INSTALLATION OPERATION MAINTENANCE

For future reference, record the following information and refer to it when

contacting the factory or an authorized service agent.

________________

Model No.

________________

Serial No.

________________

Date Purchased

________________

Purchased From

________________

Telephone No.

________________

Installation Date

________________

Installed By

INSTRUCTIONS FOR REFRIGERATORS AND FREEZERS

JADE REFRIGERATION INC.

MANUFACTURERS OF REFRIGERATED BASES

We sincerely THANK YOU for choosing JADE REFRIGERATION. We are sure you will be

satisfied with your selection.

To make certain that you are satisfied with your new equipment, please spend a few minutes

and read these important instructions.

Jade Part No. 2451300000B 2650 Orbiter Street, Brea, CA 92821

Jan 30, 2017 Phone: (714) 961-2400 Toll: (800) 884-5233

INSTALLING THE CONDENSATE EVAPORATOR

If ordered, the condensate evaporator is in a carton inside the cabinet. Unless other provisions

have been made for disposing of the condensate water, all models must have the condensate

evaporator positioned under the cabinet after it has been elevated on legs or casters. First

mount the condensate evaporator retaining bracket by attaching it to the cabinet base exterior

with thumb screws into preset rivnuts. Then, keeping the electrical cord to the front, slide the

evaporator into the condensate evaporator retaining brackets. Then insert the electrical plug

into the receptacle, which is under the middle back of the exterior cabinet base. (See attached

drawing entitled "Mounting instructions for condensate evaporator.)

INSTALLING THE SHELVES

The wire shelves can be spaced just as you want. Simply install four supports in the vertical

standards at each desired level- then set the shelf on them. Straddle shelves are supplied to

close the gap behind fluorescent light.

Note: Locating one level of shelves slightly above interior floor will assure better air circulation

and will facilitate cleaning.

ELECTRICAL REQUIREMENTS

To prevent the possibility of the circuit being overloaded, we recommend that a separate circuit

be provided for each cabinet. All cabinets must be grounded and must be operated only on the

electrical supply indicated by the rating plate on the right interior wall. Electrical supply cords

are furnished where and ampere loads permits; two types of male plugs are supplied — one

with parallel blades for 15-ampere circuits, one with perpendicular blades for 20-ampere

circuits. When a supply cord cannot be furnished, 6' leads for connection to permanent wiring

are provided in the junction box labeled "power supply".

DEFROSTS

Defrosting of all JADE REFRIGERATION models is completely automatic. In freezers, the

timer initiates is and the thermostat in the cooling coil terminates it after the coil is free of frost

and ice. (IMPORTANT- Do not be alarmed if you find that the cooling coil fans in your Freezer

are not operating. They are thermostatically controlled to prevent warm air circulation not only

during and immediately after defrost but also whenever the temperature rises because of

prolonged door opening. Operation of the fans will resume automatically when the temperature

inside the coil housing drops to a safe level.

- 2 -

SETTING THE DEFROST TIMER ON FREEZERS

The defrost timer must be set to the correct time; instructions for this are inside the cover of the

timer box. We recommend three defrosts during a 24-hour period, but the number of defrosts

actually required may vary as a result of prevailing humidity, ambient temperature or usage.

LOADING THE CABINET

Products should not be put into the cabinet until the temperature has dropped to the normal

range (approximately 40 oF in refrigerators, 0 oF in frozen storage cabinets). The way in which

the cabinet is loaded will affect its efficiency, so allow sufficient space on all sides of the

products to permit complete air circulation

IMPORTANT: Do not store products where they will impede the intake of air by the fans

or the discharge of air at the back of the cooling coil.

CLEANING

Proper cleaning done on a regular schedule will lower your operating costs, prevent costly

repairs, and extend the life of the equipment. Refrigeration equipment works continuously; give

it the care it deserves.

The acrylic viewing window for temperature control should be cleaned with care. It is

recommended to clean with wet cloth with water only to prevent scratches and chemical

damage. Please do not hose water onto the front surface.

CLEANING THE CABINET

The exterior should be cleaned with a solution of warm water and mild soap, applied with a soft

cloth. A good vinyl cleaner can be used on vinyl-clad surfaces. Never use a strong alkali

solution, solvents, steel-wool, coarse fabrics or abrasives.

The interior should be cleaned with a solution of warm water and baking soda followed by a

rinse of clear warm water, then dried with a clean, soft cloth. If juices or food are spilled, they

should be wiped up immediately.

Shelves, shelf standards, pan sides and other interior accessories should be washed

frequently with hot soapy water, and then rinsed with clear water. Shelf standards can be

removed easily by loosening the thumb screws which secure them to the walls. Do not use a

wire brush, steel-wool, or other abrasives which could damage the plating.

Door gaskets must be kept clean, particularly in the folds. A mild detergent applied with a soft

cloth should be used to prevent any build-up of grease and dirt which could interfere with

proper sealing.

- 3 -

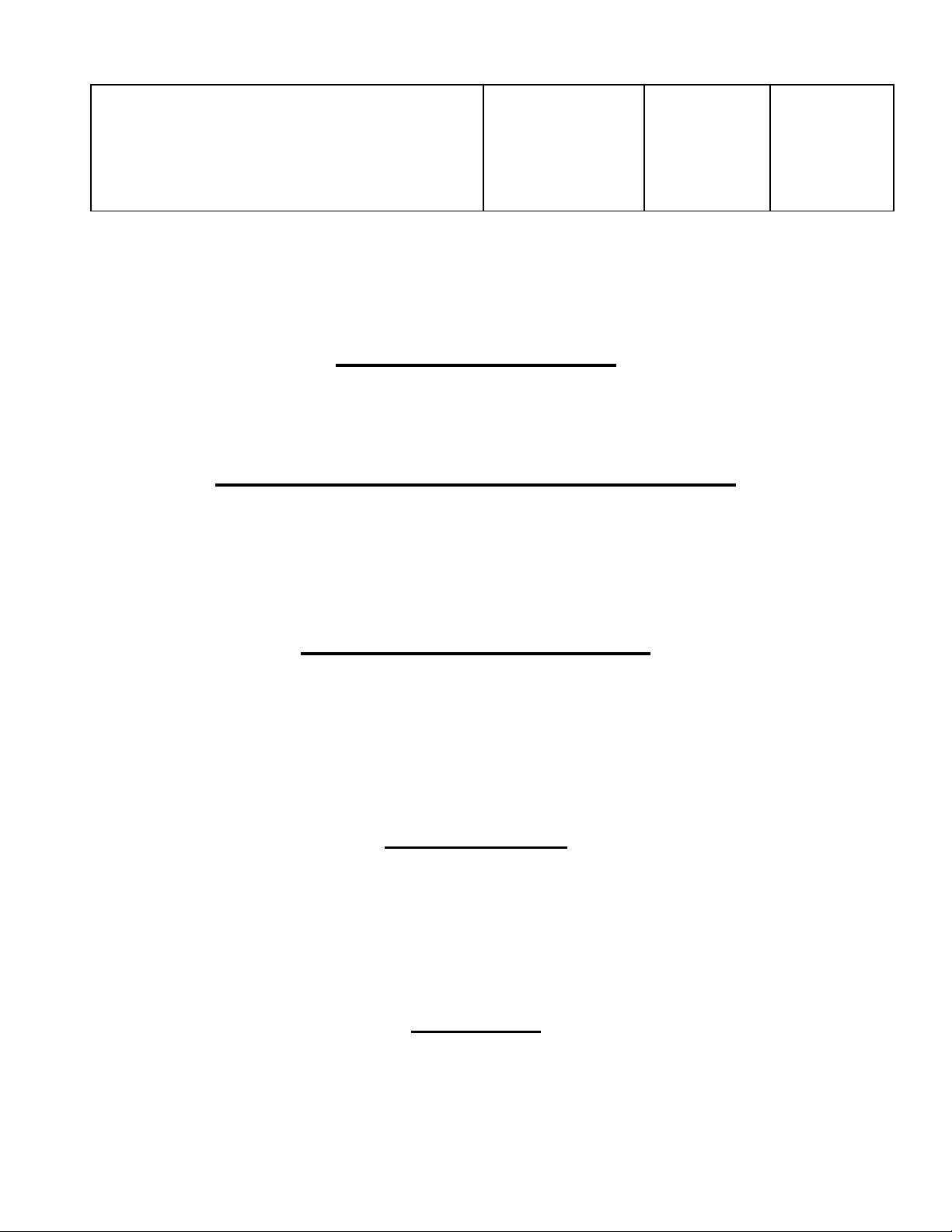

CLEANING THE CONDENSOR

REFRIGERANT

CUT-IN

CUT-OUT

REFRIGERATOR

R22MT

67# TO 69#

37# TO 39#

FREEZER

R22LT

16# TO 17#

10# TO 11#

FREEZER

404A

35# TO 38#

15# TO 17#

The fins of the condenser (the radiator-like portion of the condensing unit) must be cleaned

periodically by vacuuming or blowing out all dirt, lint and foreign matter. Any accumulation

which obstructs the flow of air through the condenser can seriously affect the performance of

the refrigeration system and eventually cause a burn-out of the compressor.

LUBRICATING THE HINGES

The hinges are designed to close the doors automatically. If not operating freely, they should

be lubricated with a light grease.

REPLACING LAMPS

Incandescent light bulbs and fluorescent lamps should be replaced only by ones which are of

the same type as the factory-installed ones.

SERVICE

In case of operational failure, check the following:

- Has the power been turned off at the source?

- Has the power supply cord been pulled from the wall receptacle?

- Has the fuse for this circuit blown?

If the failure is not due to any of the above, call the dealer from whom you purchased this

equipment, or call a qualified commercial refrigeration service firm.

IMPORTANT: UNDER NO CIRCUMSTANCES SHOULD UNTRAINED INDIVIDUALS

ATTEMPT TO PERFORM ELECTRICAL OR REFRIGERATION SERVICE

ON THIS EQUIPMENT----

Warranties do not cover service performed by unqualified persons, and they become void if

alterations are made and / or damage results from such attempts.

FOR QUALIFIED REFRIGERATION SERVICEMEN ONLY

- 4 -

Dual – Temp

Note: After Adjusting Pressure Control with

these valves, the EPR-65 (Evaporator

Pressure Regulator) must also be adjusted.

404A

75# TO 76#

15# TO 17#

These settings satisfy normal conditions. If the settings must be changed to meet

specific conditions, a compound gage must be used.

REPLACEMENT PARTS

When requesting information or ordering replacement parts, please provide the cabinet model

number and serial number which appear on the right interior wall.

CLAIM FOR LOSS OR DAMAGE IN TRANSIT

Since all merchandise is sold FOB our factory, our control and responsibility ended when the

carrier signed the bill of lading at our dock. If loss or damage is discovered, notify the

delivering carrier at once and request an inspection. We shall gladly provide all possible

assistance, but the actual filing and follow-up of the claim mist be done by you, the consignee.

MOVING THE MERCHANDISE

Caution must be exercised when moving cabinets, as upright models are somewhat top-heavy.

Also, dollies and lift-bars can damage a drain line underneath the cabinet, so the underside

should be checked to determine the location of the drain line. No cabinet should ever be put on

its front, back, or side. It is wise to leave the protective adhesive paper on stainless steel

surfaces until after the cabinet has been moved.

IT IS STRONGLY RECOMMENDED THAT THE EQUIPMENT BE INSTALLED AND PUT

INTO OPERATION BY A QUALIFIED COMMERCIAL REFRIGERATION MECHANIC.

Claims under the Extended protection Plan (if purchased) must be accompanied by proof

that this was done.

Self-contained cabinets and remote condensing units must be located in a well-ventilated area.

This is extremely important for operating efficiency and for warranty protection.

INSTALLATION

LOCATION

- 5 -

REMOVING THE CABINET DOORS

The door of the cabinet can be removed easily to obtain sufficient clearance through narrow

doorways. Solid doors and non-heated glass doors should be partially opened then lifted until

off the hinge pins. Heated glass doors cannot be removed until the plug in the cord to each

door located in the plug, unplug the cord, then open the door and lift it.

IMPORTANT: Mark the doors so that each one will be replaced on the opening from which it

was removed.

INSTALLING THE LEGS AND LEVELING THE CABINET

If ordered, legs are in a carton inside the cabinet. Tip the cabinet, screw the legs into the

mounting nuts provided on the underside of the cabinet, and then turn the "feet" of the legs to

adjust them until the cabinet is level left-to-right and front-to-back. When the tops of the doors

are in a straight horizontal line, the magnetic door gaskets will seal properly on all sides.

IMPORTANT: For proper drainage of the condensate from the forced air cooling coil and for

proper operation of the self-closing doors, the cabinet must not be lower in

front than in back.

- 6 -

- 7 -

- 8 -

- 9 -

- 10 -

- 11 -

- 12 -

- 13 -

- 14 -

Loading...

Loading...