Jacuzzi BELLAVISTA 5, ALLUSION 6636, ALLUSION 7236, ALLUSION 7242, BELLAVISTA 6 Installation & Operation Instructions

...Page 1

DESIGNER/LUXURY BATH SERIES

INSTALLATION / OPERA TION INSTRUCTIONS

Save These Instructions for Future Use.

Complete and mail-in the product registration card provided with your unit.

Write and save the model and serial number of your unit below.

Owner's Record

Date Purchased ____________________________________________________________

Purchased From ____________________________________________________________

Installed By ________________________________________________________________

Serial Number _____________________________________________________________

Model ____________________________________________________________________

Installer: Leave this manual for homeowner.

Homeowner: Read this manual and keep for future reference.

©

2005 Jacuzzi Whirlpool Bath K339000X 3/06

Page 2

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

ENGLISH

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS

WARNING — WHEN USING THIS UNIT, BASIC PRECAUTIONS SHOULD AL WAYS BE FOLLOWED,

INCLUDING THE FOLLOWING:

DANGER: — TO REDUCE THE RISK OF INJURY, DO NOT PERMIT CHILDREN TO USE THIS UNIT

UNLESS THEY ARE CLOSEL Y SUPERVISED A T ALL TIMES.

WARNING — USE THIS UNIT ONL Y FOR ITS INTENDED USE AS DESCRIBED IN THIS MANUAL. DO

NOT USE ATTACHMENTS NOT RECOMMENDED BY THE MANUFACTURER.

WARNING — NEVER DROP OR INSERT ANY OBJECT INTO ANY OPENING .

WARNING — DO NOT OPERATE THIS UNIT WITHOUT THE GUARD OVER THE SUCTION FITTING.

WARNING — THIS UNIT MUST BE CONNECTED ONLY TO A SUPPLY CIRCUIT THAT IS PROTECTED

BY A GROUND FAULT CIRCUIT INTERRUPTER (GFCI). SUCH A GFCI SHOULD BE PROVIDED BY

THE INSTALLER AND SHOULD BE TESTED ON A ROUTINE BASIS. TO TEST THE GFCI, PUSH THE

TEST BUTTON. THE GFCI SHOULD INTERRUPT POWER. PUSH THE RESET BUTTON. POWER

SHOULD BE RESTORED. IF THE GFCI FAILS TO OPERATE IN THIS MANNER, THE GFCI IS

DEFECTIVE. IF THE GFCI INTERRUPTS POWER TO THE BATHTUB WITHOUT THE TEST BUTTON

BEING PUSHED, A GROUND CURRENT FLOWING, INDICATING A POSSIBILITY OF AN ELECTRIC

SHOCK. DO NOT USE THIS HYDROMASSAGE BATHTUB. DISCONNECT THE HYDROMASSAGE

BATHTUB AND HAVE THE PROBLEM CORRECTED BY A QUALIFIED SERVICE REPRESENTATIVE

BEFORE USING.

WARNING — (FOR PERMANENTLY CONNECTED UNITS) A GREEN COLORED TERMINAL (OR A WIRE

CONNECTOR MARKED “G”, “GR”, “GROUND”, OR “GROUNDING”) IS PROVIDED WITHIN THE TERMINAL

COMPARTMENT. TO REDUCE THE RISK OF ELECTRIC SHOCK, CONNECT THE TERMINAL OR

CONNECTOR TO THE GROUNDING TERMINAL OF YOUR ELECTRIC SERVICE OR SUPPLY PANEL WITH

A CONDUCTOR EQUIVALENT IN SIZE TO THE CIRCUIT CONDUCTORS SUPPLYING THIS EQUIPMENT.

OPERATING

WARNING — PROLONGED IMMERSION IN HOT WATER MAY INDUCE HYPERTHERMIA. HYPER-

THERMIA OCCURS WHEN THE INTERNAL TEMPERA TURE OF THE BODY REACHES A LEVEL SEV ERAL DEGREES ABOVE THE NORMAL BODY TEMPERATURE OF 98.6°F. THE SYMPTOMS OF

HYPERTHERMIA INCLUDE AN INCREASE IN THE INTERNAL TEMPERATURE OF THE BODY, DIZZINESS, LETHARGY, DROWSINESS AND FAINTING. THE EFFECTS OF HYPERTHERMIA INCLUDE:

A) FAILURE TO PERCEIVE HEAT

B) FAILURE TO RECOGNIZE THE NEED TO EXIT THE SPA OR HOT TUB,

C) UNAWARENESS OF IMPENDING HAZARD,

D) FETAL DAMAGE IN PREGNANT WOMEN,

E) PHYSICAL INABILITY TO EXIT THE SPA OR HOT TUB, AND

F) UNCONSCIOUSNESS RESULTING IN DANGER OF DROWNING.

WARNING — THE USE OF ALCOHOL, DRUGS OR MEDICATION CAN GREATLY INCREASE THE

RISK OF FATAL HYPERTHERMIA.

WARNING — DO NOT TAMPER WITH USER-OPERATED CONTROLS OR SUCH DEVICES.

2

Jacuzzi Whirlpool Bath K339000X 3/06

Page 3

INST ALLATION INSTRUCTIONS

WARNING — WHEN USING THIS UNIT, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED,

INCLUDING THE FOLLOWING:

DANGER — RISK OF ELECTRIC SHOCK. CONNECT ONLY TO A CIRCUIT PROTECTED BY A GROUND

FAULT CIRCUIT INTERRUPTER (GFCI).

CAUTION — TEST THE GROUND FAULT CIRCUIT INTERRUPTER PROTECTING THIS APPLIANCE

PERIODICALLY IN ACCORDANCE WITH MANUFACTURER’S INSTRUCTIONS.

WARNING — USE THIS UNIT ONLY FOR ITS INTENDED USE AS DESCRIBED IN THIS MANUAL. DO NOT

USE ATTACHMENTS NOT RECOMMENDED BY THE MANUFACTURERS.

WARNING — TO AVOID INJURY, EXERCISE CAUTION WHEN ENTERING OR EXITING THE HYDROMASSAGE BATHTUB.

WARNING — KEEP BODY AND HAIR A MINIMUM OF 6" (15,2 cm) AWAY FROM SUCTION FITTING AT ALL

TIMES WHEN THE HYDROMASSAGE SYSTEM IS OPERATING. HAIR LONGER THAN SHOULDER

LENGTH SHOULD BE SECURED CLOSE TO THE HEAD.

WARNING — RISK OF ELECTRICAL SHOCK; DO NOT PERMIT ELECTRICAL APPLIANCES (SUCH AS HAIR

DRYER, LAMP, TELEPHONE, RADIO OR TELEVISION) WITHIN 60" (1,5 M) OF THIS HYDROMASSAGE BATHTUB.

WARNING — RISK OF ACCIDENTAL INJURY OR DROWNING; DO NOT USE DRUGS OR ALCOHOL

BEFORE OR DURING THE USE OF HYDROMASSAGE BATHTUB EQUIPPED WITH A HEATER TO AVOID

UNCONSCIOUSNESS AND POSSIBLE DROWNING.

WARNING — RISK OF FETAL INJURY; PREGNANT OR POSSIBLY PREGNANT WOMEN SHOULD

CONSULT A PHYSICIAN BEFORE USING A HYDROMASSAGE BATHTUB EQUIPPED WITH A HEATER.

WARNING — RISK OF HYPERTHERMIA AND POSSIBLE DROWNING; DO NOT USE A HYDROMASSAGE

BATHTUB EQUIPPED WITH A HEATER IMMEDIATELY FOLLOWING STRENUOUS EXERCISE.

WARNING — RISK OF HYPERTHERMIA AND POSSIBLE DROWNING; WATER TEMPERATURE IN

EXCESS OF 104°F (40°C) MAY BE INJURIOUS TO YOUR HEALTH. CHECK AND ADJUST WATER

TEMPERATURE BEFORE USE.

WARNING — RISK OF HYPERTHERMIA; PEOPLE USING MEDICATIONS AND/OR HAVING AN ADVERSE

MEDICAL HISTORY SHOULD CONSULT A PHYSICIAN BEFORE USING A HYDROMASSAGE BATHTUB

EQUIPPED WITH A HEATER.

ENGLISH

FOR BUILT-IN AND DROP-IN UNITS, INSTALL TO PERMIT ACCESS FOR SERVICING.

THIS UNIT SHOULD BE ELECTRICALLY GROUNDED AND INSTALLED BY A LICENSED CONTRACTOR, ELECTRICIAN, AND PLUMBER.

BUILDING MATERIALS AND WIRING SHOULD BE ROUTED AWAY FROM THE MOTOR/PUMP OR

BLOWER OR OTHER HEAT PRODUCING COMPONENTS OF THIS UNIT.

A PRESSURE WIRE CONNECTOR IS PROVIDED ON THE EXTERIOR OF THE MOTOR/PUMP AND

HEATER TO PERMIT CONNECTION OF AN NO. 8 AWG (8.4 MM) SOLID COPPER BONDING CONDUCTOR

BETWEEN THIS UNIT AND ALL OTHER ELECTRIC EQUIPMENT AND EXPOSED METAL IN THE VICINITY,

AS NEEDED TO COMPLY WITH LOCAL REQUIREMENTS.

PRECAUTIONS

••

• Do not operate the hydromassage system unless the bath is filled with water to at least 1" to 2" (2,5 - 5,08 cm) above the

••

highest jet.

••

• Do not immerse the control panel by overfilling the bath.

••

••

• Do not use oil-based bath additives in your hydromassage bath.

••

••

• When cleaning your bath, do not use abrasive substances which will damage the bath's surface.

••

••

• To prevent discoloration of the acrylic finish, do not fill the bath with water in excess of 140°F (60°C).

••

NOTE: This is a professional grade product. A knowledge of construction techniques, plumbing and electrical installation according to codes are required for proper installation and user satisfaction. W e recommend

that a licensed contractor perform the installation of all Jacuzzi Whirlpool Bath products. Our warranty does

not cover improper installation related problems.

PRODUCT SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

USE INSTALLATION INSTRUCTIONS SUPPLIED WITH PRODUCT.

The Company has obtained applicable code (standards) listings generally available on a national basis for products of this type.

It is the responsibility of the installer/owner to determine specific local code compliance prior to installation of the product. The

Company makes no representation or warranty regarding, and will not be responsible for any code compliance.

3

Jacuzzi Whirlpool Bath K339000X 3/06

Page 4

CONTENTS

Safety Instructions _____________________________________________________________________ 2-3

Contents _____________________________________________________________________________ 4

Specifications _________________________________________________________________________ 5-8

ENGLISH

Roughing-in Reference _________________________________________________________________ 9-13

Installations Instructions _________________________________________________________________ 14-19

Framing and Support _________________________________________________________________ 14

Service Access ______________________________________________________________________ 15

ALLUSION Installation ________________________________________________________________ 16-17

Electrical Connections _________________________________________________________________ 18

Plumbing and Water Supply ____________________________________________________________ 19

Clean Up Af ter Installation _______________________________________________________________ 19

Operating Instructions __________________________________________________________________ 20-22

Maintenance Instructions ________________________________________________________________ 23-24

General Troubleshooting Guide ___________________________________________________________ 25

Authorized Service _____________________________________________________________________ 26

Warranty _____________________________________________________________________________ 27-28

NOTE: If you need a referral for a service company near you, or need assistance with operation or maintenance

related questions, please call our Service Support Department at 1-800-288-4002. Visit our web site at http://

www.jacuzzi.com/ for products and services.

To find service agent listings for:

Electrical or Mechanical Repairs visit http://jacuzzi.com/pdf/ASA.PDF

Finish, Surface, or Shell-Related Repairs visit http://jacuzzi.com/pdf/AFC.PDF

Repair Parts or Accessories visit http://jacuzzi.com/pdf/MPD.PDF

Jacuzzi Whirlpool Bath K339000X 3/06

4

Page 5

SPECIFICATIONS

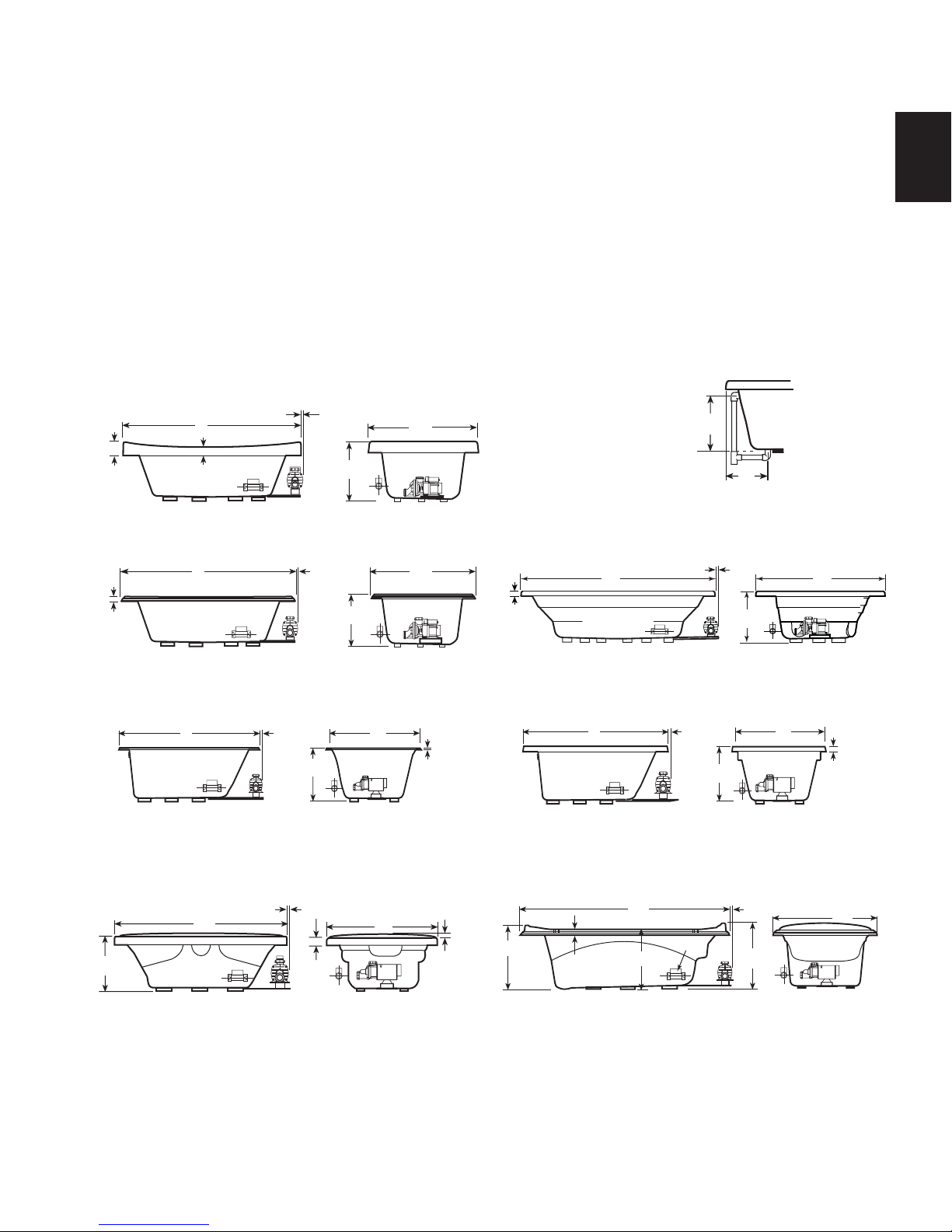

)

Important: Read complete instructions before beginning installation.

Each whirlpool bath arrives ready for installation, completely equipped with motor/pump assembly , heater , plumbing, and fittings necessary for whirlpool operation. An optional drain/overflow kit is available for installation on the

bath.

Remove the bath from the carton. Retain the shipping carton until satisfactory inspection of the product has been

made. Do not lift the bath by the plumbing at any time; handle by the shell only.

Immediately upon receipt, inspect the shell before installing. Should inspection reveal any damage or defect in the

finish, do not install the bath. Damage or defect to the finish claimed after the bath is installed is excluded from the

warranty . Jacuzzi Whirlpool Bath's responsibility for shipping damage ceases upon delivery of the products in good

order to the carrier. Refer any claims for damage to the carrier . For definitions of warranty coverage and limit ations,

refer to the published warranty information packed with the product.

All bath units are factory tested for proper operation and watertight connections prior to shipping. NOTE: Prior to

installation, the bath must be filled with water and operated to check for leaks that may have resulted from

shipping damage or mishandling. Jacuzzi Whirlpool Bath is not responsible for any defect that could have been

discovered, repaired, or avoided by following this inspection and testing procedure.

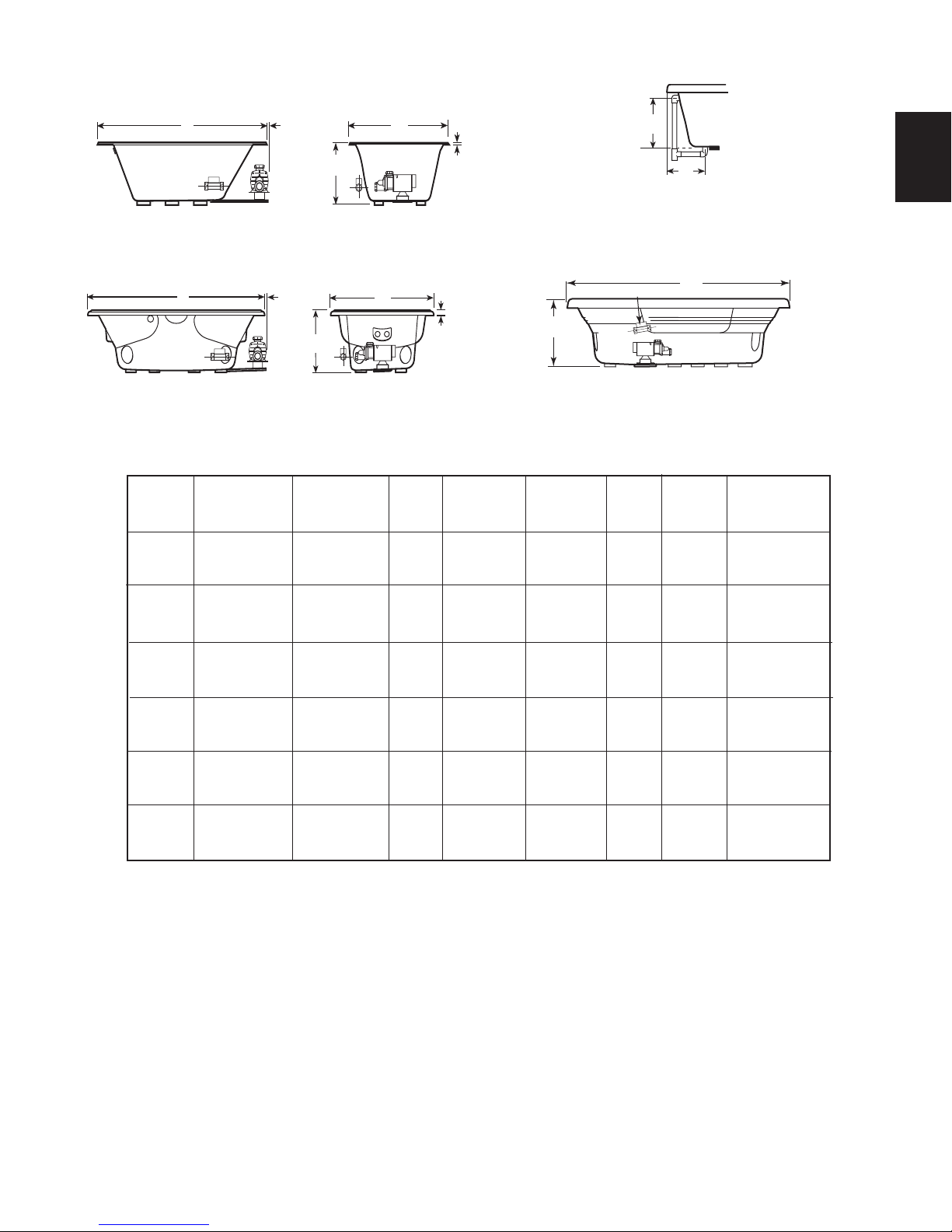

4"

(102 mm)

L

(Heater)

2"

(51 mm)

SIDE VIEW

MAX 1"

W

H

(Motor)

END VIEW

A

B

DRAIN/OVERFLOW

ALLUSION

ENGLISH

2"

(51 mm)

H

L

SIDE VIEW

L

(Heater)

SIDE VIEW

L

(Heater)

SIDE VIEW

(Heater)

(Motor)

ELARA

MAX. 1/2"

MAX. 1/2"

(Motor)

BELLAVISTA

MAX. 1/2"

H

END VIEW

(51 mm)2"

(Motor)

SABELLA

H

W

W

END VIEW

W

END VIEW

1/2"

(13 mm

1"

(25 mm)

2"

(51 mm)

H1

L

(Heater)

(Motor)

MAX. 1/2"

H

END VIEW SIDE VIEW

CIPREA™, Right Hand

L

(Heater)

(Motor)

SIDE VIEW

MAX. 1/2"

H

W

END VIEW

REÁL™, Right Hand

L

(Heater)

2"

(51 mm)

SIDE VIEW END VIEW

H2

(Motor)

MAX. 1/2"

H3

TORRETTA 36

W

2"

(51 mm)

W

5

Jacuzzi Whirlpool Bath K339000X 3/06

Page 6

SPECIFICATIONS

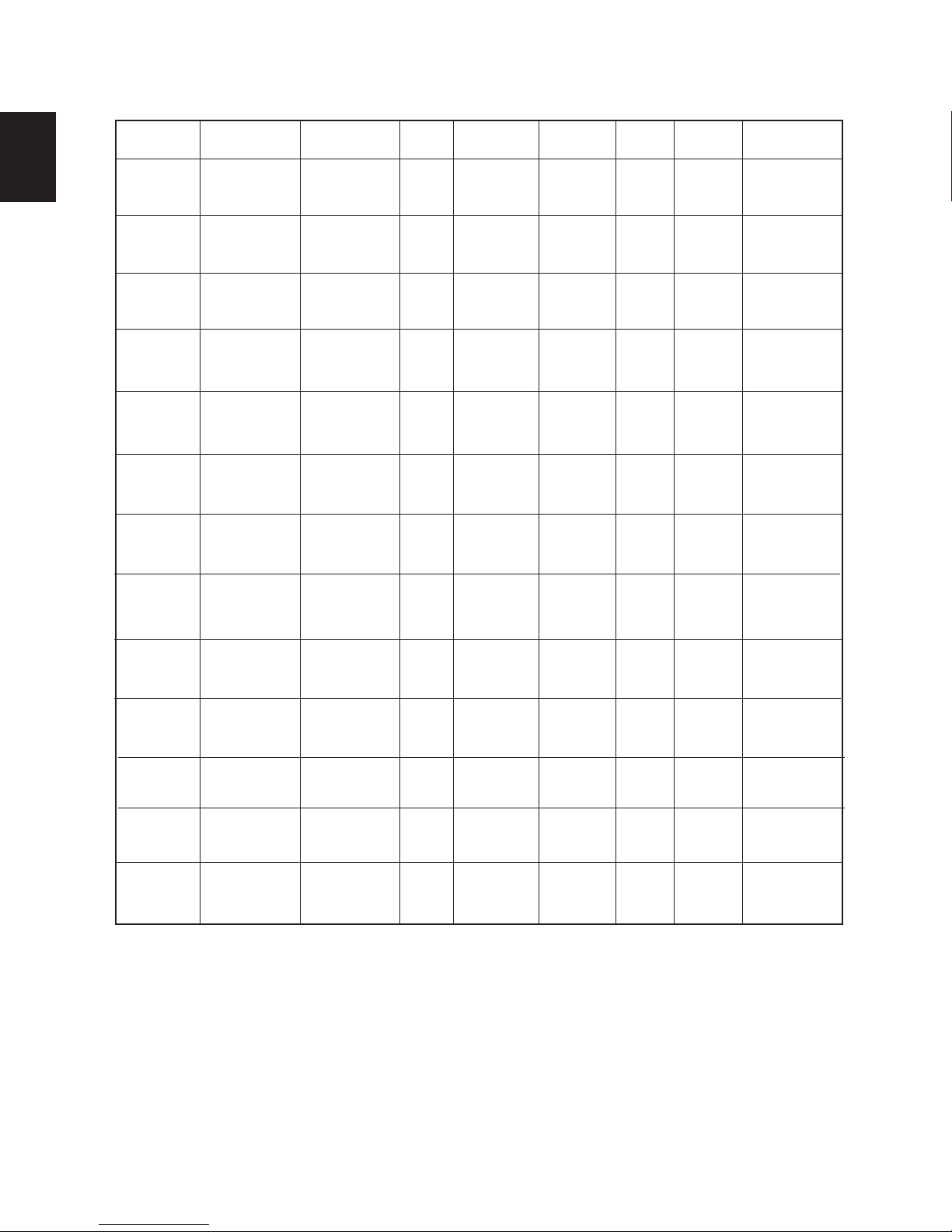

SPECIFICATIONS (Rectangular) LH = Left Hand, RH = Right Hand

ENGLISH

MODEL

ALLUSION™

6636

RH

ALLUSION™

7236

RH

ALLUSION™

7242

RH

BELLAVISTA™

5

RH

BELLAVISTA™

5.5

RH

BELLAVISTA™

6

RH

CIPREA™

RH

ELARA™ 6042

LH & RH

ELARA™ 6636

LH & RH

ELARA™ 7242

LH & RH

REÁL™

RH

SABELLA™

RH

TORRETTA™ 36 72" (1829 mm) L

66" (1676 mm) L

36" ( 914 mm) W

26" ( 660 mm) H

72" (1829 mm) L

36" ( 914 mm) W

26" ( 660 mm) H

72" (1829 mm) L

42" (1067 mm) W

26" ( 660 mm) H

60" (1524 mm) L

42" (1067 mm) W

26" ( 660 mm) H

66" (1676 mm) L

42" (1067 mm) W

26" ( 660 mm) H

72" (1829 mm) L

42" (1067 mm) W

26" ( 660 mm) H

72" (1829 mm) L†

48" (1219 mm) W

20-1/2" ( 521 mm) H

60” (1524 mm) L

42” (1067 mm) W

23-1/2” (597 mm) H

66” (1676 mm) L

36” ( 914 mm) W

23-1/2” (597 mm) H

72" (1829 mm) L

42" (1067 mm) W

23-1/2" ( 597 mm) H

72" (1829 mm) L†

42" (1067 mm) W

23" ( 584 mm) H

72" (1829 mm) L

47" (1194 mm) W

23-3/4" ( 584 mm) H

35-1/8" ( 892 mm) W

22-7/8" ( 581 mm) H1

21" ( 533 mm) H2

23-1/2" ( 597 mm) H3

DRAIN/OVERFLOW

17-3/8" (441 mm) A

11-15/16" (210 mm) B

17-3/8" (441 mm) A

11-15/16" (210 mm) B

17-3/8" (441 mm) A

11-15/16" (210 mm) B

11-3/4" (298 mm) B

20" (508 mm) A

11-3/4" (298 mm) B

20" (508 mm) A

11-3/4" (298 mm) B

16-1/4" (413 mm) A

13-1/2" (343 mm) B

18.5” (470 mm) A

10.6” (269 mm) B

18.5” (470 mm) A

10.6” (269 mm) B

18.5” (470 mm) A

10.6” (269 mm) B

20" (508 mm) A

14" (356 mm) B

20" (508 mm) A

14" (356 mm) B

18-3/16" (459 mm) A

15" (381 mm) B

CUTOUT

Template

Provided

P/N

BY20000

Template

Provided

P/N

BY20000

Template

Provided

P/N

BY20000

Template

Provided

P/N

P187000

Provided

P/N

P187000

Provided

P/N

P187000

58" x 40"

(1473 mm x

1016 mm)

Umt Template

Provided

P/N DQ50000

64" x 34"

(1626 mm x

864 mm)

Umt Template

Provided

P/N DQ51000

70" x 40"

(1778 mm x

1016 mm)

Umt Template

Provided

P/N BZ51000

70" x 40"

(1778 mm x

1016 mm)

Template

Provided

P/N

P187000

Provided

P/N

P652000

TOTAL WEIGHT/

FLOOR LOADINGDIMENSIONS

843 lb

(383 kg)/

2

51 lb/ft

(248 kg/m2)

978 lb

(489 kg)/

2

54 lb/ft

(263 kg/m2)

1127 lb

(470 kg)/

2

54 lb/ft

(263 kg/m2)

1026 lb

(466 kg)/

2

59 lb/ft

(288 kg/m2)

1078 lb

(490 kg)/

2

56 lb/ft

(273 kg/m2)

1130 lb

(514 kg)/

2

54 lb/ft

(263 kg/m2)

895 lb

(407 kg)/

2

37 lb/ft

(180 kg/m2)

(512 kg)/

2

65.4 lb/ft

(319 kg/m2)

(472 kg)/

2

63 lb/ft

(307 kg/m2)

(611 kg)/

2

64 lb/ft

(312 kg/m2)

1130 lb

(514 kg)/

2

54 lb/ft

(263 kg/m2)

1199 lb

(545 kg)/

2

51 lb/ft

(249 kg/m2)

948 lb

(431 kg)/

2

54 lb/ft

(263 kg/m2)

OPERATING

GALLONAGE

Min - 55 U.S. gal

(208 liters)

Max - 75 U.S. gal

(284 liters)

Min - 65 U.S. gal

(246 liters)

Max-85 U.S. gal

(322 liters)

Min - 75 U.S. gal

(284 liters)

Max - 99 U.S. gal

(375 liters)

80 U.S. gal

(303 liters)

85 U.S. gal

(322 liters)

90 U.S. gal

(341 liters)

57 U.S. gal

(216 liters)

Min - 83 U.S. gal

(314 liters)

Max - 92 U.S. gal

(348 liters)

Min - 75 U.S. gal

(284 liters)

Max - 83 U.S. gal

(314 liters)

Min - 95 U.S. gal

(360 liters)

Max-105 U.S. gal

(398 liters)

90 U.S. gal

(341 liters)

98 U.S. gal

(371 liters)

70 U.S. gal

(265 liters)

PRODUCT

WEIGHT

135 lb

(61 kg)

145 lb

(66 kg)

169 lb

(77 kg)

110 lb

(50 kg)

120 lb

(56 kg)

130 lb

(59 kg)

170 lb

(77 kg)

200 lb

(91 kg)

200 lb

(91 kg)

215 lb

(98 kg)

130 lb

(59 kg)

133 lb

(60 kg)

115 lb

(52 kg)

SKIRT &

MOUNTING

Not Available

Not Available

Not Available

Not Available20" (508 mm) A

Not AvailableTemplate

Not AvailableTemplate

IncludedNA

Not Available1126 lb

Not Available1039 lb

Not Available1345 lb

Not Available

Not Available

Not AvailableTemplate

† Add 1/4" to this dimension when roughing-in for 3-wall niche.

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4 mm).

FOR ALL UNITS: Electrical Service Requirements: All require a dedicated GFCI protected separate circuit.

RapidHeatTM: 120 VAC, 15 AMP, 60 Hz. dedicated GFCI protected separate circuit.

Motor/Pump: 120 VAC, 20 AMP, 60 Hz. dedicated GFCI protected separate circuit.

HEATER,

INTAKE/DISCHARGE

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

Jacuzzi Whirlpool Bath K339000X 3/06

6

Page 7

OVAL & ROUND BATHS

SPECIFICATIONS

L

(Heater)

MAX. 2-1/2"

H

W

1/2"

(13 mm)

(Motor)

SIDE VIEW

END VIEW

DUETTA™

(51 mm)

CUTOUT

70" Dia.

(1778 mm)

Hole

Template

Provided

P/N

DA09000

Template

Provided

P/N

DA08000

Template

Provided

P/N

DA07000

Template

Provided

P/N

DA06000

Template

Provided

P/N

P187000

2"

TOTAL WEIGHT/

FLOOR LOADINGDIMENSIONS

1293 lb

(588 kg)/

36 lb/ft

(176 kg/m2 )

999 lb

(454 kg)/

57.1 lb/ft

(278 kg/m2 )

1019 lb

(463 kg)/

61.8 lb/ft

(301 kg/m2 )

1106 lb

(503 kg)/

57.5 lb/ft

(280 kg/m2 )

1277 lb

(581 kg)/

60.8 lb/ft

(296 kg/m2 )

1130 lb

(514 kg)/

54 lb/ft

(263 kg/m2 )

GALLONAGE

2

2

Max - 83 U.S. gal

2

Max - 80 U.S. gal

2

Max - 95 U.S. gal

2

Max - 106 U.S. gal

2

OPERATING

100 U.S. gal

Min - 77 U.S. gal

Min - 75 U.S. gal

Min - 90 U.S. gal

Min - 98 U.S. gal

L

(Heater)

SIDE VIEW

(Motor)

MAX. 1/2"

H

W

END VIEW

VENICIA™

SPECIFICATIONS (Oval & Round) LH = Left Hand, RH = Right Hand

MODEL

CORTINA™

RH

DUETTA™

6042

RH

DUETTA™

6636

RH

DUETTA™

6642

RH

DUETTA™

7242

RH

VENICIA™

RH

72" (1829 mm) L

72" (1829 mm) W

22-1/4" ( 565 mm) H

60” (1524 mm) L

42” (1067 mm) W

26” ( 660 mm) H

66” (1676 mm) L

36” (914 mm) W

26” ( 660 mm) H

66” (1676 mm) L

42” (1067 mm) W

26” (660 mm) H

72" (1829 mm) L

42" (1067 mm) W

26" ( 660 mm) H

72" (1829 mm) L

42" (1067 mm) W

23" ( 584 mm) H

DRAIN/OVERFLOW

DIMENSIONS

16-3/4" (426 mm) A

19-1/4" (489 mm) B

18.4" (467 mm) A

11" (279 mm) B

18.4" (467 mm) A

11" (279 mm) B

18.4" (467 mm) A

11" (279 mm) B

18.4" (467 mm) A

11" (279 mm) B

20" (508 mm) A

14" (356 mm) B

W

(379 liters)

(291 liters)

(314 liters)

(284 liters)

(303 liters)

(341 liters)

(360 liters)

(371 liters)

(401 liters)

90 U.S. gal

(341 liters)

A

B

DRAIN/OVERFLOW

(Heater)

L

(Motor)

CORTINA™

PRODUCT

WEIGHT

210 lb

(95 kg)

110 lb

(50 kg)

180 lb

(82 kg)

117 lb

(53 kg)

130 lb

(59 kg)

130 lb

(59 kg)

SKIRT &

MOUNTING

Not Available

Not Available Factory Installed

Not Available Factory Installed

Not Available Factory Installed

Not Available Factory Installed

Not Available

HEATER,

INTAKE/DISCHARGE

Factory Installed

Discharge

(U394000 HEATER)

Intake

(S749000 Heater)

Intake

(S749000 Heater)

Intake

(S749000 Heater)

Intake

(S749000 Heater)

Factory Installed

Intake

(S749000 Heater)

ENGLISH

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4

mm).

FOR ALL UNITS: Electrical Service Requirements: All require a dedicated GFCI protected separate circuit.

RapidHeatTM: 120 VAC, 15 AMP, 60 Hz. dedicated GFCI protected separate circuit.

Motor/Pump: 120 VAC, 20 AMP, 60 Hz. dedicated GFCI protected separate circuit.

7

Jacuzzi Whirlpool Bath K339000X 3/06

Page 8

CORNER BATHS

SPECIFICATIONS

ENGLISH

H

SIDE VIEW

(Heater)

MAX. 1/2"

2"

(51 mm)

W

END VIEW

DRAIN/OVERFLOW

BELLAVISTA™ CORNER, Right Hand

SPECIFICATIONS (Corner) LH = Left Hand, RH = Right Hand

SKIRT &

MOUNTING

Not Available

P/N

TOTAL WEIGHT/

FLOOR LOADING

1046 lb

(475 kg)/

42 lb/ft

(205) kg/m

DRAIN/OVERFLOW

MODEL

BELLAVISTA

CORNER

RH

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4

FOR ALL UNITS: Electrical Service Requirements: All require a dedicated GFCI protected separate circuit.

mm).

RapidHeatTM: 120 VAC, 15 AMP, 60 Hz. dedicated GFCI protected separate circuit.

DIMENSIONS

TM

60" (1524 mm) L

60" (1524 mm) W

21-3/4" ( 553 mm) H

DIMENSIONS

18-7/8" (479 mm) A

14" (356 mm) B

CUTOUT

Template

Provided

P654000

2

2

OPERATING

GALLONAGE

80 U.S. gal

(303 liters)

PRODUCT

WEIGHT

130 lb

(59 kg)

Motor/Pump: 120 VAC, 20 AMP, 60 Hz. dedicated GFCI protected separate circuit.

A

B

HEATER,

INTAKE/DISCHARGE

Factory Installed

Intake

(S749000 Heater)

Jacuzzi Whirlpool Bath K339000X 3/06

8

Page 9

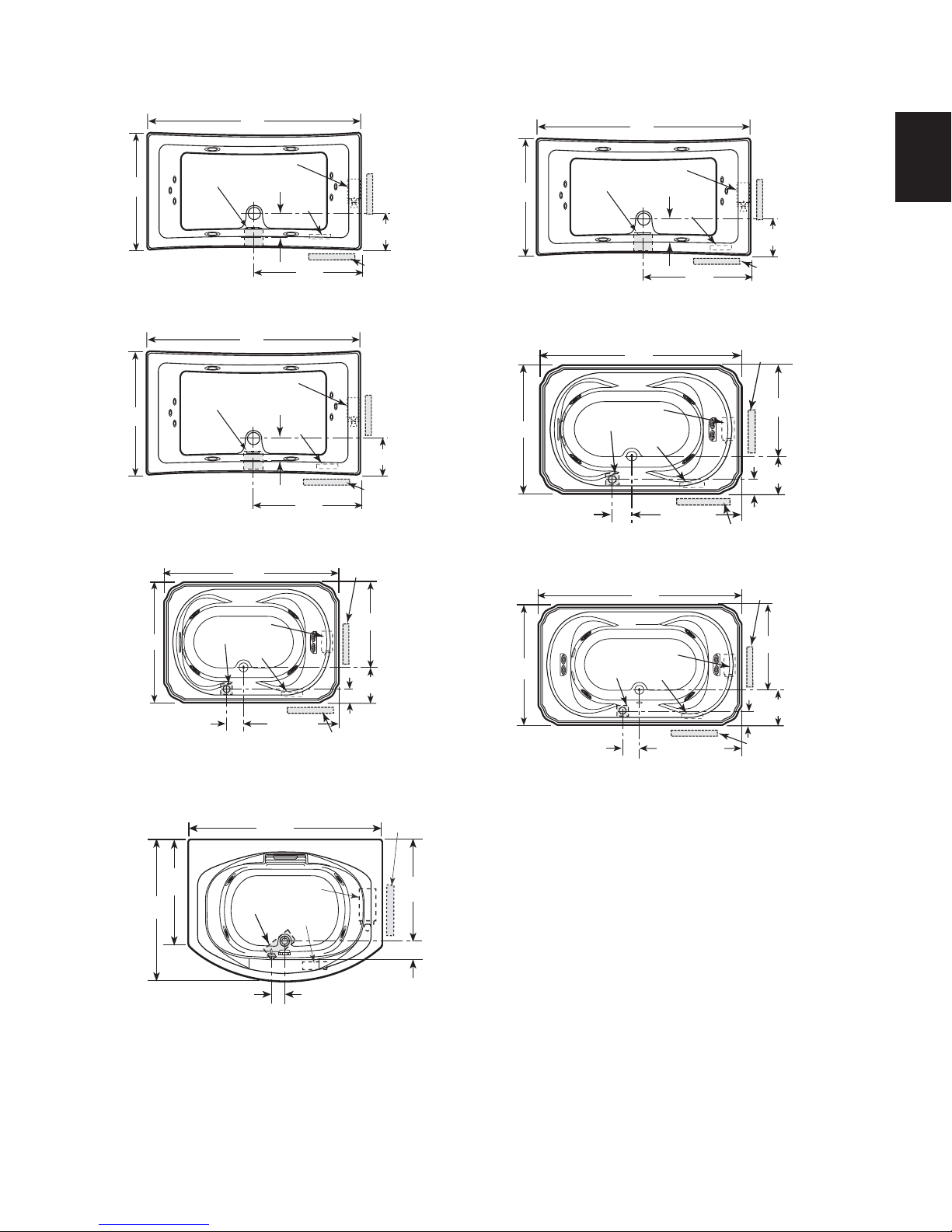

"

ROUGHING-IN REFERENCE

ROUGHING-IN REFERENCE (RECTANGULAR)

Some tubs are supplied with cutout and/or undermount template. Refer to CUTOUT on pages 6-8 for template part numbers.

66"

72"

ENGLISH

36"

42"

Motor

5" x 5"

ALLUSION™ 6636, Right Hand

72"

Motor

5" x 5"

ALLUSION™ 7242, Right Hand

66"

Motor

42"

4" x 4"

Heater

10"

BELLAVISTA™ 5.5, Right Hand

8-1/2"

Heater

8-1/2"

Heater

35-1/2"

33"

36"

12" H x 18" L

Service Access

6"

Opt. Service Access

12" H x 18" L

Service Access

11-15/16"

Opt. Service

Access

12" H x 18" L

Service Access

11-15/16"

Opt. Service

Access

30-1/8"

11-3/4"

36"

5" x 5"

ALLUSION™ 7236, Right Hand

42"

4" x 4"

7"

BELLAVISTA™ 5, Right Hand

42"

4" x 4"

10-1/2"

BELLAVISTA™ 6, Right Hand

60"

Motor

72"

Motor

8-1/2"

Heater

32-1/2"

Motor

Heater

35-13/16"

Heater

36"

Opt. Service Access

12" H x 18" L

Service Access

11-15/16"

Opt. Service

Access

12" H x 18" L

Service Access

30-1/8"

11-3/4

6"

12" H x 18" L

Service Access

30-1/8"

11-3/4"

6"

Opt. Service

Access

*72"

48"

36"

14" x 4"

Motor

Heater

4"

CIPREA™, Right Hand

* Add 1/4" to this dimension when roughing-in for 3-wall niche.

NOTE: 1. Measurements inside each unit represent cutout in floor to allow for drain/overflow.

2. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

3. Service access dimensions given are minimum size.

4. The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4 mm).

12" H x 18" L

Service Access

34-1/2"

7"

9

Jacuzzi Whirlpool Bath K339000X 3/06

Page 10

ROUGHING-IN REFERENCE

ELARA™ 6636 Right Hand

66"

36"

18 "

4.2"

10.6"

12" x 4"

Motor

Opt. Service

Access

12" H x 18" L

Service Access

Heater

2"

ROUGHING-IN REFERENCE (RECTANGULAR)

Some tubs are supplied with cutout and/or undermount template. Refer to CUTOUT on pages 6-8 for template part numbers.

60"

60"

ENGLISH

21"

4.2"

36"

12" H x 18" L

Service Access

12" x 4"

Motor

2"

Heater

10.6"

Opt. Service

Access

ELARA™ 6042 Left Hand

66"

Motor

Heater

Opt. Service

Access

12" x 4"

2"

10.6"

ELARA™ 6636 Right Hand

42"

12" H x 18" L

Service Access

4.2"

18 "

42"

12" H x 18" L

Service Access

12" x 4"

Motor

Heater

Opt. Service

Access

2"

10.6"

ELARA™ 6042 Right Hand

21"

4.2"

Opt. Service

Access

Heater

4.2"

10.6"

12" x 4"

Opt. Service

Access

Heater

12" H x 18" L

Service Access

42"

42"

Motor

72"

21"

2"

72"

Motor

12" H x 18" L

Service Access

ELARA™ 7242 Right Hand

ELARA™ 7242 Left Hand

* Add 1/4" to this dimension when roughing-in for 3-wall niche.

NOTE: 1. Measurements inside each unit represent cutout in floor to allow for drain/overflow.

2. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

3. Service access dimensions given are minimum size.

4. The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4 mm).

10.6"

12" x 4"

2"

4.2"

21"

Jacuzzi Whirlpool Bath K339000X 3/06

10

Page 11

ROUGHING-IN REFERENCE

ROUGHING-IN REFERENCE (RECTANGULAR)

Some tubs are supplied with cutout and/or undermount template. Refer to CUTOUT on pages 6-8 for template part numbers.

ENGLISH

42"

14"

5-1/4"

72"

18" x 4"*

3"

10-1/2"

Heater

REÁL™, Right Hand

Motor

36"

12" H x 18" L

Service Access

Opt. Service

Access

36"

47"

18"

1"

3"

18" x 4"

3"

10-1/4"

SABELLA™ Right Hand

6-3/4"

15-1/4"

TORRETTA™ 36, Left Hand

72"

3"

72"

15" X 4"

Motor

Heater

36"

1"

Motor

Heater

Opt. Service Access

12" H x 18" L

Service Access

7"

Opt. Service

Access

13-3/4"

12" H x 18" L

Service Access

* Add 1/4" to this dimension when roughing-in for 3-wall niche.

NOTE: 1. Measurements inside each unit represent cutout in floor to allow for drain/overflow.

2. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

3. Service access dimensions given are minimum size.

4. The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4 mm).

11

Jacuzzi Whirlpool Bath K339000X 3/06

Page 12

ROUGHING-IN REFERENCE

s

ROUGHING-IN REFERENCE (OVAL)

Some tubs are supplied with cutout and/or undermount template. Refer to CUTOUT on pages 6-8 for template part numbers.

60"

66"

ENGLISH

42"

13" x 4"

3.84"

30"

Motor

2"

11.04"

DUETTA™ 6042, Right Hand

66"

42"

13" x 4"

3.84"

33"

DUETTA™ 6642, Right Hand

Heater

2"

11.04"

Motor

Heater

Opt. Service

Access

Opt. Service

12" H x 18" L

Access

Service Access

12" H x 18" L

Service Access

36"

13" x 4"

3.84"

33"

2"

11.04"

Motor

Heater

Opt. Service Access

DUETTA™ 6636, Right Hand

72"

14" x 4"

Motor

Heater

3-1/2"

Opt. Service

36"

DUETTA™ 7242, Right Hand

2"

Access

12" H x 18" L

Service Access

42"

11"

12" H x 18" L

Service Access

12" H x 18" L

Service Acces

29-7/8"

12-1/8"

5-1/4"

42"

Opt. Service Access

10-1/2"

3"

72"

Motor

18" x 4"

Heater

36"

VENICIA™, Right Hand

NOTE: 1. Measurements inside each unit represent cutout in floor to allow for drain/overflow.

2. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

3. Service access dimensions given are minimum size.

4. The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4 mm).

Jacuzzi Whirlpool Bath K339000X 3/06

12

Page 13

ROUGHING-IN REFERENCE

ROUGHING-IN REFERENCE (ROUND, CORNER)

Some tubs are supplied with cutout and/or undermount template. Refer to CUTOUT on pages 6-8 for template part numbers.

60"

59-1/2"

Ref.

60"

34-9/16"

Motor

12"x4"

3"

BELLAVISTA™ CORNER, Right Hand

Heater

77-3/4"

7-1/2"

Service

Access

Opt.

Service

Access

16"

26"

16"

Motor

CORTINA™, Right Hand

9"

14"x5"*

5"

72"

Heater

12" H x 18" L

Service Access

4"

ENGLISH

72"

NOTE: 1. Measurements inside each unit represent cutout in floor to allow for drain/overflow.

2. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

3. Service access dimensions given are minimum size.

4. The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4 mm).

13

Jacuzzi Whirlpool Bath K339000X 3/06

Page 14

TYPICAL INSTALLATIONS

TYPICAL FLANGE MOUNTING DETAIL

INST ALLA TION INSTRUCTIONS

Framing and Support

The drain/overflow of the bath extends below the bottom of the bath. Note that this requires a cutout in the floor.

The floor structure beneath the bath must be able to support a total weight of bath, water, and bather.

Refer to the table under total weight for your model. The unit must be supported from the bottom of the bath and

not from the bath rim or tile flange. If the subfloor is level and a continuous surface, no other preparation is neces-

sary. You can proceed to install the bath. If the subfloor is not level, you MUST level the entire surface prior to

ENGLISH

installing the bath. The use of materials that provide a level installation are allowed provided the method used will

insure a level bath that is supported from the bottom. Materials that may be used are a floor leveling compound,

mortar , plaster or minimal expansion structural foam having a density of a minimum of 5 lbs./cubic feet; however the

bath must remain level in order for it to drain properly and all foam feet must make full contact with the leveling

material. Both sides of a joint or splice of subfloor should be level to each other. When attaching baths with

flanges to stud wall, use shims to fill any gaps between the bath flange and studs.

NOTE: Drop-in tubs are additionally equipped with metal anchor straps. With a level floor, when mortar or

similar anchoring material is NOT used, use construction adhesive under the foam feet and fasten the metal

anchor straps to the floor to prevent the unit from shifting while trim, deck finishes, or finish caulking cure.

The rim of the bath is not designed to support weight. If finish material is to overlap or contact the bath, the added

weight must be fully self-supporting.

The protective film liner inside the bath is used to prevent damage to the finish during installation. Before

installation, remove liner to inspect for any defects, reapply and do not remove until final cleanup.

Important: If a skirt is to be used, it must be installed at the time of unit installation – refer to skirt installation instructions. Install optional trim parts when all installation has been completed.

MORTAR OR ADHESIVE

FLASHING

1" X 4" (NOT FOR SUPPORT)

FLUSH TO WALL

STUD

CAULKING

FLANGE

SHIM IF

NECESSARY

TO FILL GAPS

BETWEEN

STUD

AND FLANGE

1/8" GAP

TILE

SEALANT

MORTAR OR ADHESIVE

SEALANT

SUB-FLOOR

FLASHING

1" X 4" (NOT FOR SUPPORT)

SEMI-SUNKEN

TILE

CEMENT

BOARD

TILE

ADHESIVE

ATTACH WITH

SCREWS

PROVIDED

SHIM IF

STUD

FLANGE

NECESSARY

TO FILL GAPS

BETWEEN

STUD

AND FLANGE

TILE

STUD

FLANGE

1/8" GAP

FINISHING

MATERIAL

PLASTER

FILLER

FLANGE

NAIL

OR

SCREW

STUD

WALL

MORTAR

CEMENT

BOARD

BATH RIM

SILICONE

SEALANT

1" X 4" (NOT FOR

SUPPORT)

OPTIONAL TILE FLANGE KIT

CAULKING

ATTACH WITH

SCREWS

PROVIDED

1"X 4"

(NOT FOR

SUPPORT)

TILE

CEMENT

BOARD

TILE

ADHESIVE

STUD

FLANGE

Jacuzzi Whirlpool Bath K339000X 3/06

14

Page 15

INST ALLA TION INSTRUCTIONS

SERVICE ACCESS

SERVICE ACCESS

Service Access

For partially or fully sunken installations, allow for access to service connections. It is the installer's responsibility to provide sufficient service access. The recommended minimum dimensions allowable for service to

the bath are shown in the "Service Access" illustration.

Provide adequate area around unit for air circulation

for cooling the motor and to supply sufficient air to the

jets. Do not insulate this area or around motor.

(WITHOUT SKIRT)

12"

ALTERNATE

ACCESS

12"

18"

MOTOR

18"

PREFERRED

ACCESS

The Duetta Whirlpool baths should access as shown

below.

DUETTA SERVICE ACCESS (WITHOUT SKIRT)

HEATER

FRONT

PREFERRED

ACCESS

12"

18"

MOTOR

18"

ALTERNATE

ACCESS

The Allusion Whirlpool baths should access as shown

below.

ALLUSION SERVICE ACCESS

PUMP/MOTOR

FRONT

ALTERNATE

ACCESS

HEATER

12"

18"

12"

18"

PREFERRED

ACCESS

ENGLISH

12"

Service Access (Corner Tubs)

For partially or fully sunken installations, allow for access to service connections. It is the installer's responsibility to provide sufficient service access. The recommended minimum dimensions allowable for service to

the bath are shown in the "Service Access" illustration.

Provide adequate area around unit for air circulation

for cooling the motor and to supply sufficient air to the

jets. Do not insulate this area or around motor.

SERVICE ACCESS

18"

RIGHT HAND UNIT SHOWN

A - Preferred access

B - Acceptable alternative if access A is not possible

C - Additional access for equipment (Optional)

(CORNER BATHS)

C

36"

In some cases, access may not have been provided

because of the design of the bath environment and having full understanding that in this case, it may be necessary to remove the unit for service.

If this is the case, diagnosing a problem may not be

possible without complete access to the plumbing system. This would necessitate the removal of the unit.

Although this practice is not commonly implemented, it

is an acceptable method.

MOTOR

AREA

A

20"

A

B

In some cases access may have been provided in

AREA

B

Area A but service is required in Area B which requires

24"

the unit to be pulled for service and reinstalled.

If service access has not been provided, it is the

home owners responsibility to remove the bath and

provide the required access, should a repair become

necessary.

15

Jacuzzi Whirlpool Bath K339000X 3/06

Page 16

INSTALLATION INSTRUCTIONS

INSTALLATION CLEARANCE RECOMMENDATIONS

The installation clearance recommendations below are to ensure that installers have enough space to maneuver and

insert tub. The Designer/Luxury line whirlpool tubs have electrical, plumbing and lighting systems installed. Do not

lift the bath by the plumbing or wiring at any time; handle by the shell only.

ENGLISH

32"

32"

TUB

CUTOUT

TUB

CUTOUT

TWO WALL INSTALLATION

3"

THREE WALL INSTALLATION

3"

32"

TUB

CUTOUT

10"

TUB

CUTOUT

10"

32"

48"

MINIMUM VERTICAL CLEARANCE

FOR INSTALLER TO POSITION TUB

32"

3"

Jacuzzi Whirlpool Bath K339000X 3/06

16

Page 17

INSTALLATION INSTRUCTIONS

Installation

Note that the motor/pump protrudes beyond the bath rim a maxi-

mum distance of 1" (25,4 mm). Care should be used when lowering

See END/SIDE VIEW in

Specification pages for

this dimension.

the tub into cutout to prevent injury to installer(s), finished surfaces,

or tub and components.

Clearance must be provided for installers. See page 16 for

(Heater)

(Motor)

recommended clearances surrounding tub. Damage to shell,

plumbing, wiring, lighting, and other components because of

failure to observe minimum clearances are not the responsibility

of Jacuzzi Whirlpool Bath.

All deck finish work must be completed before installation. Use the Cutout Template provided. Flooring surface inside

the cutout to deck height must not exceed height specification for tub.

Cover all finished surfaces to protect from damage during tub installation.

Turn OFF power supply to dedicated GFCI protected circuits.

Begin Installation

Optionally, use a washable marker to scribe a reference line 1" (25,4 mm) outside the cutout edge on the deck surface. This may assist in final alignment of the

tub.

Install any trim kits, faucets, or other tub components before installing.

To install unit insert the motor/pump end first when lowering the tub into the

cutout opening as shown in the bottom illustration. Do not use plumbing fixtures or

plumbing lines to lower unit. The clearance under the substrate is required for air

flow circulation requirements.

Place a piece of scrap lumber under each corner as a temporary support for the tub rim. Inspect all fittings, plumbing, and

control lines after inserting to insure components are not damaged, disconnected, or contacting the finish surface substrate or

support members.

Connect flex water supply lines to faucet.

Plug power cords into GFCI outlet.

Remove fingers, hands, and all other items from under the rim edge before lowering the tub.

Slightly lift one tub end and remove the scrap lumber . Gently lower the tub rim until it contacts the

deck surface. Slightly lift the remaining tub end and remove the scrap lumber. Gently lower the

tub rim until it contacts the deck surface.

If you created the optional reference lines, align the tub over the cutout.

Connect drain line.

Turn ON the power supply to the dedicated GFCI protected circuits.

Check for leaks and check system operation.

TUB

CUTOUT

REFERENCE

LINE

APPROX. 2-1/2"

SUBFLOOR

2 " MAX

THICKNESS

SUPPORT

1/2"

FINISHED SURFACE

SCRAP LUMBER

SUBSTRATE

ENGLISH

TILE OR

FINISHED

SURFACE

SUBSTRATE

SUPPORT

MEMBER

17

SUBFLOOR

** MIN CLEARANCE - DUETTA 3"-3½"

TILE OR FINISHED

SURFACE

SUBSTRATE

TYP MIN. 1-1/2"

CLEARANCE**

SUPPORT

MEMBER

Jacuzzi Whirlpool Bath K339000X 3/06

Page 18

INST ALLA TION INSTRUCTIONS

Electrical Connections

Separate circuits, each must be protected by a Ground Fault Circuit Interrupter (GFCI), are required for the pump/

motor and the RapidHeatTM Heater. Refer to the electrical specification for each model on p ages 6-8. Install duplex

outlets to the studwall underneath the bathtub, at least 4 inches (10,2 cm) above the floor or in accordance with local

building or electrical codes. Duplex outlets are not provided. Because these units are manufactured with an electronic control panel no remote switch or timer is necessary .

ENGLISH

Tubs with electronic control panels combine the electrical requirements of the pump/motor and electronic controls

into a control box. For these units the power supply cord from the pump/motor runs to the control box. The power

supply cord from the control box should be connected to the 20 AMP GFCI circuit.

Before installing electrical connections, inspect the pump/motor and heater nameplates and confirm you have 120

V AC, 20 AMP and 15 AMP service requirements. The GFCI circuit s must match these requirements. Care must be

taken to connect the 20 AMP pump/motor or control box power cord ONL Y to the 20 AMP GFCI circuit and to connect

the 15 AMP heater power cord ONLY to the 15 AMP GFCI circuit. Do NOT switch power cords and GFCI circuit s.

With a #8 solid copper wire, bond the heater to the house electrical panel or approved local bond. A bonding lug is

provided on the heater. With another #8 solid copper wire, bond the pump/motor to the house electrical panel or

approved local bond. A bonding lug is provided on the pump/motor.

At initial start-up and before each use thereafter with power ON, push the GFCI test button on each circuit. The

reset button should pop out. Push this button in to reset. If the interrupter fails to operate in this manner, there is a

ground current flowing or a device malfunction, indicating the possibility of electrical shock. Turn off power and do

not use the bath until the source of the problem has been identified and corrected.

DANGER: RISK OF ELECTRIC SHOCK. Connect only to a circuit protected by a Ground Fault Circuit Interrupter (GFCI).

CAUTION: Operating the motor/pump without enough water in the bath can cause leaking and permanent

damage to the pump. Before power is applied to the installation, make sure the switch is in the OFF position

to avoid pump damage.

ELECTRICAL CONNECTION

15 AMP, 3 PRONG PLUG

(Heater)

20 AMP, 3 PRONG PLUG

(Pump/Motor)

M

T

HEATER

* INSTALL SEPERATE

GFCI PROTECTED CIRCUITS,

DUPLEX RECEPTS NOT PROVIDED

DUPLEX

RECEPT.*

4" MIN.

OR IN

ACCORDANCE

WITH LOCAL

BUILDING OR

ELECTRICAL

CODES

Jacuzzi Whirlpool Bath K339000X 3/06

18

Page 19

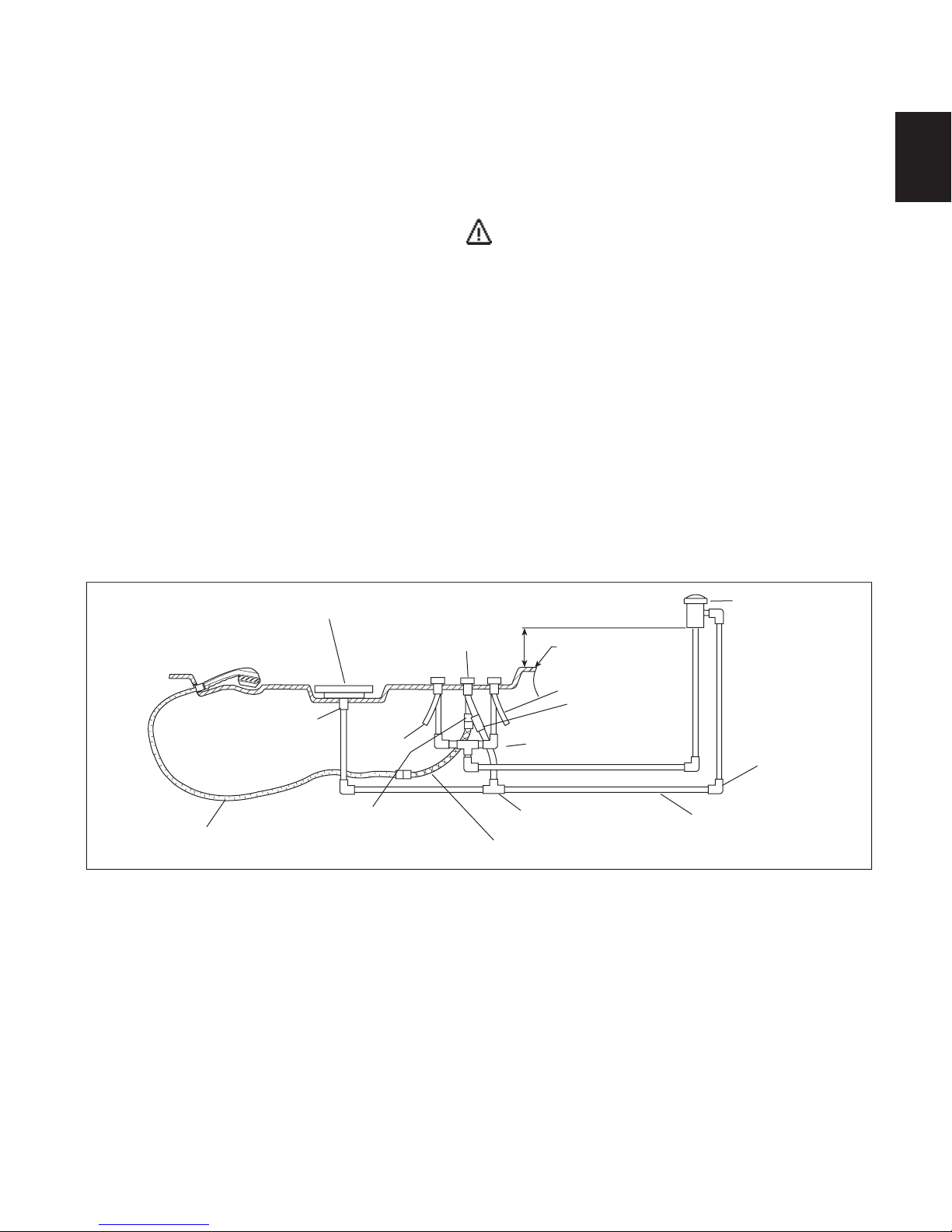

Plumbing and Water Supply

Drain Information

A drain/overflow assembly (sold separately) must be installed on the bath, water tested, and connected to the sanitary system of the house. After opening the carton, inspect

for damage and verify that the kit is of the proper finish. In the

Jacuzzi Whirlpool Bath drain/overflow kit, note that the waste

flange, strainer, overflow cover and cover screws are packaged in a separate package within the kit to protect the trim

finish. Follow the installation instructions provided with the

drain/overflow kit. After the drain is fully installed, test for

proper drainage. If the unit does not drain properly, rectify

this condition before proceeding with the installation. Jacuzzi

Whirlpool Bath is not responsible for removal and or reinstallation costs.

NOTE: Watertight installation of the drain is the inst aller's

responsibility. Drain leakage is excluded from the Jacuzzi

Whirlpool Bath warranty of this product.

Plumbing

Pump, jets, and suction fittings for the whirlpool system

are factory plumbed in schedule 40 PVC piping.

All Jacuzzi Whirlpool Bath products are factory tested for

proper operation and watertight connections prior to shipping.

If leaks are detected, notify your Jacuzzi Whirlpool Bath dealer.

Do not install the unit.

Water Supply

Consult local authorities for plumbing code requirements

in your area.

IMPORTANT: Proper installation of the fill spout plumbing and compliance with local codes are the responsibility of the installer . Jacuzzi Whirlpool Bath does not warrant connections of water supply fittings and piping, fill

systems, or drain/overflow systems. Nor is it responsible

for damage to the bath which occurs during installation.

CAUTION: A nonflammable protective barrier must be

placed between soldering work and bath unit to prevent

damage to the bath.

Shower Information

Because of some baths' unique contour design, a rigid

shower door cannot readily be installed. If a shower is desired, we recommend a hand-held shower be installed in conjunction with a shower curtain, as this will allow the user to

control the direction of the spray.

NOTE: Proper installation of a shower is the responsibility of the installer . Jacuzzi Whirlpool Bath is not responsible for damage to the unit or for water damage which

might occur due to its installation.

Anti-Siphon Valve

Optional Anti-Siphon valve installation. Anti-Siphon valve

is not supplied with the tub. Consult your local plumbing code

requirements for the minimum height above the tub rim.

ENGLISH

RECOMMENDED WATER SUPPLY CONNECTIONS

WATER RAINBOW® FILLSPOUT

3/4" FPT x 5/8" O.D.

COMPRESSION

SHOWER HOSE 1/2" FPT

COLD

WATER

SUPPLY

1/2" FPT x 3/8" NOM.

ADAPTER

(NOT ALL REQUIRE OR HAVE ALL FEATURES SHOWN)

DIVERTER HANDLE

1/2" MPT x 1/2" MPT x 18" FLEXIBLE

6"

BATH RIM

HOT WATER SUPPLY

3/8" FPT x 1/2"

NOM. COUPLING

3/8"x1/2"

NOM. ELL (2)

1/2" NOM. TEE

ANTI-SIPHON VALVE

THESE ITEMS SHOWN

FOR EXAMPLE ONLY

Consult local authorities

for plumbing code

requirements in your area.

1/2" NOM.

ELL (TYP)

1/2" NOM. COPPER (TYP.)

Clean-Up After Installation

To avoid dulling and scratching the surface of the bath, never use abrasive cleaners. A mild liquid detergent and warm water

will clean soiled surfaces.

Remove spilled plaster with a wood or plastic edge. Metal tools will scratch the surface. Spot s lef t by plaster or grout can be

removed if lightly rubbed with detergent on a damp cloth or sponge.

Paint, tar , or other difficult surface st ains can be removed with paint thinner, turpentine, or isopropyl alcohol (rubbing alcohol).

NOTE: Use these chemicals only on SURFACE stains.

Minor scratches which do not penetrate the color finish can be removed by lightly sanding with 600-grit wet/dry sandpaper.

You can restore the glossy finish to the acrylic surface of the bath with a special compound, Meguiar's #10 Mirror Glaze. If that

is not available, use automotive rubbing compound followed by an application of automotive paste wax.

Major scratches and gouges which penetrate the acrylic surface will require refinishing. Ask your Jacuzzi Whirlpool Bath

dealer for special instructions or visit our web site at http://www.jacuzzi.com/. To find service agent listings for:

Electrical or Mechanical Repairs visit http://jacuzzi.com/pdf/ASA.PDF

Finish, Surface, or Shell-Related Repairs visit http://jacuzzi.com/pdf/AFC.PDF

Repair Parts or Accessories visit http://jacuzzi.com/pdf/MPD.PDF

19

Jacuzzi Whirlpool Bath K339000X 3/06

Page 20

T

OPERATING INSTRUCTIONS

DIRECTIONALLY

ADJUSTABLE

FULLY

ADJUSTABLE

JETS

OPERATION

NOTE: These instructions pertain to all bath products manufactured by Jacuzzi Whirlpool Bath. Not all features discussed in this instruction pamphlet apply to all baths.

All baths manufactured by Jacuzzi Whirlpool Bath are designed for "fill and drain," which means the bath should be drained

after each use and filled with fresh water by the next bather. This is a health precaution, as these baths are not designed to hold

water continuously like pools or spas. If you want a unit designed to continuously hold water, see your Jacuzzi Whirlpool Bath

dealer for the complete line of whirlpool spas available.

ENGLISH

Once the bath is installed, remove any residue or foreign materials left over from construction. Paint, tar , or other difficult surface

stains can be removed with paint thinner, turpentine, or isopropyl alcohol (rubbing alcohol). NOTE: Use these chemicals only on

SURFACE stains. Other dirt can be cleaned off with a mild liquid detergent on a damp cloth. Scrape off plaster with a wooden or

plastic edge; do not use metal scrapers, wire brushes or other metal tools, as they will damage the bath's surface.

Water Level

Close the drain and fill the bath until water is at least 1" to

2" (2,5 - 5,08 cm) above the highest jet (see water line indicated in the illustration). Do not turn on the whirlpool sys-

tem at any time if the jets are not completely immersed in

water. Do not immerse the control panel by overfilling

the bath. Running the whirlpool system when there is insuf-

ficient water in the bath could result in water spraying outside

the bath area. Running the whirlpool system without water

will damage the recirculating pump.

IMPORTANT: When exiting the bath, the water level will drop

below the jets which could result in water being sprayed out

of the unit. To prevent this, you must turn unit off before

exiting bath.

FILL TO AT LEAST

1" - 2" ABOVE HIGHEST JET

1" - 2"

Controlling Whirlpool Action

The whirlpool action in your bath, controlled manually and

electronically, is influenced by three factors – direction of flow ,

force of water, and force of air. Every bath manufactured by

Jacuzzi Whirlpool Bath that is equipped with fully adjustable

PowerPro® jets, are manually adjustable for direction and water

force. Some baths have additional jets which can be adjusted

for direction only. Baths equipped with 2 speed motors and

electronic controls can also influence water force and force

of air.

Direction: T o change the direction of the water flow , swivel

the jet nozzle to the desired angle. The jets can be directed

individually toward any location on your body to provide a

hydromassage. The jets can also be adjusted so that they all

point in the same direction (clockwise or counterclockwise)

to circulate the water in a circular motion around the bath,

causing a total whirlpool effect.

Water Force: The high volume, fully adjustable PowerPro

jets can be manually adjusted to control the force of the water

coming into the bath. For robust action, increase the force of

the flow by rotating the jet handles to the left (counterclockwise). For a more gentle effect, rotate the handles to the right

(clockwise). Customize water force by lowering water volume

of one (1) jet(s) to increase water force in another jet(s). In

units with 2 speed motors the water force can be increased or

decreased using the electronic control. Never run the whirl-

pool system with all the jets closed.

Force of Air: Force of air is controlled electronically. Re-

fer to the Control panel instructions for details in adjusting

force of air.

Jacuzzi Whirlpool Bath K339000X 3/06

YPICAL BATH FITTINGS

ELECTRONIC CONTROL PANEL

FULLY ADJUSTABLE JETS

SUCTION

COVER

WATER RAINBOW

FILL SPOUT (OPTIONAL)

®

DRAIN/OVERFLOW

(OPTIONAL)

20

Page 21

OPERATING INSTRUCTIONS (cont'd)

Electronic Control Panel Operation (with optional Chromotherapy/Illumatherapy

All tubs in this product line come with electronic controls and standard Chromotherapy or IllumatherapyTM. Read and follow the

operation instructions for the control system of your unit.

General Functions

This Jacuzzi tub is equipped with a seven button electronic control panel. The seven button panel controls a two speed pump/

motor, Chromotherapy or IllumatherapyTM lighting, air controls, and wave control. LED lights (in the control panel) indicate function

levels. When switching between functions, the LED for the inactive functions will dim and the active function will brighten.

The bath is equipped with a water level sensor(s). When the water level is below the sensor, the pump/motor can not be

activated. If the ON/OFF pump/motor button is pressed at this time, the pump/motor will not operate. When the water goes

above the water level sensor, the pump/motor can be activated. If the water level drops below the level sensor, the pump/motor

will shut OFF. To restart the pump/motor after the water level goes above the level sensor, the ON/OFF pump/motor button must

be pressed. The pump/motor will automatically shut off 30 minutes after the pump/motor was turned on.

NOTE: Ensure the water level sensor located inside the bath is free of any soap or dirt buildup.

Normal Operation (with the bath filled to the proper level)

Pump/Motor Switch (ON/OFF )

Pressing the button will turn ON the two speed pump/

motor at HIGH speed. Pressing a second time will turn OFF

the pump/motor. To change speeds use the Toggle buttons.

Pump/Motor Status LED

Left Air Valve

Status LED

Pump/Motor

Status LED

Left Air Valve

TM

lighting)

Bath Light

Right Air Valve

Right Air Valve

Status LED

ENGLISH

When the pump/motor is ON at HIGH speed all four LED

indicator lights will be lit. When the pump/motor is ON at

LOW speed the bottom LED indicator light will be lit.

Left Air Valve Switch

Pressing this button will acitvate the left air valves use

the Toggle buttons to increase/decrease air flow to the left set

of jets. The air flow can be adjusted from no air to maximum

air.

Left Air Valve Status LED

The Left Air Valve Status LED will show four LED lights at

maximum air and only one LED light when the air is turned

OFF. Each additional LED indicates more air flow.

Right Air Valve Switch

Pressing this button will acitvate the right air valves. Use

the Toggle buttons to increase/decrease air flow to the right

set of jets. The air flow can be adjusted from no air to maximum air.

Right Air Valve Status LED

The Right Air Valve Status LED will show four LED lights at

maximum air and only one LED light when the air is turned

OFF. Each additional LED indicates more air flow.

Bath Light Switch (ON/OFF )

Pressing this button will turn ON the white bath light(s).

Pressing the Toggle buttons at this time will increase or decrease light intensity. Pressing the button a second time will

access the saved favorite color. To cycle lighting colors use

the Toggle button. Pressing the Toggle button again will stop

the light cycling. The color displayed when the cycle has been

stopped will be saved as your favorite color. Pressing the

button a third time to turn OFF the light.

NOTE: When switching between functions, the LED for

the inactive functions will dim and the active function will

brighten.

ON/OFF

Pump/Motor

Wave Function

Toggle Buttons

Wave Function Switch (ON/OFF )

Pressing this button activates wave action by opening

and closing both right and left air valves. Pressing a second

time will turn OFF the wave action.

T oggle Buttons

The T oggle buttons, up and down , act on each of the

other buttons to increase, decrease, or modify functionality.

Use the up arrow to increase and the down arrow to decrease.

• Pressing a toggle button after pressing the Pump/Motor

button will increase or decrease speeds on the Pump/Motor. If the pump/motor is on HIGH speed press the down

arrow to select LOW speed. If the pump/motor is on LOW

speed press the up arrow to select HIGH speed.

• Pressing an up or down toggle button after pressing the

Bath Light button once will increase or decrease the white

light brightness. Pressing an up or down toggle button

after pressing the Bath Light button twice will begin cycling

the light colors. Leave the colors cycling or press the same

toggle button again to stop the color cycling. With the lights

stopped on a color pressing the Bath Light button a third

time will turn OFF the light. (A favorite color will be saved

ONLY when the cycling has been stopped on that color

and then turned OFF.)

21

Jacuzzi Whirlpool Bath K339000X 3/06

Page 22

PUSH TO RESET

OVER HEAT

PROTECTION

HIGH LIMIT RESET

HEATER ON

HEATER ON

OPERATING INSTRUCTIONS (cont'd)

RapidHeat

TM

These units have a RapidHeatTM heater installed on the intake or discharge lines. The

heater will help maintain the temperature of the water in the bath.

Operation

ENGLISH

With the heater installed and the whirlpool pump is operating, the heating function is totally automatic. No user control required.

Vacuum/Pressure Switch

The heater is equipped with a preset vacuum/pressure switch which will not allow the heater to turn ON if the pump is not running with water flowing through the whirlpool system.

High-Limit Switch

The heater includes an exclusive High-Limit switch. This safety circuit will not false trip from hot tap water. It will only turn of f

the heater if the thermostat fails. To reset, press the button. If the high-limit trips frequently, contact your Authorized Electrical/

Mechanical Service Provider. Visit our web site at http://www.jacuzzi.com/.

To find service agent listings for:

Electrical or Mechanical Repairs visit http://jacuzzi.com/pdf/ASA.PDF

Finish, Surface, or Shell-Related Repairs visit http://jacuzzi.com/pdf/AFC.PDF

Repair Parts or Accessories visit http://jacuzzi.com/pdf/MPD.PDF

22

Jacuzzi Whirlpool Bath K339000X 3/06

Page 23

E

MAINTENANCE INSTRUCTIONS

Cleaning the Bath

To clean your bath, simply use a mild, nonabrasive liquid

detergent solution. Y ou can protect and restore the gloss to a

dulled acrylic surface by applying Meguiar's #10 Mirror Glaze,

a product specifically designed for use on acrylic finishes. If

Meguiar's is not available, an acrylic polish of equal quality or

automotive paste wax is acceptable.

Never use abrasive household cleaners on any Jacuzzi

Whirlpool Bath product.

Repairs to the Surface

Minor scratches which do not penetrate the color finish

can be removed by lightly sanding with 600-grit wet/dry sandpaper . Restore the gloss using Meguiar's Mirror Glaze or automotive paste wax.

Major scratches and gouges which penetrate the acrylic

surface will require refinishing. Ask your Jacuzzi Whirlpool

Bath dealer for special instructions.

Bath Additives

NOTE: DO NOT USE OIL OR OIL BASED BATH ADDITIVES.

If you want to use any kind of bath additive, use only a small

amount of low-foaming powder or crystal substance; the

whirlpool action intensifies the foaming properties of soaps.

The use of certain bath oils, bubble baths and bath additives may increase the level of accumulations of bath residue

in the whirlpool system. If excess accumulations persist, you

should discontinue use of these products.

Purging the Whirlpool System

NOTE: THE WHIRLPOOL SYSTEM SHOULD BE PURGED

AT LEAST TWICE A MONTH

To remove accumulations of bath residue from the whirlpool system, it is recommended that a whirlpool bath be

purged at least twice a month. For best results, however, we

recommend that you purge your whirlpool bath after each use

using, Systems Clean™, our exclusive two-part plumbing

system cleaner made specifically for whirlpool baths.

Systems Clean™ is available through an authorized Jacuzzi

Whirlpool Bath distributor or by calling us direct at 1-800-288-

4002.

Systems Clean™

Refer to the instructions on the Systems Clean™ packet.

CAUTION: DO NOT USE WHILE BATHING! USE EXTREME

CAUTION WHEN HANDLING THIS PRODUCT!

Immediately after bathing and exiting the whirlpool bath,

leave the bath water in the tub and add more hot water. The

water level in the tub must be at least 2” (5,08 cm)above the

highest jet. NOTE: Inducted air from the hydromassage

system will cause the Systems Clean™ contents to foam

increasing odor. Turn OFF the whirlpool air control or turn it to

the lowest setting and pour in the entire contents of PACKET

#1 ONLY directly into the bath water. For best results, pour the

System Clean into the tub near the intake for the circulation

pump and be sure to avoid contact with your skin. Allow the

whirlpool to run for 30 seconds and then add PACKET #2

ONLY. It is important to use PACKET #1 before PACKET

#2 to avoid a strong odor. Allow the bath to run for 5 to 10

minutes then drain the tub completely. Refill the tub with cold

water and run for 2 to 3 minutes. Drain completely and rinse

off any residue. Remember to reset the air valves to your

bathing comfort level.

Instructions for use:

ENGLISH

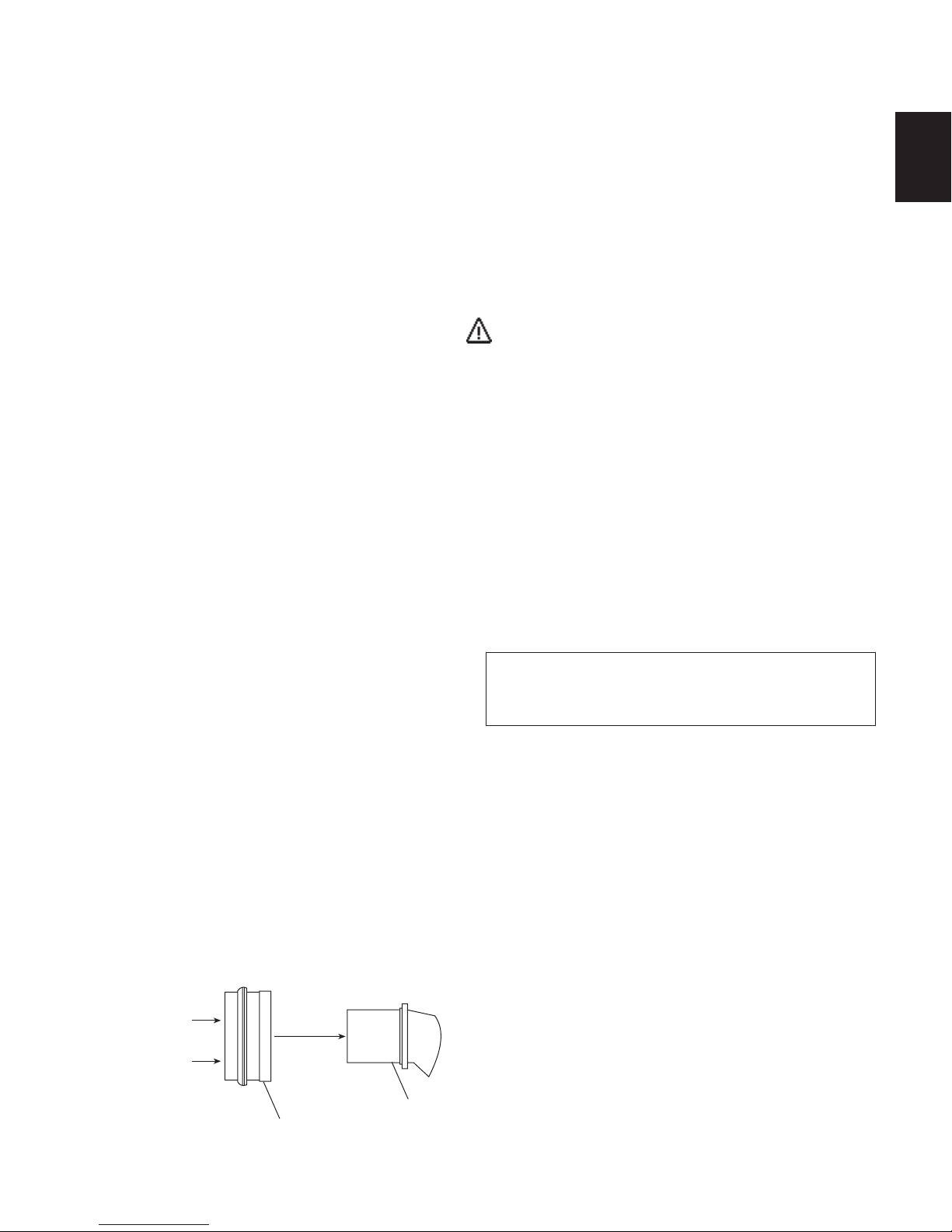

Spinning Jets Maintenance

(Models equipped with spinning jets)

If hair or other kind of debris gets caught in the bearings of

these jets, it could cause them to stop spinning. This may

require disassembly and cleaning. To do this, simply grab the

nozzle and pull straight out of the jet housing. The bearing

casing will be attached to the nozzle. These can be separated

by holding the casing and pushing the nozzle out from the rear

of the casing. After cleaning, reassemble in reverse.

PUSH FROM REAR

TO REMOVE

NOZZLE

NOZZL

BEARING CASING

DANGER: Harmful if swallowed. Eye irritant. Protect your

eyes, skin and mucus membranes from contact with this

product or its concentrated solution. A strong alkaline

product can cause severe burns to the eyes and skin.

If you have followed the standard purging instructions

above and still have an excess accumulation of bath residue

and desire an alternative cleaning mechanism, we recommend SUPER SYSTEMS CLEAN™ PLUS manufactured by

Stearns Packaging to rectify this condition. This may be

obtained by contacting us at 1-800-288-4002. It is recommended that you follow the instructions provided by the

manufacturer with the product. Repeated use may be necessary. SUPER SYSTEMS CLEAN™ PLUS does not replace

the necessity to regularly purge your whirlpool system with

Systems Clean™ as recommended.

23

Jacuzzi Whirlpool Bath K339000X 3/06

Page 24

NOTCH

GASKET

COVER STRAINER

SCREW

SUCTION

FITTING

SUCTION COVER/STRAINER ASSEMBLY

MAINTENANCE INSTRUCTIONS

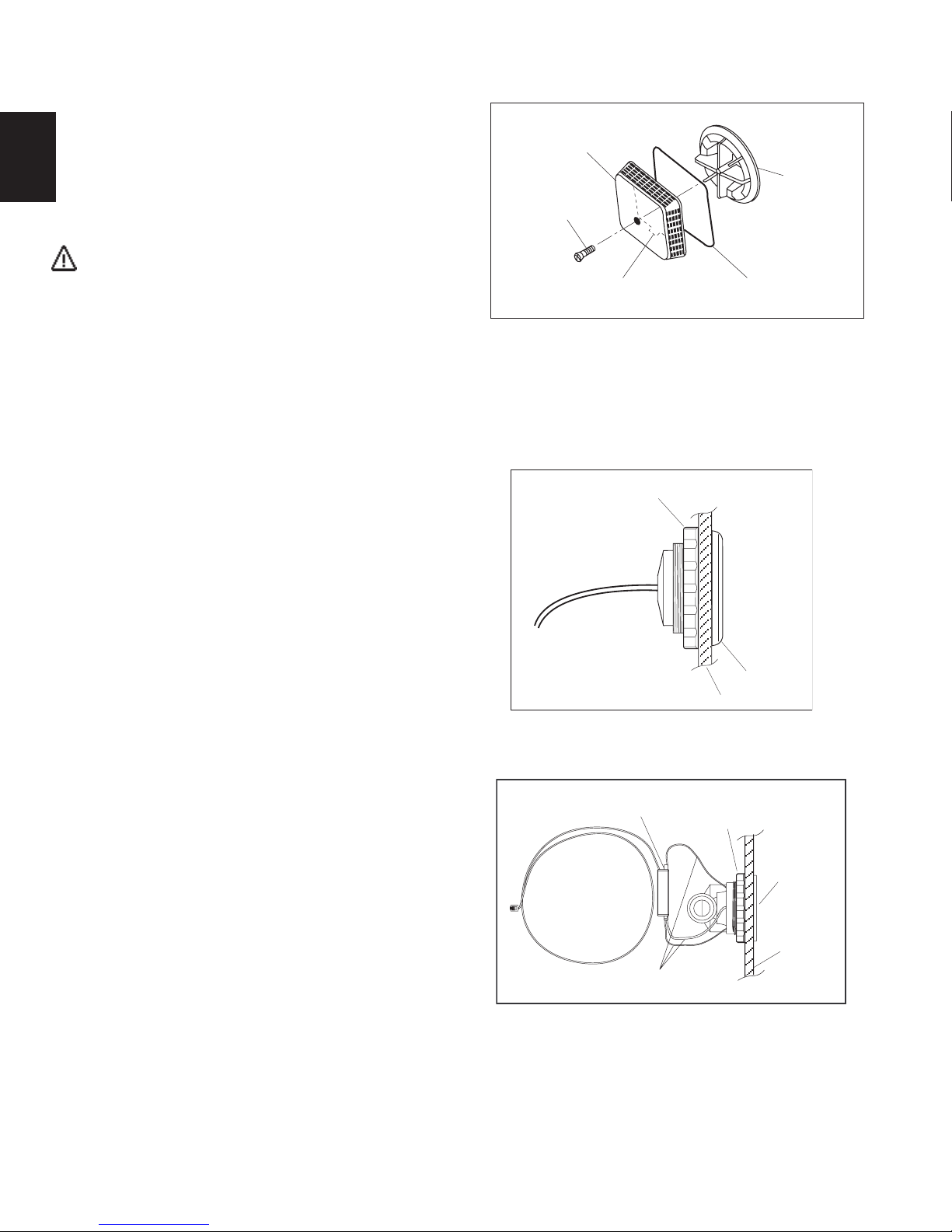

Suction/Intake Cover/Strainer Maintenance

Clean the suction/intake cover/strainer of hair and debris

when necessary. To do this, remove the center screw and

detach the square cover. Clean the cover by backflushing

debris from the holes. Replace the suction/intake cover im-

ENGLISH

mediately after cleaning. When reinstalling, orient the cover/

strainer with the small notch at the bottom. The gasket must

be inserted into the groove of the cover/strainer before reinstalling onto the suction fitting.

CAUTION: Keep hair a minimum of 6 inches (15,2 cm)

away from the suction/intake fitting at all times when the

whirlpool system is operating. Hair longer than shoulder

length should be secured close to the head, or a bathing

cap should be worn. Do not operate the whirlpool system with the suction/intake cover removed! It is a safety

device and must always be in place on the suction fitting

to minimize the potential hazard of hair and/or body entrapment.

Lighting (Chromotherapy lighting)

Your unit has Chromotherapy (LED) lighting. If the lights

fail to function contact your Jacuzzi Whirlpool Bath dealer.

There are no customer serviceable components on the Chromotherapy lighting.

Replacement fixtures are available from your Jacuzzi

Whirlpool Bath dealer.

Lighting (optional IllumatherapyTM lighting)

If your unit has Illumatherapy (fiberoptic) lighting and the

lights fail to function contact your Jacuzzi Whirlpool Bath

dealer. There are no customer serviceable components on

the Illumatherapy lighting.

Replacement fixtures are available from your Jacuzzi

Whirlpool Bath dealer.

LED LIGHT ASSEMBLY

LOCKING NUT

LIGHT BEZEL

SHELL

JET WITH FIBEROPTIC LIGHTS

DIN BOX (MOUNTED

ONTO FIBERGLASS SHELL)

LOCKING NUT

LIGHT BEZEL

FIBEROPTIC CABLE

(ROUTED TO WHIRLPOOL

CONTROL BOX)

Jacuzzi Whirlpool Bath K339000X 3/06

SHELL

FIBEROPTIC CABLES

ROUTED FROM JET TO DIN BOX

24

Page 25

General Whirlpool Bath Troubleshooting Guide

Pump/Motor does not start.

Pump/Motor operates but no fully

adjustable jets are functioning.

Pump/Motor operates but air is not

injected into water.

PROBABLE CAUSES PROBLEM REMEDY

No power to pump/motor.

Pump/motor not plugged in.

Pump/motor faulty.

Jets are closed.

Control panel cable disconnected.

Suction cover may be clogged.

Air valves closed.

Overtightened, O-ring may be

pinched or improperly seated, under

tightened.

Reset GFCI.

Insert plug fully into outlet.

Replace pump/motor assembly.

Open jets by rotating counterclockwise.

Reconnect control panel cable at control

or junction box.

With motor turned off, remove safety

cover and remove any debris. Clean

thoroughly before replacing. Replace

suction cover before operating.

Use electronic controls to open air

valves. Reset air valves to allow air flow.

Untighten unions check and reseat Oring. If O-ring has been pinched out of

shape, replace (refer to number below).

When tightening union nuts, hand

tighten only.

ENGLISH

Water leakage from pump unions.

Pump/motor shuts off by itself before

set time elapses.

Control panel not responding.

Lighting does not work

NOTE: If unit is within the warranty period, contact Jacuzzi Whirlpool Bath Service Support at 1 - (800) 288-4002 with bath's serial

number before work is started. The Serial Number is located on the Specification/Serial Number Plate. See page 26.

Motor thermal protection has deactivated pump/motor due to overheating. (Supply voltage low.)

GFCI tripped.

Inadequate supply wiring.

No power to control panel.

Cable disconnected or broken.

Let motor cool; thermal protection will

reset. Check for proper ventilation.

(Check supply voltage.)

Reset GFCI. If it continues to trip do not

use this unit. Disconnect the unit and

have the problem corrected by a

licensed electrician before using.

Consult a licensed electrician to correct

wiring to unit.

Power down the system by either unplugging the unit or shutting off the power at

the house breaker panel. Wait 15 seconds then power back up. Retry the system by activating the feature that was not

responding.

Reconnect loose cable. Repair broken

cable wires.

25

Jacuzzi Whirlpool Bath K339000X 3/06

Page 26

ADDENDUM

8-Button Electronic Control Panel for

the 240 V Control System

ELECTRICAL REQUIREMENTS

The Addendum for the 8-button Electrical Control Panel is attached to the Luxury® Salon™ Installation and Operation

Instructions, EL21000B. It provides the electrical requrements for the 240 V Control Systems.

8-Button Control Panel

SPECIFICATIONS FOR ALL UNITS

Electrical Service Requirements: Requires a separate dedicated GFCI-protected circuit

Blower: 120 VAC, 15 Amp, 60 Hz separate dedicated GFCI-protected circuit

Motor-Pump: 240 VAC, 15 Amp, 60 Hz separate dedicated GFCI-protected circuit

RapidHeat™: 120 VAC, 15 Amp, 60 Hz separate dedicated GFCI-protected circuit

DETAILS ON THE 4-WIRE, HARD WIRING

115 V

115 V

Neutral

Ground

4-Wire, Hard Wiring

Copyright © 2008 by Jacuzzi Whirlpool Bath Products Page 1 of 2 Publication GR86000A • 08-08

Page 27

The following details will replace information found in the Combination Air Bath and Whirlpool Installation and Operation

Instructions, BR28000B (4/05) manual.

CAUTION: Install all electrical services on the right side of the bath. The blower has been moved from the left

side to the right side, next to the pump motor.

NOTE: The following art replaces the similar art found on

Page 1 of the Combination Air Bath and Whirlpool manual.

L

W

4"

2"

SIDE VIEW END VIEW

Heater

Blower Motor

H

Allusion

NOTE: The following art replaces both pieces of similar art at the bottom of Page 3 of the manual. The art

"Blower Service Access" shows the blower on the left end of the bath, but it has been moved to the right end,

alongside the pump motor.

Blower

12"

FRONT

Heater

Motor

Pump Motor, Blower Service Access (Required)

Jacuzzi™ Addendum, Control Panel Electrical Requirements Page 2 of 2 Publication GR86000A • 08-08

18"

HEATER SERVICE AREA

18"

MOTOR

SERVICE

AREA

Page 28

AUTHORIZED SERVICE

r

If you need a referral for a service company near you, or need assistance with operation or maintenance related

questions, please call our Service Support Department at 1-800-288-4002. Visit our web site at http://www .jacuzzi.com/

for products and services.

To find service agent listings for:

ENGLISH

Electrical or Mechanical Repairs visit http://jacuzzi.com/pdf/ASA.PDF

Finish, Surface, or Shell-Related Repairs visit http://jacuzzi.com/pdf/AFC.PDF

Repair Parts or Accessories visit http://jacuzzi.com/pdf/MPD.PDF

When requesting service or technical assistance please have available both the model and serial number of your

unit. This information can be obtained from the product registration card provided with your unit. If the card has

been misplaced, this information can be obtained from the specification/serial number label on the unit itself (for

location of specification/serial number label see below).

BATH PRODUCTS

Whirlpool baths: The label is located on the wall of the bath near the pump/motor.

Non-jetted baths: The label is located next to the overflow .

SPECIFICATION/SERIAL NUMBER PLATE

CORE NUMBER - SERIAL NUMBER

YOU WILL FIND YOUR

SERIAL NUMBER HERE.

XXXX - XXXXXX

MODEL # XXXXXXX

NAME XXXXX

COLOR XXXXX

MFG # XXXXX

SER # XXXXXX

THIS PRODUCT MEETS OR EXCEED

THE FOLLOWING STANDARDS

BATH & SPA xxxx xxxx.x

SHOWER BASES xxxx xxxx.x

Appropriate Safety Compliance Logos for your unit.

Applicable Electrical Specifications for your unit.

ELECTRICAL SPECIFICATIONS

PRINTED IN THIS AREA

MADE IN

USA

PRODUCT SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

USE INSTALLATION INSTRUCTIONS SUPPLIED WITH PRODUCT.

Jacuzzi Whirlpool Bath has obtained applicable code (standards) listings generally available on a national basis for products of

this type. It is the responsibility of the installer/owner to determine specific local code compliance prior to installation of the product.

Jacuzzi Whirlpool Bath makes no representation or warranty regarding, and will not be responsible for any code compliance.

©

2005 Jacuzzi Whirlpool Bath K339000X 3/06

Printed on Recycled Pape

Jacuzzi Whirlpool Bath K339000X 3/06

Jacuzzi Whirlpool Bath

P.O. Box 702168, Dallas, TX 75370-2168

Service Support: (800) 288-4002

Printed in the U.S.A.

26

Page 29

Jacuzzi Whirlpool Bath Limited Warranty

Designer/Luxury Collection Bath Product

Jacuzzi Whirlpool Bath (the “Company”) offers the following express limited warranty to the original purchaser of any Jacuzzi Whirlpool

Bath Designer Collection Bath Product (“unit”) who purchases the product for personal or single family use (“user”). The Company will repair

or replace, at its sole option, the unit or its equipment in accordance with the following terms and conditions.

TWO YEAR LIMITED WARRANTY ON BATHS

Our limited warranty on Designer Collection Bath products is for two (2) years. Our warranty covers the unit and factory-installed

components (e.g., pump, motor) against defects in material or workmanship. Warranty coverage begins on the date the unit was originally

purchased by the user.

FIVE YEAR (PARTS ONLY) LIMITED WARRANTY ON PUMP AND MOTOR

Our limited warranty on the pump and motor is for five (5) years for parts only. Warranty coverage begins on the date the unit was originally

purchased by the user.

NINETY DAY (PARTS ONLY) LIMITED WARRANTY ON OPTIONS AND ACCESSORIES

Our limited warranty on options and accessories manufactured by the Company is for ninety (90) days for parts only. Our warranty covers

options and accessories manufactured by the Company (e.g., fill spout kits, trim kits, skirts) against defects in materials or workmanship. Warranty

coverage begins on the date the option or accessory was originally purchased by the user.