TM

DR1000

Dual Reader

User Manual

©2005 Precision Dynamics Corporation

Part No. RF-109-0405

DR1000 User Manual Precision Dynamics Corp.

TABLE OF CONTENTS

SAFETY PRECAUTIONS & IMPORTANT SAFETY INSTRUCTIONS.............................. 5

1 PURPOSE OF THIS DOCUMENT........................................................................................... 8

2 PRODUCT OVERVIEW ............................................................................................................... 9

2.1 GENERAL DESCRIPTION.................................................................................................................... 9

2.2 FEATURES ......................................................................................................................................... 9

2.3 DR1000 RFID TAG COMPATIBILITY ............................................................................................... 10

2.4 DR1000 BARCODE COMPATIBILITY................................................................................................. 10

3 MODELS AND MODES OF OPERATION ........................................................................... 11

3.1 COMMAND MODE ........................................................................................................................... 11

3.2 TRIGGER MODE .............................................................................................................................. 12

3.2.1 Scan Sequence................................................................................................................ 12

3.2.2 Barcode Data Style........................................................................................................ 13

3.2.3 RFID Data Style.............................................................................................................. 13

3.2.4 Keyboard Emulation (Wedge) ................................................................................... 14

3.3 SCANNING AN RFID TAG ............................................................................................................... 14

3.4 SCANNING A BARCODE ................................................................................................................... 14

3.5 FIELD INTERPRETATION ................................................................................................................. 14

3.5.1 Overview ........................................................................................................................... 14

3.5.2 Field Interpretation Arrays ......................................................................................... 15

3.5.3 Keyboard emulation and serial differences.......................................................... 16

3.5.4 Error Conditions and Handling.................................................................................. 16

4 POWER AND HOST INTERFACE CONNECTIONS....................................................... 18

4.1 POWER ............................................................................................................................................ 18

4.2 USB ................................................................................................................................................ 18

4.3 RS-232 ............................................................................................................................................ 19

4.4 PS/2................................................................................................................................................ 21

5 USER INTERFACES................................................................................................................... 23

5.1 LEDS .............................................................................................................................................. 23

5.2 BEEPER ........................................................................................................................................... 23

5.3 TRIGGER ......................................................................................................................................... 23

6 FIRMWARE UPGRADES .......................................................................................................... 24

APPENDIX 1 - BaRS SOFTWARE ................................................................................................. 25

INSTALLING BARS .................................................................................................................................... 25

INSTALLING USB SERIAL COMMUNICATION DRIVERS .............................................................................. 25

STARTING THE BARS APPLICATION .......................................................................................................... 27

MAIN TOOL BAR....................................................................................................................................... 27

APPLICATION CONFIGURATION................................................................................................................ 31

Serial Port ....................................................................................................................................... 31

Baud Rate........................................................................................................................................ 32

Barcode Scan Timeout ............................................................................................................... 32

SCANNER SETTINGS.................................................................................................................................. 32

Baud Rate........................................................................................................................................ 32

USB Mode........................................................................................................................................ 33

Barcode Scan Timeout (COMMAND MODE only).................................................................... 34

Page 2 of 44

DR1000 User Manual Precision Dynamics Corp.

Beeper .............................................................................................................................................. 34

Scan Sequence.............................................................................................................................. 34

RFID Tag Type............................................................................................................................... 34

Barcode Data Style...................................................................................................................... 34

RFID Data Style ............................................................................................................................ 34

Trigger Notification (COMMAND MODE only) .......................................................................... 35

Scanner Serial Number.............................................................................................................. 35

Scanner Firmware Version........................................................................................................ 35

Field Interpretations.................................................................................................................... 36

Apply To Scanner ......................................................................................................................... 37

Read From Scanner..................................................................................................................... 37

Load From File............................................................................................................................... 37

Save To File.................................................................................................................................... 37

Advanced......................................................................................................................................... 37

RFF VIEW................................................................................................................................................. 38

DATA VIEW .............................................................................................................................................. 38

Raw RFID......................................................................................................................................... 39

Formatted RFID............................................................................................................................. 39

Barcode ............................................................................................................................................ 39

Trigger Operation ......................................................................................................................... 39

FORMATTED READ FORM ......................................................................................................................... 40

APPENDIX 2 - DR1000 DEMONSTRATION.............................................................................. 41

START THE APPLICATION.......................................................................................................................... 41

PREPARING THE RFID TAG...................................................................................................................... 41

APPLYING THE SCANNER CONFIGURATIONS ............................................................................................ 42

KEYBOARD EMULATION READ (USB AND PS/2 VERSIONS)..................................................................... 42

CHANGING THE SCANNER CONFIGURATION (USB VERSION) ................................................................... 43

COMMAND MODE READ........................................................................................................................... 44

TRIGGER EVENTS ..................................................................................................................................... 44

Page 3 of 44

DR1000 User Manual Precision Dynamics Corp.

© Copyright 2005

Precision Dynamics Corporation

All Rights Reserved

No portion of this manual may be copied, photocopied, transcribed or otherwise duplicated

for commercial purposes except with the express and written permission of the Precision

Dynamics Corporation and/or its legally authorized representative.

DISCLAIMER

The operations represented in this manual are for guideline purposes only and in no way are

to be construed as a warranty or other operation obligation, legal or otherwise. For

information on warranty, service and other legal rights and obligations regarding the product

covered by this manual, refer to the warranty/service information provided by the seller or

reseller of this product.

Page 4 of 44

Safety Precautions & Warnings

Safety Precautions & Important

Safety Instructions

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK

OF ELECTRIC SHOCK

DO NOT REMOVE THE COVER (OR BACK).

NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

The lightening flash with arrowhead symbol within an equilateral triangle is

intended to alert the user to the presence of uninsulated dangerous voltage within

the product’s enclosure that may be of sufficient magnitude to constitute a risk of

electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user to

the presence of important operating and maintenance (servicing) instructions in

the literature accompanying the product..

USE OF THIS PRODUCT IN A MANNER OTHER THAN DEFINED

IN THIS MANUAL MANY CAUSE DAMAGE TO EQUIPMENT

OR INJURY TO PERSONNEL.

FCC WARNING: This equipment has been tested and found to comply with the

limits for a device pursuant to Part 15 of the FCC Rules, to wit, operation is

subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that

may cause undesired operations

Page 5 of 44

Safety Precautions & Warnings

These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. However, there is no guarantee that this

interference will not occur in a particular installation. If this product does cause

harmful interference to radio or television or other wireless reception, which can

be determined by turning the product off and on, the user is encouraged to

correct the interference by one or more of the following measures:

• Reorient or relocate this product or the unit experiencing interference.

• Increase the separation between this product and the unit experiencing

interference.

• Connect this product into an outlet or circuit different from that to which

the unit experiencing interference is connected.

• Consult the dealer for technical support.

Changes or modifications to this equipment may cause harmful interference unless

the modifications are expressly approved in the instruction manual. The user

could lose the authority to operate this equipment if an unauthorized change or

modification is made.

Warnings & Safety Precautions

The DR1000 is designed and manufactured to provide long, trouble-free

service. No maintenance other than cleaning is required. Use a soft dry cloth to

clean the surface. Never use solvents such as alcohol or thinner to clean the

surface.

To ensure your safety when installing this equipment, for operating safety and to

avoid damage to the apparatus, read carefully and observe the following

precautions and instructions:

1. For performance and safety reasons, only the power supplies listed for use with

this equipment should be used.

2. Connect the unit only to a properly rated supply circuit.

3. All wiring external to this product should follow the local wiring codes.

4. This unit is for use in dry locations only. Do not expose the unit to water or

moisture.

5. Do not operate in ambient environments with a temperature greater than

6 Do not open the DR1000. If the unit is damaged in this way, the warranty will

0

F/400C or lower than 410F/50C.

104

be void. Moreover, there is a risk of shock.

10. Do not attempt to service or repair the DR1000 unit. The unit’s components

are not user serviceable. Only authorized, qualified personnel should service

Page 6 of 44

Safety Precautions & Warnings

this system. The Precision Dynamics Corporation is not liable for any bodily

harm or damage caused if unqualified persons attempt service or open the

cover(s) to any component of the system. Refer all service to authorized

DR1000 service technicians.

To avoid damage and prolong operating life:

• Handle the unit carefully when installing and do not drop.

• Set the unit away from heat, excessive dust and direct sunlight..

• Protect the inside of the unit’s components from liquids. In case of

accident, unplug the console and have the damage serviced by an

authorized technician.

• Do not hit or scratch the unit’s light-sensor window surface as this causes

flaws on the surface of the window and may damage operation.

• Do not connect the PS/2 cable to the host when the 5V power supply is

also connected, as it may damage the DR1000 or the host computer

Page 7 of 44

1: Purpose of the Document

1 Purpose of this Document

The purpose of this document is twofold:

• First, to introduce the user to the capabilities of the DR1000 Dual Reader.

• Second, to enable a user to configure the device to scan RFID tags and

barcode data and send data to a host device as if it were entered from a

keyboard.

This document describes two critical interfaces of the DR1000:

• the User Interface

• the Host Interface

The User Interface consists of the trigger, two multi-color LEDs, and a beeper. The

Host Interface is implemented as a keyboard emulation or ‘wedge’ interface which is

available in the USB and PS/2 models: the DR1000 sends data to the host in the

form of keystrokes, but the host cannot send any information or commands to the

DR1000. In this manner, the DR1000 can be used to input barcode and RFID

data directly into any application which accepts keystrokes. This allows a user to

quickly incorporate the DR1000 into an existing application without requiring any

programming effort.

For users who require functionality beyond what is available with keyboard

emulation, a Software Development Kit (SDK) is available. The SDK includes

user documentation, sample code and both DLL and ActiveX components to

allow a programmer to easily harness the full functionality of the DR1000 Dual

Reader.

Page 8 of 44

2: Product Overview

2 Product Overview

2.1 General Description

The DR1000 Dual Reader is a handheld, tethered barcode/RFID reader for use

with most industry standard linear and 2-D barcode symbols, as well as 13.56

MHz RFID tags and labels. The DR1000 is compatible with ISO 15693

transponders and several previous generation proprietary protocols.

The DR1000 Dual Reader is available with three different interface options:

- USB

- RS-232 (serial)

- PS/2

The Dual Reader allows firmware upgrades in the field. This guarantees a forward

migration path and sound investment as new features and enhancements become

available.

2.2 Features

• Operates from 5V DC

• ISO 15693 compatible

• Flash upgradeable in the field for future product updates

• RFID Read Range: 6.5 inches (16.5 cm) read range with credit card size

tags, 5.0 inches (12.5 cm) with wristband-size tags

• Keyboard emulation operation available with PS/2 and USB models

• User feedback via two multi-color LEDs and a beeper

• Trigger operation – point and scan barcodes and RFID tags

• Host control mode – powerful, easy to use software interface (requires

SDK)

Page 9 of 44

2: Product Overview

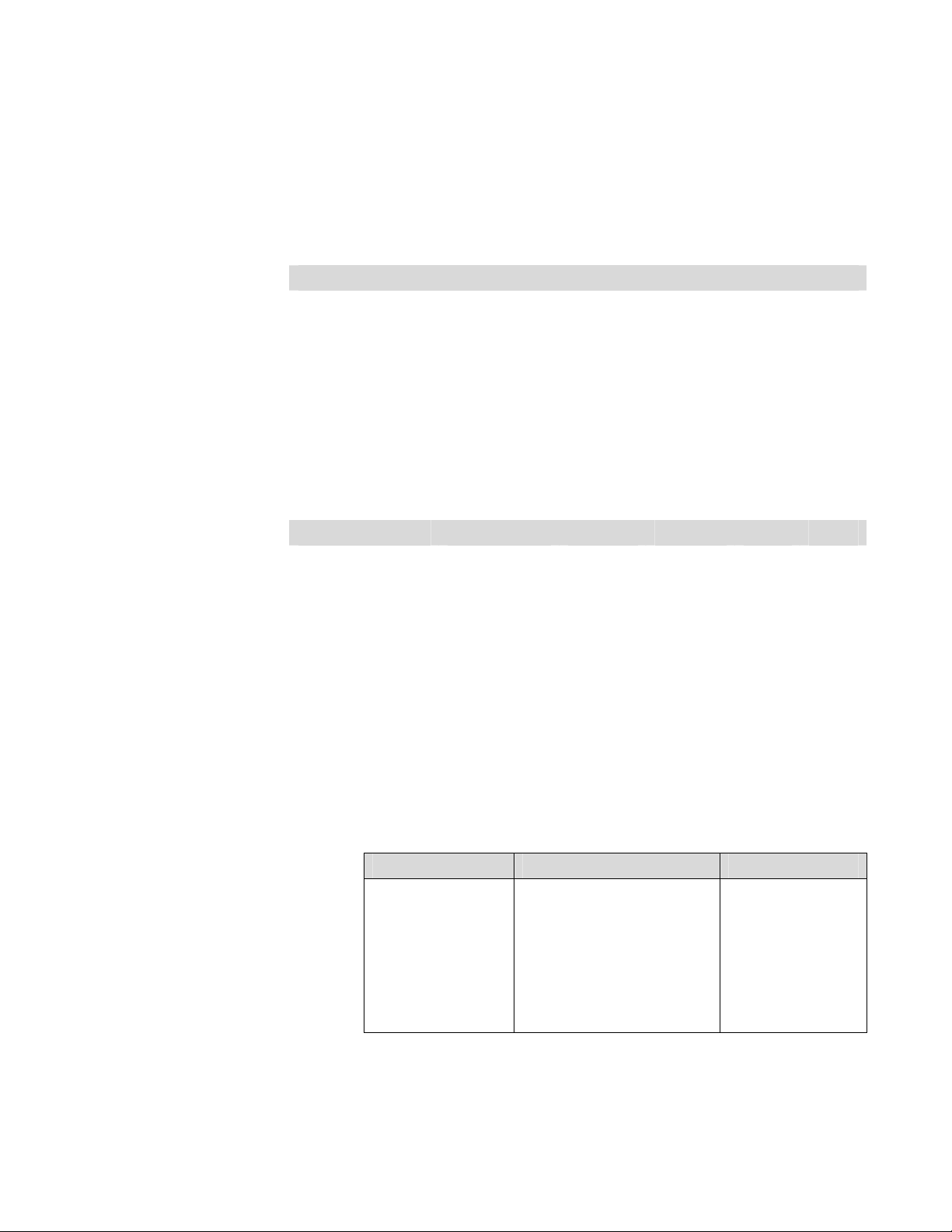

2.3 DR1000 RFID Tag Compatibility

The DR1000 Dual Reader supports the RFID tag types and features shown in

Table 1 below. By default, the DR1000 will read all compatible tag types (autodetect), but it may be configured to only read a single tag type to optimize

performance.

Table 1 – DR1000 Tag Compatibility

ISO-15693 (-2 and -3 compliant)

Memory

Manufacturer Product

Texas Instruments Tag-it HF-I 2048 yes yes yes

Philips I·CODE SLI

(SL2)

Infineon my-d

SRF55V10P

ST

Microelectronics

LR512 512 yes yes yes

(bits)

1024 yes yes yes

10k yes yes yes

Anti-

collision Read Write

Proprietary

Memory

Manufacturer Product

Texas Instruments Tag-it HF 256 yes yes yes

Philips I·CODE (SL1) 512 yes yes yes

Inside Contactless PicoTag 2K 2k no id only no

(bits)

Anti-

collision Read Write

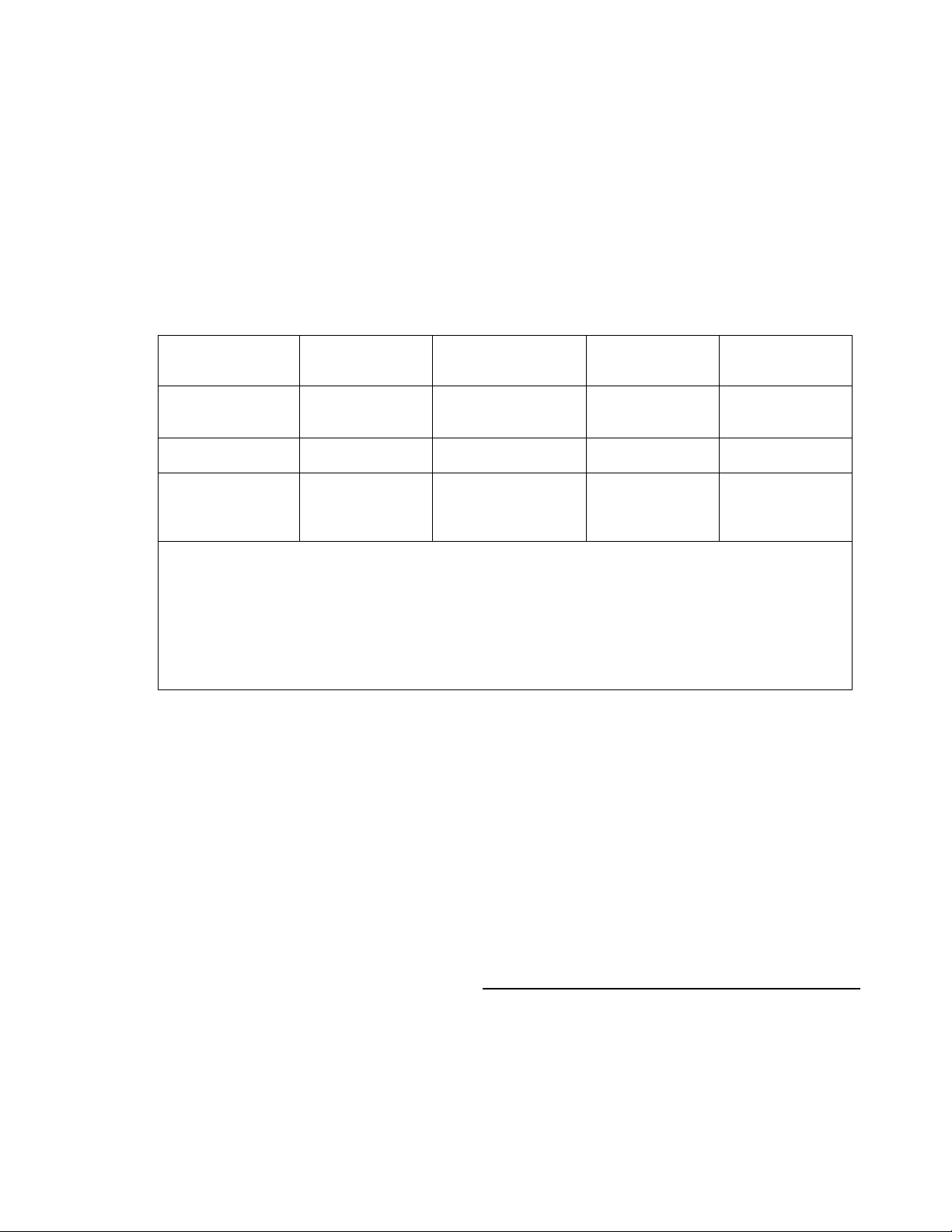

2.4 DR1000 Barcode Compatibility

The DR1000 Dual Reader decodes the linear and 2-D barcodes listed in Table 2

below:

Table 2 – DR1000 Barcode Compatibility

Linear: 2-Dimensional: Postal:

Code 39

Code 128

Codabar

UPC

EAN

I 2of5

RSS

Code 93

Codablock

PDF417

MicroPDF417

MaxiCode

Data Matrix

QR Code

Aztec

Aztec Mesa

Code 49

UCC Composite

Posnet

Planet Code

BPO 4 State

Canadian 4 State

Japanese Post

Kix

Page 10 of 44

3: Models & Modes of Operation

3 Models and Modes of

Operation

Table 3 lists the three available models and the corresponding modes of

operation. The DR1000 has two (2) operating modes, Trigger Mode and

Command Mode.

Table 3 – DR1000 Models and Modes

Trigger Mode 3

Command Mode 4

Power Source

1

Keyboard emulation mode is automatically entered at power-on if the HID Mode is set to HID and the

trigger is not pulled, or if HID Mode is set to Serial and the trigger is pulled at power-on and then released

(USB model only).

2

Serial Emulation mode is automatically entered at power-on if the HID Mode is set to Serial and the

trigger is not pulled, or if HID Mode is set to HID and the trigger is pulled at power-on and then released

(USB model only).

3

Configurable ASCII read-only mode under DR1000 firmware control.

4

To configure the device for trigger mode operation and/or to perform read and write operations under

application control.

USB

(Keyboard

Emulation)

Keyboard

emulation via

Host USB

connection

USB

N/A

1

USB

(Serial Emulation)

[default setting]

ASCII data via

virtual COM port

Via virtual COM

port

Host USB

connection

2

RS-232 Serial PS/2

ASCII data via

RS-232

connector

Via RS-232

connector

External Power

Supply Adaptor

Keyboard

emulation via

PS/2 Connector

Via RS-232

Connector

External Power

Supply Adaptor

or via the Host

PS/2 interface

3.1 Command Mode

Command Mode is used to configure a device for trigger mode operation, and/or as

the primary method to control the device. The BaRS utility software may be used

to easily configure the DR1000 for keyboard emulation applications (see Appendix

1 for additional information). Host control of the DR1000 requires programming

which is facilitated by the SDK (sold separately).

As long as the DR1000 has power, Command Mode is active when the trigger is in

the released position. In Command Mode the DR1000 is listening for a command

from the host. It is not required that a host have the capability to send a

command to the DR1000.

N

OTE

The DR1000-PS/2 or DR1000 USB in keyboard emulation

can

never

receive a command from a host. The DR1000

USB can receive commands if it is re-initialized in serial

emulation mode. The DR1000-PS/2 can receive commands

if its serial connector is plugged in. Writing to a tag can only

be done in command mode.

Page 11 of 44

3: Models & Modes of Operation

3.2 Trigger Mode

Trigger Mode is designed to read formatted ASCII data from a combination of

RFID or barcode data sources, and supply the data to a host device as if it was

entered from a keyboard. The user may specify up to three events in a Scan

Sequence to capture data from three different RFID or bar code data sources, and

quickly populate multiple text fields of a form without the use of a keyboard.

Trigger Mode is activated when a user pulls the trigger (if Trigger Mode is not

disabled). While in Trigger Mode, the DR1000 begins scanning immediately and

continues to scan until a RFID tag or barcode is read, or until the trigger is

released. The maximum data string length is 1024 bytes. Data strings that exceed

1024 bytes will be truncated.

The operating characteristics of the DR1000, while in Trigger Mode, are defined by

the following parameters: Scan Sequence, RFID Data Style, and Barcode Data

Style. Each parameter may be configured to match the needs of the application.

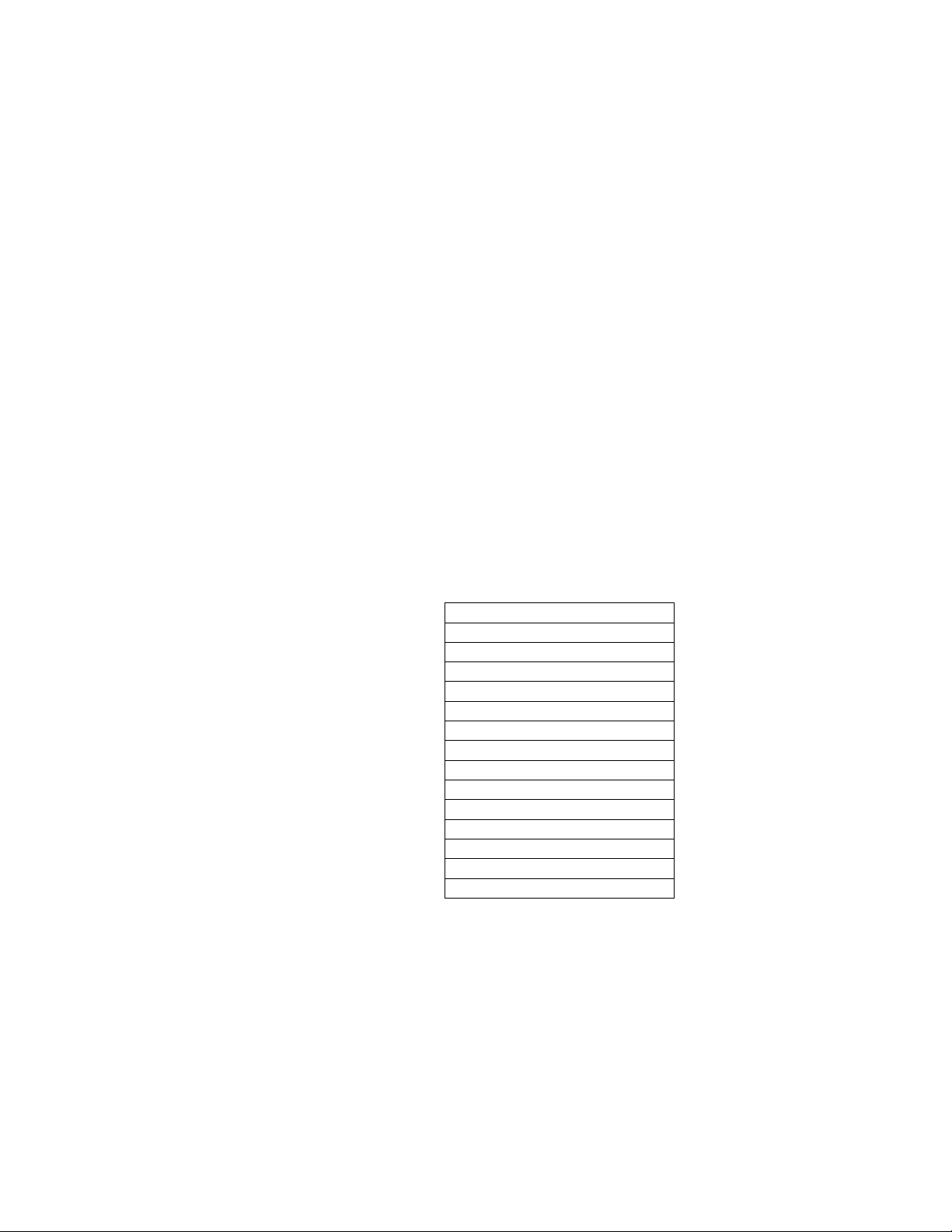

3.2.1 Scan Sequence

When Scan Sequence is enabled, a maximum of three events may be defined to

capture information from any combination of RFID or barcode data sources. The

possible Scan Sequence options are listed in Table 4. If Scan Sequence is

disabled, Trigger Mode is disabled.

Table 4 – Trigger Mode Setting: Scan Sequence

Disabled

Barcode

RFID

Barcode, RFID (default)

RFID, Barcode

Barcode, Barcode

RFID, RFID

Barcode, Barcode, Barcode

Barcode, Barcode, RFID

Barcode, RFID, Barcode

RFID, Barcode, Barcode

Barcode, RFID, RFID

RFID, RFID, Barcode

RFID, Barcode, RFID

RFID, RFID, RFID

Page 12 of 44

3: Models & Modes of Operation

EXAMPLE

In a hospital, a nurse wishes to administer medication to a patient and must record

the event in an electronic record. The record consists of nurse’s name, medication

information, and patient information. The nurse name and medication

information will be read from two separate barcodes, and the patient information

will be read from a RFID wristband. The Scan Sequence is nurse name (barcode),

patient information (RFID tag), and medication information (barcode). Using the

DR1000 Dual Reader, this information may be scanned into text fields of an

electronic form without using a keyboard. In use, the nurse positions the cursor in

the text box for the nurse’s name, points the DR1000 at the nurse’s badge, and

pulls the trigger. The name from the barcode is automatically entered into the text

box. The nurse then repeats this operation to capture the patient and medication

information.

3.2.2 Barcode Data Style

Barcode Data Style defines how barcode data is transmitted back to the host. The

DR1000 has two options as indicated in Table 5 below.

By default, the Complete Barcode Data option causes the DR1000 to

read the barcode and send the entire data string to the host.

If the DR1000 is configured for Use Field Interpretation, barcode data

may be parsed into separate data fields (multiple text boxes), and sent to

the host with header and trailer characters, if desired. The header and

trailer characters may contain tabs, carriage returns or line-feeds to

navigate between different text boxes by reading only one barcode.

The Barcode Data Style setting applies to all barcodes defined by the Scan Sequence.

Table 5 – Trigger Mode Setting: Barcode Data Style

Complete Barcode Data (default)

Use Field Interpretation

3.2.3 RFID Data Style

RFID Data Style defines the content and structure of RFID data transmitted back

to the host. The RFID Data Style options are identified in Table 6 below. The Tag

UID setting allows the DR1000 to read and transmit the RFID tag Unique

IDentification (UID) number. RFID Data Style also supports Field Interpretation

and operates in the same way as Barcode Data Style. The RFID Data Style setting

applies to all RFID tags defined by the Scan Sequence.

Table 6 – Trigger Mode Setting: RFID Data Style

UID Only

Data Only (default)

UID and Data

Use Field Interpretation

In general, RFID tag ASCII data is read and transmitted to the host until a NUL

character is encountered. If multiple tags are present within the read-range of the

dual reader, the DR1000 will only read the UID of the first tag it detects.

Page 13 of 44

3: Models & Modes of Operation

3.2.4 Keyboard Emulation (Wedge)

In PS/2 or USB Keyboard Emulation Mode, the DR1000 will map each byte value of

a data string to an equivalent keystroke. Only valid ASCII characters are output to

the host. Any other barcode or RFID tag data not part of the ASCII character set

is ignored. That is, the following ASCII values are discarded: SOH, STX, ETX,

EOT, ENA, ACK, BEL, BS, VT, FF, SO, SI, DLE, DC1, DC2, DC3, DC4,

NAK, SYN, ETB, CAN, EM, SUB, FS, GS, RS, US, DEL. Also, any byte value

with the MSB set (high bit) is ignored. When a NUL character is encountered, the

string is terminated and any additional characters are ignored.

ASCII chart

0 1 2 3 4 5 6 7 8 9 A B C D E F

0 HT LF CR

1 ESC

2 SP ! " # $ % & ' ( ) * + , - . /

3 0 1 2 3 4 5 6 7 8 9 : ; < = > ?

4 @ A B C D E F G H I J K L M N O

5 P Q R S T U V W X Y Z [ \ ] ^ _

6 ` a b c d e f g h i j k l m n o

7 p q r s t u v w x y z { | } ~

3.3 Scanning an RFID Tag

A RFID tag must be oriented parallel to the face of the DR1000 at no more than

5.0 inches for a wristband sized tag and 6.5 inches for a credit card sized tag.

Upon a trigger pull, the DR1000 will scan for a RFID tag until a RFID tag is read

or the trigger is released. The DR1000 outputs all data to the host as soon as it is

read. However, the next scan cannot start until the trigger is released and pulled

again.

3.4 Scanning a Barcode

The proper method for scanning a barcode is to hold the face of the DR1000 4-6

inches from the barcode. When the trigger is depressed, a red or green light bar

darker than the surrounding red laser appears on or over the barcode. The bar

should line up with the barcode horizontally. The DR1000 continuously scans for

a barcode until one is read or the trigger is released.

3.5 Field Interpretation

3.5.1 Overview

Field Interpretation is a useful and powerful feature of the DR1000 to

automatically parse a data string into multiple segments, or append fixed

characters before or after a data string. This capability allows a user to

automatically populate and navigate multiple text boxes in a form, simply by

scanning a single barcode or RFID tag.

Page 14 of 44

3: Models & Modes of Operation

EXAMPLE

A single barcode is scanned which has 10 characters of name, 10 characters of

social security number, and 8 characters of date. An example data stream might

be First_Name123456789002142005. The data is scanned into a form that has

Name, SSN and Date text boxes. A tab character will navigate between the 3 text

boxes. It is desired to scan the data into the form as:

Name: First_Name

SSN: 123-456-7890

Date: 02/14/2005

This can be handled readily using Field Interpretation arrays.

In this case, the BaRS program allows the field interpretation parameters to be

configured. There are two components to interpretation arrays; how to store

interpretation arrays into the DR1000, and how the DR1000 will output data

according to the interpretation arrays stored. This section will detail both how to

store interpretation array data into the DR1000, how the DR1000 will output data

according to the interpretation array stored, and also error conditions that the

DR1000 can encounter and its responses.

3.5.2 Field Interpretation Arrays

A raw data string can be parsed into multiple segments by defining field

interpretation arrays. A field interpretation array consists of individual records (up

to 64), each defined by the following parameters:

Field Address – the starting location of the data string.

Field Length – the maximum length of the data, in number of bytes, to output

starting at the field address value. The data is output sequentially from the Field

Address to the Field Address + Field Length-1. Field length can be any length from

0x0000 to 0x03FF. A field length value of 0x0000 indicates that field

interpretation is terminated, and that the last field sent to the host was the last

field to be sent for the current scan.

Header – a 4-character field sent at the beginning of each field. Each field can

have a unique header and can be 0 to 4 characters.

Trailer – a 4-character field sent at the end of each field. Each field can have a

unique trailer and can be 0 to 4 characters.

All interpretation array data is output in the following format, where H stands for

header, T stands for trailer, and FxL is the data of size length L in Field X.

Field 1 ----------------------------------------------------------------------------- > Field N

H1 F1L T1 H2 F2L T2 H3 F3L T3 …... HN F(N < 64)L TN

Page 15 of 44

3: Models & Modes of Operation

EXAMPLE

In the previous example, the barcode data stream is broken into seven segments

as shown in the following chart.

Field

Address

0 10 <tab>

10 3 -

13 3 -

16 4 <tab>

20 2 /

22 2 /

24 4

Field

Length

Header Trailer Comment

Output name followed by a tab

character to move to the SSN text

box

Insert a ‘-‘ between the 3rd & 4th

digit

Insert a ‘-‘ between the 6th & 7th

digit

Output last 4 SSN digits followed

by a tab character to move to the

Date text box

Insert a ‘/‘ between the day and

month

Insert a ‘/‘ between the month

and year

This table is entered using the BaRS software utility and downloaded to the

DR1000. In operation, the user positions the cursor on the Name text box and

scans the barcode to populate each field in the form.

A field interpretation array is terminated when it encounters a field with a length

of 0. The field address does not have to be sequential. That is, the fields in the

interpretation array can jump to different addresses in the scanned data. The

DR1000 supports up to three separate interpretation arrays, one for each scan that

is enabled by the Scan Sequence parameter.

OTE

N

The field interpretation may be written to the DR1000, but it

cannot be read back from the device. For this reason, it is

important to use the BaRS software’s Save to File feature to

save the configuration before exiting the program.

3.5.3 Keyboard emulation and serial differences

In the case of a PS/2 unit or a USB unit in keyboard emulation mode, only normal

ASCII characters can be transferred to the host. There are no limitations to a RS232 or USB unit in serial emulation mode. All raw bytes will be sent to a COM

port on the host.

3.5.4 Error Conditions and Handling

There are several error conditions that can occur when a DR1000 outputs data

according to field interpretation arrays. The DR1000, in most instances, will

output a trailer when it encounters an error and indicate to the user an error

occurred via the LEDs and beeper. The errors and the DR1000’s handling of

these errors are described below:

Page 16 of 44

3: Models & Modes of Operation

Error: The Field Address attempts to address data outside the scanned data range.

For example, an error occurs if the DR1000 scanned 50 bytes of data from an

RFID tag or barcode and the field address pointed to location 51.

DR1000 Response: The DR1000 will output the header and the trailer and

indicate to the user an error occurred via the LEDs and/or the beeper.

Error: The Field Address attempts to address data inside the scanned data range,

but the Field Length exceeds the available scanned data in the DR1000 data

buffer. That is, if the DR1000 scanned 50 bytes of data from an RFID tag or

barcode and the address pointed to location 49 but had a Field Length of 15.

DR1000 Response: The DR1000 will output data until it gets to the end of

available data, and then output the trailer. An error will be indicated to the

operator via the LEDs and/or beeper.

Page 17 of 44

4: Power and Host Interface Connections

4 Power and Host Interface

Connections

This section describes the available host interfaces, their specific modes of

operation and differences, and power configurations for each model.

4.1 Power

Depending on the interface type, the DR1000 receives power from the PS/2 port,

from the USB port, or from a separate 5V power supply. The maximum current

required by the DR1000 is 450mA at 5V. The DR1000 operates optimally at 5V,

with some read-range degradation at lower supply voltages.

4.2 USB

The USB model supports two modes of operation: serial communication and

keyboard emulation. The current mode of operation may be determined by

viewing the Windows Device Manager. If the DR1000 is in keyboard emulation

mode, the device will register with the operating system as a Human Interface Device

(HID). Conversely, if the DR1000 is in serial communication mode, the device

will register with the operating system as a serial device, with the emulated serial

port number identified in the Device Manager.

If the DR1000 is in keyboard emulation (HID) mode, it cannot receive

commands from the host. Therefore, there is a method to change the DR1000

from keyboard emulation mode to serial communication mode without using a

host command:

1. Disconnect the USB cable from the host.

2. Depress and hold the trigger of the DR1000.

3. Connect the USB cable to the host.

If the trigger of the DR1000 is depressed during startup (connection to the host),

the DR1000 will toggle modes based on the HID mode previously stored in

memory. For example, if the HID mode is set to serial communication and the

trigger is depressed during startup, the DR1000 will switch modes and startup in

keyboard emulation mode, and vice versa.

The USB model has a Type A male USB connector at the end of a 2-meter cable,

tethered and permanently connected at the DR1000 side. The DR1000 is powered

from the USB host via the USB cable. The Type A male USB connector mates

with any standard host device with a Type A female USB connector.

Page 18 of 44

4: Power and Host Interface Connections

Table 7 - USB Power and Communications Connection

Table 8 - Mating face USB type A female (host)

Pin

Number

1 +5 Vcc Supply for USB device

2 -D Negative differential data signal

3 +D Positive differential data signal

4 GND Ground for USB device

4.3 RS-232

DR1000-USB

USB Type A Male

(To Host)

Table 9 USB Connector Pin Assignments

Pin

Name

Pin

Description

For the RS-232 model, the power supply must be connected to an active power

outlet, and the RS-232 cable must be connected to the host computer.

The RS-232 model has a female DB-9 connector with integrated power dongle

input connector at the end of a 2-meter cable, tethered and permanently

connected at the DR1000 side. The 2.5mm x 5.5mm center positive power jack

option at the end of the power dongle requires power input from an external 5V

power supply (wall transformer).

The female DB-9 connector mates with any standard host device with a male DB9 connector.

Page 19 of 44

4: Power and Host Interface Connections

Table 10 – RS232 Power and Communications Connections

90 - 240V AC

50 - 60 Hz

PS 5V

DR1000-232

2.5mm x 5.5mm

5V DC, 1A

Center Positive

DB9 Female

(To Host)

Table 11 - Mating face of DB9 male (host)

Table 12 below identifies the pin assignments for the RS-232 DB9 connector.

The DR1000 communication interface supports baud rates of 9600, 19200, 38400,

57600 and 115200 with 8 data bits, 1 stop bit and no parity. Flow control is not

supported. The default baud rate is 9600.

Table 12 RS-232 DB9 Pin Assignments

Pin

Number

1

2 Tx_232 RS-232 transmit to host

3 Rx_232 RS-232 receive from host

4

5 GND Ground for RS-232 host

6

7

8

9

Pin

Name

Pin

Description

Page 20 of 44

4: Power and Host Interface Connections

4.4 PS/2

The PS/2 model is intended for use with applications that require keyboard

emulation only. However, since the DR1000 cannot receive configuration

commands while connected to the PS/2 port, the PS/2 model is also equipped

with a RS-232 cable. Follow the connection instructions below to configure a

PS/2 model:

1. Disconnect the PS/2 cable from the host computer.

2. Connect the RS-232 cable to a host computer.

3. Connect the 5V power supply into a power outlet and connect the power

supply to the RS-232 dongle.

WARNING:

Do not connect the PS/2 cable to the host when

the 5V power supply is also connected, as it may

damage the DR1000 or the host computer.

During normal operation, the PS/2 model is powered from the host computer via

the PS/2 port. The 6-pin mini-DIN male connector at the end of the DR1000

PS/2 cable connects to any standard host device with a 6-pin mini-DIN female

connector.

Table 13 - PS/2 Operational - Power and Communications Connection

DR1000

power on PS / 2 cable

PS/2 keyboard

PS/2 Operational configuration

not

connected

RS

PS

232

-

/ 2

host

Page 21 of 44

4: Power and Host Interface Connections

Table 14 - Mating face of 6-pin mini-DIN female

Table 15 PS/2 Connector Pin Assignments

Pin

Number

1 Data

2 N/C

3 GND

4 +5

5 CLK

6 N/C

Pin

Name

Pin

Description

Data signal on PS/2 Bus

Not Connected (Can be used for alternate Data Signal)

PS/2 Supply Ground

Vcc PS/2 Supply

Data Clock on PS/2 Bus

Not connected (Can be used for alternate Clock Signal)

Table 16 - PS/2 Configuration with RS-232 Communication and

Power Connections

PS/2

DR1000

RS -232

power on cable

host

5V power supply

(connect to power outlet)l

Page 22 of 44

5: User Interfaces

5 User Interfaces

The DR1000 has a trigger, a beeper and two LEDs for feedback and interaction

with the device.

5.1 LEDs

The DR1000 has two multi-colored LEDs (red, green or yellow) controlled by the

device firmware or via host control. In Trigger Mode, the LEDs are controlled by

the device firmware in the following manner:

1. The top LED (closest to the reader face) indicates “scanning in process”.

2. The bottom LED (closest to the handle) indicates the “read” status.

3. When the trigger is not pulled, the “scanning” LED is off.

4. When the trigger is pulled, the “scanning” LED is green and remains green until

either a valid read is processed, or the trigger is released. At this point, the

LED turns off.

5. When a scan is complete, the color of the “read” LED turns to either green or

red depending on whether the read passed or failed, respectively. The LED

remains that color until the trigger is pressed again. When the trigger is

pressed, the LED turns off and remains off until a valid barcode or RFID tag

is read, or the trigger is released.

The color and operation of each LED is fully configurable if the DR1000 is under

host control. The configuration instructions are beyond the scope of this

document, but are fully explained in the SDK documentation.

5.2 Beeper

At power on, a low-frequency beep indicates an error condition in the RFID or

the barcode reader modules. In Trigger Mode, a beep indicates a successful read.

This feature may be disabled, but is on by default.

5.3 Trigger

The DR1000 has a single trigger to activate the DR1000 in a typical “point and

scan” application. During Trigger Mode, the DR1000 outputs all data immediately

after a successful read, and the next scan cannot start until the trigger is released

and pulled again.

Page 23 of 44

6: Firmware Upgrades

6 Firmware Upgrades

The DR1000 has a built-in boot loader to allow firmware upgrades in the field

through a software interface. Complete instructions will be included to support

future firmware upgrades.

Page 24 of 44

Appendix1 – BaRs Software

Appendix 1 - BaRS Software

The BaRS software application is a powerful tool that allows a user to configure

the DR1000 Dual Reader for a specific application, and also demonstrate the

advanced capabilities of the device through a hands-on example. The remainder of

this manual will fully explain the features and operation of the BaRS software

application.

Installing BaRS

The BaRS application software can be installed on any Microsoft Windows XP

and 2000 based personal computer. Insert the BaRS Software CD into the

computer and click on the INSTALL BaRS button to begin the installation

process. Follow the instructions on the screen.

If a USB version of the DR1000 is to be used with the BaRS application or any

host application, the USB serial port emulation drivers must be installed on the

host computer to enable serial communication with the DR1000. This driver

package is included with the BaRS Software CD.

Installing USB Serial Communication Drivers

Once BaRS has been installed, follow the instructions below to install the USB

serial communication drivers. The USB serial emulation drivers are required for

USB models only.

1. Insert the DR1000’s USB connector into the appropriate slot on the host

computer.

2. Open the Windows Device Manager. (Right click on My Computer,

select Properties, select the Hardware tab, click on the Device Manager

button)

3. Find the Human Interface Device key related to USB to Serial and

right click on it. (Select Human Interface Devices, right click on USB Human

Interface Device)

4. Select update driver.

5. Select “Install from list from specific location” and click Next.

6. Select “Don’t search, I will choose the driver to install”. Then click

Next.

7. Select Have Disk. Click Browse.

Page 25 of 44

Appendix1 – BaRs Software

8. Navigate to C:\Program Files\Precision Dynamics

Corporation\BaRS and select the hidcom.inf file. Click Open and then

click OK.

OTE

N

If an error message appears at this point, the

DR1000 may be set for keyboard emulation mode.

In this case, disconnect the USB from the host, pull

the trigger on the DR1000, re-connect the USB to

the host and release the trigger. Return to step 2.

9. Select “Cypress USB-HID->COM device” and click Next.

10. If a dialog box appears warning about the driver, click on the Continue-

Anyway button. When the installation completes, click on Finish.

11. The Device Manager window will now reappear with the Ports (COM &

LPT) section highlighted (Cypress USB-HID->COM device

(COMn). Make note of which COM port has been assigned as this will

be needed later.

12. Select File and then Exit to close the Device Manager window.

Page 26 of 44

Appendix1 – BaRs Software

Starting the BaRS Application

During the installation of the BaRS software application, two shortcuts are

installed on the host computer, one on the Desktop, and one in the Windows

Start menu. To run the BaRS application, double-click on the BaRS shortcut on

the Desktop, or select the BaRS shortcut from the Start menu. The following

opening screen of the application will appear.

To exit the application, select “File | Exit” from the menu bar.

Main Tool Bar

The Main Tool Bar contains the icons to activate each of the functions of the

BaRS software. Each button and associated function is described in detail below.

Open RFF File

The Open RFF File button allows the user to open an RFF file and apply

it to the RFF view of the application. RFF view is an advanced feature of the

BaRS application. RFF files are XML-based files that define the format of the

displayed form and the RFID data read from a RFID tag. The details of how RFF

files are created and used is outside the scope of this document, however, several

samples of RFF files are provided for demonstration purposes.

Page 27 of 44

Appendix1 – BaRs Software

Application Settings

The Application Settings button opens the Application Settings dialog

box and allows the user to set the desired serial port, baud rate, and barcode scan

timeout duration.

Start Scanner

The Start Scanner button initializes serial communication between the

DR1000 Dual Reader and the host computer.

Scanner Settings

The Scanner Settings button opens the Scanner Settings dialog box to allow

the user to configure the DR1000 Dual Reader for many of its advanced features.

Each configuration parameter of the DR1000 is explained in later sections of this

document.

Page 28 of 44

Appendix1 – BaRs Software

RFF View

The RFF View button displays the RFF file that was opened and applied

to the application.

Data View

The Data View button displays the data view of the application. This view

exercises many of the features of the DR1000 Dual Reader.

Page 29 of 44

Appendix1 – BaRs Software

Form Dialog

The Form Dialog button opens a Form dialog box used to demonstrate

the keyboard emulation feature of the DR1000 Dual Reader.

About

The About button identifies the application name, version, and copyright

statement.

Page 30 of 44

Appendix1 – BaRs Software

Application Configuration

Click on the Application Settings button to open the dialog box as

shown below. The serial port, baud rate, and barcode scan timeout duration may

be set as follows:

Serial Port

The Serial Port setting must match the COM port assigned by the operating

system, either the RS-232 port address, typically COM 1, or the emulated serial

port number if the DR1000 is connected via USB. The emulated port number can

be found by exploring the Device Manager of the operating system. Use the arrow

at the right of the control to select the appropriate serial port.

Page 31 of 44

Appendix1 – BaRs Software

Baud Rate

The Baud Rate setting controls the communication speed with the DR1000. The

baud rate must match the baud rate setting of the DR1000 as explained in later

sections. The default setting is 9600 baud.

Barcode Scan Timeout

The Barcode Scan Timeout setting defines the maximum length of time (in

seconds) the BaRS software waits for the DR1000 to read a barcode. This setting

must match the corresponding setting of the DR1000 as described in later

sections. The value may be incremented or decremented using the arrows at the

right side of the control.

Scanner Settings

Click on the Scanner Settings button to open the Scanner Settings dialog

box and configure the DR1000 for a specific application. Note that any number

of configurations may be saved to a file for later recall and download to the

DR1000. Once a configuration set is applied to the DR1000, it is stored in the

device memory and preserved over a power cycle. It is not necessary to reapply

the Scanner Settings unless a change is desired.

Baud Rate

The Baud Rate setting defines the serial communication rate of the DR1000 with

the host system. This parameter must match the baud rate of the application.

Page 32 of 44

Appendix1 – BaRs Software

USB Mode

The USB model of the DR1000 can operate in either a keyboard emulation mode,

called “HID” (Human Interface Device), or in a serial communication mode. This

setting applies to the USB Mode only and does not affect the operation of the RS232 or PS/2 models.

HID (USB model only)

If the USB mode is set to ‘HID’ and the DR1000 is connected to the host

computer, the dual reader will register as a “Human Interface Device” with

the operating system. The DR1000 may be registered with the operating

system as a serial device by holding the trigger in the pulled position

before connecting the device to the host computer, followed by releasing

the trigger after the connection is made.

Conversely, if the USB mode is set to ‘Serial’ and the DR1000 is connected

to the host computer, the dual reader will register as a serial device with

the operating system. The DR1000 may be registered with the operating

system as a Human Interface Device by holding the trigger in the pulled

position before connecting the device to the host computer, followed by

releasing the trigger after the connection is made.

Page 33 of 44

Appendix1 – BaRs Software

Barcode Scan Timeout (C

OMMAND MODE

only)

The Barcode Scan Timeout specifies the length of time (in seconds) the

DR1000 will attempt to read a barcode before terminating the operation. This

parameter must match the Barcode Scan Timeout setting in the Application

Settings described above. The value may be incremented or decremented using

the arrow to the right of the control.

Beeper

The Beeper check box specifies whether the DR1000 beeper is enabled or

disabled.

Scan Sequence

This parameter sets the scanning sequence of the dual reader when the trigger is

pulled. The Scan Sequence and the Trigger Notification parameters are

interrelated, and should be set appropriately.

If Trigger Notification is set to anything other than “None”, the Scan Sequence

parameter should be set to “Disable”.

If Trigger Notification is set to “None”, then the user can specify the action the

dual reader should take when trigger is pulled.

EXAMPLE

Upon the first trigger pull, the dual reader should scan a barcode, and upon the second trigger pull

the dual reader should scan an RFID tag, and repeat the sequence again.

RFID Tag Type

The BaRS software application is only capable of reading and writing to RFID

tags that meet the ISO 15693 protocol. If the DR1000 is intended for use with

other

tag types, a Software Development Kit is available.

Barcode Data Style

Upon reading the barcode data, the DR1000 Dual Reader is capable of sending

the complete raw data stream to the host computer, or applying the “Field

Interpretations” before sending the data to the host computer. Select the

appropriate action to match the application.

RFID Data Style

Upon reading the RFID data, the DR1000 is capable of sending the tag UID to

the host computer, sending the RFID data to the host computer, sending the tag

UID and data to the host computer, or applying the “Field Interpretations” before

sending the data to the host computer. Select the appropriate action to match the

application.

Page 34 of 44

Appendix1 – BaRs Software

Trigger Notification (C

OMMAND MODE

only

)

The DR1000 may be configured to send notification to the host computer upon

trigger actions by the operator.

NOTE

If Trigger Notification is set to anything other than

“None”, then the Scan Sequence must be set to

“Disable”.

Scanner Serial Number

The Scanner Serial Number is a read-only parameter from the DR1000. This is

a factory-programmed serial number and is displayed in the Scanner Settings

dialog box if a DR1000 is properly connected to a host computer.

Scanner Firmware Version

The Scanner Firmware Version is displayed in the Scanner Settings dialog box if

a DR1000 is properly connected to a host computer.

Page 35 of 44

Appendix1 – BaRs Software

Field Interpretations

Field Interpretations are a set of user-defined formatting statements

applied by the DR1000 Dual Reader to the data stream read from a barcode

or RFID tag before it is sent to the host computer. There are three sets of

sixty-four field interpretations available. Each set will apply the template to the

scanned data based on the Scan Sequence settings.

EXAMPLE

If the Scan Sequence is set to “Barcode RFID”, the first sixty-four interpretation fields labeled with

“Scan” number “1” are applied to the barcode data, and the next sixty-four interpretation fields

labeled with “Scan” number “2” are applied to the RFID tag data. In this case the last sixty-four

interpretation fields labeled with “Scan” number “3” are ignored. The same principal applies to

other Scan Sequence settings and interpretation fields, accordingly

When defining interpretation fields for each Scan

Sequence, it is important that the interpretation

fields are consecutive, and no gap is present within

each sequence.

.

To make an entry in the interpretation field grid or edit an existing entry, doubleclick in the desired row and the “Field Interpretation” editing dialog box opens.

Enter the starting address of the field data from the scanned raw data.

XAMPLE

E

If an RFID tag is scanned and the RFID tag contains 256 bytes, and the desired data location is at

byte number 10 of the raw data, then enter “10” in the “Field Address”.

Enter the maximum length of the data in “Field Length”. “Field Header”

represents the data that is appended before the raw data prior to transmission to

the host. “Field Trailer” represents the data that is appended after the raw data

prior to transmission to the host.

To append special characters such as “Space”, “Tab”, “Carriage Return”, and

“Line Feed”, use the buttons provided.

The maximum length of field headers and field trailers is 4 characters.

Page 36 of 44

Appendix1 – BaRs Software

Apply To Scanner

The Apply To Scanner button downloads the present configuration settings into

the dual reader. After downloading the configuration settings into the DR1000,

the power must be cycled before the changes take effect.

Read From Scanner

The Read From Scanner button reads the current configuration settings of the

DR1000. Baud Rate and Field Interpretations cannot be read back from the device.

Load From File

The Load From File button loads a previously saved configuration file into the

Scanner Settings dialog box. This feature allows previously saved configuration

settings to be easily applied to one or more devices. The user must explicitly apply

the configuration settings to each desired DR1000 by clicking the “Apply To

Scanner” button.

Save To File

The Save To File button stores the defined Scanner Settings to a file for later

retrieval.

Advanced

The Advanced button enables expanded options available for the DR1000 Dual

Reader. Advanced features include: the ability to set each DR1000 configuration

individually; update firmware; turn LEDs on or off; and sound the DR1000

beeper.

NOTE

The caption of the “Advanced” button will change to

“Normal” when the dialog box is in Advanced mode. Click

the “Normal” button to return to Normal mode

.

Page 37 of 44

Appendix1 – BaRs Software

RFF View

RFF View allows the user to load a predefined form to display formatted data.

RFF forms are defined and saved in an XML document and loaded into the BaRS

application. Creating RFF forms is an advanced function beyond the scope of this

document; however, several sample forms are included with the BaRS software.

Data View

The Data View is designed to demonstrate the read, write and display capabilities

of the DR1000 Dual Reader.

Page 38 of 44

Appendix1 – BaRs Software

Raw RFID

The Raw RFID section displays the data read from a selected RFID tag, both in

text mode and in binary mode. Click the Select button to read a RFID tag in the

field of the DR1000. After a RFID tag is successfully selected, the UID of the tag

is displayed above the Select button. A RFID tag must be selected before

attempting to read or write to the tag.

• Click the Read RFID Tag button to read and display the data stored to

an RFID tag.

• Click the Write RFID Tag button to write the data that is in the “Binary”

section to a RFID tag.

• Click the Continuous RFID Scan button to set the application in a

continuous scan mode. In this mode, the application continuously

monitors the DR1000 and displays the data of any tag present in the field

of the reader.

• Click the Clear button to clear the “Binary” and “Text” data sections.

Formatted RFID

The Formatted RFID section is designed to write formatted data to a RFID tag.

Seven fields are available, each with a corresponding variable length. Enter the

desired data into one or more of the available fields and define the appropriate

length of each data string. Place a RFID tag within the field of the DR1000 and

click the Write RFID Tag button to write the formatted data.

Note that if the length of the data in each field is smaller than the defined field

length, null characters are added after the data prior to the write. Similarly, if the

length of the data is larger than the corresponding length, the data string is

truncated to the defined length prior to the write.

Barcode

The Barcode section demonstrates reading and displaying data read from a

barcode. Click the Read barcode button to read a barcode. The barcode data is

displayed in the “Barcode Data” window. Click the Clear button to delete the

contents of the “Barcode Data” window.

Trigger Operation

The DR1000 Dual Reader is capable of sending trigger events to the host

computer. These are defined in the “Trigger” section of the Data View window.

The DR1000 can read a barcode upon trigger pull, read a RFID tag upon trigger

pull, or do nothing, depending on the selected operation. A short beep is heard

after the completion of a trigger pull event.

Page 39 of 44

Appendix1 – BaRs Software

Formatted Read Form

The Formatted Read Form demonstrates the ability of the DR1000 to act as a

keyboard emulation device. Once proper field interpretations are designed for a

particular application, this form may be used to demonstrate how the DR1000 can

populate the fields of the form.

Page 40 of 44

This demonstration

assumes that BaRS

software is installed

on the host computer,

and that serial

emulation drivers, if

using the USB model,

are also installed and

configured properly

Appendix2 – DR1000 Demonstration

Appendix 2 - DR1000

Demonstration

This demonstration is designed to walk a user step-by-step through the process of

writing and reading data from an RFID tag, and reading data from a barcode. It

demonstrates the field interpretations capability, trigger event detection, and

command mode operation of the DR1000.

Start the Application

.

Double-click the BaRS icon placed on the Windows desktop, or select the BaRS

option from the Start menu to launch the application.

Preparing the RFID Tag

• Click the Application Settings button to set the desired

parameters for communication with the DR1000 Dual Reader. Set the

serial port to match the appropriate COM port defined in the Device

Manager, and then click OK.

• Click the Start Scanner button to initialize communication with

the DR1000.

• Click the Data View button to open the data view of the

application.

• Enter the following data into the Formatted RFID section of the Data View

window:

(Use the Down arrow buttons to set the lengths)

Field 1: First Name Length: 15

Field 2: Last Name Length: 15

Field 3: 12345 First Street Length: 20

Field 4: New Town Length: 15

Field 5: CA Length: 5

Field 6: 91340 Length: 5

Field 7: (987)654-3210 Length: 15

• Place a RFID tag within 5 inches of the face of the reader and click on the

Write RFID Tag button. The data will be written to the RFID tag as

defined in the Formatted RFID section.

Page 41 of 44

Appendix2 – DR1000 Demonstration

Applying the Scanner Configurations

• Click the Scanner Settings button to open the Scanner Settings

dialog box.

NOTE

If the dual reader settings dialog box does not appear,

navigate to the C:\Program Files\Precision Dynamics

Corporation\BaRS directory and double-click on the

RegisterMSFlsGrd icon. Then try to open the dialog box

again.

• Click the Load From File button, and select the “DEMO1.DRC”

configuration file from the Configuration Files folder.

• Click the Apply To Scanner button to download the configuration

settings to the DR1000.

• Click the Close button to exit the Scanner Settings dialog box.

• Click the Start Scanner button to stop communication with the

reader.

• Exit the BaRS application.

• The power to the DR1000 must be cycled before the new configuration

settings may be applied to the device. Disconnect the DR1000 from its

power source and reconnect for the new settings to take affect.

Keyboard Emulation Read (USB and PS/2 versions)

• Double-click the BaRS icon placed on the Windows desktop, or select the

BaRS option from the Start menu to launch the application.

• Click the Form Dialog button to open the formatted read dialog

box.

• Point the DR1000 at a barcode, pull the trigger, and the “Field 1” data will

be populated.

• Point the DR1000 at the RFID tag programmed previously and pull the

trigger. Fields 2 through 8 will be populated.

The above exercise demonstrated how the DR1000 may be used to emulate

keyboard entry by applying “Field Interpretations” to the data read from both a

barcode and a RFID tag. Close the Formatted Read form and exit the BaRS

application.

Page 42 of 44

Appendix2 – DR1000 Demonstration

Changing the Scanner Configuration (USB version)

• Disconnect the DR1000 from the host computer.

• Pull and hold the trigger and reconnect the device into the computer’s

USB port. Once the device is again connected to the host, release the

trigger. This action causes the DR1000 to register as a serial device with

the computer.

• Start the BaRS application.

• Click the Start Scanner button to initialize communication with

the DR1000.

• Click the Scanner Settings button to open the Scanner Settings

dialog box.

• Click the Read From Scanner button to display the current configuration

settings of the device.

• Select “Serial” from the “USB Mode” drop down list.

• Select “Disable” from the “Scan Sequence” drop down list.

• Select “Pull” from the “Trigger Notification” drop down list.

• Click the Apply To Scanner button.

• Click the Close button to exit the Scanner Settings dialog box.

• Click the Start Scanner button to stop communication with the

reader.

• Disconnect the DR1000 from the computer, and then reconnect without

pulling the trigger.

The new settings are now stored in the device memory and preserved over a

power cycle. Repeat the procedure above if changes to the configuration

settings are desired.

Page 43 of 44

Appendix2 – DR1000 Demonstration

Command Mode Read

The following steps illustrate the various RFID and barcode read events of the

DR1000 if operated in Command (host) mode.

• Start the BaRS application if it is not already running.

• Click the Start Scanner button to initialize communication with

the DR1000.

• Click the Data View button to open the data view of the

application.

• Place an RFID tag in front of the dual reader and click the Read RFID

Tag button. The data from the RFID tag will be read and displayed in the

“Binary”, and “Text” fields of the “Raw RFID” section.

• Click the Continuous RFID Scan button and place an RFID tag in front

of the dual reader. The data from the RFID tag will be read and displayed

in the “Binary”, and “Text” fields of the “Raw RFID” section. Remove

the RFID tag from the field of the reader and the data will clear

automatically.

• Click the Continuous RFID Scan button to end the continuous scan.

• Point the DR1000 at a barcode and click the Read Barcode button. The

barcode data will be displayed in the Barcode Data section of the Data

View window. Click the Clear button to clear the data.

Trigger Events

The following steps illustrate the trigger events of the DR1000 if operated in

Command (host) mode.

• Click the Barcode button in the “Trigger” section.

• Point the DR1000 at a barcode and pull the trigger. The DR1000 will read

a barcode and beep at the end of the operation.

• Click the RFID button in the “Trigger” section.

• Place an RFID tag in front of the dual reader and pull the trigger. The

DR1000 will read the data of the RFID tag and beep at the end of the

operation.

• Click the Nothing button in the “Trigger” section.

• Pull the trigger and the DR1000 will beep without scanning anything.

• This demonstrates the trigger event and Command (host) mode

capabilities of the dual reader.

Page 44 of 44

Loading...

Loading...