Page 1

OPTICA

SHOWER MIXER/TRANSFER VALVE

INSTALLATION INSTRUCTIONS

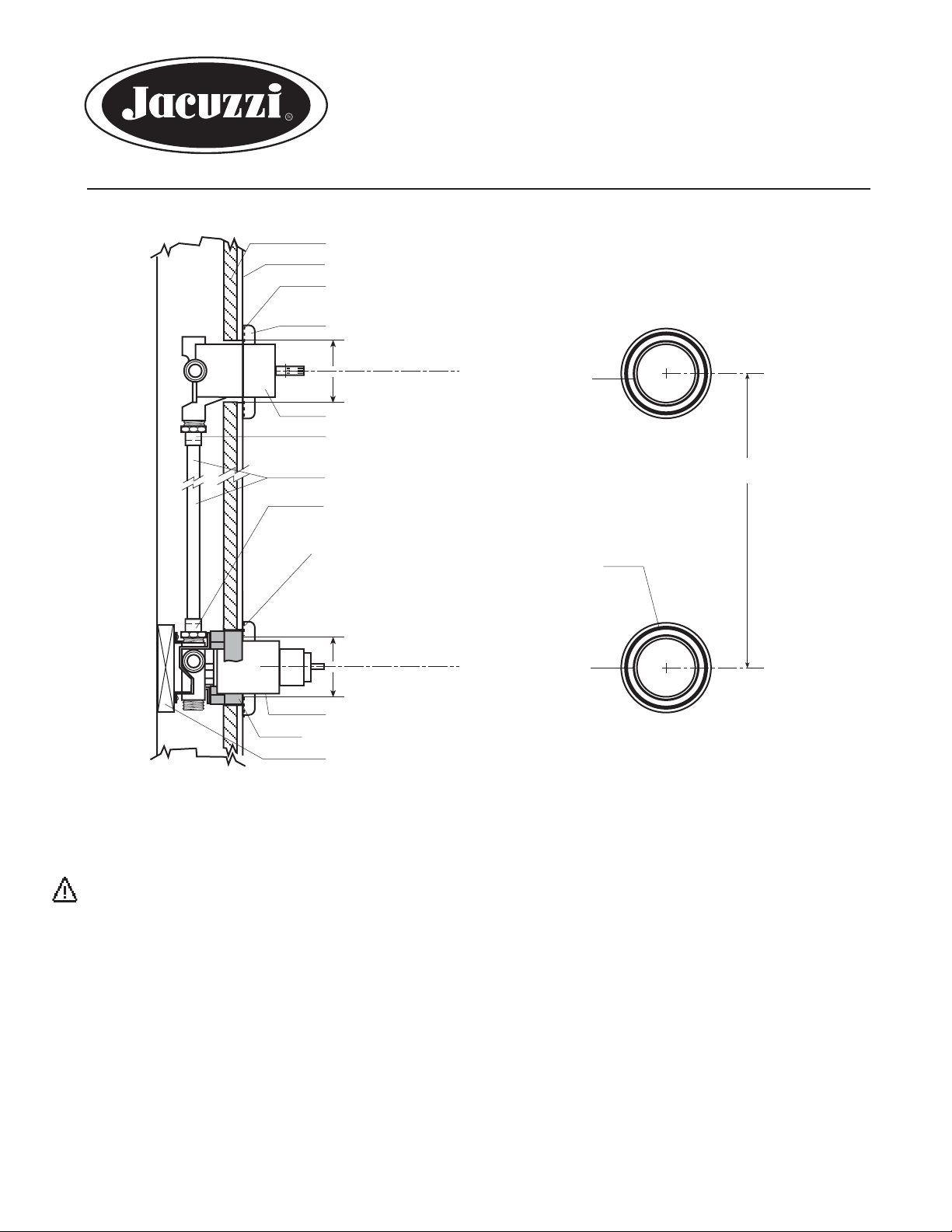

FINISHING WALL

TILE (FINISH SURFACE)

SEALANT (SILICONE) ON BACKSIDE OF

FACEPLATE

FACEPLATE (SEALANT NOT PROVIDED)

2-3/8" DIA.

GASKET

TRIM SLEEVE OF TRANSFER VALVE

LEFT-HAND THREAD TO

SWEAT ADAPTOR (NOT PROVIDED)

COPPER PIPE (NOT PROVIDED)

FEMALE THREAD TO SWEAT ADAPTOR

(NOT PROVIDED)

™

300

REAR VIEW

4-15/16" MINIMUM

SEALANT (100% SILICONE) ON BACKSIDE OF

FACEPLATE (SEALANT NOT PROVIDED)

NOTE: WHEN INSTALLING BAND, RING, ROPE

OR FACETED HANDLE, PULL TRIM SLEEVE OUT

TO MEET HANDLE.

2-3/8" DIA.

TRIM SLEEVE

PLASTER GUARD

WOOD CROSS MEMBER

GASKET

REAR VIEW

(FRONT HAS RED

AND BLUE DOTS)

OPTICA 300

WARNING: This system/device must be set by the installer to ensure safe, maximum temperature. Any change in

the setting may raise the discharge temperature above the limit considered safe and may lead to scalds.

CAUTION: As the installer of this valve, it is your responsibility to properly install and adjust this valve per the

instructions given. This valve does not automatically adjust for inlet temperature changes, therefore, it is necessary

to adjust the Rotational Limit Stop at the time of installation. You must inform the owner/user of this requirement by

following the instructions below. After installation and adjustment, you must write in the temperature and the date

you adjusted the Rotational Limit Stop on the warning label provided and apply or attach it to the hot water heater.

Be sure this instruction sheet is delivered to the owner/user.

WARNING: This pressure balanced bath valve is designed to minimize the effects of outlet water temperature

changes due to inlet pressure changes, commonly caused by dishwashers, washing machines, toilets and the like.

It may not provide protection from scalding when there is a failure of other temperature controlling devices elsewhere

in the plumbing system if the Rotational Limit Stop is not properly set, or if the hot water temperature is changed after

the Rotational Limit Stop is set, or if the water inlet temperature changes due to seasonal changes.

INSTALLER: LEAVE THIS INSTRUCTION MANUAL FOR OWNER'S/USER'S REFERENCE

©1995 Jacuzzi Whirlpool Bath G570000 D 12/06 Page 1

Page 2

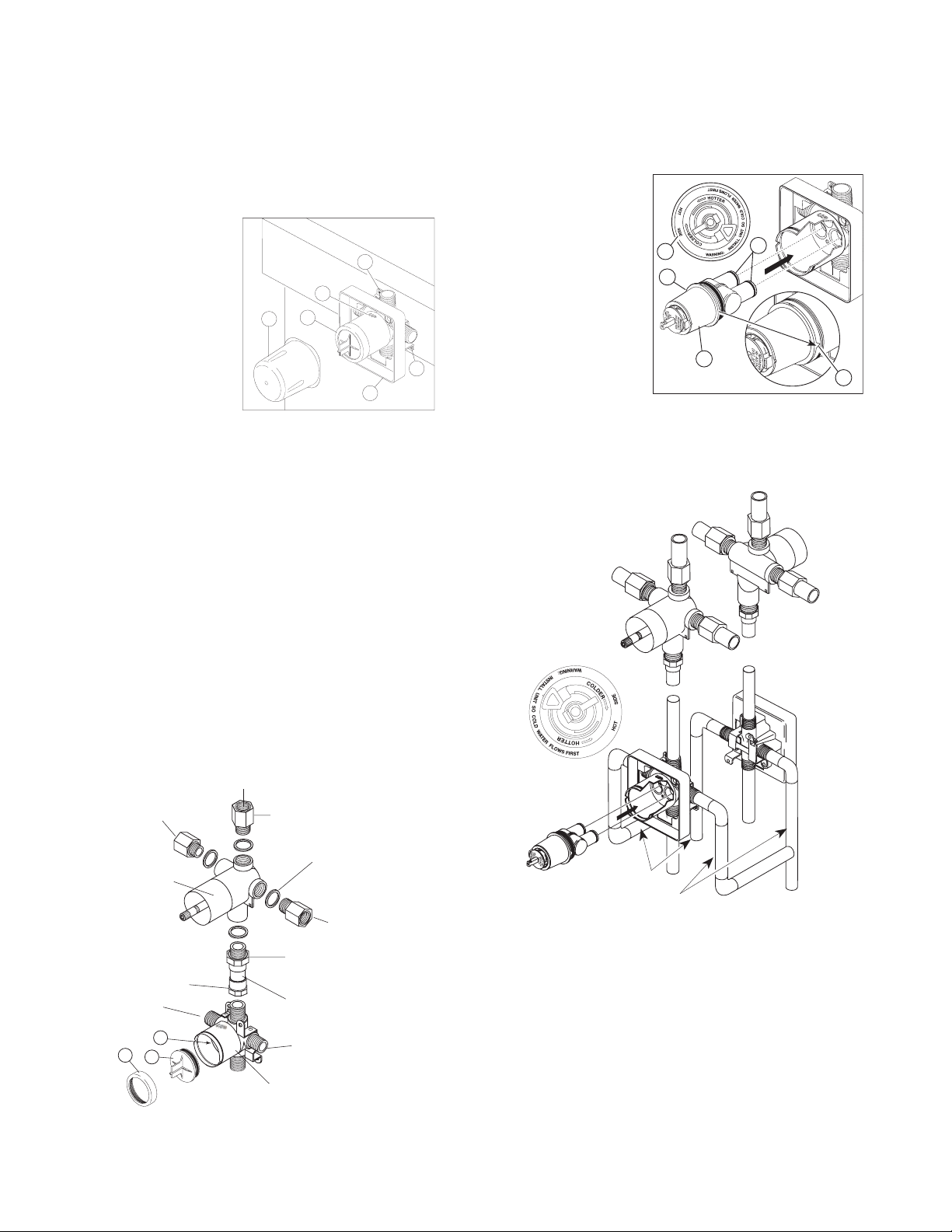

INSTALLATION INSTRUCTIONS

4

1

2

3

3

5

WARNING: Failure to follow these instructions could

prevent the mixer/transfer valve from functioning

properly.

1. Shut OFF water supplies.

2. Install the body (1) so the surface of the fi nished

wall is fl ush with the front of the plasterguard (2).

The plasterguard is

mounted on the body

using the two stringer

mounting holes (3) on

the bracket. NOTE:

Remove cover (4) to

access body mounting holes. Ensure the

word "UP" (5) is on top

of the valve body when

installing.

3. Install transfer valve

so that the transfer valve inlet connects to the top port

of the mixer valve. See below. The transfer valve must

be located at least 4-15/16" (center to center) away from

the mixer valve. A left-hand thread to sweat adaptor

and gasket are required for this connection. Use a 1/2"

copper pipe size, a taper to sweat adaptor, and a female

thread to sweat adaptor to fi nish the connections from

transfer valve to mixer valve. Copper pipe and adaptors

not provided.

Connect hot and cold supply lines to left and right inlets of

mixer body. Left is hot and right is cold (as viewed from

front). Threaded inlets are 1/2" NPT (iron pipe size). Use

an approved thread sealant for threaded connections.

Remove bonnet (1) and test cap (2) before soldering.

Leave screen (3) installed. WARNING: Avoid soldering

at high temperature. Exposure to high temperatures

may damage screen.

4. Rotate the cartridge (1) so the words “hot side” (2)

appear on the left. Insert cartridge into valve body as

shown. Make sure the cartridge tubes and o-rings (3)

are properly seated in holes at the base of the body.

Ensure the keys on the body are fully engaged with the

slots in the body (4).

For s howe r h ead

installation connect

plumbing from top

outlet of transfer valve

to shower head arm

with proper fi ttings. Do

2

4

3

NOT install the shower

head onto arm at this

time.

1

4

5. For cascade installation connect right outlet of transfer

valve to cascade line. The left outlet is for body spray jets.

Plug unused ports if other arrangements are used.

NORMAL INSTALLATION

(CHANGES NOT REQUIRED)

REVERSE

INSTALLATION

TRANSFER VALVE

TRANSFER

VALVE

TO

BODY

SPRAY

TRANSFER

VALVE

*FEMALE

THREAD TO

SWEAT ADAPTER

HOT IN

3

1

2

OPTICA 300 CONNECTIONS

TO SHOWER

*NOT PROVIDED

M

xF ADAPTER (3)

COPPER GASKET (4)

TO

CASCADE

*LEFT-HAND

THREAD TO

SWEAT ADAPTER

*COPPER PIPE

COLD IN

MIXER VALVE

COLD

HOT

BACK TO BACK OR REVERSE INSTALLATION

6. For back to back or reverse installations only

(hot on right and cold on left), follow instructions below.

If you are not making a reverse or back to back installation skip Steps 6 and 7 and continue with Step 8.

Make sure water supplies are OFF. Install mixing valve

as directed in the previous steps.

7. For back to back or reverse installations only

(hot on right and cold on left). Connect hot and cold

supply lines to left and right inlets of mixer body. Right

is hot and left is cold (as viewed from front).

Page 2 ©1995 Jacuzzi Whirlpool Bath G570000 D 12/06

Page 3

8. Slide bonnet nut (1) over the cartridge and thread

onto the body. Hand tighten securely.

1

9. Flush your system prior to installing the shower

head. Place handle on valve stem and turn handle to

full mix position. Turn ON water supplies, check for

leaks and let lines fl ush for one minute without moving

faucet handle. Divert water to shower head and fl ush

for 30 seconds. This will remove any debris from lines

which can damage internal parts of the faucet and

create leaks. After fl ushing, shut OFF water at faucet.

Remove handle and attach escutcheon. Attach shower

head.

CAUTION: Connection of deck-mount spouts to in-

wall valves is not recommended. Neither is the use of

hand showers connected to bath spouts in a bath/shower

push button diverter combination.

WARNING: In some instances, setting the Rotational

Limit Stop in the hottest position (full counterclockwise) could result in scald injury. It is necessary to

adjust the Rotational Limit Stop so that the water

coming out of the valve will not scald the user when

the handle of the valve is rotated to the hot side.

Adjust rotational limit stop. After water has run a suffi cient

length of time so that cold water is as cold as it will get,

and hot water is as hot as it will get, place handle back

on stem and rotate handle counter clockwise to the hottest position. Place a thermometer in a plastic tumbler,

and hold the tumbler in the water stream. Record the

temperature reading and note or mark the position of

the Rotational Limit Stop on the mating part. If the water

temperature is above 120°F the Rotational Limit Stop

must be rotated clockwise to reduce the temperature

(See illustration).

Remove the Rotational Limit Stop and replace it one tooth

counter clockwise for every 6° F (approximate) reduction

in temperature that must be made. If water temperature

is below 90° F, rotate the stop counter-clockwise. Repeat

as necessary. Make sure cold water fl ows from the valve

fi rst and does not exceed 120°F at the hottest fl ow. A

guide to setting the approximate outlet temperature is

included. This is only a guide and any setting must be

verifi ed by using the above procedure.

Hotter

Disc

Stem

Rotational Limit Stop

Colder

1st Position

10. IMPORTANT: The Rotational Limit Stop is used to

limit the amount of hot water available such that, if set

properly, the user will not be scalded if the handle accidentally is rotated all the way to “hot” when a person

is showering or fi lling a tub. The fi rst position allows the

LEAST amount of hot water to mix with the cold water

in the system. In the fi rst position the water will be the

coldest possible when the handle is turned all the way to

hot. As you move the Rotational Limit Stop counterclockwise, you progressively add more and more hot water

in the mix. The last position to the left will result in the

greatest amount of hot water to the mix, and the greatest risk of scald injury if someone accidentally turns the

valve handle all the way to the hot side while showering

or fi lling a tub.

©1995 Jacuzzi Whirlpool Bath G570000 D 12/06 Page 3

Page 4

HELPFUL HINTS:

1. Before removing cartridge assembly for any maintenance, be sure to note the position of the stop on the cap.

The cartridge assembly must always be put back in the same position. For normal installations, the stop on the cap

will face the left. To be safe, after you have fi nished the installation turn ON valve to make sure cold water fl ow

fi rst.

2. To remove cartridge from body, shut OFF water supplies and remove handle, trim sleeve and bonnet. Place

handle on stem and rotate clockwise while lifting cartridge out of body.

3. To remove seats and springs, remove cartridge (see above). Separate cap assembly from the housing assembly by rotating the cap counter clockwise 90 degrees. Separate cap and housing assemblies. Remove seats and

springs. Place new seats and spring. Place the largest diameter of the spring into the seat pocket fi rst and then

press the tapered end of the seal over the spring. Reassemble cartridge and replace in body following instructions

given in Step 1 above.

4. If the water in your area has lime, rust, sand or other contaminants in it, your pressure balanced valve will require

periodic inspection. The frequency of the inspection will depend on the amount of contaminants in the water. To

inspect cartridge, remove it and follow Step 1. Turn the valve to the full mix position and shake the cartridge rigorously. If there is a rattling sound, the unit is functional and can be reinstalled following instructions given in Step 1

as listed. If there is no rattle, replace housing assembly.

No adjustment to the Optica shower mixer Rotational Limit Stop should be made except by a trained installer.

CARE INSTRUCTIONS

Your Optica Faucet is designed and engineered in accordance with the highest quality and performance standards.

With proper care, it will give you years of trouble free service. Care should be given to the cleaning of this product.

Although its fi nish is extremely durable, it can be damaged by harsh abrasives or polish. To clean, wipe gently with

a damp cloth and blot dry with a soft towel.

TROUBLESHOOTING

CONDITION

Faucet leaks from bath spout/showerhead – SHUT

OFF WATER SUPPLIES

If leak persists – SHUT OFF WATER SUPPLIES

Unable to maintain constant water temperature Replace housing assembly with RP19805 or follow

REMEDY

Replace seats and springs – Repair Kit RP4993.

Check conditions of lower o-rings and replace if

necessary.

Replace housing assembly (PN D513000) – Repair Kit RP19805

Helpful Hint #4.

If your Optica 300 components do not match this unit, please contact Service Support: 1-800-288-4002

Page 4 ©1995 Jacuzzi Whirlpool Bath G570000 D 12/06

Page 5

WARNING: This is a guide to help you set the Rotational Limit Stop. This is only a guide and should be verifi ed by

following the instructions on setting the rotational limit stop given in this installation and instruction sheet.

MIX TEMPERATURE-VS-POSITION OF ROTATIONAL LIMIT STOP

APPROXIMATE MIX TEMPERATURE (°F) WITH VARYING INLET TEMPERATURES

Cold Hot

Setting of limiter

1st Position

2nd Position 50 70 50 70 70 70 40 85

3rd Position 61 79 67 83 74 89 70 101

4th Position 68 83 75 90 84 97 84 110

5th Position 74 87 85 96 91 104 95 117

6th Position 79 90 91 101 99 110 103 125

7th Position 82 93 97 104 104 115 109 130

8th Position 85 95 104 107 108 118 115 135

(Factory Set)

9th Position 89 100 117 111 115 124 124 141

10th Position 98 105 134 121 128 136 140 153

11th Position 111 115 138 133 149 151 165 172

50°F 120°F

Cold Hot

70°F 120°F

SHUT OFF ZONE: NO FLOW APPROXIMATELY 0-20 DEGREES OF HANDLE ROTATION

Cold Hot

50°F 140°F

Cold Hot

70°F 140°F

Cold Hot

50°F 160°F

Cold Hot

70°F 160°F

Cold Hot

40°F 180°F

Cold Hot

85°F 180°F

Setting of limiter

The fi rst position of the Rotational Limit Stop (the Limiter) is that position that restricts the rotation of the stem the

most and is at the maximum counterclockwise setting. According to industry standards, the maximum allowable

temperature of the water exiting from the valve is 120°F. This temperature may vary in your local area. The Rotational Limit Stop may need to be readjusted if the inlet water temperature changes. For instance, during the winter,

the cold water temperature is colder than it is during the summer which could result in varying outlet temperatures.

Typical temperature for a comfortable bath or shower is between 90°-110°F.

©1995 Jacuzzi Whirlpool Bath G570000 D 12/06 Page 5

Page 6

This page left blank.

CAUTION

Since plumbing fi ttings may contribute detectable amounts of lead to water, the following notice is required by Califor-

nia law ( Proposition 65). "This product contains a chemical known to the State of California to cause birth defects or

reproductive harm." In normal use, any lead exposure can be minimized by allowing the water to run free for several

seconds before drinking.

Proper Installation of the fi ll spout and compliance with local codes is the responsibility of the installer. Jacuzzi

Whirlpool Bath does not warrant connections of water supply fi ttings and piping, fi ll systems, or drain/overfl ow sys-

tems. Nor is it responsible for damage to the bath (or spa) which occurs during any installation procedure.

Jacuzzi Whirlpool Bath

14801 Quorum Dr., Suite 400, Dallas, TX 75254

Service Support: Call 1-800-288-4002

©1995 Jacuzzi Whirlpool Bath G570000 D 12/06

Printed on Recycled Paper

Printed in the U.S.A.

Loading...

Loading...