Page 1

SUMMER RAIN

™

2 WALL & 3 WALL

WALK-IN SHOWER SYSTEMS

INSTALLATION AND OPERATING INSTRUCTIONS

Page 2

IMPORTANT SAFETY INFORMATION

Do not place or use electrically connected devices, such as television, radio, or stereo speakers, lights, hair

dryers, or telephones, within 1.5 m (5 feet) of shower.

Note: This is a professional grade product. A knowledge of construction techniques, plumbing and electrical

installation according to codes are required for proper installation and user satisfaction. We recommend that

a licensed contractor perform the installation of all Jacuzzi Whirlpool Bath products. Our warranty does not

cover improper installation related problems.

Page 3

CONTENTS

2 WALL

Specifications _________________________________________________________________________ 2

Rough-in Reference ____________________________________________________________________ 3

Component Identification ________________________________________________________________ 4

Base Installation _______________________________________________________________________ 5-7

Tower and Glass Panels Installation________________________________________________________ 8-12

3 WALL

Specifications _________________________________________________________________________ 13

Rough-in Reference ____________________________________________________________________ 14

Component Identification ________________________________________________________________ 15

Base Installation _______________________________________________________________________ 16-18

Tower and Glass Panels Installation________________________________________________________ 19-22

2 & 3 WALL

Operation ___________________________________________________________________________ 23

Maintenance __________________________________________________________________________ 24

Tower Fixture Repair Parts _______________________________________________________________ 25

Tower Plumbing Repair Parts _____________________________________________________________ 26

2 Wall Unit Repair Parts _________________________________________________________________ 27

3 Wall Unit Repair Parts _________________________________________________________________ 28

Warranty _____________________________________________________________________________ 29-30

Save These Instructions for Future Use.

Owner's Record

Date Purchased ____________________________________________________________

Purchased From ____________________________________________________________

Installed By ________________________________________________________________

Serial Number _____________________________________________________________

Model ____________________________________________________________________

1

Page 4

2 WALL SPECIFICATIONS

Important: Read complete instructions before beginning installation.

Each unit arrives ready for installation, equipped with base, glass and associated hardware.

Remove the unit from the carton. Retain the shipping carton until satisfactory inspection of the product has been

made.

Immediately upon receipt, inspect the base and other components before installing. Check all carton inserts for

parts and hardware. Should inspection reveal any damage or defect in any component, do not install the unit. Damage

or defect to any component claimed after the unit is installed is excluded from the warranty. Jacuzzi Whirlpool Bath's

responsibility for shipping damage ceases upon delivery of the products in good order to the carrier. Refer any claims

for damage to the carrier. For definitions of warranty coverage and limitations, refer to the published warranty

information packed with the product.

Jacuzzi Whirlpool Bath is not responsible for any defect that could have been discovered, repaired, or avoided by

following this inspection.

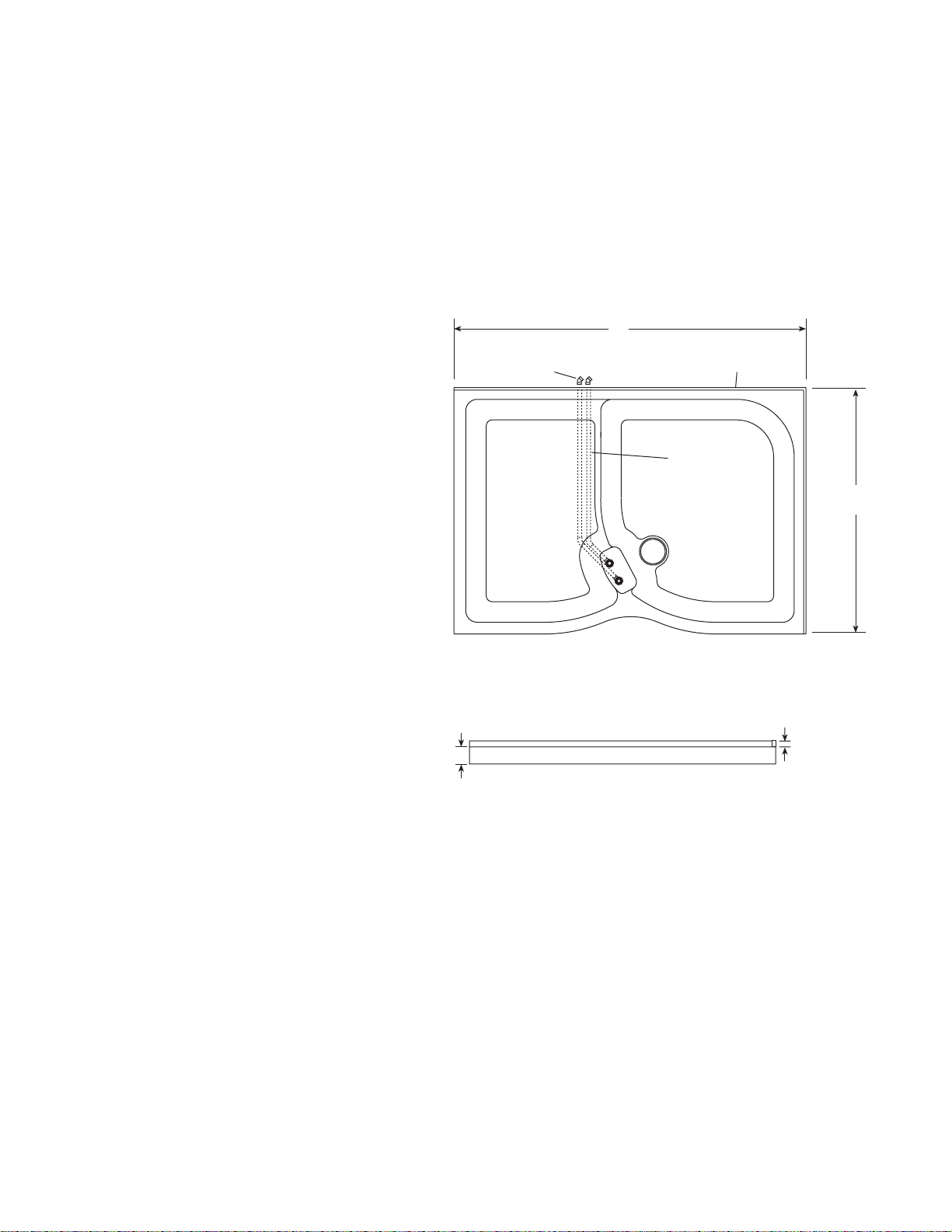

BASE SPECIFICATIONS

DIMENSIONS

60" (1219 mm) L

42-5/16" ( 1075 mm) W

4" ( 102 mm) H

PRODUCT WEIGHT (Base + Enclosure )

196 lb

(89 kg)

TOTAL WEIGHT/

FLOOR LOADING

396 lb

(180 kg)/

23 lb/sq. ft.

(112 kg/sq. m)

NOTE: MINIMUM WATER PRESSURE

FOR THE SYSTEM IS 40 PSI.

45° ELBOW

2 PROVIDED

(LOOSE)

H

L

1-1/2" TILE FLANGE

1/2" RIGID

COPPER PIPE

UNDER BASE

W

TOP VIEW

1-1/2" TILE FLANGE

FRONT VIEW

2

Page 5

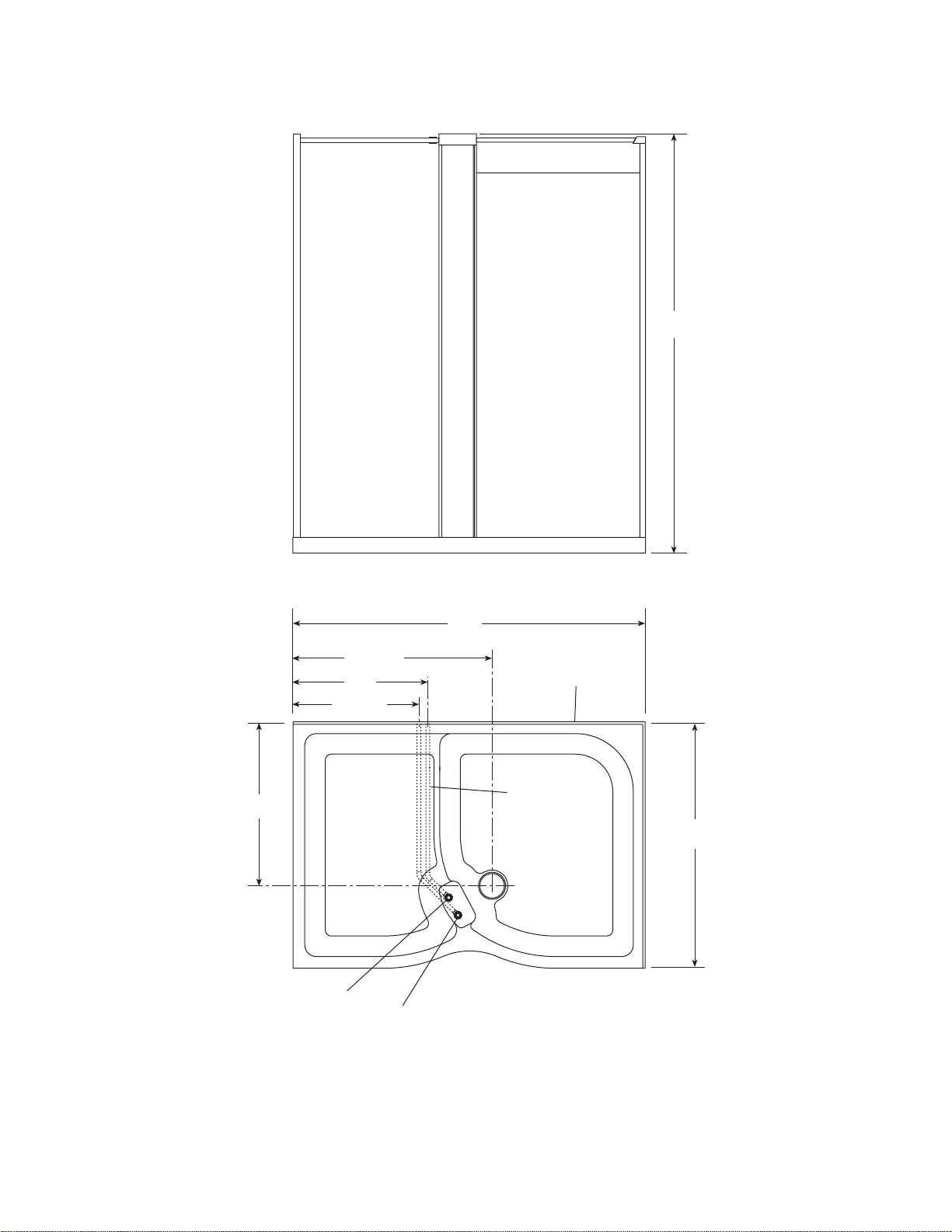

2 WALL ROUGH-IN REFERENCE

84"

33-3/4"

23"

21-1/2"

27-15/16"

COLD SUPPLY

HOT SUPPLY

MINIMUM WATER PRESSURE

FOR THE SYSTEM IS 40PSI

FRONT VIEW

60"

1-1/2" TILE FLANGE

1/2" RIGID

COPPER PIPE

UNDER BASE

42-5/16"

TOP VIEW

3

Page 6

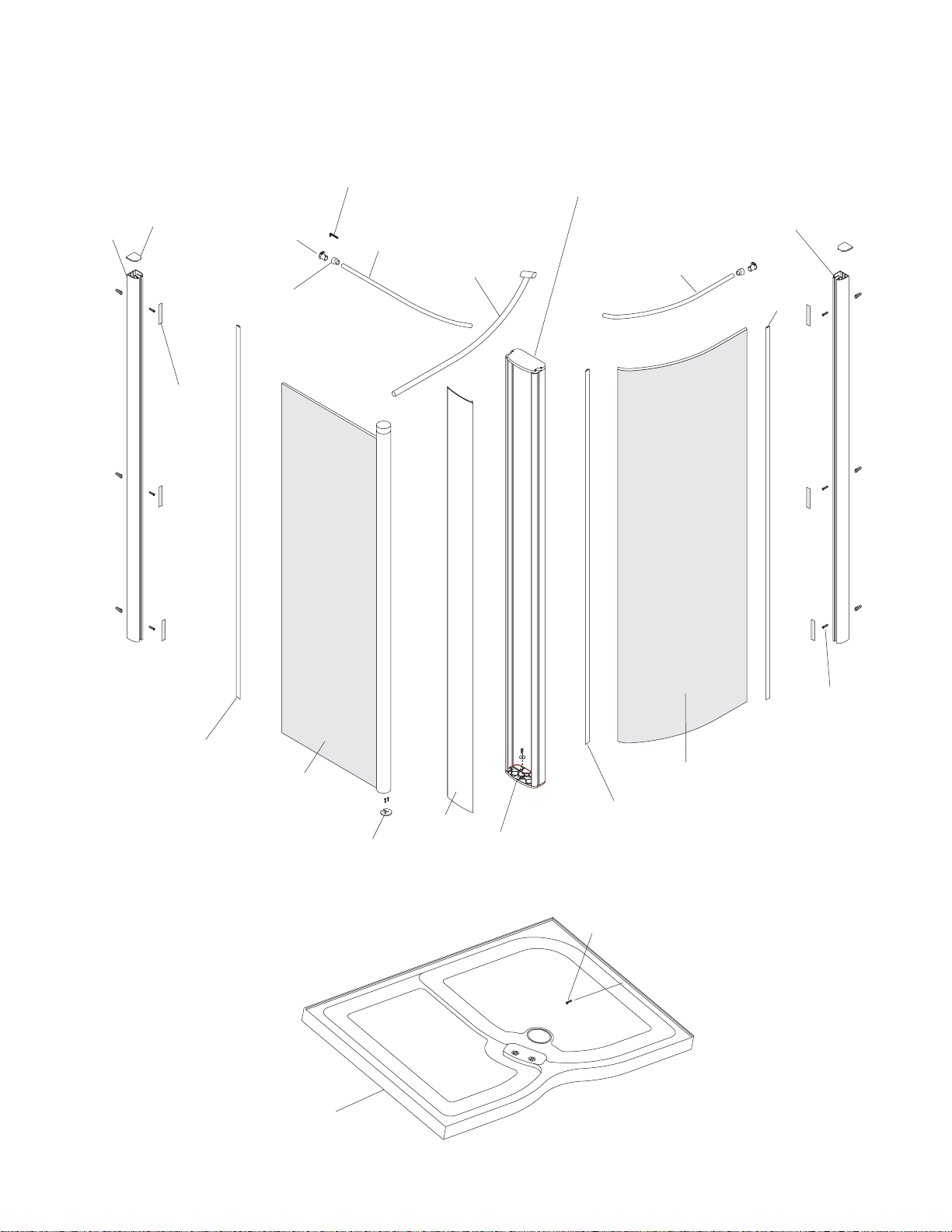

STRAIGHT

GLASS

WALL

MOUNTING

POST

MOUNTING

POST

CAP (2)

TAPE

(6 PIECES)

2 WALL COMPONENT IDENTIFICATION

WALL

MOUNT

BRACKET (2)

BRACKET

COVER (2)

HEX WRENCH (1)

(PROVIDED)

TOWER

SUPPORT

RAIL

TOWER WITH PLUMBING,

FIXTURES, MAGNETIC

GASKET, BOTTOM PLATE

AND TOP COVER

(PREASSEMBLED)

GLASS

PANEL

SUPPORT

RAIL

CURVED

GLASS

WALL

MOUNTING

POST

FRONT

RAIL

GLAZING

GASKET

GLAZING GASKET (3)

STRAIGHT

GLASS

PANEL

BOTTOM

BRACKET

CORNER

BASE

POST

TOWER

COVER

3 SCREWS AND

3 WALL ANCHORS

PER MOUNTING

POST

CURVED

GLASS

GLAZING GASKET

TOWER MOUNTING

BOLT & WASHER

SELF

DRILLING

SCREW

4

Page 7

STRAINER

DRAIN

ASSEMBLY

SILICONE

SEALANT

SHOWER BASE

RUBBER WASHER

FIBER WASHER

NUT

APPLY LUBRICANT

2 WALL BASE INSTALLATION

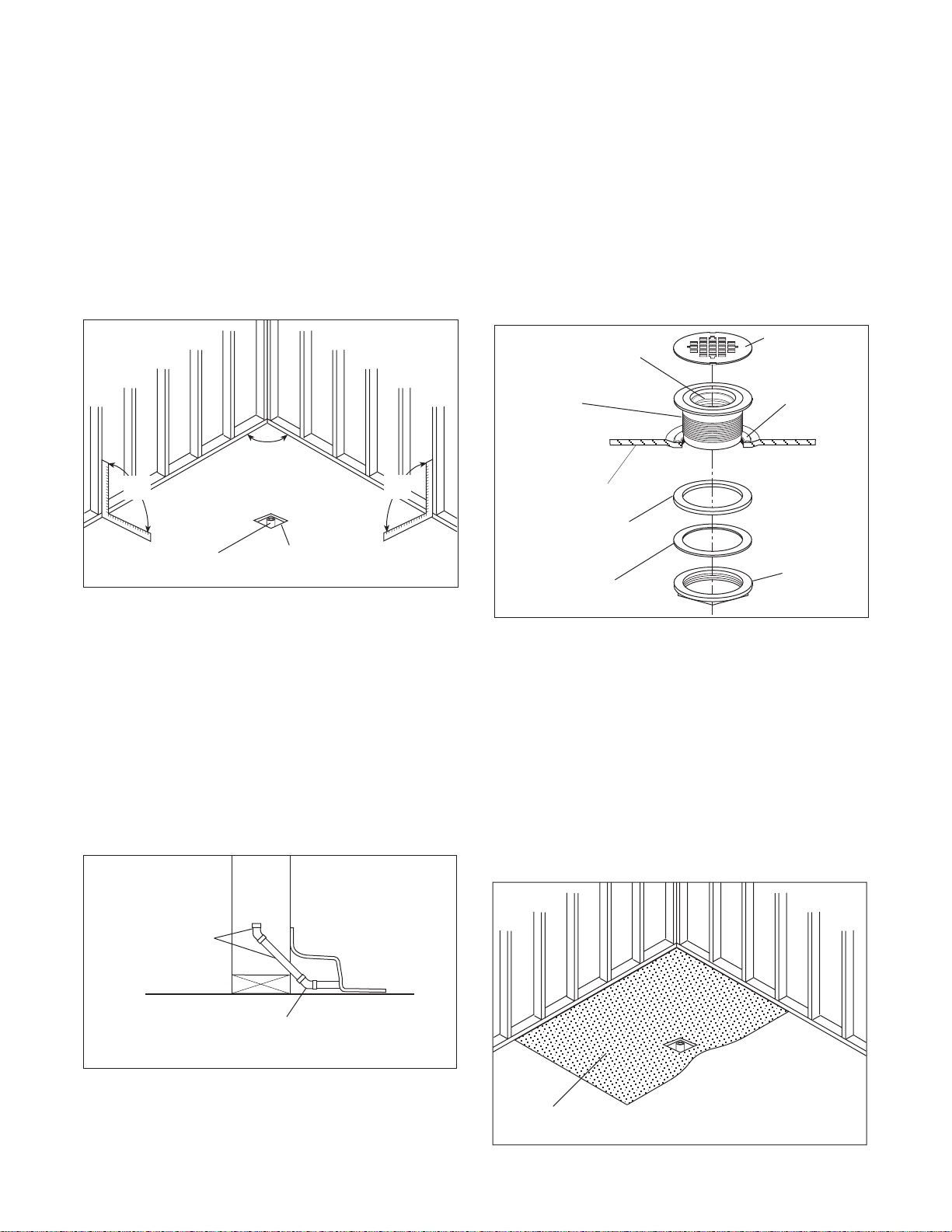

PRELIMINARY ROUGH-IN

The floor structure beneath the unit must be able to

support a total weight of the unit and bather. Refer

to the table under total weight.

STEP 1

Provide an opening in the subfloor no less than 5" x 5"

square. This opening should be located on the center

lines of the shower base drain hole (See Product Chart).

The opening is to accommodate a 2" waste pipe. The

waste pipe should be 1/4" to 1/2" above the surface of

the subfloor.

90°

90°

90°

INSTALLATION INSTRUCTIONS

STEP 2

Remove the stainless steel strainer from the drain

assembly. Disassemble the locknut and two gaskets

from the back of the drain assembly. Apply a 1/4" bead

of caulking (silicone) to the drain hole and insert the drain

assembly. Replace the rubber washer, fiber washer,

and lock nut in that order. Hand tighten the locknut.

Remove excess sealant from finished side.

Apply a lubricant (common household liquid soap

works well) to the inside of the rubber seal of the drain

assembly.

As shown in top view, 1/2" copper pipes are provided

to connect to the water supply. Also provided are 2 loose

45° elbows as shown for installation in Detail 1.

CAUTION: A nonflammable protective barrier must

be placed between soldering work and base unit to

prevent damage to the base.

When connecting the supply lines, the toe plate can be

notched to accommodate the pipes.

The pipe under the base can be cut to length. To do so,

remove the pipe clamps under the base, cut the pipe and

reinstall pipes.

NOT PROVIDED

2" WASTE PIPE

STUD

WALL

45° ELBOW

PROVIDED (2)

DEATAIL 1

5"x5" OPENING

(MIN. AS POSSIBLE)

STEP 3

If the subfloor is level, no other preparation is necessary. You can proceed to install the shower base. If the

subfloor is not level, level shower base by spreading

floor leveling compound, mortar, plaster or minimal

expansion structural foam with a minimum density of 5

lbs./cubic feet EVENLY over ENTIRE area where base

will be installed. The compound used MUST make

contact with the entire bottom surface of the base. Both

sides of a joint or splice of subfloor should be level to

each other. Level and support waste pipe cutout area

greater than 5" x 5". The base is NOT to be supported

by the tile flange.

SPREAD MORTAR OR LEVELING COMPOUND ETC.

EVENLY OVER ENTIRE AREA

5

Page 8

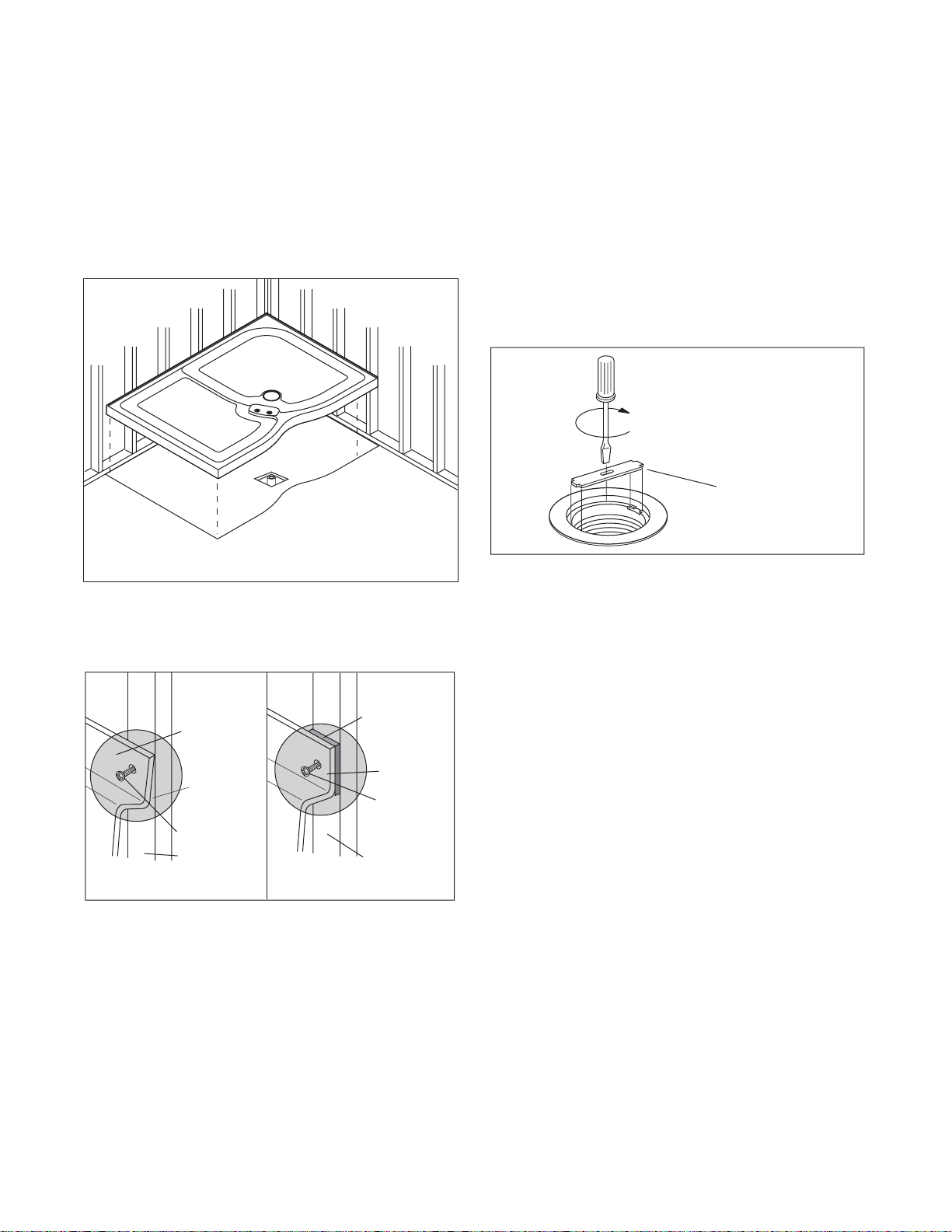

2 WALL BASE INSTALLATION

STEP 4

With the drain fitting passing over the center of the

drainpipe, lower the shower base carefully into place,

push down firmly until the base is in place. You must

check the level of the base in two directions. Do not lift

a corner to level the base. This will cause a loss of

contact with the mortar. Attach the shower base flange

to the stud wall and blocking with self-drilling screws

(included). Use a minimum of 3 screws per flange

section.

STEP 5

With a large screwdriver and the tool included with the

drain, tighten the inside compression nut to seal the

drain pipe connection. After drain is fully installed, test

for proper drainage. If the shower base does not drain

properly, rectify this condition before proceeding with

the installation. Jacuzzi Whirlpool Bath is not respon-

sible for removal and/ or reinstallation costs.

NOTE: Watertight installation of the drain is the

installer’s responsibility. Drain leakage is excluded

from the Jacuzzi Whirlpool Bath warranty.

Replace the strainer and tape over the drain hole to

prevent finishing material from entering drain.

TIGHTEN SEALING NUT

TOOL

(INCLUDED)

POSITION BASE OVER CENTER OF

DRAIN PIPE AND SET INTO PLACE

NOTE: If there is any gap between base flange and

stud or blocking, shims MUST be used to prevent

distortion or cracking of the flange.

TILE

FLANGE

GAP

USE

SCREWS

(PROVIDED)

STUD

INCORRECT

SHIM

TILE

FLANGE

USE

SCREWS

(PROVIDED)

STUD

CORRECT

6

Page 9

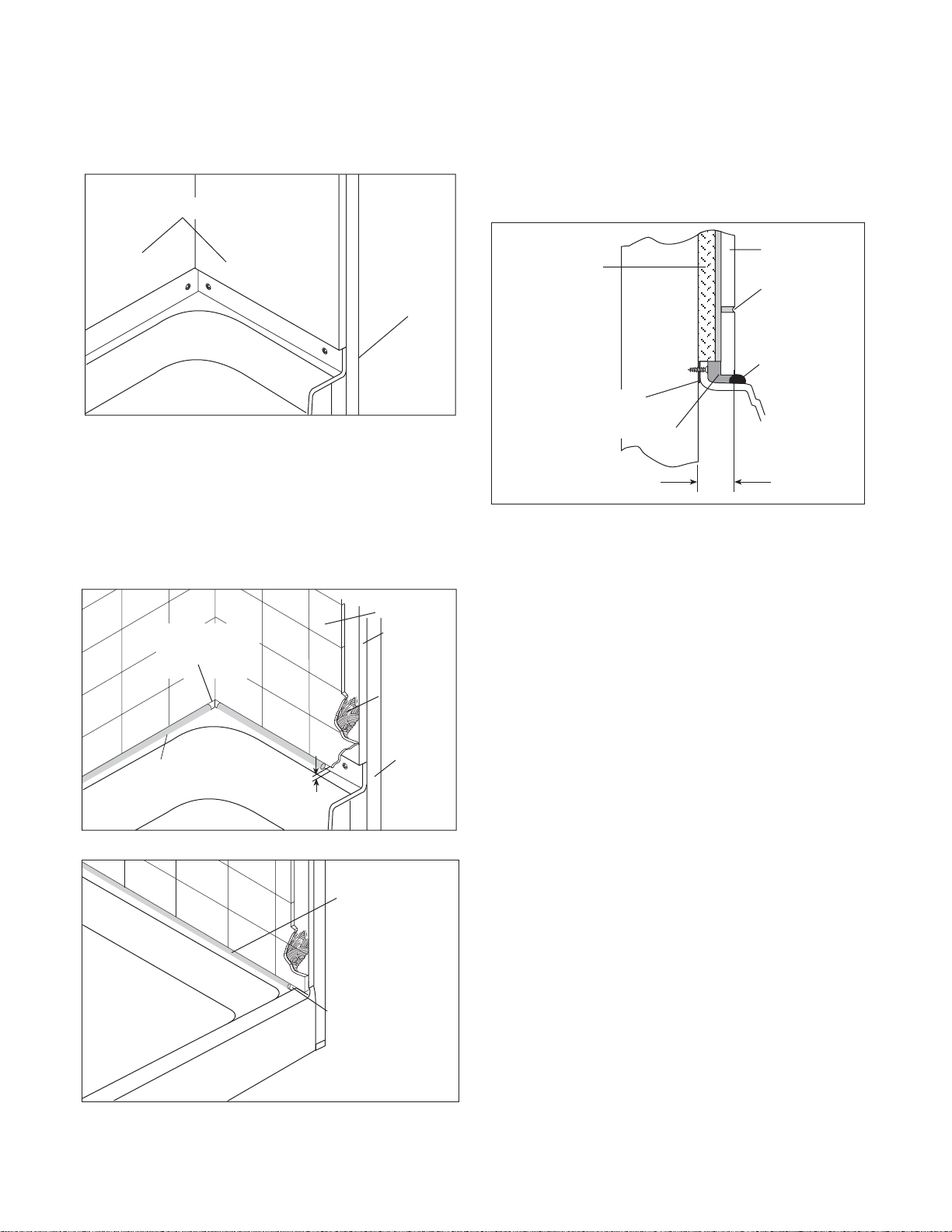

2 WALL BASE INSTALLATION

STEP 6

Place cement board or equivalent on top of shower

base flange and secure to studwall.

CEMENT BOARD

STUD

STEP 7

Apply tile (or other finishing material) leaving a 1/8" gap

between the finishing material and the shower base

flange lip. Seal this gap with silicone sealant. Leave a

minimum 1/4" gap at the back and front corners of the

shower base to allow drainage from leakage through

unsealed tiled grout.

TILE

1/4" MINIMUM

GAP

SILICONE

SEALANT

1/8" GAP

SILICONE

SEALANT

CEMENT

BOARD

TILE

ADHESIVE

STUD

STEP 8

Filling the area marked DO NOT FILL will prevent

moisture from draining back into the base through the

weep holes. This moisture is due to leakage through the

tile grout. Sealing the tile grout will prevent this leakage.

CEMENT

BOARD

STUD

SHIM IF NECESSARY

DO NOT FILL

1-1/8" MAXIMUM

NO MINIMUM

TILE

GROUT

SILICONE

SEALANT

CLEAN-UP AFTER INSTALLATION

To avoid dulling and scratching the acrylic surface of

the base, never use abrasive cleaners. A mild liquid

detergent and warm water clean soiled surfaces.

Remove spilled plaster with a wood or plastic edge.

Metal tools scratch the surface. Spots left by plaster or

grout can be removed if lightly rubbed with detergent on

a damp cloth or sponge.

Paint, tar, or other difficult stains can be removed with

paint thinner, turpentine, or isopropyl alcohol (rubbing

alcohol).

Minor scratches which do not penetrate the color

finish can be removed by lightly sanding with 600-grit

wet/dry sandpaper. You can restore the glossy finish to

the acrylic surface of the base with a special compound,

Meguiar’s #10 Mirror Glaze. If not available, use automotive rubbing compound followed by an application of

automotive paste wax.

Major scratches and gouges which penetrate the

acrylic surface require refinishing. Ask your Jacuzzi

Whirlpool Bath dealer for special instructions.

1/4" MINIMUM GAP

7

Page 10

2 WALL: TOWER, FIXED WALL AND CURVED GLASS INSTALLATION

MARK POSITION

STEP 1

Position the wall posts so the edge of the post is set back

3/4" (19 mm) in from the edge of the base

3/4"

(19 mm)

FINISH WALL

EDGE OF BASE

STEP 2

Level both wall posts in their proper position and mark

where screw holes are to be drilled. Drill 3/16" holes and

secure with wall anchors and screws provided. Cut a 12"

strip of tape (provided) and apply firmly over screw

heads.

TAPE

6 PLACES)

STEP 3A

Slide straight glass panel all the way into wall post. Mark

position of glass post. Remove panel.

STEP 3B

Apply a bead of silicone sealant on underside of bottom

bracket corner post and place bracket where marked.

Drill pilot holes (#8 screw) and secure bracket to base.

Reinsert panel into wall post and position glass post over

bracket.

APPLY BEAD OF

SILICONE SEALANT

ON UNDERSIDE OF

BOTTOM BRACKET

CORNER POST

8

Page 11

2 WALL: TOWER, FIXED WALL AND CURVED GLASS INSTALLATION

GLASS PANEL

SUPPORT RAIL

TOWER SUPPORT RAIL

STEP 4

Slide the glass panel into the wall post. Make sure that

the corner notch is positioned toward the base of the

tower.

NOTCH

STEP 6

Insert tower support rail into glass panel rail but do not

tighten at this time.

STEP 7

Insert support rails into brackets in top moulding of tower

but do not tighten at this time. Front and tower support

rails may have to be cut if they are too long.

TOWER SUPPORT RAIL

FRONT RAIL

STEP 5

Place the tower onto base. Ensure the curved glass

locates into the glazing channel. Install bolt but do not

tighten.

BOLT (5/16")

WASHER

GLAZING

CHANNEL

GLASS PANEL

SUPPORT RAIL

STEP 8

Slide mounting bracket covers and mounting brackets

onto front rail and tower support rail.

MOUNTING

BRACKET

RAIL

COVER

RAIL WALL

MOUNTING BRACKET

9

Page 12

2 WALL: TOWER, FIXED WALL AND CURVED GLASS INSTALLATION

SHUT OFF

VALVES

(PROVIDED)

COLD

HOT

BOLT

STEP 9

Place the front rail and tower support rail against the

walls. Check level and mark the position for the rail

mounting bracket. The screw position will be above the

rail. Drill the wall with a 3/16" bit and secure bracket with

screws and wall anchors provided.

ATTACH RAIL

BRACKET TO WALL

SECURE RAIL TO

BRACKET (TURN CW

TO TIGHTEN)

MOVE COVER CAP

OVER BRACKET

STEP 10

Adjust the rails until tower is vertical in 2 planes.

STEP 11

Secure the rails.

STEP 12

Tighten the tower base bolt. Two shut-off valves are

provided. To hook up supply lines, unscrew valves from

braided line. Using thread sealant, screw valve to stub

outs at bottom of tower. Then reconnect braided line

using provided gasket. Do not twist or kink supply lines

when connecting.

10

Page 13

2 WALL: TOWER, FIXED WALL AND CURVED GLASS INSTALLATION

GLAZING GASKET

INSIDE OF

ENCLOSURE

TOWER TOP PLATE

STEP 13A

Insert fixed glass support rail into panel post and tighten

set screw.

STEP 13B

Drill a 1/8" pilot hole into tower support rail using the hole

in the glass panel support rail. Screw M3.5X9.5 mm

screw into hole.

STEP 14

Install cover cap on fixed glass wall post.

COVER CAP

STEP 15

Install glazing gasket on fixed glass wall post and curved

glass wall post on the inside. Note orientation of gasket.

Soapy water may help to insert the glazing gasket.

GLASS PANEL

SUPPORT RAIL

DRILL 1/8" PILOT HOLE AND

SCREW M3.5X9.5 mm SCREW

INTO HOLE

WALL POST

GLASS

INSIDE OF

ENCLOSURE

GLAZING GASKET

11

Page 14

2 WALL: TOWER, FIXED WALL AND CURVED GLASS INSTALLATION

STEP 16

Turn on water supply and check for leaks. Correct any

leaks before installing tower cover.

STEP 17

Install tower cover as shown. Insert cover at top first.

TOWER TOP PLATE

TOWER COVER

INSERT THIS SIDE FIRST

TOWER COVER

STEP 18

Seal all around the base of tower with silicone sealant.

Also seal the inside of both wall posts, glass post and the

bottom of both glass panels on the inside only.

APPLY SEALANT

ALONG BASE

AND SIDE OF

WALL POST

APPLY SEALANT

ALONG BASE

OF GLASS

APPLY SEALANT

AROUND

GLASS POST

APPLY SEALANT

ALL AROUND

TOWER BASE

APPLY SEALANT

ALONG BASE

OF GLASS

APPLY SEALANT

ALONG BASE

AND SIDE OF

WALL POST

(RAILS NOT SHOWN)

TOP VIEW

12

Page 15

3 WALL SPECIFICATIONS

Important: Read complete instructions before beginning installation.

Each unit arrives ready for installation, equipped with base, glass and associated hardware.

Remove the unit from the carton. Retain the shipping carton until satisfactory inspection of the product has been

made.

Immediately upon receipt, inspect the base and other components before installing. Check all carton inserts for

parts and hardware. Should inspection reveal any damage or defect in any component, do not install the unit. Damage

or defect to any component claimed after the unit is installed is excluded from the warranty. Jacuzzi Whirlpool Bath's

responsibility for shipping damage ceases upon delivery of the products in good order to the carrier. Refer any claims

for damage to the carrier. For definitions of warranty coverage and limitations, refer to the published warranty

information packed with the product.

Jacuzzi Whirlpool Bath is not responsible for any defect that could have been discovered, repaired, or avoided by

following this inspection.

BASE SPECIFICATIONS

DIMENSIONS

60" (1219 mm) L

42-5/16" ( 1075 mm) W

4" ( 102 mm) H

PRODUCT WEIGHT (Base + Enclosure )

140 lb

(64 kg)

TOTAL WEIGHT/

FLOOR LOADING

340 lb

(155 kg)/

23 lb/sq. ft.

(97 kg/sq. m)

NOTE: MINIMUM WATER PRESSURE

FOR THE SYSTEM IS 40 PSI.

45° ELBOW

2 PROVIDED

(LOOSE)

H

L

1-1/2" TILE FLANGE

1/2" RIGID

COPPER PIPE

UNDER BASE

W

TOP VIEW

1-1/2" TILE FLANGE

13

FRONT VIEW

Page 16

3 WALL ROUGH-IN REFERENCE

84"

33-3/4"

23"

21-1/2"

27-15/16"

COLD SUPPLY

HOT SUPPLY

MINIMUM WATER PRESSURE

FOR THE SYSTEM IS 40PSI

FRONT VIEW

60"

1-1/2" TILE FLANGE

1/2" RIGID

COPPER PIPE

UNDER BASE

42-5/16"

TOP VIEW

14

Page 17

WALL

MOUNT

BRACKET (2)

BRACKET

COVER (2)

HEX WRENCH (1)

(PROVIDED)

TOWER

SUPPORT

RAIL

3 WALL COMPONENT IDENTIFICATION

TOWER WITH PLUMBING,

FIXTURES, MAGNETIC

GASKET, BOTTOM PLATE

AND TOP COVER

(PREASSEMBLED)

FRONT

RAIL

CURVED

GLASS

WALL

MOUNTING

POST

TAPE

(3 PLACES)

MOUNTING

POST

CAP

TOWER COVER

TOWER MOUNTING

BOLT & WASHER

BASE

CURVED

GLASS

GLAZING GASKET (2)

GLAZING

GASKET

SELF

DRILLING

SCREW

3 SCREWS AND

3 WALL ANCHORS

15

Page 18

3 WALL BASE INSTALLATION

STRAINER

DRAIN

ASSEMBLY

SILICONE

SEALANT

SHOWER BASE

RUBBER WASHER

FIBER WASHER

NUT

APPLY LUBRICANT

PRELIMINARY ROUGH-IN INSTALLATION INSTRUCTIONS

The floor structure beneath the unit must be able to

support a total weight of the unit and bather. Refer

to the table under total weight.

STEP 1

Provide an opening in the subfloor no less than 5" x 5"

square. This opening should be located on the center

lines of the shower base drain hole (See Product Chart).

The opening is to accommodate a 2" waste pipe. The

waste pipe should be 1/4" to 1/2" above the surface of

the subfloor.

90°

2" WASTE PIPE

5"x5" OPENING (MIN. AS POSSIBLE)

90°

STEP 2

Remove the stainless steel strainer from the drain

assembly. Disassemble the locknut and two gaskets

from the back of the drain assembly. Apply a 1/4" bead

of caulking (silicone) to the drain hole and insert the drain

assembly. Replace the rubber washer, fiber washer,

and lock nut in that order. Hand tighten the locknut.

Remove excess sealant from finished side.

Apply a lubricant (common household liquid soap

works well) to the inside of the rubber seal of the drain

assembly.

As shown in top view, 1/2" copper pipes are provided

to connect to the water supply. Also provided are 2 loose

45° elbows as shown for installation in Detail 1.

CAUTION: A nonflammable protective barrier must

be placed between soldering work and base unit to

prevent damage to the base.

When connecting the supply lines, the toe plate can be

notched to accommodate the pipes.

The pipe under the base can be cut to length. To do so,

remove the pipe clamps under the base, cut the pipe and

reinstall pipes.

NOT PROVIDED

STUD

WALL

45° ELBOW

PROVIDED (2)

DEATAIL 1

STEP 3

If the subfloor is level, no other preparation is necessary. You can proceed to install the shower base. If the

subfloor is not level, level shower base by spreading

floor leveling compound, mortar, plaster or minimal

expansion structural foam with a minimum density of 5

lbs./cubic feet EVENLY over ENTIRE area where base

will be installed. The compound used MUST make

contact with the entire bottom surface of the base. Both

sides of a joint or splice of subfloor should be level to

each other. Level and support waste pipe cutout area

greater than 5" x 5". The base is NOT to be supported

by the tile flange.

SPREAD MORTAR OR LEVELING COMPOUND ETC.

EVENLY OVER ENTIRE AREA

16

Page 19

3 WALL BASE INSTALLATION

STEP 4

With the drain fitting passing over the center of the

drainpipe, lower the shower base carefully into place,

push down firmly until the base is in place. You must

check the level of the base in two directions. Do not lift

a corner to level the base. This will cause a loss of

contact with the mortar. Attach the shower base flange

to the stud wall and blocking with self-drilling screws

(included). Use a minimum of 3 screws per flange

section.

WHEN SCREWING FLANGE TO STUD

WALL START WITH THIS SIDE

POSITION BASE OVER CENTER OF

DRAIN PIPE AND SET INTO PLACE

STEP 5

With a large screwdriver and the tool included with the

drain, tighten the inside compression nut to seal the

drain pipe connection. After drain is fully installed, test

for proper drainage. If the shower base does not drain

properly, rectify this condition before proceeding with

the installation. Jacuzzi Whirlpool Bath is not respon-

sible for removal and/ or reinstallation costs.

NOTE: Watertight installation of the drain is the

installer’s responsibility. Drain leakage is excluded

from the Jacuzzi Whirlpool Bath warranty.

Replace the strainer and tape over the drain hole to

prevent finishing material from entering drain.

TIGHTEN SEALING NUT

TOOL

(INCLUDED)

NOTE: If there is any gap between base flange and

stud or blocking, shims MUST be used to prevent

distortion or cracking of the flange.

TILE

FLANGE

GAP

USE

SCREWS

(PROVIDED)

STUD

INCORRECT

SHIM

TILE

FLANGE

USE

SCREWS

(PROVIDED)

STUD

CORRECT

17

Page 20

GROUT

STUD

SHIM IF NECESSARY

DO NOT FILL

CEMENT

BOARD

TILE

SILICONE

SEALANT

1-1/8" MAXIMUM

NO MINIMUM

3 WALL BASE INSTALLATION

STEP 6

With the drain fitting passing over the center of the

drainpipe, lower the shower base carefully into place,

push down firmly until the base is in place. You must

check the level of the base in two directions. Do not lift

a corner to level the base. This will cause a loss of

contact with the mortar. Attach the shower base flange

to the stud wall and blocking with self-drilling screws

(included). Use a minimum of 3 screws per flange

section.

CEMENT BOARD

STUD

STEP 7

With a large screwdriver and the tool included with the

drain, tighten the inside compression nut to seal the

drain pipe connection. After drain is fully installed, test

for proper drainage. If the shower base does not drain

properly, rectify this condition before proceeding with

the installation. Jacuzzi Whirlpool Bath is not respon-

sible for removal and/ or reinstallation costs.

NOTE: Watertight installation of the drain is the

installer’s responsibility. Drain leakage is excluded

from the Jacuzzi Whirlpool Bath warranty.

Replace the strainer and tape over the drain hole to

prevent finishing material from entering drain.

NOTE: If there is any gap between base flange and

stud or blocking, shims MUST be used to prevent

distortion or cracking of the flange.

SILICONE

SEALANT

1/4" MINIMUM GAP

1/4" MINIMUM

GAP

TILE

CEMENT

BOARD

TILE

ADHESIVE

CLEAN-UP AFTER INSTALLATION

To avoid dulling and scratching the acrylic surface of

the base, never use abrasive cleaners. A mild liquid

detergent and warm water clean soiled surfaces.

Remove spilled plaster with a wood or plastic edge.

Metal tools scratch the surface. Spots left by plaster or

grout can be removed if lightly rubbed with detergent on

a damp cloth or sponge.

Paint, tar, or other difficult stains can be removed with

paint thinner, turpentine, or isopropyl alcohol (rubbing

alcohol).

Minor scratches which do not penetrate the color

finish can be removed by lightly sanding with 600-grit

wet/dry sandpaper. You can restore the glossy finish to

the acrylic surface of the base with a special compound,

Meguiar’s #10 Mirror Glaze. If not available, use automotive rubbing compound followed by an application of

automotive paste wax.

Major scratches and gouges which penetrate the

acrylic surface require refinishing. Ask your Jacuzzi

Whirlpool Bath dealer for special instructions.

SILICONE

SEALANT

1/8" GAP

STUD

18

Page 21

3 WALL: TOWER AND CURVED GLASS INSTALLATION

NOTCH

STEP 1

Position the wall post so the edge of the post is set back

3/4" (19 mm) in from the finish wall.

FINISH WALL

3/4"

(19 mm)

STEP 2

Level the post in its proper position and mark where

screw holes are to be drilled. Drill 3/16" holes and secure

with wall anchors and screws provided. Cut a 12" strip

of tape (provided) and apply firmly over screw heads.

STEP 3

Slide the glass panel into the wall post. Make sure that

the corner notch is positioned toward the base of the

tower.

TAPE

3 PLACES)

STEP 4

Place the tower onto base. Ensure the curved glass

locates into the glazing channel. Install bolt but do not

tighten.

BOLT (5/16")

WASHER

GLAZING

CHANNEL

19

Page 22

3 WALL: TOWER AND CURVED GLASS INSTALLATION

STEP 5

Insert support rails into brackets in top moulding of tower

but do not tighten at this time.

TOWER SUPPORT RAIL

FRONT RAIL

STEP 6

Slide mounting bracket covers and mounting brackets

onto front rail and tower support rail.

STEP 7

Place the front rail and tower support rail against the

walls. Check level and mark the position for the rail

mounting bracket. The screw position will be above the

rail. Drill the wall with a 3/16" bit and secure bracket with

screws and wall anchors provided.

ATTACH RAIL

BRACKET TO WALL

SECURE RAIL TO

BRACKET (TURN CW

TO TIGHTEN)

MOVE COVER CAP

OVER BRACKET

MOUNTING

BRACKET

RAIL

MOUNTING BRACKET

COVER

RAIL WALL

STEP 8

Adjust the rails until tower is vertical in 2 planes.

20

Page 23

3 WALL: TOWER AND CURVED GLASS INSTALLATION

COVER CAP

GLAZING GASKET

INSIDE OF

ENCLOSURE

TOWER TOP PLATE

STEP 9

Secure the rails.

STEP 10

Tighten the tower base bolt. Two shut-off valves are

provided. To hook up supply lines, unscrew valves from

braided line. Using thread sealant, screw valve to stub

outs at bottom of tower. Then reconnect braided line

using provided gasket. Do not twist or kink supply lines

when connecting.

STEP 11

Install cover cap on wall post.

STEP 12

Install glazing gasket on curved glass wall post on the

inside. Note orientation of gasket. Soapy water may

help to insert the glazing gasket.

COLD

BOLT

SHUT OFF

VALVES

(PROVIDED)

HOT

WALL POST

GLASS

INSIDE OF

ENCLOSURE

GLAZING GASKET

21

Page 24

3 WALL: TOWER AND CURVED GLASS INSTALLATION

TOP VIEW

(RAILS NOT SHOWN)

APPLY SEALANT

ALONG BASE

OF GLASS

APPLY SEALANT

ALONG BASE

AND SIDE OF

WALL POST

APPLY SEALANT

ALL AROUND

TOWER BASE

STEP 13

Turn on water supply and check for leaks. Correct any

leaks before installing tower cover.

STEP 14

Install tower cover as shown. Insert cover at top first.

TOWER TOP PLATE

TOWER COVER

INSERT THIS SIDE FIRST

TOWER COVER

STEP 15

Seal all around the base of tower with silicone sealant.

Also seal the inside of both wall posts, bottom of both

glass panels on the inside only.

22

Page 25

2 & 3 WALL OPERATION

STOP RELEASE

Shower Head

There are four selectable positions: Jet, normal pulsating and

aerated flow.

Body Sprays (2 Upper & 2 Lower)

To adjust the flow and intensity, turn as shown. The spray can also

be turned to change the direction of the spray.

LESS FLOW AND INTENSITY

MORE FLOW AND INTENSITY

Diverter Control

To turn On water, turn the inner knob clockwise and adjust for more

or less flow.

The outer knob will divert the water to body sprays, shower head

(shown in this position) and foot temperature tester. If the knob is

pointing anywhere between main functions, the amount of water

will be proportional to where the knob is pointing. If the knob is

pointing to the white line between positions, the water will be

diverted equally to both functions on either side of the white line.

SHOWER

HEAD

BODY

SPRAY

OUTER

KNOB

FOOT

TEMPERATURE

TESTER

INNER

KNOB

Temperature Valve

The temperature of the mixed water is adjusted by means of the

graduated handle. This handle has a safety stop set at 100°F

(38°C). To increase the temperature, press the red button to release

the stop and keep turning the handle.

Foot Temperature Testor

23

Page 26

2 & 3 WALL MAINTENANCE

To remove any lime scale from the shower head and body sprays , rub with your finger the outer ring of nozzles on

the shower head and all nozzles on the body spray.

To clean the foot temperature tester, unscrew the nozzle and back flush the wire mesh filter. Do not use metal tools

(such as scissors or screwdrivers, etc.) to clean the body sprays, shower head or foot temperature tester.

To cleanthe base, simply use a mild, nonabrasive liquid detergent solution. You can protect and restore the gloss to

a dulled acrylic surface by applying Meguiar's #10 Mirror Glaze, a product specifically designed for use on acrylic

finishes. If Meguiar's is not available, an acrylic polish of equal quality or automotive paste wax is acceptable.

The glass can be cleaned with any glass-cleaning product available on the market.

Do not use abrasives, alcohol, acetone, ammonia or other solvents on any tower component.

The thermostatic valve has 2 screen filters that should be cleaned periodically. To remove the filters turn off hot and

cold supplies. Remove tower cover. Disconnect the supply hoses from the valve and remove filter from the hose.

Clean any debris. Reinstallation is the reverse of removal. Turn on hot and cold supply and check for leaks.

PRODUCT SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

USE INSTALLATION INSTRUCTIONS SUPPLIED WITH PRODUCT.

Jacuzzi Whirlpool Bath has obtained applicable code (standards) listings generally available on a national basis for products of

this type. It is the responsibility of the installer/owner to determine specific local code compliance prior to installation of the product.

Jacuzzi Whirlpool Bath makes no representation or warranty regarding, and will not be responsible for any code compliance.

Jacuzzi Whirlpool Bath National Headquarters

P.O. Drawer J, Walnut Creek, CA 94596 (925) 938-7070

Service Support: Call (925) 938-7411

Printed on Recycled Paper

© 2002 Jacuzzi Whirlpool Bath U223000D 2/04

Printed in U.S.A.

24

Page 27

TOWER FIXTURES REPAIR PARTS

1 (5X)

2 (5X)

3 (5X)

TOWER ASSEMBL Y

6

7 (Part of U547000)

PART OF D709827

4

5

8

9 (5X)

10

11 (4X)

12

13

14

15

16

17

18

WASHER (PART OF D709827)

19

1. C546000 Lock Nut, 1/2" NPT WP (5X)

2. G559000 Ring Compression SS (5X)

3. G560000 Washer Rubber (5X)

4. U546000 (Part of U547000) Nut Transfer Valve, Chrome

5. U566000 Gasket, 1.41 ID X .063 Thick

6. U547000 Valve, Mixer/Transfer Assembly

7. U550827 (Part of U547000) 567000Nut, Mixer Valve, Chrome

8. U567000 Gasket, 1.9 ID X .063 Thick

9. G432000 Nipple,1/2" Close

10. U217827 Shower Head, Chrome

11. U215827 Jet, Wall Body, Chrome

12. U219827 Face Plate, Transfer Valve, Chrome

13. U546827 Nut Transfer Valve, Chrome

14. U545827 Collar, Transfer Valve, Chrome

15. U544000 O-Ring, Transfer Valve

16. U543827 Knob, Flow Control, Chrome

17. U549827 Collar, Mixer Valve, Chrome

18. U548827 Knob, Mixer Valve Chrome

19. D709827 Fill Spout Assembly, Stubby, Chrome

25

Page 28

TOWER PLUMBING REPAIR PARTS

1. A944000 (9X) Spring Clamp, .625 OD Hose

2. U405000 L=31.0" Tubing, PVC Reinforced, 10mm Barb

3. U405000 L=5.5" Tubing, PVC Reinforced, 10mm Barb

4. A945000 (7X) Spring Clip, .75 OD Hose

5. U400000 FTG, Straight, 1/2" FTS X 10mm Barb

6. U403000 (2X) Cap, 1/2" FST

7. U711000 (2X) Strainer Washer, 1/2" Dia.

8. U405000 L=31.0" Tubing, PVC Reinforced, 10mm Barb

9. U540000 (2X) 1/2" Flexhose 38", Female Swivel Heads

10. GASKET (2X) Gaskets Supplied with Hose

11. U827000 (2X) Ball Valve, .5 FTP X .5 MPT L

12. U421000 (11X) Washer, FTG .7 OD

13. U401000 (7X) FTG, Ell, 1/2" FST X 10mm Barb

14. U405000 L=4.5" Tubing, PVC Reinforced, 10mm Barb

15. U404000 (2X) FTG, Y, 10mm X 10mm X 10mm Barb

16. U405000 L=2.5" Tubing, PVC Reinforced, 10mm Barb

17. U402000 FTG, Tee, 1/2" FST X 10mm Barb

18. U405000 L=10.0" Tubing, PVC Reinforced, 10mm Barb

19. U405000 L=4.5" Tubing, PVC Reinforced, 10mm Barb

20. U405000 L=5.5" Tubing, PVC Reinforced, 10mm Barb

1 (9X)

See Note 1

2

3

4 (7X)

See Note 2

5

12 (11X)

13 (7X)

14

15 (2X)

16

Note 1: For Clamping U405000 to U401000 or U402000.

Note 2: For Clmping U405000 to U400000 or U404000.

17

18

6

7

19

8

9 (2X)

20

10 (2X)

26

11

Page 29

5

(2X)6 (2X)

7

(6X)

2 WALL UNIT REPAIR PARTS

4

1

2

8

11

9

10

12

3

14

(6X)

13

(6X)

15

1. U134827 Rail Back Walk-in

2. U133827 Rail 2 Wall Walk-in

3. U245827 Rail Assembly Walk-in

4. U149000 Bracket, Mounting Rail

5. U119827 Wall Post, Panel

6. U138827 Cap, Wall Post

7. J686000 Tape High Bond, 2 Sided

8. U159000 Gasket,Vinyl, Glass Panel

9. U479XXX Glass Panel Assembly, Walk-in

10. U124XXX Tower Cover

11. U257XXX Final Shell, Tower Walk-in

U126XXX Tower Body Walk-in

U136XXX Cap, Top, Tower

U137XXX Cap, Bottom, Tower

U149000 Bracket, Mounting Rail

U354000 Screw, Self Tap, #8-1.25" L

U355000 Screw, Self Tap, #8-2.0" L

12. U113000 Glass Panel, Front, Wlak-in

13. U354000 Screw Self Tap #8 X 1.25" L

14. U703000 Anchor, #6-8-10

15. 5374832 Screw, Sheet Metal PHP, #6 X .88" L

16. U196000 Bracket Corner Post, Bottom

17. 3952832 Bolt Hex FL Thrd 5/16

18. 3983832 Washer 5/16 Flat Type A Plnwdser

19. U247000 Gasket,Vinyl, Glass Panel

20. U174XXX Shower base Walk-in 2 Wall

21. U220000 Screw Self Drilling, #8 X 1.63" L

22 9959000 Drain, Non-Caulk

16

17

19

18

20

For finishes for U124XXX Tower

Cover and U257XXX Tower Final

Shell substitute XXX for:

801 Satin

827 Chrome

938 Timber

959 White

(Used with Tower with Timber Finish Only)

21

22

For colors for U174XXX Shower Base

substitute XXX for:

Standard

959 White

958 Almond

969 Oyster

945 Silver

High Fashion

917 Black

949 Rose

951 Shell

978 Forest Green

984 Shy Blue

999 Sand

27

Page 30

3 WALL UNIT REPAIR PARTS

1

1. U134827 Rail Back Walk-in 3 Wall

2. U245827 Rail Assembly Walk-in 3 Wall

3. U149000 Bracket, Mounting Rail

4. U119827 Wall Post, Panel

5. U138827 Cap, Wall Post

6. U124XXX Tower Cover

7. U257XXX Final Shell, Tower, Walk-in 3-Wall

U126XXX Tower Body Walk-in

U136XXX Cap, Top Tower

U137XXX Cap, Bottom, Tower

U149000 Bracket, Mounting Rail

U354000 Screw, Self Tap,#8-1.25" L

U355000 Screw, Self Tap,#8-2.0" L

8. U247000 Gasket,Vinyl, Glass Panel

9. U113000 Glass, Panel, Front, Walk-in

10. U159000 Gasket,Vinyl, Glass Panel

11. J686000 Tape, High Bond, 2-Sided

12. U354000 Screw Self Tap, #8-1.25" L

13. U703000 Anchor, #6-8-10

14. 3952832 Bolt Full Thread, 5/16

15. 3983832 Washer, 5/16, Flat, Type 2 Plnwser

16. U171XXX Shower base, Walk-in, 3-Wall

17. U220000 Screw Self Drilling, #8 X 1.63" L

18. 9959000 Drain, Non-Caulk

6

5

3 (2X)

2

10

7

8 (2X)

9

11

4

12

13

For finishes for U124XXX Tower

Cover and U257XXX Tower Final

Shell substitute XXX for:

801 Satin

827 Chrome

938 Timber

959 White

For colors for U171XXX Shower Base

substitute XXX for:

Standard

959 White

958 Almond

969 Oyster

945 Silver

High Fashion

917 Black

949 Rose

951 Shell

978 Forest Green

984 Shy Blue

999 Sand

14

17 (10X)

15

18

16

28

Page 31

Jacuzzi Whirlpool Bath Limited Warranty

Designer Collection Shower Product

WARRANTY COVERAGE

Jacuzzi Whirlpool Bath (the “Company”) offers the following express limited warranty to the original purchaser of any Jacuzzi Whirlpool Bath Designer

Collection Bath Product (“unit”) who purchases the product for personal or single family use (“user”). The Company will repair or replace, at its option, the

unit or its equipment in accordance with the following terms and conditions.

TWO YEAR LIMITED WARRANTY ON BATHS

Our limited warranty on Designer Collection Bath products is for two (2) years. Our warranty covers the unit and factory-installed components against

defects in material or workmanship. Warranty coverage begins on the date the unit was originally purchased by the user.

NINETY DAY (PARTS ONLY) LIMITED WARRANTY ON OPTIONS AND ACCESSORIES

Our limited warranty on options and accessories manufactured by the Company is for ninety (90) days for parts only. Our warranty covers options and

accessories manufactured by the Company against defects of material or workmanship. Warranty coverage begins on the date the option or accessory was originally

purchased by the user.

WARRANTY LIMITATIONS

Our limited warranty does not cover defects, damage, or failure caused by the common carrier, installer, user, or other person, or resulting from, without

limitation, any of the following: careless handling (lifting unit by plumbing, abrading finish, etc.); modification of any type for any reason (including modification

to meet local codes); improper installation (including installation not in accordance with instructions and specifications provided with the unit); connections

supplied by the installer of the equipment; improper voltage supply or unauthorized electrical modification; misuse; incorrect operation, or lack of proper routine

maintenance; operation of the unit without specified minimum amount of water or at inappropriate water temperature; use of abrasive or improper cleaners; or

acts of God, such as lightning, floods, earthquakes, etc.

In addition, THE COMPANY WILL NOT BE RESPONSIBLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES or losses arising from any cause

(e.g., water damage to carpet, ceiling, loss of use, etc.) including its own negligence; damages to, respecting, or resulting from: plated parts when pool and/or spa

chemicals are used in the unit; optional bath equipment not manufactured by the Company but supplied by Dealer, installer or the Company; the unit's prior usage

as an operational display; or defects that should have been discovered before installation. This limited warranty does not include: labor, transportation, or other

costs incurred in the removal and/or reinstallation of the original unit and/or installation of a replacement unit; any costs relating to obtaining access for repair;

or loss of use damage, including loss of sales, profit or business advantage of any kind under any circumstances. Bath units are excluded from any warranty coverage

if any addition, deletion, or modification of any kind whatsoever has been made to the unit (or to any component).

Warranty coverage is provided in the United States of America and Canada.

EXCLUSION OF IMPLIED WARRANTIES

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED ALTOGETHER OR TO

THE FULL EXTENT ALLOWED BY LAW.

NOTICE: This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. There are no warranties applicable

to Jacuzzi Whirlpool Bath products except as expressly stated herein or as implied by applicable state and federal laws. The Company will not be responsible for

any statements or representations made in any form that go beyond, are broader than or are inconsistent with any authorized literature or specifications furnished

by the Company.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or consequential damages, so the above

limitations and exclusions may not apply to you.

RETURN OF WARRANTY CARD

The attached Warranty Registration Card MUST be filled out by the purchaser within thirty (30) days from purchase and mailed to Jacuzzi Whirlpool Bath

in order for this warranty to become effective.

Jacuzzi Whirlpool Bath

P.O. Drawer J

Walnut Creek, CA 94596-9885

Page 32

RESPONSIBILITIES OF OTHERS

Inspecting the unit prior to installation is the responsibility of the installer or building contractor who acts on behalf of the user. They are responsible for ensuring

the unit is free of defect or damage. Notices are placed on and in the unit and on the shipping carton advising the installer of this responsibility. In the event of

a problem, the unit must not be installed. The Company is not responsible for failures or damage that could have been discovered, repaired, or avoided by proper

inspection and testing prior to installation.

Damage occurring in transit is the responsibility of the carrier. The user or installer MUST open the crate and inspect the unit for damage when it is delivered.

If damage is discovered, it must be reported immediately to the seller and the carrier in writing, and an inspection requested. Failure of the carrier to respond should

be reported to the seller and the carrier. Your freight claims should be filed promptly thereafter.

It is the responsibility of the installer, building contractor, or user to provide access for service. The Company is not responsible for any costs relating to

obtaining access for repair. The user shall bear such costs and, if appropriate, must seek recovery from the installer.

Damage occurring to the unit during installation is the responsibility of the installer and/or building contractor and damage occurring thereafter is the

responsibility of the user.

Failure of any optional equipment is the sole responsibility of the equipment manufacturer. (Options and accessories manufactured by the Company are

warranted for ninety (90) days from the original date of purchase for parts only.)

The Distributor or Dealer is responsible for knowing local code requirements and notifying the installing contractor and/or user of these requirements at the

time of purchase. The Company is not responsible for costs to modify any product to obtain any code approval, such as city, county, or state building codes in

U.S.A. or municipal or provincial codes in Canada.

WARRANTY SERVICE

For the customer's benefit, the Company maintains a list of independent service personnel to perform required warranty service repairs. Such firms are not agents

or representatives of the Company and cannot bind the Company by words or conduct.

The Company will provide the warranty service described above when the following conditions have been met: the failure is of the nature or type covered

by the warranty; the user has informed an Authorized Jacuzzi Whirlpool Bath Service Agent or Warranty Service Department Representative of the nature of the

problem during the warranty period; conclusive evidence (e.g., proof of purchase or installation) is provided to the foregoing by the user proving that the failure

occurred or was discovered within the warranty period; an authorized independent service person or Company representative has been permitted to inspect the

unit during regular business hours within a reasonable time after the problem was reported by the user.

In order to obtain warranty service, consult your local telephone book for the location of the nearest Jacuzzi Whirlpool Bath Authorized Service Agent. Describe

the problem and the Authorized Service Agent will inspect the unit and provide the required warranty service.

If you are unable to contact a Jacuzzi Whirlpool Bath Authorized Service Agent, call or write:

Jacuzzi Whirlpool Bath

Warranty Service Department

P.O. Drawer J

Walnut Creek, California 94596

Call: (925) 938-7411

To obtain warranty replacement for factory-installed components for Company supplied options and accessories manufactured and supplied by the Company,

call or write the above. Provide a description of the problem and proof of purchase. You will be instructed how to obtain replacements and where to return, at

your expense, the failed component(s), option(s), or accessory(ies).

All replacement parts, equipment, and repairs shall assume the remaining warranty period of the part(s) replaced.

The Company's warranty obligation shall be discharged upon tender of replacement or repair. The customer's refusal to accept the tender terminates the

Company's warranty obligation.

©2002 Jacuzzi Whirlpool Bath U223000D 2/04

Limited Warranty

Accessory(ies)

Ninety-Day

Parts Only

On

1. How did you first hear about this Jacuzzi® product?

( ) Advertisement ( ) Article in Magazine/Newspaper

( ) Visited Dealer/Plumbing Supplier ( ) Yellow Pages

( ) Builder/Plumber/Remodeler ( ) Decorator/Architect

( ) Visited Retailer/Home Center Store

Limited Warranty

Accessory(ies)

Ninety-Day

Parts Only

10.Approximately how long have you lived in this home? ___________

12.Was your purchase process?

13.How technically aware were you of the patented Jacuzzi® jet system

( ) $40,000 to $49,999 ( ) $150,000 and Above

( ) Very easy ( ) Easy ( ) Difficult ( ) Very Difficult

prior to your puchase?

( ) Not aware ( ) Somewhat aware ( ) Very aware

11.Please indicate, approximately, the total annual income of your

( ) 1 month-2 months

household.

( ) Up to $24,999 ( ) $50,000 to $74,999

( ) $25,000 to $29,999 ( ) $75,000 to $99,999

( ) $30,000 to $39,999 ( ) $100,000 to $149,999

9. How long did you shop before purchasing unit?

Please estimate $ _______________________________________

( ) Eljer ( ) Lasco ( ) Price Pfister ( ) Aqua Glass

( ) Kohler ( ) American Standard ( ) Sterling

( ) Other (Specify) _____________________________________

( ) 1 day ( ) 2 months-6 months

( ) 2-7 days ( ) 6 months-1year

( ) 1 week-2 weeks ( ) 1 year-2 years

( ) 2 weeks-4 weeks ( ) +2 years

6. What is the current market value of this property?

7. What is the age of the head of the household?_____________ years

8. What other manufacturers did you consider?

4. Who finally decided which product you would buy?

5. Who installed? ( ) Already installed/New Home

( ) Self ( ) Spouse ( ) Self and Spouse Together

( ) Other Family Member ( ) Designer/Architect

( ) Builder/Plumber/Remodeler ( ) Already Installed

( ) Contractor/Plumber when remodeling

( ) Self/Spouse when remodeling

( ) Other _____________________________________________

3. What was the main reason for purchase?

( ) Styling ( ) Warranty Service ( ) Product Features

( ) Brand Name ( ) Price ( ) Hydrotherapy

( ) Home Resale _______________________________________

( ) Other _____________________________________________

2. Who first gave you specific information about this product (specifications,

( ) Word of Mouth . . . Friend/Relative/Acquaintance

( ) Other (Please Describe)_______________________________

prices, etc.)?

( ) Dealer/Plumbing Supplier ( ) Builder ( ) Remodeler

( ) Plumbing Contractor ( ) Retailer/Home Center Store

( ) Decorator/Architect ( ) Already Installed

Date of Purchase _________________________________________

Model Name _____________________________________________

Serial Number ___________________________________________

Dealer's Name ___________________________________________

Dealer's Address__________________________________________

On

This card must be filled out and returned to the address printed on the other

side within thirty (30) days from date of purchase in order for this warranty to

be come effective.

Purchaser's Name ________________________________________

Purchaser's Address _______________________________________

City _____________________________ State _____ Zip________

U223000D

Warranty

Registration Card

Loading...

Loading...