Page 1

J-CORNER SHOWER TOWER

™

ENCLOSURE-Verona

INSTALLATION AND OPERATING MANUAL

™

WHIRLPOOL

BATH

R

Page 2

Page 3

Important

The bath must be installed according to installation instructions (F258000) for the Verona™ whirlpool bath.

Follow the instructions to ensure that proper framing has been provided to support the J-Corner Shower Tower.

Finishing materials must be waterproof and sealed so that spray and condensation do not cause moisture damage.

NOTE: The J-Corner Shower Tower has been partially pre-assembled for your convenience during

installation. The installer must still follow the instructions to ensure proper installation of the tower and

components (see page 11). We recommend that two persons perform this installation.

Contents

Exploded View of J-Corner Shower Tower _________________________________________________ 2

Shower Tower Hardware Identification Chart __________________________________________________ 4

Tower Assembly _______________________________________________________________________ 6

Water Lines to Mixer/Diverter Valve _________________________________________________________ 8

Attaching Diverter Valve to Shower Wall _____________________________________________________ 8

Tower Installation ______________________________________________________________________ 10

Tower Disassembly______________________________________________________________________ 11

Placing Tower __________________________________________________________________________ 12

Fixed Panel Assembly____________________________________________________________________ 13

Mounting Top Ring and Wall Bracket to Tower_________________________________________________ 15

Fixed Glass Frame End Attachment _________________________________________________________ 17

Sealing and Trimming ____________________________________________________________________ 18

Attaching Face Plate _____________________________________________________________________ 19

Handle Installation and Operation___________________________________________________________ 19

Tools Required

1. Drill.

2. Drill bits: 3/32", 1/8", 3/16", 5/16" and 9/32".

3. Flat blade screw driver, No. 1.

4. Phillips type blade screw driver, No. 2.

5. 5/16" or 8 mm deep socket or nut driver.

6. Caulking gun.

7. Sealant (silicone).

8. Adjustable wrenches (small and medium).

9. Allen wrenches: 1.5 mm, 2.5 mm, 3 mm and 5/64".

10. Step ladder.

1

Page 4

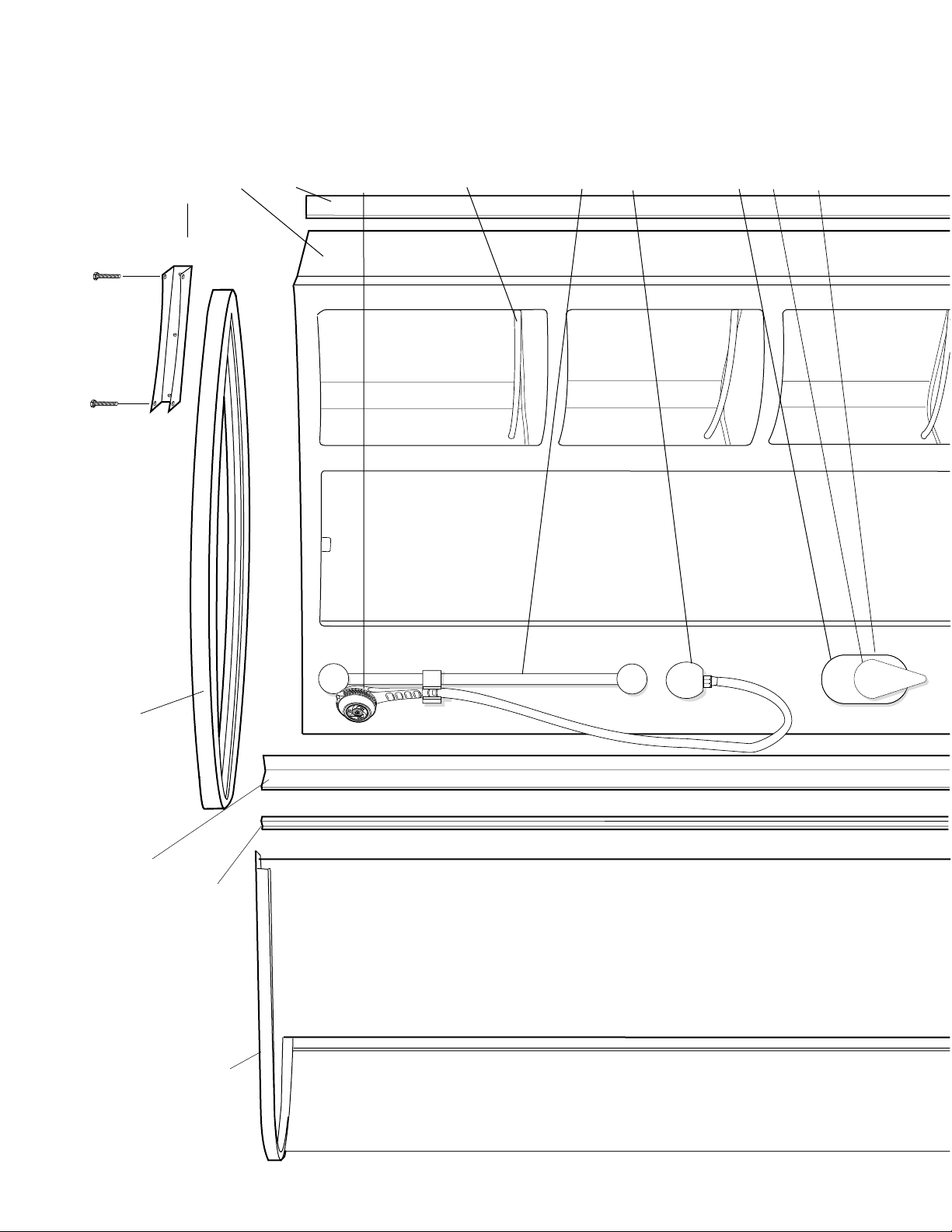

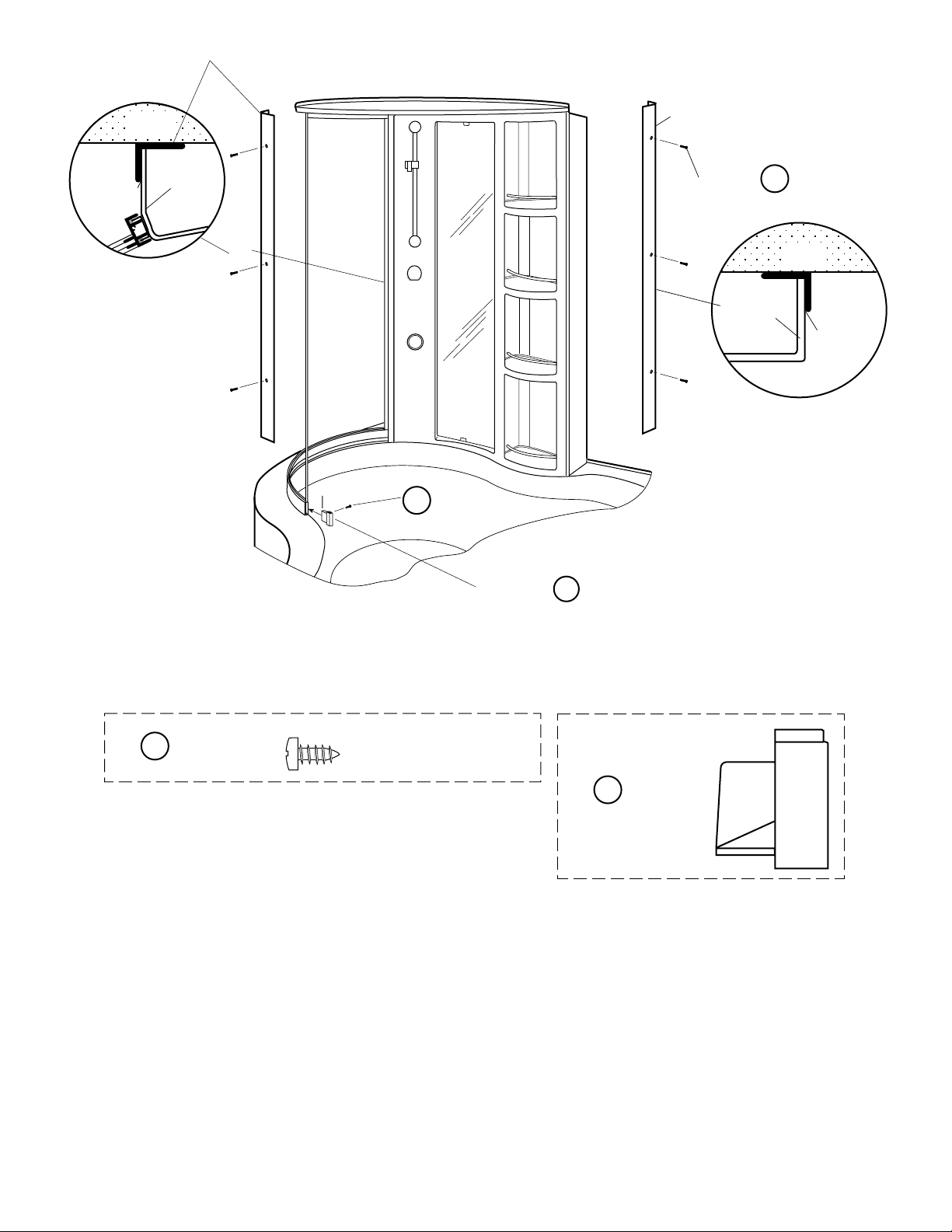

FIXED PANEL

SEE PAGE 13 & 14

BAILS

SEE PAGE 6

FACEPLATE

SEE PAGE 19

WALLBAR

SEE PAGE 7

MIXER (INCLUDING

HOSE CONNECTIONS)

SEE PAGES 8 & 11

L EXTRUSION

SEE PAGE 18

L EXTRUSION

SEE PAGE 18

TOP RING

SEE PAGE 15 & 16

WALL BRACKET

SEE PAGE 15 & 16

TOWER

SEE PAGE 10

HANDLE

SEE PAGE 19

HAND HELD

SHOWER,

FLEX HOSE

SEE PAGE 19

WATER INLET

SEE PAGE 6

END EXTRUSION

SEE PAGE 17

2

Page 5

EXPLODED VIEW OF J-CORNER SHOWER TOWER

END CAP

SEE PAGE 18

BOTTOM RAIL

SEE PAGE 13 & 14

SET SCREW

SEE PAGE 14

3

Page 6

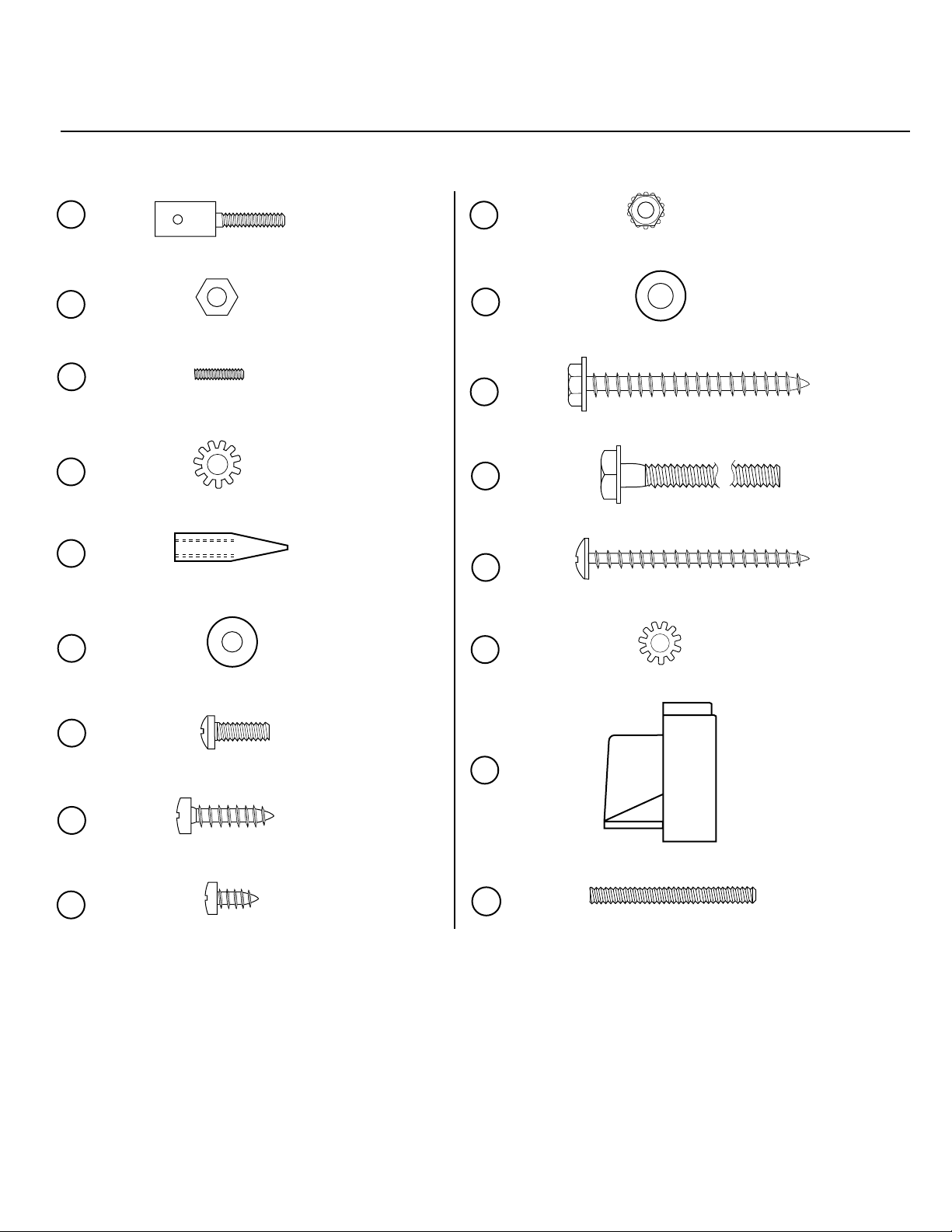

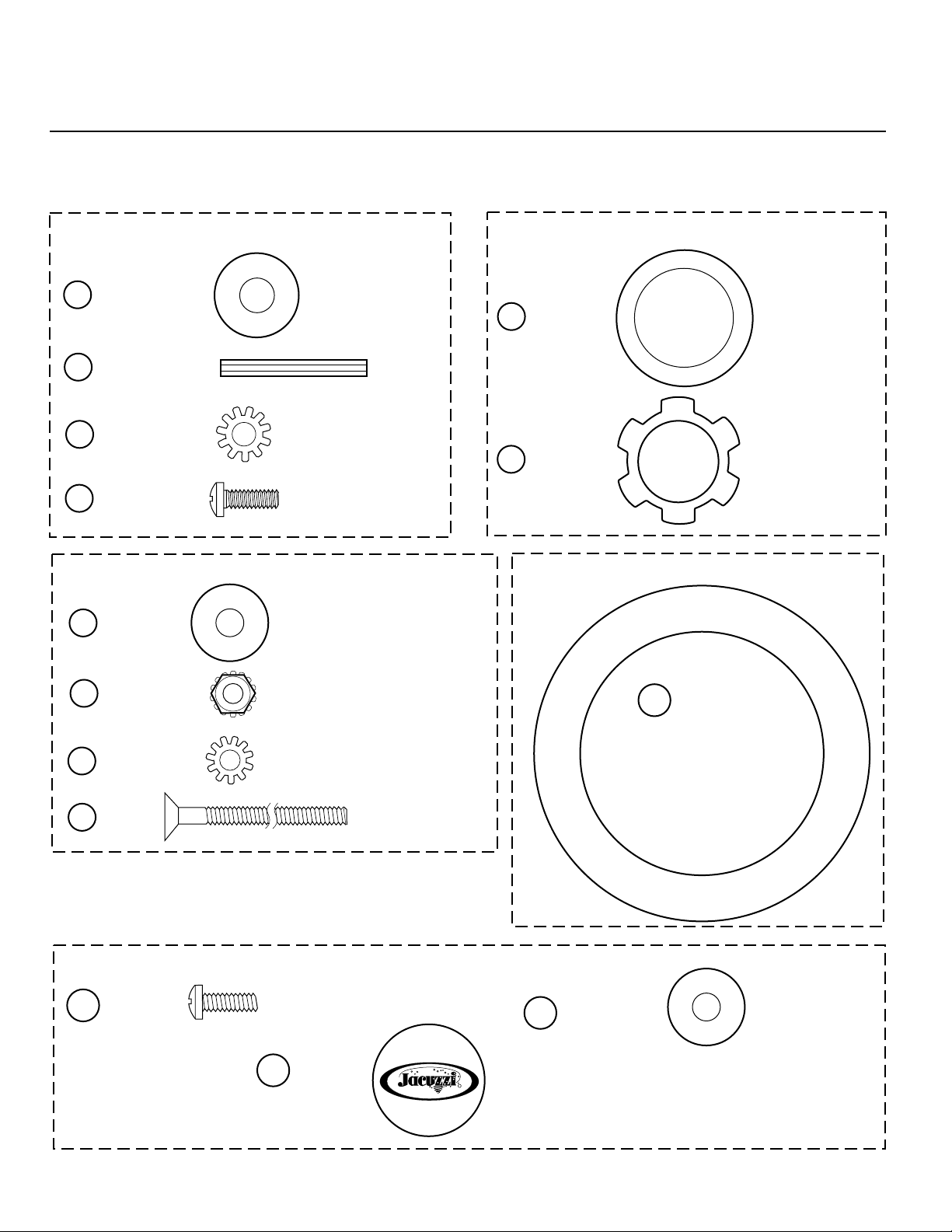

Shower Tower Hardware

Identification Chart

The diagrams for these fasteners are shown actual size for fast identification.

HARDWARE

A

B

BOLT

QTY.-8

NUT

QTY.-8

SLOT FASTENER

10X32

HEX NUT

10X32

T

U

NUT

QTY.-1

WASHER

QTY.-3

HEX LOCKNUT #8-32

FLAT WASHER

#10 TYPE A

STAINLESS STEEL

SCREW

C

QTY.-8

WASHER

D

QTY.-8

PIN

O

QTY.-3

WASHER

P

QTY.-8

SCREW

Q

QTY.-3

SCREW

R

QTY.-9

SET SCREW

6X32

EXTERNAL TOOTH

LOCK-WASHER #10

STAINLESS STEEL

PIN #8-32

.25DIAX1"

FLAT WASHER

#8 TYPE B

STAINLESS STEEL

PAN HEAD SCREW

#8-32X1/2"

STAINLESS STEEL

M4.2X19MM

STAINLESS STEEL

V

W

X

Y

Z

SCREW

QTY.-3

BOLT

QTY.-2

SCREW

QTY.-1

WASHER

QTY.-1

CAP

QTY. -1

SHEET MET AL

SCREW

#10-16X2" S.S.

SCREW, HEX

WASHER BOLT

1/4-20X2.5"

SHEET MET AL

SCREW

#8-18X2" S.S.

EXTERNAL TOOTH

LOCK-WASHER #8

STAINLESS STEEL

LOW TRACK

END CAP

S

SCREW

QTY.-10

M3.5X9.5MM

STAINLESS STEEL

AA

4

SCREW

QTY.-1

SET SCREW

#8-32 x 1 1/2"

Page 7

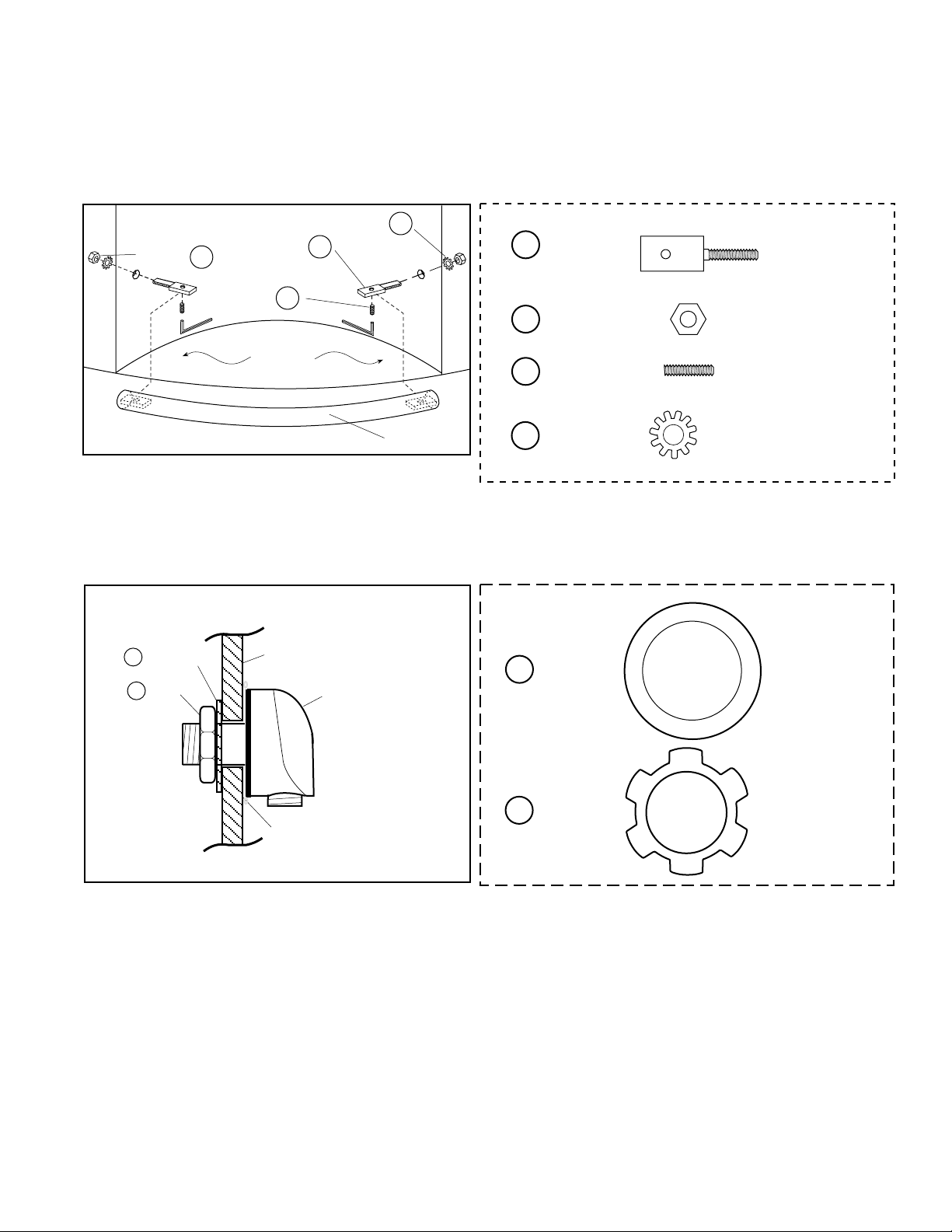

Shower Tower Hardware

Identification Chart

The diagrams for these fasteners are shown actual size for fast identification.

HARDWARE

PLUMBING HARDWARE

WASHER

K

QTY.-1

STANDOFF

L

QTY.-3

M

WASHER

QTY.-3

N

SCREW

QTY.-6

WALL BAR HARDWARE

WASHER

G

QTY.-2

FIBER WASHER

.75 O.D.

EXTERNAL TOOTH

LOCK-WASHER M4

STAINLESS STEEL

CROSS RECESS

SCREW M4X12

STAINLESS STEEL

FLAT WASHER

#10, TYPE B

WATER INLET HARDWARE

WASHER

I

QTY.-1

J

NUT

QTY.-1

MIXER HARDWARE

FIBRE WA SHER

1.24 DIA

LOCKNUT

1/2"-14NPT

H

NUT

QTY.-2

F

WASHER

QTY.-2

SCREW

E

QTY.-2

HANDLE HARDWARE

BB

SCREW

QTY.-1

SCREW

#10-24

CC

HEX LOCKNUT

#10-24

EXTERNAL TOOTH

LOCK-WASHER #10

STAINLESS STEEL

FLATHEAD SCREW

#10-24 x 2 1/2"

STAINLESS STEEL

CAP

QTY.-1

WHIRLPOOL

GASKET

EE

QTY.-1

FOAM GASKET

3"O.D.

WASHER

DD

QTY.-1

R

BATH

FLAT WASHER

#10

5

Page 8

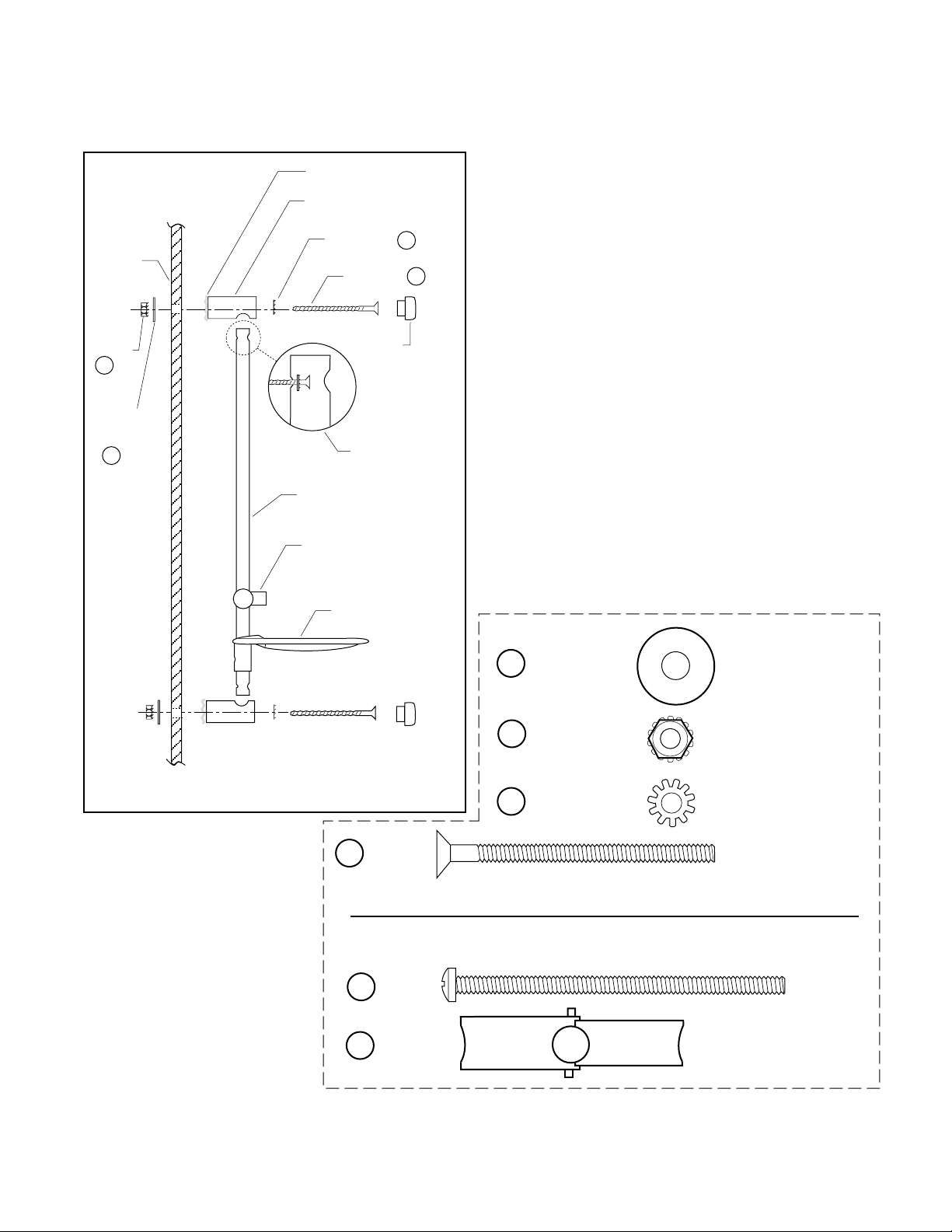

TOWER ASSEMBLY

1. Assemble the four (4) bails to the tower wall.

(See Illustration 1.) Do not overtighten the

nuts on the threaded shaft end. Overtightening may break the stud.

BAIL

WASHER (8)

NUT (8)

B

BOLT (8)

SET SCREW (8)

SHELF

A

C

ILLUSTRATION 1

2. Attach the water inlet to the tower wall.

(See Illustration 2.)

WATER INLET

I WASHER

J NUT

TOWER

WALL

WATER

INLET

D

BAIL

A

B

C

D

WASHER

QTY.-8

WASHER

I

QTY.-1

BOLT

QTY.-8

NUT

QTY.-8

SCREW

QTY.-8

SLOT

FASTENER

10 X32

HEX NUT

10 x 32

SET SCREW

6 x 32

EXTERNAL TOOTH

LOCK-WASHER #10

STAINLESS STEEL

FIBER WA SHER

1.24 DIA

ILLUSTRA TION 2

CAULK

J

NUT

QTY.-1

LOCKNUT

1/2"-14NPT

6

Page 9

WALL BAR

SHOWER

WALL

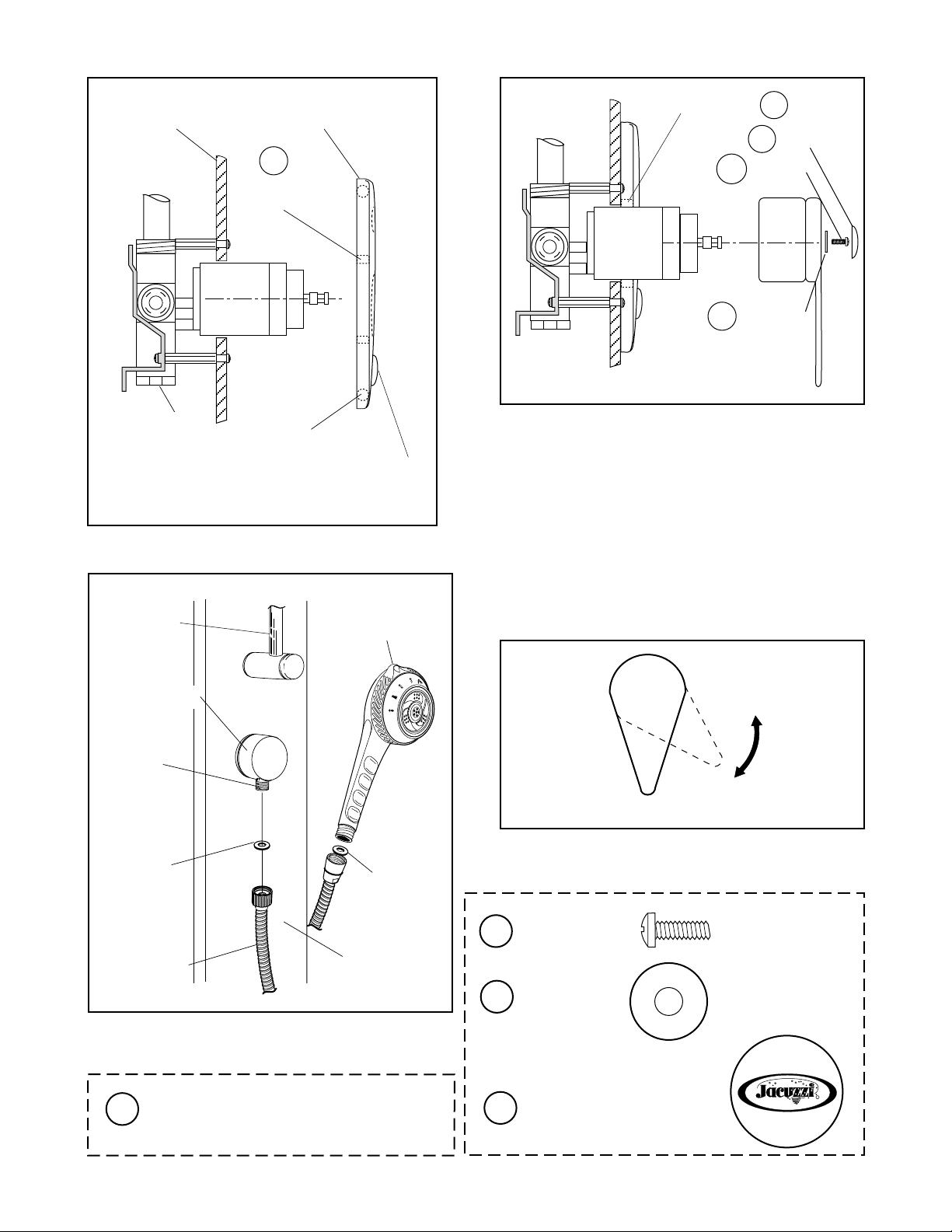

3. Attach the wallbar assembly to the tower wall.

(See Illustration 3.)

1/8" BEAD OF CAULK

WALLBAR STAND-OFF

EXTERNAL TOOTH

WASHER F (2)

SCREW E (2)

KEP

NUT

H (2)

FLAT

WASHER

G (2)

ILLUSTRA TION 3

CAP

SIDE VIEW

OF WALLBAR

WALLBAR

SHOWER HEAD

BRACKET

SOAPDISH

SCREW

E

QTY.-2

WASHER

G

QTY.-2

H

F

WASHER

QTY.-2

NUT

QTY.-2

FLAT WASHER

#10, TYPE B

HEX LOCKNUT

#10-24

EXTERNAL TOOTH

LOCK-WASHER #10

STAINLESS STEEL

FLATHEAD SCREW

#10-24 x 2 1/2"

STAINLESS STEEL

PARTS NOT NEEDED

1

SCREW

QTY.-2

2

NUT

QTY.-2

7

SCREW

#10-24x4"

S.S.

TOGGLE NUT

10-24

Page 10

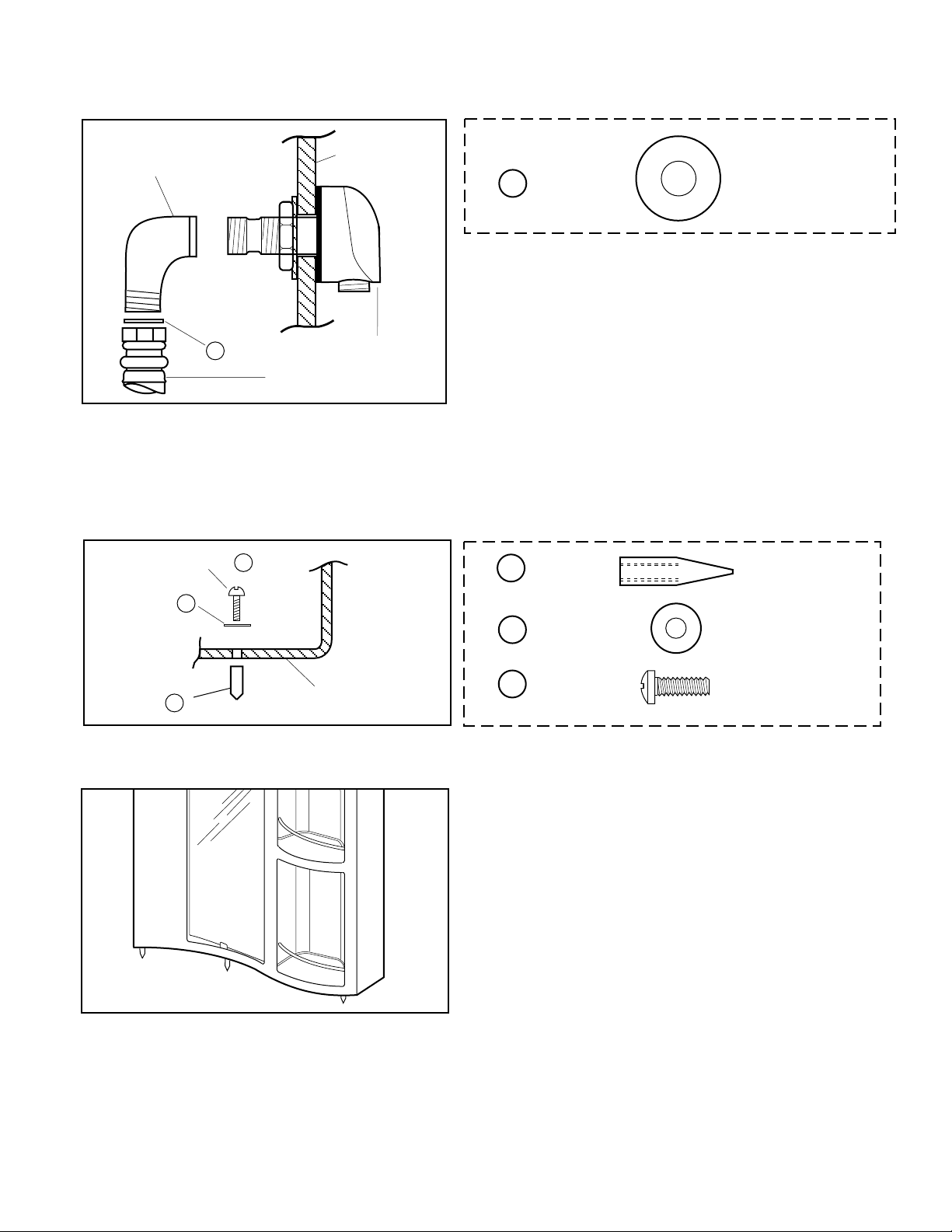

WATER LINES TO MIXER VALVE

✳

M/F 90°

ELBOW

MIXER VALVE

✳

HOT WATER

LINE (48")

M/F 90° ELBOW

WASHER

WATER SUPPLY

TO SHOWER (12")

✳

SCREW (6)

WASHER

K

K

QTY.-1

FIBER WASHER

.75 O.D.

N

ST ANDOFF (3)

L

PLUG

N

SCREW

QTY.-3

STANDOFF

L

QTY.-3

ILLUSTRA TION 4

ATTACHING MIXER VALVE TO SHOWER WALL

TO WATER INLET

SCREWS (3)

✳

M/F 90° ELBOW

✳

COLD WATER

LINE (48")

✳

USE

THREAD

SEALANT

4. Attach the Hot/Cold water lines and shower line to the

mixer valve. Use an approved thread sealant on

threads. Attach standoffs to the mixer valve. (See

Illustration 4.)

5. Attach the mixer valve to the shower wall. (See Illustration 5.)

N

ILLUSTRA TION 5

WASHER (3)

M

WASHER

QTY.-3

N

SCREW

M

QTY.-3

EXTERNAL TOOTH

LOCK-WASHER M4

STAINLESS STEEL

CROSS RECESS

HEAD SCREW M4X12

STAINLESS STEEL

8

Page 11

6. Attach the shower line to the water inlet (12" hose).

(See Illustration 6.)

TOWER

90° ELBOW

FIBER WASHER

K

12" HOSE

WALL

WATER

INLET

ILLUSTRATION 6

7. Attach the three (3) pins to the bottom of the tower.

(See Illustrations 7 and 8.)

WASHER

K

QTY.-1

FIBER WASHER

.75 O.D.

TOWER PINS

SCREW Q

WASHER P

PIN O

ILLUSTRA TION 7

TOWER

BOTTOM

LOCATED IN HARDWARE PACK

O

PIN

QTY.-3

P

WASHER

QTY.-3

Q

SCREW

QTY.-3

PIN #8-32

.25DIA X 1"

FLAT WASHER

#8 TYPE B

STAINLESS STEEL

PAN HEAD SCREW

#8-32 x 1/2"

STAINLESS STEEL

ILLUSTRA TION 8

8. After these steps are completed, set the tower aside.

9

Page 12

TOWER INSTALLATION

A

BATH FLANGE EDGE

TEMPLATE

BATH FLANGE EDGE

9/32" HOLE (3)

TAPE FIRMLY

(TYP)

3/16" HOLE (5)

INNER ORANGE CIRCLE

TOWER

WALL

ILLUSTRATION 9 (LEFT HAND SHOWN)

CEMENT

BOARD

STUD WALL

FLANGE

MORTAR & FINISH

MATERIAL THICKNESS

TILE OR FINISH

MATERIAL

MORTAR

CAULKING

BATH RIM

ILLUSTRATION 9A

1. To locate the drilling template, place it over the bath. The template should be against the bath flange edge

and template corner 'A' should be at the bath's corner. (See Illustration 9.)

Note: If bath has been installed with finish materials over bath flange, trim an amount off the template along

the bath flange edge equal to the thickness of mortar and finish materials. (See Illustration 9A.)

2. The inner orange circle should be centered over the circular opening of the bathtub. (See Illustration 9.) The

edge marked “BATH FLANGE EDGE” must be parallel with the back wall. With the template lying flat, tape

firmly to eliminate any shifting.

3 Using a sharp center punch, lightly tap through the template hole center location marks onto the bath surface.

Remove the template.

4. Drill two (3) 9/32" diameter holes for the tower and five (5) 3/16" holes for the bottom rail. (Do not drill through

the template.)

IMPORTANT: THE HOLES MUST BE DRILLED AS ACCURATELY AS POSSIBLE TO INSURE PROPER

INSTALLATION AND OPERATION OF THE SHOWER DOOR.

10

Page 13

DISASSEMBLY INSTRUCTIONS

Although the J-Shower Tower is shipped partially assembled, it will have to be partially disassembled to

install. After removing packing materials, follow the instructions below.

1. Remove end cap on the lower track. (Page 18, illustration 24.)

2. Remove the top ring. (Page 15, illustration 19.)

3. Remove the fixed panel with bottom rail. (Page 14, illustration 15 .)

4. It is not necessary to remove bails or wall bar. Water connections will have to be removed to apply sealant.

HOT WATER

SUPPLY LINE

HOT/COLD WATER

STUB-OUT WITH

VALVES

(NOT PROVIDED)

COLD WATER

SUPPLY LINE

48" HOSE

ILLUSTRATION 10

5. Attach Hot and Cold water supply lines of the mixer to the stub-out supply lines. (See Illustration 10.)

6. Locate the on/off handle and temporarily place it on the mixer valve. (See Illustration 26 on page 19.) With the

mixer valve in the OFF position, turn on the water supply. Check for leaks at all connectors. Seal any leaks

and continue.

11

Page 14

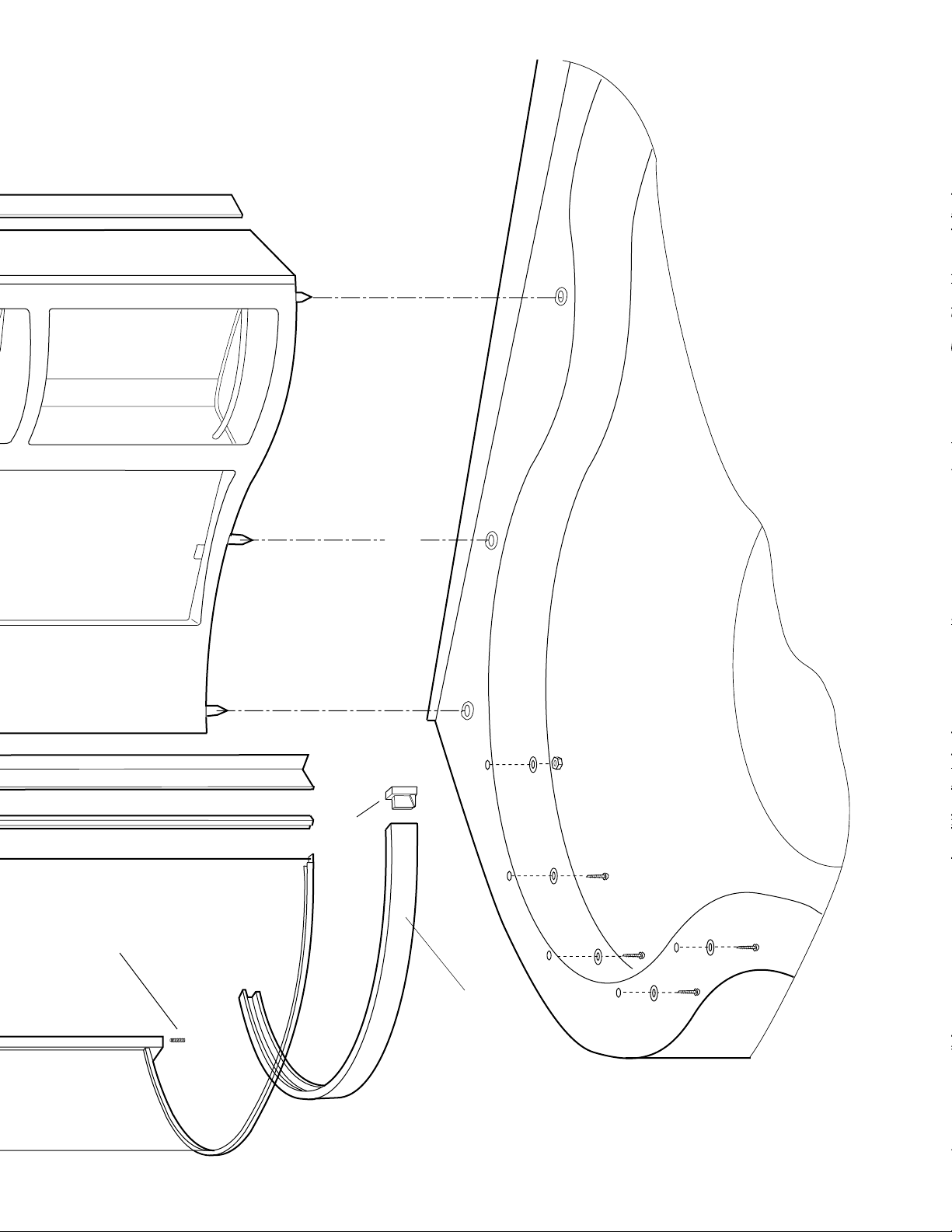

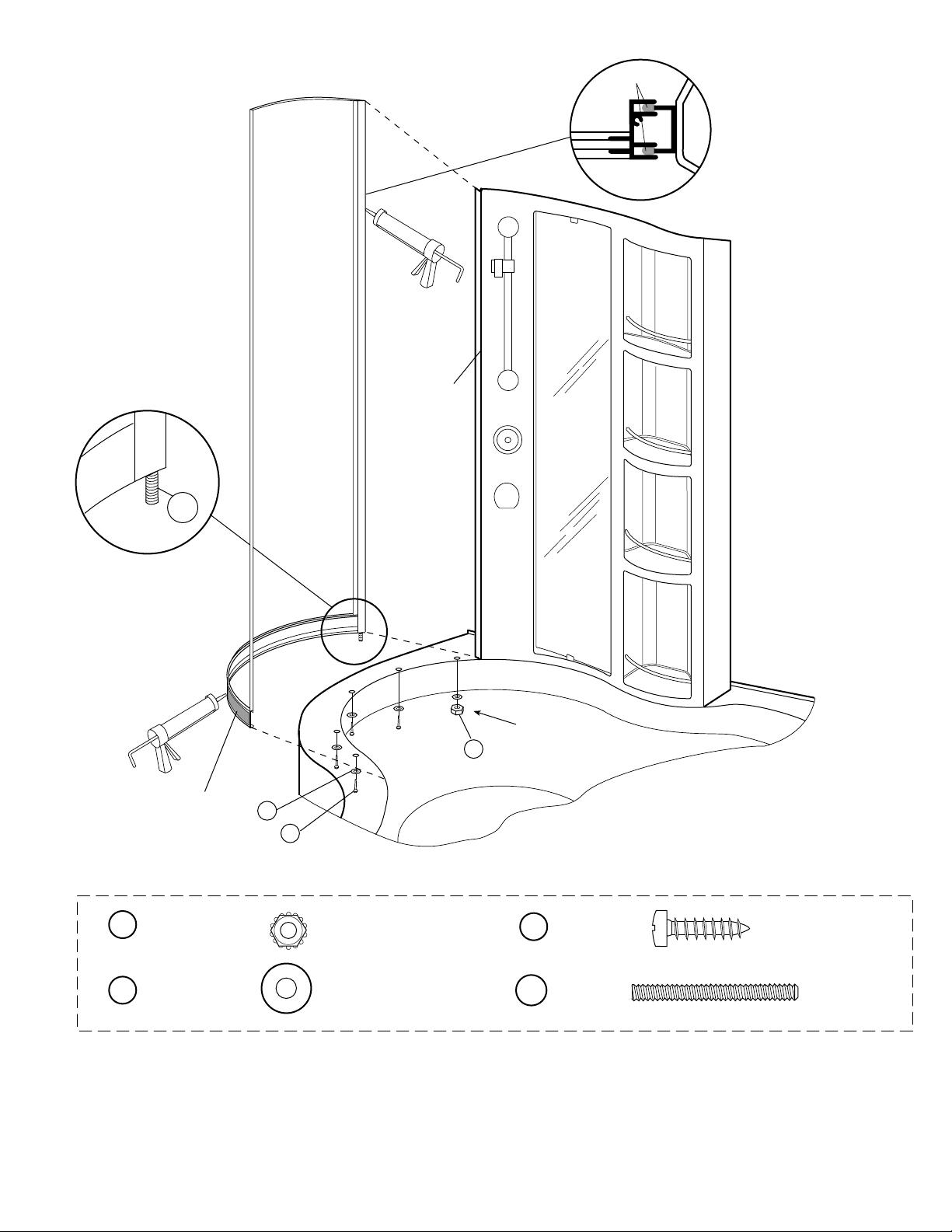

PLACING TOWER

CAULK

SET BACK 13/32"

R

SCREW

QTY.-3

M4.2X19MM

STAINLESS STEEL

ILLUSTRATION 11

7. Dry fit tower pins into holes to check hole location. Apply sealant around the three tower wall holes on the

bath and around the perimeter where the tower will sit. (See Illustration 11.)

8. Place the tower pins in the holes and push the tower down firmly. The tower will stand temporarily on its

own. Clean off excess sealant.

9. Place the U-extrusion against the wall edge, set back 13/32" from front edge. Drill three (3) 1/8" holes into

the wall and U-extrusion. Put sealant on the mating surface of the U-extrusion, or on the wall, and secure the

U-extrusion to the wall with the stainless steel screws, R.

12

Page 15

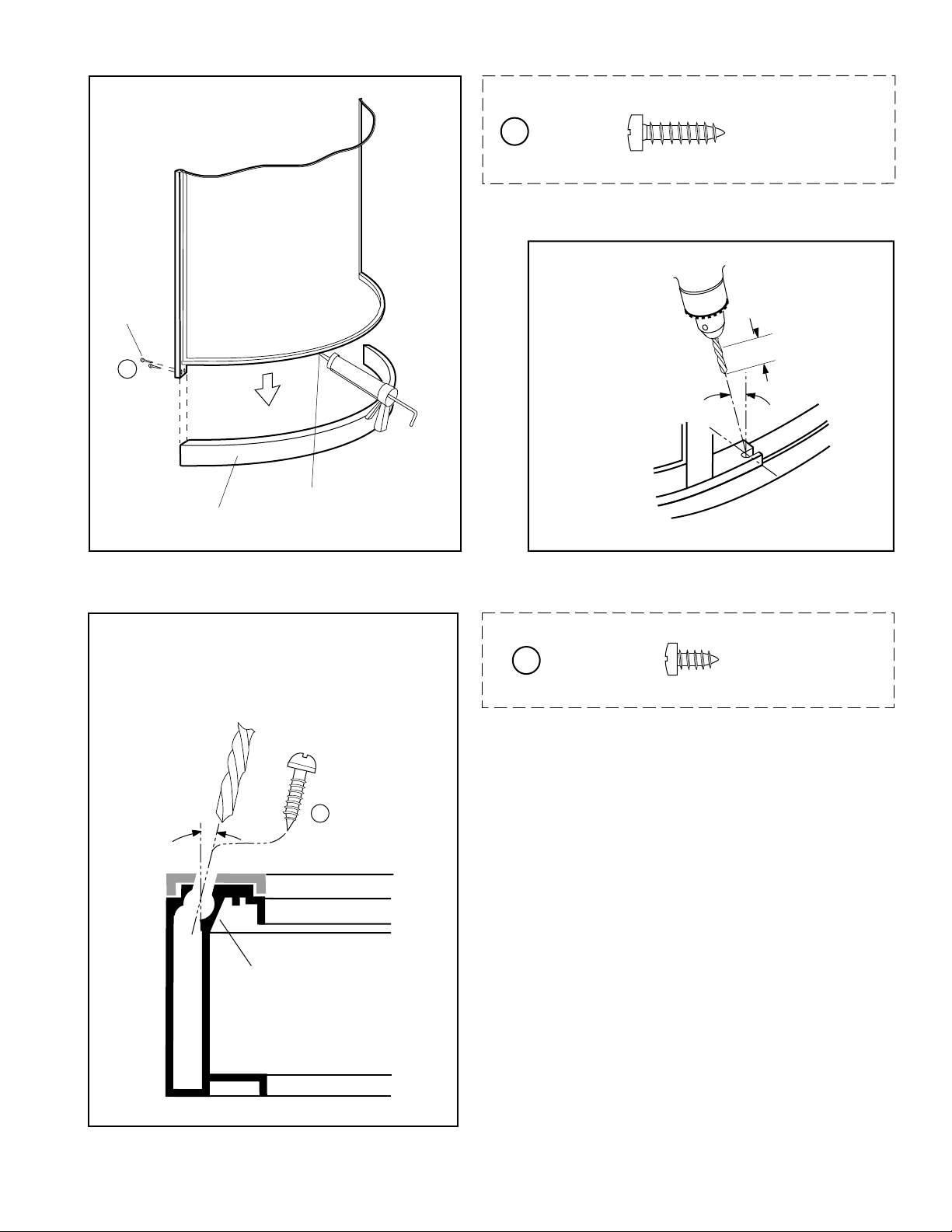

FIXED PANEL TO BOTTOM RAIL

TWO

SCREWS

R

BOTTOM RAIL

ILLUSTRATION 12

FIXED PANEL

LAY A 1/4" BEAD OF

SEALANT UNDER THE

FIXED PANEL

R

SCREW

QTY.-2

DRILLING FIXED PANEL

IMPORTANT:

MUST DRILL AT A 15°

ANGLE TO AVOID

DRILLING THROUGH

SIDE OF RAIL.

ILLUSTRATION 13

15°

M4.2X19MM

STAINLESS STEEL

1/8"

E

D

I

S

T

U

O

DRILLING FIXED PANEL

IMPORTANT:

MUST DRILL AT A 15°

ANGLE TO AVOID

DRILLING THROUGH

DOOR GUIDE AREA.

15°

S

DOOR GUIDE

AREA

S

SCREW

QTY.-1

M3.5X9.5MM

STAINLESS STEEL

10. Locate the bottom rail and the fixed panel. Lay a

bead of sealant on the bottom of the fixed panel.

Secure the bottom rail to the fixed panel. (See

Illustration 12.) Drill a 3/32" diameter hole into the

bottom rail at a 15° angle. Drill only through the first

aluminum thickness. (See Illustration 13.) Secure

the front of the fixed panel to the bottom rail. (See

Illustration 14.) Clean off excess sealant.

ILLUSTRATION 14

13

Page 16

FIXED PANEL ASSEMBLE TO BATH

AA

CAULK

VERTICAL

EDGE OF

TOWER

1

T

FASTENING

SEQUENCE

GENTLY PUSH

THIS AREA

(5)

P

(4)

2

3

4

5

R

ILLU STRAT ION 15

LOCATED IN HARDWARE KIT

T

P

NUT

QTY.-1

WASHER

QTY.-5

HEX LOCKNUT

#8-32

FLAT WASHER

#8 TYPE B

STAINLESS STEEL

R

AA

SCREW

QTY.-4

SCREW

QTY.-1

M4.2X19MM

STAINLESS STEEL

SET SCREW

#8-32 x 1 1/2"

11. Screw 1 1/2" Allen set screw 3/4" deep into the bottom of the fixed panel. Lay a 1/4" bead of sealant under

the bottom rail and inside the back channel of the vertical frame. Place the assembly against the vertical

edge of the tower and onto the bath surface, interlocking the two extrusions. (See Illustration 15.) Secure the

assembly to the bathtub using one (1) nut and washer and four (4) screws and washers following the fastening sequence. Gently push on the shaded portion of the bottom rail (see Illustration 15) to align with the holes

in the bath shell. After installing the fixed panel, apply sealant along all four inside edges of the glass frame.

Clean up excess sealant.

14

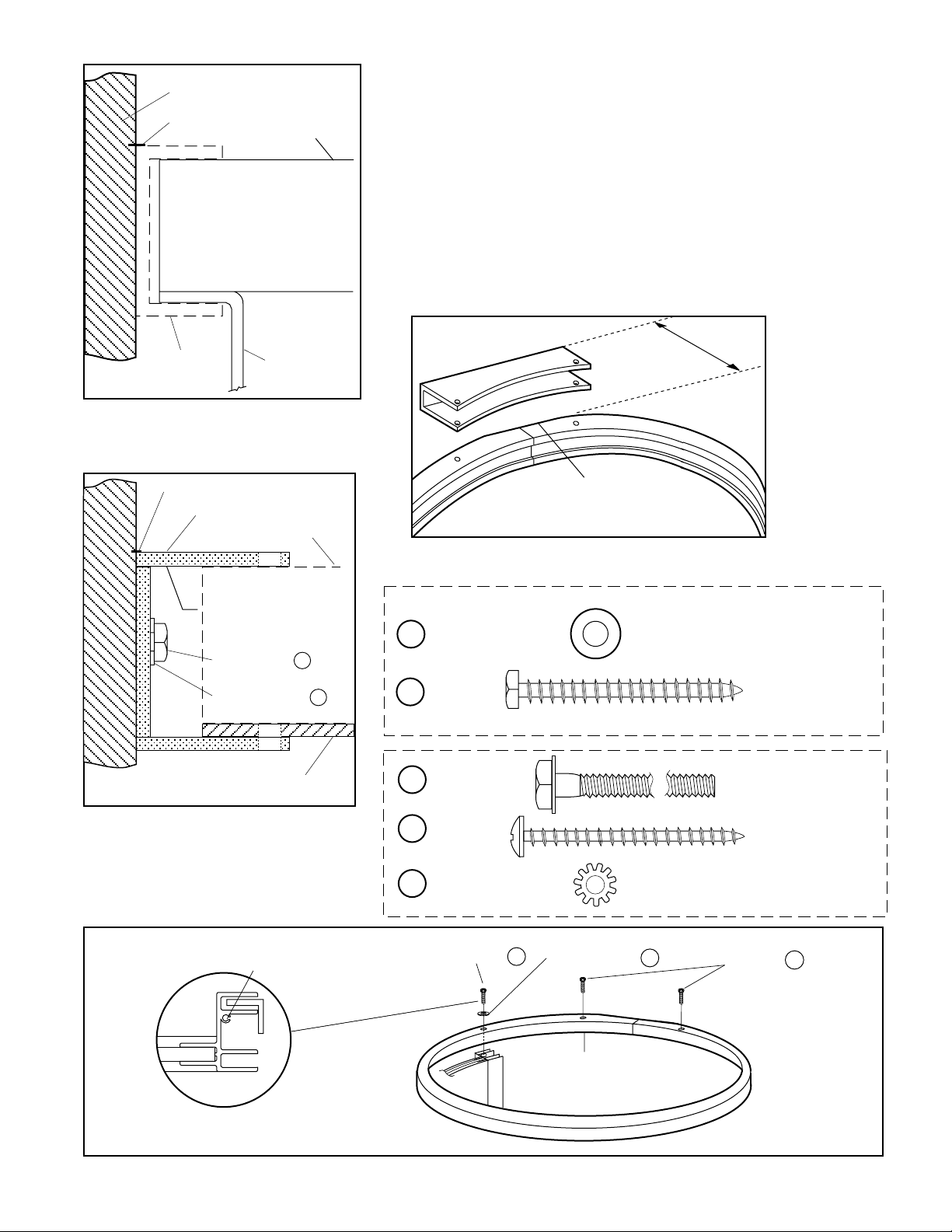

Page 17

RING TOP PLANE MARK

STUD WALL

MARK LINE

TOP RING

TOP PLANE

OF RING

12.Locate the top ring. Remove the plastic retainer extrusion and set

it aside for later use. Place the top ring on the fixed panel and

tower wall. The top ring groove on the underside of the top ring

must mate with the top of the fixed panel. The flat portion of the

ring should be parallel with the stud wall. (See Illustration 16.)

Mark a line on the stud wall indicating the top plane of the bracket.

(See Illustration 17.) Remove the ring. The top surface of the

bracket upper leg must align with the top ring line previously

marked. (See Illustration 18.) Locate and secure the bracket to

the wall.

13.Place the top ring on the tower and fixed panel. Align the three

holes in the top ring with the two tower holes and one hole in the

fixed panel. (See Illustration 19.) Secure the top ring to the tower.

BRACKET LOCATING

WALL

BRACKET

ILLU STRAT ION 17

BRACKET TO WALL

MARK LINE

WALL BRACKET

INNER SURFACE OF

BRACKET UPPER LEG

SCREW (3)

TOWER WALL

TOWER

WALL

RING

WASHERS(3)

PARALLEL

WITH

STUD WALL

FLAT PORTION

OF TOP RING

ILLU STRAT ION 16

LOCATED IN HARDWARE PACK

FLAT WASHER

U

WASHER

V

W

QTY.-3

SCREW

QTY.-3

BOLT

QTY.-2

W

V

TYPE A

STAINLESS STEEL

WOOD SCREW

SCREW, HEX

WASHER BOLT

1/4-20X2.5"

ILLU STRAT ION 18

RING TO TOWER

ILLU STRAT ION 19

SCREW HERE

SCREW INTO

FIXED PANEL

X

SCREW

QTY.-1

Y

WASHER

QTY.-1

SCREW(1)

15

X

WASHER (1)

EXTERNAL TOOTH

LOCK-WASHER #8

STAINLESS STEEL

Y

SCREWS (2)

SHEET MET AL

SCREW

#8-18X 2" S.S.

W

Page 18

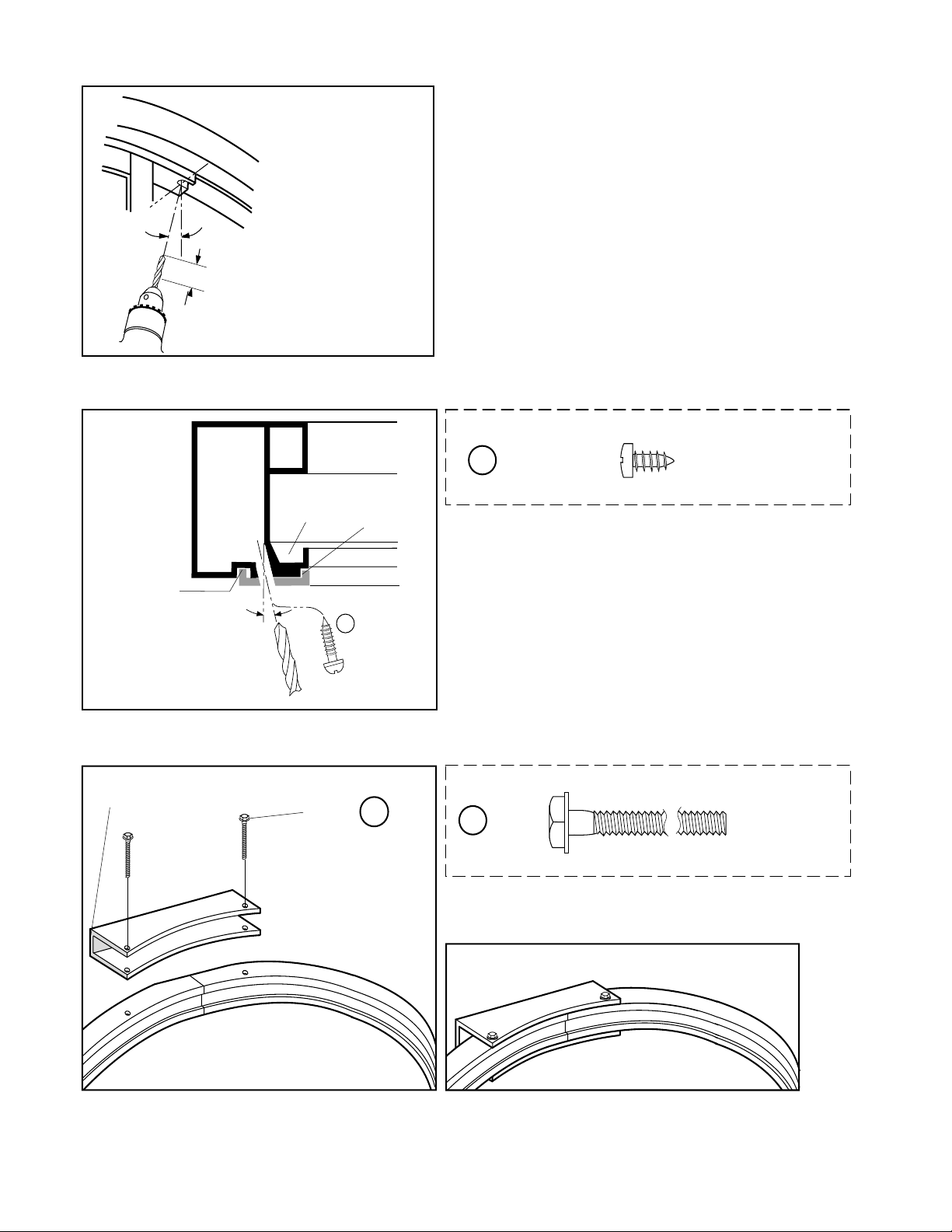

DRILLING TOP RING

O

U

T

S

I

D

E

14.Drill a 3/32" diameter hole into the top ring at a 15°

angle. (See Illustration 20.) Engage the top of the fixed

panel with the top ring groove. Secure the top of the

fixed panel to the top ring. (See Illustration 21.)

15°

1/8"

ILLUSTRATION 20

DRILLING TOP RING

TOP

RING

GROOVE

IMPORTANT:

MUST DRILL A T A 15°

ANGLE TO AVOID

DRILLING THROUGH

ROLLER TRACK.

15°

IMPORTANT:

MUST DRILL A T A 15°

ANGLE TO AVOID

DRILLING THROUGH

ROLLER TRACK OF

TOP RING.

ROLLER

TRACK

FIXED

PANEL

S

S

SCREW

QTY.-1

M3.5X9.5MM

STAINLESS STEEL

15.Plumb and square the tower. (See Illustrations 22A and

22B.) Secure the top ring to the wall bracket by inserting

the hex bolts through the wall bracket into the top ring

and tighten (wall bracket is pre-threaded).

ILLUSTRATION 21

RING TO BRACKET

PAINT OUTSIDE EDGE TO

MATCH BATHROOM FINISH

ILLU STR ATI ON 22A

BOLT

QTY.-2

W

LOCATED IN HARDWARE PACK

BOLT

W

QTY.-2

RING TO BRACKET

ILLU STR ATI ON 22B

SCREW, HEX

WASHER BOLT

1/4-20X2.5"

16

Page 19

FIXED GLASS FRAME END ATTACHMENT

END

EXTRUSION

SEALANT

FIXED

GLASS

ILLU STRAT ION 23

16. Apply sealant in frame and extrusion. Align and place extrusion above end cap onto the fixed glass.

17

Page 20

L-EXTRUSION

SEALANT

WALL

BACK

WALL

S

SCREW

L-EXTRUSION

SCREW

BACK

WALL

S

WALL

SEALANT

END CAP

Z

ILLUSTRA TION 24

LOCATED IN HARDWARE PACK

S

SCREW

QTY.-1

M3.5X9.5MM

STAINLESS STEEL

Z

CAP

QTY. -1

17. Install on the sides of the tower the aluminum extrusions provided. They may be sealed in place or secured

with screws (S, quantity 6). Seal the end cap by applying clear silicone sealant prior to placing into the end of

the lower track. Secure with self-tapping screw S.

18

Page 21

ATTACHING FACE PLATE

HANDLE INSTALLATION

TOWER WALL

PLUG

ILLU STRAT ION 25

FACEPLATE

EE

FOAM

GASKET

SEALANT

NAME PLATE LOGO

QTY.-1

FOAM GASKET

CC

DD

BB

SCREW

WASHER

EE

CAP

ILLUSTRATION 26

18. Assemble the face plate and handles as shown in

Illustrations 25 and 26. Attach the shower hose to

the hand held shower. Use the washer supplied

with the shower hose. (See Illustration 27.)

19. Attach the shower hose. (See Illustration 27.) Use

the washer supplied with the shower hose.

WALL BAR

WATER

CONNECTOR

TEFLON

TAPE

WASHER

FLEX HOSE

ILLU STRAT ION 27

HAND HELD

SHOWER

WASHER

TOWER WALL

20. For hot and cold operation of the handle, see

Illustration 28.

HOT

COLD

OFF

ILLU STRAT ION 28

LOCATED IN HANDLE KIT

SCREW

BB

QTY.-1

WASHER

CC

QTY.-1

FLAT WASHER

#10

SCREW

#10-24

LOCATED IN HARDWARE KIT

EE

GASKET

QTY.-1

(NOT SHOWN

SEE PAGE 5)

FOAM GASKET

3"O.D.

19

DD

CAP

QTY.-1

WHIRLPOOL

R

BATH

Page 22

Page 23

Page 24

PRODUCT SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

USE INSTALLATION INSTRUCTIONS SUPPLIED WITH PRODUCT.

Jacuzzi Whirlpool Bath has obtained applicable code (standards) listings generally available on a national basis for products of this type.

It is the responsibility of the installer/owner to determine specific local code compliance prior to installation of this product. Jacuzzi Whirlpool

Bath makes no representation or warranty regarding, and will not be responsible for any code compliance.

Jacuzzi Whirlpool Bath National Headquarters

P.O. Drawer J, Walnut Creek, CA 94596 (925) 938-7070

Service Support: Call (800) 288-4002

©1995 Jacuzzi Whirlpool Bath J683000 7/96

Printed on Recycled Paper

Printed in the U.S.A.

Loading...

Loading...