPa)

NOTE: Gas Pressure Regulator must be installed

in an accessible “cool zone” protected from grease

and debris.

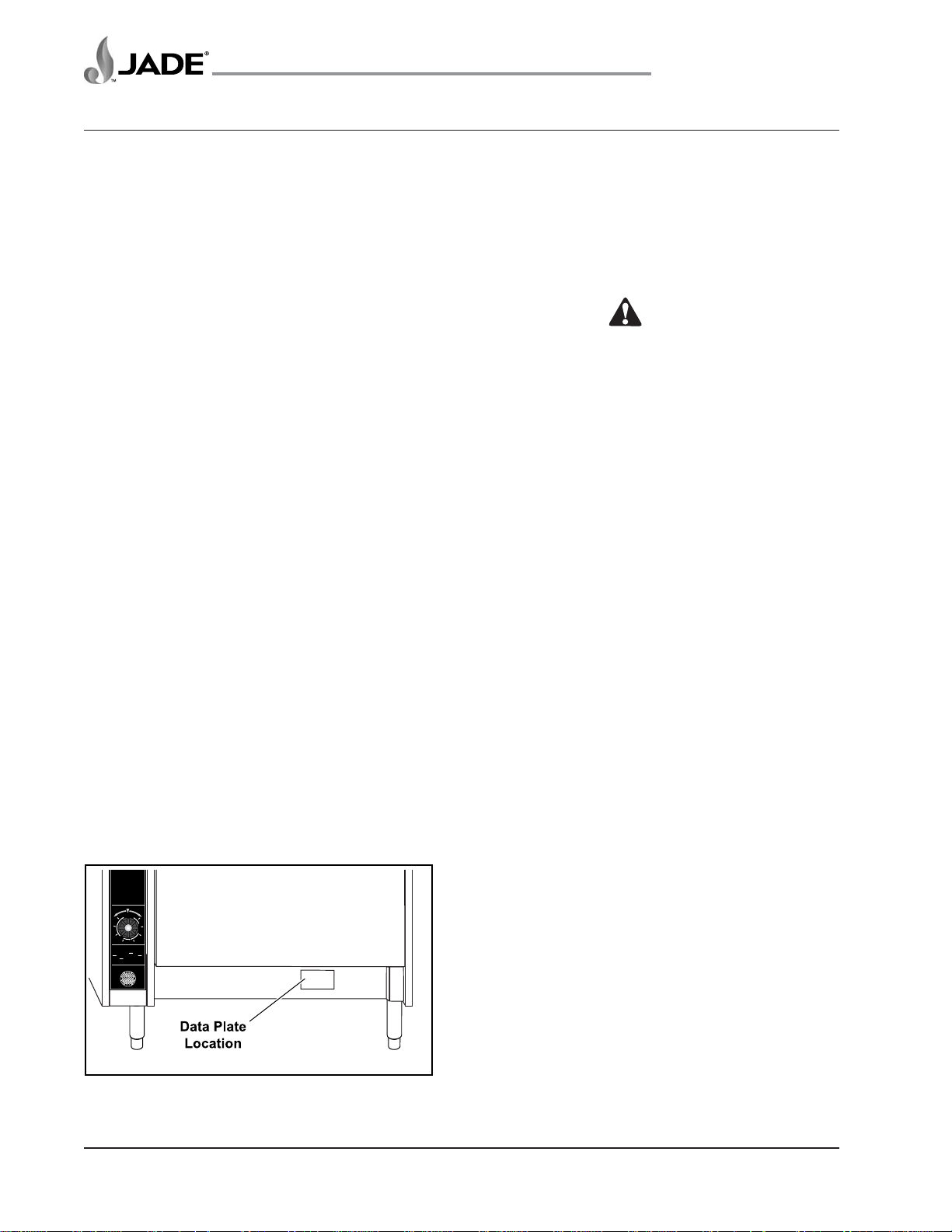

DATA PLATE LOCATION

Remove the kick plate. The data plate is located

to the right of center (behind the kick plate) beneath

the oven door. If gas orifices or regulator types

(gas or propane) are changed in the field, the

rating plate must be changed to reflect the new

orifice or gas type. All work should be performed

by a licensed and qualified professional.

WARNING

WHEN MAIN GAS TO THE

APPLIANCE IS OFF, POWER

ON SWITCH MUST BE OFF.

THERMOSTAT

150

550

200

L

500

O

250

R

O

A

S

450

T

G

N

300

I

K

A

B

400

350

WARNING

WHEN MAIN GAS TO THE

APPLIANCE IS OFF, POWER

ON SWITCH MUST BE OFF.

TURN OFF ELECTRIC & GAS

TO APPLIANCE BEFORE

SERVICING ALL CONTROLS.

Figure 1: Data Plate

NOTE: Use a pipe joint compound that has been

approved for use with liquefied petroleum gases.

IO-4

Jade Range LLC – A Middleby Company

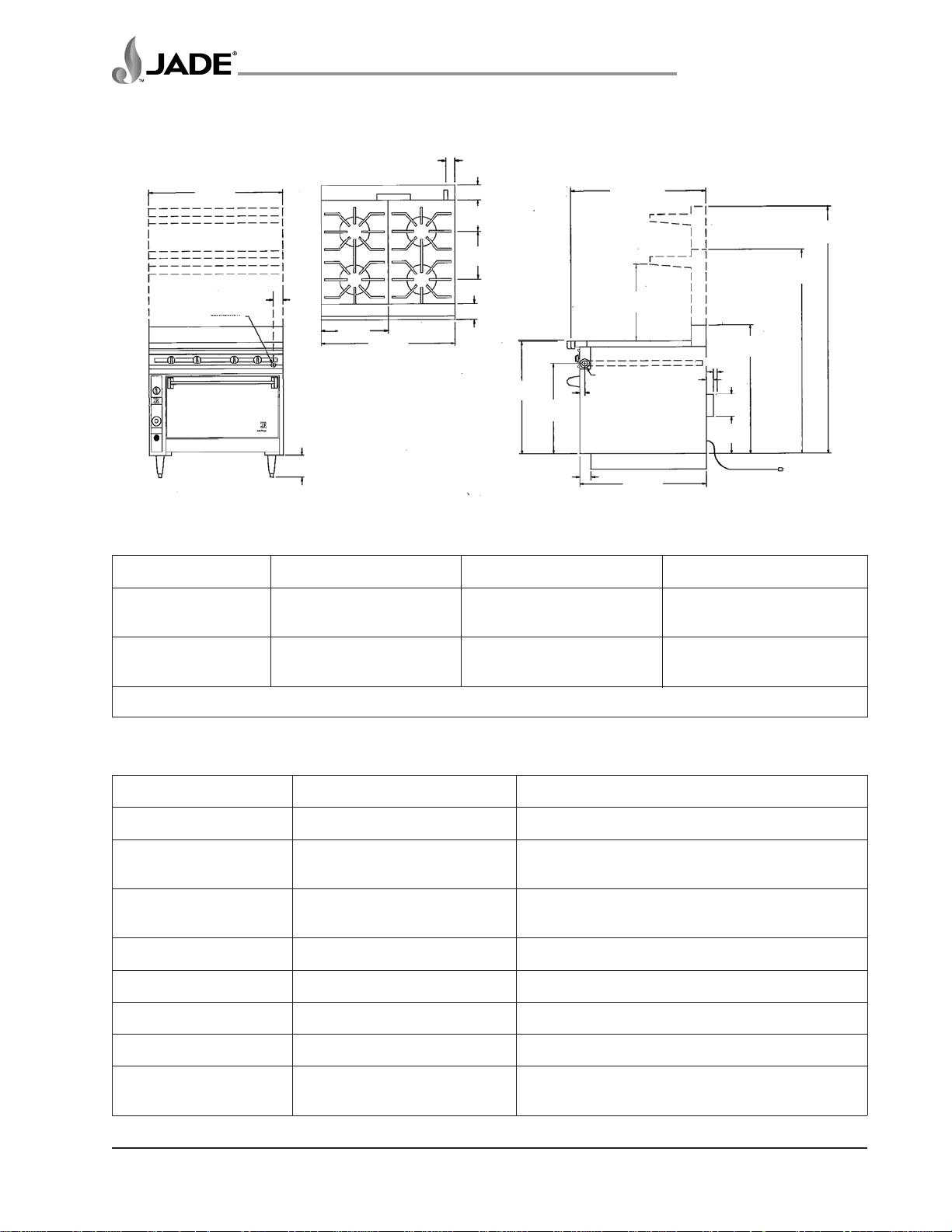

36"

(914)

2 1/2"

REAR GAS CONNECTION

(64)

GENERAL RANGE SPECIFICATIONS

2 1/2"

36"

(914)

(64)

4" (102)

8 1/2"

(216)

13"

(330)

4 1/4" (108)

30 1/2"

(775)

24 3/8"

(619)

(76)

3"

6"

(152)

REAR GAS CONNECTION

18"

(457)

( ) = MILLIMETERS

Titan

36 1/4"

(921)

20 1/2"

(521)

REAR GAS CONNECTION

1 1/4" MANIFOLD

(32)

1 1/2"

(38)

BLOWER MOTOR FOR

CONVECTION OVEN ONLY

CURB

34" (864)

TM

Series Heavy Duty Range

Model Series JTRH & JTRHE

DOUBLE DECK SHELF

SINGLE DECK SHELF

STUB

34 3/4"

BACK

(883)

CLEARANCE

1"

2"

(25)

(51)

6"

(1525)

10"

(254)

115V, 60c. Elect. Supply Cord (9 ft long)

Convection Oven Only

55"

(1397)

66 1/2"

(1689)

TITAN OVEN SPECIFICATIONS

Model Width Height Depth

Standard Oven 28-1/4″ 14″ 27-3/4″

(71.75 cm) (35.56 cm) (70.48 cm)

Convection Oven 28″ 13-3/4″ 24-1/2″

(71.12 cm) (34.92 cm) (62.23 cm)

Convection ovens are provided with 1/4 HP, 115 Volt, 60HZ, 1-Phase Blower Motor

GAS BURNER BTU SPECIFICATIONS

MODEL/FEATURE BTU NOTES

Open Burners 35,000 BTU per burner Lift-off octagon type

Manual Griddle 30,000 BTU per burner

Thermo Griddle 25,000 BTU per burner 1 every 12" of griddle width

Hot Top 35,000 BTU per burner 12" or 18" width full front to rear

Half Hot Top 17,500 BTU per burner Rear only

Robata/Satay 35,000 BTU per burner 2 IR burners per grid section

French Top Range 30,000 BTU per burner 1 for each top section

Char Broilers 15,000 BTU per burner 1 every 6" of broiler width

Plancha 20,000 BTU per burner 18"/24" – 1 burner / 36" – 2 burners

Standard Oven 35,000 BTU per burner

Convection Oven 30,000 BTU per burner

Jade Range LLC – A Middleby Company

Thermostat adjustable from 150°F to 550°F

IO-5

INSTALLATION

TitanTM Series Heavy Duty Range

Model Series JTRH & JTRHE

HOOD AND VENTILATION

REQUIREMENTS

Combustion Air

This appliance should be installed in an environment

capable of providing adequate combustion air for

the range. Titan ranges and the BTU consumption

for each feature are listed under GAS BURNER

BTU SPECIFICATIONS chart at the beginning of

this manual. Locate the particular model/features

being installed and note its BTU output of the features

of each appliance, then add the BTU rate for all

burners operating at once. IT IS IMPORTANT THAT

ADEQUATE COMBUSTION AIR BE PROVIDED

FOR THE TOTAL BTU CALCULATED. Avoid

locating the appliance in a tightly confined area that

is incapable of providing sufficient combustion air.

Clear space MUST be provided in front of the

appliance to allow for entry of combustion air.

Ventilation

An exhaust hood with code-approved fire controls

and sufficient CFM exhaust must be provided to

remove excess heat/steam/grease, etc. from

cooking. The hood canopy must extend beyond all

sides of the appliance. Refer to Standard NFPA No.

96 (latest edition) for the removal of smoke and

grease laden vapors from commercial cooking

equipment. Use the BTU listings under GAS

BURNER BTU SPECIFICATIONS chart at the

beginning of this manual to calculate the total BTU,

and then furnish exhaust air CFM required. Room

ventilation (make-up air) must be provided to

compensate for air being removed by exhaust

system. Excessive negative room air pressure will

result if this is not done. Lack of exhaust and/or

excessive negative pressure will interfere with oven

and pilot light operation and result in pilot outage,

improper combustion, and poor overall performance.

can be connected via plumbing unions. Failure to

level all appliances to the same plane will prevent

the proper interconnection of gas manifolds. If the

manifolds do not line up from one appliance to

another, re-check the level and correct so that

appliances are leveled to the same plane.

Install the first appliance in the position it will

occupy in the battery. Align and level the second

appliance to it and connect gas manifolds together.

Continue until all appliances are installed.

CAUTION

Provisions for gas and electrical shut offs must be

incorporated in the design of the “battery” and

accessible in the event the appliance is to be serviced.

CAUTION

All gas manifolds must align correctly to each

other. Failure to provide proper alignment can

damage gas manifolds, pilots and gas valves.

Adequate air supply must be provided for

combustion air. Provide a minimum of 36" of free

space in front of all appliances. Provide adequate

clearance for all air openings into combustion

chamber on all appliances.

Provide a gas regulator sufficient to supply adequate

gas flow for the total BTU requirement of all

appliances that have connecting manifolds. Set gas

regulators for 5.0" W.C. for natural gas regulators

and 10.0" W.C. for propane gas regulators.

Plate shelves and high shelves can be locked

together with standard 3/8" bolts.

When installed and individually connected to the

gas supply, each appliance must have its own

shutoff valve for servicing of the appliance.

BATTERY INSTALLATION

REQUIREMENTS

Ranges that are installed in a battery (two or

more) must be aligned, leveled, with manifolds

leveled and connected to each other.

Care must be exercised in leveling all appliances to

the same plane. This is important so that the 1-1/4"

gas manifolds located at the front of each appliance

IO-6

Waldorf Configuration

In Waldorf configuration, appliances are grouped

together to form an appliance island. Care must be

exercised in leveling all appliances to the same plane.

Establishing a level line around the entire perimeter of

the island will assist in installing all appliances. This is

important so that the 1-1/4" gas manifolds located at

the front of each appliance can be connected via

plumbing unions. Failure to level all ranges to the same

plane will prevent the proper interconnection of gas

Jade Range LLC – A Middleby Company

Loading...

Loading...